牵引车自动变速器换挡规律的研究

- 格式:pdf

- 大小:208.01 KB

- 文档页数:3

汽车自动变速器换挡规律的优化设计方法发表时间:2018-09-12T13:57:22.107Z 来源:《科技新时代》2018年7期作者:葛振伟[导读] 文中在对汽车换挡规律的原理进行分析之后,又对其动态规划算法的换挡规律优化进行阐述。

柳州上汽汽车变速器有限公司广西柳州 545006摘要:汽车运行的过程中,在进行加速或者减速的操作时,属于一个动态的换挡过程。

在此过程中,如果操作换挡频繁就会产生一定的耗油量,对于汽车运行的经济性性带来严重影响。

我国每在汽车换挡操作中就会产生大量的燃油能源浪费,为了改善这种局面,就必须对汽车自动变速器的换挡规律进行分析,并且对其展开优化设计,降低换挡操作时所产生的流量消耗。

文中在对汽车换挡规律的原理进行分析之后,又对其动态规划算法的换挡规律优化进行阐述。

关键词:汽车性能;自动变速器;换挡规律在科学技术快速发展的基础上,自动化技术获得了全面的发展,在多个领域中均表现出良好的有一种效果。

汽车运行中所使用的自动变速器就是在此基础上发展起来的,对原有的手动变速器进行升级与改装,应用电子控制系统,实现变速器的自动化发展,这样不仅能够提升燃油的利用率,使其经济效益更大得到更好发挥,还能够在一定程度上节省制造成本。

燃油的经济性属于评价汽车性能的一项重点内容,不仅会对车辆的驾驶成本造成影响,还关乎大气环境。

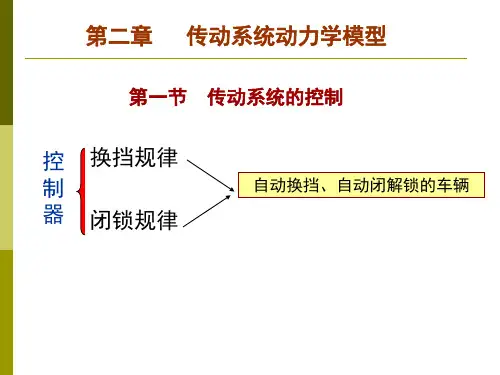

一、汽车换挡规律的原理1、换挡规律原理规律指的是事物在运行过程中的规律变化。

就汽车的换挡规律而言,主要指的是汽车在行驶的过程中,利用变速器的挡位,对汽车行驶状态和速度进行调节时所产生的变化值。

我们将处于不同行驶速度下的参数变化值进行分析之后,找出参数变化的关系,这便是对换挡规律的确定。

在实际运行的过程中,可以根据汽车行驶状态下,所进行的换挡操作来确定换挡规律。

一般而言,根据控制参数的不同,我们可以将其分成单参数、两参数和三参数。

其中的单参数指的是,车辆的运行速度,但是由于换挡操作属于驾驶员的自主行为,自动变速器无法实现对驾驶人自身行为的有效干预。

车辆自动变速器换挡规律的研究现状与展望摘要:车辆自动变速器作为汽车传动系统中的核心组成部分,在提高汽车行驶舒适性、经济性、安全性等方面发挥了重要作用。

本文对车辆自动变速器换挡规律的研究现状进行了综述,并对其未来的发展进行了展望。

研究表明,当前车辆自动变速器换挡规律的研究重点在于提高换挡的速度和平稳性,减少振动和噪声,同时还需要进一步探究不同工况下的最佳换挡策略。

未来的研究重点将会在使用新材料、新技术改进自动变速器的性能和效率,同时优化变速器的控制策略,进一步提高汽车的经济性、安全性和环保性能。

关键词:车辆自动变速器;换挡规律;平稳性;控制策略;环保性能随着汽车工业的快速发展和人们对汽车性能和舒适性的要求不断提高,车辆自动变速器作为传动系统中的核心部件,其在提高汽车行驶舒适性、经济性和安全性等方面发挥了越来越重要的作用。

车辆自动变速器的换挡规律对其性能和效率具有重要影响,因此研究车辆自动变速器的换挡规律是提高其性能和效率的关键。

一、车辆自动变速器换挡规律的研究现状车辆自动变速器的换挡规律是指在不同的工况下,车辆自动变速器实现换挡的具体策略和方式。

当前的研究重点在于提高换挡的速度和平稳性,减少振动和噪声,同时还需要进一步探究不同工况下的最佳换挡策略。

(一)换挡速度和平稳性的研究换挡速度和平稳性是影响车辆自动变速器性能和效率的重要因素。

在传统的液压控制系统中,换挡的速度和平稳性受到液压阻尼的限制,因此存在一定的局限性。

随着电子控制技术的发展,越来越多的车辆自动变速器采用电子控制系统来控制换挡过程,从而实现更加精准和平稳的换挡。

电子控制系统能够通过调节离合器的开合和变速器齿轮的转速来实现换挡过程,可以精确控制换挡的时间和速度,提高换挡的平稳性和减少换挡的时间。

近年来,一些学者对车辆自动变速器的换挡速度和平稳性进行了深入研究。

例如,通过实验研究发现,在采用电子控制系统的情况下,使用先进的换挡策略可以显著提高换挡的速度和平稳性。

2003年5月农业机械学报第34卷第3期车辆自动变速器换挡规律的研究现状与展望3周学建 付主木 张文春 周志立 【摘要】 综合分析了国内外车辆自动变速器换挡规律的发展过程及研究现状,预测综合智能控制将成为未来研究的焦点,同时对自动换挡规律在拖拉机上的应用进行了展望。

关键词:车辆工程 自动变速装置 换挡规律 控制中图分类号:U 27011文献标识码:AResearch and D evelopm en t of Sh if t Schedule of Veh icleAutoma tic Tran s m issionZhou Xuejian Fu Zhum u Zhang W enchun Zhou Zh ili(H e ’nan U n iversity of S cience and T echnology )AbstractT he developm en t of the p aram etric con tro l sh ift schedu le of veh icle au tom atic tran s m issi on bo th at hom e and ab road w ere review ed .T he sh ift schedu le has exp erienced th ree stages ,con 2tro lled by single p aram eter ,doub le p aram eter and dynam ic th ree 2p aram eter .N ow adays in o rder to rati onalize sh ift oppo rtun ity and decrease sh ift ti m es ,the in telligen t con tro l is in troduced to m odify the sh ift schedu le of the conven ti onal p aram eter con tro l.T he fuzzy logic sh ift and the neu ral netw o rk m ethod have also com e in to u se .A t the sam e ti m e ,it p redicts that the in tegrated in telligen t con tro l w ill becom e the focu s of the fu tu re research w ith the developm en t of m odern in telligen t con tro l theo ry and that the au tom atic sh ift schedu le w ill be b roadly app lied to tracto rs.Key words V eh icle engineering ,A u tom atic tran s m issi on ,Sh ift schedu le ,Con tro l收稿日期:200205313河南省高校杰出科研人才创新工程项目(项目编号:2002KYCX 010)周学建 河南科技大学车辆与动力工程学院 副教授,471003 洛阳市付主木 河南科技大学车辆与动力工程学院 硕士生张文春 河南科技大学车辆与动力工程学院 教授周志立 河南科技大学车辆与动力工程学院 教授 博士生导师 前言自动变速器可分为液力自动变速器(A T )、电控机械式自动变速器(AM T )、无级自动变速器(CV T )。

汽车自动变速器换档规律研究

自动变速器是一种能够自动控制车辆换挡的装置,其换挡规律

是通过车速、油门踏板位置及发动机转速等因素来判断适宜的档位,并进行换挡操作。

汽车自动变速器换挡规律研究主要涉及以下几个

方面:

1. 换挡时间和顺畅度:研究自动变速器在不同车速、不同油门

踏板位置以及不同发动机转速下的换挡时间和顺畅度,以便优化自

动变速器换挡算法。

2. 换挡策略:研究自动变速器在不同路况、不同驾驶风格以及

不同车辆负载情况下的换挡策略,以便实现更加平稳、高效的换挡

过程。

3. 换挡信号控制:研究自动变速器的控制系统,包括换挡信号

的检测和控制逻辑等,以便提高控制精度和鲁棒性。

4. 换挡力学特性:研究自动变速器换挡过程中的力学特性,如

离合器片的耐磨性、离合器片的接触面积、换挡过程中的离合器离

合精度等,以便提高换挡的可靠性和耐久性。

总之,汽车自动变速器换挡规律的研究对于提高驾驶体验、实

现更高效、安全的汽车驾驶具有重要的意义。

论自动变速器档位动力传递的规律作者:郭能强来源:《职业·中旬》2009年第06期行星齿轮机构各档位的动力传递是十分晦涩的知识点。

笔者查阅大量参考书籍,并结合自己十几年的教学经验,对此进行了总结。

一、齿轮基础1. 转速与传动比转速为单位时间内齿轮或轴的旋转速度,用r/min表示。

传动比D=从动齿轮齿数/主动齿轮齿数=主动齿轮转速/从动齿轮转速(式1)由式1可知,齿轮齿数与其转速成反比。

简记为:大轮带小轮,输出高速(实现高速档);小轮带大轮,输出低速(实现低速档)。

2. 旋转方向外啮合方式:两个外齿轮互相啮合进行旋转,转向相反,见图1a。

内啮合方式:一外齿轮和一内齿轮互相啮合进行旋转,转向相同,见图1b。

3. 中间齿轮中间齿轮也称过渡齿轮或惰轮,是在主动和从动齿轮之间加入另一齿轮,与主、从动齿轮啮合。

如图1c所示,惰轮只是改变主、从动齿轮的旋转方向,丝毫不影响传动比。

在行星齿轮机构中,行星齿轮就等同于惰轮。

转矩转矩也称扭矩。

齿轮的转速改变,转矩也改变。

假设主动齿轮转速和转矩分别为N1和T1,从动齿轮转速和转矩为N2和T2,它们之间的关系如下:N1/N2=D=T2/T1(式2)由式2公可知,齿轮转速与转矩成反比。

简记为:减速增扭。

二、单排行星齿轮机构的运动规律1. 基本结构单排行星齿轮机构主要由一个太阳轮、一个带有3~6个行星齿轮的行星架和一个齿圈组成如图2所示。

太阳轮位于机构中心,为外齿轮;行星齿轮位于太阳轮和齿圈之间,为外齿轮,等同惰轮;齿圈位于机构最外面,为内齿轮。

行星齿轮机构传动比的计算不像两个相互啮合的齿轮那样简单。

与传动比有关的是行星架、齿圈、太阳轮的齿数。

其中,行星架的齿数是人们为方便计算而假想的,可用式3计算:Z3=Z1+Z2 (式3)式中,Z3、Z1、Z2分别为行星架、太阳轮、齿圈齿数。

其关系:Z3>Z2>Z1 (式4)为简化传动比的计算方法以及分析各齿轮的转向,可将式4等效成图3所示的齿数关系。

客车自动换档原理研究及执行系统开发的开题报告【摘要】本文先介绍了客车自动换挡的原理及其优点,然后对于传统机械式换挡系统进行了改进,提出了一种电子式换挡系统的设计方案。

随后介绍了该方案的主要组成部分、硬件和软件设计,并对其进行了详细阐述。

最后,对该方案进行了初步实验验证,并对未来工作进行了展望。

【关键词】客车、自动换挡、电子式换挡、执行系统、实验验证【中文部分】一、选题背景现代客车的运行效率不仅仅取决于发动机的性能,同时还与换挡系统的性能有关。

传统的机械式换挡设计虽然操作简单,但效率和精准度较低,且容易出现故障。

为了克服这些问题,研究人员对客车的换挡系统进行了改进,提出了一种电子式换挡系统的设计方案。

该方案可以有效快速地进行换挡,不仅提高了运行效率,还可以更好地保护发动机和其他机械设备的安全。

二、选题意义客车自动换挡系统的研究是现代交通运输事业中的重要组成部分,其对提高客车的运行效率、维护交通安全有着重要意义。

本研究的目的是设计出一种电子式换挡方案,并通过实验验证其可行性,为现代化交通运输事业的发展做出贡献。

三、研究内容和方法1.自动换挡的原理与优点在传统车辆中,变速器是由人工操作来实现的,但这种操作需要准确的时间和协调的脚和手操作,容易出错。

而自动换挡系统则具有更高的预判、判断和控制能力,不需要人工干预,因而更为快捷高效。

2.电子式自动换挡系统的设计方案改进旧的机械式自动换挡机构,引入新的电子式自动换挡机械构,分析其优点,并对其功能进行逐步改进。

通过传感器和控制模块通过舱门开关等信号,实现更快、更准确的自动换挡。

3.电子式自动换挡系统的执行系统开发设计数字/模拟混合控制器,使用多种通讯协议,实现执行系统和状态追踪。

并设计并进行验证程序和算法,检验其可行性和可靠性。

四、预期成果和创新点本研究提出的电子自动换挡方案可以更快、更准确地进行换挡,提高了客车的运行效率和安全性。

其管理系统的开发和研究可以为自动化交通运输作出贡献,是一项具有很大的创新性。

大马力拖拉机牵引作业工况下换挡控制分析摘要:组合式档位自动变速传动模块,会明显增加大马力拖拉机作业阻力范围,文章根据四速动力换挡模块,并结合输出轴转速、油门开度等换挡参数,进一步提出了拖拉机牵引作业工况下的换挡控制措施,并构建了仿真模型。

数据结果显示,合理的换挡控制,当工作阻力变小的情况下,变速传动模块升挡,阻力变大情况下降挡,并且有效避免了循环换挡的情况,大幅度提升了拖拉机的燃油利用率,保障拖拉机在大阻力范围下能够持续的进行作业,从而不断提升大马力拖拉机的整体生产效率。

关键词:大马力拖拉机;牵引作业;循环换挡控制;生产效率前言:传统拖拉机主要是手动变速器,在实际作业过程中,如果土壤环境与质地不均匀,其工作阻力便会增大,导致出现较大的波动,这样很容易会导致拖拉机因为频繁的进行换挡,停车之后又重新起步,这样也会增加操作强度,对生产率产生一定的影响。

为了增加持续作业的实际阻力范围,通过在变速传动模块当中增加动力换挡模块,从而实现自动变速,这样能够让大马力拖拉机即使在负载情况下,可自动变速,不用停车换挡,从而提升作业效率。

1.拖拉机变速传动模块路线大马力拖拉机变速传动模块通常情况下档位数多,且覆盖范围很广,但在实际作业过程中,一般只是在特定范围之内匀速行驶,为了有效降低液压系统的整体复杂性,可通过档位自动变速减少频繁停车换挡的情况[1]。

某拖拉机变速传动模块具体如下图1。

图1 某拖拉机组合式变速传动模块图中显示,该变速传动模块主要是由动力换挡、高/低档变速器以及手动变速器等部分共同组成,高/低档变速器主要有2个挡位,手动变速器主要有6个[2]。

表1 动力换挡模块各档传动比与传动比设计从表中能够看出,动力换挡模块呈等比数列,和传统手动变速器方式相比较,拖拉机在实际作业中,不会出现停车换挡状况,传动比变化明显增加约为72%,当发动机输出功率不便时,其持续作业的阻力范围会增加大约72%[3]。

1.大马力拖拉机换挡控制策略2.1、自动变速特性图2 80%油门开度状态的转矩与油耗特性从图中可以看出,负载较小状况下,柴油机处于A点时,燃油的经济性比较差,如果负载增大,柴油机处于B点时,发动机的转速会逐渐下降,很容易会熄火。

毕业设计(论文)外文文献翻译文献、资料中文题目:自动变速器换挡规律的研究文献、资料英文题目:文献、资料来源:文献、资料发表(出版)日期:院(部):专业:班级:姓名:学号:指导教师:翻译日期: 2017.02.14毕业论文(设计)外文翻译机械工程学院机械制造及其自动化专业(本科)2008级机制二班课题名称:某变速箱上盖零件大批生产的工艺工装设计THE RESEARCHS OFAMT SHIFTING SCHEDULESVehicular Automatic Transmission can be divided into three types: Automatic Transmission (AT), Automated Mechanical Transmission (AMT) and Continuously Variable Transmission (CVT). AMT has become a kind of transmission that is full of potentiality, due to its high transfer efficiency, low cost and easiness to manufacture.The research on AMT shifting performance is key technology in the developing. Shifting performance directly influence the market competition and industrialization of AMT.AMT has good market expectation, but during the shifting procedure, the power must be cut off which causes the poor shifting performance than AT and CVT. Only through improving the shifting performance can the commercial competence be established. So the virtual important thing is to find the way to improve shifting performance.The development of AMT can be divided into three phases: semi-automatic, automatic and intelligent. The two major part of AMT are: the hardware including the mastered object, executor, sensors and TCU; and the software performing the control strategy.The performance of AT shift influences greatly the performance of the vehicle. So the research on at shift quality is an important problem in the domain of AT researching. Shift quality control of AT is accomplished by electronic and hydraulic system. To shift smoothly, according the real time throttle valve opening and vehicle speed signal, the controller sends electronic signals to control oil pressure changing curve of the applying elements. this paper analyzes and research detailed shift quality control system,the analyzing model of shifting process and pressure changing curve of the applying elementsFirstly this paper summarizes the existing evaluated quota of shift quality, and fully analyzesand introduces the existing control manner of AT shift quality.To meet the needs of research of vehicle starting and the real time control of shift, this paper puts forward a simplified model of engine-torque and a dynamics model of AT shifting process. Through the applying of the established model, this paper fully analyzes the process of the AT shifting.This paper drafts the proper oil pressure changing curve of the applying elements which can improve the AT shift quality, and gives the material calculated methods of the AG4 AT. This paper simulates the AG4 AT’s shifting process of 2H to 3H.The results of the simulation validate the established simplified models and the expected oil pressure changing curve.This paper fully analyzes the mechanism of the pressure regulating and flow controlling system of the AG4 AT, and preparatory discusses the design of the block-diagram of the shift quality control. This paper test the control system and hydraulic system of the AG4 AT by the AT hydraulic-electronic testing-bed. The result of the test validates the correction of these analyses.Automated Mechanical Transmission, as so called AMT, is a new-style transmission system. AMT technology applies the automatic technology to the manual mechanical transmission and makes the selection-gear, shift, clutch and throttle implement automatically. AMT technology is suitable for the situation of our country, and has an expansive market and development foreground. Shift schedules decide the time to shift and are the soul of the AMT. When the AMT is working, by comparing the states of the vehicle with the optimal shift schedules, the AMT decides the optimal shift time and achieves the shift automatically. This will lessen the tiredness of the driver and improve the safety. At the same time, the power and fuel-economy of the vehicle can also be improved. The author chooses the shift schedule as the key technology problem to be researched and the main study aim of this thesis is to get the optimal shift schedules for the AMT and so improve the power and fuel-economy of the vehicle. Through analyzing the influence factors of power and fuel-economy for the automobile, the author get the establishment methods for the optimal-power shift schedule and optimal fuel-economy shift schedule. In order to solve the influence of mass on the shift schedule, the author presents a variable-structure-controlled shift system. This enriches the theory of shift schedules. Because the computer simulation can save a lot of manpower and material resources comparing with the true-car test, so in this thesis, the author uses the simulation toolbox MATLAB/Simulate to setup the simulation model for shift schedules. Using this model, the optimal-power shift schedule and optimal fuel-economy shift schedule above are simulated and proved to be reasonable.Shifting performance is defined as the extent of swiftness and softness during the procedure of non-power shifting and to extend the life of the power train. The index is comfort of passenger, time duration and shock, nine factors maybe influence the shifting performance, and two experimental methods can be used to investigate the nature of this performance: one is collecting real-time data during road experiment and analyzing them, the other is the simulation of the operation conditions of the vehicle.The core of the AMT system is the control strategy, the principle of the clutch engagement, shifting procedure, the choice of control method and the CAN communication between TCU and ECU can influence the shifting performance.Shifting schedule is the schedule of auto shifting time between two shifts with controlling parameters. It includes economical and dynamical shifting schedule. At present, shifting schedule of two controlling parameters (vehicle speed and opening on throttle) is mainly used. If shiftingschedule is not good, shifting will not happen at right time and the working condition of engine will be severe. It will make the sound of engine abnormally and stability badly through the whole shifting procession. Sometimes even flame out Schedule of clutch engagement is determined by releasing journey of clutch, opening of throttle, shifting, vehicle speed and loading. The main Controlling goals are engaging quantity and engaging speed. The engaging control of clutch is mainly referred to the control of engaging speed. It is divided into three stages: fast, slow, fast. Shifting quality is directly influenced by the second stage. If engaging harder, it will make shifting concussion, even flame out; if engaging more slowly, it will make the friction time longer and reduce its longevity. The main controlling parameters are difference between initiative and passive and torques on both sides. When torques being approximately equal, it is proved by experiments that it can guarantee shifting time and not make concussion through the procession of engagement at the time of difference of rotating speed below some value. Meanwhile, the abrasion of clutch is not severe.Shifting procedure is the procedure through working harmoniously among engine, clutch and transmission. Their cooperation will affect shifting time heavily. In order to decrease the shifting time, the time that is spent on the friction of the clutch should be decreased first. If we intend to increase the time of non-load stage, which helps to minimize the difference of the rotary speed between the driving disc and the driven disc. If we intend to shorten the time of the non-load stage, engage the clutch immediately after the gear change. The clutch can engage in a satisfying period if the new method of controlling the engaging speed of the clutch is realizable. And the time that is spent on synchronizing the gears should also be shortened. It can be realized in the following two ways. The first is to decrease the difference of the driving gear and the driven gear. The second is to increase the shifting force. If realizing the union control between ECU and TCU by CAN bus, AMT has the best control and the best shifting performance by use of communication strategy between TCU and ECU.Influence on shifting performance by hardwareThe elements in hardware system are the basis of proper functions of AMT. Executors, sensors, electronic components, hydraulic systems have influences on shifting performance, the choice of hardware parameters is of vital important to improvement of shifting performance.With the development of the theory and technology of vehicle, the technical increasingly mature of microprocessor and the extensive application of electronic technique on the car, people have no limit at satisfying the automotive means of transportation only, facing gradually from the request of the car power, economy and easily manipulating, flexibility, safety, an d the intelligent type of car becomes the focus in the vision of people increasingly. Company’s publicity slogan of" person, car, life"," make people the center" etc. On the side exhibit the expectation of people to the automotive individuation, humanity.In the development direction of the car intelligence, the intelligence of the automatic gearbox has important effect. But the intelligence of the automatic gearbox embodies at the establishment of the shift regulation. For the fashion, for satisfying people to the new automotive request, for competitive advantage of the car type, at present, each big factory in world worked very much in shift regulation of new car type. Among those, the most arresting is AL4 automatic gearbox developed by PEUGEOT/CITROEN and RENAULT in that there unexpectedly are the 10 kinds of so many shift regulations. In the big system of person— car — road, the good and bad of the car control, reflect primarily in the coordination of the vehicle and environment (road), thecoordination of the vehicle and person. And so, the electronic automatic control system can save various regulations to provide the driver to choose to use, not only having the economic regulation, motive (call to sport the type again) regulation, but also still having the general (usual) regulation, environment temperature and regulation with the outsider condition variety etc. Namely, the point of shifting can be freely enacted for every kind of regulation. In the intelligence direction of the shift regulation, everyone has made much work up to now, parts of the results has been applied on the car. But the work that developing this intelligent shift regulation still is hard, this is mainly because of:1. The intelligence degree of the current intelligent gearbox needs to be increased, and it expresses at that accurate degree to identify environment is not high and t o identify the driver’s driving can't give satisfaction.2. The intelligence function is still not perfect. The intelligent automatically shift system is an open system; it must be continuously perfect and plentiful on the current foundation. Only this way, it can adapt to the driving request of the different drivers, reducing the driver’s labor strength, increasing the performance of the whole vehicle.Conventional design method which used in the structure parameters' design of automobile gear box and synchronizer is a time-wasting job and hard work, and it is difficult to get idea design parameters and no good to the enhancement of products qualities. The optimum design of automobile gearbox and synchronizer which take the advantage of computers seeking the best structure parameters within constrains is a perfect and high-quality design method. The main target of this article is to set up a optimum mathematical model of structure parameters of the truck's gearbox and synchronizer, the auth or use a optimum method based on K-T equation to improve the design level of automobile gearbox and synchronizer. Gear box is a important part of transmission, so the optimization of automobile gearbox is very important because the transmission is a main part of automobile. According to the design request and character sofa sort of truck, the optimum mathematical model of truck's gearbox is analyzed and set up in this article to decrease its weight and volume when the strength, stiffness, and lifetime of parts are permitted. And we can receive a satisfaction result through optimizing it's parameter for instance.Synchronizer is a important part of automobile gearbox, it make drive gear and driven gear engaged after their synchronized, so it can decrease engaged shock and noise, it can decrease shift forcing and make it comfort to gear shift and increase the life of synchronizer. The synchronized process of synchronizer is analyzed in this article; we can receive a satisfaction result through optimizing its influence parameter for instance when the synchronized time is the shortest. The optimum toolbox of MATLAB is a convenient of ware of modern optimization with fast speed and powerful function. The algorithms of different mathematical subsets are divided into different librarians in the form of functions in MATLAB optimum toolbox. When we use them, we just call the functions and give special parameters to solve the problems and this will be fast and accurate. The author gives an optimum design for automobile gearbox and synchronizer by using the optimum toolbox of MATLAB and receives a satisfaction result.自动变速器换挡规律的研究车辆自动变速器通常分为液力机械式自动变速器(简称AT)、电控机械式自动变速器(简称AMT)和机械式无级变速器(简称CVT)。

汽车自动变速器换档规律的动态评价方法研究程秀生1,任传祥2(1.吉林大学汽车学院液力机械传动研究所,吉林长春,130025.;2北京航空航天大学,北京,100083)摘要:本文根据自动变速器的换档特性,应用计算机仿真技术,通过建立换档规律的动态评价系统,分析了不同换档规律对AMT车辆燃料经济性的影响,其分析结果与试验结果有很好的一致性。

所建立的动态评价系统和相应的分析方法对进一步研究机械式及其它类型自动变速器换档规律的动态特性及其对汽车性能的影响有一定的参考价值。

关键词:自动变速器换档规律动态评价计算机仿真Research on Dynamic Evaluating Method for Shift Schedule of Automated TransmissionCheng Xiu-sheng 1,Ren Chuan-xiang 2(1. JiLin University,130025;2. Beijing University of Aeronautics and Astronautics,100083)Abstract:This paper sets up shift schedule dynamic evaluating system using emulation of computer based on shift properties of automated mechanical transmission, then analyzes the influences of different shift schedule on AMT vehicle fuel economy and power which consist with the results of the real car testing. Dynamic evaluating system and corresponding analyzing methods have certain reference value for farther research on AMT shift schedule dynamic properties and influences on automobile performance.Keywords: Automated Transmission Shift Schedule Dynamic Evaluating Emulation of the Computer0概述换档规律是自动变速器开发的重要内容[1],由于换档规律对燃料经济性的影响不但和换档点的瞬时油耗有关,而且和换档前后发动机工作区对应的累计油耗有关,因而换档规律对燃料经济性的影响最终应反映到发动机的工作状况上来,尽管文献[2]中提出了以相对油耗率作为评价指标,但该方法仅以等功率线上不同换档点进行静态评价,而实际车辆在不同换档规律下行驶时,发动机的工作点在功率线上的分布是动态分布,因而,需要对换档规律的评价方法进行更深入研究。

汽车自动变速器的工作原理及换挡规律分析摘要:换挡规律属于变速器掌控系统中的中心技能,它的掌控参数选择的正确性会对电动汽车的动力性、舒适性及续驶里程有着径直的作用。

用汽车行驶加速度和加速踏方位当做换挡掌控参数,依次设定出动力性及经济性这两个换挡规律,且用 CRUISE 软件做仿真及改良,获得与某种电动车变速器的换挡规律,完成了节能和提高续驶距离的目的。

关键词:汽车;换挡规律;动力性;燃油经济性一、汽车自动变速器的发展及现状介绍(一)汽车自动变速器的发展一直以来,变速器都是汽车转动系统中十分重要的零部件之一,伴随着汽车工业的不断进步,车辆性能方面也在逐步优化中,电子化程度也在持续加强,具有汽车自动变速器的轿车无形中已经成为主体,同时也是未来汽车变速器发展过程中的重要方向。

当前来说,在自动变速器的发展中,所存在的较为成熟的自动变速器卒中如下四种方式:液体自动变速器DCT/电控机械式自动变速器AMT、无极自动变速器CVT和双离合自动变速器DCT。

当前而言,越来越严格化的法律法规以及汽车驾驶过程中不断提升的环保意识促使汽车产业也越来越看到了混合动力在汽车行业发展中所存在的重要性。

在此背景下,一个全新的驱动系统应运而生,混合动力专用变速器DHT,本身属于一种新型混合动力驱动,几乎发展在欧洲地区。

伴随着时间的不断发展,手动变速器的市场占有率不断降低,自动变速器比例不断增加。

在未来发展过程中,主要是以安全、节能、环保、操作便捷性等等特点为基本核心开展。

在变速器传动效率中,手动变速器5MT和6MT在NEDC循环背景下油耗差别并不明显,然而在高速以及非拥堵情况下,6MT能够省油5%左右。

在进行设计优化过程中,重点内容则是在降油损失等等方面,手动变速器依然能够有效的提升效率2%左右。

在运用手动变速器与自动变速器的逐步优化过程中,能够为整车油耗给予3%-5%左右的降低贡献率。

(二)汽车自动变速器的现状介绍最近几年,我国有些汽车和变速器企业利用引入超前技能和设施,且利用持续的吸收改进,慢慢的缩减了在自动变速器范畴和全球国际先进水平的间距。