钢 汽车大梁用钢 WL590 WL610

- 格式:pdf

- 大小:53.85 KB

- 文档页数:3

QSTE550TM QSTE550TM上海振钰实业供应汽车大梁钢QSTE550TM,QSTE460TM等。

何先生021-********/189********QSTE550TM具有良好冷成型性能的碳素及微合金钢。

产品供制造汽车大梁、横梁、滚型车轮、汽车传动轴管、汽车桥壳等结构用。

常用规格为:2.0MM-14.0MM厚度。

牌号化学成分a,%牌号C Si Mn P S Alt 其它QStE340TM≤0.1 2 ≤0.50≤1.30≤0.030≤0.025≥0.015QStE380TM ≤1.40 QStE420TM ≤1.50 QStE460TM ≤1.60QStE500TM ≤1.70Nb≤0.09 V≤0.20 Ti≤0.15a为改善钢的性能,根据需要可可添加Nb、V、Ti中一种或几种合金元素,但Nb+V+Ti ≤ 0.22 %。

QStE550TM(热轧、酸洗)2.0*实宽(mm)*C 宝钢梅钢武钢QStE550TM(热轧、酸洗)2.3*实宽(mm)*C 宝钢梅钢武钢QStE550TM(热轧、酸洗)2.5*实宽(mm)*C 宝钢梅钢武钢QStE550TM(热轧、酸洗)3.0*实宽(mm)*C 宝钢梅钢武钢QStE550TM(热轧、酸洗)3.5*实宽(mm)*C 宝钢梅钢武钢QStE550TM(热轧、酸洗)4.0*实宽(mm)*C 宝钢梅钢武钢QStE550TM(热轧、酸洗)4.5*实宽(mm)*C 宝钢梅钢武钢QStE550TM(热轧、酸洗)5.0*实宽(mm)*C 宝钢梅钢武钢QStE550TM(热轧、酸洗)5.5*实宽(mm)*C 宝钢梅钢武钢QStE550TM(热轧、酸洗)6.0*实宽(mm)*C 宝钢梅钢武钢QStE550TM(热轧、酸洗)6.5*实宽(mm)*C 宝钢梅钢武钢QStE550TM(热轧、酸洗)7.0*实宽(mm)*C 宝钢梅钢武钢QStE550TM(热轧、酸洗)7.5*实宽(mm)*C 宝钢梅钢武钢QStE550TM(热轧、酸洗)8.0*实宽(mm)*C 宝钢梅钢武钢QStE550TM(热轧、酸洗)8.5*实宽(mm)*C 宝钢梅钢武钢QStE550TM(热轧、酸洗)9.0*实宽(mm)*C 宝钢梅钢武钢QStE550TM(热轧、酸洗)9.5*实宽(mm)*C 宝钢梅钢武钢QStE550TM(热轧、酸洗)10*实宽(mm)*C 宝钢梅钢武钢QStE550TM(热轧、酸洗)12*实宽(mm)*C 宝钢梅钢武钢QStE550TM(热轧、酸洗)14*实宽(mm)*C 宝钢梅钢武钢QStE550TM QStE550TM QStE550TM上海振钰实业有限公司是一家集钢材贸易、板材配送、部件加工、货运代理于一体的综合性贸易公司。

首先感谢您选用我公司的产品!在使用本产品之前请仔细阅读一遍本说明书!本产品设计引用如下标准1. GB/T9462-19992. GB/T13752-19923. JG/T5037-19934. GB5144-1994 塔式起重机技术文件塔式起重机设计规范塔式起重机分类塔式起重机安全规范第一章概述 (3)1.1 前言................................................................ ..3 1.2性能表................................................................ (4)1.3塔机部件数量,规格、重量表........................................ ..81.4塔机基础受力简图....................................................... ..9第二章场地准备......................................................... ..10 2.1场地与空间............................................................ .10 2.2 固定基础节基础...................................................... .14 2.3底座固定式的砼基础.................................................... .18 2.4行走式底座安装........................................................ .20 2.5 接地................................................................. .24 2.6压重块安装图.......................................................... .25 2.7配重(平衡重)....................................................... ..28 2.8 附着................................................................. .33第三章用汽车吊安装塔机说明及塔机主要部件重量.......................... ..43 3.1重量和高度............................................................ .43 3.2 底盘................................................................. .45 3.3 通道................................................................. .46 3.4 塔头................................................................. .47 3.5平衡臂................................................................ .48 3.6起重臂和拉杆......................................................... .49第四章塔机的安装........................................................ ..52 4.1安装程序.............................................................. .52 4.2安装调平底盘......................................................... .58 4.3安装塔身标准节........................................................ .59 4.4安装通道.............................................................. .62 4.5安装顶升外套架....................................................... .64 4.6安装回转支承......................................................... .67 4.7安装塔头.............................................................. .70 4.8装配起重臂和平衡臂.................................................... .73 4.9安装牵引小车和滑轮组................................................... .80 4.10安装平衡臂和起重臂 ................................................ (84)4.11穿绕起升钢丝绳 .................................................... (92)4.12安装平衡重 ......................................................... (94)4.13顶升准备 ........................................................... (95)4.14塔机顶升配平 ...................................................... (99)4.15顶升加节 ........................................................... .102 4.16使用前的准备工作 .................................................. .107第五章拆塔.. (110)5.1 引言.............................................................. ..110 5.2拆塔前的准备工作.................................................. (111)5.3拆卸塔身........................................................... (111)5.4拆除钢丝绳和配重.................................................. (114)5.5拆卸起重臂(用辅助吊车).......................................... (115)5.6拆卸平衡臂......................................................... (118)5.7 拆卸塔头、回转支承、塔身第一节及套架119 第六章安全须知 (121)6.1 说明.............................................................. ..121 6.2安全须知........................................................ (121)第七章电气系统 (126)第八章起升机构 (142)第九章回转机构 (148)9.1说明............................................................ (148)9.2回转机构传动示意图................................................. (148)9.3工作原理............................................................ (148)9.4回转限位器.......................................................... (148)9.5回转齿圈紧固螺栓的定期检查......................................... (149)9.6回转机构的保养..................................................... (150)第十章小车变幅机构 (151)10.1 说明 .............................................................. ..151 10.2工作原理 .......................................................... ..152 10.3幅度限位器 ......................................................... .152 10.4小车变幅机构的维护和保养 ......................................... ..153 10.5变幅小车机构交流变频器调速原理简介 ............................... ..153第^一章安全装置 (156)11.1 概述 ............................................................... .157 11.2力矩限制器 ......................................................... .158 11.3 调整 ............................................................... .158 11.4载荷限制器 ......................................................... .159第十二章液压顶升系统............................................... ..164 12.1液压系统的原理以及组成 (164)12.2液压系统的安装 ..................................................... .165 12.3液压系统的操作和使用 .............................................. .166 12.4液压系统的调整 ................................................ .. (167)12.5液压系统的维护,保养及主要事项 .................................... .169 12.6常见故障因分析及排除 .................................... ... .... . (170)第十三章润滑 (171)13.1塔机各润滑部位 ................................................ .. (171)13.2润滑用油表 ......................................................... .172售后服务和三包期限..................................................... .171附件:QTZ7520塔式起重机电气维修手册第一章概述1.1 前言QTZ7520 塔式起重机是广西建工集团建筑机械制造有限责任公司为满足国内外市场的需要,按照国家和行业标准,参照相应的国标标准,自行设计、制造的一种上回转、水平变幅、自升式塔式起重机。

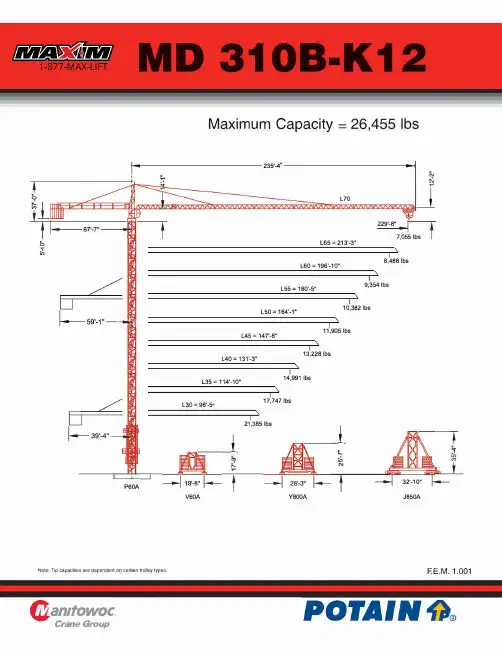

Maximum Capacity 26,455 lbs-------------235'-4'-------------binI---59'-1" ----IJI II---39'-4"P60ANote: Tip capacities are dependent on certain trolley types.L70L65 = 213'-3'L60 = 196'-10"L55 = 180'-5'_l229'-8' --17,055 lbs8,4881bs9,354 lbsL50 = 164'-1"10,382 lbsL45 = 147-8"11,905 lbsL40 = 131'-3'13,228 lbsL35 = 114'-10'14,991 lbsL30 = 98'-5'17,747 lbs21,385 lbstV60A Y800At�in--j 32'-10' I-J850AF.E.M. 1.001Maximum Free-Standing Hook HeightsMechanical Data2-part (lifting)4-part (lifting)Function HoistTypeSpeed vs Weight 1st Gear 2nd Gear 3rd Gear 4th Gear 5th Gear 1st Gear 2nd Gear 3rd Gear 4th Gear 5th Gear Motor (hp)Motor (kW)Rope Length (ft)50 LVF 30Optimaft/min lbs 9913,2281259,9211786,6142563,3075026,4556319,8428913,2281286,61450371,11575 LVF 30Optimaft/min lbs 14513,2281849,9212636,6143753,3077326,4559219,84213213,2281886,61475551,870100 LVF 30Optimaft/min lbs 19713,2282509,9213556,6145193,3079926,45512519,84217813,2282606,614100751,926or 3,343150 LCC 30ft/minlbs28313,2283389,9214246,6145653,3076761,65314226,45517119,84221413,2282836,6143383,3071501102,139Trolley 6 DVF 4ft/min 5.5 4.0Swing RVF 162Optima rpm 2 x 7.5 2 x 5.5P o w e r R e q u i r e m e n t s :480V (+6%o r -10%)60H z m e a s u r e d a t t u r n t a b l e .A m p e r a g e :50L V F 30:88A m p (3p h a s e s e r v i c e w i t h g r o u n d )A m p e r a g e :75L V F 30:118A m p (3p h a s e s e r v i c e w i t h g r o u n d )A m p e r a g e :100L V F 30:147A m p (3p h a s e s e r v i c e w i t h g r o u n d )A m p e r a g e :150L C C 30:245A m p (3p h a s e s e r v i c e w i t h g r o u n d )Notes:1. The 50 LVF 30 is the standard hoist option for the MD 310B-K12. Other hoist options must be at the request of the customer.2. Hoist speeds with "Optima" hoist units are 25% faster than the speeds listed above when lowering the hook.3. The 100 LVF 30 hoist drum can be purchased in either a small or large drum size depending on the customers needs.4. Values given under "Rope Length" are for drum spooling capacity only.Hoist165 (26,455 lbs) 329 (13,228 lbs) 394 (6,614 lbs)0.70Rated Load Chart C a p a c i t y (l b s )229'-8"213'-3"196'-10"180'-5"164'-1"147'-8"131'-3"114'-10"98'-5"20'-0"26,45526,45526,45526,45526,45526,45526,45526,45526,45530'-0"26,45526,45526,45526,45526,45526,45526,45526,45526,45540'-0"26,45526,45526,45526,45526,45526,45526,45526,45526,45550'-0"26,45526,45526,45526,45526,45526,45526,45526,45526,45560'-0"26,45526,45526,45526,45526,45526,45526,45526,45526,45570'-0"26,45526,45526,45526,45526,45526,45526,45526,45526,45580'-0"22,97824,57024,82424,83125,37325,98526,45526,45526,45590'-0"19,93721,37221,62221,62822,10822,65023,56323,69023,77998'-5"17,86619,19519,44219,44819,886 20,380 21,213 21,32921,385100'-0"17,51918,83019,07619,08219,51320,00020,81920,933110'-0"15,55116,76017,00417,00917,40017,84218,58518,688114'-10"14,72615,89316,13616,14016,515 16,937 17,64817,747120'-0"13,91715,04315,28515,28915,647 16,051 16,731130'-0"12,94413,59413,83513,83914,16914,54115,167131'-3"12,78913,43113,67213,67614,002 14,37114,991140'-0"11,76712,76213,00013,00113,228 13,250147'-8"10,97711,93112,16812,17012,46312,787150'-0"10,74911,69211,92911,93012,218160'-0"9,86110,75710,99310,99511,265164'-1"9,53310,41310,64810,64910,913170'-0"9,0799,93510,17010,171180'-0"8,3849,2059,4399,440180'-5"8,3559,1749,4089,409190'-0"7,7648,5538,786196'-10"7,3768,1458,378200'-0"7,2077,966210'-0"6,7037,437213'-3"6,5507,275220'-0"6,246229'-8"5,842M a x .L o a d R a d i u s F r o m8'-6"8'-6"8'-6"8'-6"8'-6"8'-6"8'-6"8'-6"8'-6"T o71'-1"75'-1"75'-9"75'-9"77'-2"78'-9"81'-6"81'-10"82'-2"Notes:1. The above load chart was calculated using the SM-DM trolley system.2. Values above the red line can be achieved with 4-part line configuration only.3. Deduct 551 lbs from values below the red line when using 4-part line configuration instead of 2-part.H o o kR a d i u sRated Load Chart 2-P a r t C a p a c i t y (l b s )229'-8"213'-3"196'-10"180'-5"164'-1"147'-8"131'-3"114'-10"98'-5"20'-0"13,22813,22813,22813,22813,22813,22813,22813,22813,22830'-0"13,22813,22813,22813,22813,22813,22813,22813,22813,22840'-0"13,22813,22813,22813,22813,22813,22813,22813,22813,22850'-0"13,22813,22813,22813,22813,22813,22813,22813,22813,22860'-0"13,22813,22813,22813,22813,22813,22813,22813,22813,22870'-0"13,22813,22813,22813,22813,22813,22813,22813,22813,22880'-0"13,22813,22813,22813,22813,22813,22813,22813,22813,22890'-0"13,22813,22813,22813,22813,22813,22813,22813,22813,22898'-5"13,22813,22813,22813,22813,22813,22813,22813,22813,228100'-0"13,22813,22813,22813,22813,22813,22813,22813,228110'-0"13,22813,22813,22813,22813,22813,22813,22813,228114'-10"13,22813,22813,22813,22813,22813,22813,22813,228120'-0"13,22813,22813,22813,22813,22813,22813,228130'-0"13,22813,22813,22813,22813,22813,22813,228131'-3"13,22813,22813,22813,22813,22813,22813,228140'-0"12,96113,22813,22813,22813,22813,228147'-8"12,17313,13113,13013,13113,22813,228150'-0"11,94612,89212,89112,89213,208160'-0"11,06111,96011,96011,96112,256164'-1"10,73411,61611,61611,61711,905170'-0"10,28111,14011,13911,140180'-0"9,58910,41210,41110,412180'-5"9,56010,38110,38110,382190'-0"8,9719,7629,761196'-10"8,5849,3559,354200'-0"8,4159,177210'-0"7,9138,649213'-3"7,7608,488220'-0"7,457229'-8"7,055M a x .L o a d R a d i u s F r o m10'-2"10'-2"10'-2"10'-2"10'-2"10'-2"10'-2"10'-2"10'-2"T o 137'-7"146'-8"146'-8"146'-8"149'-10"147'-8"131'-3"114'-10"98'-5"H o o kR a d i u sRated Load Chart 4-P a r t C a p a c i t y (l b s )229'-8"213'-3"196'-10"180'-5"164'-1"147'-8"131'-3"114'-10"98'-5"20'-0"26,45526,45526,45526,45526,45526,45526,45526,45526,45530'-0"26,45526,45526,45526,45526,45526,45526,45526,45526,45540'-0"26,45526,45526,45526,45526,45526,45526,45526,45526,45550'-0"26,45526,45526,45526,45526,45526,45526,45526,45526,45560'-0"26,45526,45526,45526,45526,45526,45526,45526,45526,45570'-0"26,45526,45526,45526,45526,45526,45526,45526,45526,45580'-0"22,66924,48524,48524,48525,08425,70026,45526,45526,45590'-0"19,63721,29521,29521,29521,82622,37223,34723,47223,55998'-5"17,57319,12419,12419,12419,60920,10620,99621,11021,164100'-0"17,22618,76018,76018,76019,23619,72620,60120,714110'-0"15,26416,69616,69616,69617,12817,57218,36618,468114'-10"14,44115,83115,83115,83116,24416,66917,42917,527120'-0"13,63514,98314,98314,98315,37915,78516,511130'-0"12,26213,53913,53913,53913,90314,27814,947131'-3"12,10813,37613,37613,37613,73714,10814,771140'-0"11,08912,30512,30512,30512,64312,990147'-8"10,30111,47611,47611,47611,79712,125150'-0"10,07411,23811,23811,23811,553160'-0"9,18910,30610,30610,30610,601164'-1"8,8629,9629,9629,96210,250170'-0"8,4099,4869,4869,486180'-0"7,7178,7588,7588,758180'-5"7,6888,7278,7278,727190'-0"7,0988,1088,108196'-10"6,7117,7017,701200'-0"6,5437,523210'-0"6,0406,995213'-3"5,8876,834220'-0"5,584229'-8"5,182M a x .L o a d R a d i u s F r o m10'-2"10'-2"10'-2"10'-2"10'-2"10'-2"10'-2"10'-2"10'-2"T o 70'-4"74'-11"74'-11"74'-11"76'-5"78'-0"80'-11"81'-3"81'-7"H o o kR a d i u sManitowoc Crane Group - Americas Shady Grove, Pennsylvania Facility1565 Buchanan Trail EastShady Grove, PA 17256-0021, USATel:[Int + 001] 717 597 8121Fax:[Int + 001] 717 597 4062。

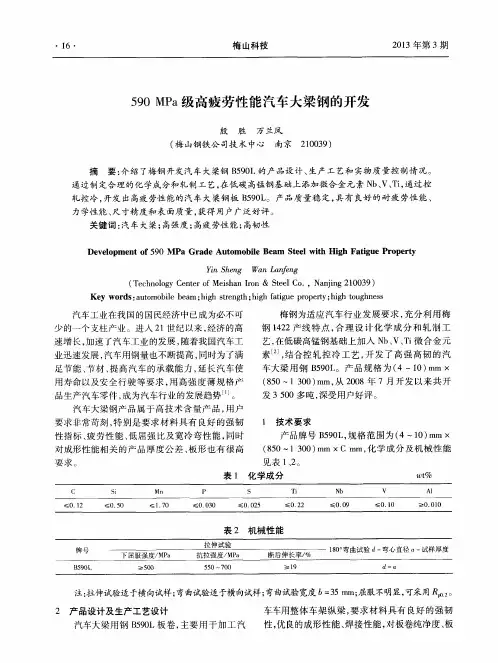

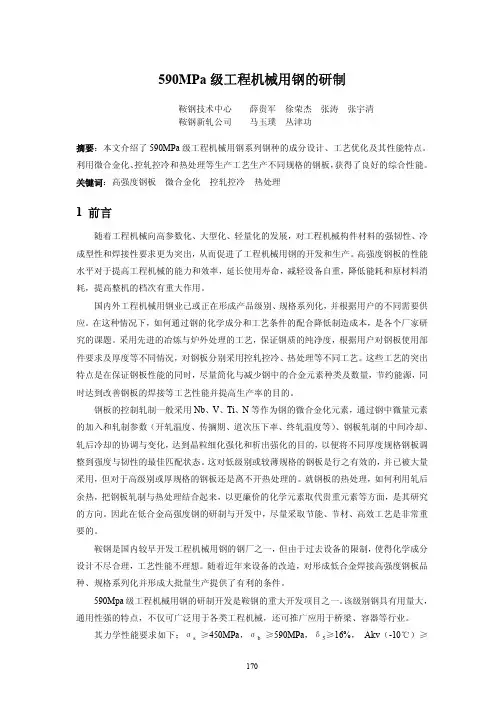

590MPa级工程机械用钢的研制鞍钢技术中心薛贵军徐荣杰张涛张宇清鞍钢新轧公司马玉璞丛津功摘要:本文介绍了590MPa级工程机械用钢系列钢种的成分设计、工艺优化及其性能特点。

利用微合金化、控轧控冷和热处理等生产工艺生产不同规格的钢板,获得了良好的综合性能。

关键词:高强度钢板微合金化控轧控冷热处理1 前言随着工程机械向高参数化、大型化、轻量化的发展,对工程机械构件材料的强韧性、冷成型性和焊接性要求更为突出,从而促进了工程机械用钢的开发和生产。

高强度钢板的性能水平对于提高工程机械的能力和效率,延长使用寿命,减轻设备自重,降低能耗和原材料消耗,提高整机的档次有重大作用。

国内外工程机械用钢业已或正在形成产品级别、规格系列化,并根据用户的不同需要供应。

在这种情况下,如何通过钢的化学成分和工艺条件的配合降低制造成本,是各个厂家研究的课题。

采用先进的冶炼与炉外处理的工艺,保证钢质的纯净度,根据用户对钢板使用部件要求及厚度等不同情况,对钢板分别采用控轧控冷、热处理等不同工艺。

这些工艺的突出特点是在保证钢板性能的同时,尽量简化与减少钢中的合金元素种类及数量,节约能源,同时达到改善钢板的焊接等工艺性能并提高生产率的目的。

钢板的控制轧制一般采用Nb、V、Ti、N等作为钢的微合金化元素,通过钢中微量元素的加入和轧制参数(开轧温度、传搁期、道次压下率、终轧温度等)、钢板轧制的中间冷却、轧后冷却的协调与变化,达到晶粒细化强化和析出强化的目的,以便将不同厚度规格钢板调整到强度与韧性的最佳匹配状态。

这对低级别或较薄规格的钢板是行之有效的,并已被大量采用,但对于高级别或厚规格的钢板还是离不开热处理的。

就钢板的热处理,如何利用轧后余热,把钢板轧制与热处理结合起来,以更廉价的化学元素取代贵重元素等方面,是其研究的方向。

因此在低合金高强度钢的研制与开发中,尽量采取节能、节材、高效工艺是非常重要的。

鞍钢是国内较早开发工程机械用钢的钢厂之一,但由于过去设备的限制,使得化学成分设计不尽合理,工艺性能不理想。

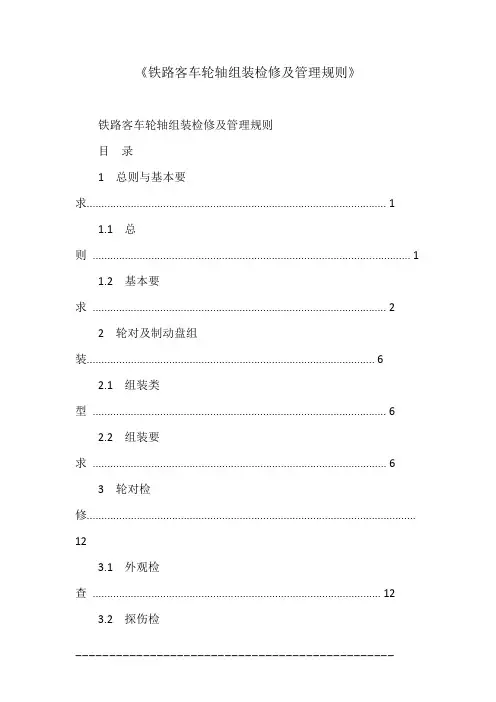

《铁路客车轮轴组装检修及管理规则》铁路客车轮轴组装检修及管理规则目录1 总则与基本要求 (1)1.1 总则 (1)1.2 基本要求 (2)2 轮对及制动盘组装 (6)2.1 组装类型 (6)2.2 组装要求 (6)3 轮对检修................................................................................................................123.1 外观检查 (12)3.2 探伤检查 (12)3.3 退轮及退盘检查 (12)3.4 更换车轴 (12)3.5 更换车轮 (13)3.6 更换制动盘 (13)3.7 加工修理 (14)3.8 轮对分解技术要求 (15)3.9 车轮加修及处理技术要求 (15)3.10 车轴加修及处理技术要求 (16)3.11 制动盘加修及处理技术要求 (20)3.12 车轴裂纹及发纹限度要求 (21)3.13 动平衡试验要求 (22)3.14 涂装要求 (22)4 轴承及轴箱装置组装及检修 (23)4.1 热组装圆柱滚子轴承及轴箱装置的检修和组装 (23)4.2 冷压装滚子轴承及轴箱装置的检修和压装 (35)5 轮轴探伤................................................................................................................405.1 综合要求 (40)5.2 铁路客车轮轴、轮对、车轴手工超声波探伤 (41)5.3 铁路客车车轮轮辋手工超声波探伤 (70)5.4 铁路客车轮轴、轮对、车轴磁粉探伤 (78)5.5 铁路客车滚动轴承零件磁粉探伤 (89)5.6 铁路客车轮轴、轮对超声波自动探伤 (97)5.7 铁路客车车轮轮辋超声波自动探伤.................................................... 107 6 轮轴标记.. (118)6.1 车轮标记 (118)6.2 车轴标记 (123)6.3 轴承标记 (125)6.4 轴箱前盖标记 (129)6.5 制动盘组装标记 (130)6.6 标志板标记............................................................................................ 131 7 轮轴信息化管理.. (133)7.1 综合要求 (133)7.2 输入、输出原始记录............................................................................ 134 8 备用轮轴管理 (138)8.1 适用范围 (138)8.2 基本要求 (138)8.3 备用轮轴、轮对的管理 (138)8.4 备用轴承管理........................................................................................ 142 附件1 术语解释..................................................................................................... 144 附件2 轮轴及零部件名称、型式、基本尺寸及材质信息................................. 147 附件3 轮对组装压装力曲线及说明..................................................................... 165 附件4 铁道车辆车轮、轴承外观缺陷术语及程度分类..................................... 174 附件5 轴承组装前的清洁度及工作间环境质量要求......................................... 185 附件6 NJ(P)3226X1型轴承用工程塑料保持架技术说明................................. 190 附件7 铁路客车轮轴、轮对、车轴手工超声波探伤附录................................. 192 附件8 铁路客车车轮轮辋手工超声波探伤附录................................................. 222 附件9 铁路客车轮轴、轮对、车轴磁粉探伤附录............................................. 225 附件10 铁路客车滚动轴承零件磁粉探伤灵敏度试块....................................... 236 附件11 铁路客车轮轴、轮对超声波自动探伤用对比试样轮轴(轮对)....... 239 附件12 轮轴探伤、检修及组装记录单............................................................... 244 附件13铁路客车及轮轴零部件造修单位简称及代号....................................... 301 附件14 轮对、轴承和轴箱装置检修限度表....................................................... 305 附件15 新轴承抽检项目表................................................................................... 315 附件16 轴承注油脂量及润滑脂质量检测项目 (316)IITG/CL206-20131 总则与基本要求1.1 总则铁路客车轮对、轴承和轴箱装臵是铁路客车的重要部件,其技术状态直接关系到客车的运行品质和安全。

第21卷第6期 2011年6月中国冶金China M etallurg yVo l.21,N o.6June 2011汽车大梁钢610L 的研究马正伟, 王俊海, 亓俊鸿, 谷国华(山东泰山钢铁集团新材料研究所,山东莱芜271100)摘 要:利用真空中频感应熔炼炉按照设计的化学成分冶炼出汽车大梁钢610L 铸锭,将铸锭锻造成厚度为130mm 方坯后,用最大轧制力为3500kN 的试验轧机根据制定的试轧方案经过12道次轧制成厚度度为10mm 的钢板,并将钢板进行解剖分析。

分析结果表明:钢板的化学成分符合预先设定的低碳高锰微合金的原则;钢板的抗拉强度达到610M Pa 以上,伸长率低于24%;钢中出现贝氏体组织,晶粒度达到11级。

从而确定研发钢种的成分,确定了轧钢过程中的控制要点。

关键词:汽车大梁钢610L ;研发;层流冷却;贝氏体中图分类号:T F 777.2 文献标志码:A 文章编号:1006 9356(2011)06 0001 04Research on Automobile Beam Steel 610LM A Zheng w ei, WANG Jun hai, QI Jun ho ng , GU Guo hua(N ew M aterial Research Institute o f Shandong T a ishan Steel G roup,L aiw u 271100,Shandong,China)Abstract:A n automo bile frames steel 610L w as melt in vacuum inter mediate frequency inductio n w ith t he pre set chemical co mpo sitio n,for ged into a billet in 130mm thickness,using r olled into g aug e 10mm of steel plate w ith 12pass according to the pro gr am develo ped o n ex per imental ro lling mill w ith the maximum ro lling for ce 3500kN.T he results fro m the plate test show that the chemical composit ion of steel plat e co nforms t o the pr inciples that pre set low carbon hig h mang anese micro alloy s;the tensile strength of steel reaches mor e than 610M Pa;the elongation is less than 24%;there are bainite micro st ructur e and t he index 11of g rain size.T he com position of the steel and key po int of r olling pr ocess w ere affirmed by cur rent trial.Key words:auto mobile beam steel 610L ;research and dev elo pment;laminar coo ling ;bainite作者简介:马正伟(1982 ),男,硕士,工程师; E mail :zh iqiuo@; 收稿日期:2010 06 09随着中国汽车工业的飞速发展,各汽车制造厂对汽车用钢的需求量大大增加,对产品综合性能的要求也越来越高。

汽车用高强钢DP590的材料性能对压溃吸能的影响王秋雨;孟根巴根;张赛娟;张茜【摘要】基于Comper-Symonds模型建立了DP590的本构方程,拟合得到应变速率系数分别为C=1023260、P=4.46.结果表明,随着屈服强度和抗拉强度、板料厚度的增大,吸能能力呈增大趋势,压缩时间和最大位移均呈递减趋势,但是最大碰撞力也随之增大,且抗拉强度对吸能的影响程度明显高于屈服强度,最大碰撞力Fmax、吸能数值Ea均与板料厚度的平方t2呈很好的线性关系,Fmax/t2、Ea/t2与材料的屈服强度、抗拉强度也呈线性关系.【期刊名称】《汽车工艺与材料》【年(卷),期】2018(000)012【总页数】4页(P63-66)【关键词】DP590;压溃吸能;前纵梁;屈服强度;抗拉强度【作者】王秋雨;孟根巴根;张赛娟;张茜【作者单位】河钢股份有限公司唐山分公司,唐山 063000;河钢股份有限公司唐山分公司,唐山 063000;河钢股份有限公司唐山分公司,唐山 063000;河钢股份有限公司唐山分公司,唐山 063000【正文语种】中文【中图分类】U461.911 前言对于汽车上大多数梁结构,最有效的轻量化方式就是采用先进高强钢,从而降低材料的厚度[1]。

同时,汽车的轻量化也给汽车碰撞带来新的难题和研究方向。

汽车以48 km/h的速度发生正面碰撞时,前纵梁可以吸收50%~70%的碰撞能量,吸能效果最为显著[2]。

因此,前纵梁的设计在被动安全中具有重要意义。

本文利用有限元软件研究材料的屈服强度、抗拉强度和材料厚度对前纵梁压溃吸能的影响,为先进高强钢在汽车轻量化中的使用提供参考。

2 前纵梁仿真模型的建立2.1 梁的结构模型将前纵梁简化成帽形梁结构进行研究,以提高效率[3]。

帽形梁的尺寸规格及焊点位置,如图1所示。

帽形梁总长度为300 mm,将钢板折弯呈Ω形,折弯处的圆角半径为10 mm,然后与底面同材质的钢板进行焊接。

汽车大梁钢610L的试制开发陈培敦;马正伟;陈坤【摘要】按照低碳高锰微合金的成分设计原则,利用真空巾频感应熔炼炉冶炼并浇铸成130mm×350mm的铸坯,经过12道次轧制成厚度为10mm的钢板,实验室试制了汽车大梁钢610L.检测分析表明:钢中出现了贝氏体组织,伸长率偏低.工业试制在降低氧含量的前提下进行了Si-Ca线变质处理,同时降低轧制温度和严格控冷,得到了以针状铁素体+珠光体为主的组织,晶粒度12级,其抗拉强度在625MPa以上,延伸率在24%以上,成功开发了高强度610L钢.【期刊名称】《山东冶金》【年(卷),期】2010(032)005【总页数】3页(P27-29)【关键词】汽车大梁钢;层流冷却;轧制温度;变质处理【作者】陈培敦;马正伟;陈坤【作者单位】山东泰山钢铁集团有限公司,山东,莱芜,271100;山东泰山钢铁集团有限公司,山东,莱芜,271100;山东泰山钢铁集团有限公司,山东,莱芜,271100【正文语种】中文【中图分类】TG142.4汽车大梁钢主要用于各类汽车车架纵梁、横梁等结构件。

随着汽车工业的发展,各汽车制造厂家对汽车用钢的需求量大大增加,根据汽车轻量化的要求,对汽车大梁钢综合性能的要求也越来越高,不仅要求具有更高的强度,而且还需要良好的塑性、韧性以及优良的冷弯性能[1-2]。

为此,泰钢试制开发了汽车大梁钢610L。

利用最高加热温度为1 700℃、坩埚容积为50 kg、中频频率为1 500~2 500 Hz 的真空中频感应熔炼炉,按照表1成分进行冶炼。

将冶炼的试验铸坯放入最高加热温度为1 350℃的加热炉中加热到1 240℃,驻炉200 min;利用最大轧制力为3 500 kN、轧制速度0~1.5 m/s的实验轧机按照表2工艺,轧制12道次至板厚10 mm;在自制水幕冷却设备上控制冷却;冷却后将试样放在石棉中缓冷模拟卷取温度。

精轧开轧温度930~950℃,终轧温度800~820℃;层流冷却5~8℃/s,冷后温度580℃。

载重汽车大梁用高强度钢板及钢带1 范围本标准规定了载重汽车大梁用高强度钢板及钢带的牌号、分类及代号、订货内容、尺寸、外形、重量及允许偏差、技术要求、试验方法、检验规则、包装、标志及质量证明书。

本标准适用于制造载重汽车大梁(纵梁,横梁)用厚度为1.5mm~16.0 mm的热轧钢板和钢带(以下简称钢板和钢带)。

2 规范性引用文件下列文件中的条款通过本标准的引用而成为本标准的条款。

凡是注日期的引用文件,仅注日期的版本适用于本标准。

凡是不注日期的引用文件,其最新版本(包括所有的修改单)适用于本标准。

GB/T 222 钢的成品化学成分允许偏差GB/T 223.3 钢铁及合金化学分析方法二安替比林甲烷磷钼酸重量法测定磷量GB/T 223.9 钢铁及合金铝含量的测定铬天青S分光光度法GB/T 223.11 钢铁及合金铬含量的测定可视滴定或电位滴定法GB/T 223.13 钢铁及合金化学分析方法硫酸亚铁铵滴定法测定钒含量GB/T 223.17 钢铁及合金化学分析方法二安替比林甲烷光度法测定钛量GB/T 223.18 钢铁及合金化学分析方法硫代硫酸钠分离-碘量法测定铜量GB/T 223.23 钢铁及合金镍含量的测定丁二酮肟分光光度法GB/T 223.40 钢铁及合金铌含量的测定氯磺酚S分光光度法GB/T 223.49 钢铁及合金化学分析方法萃取分离-偶氮氯膦mA分光光度法测定稀土总量GB/T 223.60 钢铁及合金化学分析方法高氯酸脱水重量法则定硅含量GB/T 223.63 钢铁及合金化学分析方法高碘酸钠(钾)光度法则测定锰量GB/T 223.68 钢铁及合金化学分析方法管式炉内燃烧后碘酸钾滴定法测定硫含量GB/T 223.69 钢铁及合金碳含量的测定管式炉内燃烧后气体容量法GB/T 223.79 钢铁多元素含量的测定X-射线荧光光谱法(常规法)GB/T 228.1 金属材料拉伸试验第1部分:室温试验方法GB/T 229 金属材料夏比摆锤冲击试验方法GB/T 232 金属材料弯曲试验方法GB/T 247 钢板和钢带包装、标志及质量证明书的一般规定GB/T 709 热轧钢板和钢带的尺寸、外形、重量及允许偏差GB/T 2975 钢及钢产品力学性能试验取样位置及试样制备GB/T 3273 汽车大梁用热轧钢板和钢带GB/T 4336 碳素钢和中低合金钢多元素含量的测定火花源原子发射光谱分析方法(常规法)GB/T 6394 金属平均晶粒度测定法GB/T 8170 数值修约规则与极限数值的表示和判定GB/T 13298 金属显微组织检验方法GB/T 13299 钢的显微组织评定方法GB/T 17505 钢及钢产品交货一般技术要求GB/T 20066 钢和铁化学成分测定用试样的取样和制样方法GB/T 20123 钢铁总碳硫含量的测定高频感应炉燃烧后红外吸收法(常规方法)3 牌号、分类及代号3.1 牌号表示方法钢的牌号由抗拉强度下限值和汉语拼音“梁”的首位字母L两个部分组成。