空气悬架系统WABCO

- 格式:ppt

- 大小:5.32 MB

- 文档页数:27

Systems And Components In Commercial Vehicles Edition 1998© Copyright WABCO 1998WABCOFahrzeugbremsenA Division ofWABCO Standard GmbHThe right of amendment is reservedTable of ContentsPage Operation of Air Braking Systems (4)1. MotorVehiclesBraking System (6)Components of the Motor Vehicle’s Braking System (7)2. TrailersBraking System (62)Equipment For Trailer Braking Systems (64)3.Anti-Lock Braking System (ABS) (79)4.Sustained-Action Braking Systems On Motor Vehicles (89)5. EBS - Elektronisch geregeltes Bremssystem (93)6.Air Suspension Systems and ECAS(Electronically Controlled Air Suspension) (105)7.Clutch Servo (117)8.Air Braking Systems InAgricultural Vehicles (121)9.ETS-Elektronic Door Control SystemFor Motor Coaches (131)10.Installation Of Pipes And Screw Unions (139)11.Index (151)Operation of Air Braking Systems1. Compressed Air Supply The compressed air supplied by the com-pressor (1) flows to the air dryer (3) via the unloader (2) which automatically con-trols the pressure within the system with-in a range of between 7.2 and 8.1 bar, for instance. In the air dryer, the water va-pour in the air is extracted and expelled through the air dryer’s vent. The dried air then flows to the quadruple-circuit pro-tection valve (4) which, if one or several circuits are defective, secures the intact circuits against any loss in pressure. Within the service braking circuits I and II, the air supply from the reservoirs (6 and 7) flows to the brake valve (15). In Circuit III the air supply from the reservoir (5) flows through the 2/2-way valve which is integrated in the trailer control valve (17) to the automatic hose coupling (11) and on to the check valve (13), the hand brake valve (16) and the relay valve (20) into the spring-loaded portion of the Tris-top spring brake actuators (19). Circuit IV supplies air to any ancillary consumers, in this case an exhaust brake.The trailer’s braking system receives compressed air through the hose cou-pling (11) with its supply hose connected. This air then passes the line filter (25)and the relay emergency valve (27) be-fore reaching the reservoir (28) and alsoflows to the supply ports of the ABS relayvalves (38).2. Operation:2.1 Service Braking SystemWhen the brake valve (15) is actuated,compressed air flows via the ABS sole-noid control valve (39) into the brakechambers (14) of the front axle and to theload-sensing valve (18). This valve re-verses and the air flows via the ABS so-lenoid control valve (40) into the servicebrake portion (brake chambers) of theTristop spring brake actuators (19). Thepressure in the brake cylinders generat-ing the force required for the wheel brakedepends on the amount of force appliedto the brake valve, and on the load car-ried on the vehicle. This brake pressureis controlled by the load-sensing valve(18) which is connected to the rear axleby means of a linkage. Any change in thedistance between the vehicle’s chassisand its axle caused by loading or unload-ing the vehicle causes the brake pres-sure to be continuously adjusted. At thesame time, via a pilot line, the load-emptyvalve integrated in the brake valve is af-fected by the load-sensing valve. Thusthe brake pressure on the front axle isalso adjusted to the load carried on thevehicle (mostly on lorries).The trailer control valve (17) actuated bythe two service braking circuits pressuriz-es the pilot connection of the relay emer-gency valve (27) after passing the hosecoupling (12) and the connecting “con-trol“ hose. The air supply from the air res-ervoir (28) is thus allowed to passthrough the relay-emergency valve, thetrailer release valve (32), the adaptervalve (33) and on to the load-sensingvalve (34) and the ABS relay valve (37).The relay valve (37) is actuated by theload-sensing valve (34) and the com-pressed air flows to the brake chambers(29) on the front axle. The ABS relayvalves (38) are actuated by the load-sensing valve (35), and the compressedair is allowed to pass to the brake cham-bers (30 and 31). The service pressureon the trailer, which is similar to the out-put pressure from the towing vehicle, isautomatically adjusted by the load-sens-ing valves (34 and 35) for the load carriedon the trailer. In order to prevent overb-raking of the wheel brake on the frontaxle in the partial-braking range, theservice pressure is reduced by the adapt-er valve (33). The ABS relay valves (onthe trailer) and the ABS solenoid control valves (on the towing vehicle) are used to control (pressure increase, pressure hold, pressure release) the brake cylin-ders. If these valves are activated by the ABS ECU (36 or 41), this control process is achieved regardless of the pressure al-lowed to pass by the brake valve or the relay emergency valve.When they are not needed (solenoids are dead), the valves operate as relay valves and achieve a faster increase or de-crease of the pressure for the brake cyl-inders.2.2Parking Braking System When the hand brake valve (16) is actu-ated and locked, the spring-loaded por-tions of the Tristop spring brake actua-tors (19) are exhausted fully. The force needed for the wheel brake is now pro-vided by the heavily preloaded springs of the Tristop spring brake actuators. At the same time, the pressure in the line lead-ing from the hand brake valve (16) to the trailer control valve (17) is reduced. Brak-ing of the trailer commences by the pres-sure increasing in the connecting ‘supply’hose. Since the guideline of the Council of the European Communities (RREG) that a tractor-trailer combination must be held by the motor vehicle alone, the pres-sure in the trailer’s braking system can bereleased by moving the hand brake leverinto its ‘control’ position. This permits theparking braking system to be examinedas to whether it fulfills the provisions ofthe RREG.2.3 Auxiliary Braking SystemDue to sensitive graduation of the handbrake valve (16) the lorry can be brakedby means of the spring-loaded portionseven if the service braking systems I andII have failed. The brake force for thewheel brake is produced by the force ofthe preloaded springs of the Tristopspring brake actuators (19) as describedunder ‘Parking Braking System’ althoughthe spring-loaded portions are not ex-hausted fully but only to the extent re-quired for the braking performance.3. Automatic Braking of theTrailerIn the event of the connecting ‘supply’line breaking, the pressure will drop rap-idly and the relay emergency valve (27)will cause full application of the trailer’sbrakes. In the event of the connecting‘control’ line breaking, the 2/2-way valveintegrated in the trailer control valve (17)will, when the service braking system isactuated, throttle the passage of the sup-ply line leading to the hose coupling (11)to such an extent that the rupture of thesupply line causes a rapid drop in pres-sure in the supply line and the relayemergency valve (27) causes the trailerto be braked automatically within the le-gally stipulated time of no more than 2seconds. The check valve (13) securesthe parking braking system against anyinadvertent actuation if the pressuredrops in the supply line leading to thetrailer.4. ABS ComponentsThe motor vehicle usually has three tell-tale lamps (ASR having one additionallamp) fitted for indicating functions andfor continuously monitoring the system. Italso has a relay, an information moduleand an ABS socket (24).After actuating the driving switch, the yel-low telltale lamp will come on if the trailerhas no ABS or if the connection has notbeen established. The red lamp will go offwhen the vehicle exceeds a speed of ap-prox. 7 k.p.h. and the safety circuit of theABS electronics has not detected an er-ror.Air braking system with ABS/ASR (4S/4M)Legend:Pos.1Compressor2Air dryer with combined unloader3Four circuit protection valve 4Air reservoir 5Clamps6Test coupling 7Drain valve 8Check valve9Brake valve with integralauto load proportioning valve 10Hand control valve with trailer control 11Relay valve 12Piston cylinder 13Brake chamber14ASR-Control cylinder153/2 Solenoid valve 16Tristop-Brake actuator 17Quick release valve 18Load sensing valve 19Knuckle joint20Trailer control valve 21Hose coupling, supply 22Hose coupling, control 23Two-Way valve 24ABS Warning lamp 25ABS Info lamp 26ABS-socket27Sensor extension cable 28Solenoid cable 29Socket30Sensor braket31Sensor with cable 32Pole wheel33ABS-Solenoid valve 34Electronic control unit 35Info module 36Pressure switch 37Proportional valve383/2 Directional control valve12381234,5714379171333282729,3031,3224253435181915626112316212220108361.Components Of The Motor Vehicle’s Braking SystemAir Intake Filters1.Moist Air FilterPurpose:To prevent impurities from the air getting into the compressor (by using suction fil-ters) or into the vents of compressed air equipment (by using vent filters); they also serve to muffle the noise caused by the intake of air or by blowing it off.Operation:Moist air filters (for normal operating con-ditions). The air is taken in through an opening in the cap, flows through the fil-ter medium where it is cleaned and then flows on to the air intake of the compres-sor.Oil Bath Air CleanerOperation:Oil bath air cleaner (for air containing a large mount of dust)The air is taken in through the sieve plate below the cap and the central pipe, and then passed across the surface of the oil where any dust particles can settle. From the surface of the oil, the air is pushed upward, flows through a filter package which retains any impurities which may still be contained in the air and any oil particles carried over before reaching the air intake of the compressor.Moist Air Filter432 600 . . . 0 to 432 607 . . . 0Oil Bath Air Cleaner432 693 . . . 0 to 432 699 . . . 0Purpose:Production of compressed air for road vehicles and static systems. Operation:The pulley on the end of the crankshaft is rotated by a vee-belt driven off the vehi-cle’s engine. This rotation causes the connecting rods to to move the pistons. As the piston travels downwards clean air from either the engine air cleaner or the moist air filter (or alternatively an oil bath air cleaner) is drawn in trough the inlet valve. As the piston moves up-wards, the inlet valve closes, and air is pumped through the delivery valve into the the reservoir.The type of lubrication depends on the construction of the compressor, and can be splash or pressure fed.Single Cylinder Air Compressor 411 1 . . . . . 0 and 911 . . .. . . 0Twin CylinderAir Compressor 411 5 . . . . . 0 and 911 5 . . . . . 0Air Cleaner1.Purpose:To clean the air delivered by the com-pressor and to precipitate the humidity it contains.Operation:The air entering at port 1 flows through annular gap A into Chamber B. As it passes through the gap A, the air cools and some of the water vapour it contains will condensate. The air then flows through the filter (a) to Port 2.At the same time, the pressure in Cham-ber B opens the inlet (3) of the valve body (d) and the condensate runs through the filter (f) into Chamber C. As the pressure in Chamber B falls, the inlet(3) closes and the outlet (b) opens. The condensate is now blown outside by the pressure in Chamber C. When the pres-sures in Chambers B and C are bal-anced, outlet (b) closes.Pin (C) can be used to check whether the automatic drain valve is working proper-ly.Air Cleaner 432 511 . . . 0Air Dryer432 410 . . . 0 and432 420 . . . 0Purpose:Drying of the compressed air supplied by the compressor by extracting the mois-ture present in the air. This is effected by a progress of cold regenerated adsorp-tion drying where the air compressed by the compressor is led through granulates (adsorbens) capable of adsorbing the moisture contained in the air. Operation:Variant 1 (Control Via Separate Un-loader Valve 432 420 ... 0)In the feed phase, the compressed air supplied by the compressor flows via Port 1 into Chamber A. Here the conden-sate caused by the reduction in tempera-ture will collect, reaching Outlet (e) via Duct C.Via Fine Filter (g) integrated in the car-tridge, and via Annulus (h), the air will reach the upper side of Desiccant Car-trige (b), being cooled in the process, and further condensate will precipitate. Moisture is extracted from the air as it passes through Granulate (a) this mois-ture is absorbed by the surface and the fine ducts [diameter: 4 x 106 m = 4Å(Angström)] of the extremely porousgranulate.Since the oil molecules are more than 4Åin size they cannot enter the fine ducts ofthe granulates. This makes the granulaterobust. The steam portion of the oil is notadsorbed. The dried air reaches the airreservoirs via Check Valve (c) and Port21. At the same time, the dried air alsoreaches the re-generation reservoir viathrottling port and Port 22.When cut-out pressure in the system isreached, Chamber B is pressurized fromthe unloader valve via Port 4. Piston (d)moves downwards, opening Outlet (e).The air, the condensate plus any impuri-ties and oil carbon from Chamber A willbe emitted via Duct C and Outlet (e).When cut-in pressure at the unloadervalve is reached, Chamber B is ventedonce again. Outlet (e) closes and the dry-ing process will commence as describedabove.Any malfunction due to icing in extremeconditions in the area of Piston (d) canbe prevented by fitting a Heating Car-tridge (f) which will switch on at tempera-tures below 6°C and switch off againwhen the temperature reaches approx.30°C.Variant 2 (Control Via Integral Unload-er Valve 432 410 ... 0)The process of drying the air is as de-scribed under Variant 1 In this version,however, the cut-out pressure will reachChamber D via Bore (l), acting on Dia-phragm (m). After overcoming the springresistance, Inlet (n) will open, and Piston(d), now pressurized, will open Outlet (e).The air supplied by the compressor willnow be emitted via Chamber A, Duct Cand Vent 3. Piston (d) also acts as apressure relief valve. In the event of anyexcess pressure, Piston (d) will auto-matically open Outlet (e). If, due to airconsumption, the supply pressure in thesystem falls to a value below cut-in pres-sure, Inlet (n) will close and the pressurefrom Chamber B will be reduced via theunloader valve's vent. Outlet (e) willclose and the drying process will com-mence once again.432 420 432 410Air Dryer 1.Air Dryer With Return-Flow Limiting Valve432 413 . . . 0 and432 415 . . . 0The single-chamber air dryers from this series have an integrated return-flow lim-iting valve which permits the required amount of air to be taken from the main reservoir provided the multiple-circuit protection valve permits a return flow. Thus no separate regenerating reservoir is required.Operation:Variant 1 (Control Via Separate Un-loader Valve432 413 ... 0)In the delivery phase the compressed air supplied by the compressor flows through Port 1, opens the check valve (i) and flows into Chamber A. Due to the drop in temperature, condensation water collects there which reaches the outlet (e) through Duct C.The air is dried as described under 432 420. At the same time, dried air also flows into Chamber E, pressurizing dia-phragm (o). This arches towards the right, releasing the passage between Chambers E and G via Throttling Port (s). The air supply also reaches Chamber H via Filter (l), pressurizing Valve (q). Once the force of the pressure spring, preset by means of Screw (r), has been over-come, Valve (q) is lifted. The air supplywill now reach Chamber F, acting on theother side of the diaphragm (o) with aslightly lower pressure in keeping withthe retention of Valve (q).When the cut-off pressure within the sys-tem has been reached, Chamber B ispressurized by the unloader via Port 4.The piston (d) moves downwards andopens the outlet (e). The check valve (i)closes the passage to Port 1 and the airfrom Chamber A flows through Duct Cand is emitted to atmosphere at the outlet(e).Due to the drop in pressure in ChamberG, the check valve (c) closes. The air tobe regenerated is now taken from the airreservoirs, which is why a multiple-circuitprotection valve must permit its returnflow. The air supply at Port 21 flowsthrough Chamber E, the throttling port (s)where it expands, on into Chamber Gand thus to the underside of the granu-late cartridge (b).As it passes through the granulate car-tridge (b) in an upward direction, the hu-midity on the surface of the granulate (a)is taken up by the air and emitted to at-mosphere at Vent 3 after passing Duct Cand the opened outlet (e). The return flowis completed when the pressure on theleft of the diaphragm (q) has been re-duced to a point where it reaches its clos-ing position.When the cut-in pressure at the unloaderis reached, the pressure in Chamber B isreduced once again. The outlet (e) clos-es and the drying process starts again asdescribed above. Outlet 31 also has asafety valve for the pressure side.Variant 2 (Control Via Integral Unload-er Valve 432 415 ... 0)In this variant, the cut-off pressure reach-es Chamber J via the connecting holeinto Chamber J and acts on the dia-phragm (m). After the spring force hasbeen overcome, the inlet (n) opens andthe piston (d) which is now pressurizedopens the outlet (e).The air delivered by the compressor nowflows through Chamber A, Duct C and isemitted to atmosphere at Vent 3. The pis-ton (d) at the same time acts as a popvalve. When the pressure is excessive,the piston (d) automatically opens theoutlet (e).If air consumption causes the supplypressure within the system to fall belowthe cut-in pressure, the inlet (n) closesand the pressure from Chamber B is re-duced through the vent of the unloadervalve. The outlet (e) closes and the dry-ing process begins again.432 413 432 415Twin Chamber Air Dryer 432 431 . . . 0 and432 432 . . . 0Operation:a) Control without Integral Un-loader ValveThe compressed air supplied by the compressor flows to Bore E via Port 1. Due to a reduction in temperature, con-densate may form at Bore E, reaching Idling Control Valve (m) via Bore L. From Bore E, the compressed air will pass Valve (k), enter Chamber B, and reach the upper side of Desiccant Cartridge (c) via Fine Filter (e) integrated into the car-tridge, and via Annulus A.Through Sieve Plate (a), the pre-cleaned compressed air will pass downwards through Granulate (b) sewn into a filter bag in Cartridge (c), reaching Bore G via Sieve Plate (d) and Check Valve (f).As the air passes through Granulate (b), the inherent moisture is retained by the extremely porous granulate. From Bore G, the compressed air reaches the air reservoirs through Check Valve (g) and via Port 2.Through the throttling port of Valves (fand p) designed according to the sweptvolume of the compressor used, part ofthe dried compressed air from Bore Gwill reach the underside of Cartridge (s),passing Granulate (r) in an upward direc-tion (backflush). In this process, themoisture adhering to the fine ducts of theextremely porous Granulate (r) is takenup by the dried air and reaches Vent 3via Annulus K, Chamber H and past theopen rear side of Valve (o).The additional Charging Valve (h) en-sures that Control Valves (k and o) donot switch over when the system is filledinitially. Valve (h) will not open until asupply pressure of > 5 bar has beenreached at Port 2, permitting com-pressed air to reach Chamber C. If thetimeswitch element integrated in the so-lenoid valve then opens the current sup-ply to Trip Coil (j), Armature (i) will be at-tracted. Compressed air from ChamberC will now flow into ChamberD and, viaBore F, into Chamber M, moving the con-trol valves against the spring force intotheir end positions on the left.The passage from Bore E to Chamber Bis closed. The compressed air present inChamber B will now be emitted at Port 3after passing by the open rear side ofControl Valve (k) and going through BoreN. Check Valve (g) will close and thepressure in the system continues to beensured. As a consequence of the pres-sure reduction in Chamber B, CheckValve (f) will also close.The compressed air supplied by thecompressor will now flow from Bore Ethrough Chamber H, Annulus K andthrough Granulate (r) of Cartridge (s).The drying process of the compressedair is as described before. After Valve (p)and Check Valve (g) have opened, thedried air reaches the reservoirs via Port2. Through the throttling port of Valve (f),dried air reaches the underside of Gran-ulate (b), causing a back-flushing proc-ess to take place here, too.After approx. 1 minute, the time-switchelement will break the current supply tothe trip coil. Armature (i) will close thepassage from Chanber C, opening thevent, thus reducing the pressure inChambers D and M. Through the springforce and the pressure in Bore G, thecontrol valves are returned to their endpositions on the right. Control Valve (o)will close the passage to Chamber H,and Control Valve (k) will open the pas-432 431Air Dryer 1.sage to Chamber B. The compressed air supplied by the compressor is now again fed into Granulate (b), and the drying process will commence as described be-fore, with alternating cartridges continu-ing to be used at one-minute intervals. When the unloader valve switches to idling once the input cut-out pressure has been reached, pressure is being fed in at Port 4, pressurizing, and moving down-wards, Piston (m), opening the idling control valve. Any condensate and impu-rities will be emitted together with the air supplied in the idling phase via Vent 3. When the unloader valve switches to load, Port 4 is vented and the idling con-trol valve closes the passage to Vent 3. Any malfunction due to icing in extreme conditions in the area of Piston (m) can be prevented by fitting a Heating Car-tridge (l) which will switch on at tempera-tures below 6°C and switch off again when the temperature reaches approx. 30°C.b) Control Via Integral UnloaderValveThe air is dried as described under a). The pressure building up at Port 2 when the system is being filled is also present in Chamber P, pressurizing the under-side of Diaphragm (t). As soon as theforce resulting therefrom is larger thanthe force of Pressure Spring (n), Dia-phragm (t) will arch, taking with it Piston(q). This opens Inlet (u), and Piston (m),now pressurized, is moved downward,opening the idling control valve. Any con-densate and impurities will be emitted to-gether with the air supplied in the idlingphase via Vent 3. The compressor willcontinue to run idle until the pressurewithin the system has fallen to a valuebelow the unloader valve's cut-in pres-sure. The pressure in Chamber P belowDiaphragm (t) will fall simultaneously.Pressure Spring (n) will move Piston (q)and Diaphragm (t) back to their originalpositions. Outlet (u) will close, and thepressure from Chamber O will be re-duced via the vent of the unloader valve.The idling control valve with Piston (m)will close once again. The compressedair will now again flow into Bore E andreach the air reservoirs via Port 2 afterbeing dried in Desiccant Containers (b orr). The system is subsequently filledonce again up to the cut-out pressure ofthe unloader valve.Application:Depending on the respective application,WABCO provides Single and TwinChamber Air Dryers.The decision of whether to use a Singleor a Twin Chamber Air Dryer will dependon the compressor's swept volume andon its duty cycle.Single Chamber Air Dryerscan normally be used for applications upto a swept volume of ≈ 500 litres/minuteand a duty cycle of up to ≈ 50%. Any de-viations of these standard values shouldbe tested in road-test runs.Twin Chamber Air Drierscover the area > 500 litres/minute and >50% up to 100% duty cycle. Swept vol-umes in excess of 1000 litres/ minuteshould be tested in road-test runs 432 432Purpose:To automatically control the operating pressure in an air braking system and to protect its pipes and valves from contam-ination. Depending on the variant used, it also serves to control a downstream anti-freeze pump or single chamber air dryer. Operation:a)UnloaderThe compressed air supplied by the compressor flows via Port 1 and Filter (g) to Chamber B. When Check Valve (e) has opened, it flows through the line leading from Port 21 to the air reservoirs and to Chamber E. Port 22 is intended for controlling a downstream anti-freeze pump.Pressure builds up in Chamber E, acting the underside of Diaphragm (c). As soon as that pressure is greater than the force of Compression Spring (b), preset by means of Screw (a), diaphragm (c) will arch upward, taking with it Piston (m). Outlet (l) closes and Inlet (d) opens, per-mitting the compressed air to pass from Chamber E to Chamber C, forcing Piston (k) downwards against the force of Com-pression Spring (h). Outlet (i) opens and the compressed air supplied by the com-pressor is released to atmosphere via Exhaust 3. The fall in pressure in Cham-ber B closes Check Valve (e), thus se-curing the pressure in the system.The compressor will now continue to idleuntil the pressure within the system fallsbelow the Unloader’s cut-in pressure.The pressure in Chamber E below Dia-phragm (c) continues to fall. This causesthe force of Compression Spring (b) topush the diaphragm, together with Piston(m), downwards. Inlet (d) closes, Outlet(l) opens and the air from Chamber C isreleased to atmosphere at Exhaust 3 af-ter passing Chamber F and a connectinghole. Compression Spring (h) forces upPiston (k) and outlet (i) is closed. The airsupplied by the compressor now flowsinto Chamber B, passing Filter (g), andopens Check Valve (e). The system isonce again being filled until the Unload-er’s cut-off pressure has been reached.b) Unloader with Pilot Connec-tion 4 and Port 23This type of Unloader differs from thetype described under a) merely in theway the cut-off pressure is controlled.The cut-off pressure is not taken from in-side the unloader but from the supply linedownstream from the air dryer. The pas-sage from Chamber B to Chamber E isclosed, and there is no Check Valve (e).Via Port 4 and Chamber A, the air fromthe reservoir flows to Chamber E, actingon Diaphragm (c). After that it continuesto operate as described under a). Thepassage between Chambers C and D isopen, permitting pilot pressure fromChamber C to be taken at Port 23 to ac-tuate the single chamber air dryer.c) Tyre inflation connectionAfter removing the protective cap, thetyre inflation hose is fastened by meansof a union nut moving Pin (f). The pas-sage between Chamber B and Port 21 isclosed. The air supplied by the compres-sor now flows from Chamber B to the tyreinflation hose, passing Pin (f). In theevent of the pressure in the system ex-ceeding 12+2 bar or 20 bar respective-ly during this process, Piston (k) which isdesigned to act as a safety valve willopen Outlet (i) and the pressure is re-leased to atmosphere via Exhaust 3.Before using the tyre inflation facility, thereservoir pressure must be reduced to avalue below the Unloader’s cut-in pres-sure since no air can be extracted whilstthe compressor is running idle12–Combined Unloader975 303 . . . 0。

TRAINING培训ABS/ASREBL/TPMCNHTC ABS CNHTC ABS培训教程培训教程气制动系统或空气干燥器空压机前轮盘式制动器悬架控制温度控制缓速器控制贮气筒后轮盘式制动器盘式制动器ABS, EBS电子控制空气悬挂挂车电子中央控制车辆中央控制变速箱控制ABS / ASR/ APU EBS 带稳定性控制离合器控制压力监测(IVTM)或气制动系统和高度传感器ECU全球主要主机客户6060年代中期年代中期年代中期::研制参数模型并将成果应用于飞机19721972 年年:研制出了第一代模拟技术系统19751975 年年:展出展出ABS ABS ABS系统及微处理器技术系统及微处理器技术19811981 年年:展出批量生产的展出批量生产的A A 型ABS(ABS(第一代第一代第一代))19821982 年年:开始大批量生产开始大批量生产A A 型ABS 19851985 年年:开始批量生产开始批量生产B B 型ABS(ABS(第二代第二代第二代))19861986 年年:开始批量生产开始批量生产66通道带通道带ASR ASR ASR功能的功能的功能的ABS ABS 19891989 年年:开始生产挂车开始生产挂车C C 型ABS ABS Vario Vario Vario--C 19901990 年年:开始生产开始生产C C 型ABS (ABS (第三代第三代第三代))19961996 年年:开始批量生产开始批量生产D D -Full Full和和D -Basic Basic型型ABS(ABS(第四代第四代第四代))2000 2000 年年:开始批量生产开始批量生产E E 型ABS (ABS (第五代第五代第五代))WABCO -ABS 发展历史ABS ABS--D D 到到ABS ABS--EABS ABS 的的概念ABS –A nti nti--lock B raking S ystem是在制动期间控制和监视车辆速度的电子系统是在制动期间控制和监视车辆速度的电子系统。

FOR 2005-2011 MERCEDES-BENZ CLS-CLASS FOR 2002-2013 MA YBACH 57S & 62SWARNING: The air suspension system is under pressure (up to 10 bar, or 150 lbf/in). Verify pressure has been relieved and disconnect power to the air suspension system prior to disassembly. Do not allow dirt or grease to enter the system. Always wear standard hand, ear, and eye protection when servicing the air suspension system."Engineered to Ride, Built to Last ®"Congratulations on your purchase of an Arnott ® air suspension product. We at Arnott Incorporated are proud to offer a high quality product at the industry’s most competitive pricing. T hank you for your confidence in usand our product.Proper installation is essential to experience and appreciate the benefits of this system. Please take a moment to review these installation instructions before you begin to install these components on your vehicle. T he removal and installation of air suspension products should only be performed by a fully qualified, ASECertified, professional.It is equally important to be aware of all necessary safety measures while installing your new Air Suspension System. T his includes proper lifting and immobilizing of the vehicle and isolation of any stored energy toprevent personal injury or property damage.Arnott ® is committed to the quality of its products. If you have a question or problem with any Arnott product, ****************************************************************************************************.(IntheEUpleasecall+31(0)*************************************)COMPRESSOR COMPRESSOR (left side of vehicle)(right side of vehicle)AIR LINEINTAKE T UBEFIGURE BWO (2) ELECTRICAL CONNECTORS FROM T HE COMPRESSOR UNITELECTRICAL CONNECTORSFIGURE CFIGURE DFOR 2005-2011 MERCEDES-BENZ CLS-CLASSFOR 2002-2013 MA YBACH 57S & 62SCRACKED AIR SPRINGS MUST BE CHANGEDTO VALIDATE THE WARRANTY ON THE COMPRESSORPLEASE READ ADDITIONAL WARRANTY INFORMATION ON THE BACK OF YOUR INVOICEPROPER PROCEDURE FOR ASSESSING YOUR AIR SPRINGS CONDITION:1. TURN OFF AIR SUSPENSION SWITCH IF EQUIPPED.2. REFER T O OWNER’S MANUAL FOR PROPER LIFTING T ECHNIQUES AND JACKING POINTS.3. RAISE T HE VEHICLE.4. INSPECT AIR SPRINGS FOR ANY T YPE OF CRACKS OR EXCESSIVE WEAR. LOOK FOR DRY ROTNEAR WHERE T HE AIR SPRING FOLDS. Y OU MAY ALSO WISH T O SPRAY A SOLUTION OFSOAP AND WATER ON T HE AIR BLADDER. EXPANDING BUBBLES WILL BE NOTICEABLEAROUND T HE LEAKING AREA.REFER TO FOR REPLACEMENT AIR SPRINGS AND AIR STRUTS.WARNINGArnott® is committed to the quality of its products. If you have a question or problem with any Arnott product, ****************************************************************************************************.(IntheEUpleasecall+31(0)*************************************)。

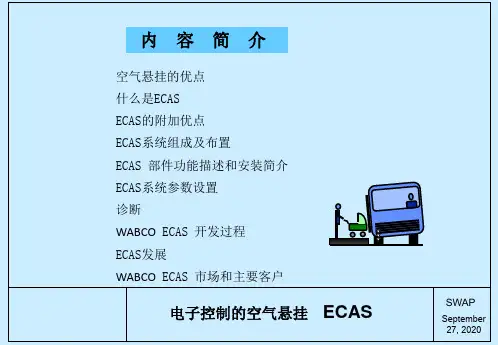

ECAS-空气悬架知识介绍WABCOVehicle Control SystemsElectronicallyControlledAirSuspension15032002pptDMG Meise1WABCOVehicle Control Systems 内容简介什么是ECASWABCO ECAS 开发过程WABCO ECAS 市场和主要客户空气悬挂的优点ECAS的附加优点ECAS系统组成及布置ECAS 部件功能描述和安装简介 ECAS系统参数设置故障诊断15032002pptDM2WABCOVehicle Control Systems ECAS 定义EE ElectronicallyElectronicallyCC ControlledControlledAA AirAirSS SuspensionSuspension电子控制空气悬挂系统ECAS15032002pptDM3WABCOVehicle Control Systems ECAS 简介客车电子控制的空气悬架系统 ECAS 由ECAS 电控单元电磁阀高度传感器气囊等部件组成高度调节器负责检测车辆高度的变化电控单元将接受输入信息判断当前车辆状态激发电磁阀工作几电磁阀实现对各个气囊的充放气调节随着人们对车辆乘坐舒适性要求的提高和我国客车悬架技术的发展空气悬架在客车上的应用日益广泛传统的空气悬架控制模式是采用机械高度阀即通过高度阀阀门的开启调节对气囊的充放气从而保持车辆恒定的行驶高度随着系统应用的推广和车辆控制技术的发展电子控制逐渐取代传统的机械控制电子控制系统不仅提高了操作的舒适性和反应的灵敏度而且可以附加很多辅助功能威伯科汽车控制系统有限公司早在1986年就开始了电子控制空气悬架系统ECAS electroni-controlled air suspension 的开发和应用它是世界上最为先进并且应用最为广泛的电控空气悬架控制系统15032002pptDMG Meise4WABCOVehicle Control Systems ECAS开发过程和客户RVI KssbohrerDAFMAN ScaniaDCIveco15032002pptDMG Meise5WABCOVehicle Control SystemsAuwrter Nissan MitsubishiMenarini Freightliner MCITatra MAZ Sisu LiazISUZU HINO15032002pptDMG Meise6WABCOECAS ECAS 的开发过程的开发过程Vehicle Control Systems19861986年年开始采用模块概念开始采用模块概念19911991年年采用了新的采用了新的ECUECU和改善了功能的和改善了功能的可靠的可靠的便宜的第二代电磁阀便宜的第二代电磁阀 ECAS IIECAS II19921992年年开发出用于挂车的特殊的开发出用于挂车的特殊的ECASECAS将将ECASECAS引入美国市场引入美国市场 12 12 VV19951995年年开始生产开始生产ESACESAC并将其控制功能集合于并将其控制功能集合于ECASECAS的的ECUECU19961996年年开发出带开发出带CANCAN接口的接口的ECASECAS ECAS CAN 1ECAS CAN 119991999年年开始研制新一代的被称为开始研制新一代的被称为ECAS CAN2ECAS CAN2的的ECUECU19991999年年开始生产开始生产ELMELM一种将高度传感器集合在一个模块中的主要用于挂车的一种将高度传感器集合在一个模块中的主要用于挂车的紧凑式紧凑式ECASECAS20012001年年批量生产新一代电磁阀批量生产新一代电磁阀 ECASIIIECAS III取代取代 ECAS IECAS I和新一代和新一代ECUECUECAS CAN 2ECAS CAN 215032002pptDMG Meise7WABCOVehicle Control SystemsMain CustomersWABCO ECAS Systems Sold World - Wide DaimlerChryslerWABCO SOM 90 since 1997 DAF180000EvoBus160000140000 Freightliner120000100000 共213 000 套IVECO80000 约 12 000 busesMAN6000040000 RVI200000 Scania7 8 9 Truck Bus8 8 8 0 19 9 9 2Total 800011 Systems Truck Bus 791711 Trailer 83001 1 9 9 9 9 3 4 5Trailer K鰃el1 1 9 9 9 9 9 6 71 1 9 9 9 9 9 8 91 1 1 9 9 9 91 1 9 9 Feldbinder1 11987 1988 1989 1990 1991 1992 1993 1994 1995 1996 1997 1998 1999Truck Bus 4000 7050 8500 10400 15990 34363 29640 49546 73520 91439 110154 177109 180000Trailer700 1400 2200 4000销量与主要客户 15032002pptDMG Meise8WABCOVehicle Control Systems 空气悬挂系统常规空气悬挂高度阀旋转滑阀管路滤清器溢流阀电磁阀电子控制空气悬挂ECASECU电磁阀及导线高度传感器及导线压力开关压力传感器遥控器15032002pptDMG Meise9WABCOVehicle Control Systems空气悬挂系统的优点空气悬挂系统的优点由于较小的弹簧刚度和较低的固有频率而增加了驾驶的舒适性保持路面和车身间的距离恒定对感载阀控制的良好的适应性用于可换车身车辆上车身下降功能 kneeling 方便乘客上下车空气悬挂的优点15032002pptDMG Meise10WABCOVehicle Control Systems常规空气悬挂管路图15032002pptDMG Meise11WABCOVehicle Control Systems ECAS 工作原理它的基本工作原理是高度传感器负责检测车辆高度车架和车桥间的距离的变化并把这一信息传递给ECU 除高度信息外ECU还接受其它的输入信息如车速信息制动信息车门信息和供气压力信息等然后ECU综合所有的输入信息判断当前车辆状态按照其内部的控制逻辑激发电磁阀工作电磁阀实现对各个气囊的充放气调节15032002pptDMG Meise12WABCOVehicle Control Systems ECAS系统的功能和优势ECAS ECAS 的的优优点点减少了空气消耗--在车辆行驶过程中无空气消耗以低地板城市客车为例与常规空气悬挂相比ECAS可节省25的空气消耗通过自动调节可实现车辆保持不同高度可对两个行驶高度进行编程记忆尽管系统复杂但安装非常简单由于使用了大截面的进出气口而使所有控制过程变得非常迅速通过参数设置ECU可实现不同功能通过使用遥控器减少了装卸操作的危险性增加了许多辅助功能例如升降功能kneeling 侧倾过载保护提升桥控制等压力监视功能ECU检测供气压力处于安全的考虑如果气压低于一定值下降和侧倾功能将受限安全控制ECU根据当前车门开关信息判断是否能提升/下降车辆综合安全概念故障记忆和诊断功能维修检测专用诊断软件和检测设备可做到下线时快速检测及调整方便的闪码功能便于售后维修检测15032002pptDMG Meise13WABCOVehicle Control Systems 常规客车空气悬挂系统带kneeling 功能ECAS 优点举例15032002pptDMG Meise14WABCOVehicle Control SystemsECU度 MV高1 5常正 WS2431 电子控制器 ECU 4 气囊2 电磁阀 5 遥控器3 高度传感器ECAS 系统15032002pptDMG Meise15WABCOVehicle Control Systems ECAS 主要部件1.电控单元电控单元 ECU通常安装在驾驶室或者电气仓内可实现不同高度值的管理和储存控制包括正常高度在内的多个车辆高度ECU负责与诊断工具进行数据交换同时监测系统所有部件的操作检测并储存系统故障2 .电磁阀电磁阀通常安装在车架或车架横梁上ECAS电磁阀是高度集成化和模块化的设计取决于不同的配置在通用的外部壳体内可以布置不同数量的电磁阀部件ECAS组合电磁阀可大大节省了零部件数量和安装空间以及装配费用为了降低排气噪声电磁阀排气口带有消音器3.高度传感器高度传感器的外形看起来与机械高度阀相似它们的安装方式和安装位置完全相同通常布置在车架上传感器内部包含线圈和枢轴当车桥与车身之间的距离发生变化时高度横摆杆转动并带动相应的电枢在线圈中上下直线运动造成线圈的感应系数变化ECU检测此感应系数的变化并将其转换成高度数字信号15032002pptDMG Meise16WABCOECAS - Electronically ControlledAir SuspensionVehicle Control Systems系统部件15032002pptDMG Meise17WABCO系统配置清单 Vehicle Control Systems图号名称备注单车用量个446 055 506 0 ECU 速度信号为 8 脉冲信号 1441 050 011 0 高度传感器单车用量 3 件 3472 900 056 0 电磁阀带 KNEELING 功能 1449 422 100120150 0 电磁阀导线长度101215 米可选 2449 742 100120150 0 高度传感器导线长度101215 米可选 3894 510 764 2 插头体1894 510 297 4 2 30插头用于 05-15 mm 导线894 510 298 4 插头用于 15-25mm2 导线 3441 050 718 2 高度传感器摆杆单车用量 3 件 3433 401 003 0 连接杆单车用量 3 件 3441 014 025 0 压力开关60 bar 1空气悬挂系统15032002pptDMG Meise18WABCOVehicle Control Systems 仅后桥为空气悬挂的ECAS 系统遥控器高度传感器ECU电磁阀气囊后桥4 ×2 车仅后桥为空气悬挂系统布置示意图15032002pptDMG Meise19WABCOVehicle Control Systems客车ECAS前后桥均为空气悬挂的ECAS系统前轴后桥前后桥均为空气悬挂的4 ×2车系统布置 15032002pptDMG Meise20WABCOpair-suspensionVehicle Control SystemsECU 446 055 50 0指标高度的控制正常高度 III用开关按键进行手动高度调节Kneeling监视供气压力如只有特定的环境下允许Kneeling借助压力传感器对轴荷进检测35 Pin ECUECU 功能15032002pptDMG Meise21WABCOVehicle Control SystemsECU 446 055 50 0 ECU 446 055 50 0 工工作作原原理理连续监视输入信号将信号转换为计数比较输入值与指标值在出现偏差的情况下估计所需要的控制反应激发电磁阀不同指标值的管理和储存正常高度故障记忆等系统所有部件可操作性的有规律的监视监视轴荷借助压力传感器用于故障检测的接收信号的可能性检查发现故障ECU15032002pptDMG Meise22WABCOVehicle Control SystemsECU 446 055 50 0 ECU 446 055 50 0 安安装装要要求求ECU 的型号选择446 055 503 0 对应速度信号为C3 信号446 055 506 0 对应速度信号为8 脉冲速度传感器信号安装在防水防尘的位置推荐在驾驶室内接近性要好便于诊断ECU 工作温度范围-40 °C -+80 °用外接电源为车辆充电时要将ECU 电源断开防止外界高电压损伤ECU当车辆需要电焊时断开CEU 不得用万用表测量ECU各部件的拆装必须在停电后进行并保持各部件清洁干燥不得随意改变保险丝容量指示灯坏了应及时更换清洁车辆时ECU 不得进水ECU15032002pptDMG Meise23WABCOVehicle Control Systems通过选择参数对车辆性能进行设置例如参数1的bit2 =0带一个高度传感器的桥的左右kneeling bit2 1 则只有右边kneeling由于有参数设置使得同样的系统部件可以有非常个性化的布置根据需要选用指示灯和开关PARAMETER SETTING参数设置15032002pptDMG Meise24WABCOVehicle Control Systems ECAS 系统指示灯通常系统具有故障灯红色高度指示灯黄色根据车辆功能设置还可具有侧跪灯特殊高度Ⅱ指示灯打开点火开关后故障灯和高度指示灯亮 2 秒然后灭掉表示ECAS系统正常如果高度指示灯黄亮说明当前高度不在正常高度上如车辆气压充足按下恢复正常高度按键黄灯应灭如果故障指示灯红亮说明ECAS系统存在故障当系统出现故障时取决于故障的严重性警告灯将一直亮不严重或闪烁严重以提醒驾驶员系统出现故障当车辆侧跪时当达到侧跪高度时侧跪指示灯亮当按下特殊高度Ⅱ开关时特殊高度Ⅱ指示灯亮15032002pptDMG Meise25WABCOVehicle Control Systems ECAS 系统开关上升下降开关从安全角度考虑ECU允许在一定车速下实现车辆高度的提升或者降低该车速可通过ECU参数设置提升和下降开关均是复位开关下降开关在供气气压大于6 bar时有效当车辆超过设定车速通常15kmh20kmh 时自动回复正常高度-高度复位开关恢复车辆正常行程高度-侧跪开关在车速低于5kmh时使用侧跪开关在供气气压大于6 bar时有效车辆侧跪后当车速大于7 kmh时车辆自动恢复正常行程高度-特殊高度Ⅱ开关仅供特殊路况下短时使用按下特殊高度Ⅱ开关后同时特殊高度Ⅱ指示灯亮不能长时间使用特殊高度Ⅱ15032002pptDMG Meise26WABCOVehicle Control Systems 灯与开关的安装取决于客户对ECAS 功能的选择在仪表板上需增加功能选择开关和指示灯如ECAS 系统警告灯选用红色功率小于5WECAS 指示灯选用黄色功率小于5W用来指示车辆是否在规定高度上特殊高度II 指示灯Kneeling 指示灯正常高度 III 转换开关手动自动提升降低底盘的开关Kneeling 开关Kneeling 停止开关等并非所有开关和指示灯在同一底盘上都需要具体开关和灯的位置及标识由主机厂确定所有指示灯不允许用发光二极管代替15032002pptDMG Meise27WABCOVehicle Control Systems 安装后的测试安装完成后可以通过诊断软件或者诊断仪对系统部件安装情况进行检测如激发电磁阀测试灯与开关测量高度传感器读数检查车速表信号测量工作电压和电磁阀的继动电压等15032002pptDMG Meise28WABCOVehicle Control Systems ECAS Level Sensor功能高度传感器连续不断地测量实际高度的变化并将其转换为电信号传递至ECU可以安装在车架上正常状况传感器两极角间电阻120欧姆左右请注意因为高度传感器靠感应系数工作所以不能在工作时用欧姆表直接测量电阻15032002pptDMG Meise29WABCOVehicle Control Systems通常安装3个高度传感器一个桥安装一个高度传感器 1HSA一个桥安装两个高度传感器 2HSA安装高度传感器测量原理为角度的变化对应高度变化高度传感器左右对称摆杆和连接臂长度相等尽量大地应用其工作范围为充分利用高度传感器的测量范围尽可能地将摆杆中间位置位于车辆正常高度允许垂直或水平安装在所有行程范围内不允许与底盘件干涉允许传感器壳体与摆杆呈一定角度在固定传感器前确定当车身上升时摆杆是顺时针还是逆时针转动很重要避免用力弯摆杆否则会在凸轮上产生扭矩安装时需考虑合适的连接杆长度如长度太短易发生连接杆反跳故障15032002pptDMG Meise30WABCO 高度传感器的安装Vehicle Control Systems多种可能的安装位置感应值增加车身上升感应值减小车身降低观察筋到摆杆位置通过4h8的心轴固定传感器在中心的位置导线无极性之分传感器和ECU之间的导线长度最长15米安装关键 2个原则圆形连接面上的2个凸块应在高度传感器轴线的两侧当车辆上升时2个凸块都应朝高度传感器电插口方向运动15032002pptDMG Meise31WABCOECAS Solenoid ValvesVehicle Control SystemsECAS II ECAS III15032002pptDMG Meise32WABCOVehicle Control Systems双高度传感器桥 2HSA 的电磁阀带一个高度传感器的桥 1HSA 的电磁阀客车带 Kneeling功能的电磁阀正常状态电磁阀每一极角对地电阻75欧姆左右ECAS II电磁阀组件节省了空间和安装费用采用模块设计原则取决于不同的配置用同样的壳体可以包含数量不同的部件ECAS 电磁阀15032002pptDMG Meise33WABCOVehicle Control Systems阀前桥右气囊前桥左气囊供气11 后桥左气囊后桥右气囊供气出气22232627电磁控制611 612 613 614 621622 623 624 631 632 634 472 900 056 0电磁阀安装15032002pptDMG MeiseWABCO供气11Vehicle Control Systems 出气22232627 2223电磁控制611 612 613 614 621 622 624472 900 057 0阀阀前桥右气囊前桥左气囊后桥左气囊后桥右气囊供气电磁阀安装15032002pptDMG Meise35WABCOECAS Solenoid ValvesVehicle Control Systems前桥不带12 12Kneelin 前桥一侧kneelingg23 22 27 2614211411驱动桥2C23 22315032002pptDM。

英文缩写及注解ABS(Anti-block braking system)制动防抱死系统。

目前WABCO ABS系统可扩展的功能有ASR、EBL、ESC、HSA等功能。

ABS E8,其中ABS(Anti-block braking system)制动防抱死系统,其中E8是WABCO的版本号,即WABCO的最新一代的制动防抱死系统,具有强大的扩展功能。

目前还在研发过程中。

在此系统的基础上可以扩展AEBS、ACC、FCW、CMS、ESCsmart、EC-APU等先进的安全和节能系统。

也包括目前ABS具有的扩展功能ASR、EBL、HSA等。

EBS(Electronic Braking System)电子制动系统。

它是电控气制动系统的简称。

此系统是欧洲主流的商用车制动系统方案。

它可以显著的降低制动系统的响应时间,缩短制动距离,优化制动力分配,提高制动舒适性等优点,同时此系统具有ABS的相应功能。

ASR(Anti-Spin Regulation)或ATC(Automatic Traction Control)驱动防滑控制,防止车辆在不同路面上加速时车轮空转,防止一个或多个车轮失去牵引力。

EBL(Electronic Braking Limit)电子制动力限制,在一定的范围内可以调整后桥滑移率(与前桥对比),从而限制过制动。

当前桥失去制动力时,后桥会进行全制动,直到达到额定减速度或最大压力为止。

ESC(Electronic Stability Control)电子稳定控制,包括防侧翻功能(RSC,Roll stability control)和方向控制功能(YC,Yaw Control)。

防侧翻功能主要针对高速高附附着路面过弯时,车辆容易发生侧翻风险的相应控制功能。

而方向控制功能,主要针对车辆在转向、变道时,路面无法提供足够的侧向附着力导致的车辆偏航的方向纠正功能。

(欧盟法规,2013年起开始逐步实施)ESCsmart,ESC的升级版本。

wabco气囊控制器遥控说明一种用于车辆的控制器,包括处理器和存储处理器可执行指令的存储器。

控制器的处理器编程为:接收表示与车辆的侧面碰撞的侧面撞击信号:接收表明车辆的第一后排座椅被占用的占用信号:并且仅当邻近车辆的该侧面的第二后排座椅未占用时,响应于侧面撞击信号和占用信号而发送用于在邻近车辆的该侧面的前排座椅和该第二后排座椅之间展开安全气囊的输出控制信号。

安全气囊控制器是用于接收碰撞信号并控制安全气囊起爆,向安全气囊发出引爆指令的元件,一般装置于选换档操纵机构下部,驻车制动手刹前部的车体中央通道上。

安全气囊控制器作为整个系统的核心,它是随着电子控制技术逐步发展的。

其核心关键技术的发展将会体现在:对碰撞的准确判断、点火时刻的精确控制、超强的抗干扰能力和超高的可靠性及稳定性。

安全、环保、节能是衡量现代汽车技术发展水平的三个主要指标,而汽车安全技术列居首位。

安全气囊系统是被动安全技术的一种,它是在车辆发生碰撞后,用来保护司机和乘员安全的系统,由碰撞传感器、控制器、气体发生器和气囊组件等部分组成。

其工作原理是:当发生撞车时,通过加速度传感器捕获碰撞信号,安全气囊控制器对捕获的碰撞信号进行采集、分析、判断及处理,对可能会造成司机和乘员安全的碰撞适时地发出点火指令驱动气体发生器点火,从而引爆安全气囊,这样,司机和乘员通过和柔性的安全气囊接触,避免了和车内刚性物体碰撞而引起人员伤害。

从工作原理可以看出,安全气囊控制器是整个系统的核心,它既是传感器获取的碰撞信号的分析与处理装置,同时也是点火指令发出与否的判断装置;除此之外,它还应该能够准确判断碰撞强度,引爆车速、准确判断点火时刻、抗干扰能力等。

安全气囊控制器系统主要有机械式、模拟电子式和智能式几种,带微处理器的智能式安全气囊控制器是目前发展的主流,也是本文的研究对象,它由系统硬件和系统软件构成。

安全气囊控制器是整个安全气囊系统的核心,一方面它接收并处理碰撞传感器获取的碰撞信号;另一方面,碰撞信号经过一点的算法处理后,做出是否发出点火信号的判断,并根据判断结果发出相关指令;同时,还需要和车身其他单元通信等。

WABCO产品类型WABCO产品系列:空气管理系统、执行器及主制动器、防抱死制动系统、自动牵引控制系统、智能化挂车应用程序、汽车系统、轿车产品电子控制气囊悬挂、真空泵、传动控制、TASC –挂车空气悬挂控制阀、防抱死制动系统、离合器控制、制动气室、电子制动和稳定控制、悬挂控制、制动器、常规制动控制、空气压缩机、整车电控体系、变速自动控制、空气处理系统、先进的驾驶员辅助驾驶系统、悬挂控制、空气气囊空气悬挂高度控制阀、车身高度控制模块、减振器、电控高度调节模块、电子减振控制系统、ECAS(卡车和客车)、提升桥控制阀、旋转滑阀威伯科离合器分泵 | 威伯科气动控制阀 | WABCO空气干燥器总成 |威伯科高度控制阀| WABCO气动阀 | WABCO四LIAN阀 | WABCO调压阀 | WABCO离合器助力泵JDF进口接通储气筒,出气口接制动气室。

当踩下制动踏板时,JDF输出气压作为J 的控制压力输入,在控制压力作用下,将进气阀推开,于是压缩空气便由储气筒直接通进气口进入制动气室,而不用流经制动阀,这大大缩短了制动气室的充气管路,加速了室的充气过程。

因此JDF又叫加速阀。

JDF维修保养:JDF一般装在制动阀至中、后桥的管路中,因为中、后桥离制动阀较远、管道较长,动时高压空气进入制动气室的阻力大,易出现制动滞后;解除制动也出现缓慢现象。

JDF在使用保养。

JDF保养时应注意:①JDF内部应保持清洁,避免活塞及阀杆发卡。

②橡皮膜老化变质,失去弹性,会影响制动强度并使回位慢,应及时更换。

③阀杆密封不严,会使高压空气漏气制动气室而使制动发咬,对此应检查更换阀杆。

JDF作用:JDF用于长管路的末端,储气筒的压缩空气快速充满制动气室,如在挂车或半挂车制动统中。

在载重汽车的制动系统里,JDF起缩短反应时间和压力建立时间的作用,JDF属于汽车制动系统的一部分。

JDF于长管路的末端,储气筒的压缩空气快速充满制动气室,如在挂车或半挂车制动系统中。

wabco abs 原理WABCO ABS 原理引言:WABCO ABS(Anti-lock Braking System,防抱死制动系统)是一种先进的汽车制动系统,旨在提高车辆制动性能和安全性。

本文将介绍WABCO ABS的原理及其工作过程。

一、WABCO ABS的原理WABCO ABS采用了电子控制单元(ECU)和传感器等组件,通过监测车轮的转速和制动压力,实现对车轮制动的准确控制。

其主要原理如下:1. 传感器:WABCO ABS系统通过安装在车轮上的传感器来检测车轮的转速。

这些传感器能够实时监测每个车轮的转速,并将数据传输给ECU。

2. 电子控制单元(ECU):ECU是WABCO ABS系统的核心控制单元,它接收来自传感器的数据,并根据这些数据来判断车轮是否会出现抱死现象。

ECU还控制着制动液的压力,以便在需要时调整制动力度。

3. 制动液压力调节器:当ECU检测到车轮即将抱死时,它会通过制动液压力调节器来减小制动液的压力。

这样可以减少制动力度,避免车轮抱死,保持车辆的稳定性。

4. 制动踏板传感器:WABCO ABS系统还配备了制动踏板传感器,用于监测驾驶员对制动踏板的踩踏力度。

当驾驶员踩下制动踏板时,传感器会将信号发送给ECU,以便系统能够实时调整制动力度。

二、WABCO ABS的工作过程WABCO ABS系统的工作过程如下:1. 启动:当驾驶员启动车辆时,WABCO ABS系统会进行自检,确保系统正常运行。

2. 数据采集:当车辆行驶时,传感器会实时采集每个车轮的转速,并将数据传输给ECU。

3. 数据分析:ECU会对传感器采集到的数据进行分析,并根据预设的算法来判断车轮是否会出现抱死现象。

4. 制动力调节:当ECU检测到车轮即将抱死时,它会通过制动液压力调节器来减小制动液的压力,以调整制动力度。

5. 驾驶员反馈:WABCO ABS系统还会通过制动踏板传感器来感知驾驶员对制动踏板的踩踏力度,并根据驾驶员的需求调整制动力度。