Honeywell PC42t产品培训资料

- 格式:pptx

- 大小:5.49 MB

- 文档页数:50

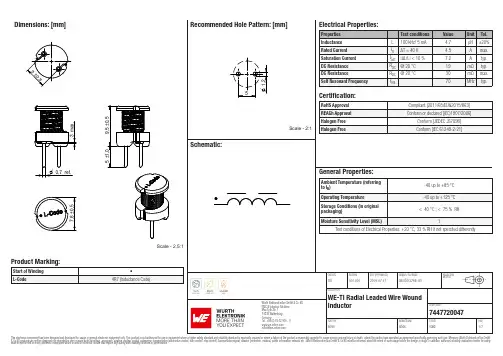

Dimensions: [mm]Scale - 2,5:17447720047A74477200477447720047T e m p e r a t u r eT T T 7447720047Cautions and Warnings:The following conditions apply to all goods within the product series of WE-TI of Würth Elektronik eiSos GmbH & Co. KG:General:•This electronic component was designed and manufactured for use in general electronic equipment.•Würth Elektronik must be asked for written approval (following the PPAP procedure) before incorporating the components into any equipment in fields such as military, aerospace, aviation, nuclear control, submarine, transportation (automotive control, train control, ship control), transportation signal, disaster prevention, medical, public information network, etc. where higher safety and reliability are especially required and/or if there is the possibility of direct damage or human injury.•Electronic components that will be used in safety-critical or high-reliability applications, should be pre-evaluated by the customer. •The component is designed and manufactured to be used within the datasheet specified values. If the usage and operation conditions specified in the datasheet are not met, the wire insulation may be damaged or dissolved.•Do not drop or impact the components, the component may be damaged.•Würth Elektronik products are qualified according to international standards, which are listed in each product reliability report. Würth Elektronik does not warrant any customer qualified product characteristics beyond Würth Elektroniks’ specifications, for its validity and sustainability over time.•The customer is responsible for the functionality of their own products. All technical specifications for standard products also apply to customer specific products.Product specific:Soldering:•The solder profile must comply with the technical product specifications. All other profiles will void the warranty.•All other soldering methods are at the customers’ own risk.Cleaning and Washing:•Washing agents used during the production to clean the customer application might damage or change the characteristics of the wire insulation, marking or plating. Washing agents may have a negative effect on the long-term functionality of the product. Potting:•If the product is potted in the costumer application, the potting material might shrink or expand during and after hardening. Shrinking could lead to an incomplete seal, allowing contaminants into the core. Expansion could damage the components. We recommend a manual inspection after potting to avoid these effects. Storage Conditions:• A storage of Würth Elektronik products for longer than 12 months is not recommended. Within other effects, the terminals may suffer degradation, resulting in bad solderability. Therefore, all products shall be used within the period of 12 months based on the day of shipment.•Do not expose the components to direct sunlight.•The storage conditions in the original packaging are defined according to DIN EN 61760-2.•The storage conditions stated in the original packaging apply to the storage time and not to the transportation time of the components. Packaging:•The packaging specifications apply only to purchase orders comprising whole packaging units. If the ordered quantity exceeds or is lower than the specified packaging unit, packaging in accordance with the packaging specifications cannot be ensured. Handling:•Violation of the technical product specifications such as exceeding the nominal rated current will void the warranty.•Applying currents with audio-frequency signals might result in audible noise due to the magnetostrictive material properties. •Due to heavy weight of the components, strong forces and high accelerations might have the effect to damage the electrical connection or to harm the circuit board and will void the warranty.•Please be aware that products provided in bulk packaging may get bent and might lead to derivations from the mechanical manufacturing tolerances mentioned in our datasheet, which is not considered to be a material defect.•The temperature rise of the component must be taken into consideration. The operating temperature is comprised of ambient temperature and temperature rise of the component.The operating temperature of the component shall not exceed the maximum temperature specified.These cautions and warnings comply with the state of the scientific and technical knowledge and are believed to be accurate and reliable.However, no responsibility is assumed for inaccuracies or incompleteness.Würth Elektronik eiSos GmbH & Co. KGEMC & Inductive SolutionsMax-Eyth-Str. 174638 WaldenburgGermanyCHECKED REVISION DATE (YYYY-MM-DD)GENERAL TOLERANCE PROJECTIONMETHODTRi001.0012019-07-17DIN ISO 2768-1mDESCRIPTIONWE-TI Radial Leaded Wire WoundInductor ORDER CODE7447720047SIZE/TYPE BUSINESS UNIT STATUS PAGEImportant NotesThe following conditions apply to all goods within the product range of Würth Elektronik eiSos GmbH & Co. KG:1. General Customer ResponsibilitySome goods within the product range of Würth Elektronik eiSos GmbH & Co. KG contain statements regarding general suitability for certain application areas. These statements about suitability are based on our knowledge and experience of typical requirements concerning the areas, serve as general guidance and cannot be estimated as binding statements about the suitability for a customer application. The responsibility for the applicability and use in a particular customer design is always solely within the authority of the customer. Due to this fact it is up to the customer to evaluate, where appropriate to investigate and decide whether the device with the specific product characteristics described in the product specification is valid and suitable for the respective customer application or not.2. Customer Responsibility related to Specific, in particular Safety-Relevant ApplicationsIt has to be clearly pointed out that the possibility of a malfunction of electronic components or failure before the end of the usual lifetime cannot be completely eliminated in the current state of the art, even if the products are operated within the range of the specifications.In certain customer applications requiring a very high level of safety and especially in customer applications in which the malfunction or failure of an electronic component could endanger human life or health it must be ensured by most advanced technological aid of suitable design of the customer application that no injury or damage is caused to third parties in the event of malfunction or failure of an electronic component. Therefore, customer is cautioned to verify that data sheets are current before placing orders. The current data sheets can be downloaded at .3. Best Care and AttentionAny product-specific notes, cautions and warnings must be strictly observed. Any disregard will result in the loss of warranty.4. Customer Support for Product SpecificationsSome products within the product range may contain substances which are subject to restrictions in certain jurisdictions in order to serve specific technical requirements. Necessary information is available on request. In this case the field sales engineer or the internal sales person in charge should be contacted who will be happy to support in this matter.5. Product R&DDue to constant product improvement product specifications may change from time to time. As a standard reporting procedure of the Product Change Notification (PCN) according to the JEDEC-Standard inform about minor and major changes. In case of further queries regarding the PCN, the field sales engineer or the internal sales person in charge should be contacted. The basic responsibility of the customer as per Section 1 and 2 remains unaffected.6. Product Life CycleDue to technical progress and economical evaluation we also reserve the right to discontinue production and delivery of products. As a standard reporting procedure of the Product Termination Notification (PTN) according to the JEDEC-Standard we will inform at an early stage about inevitable product discontinuance. According to this we cannot guarantee that all products within our product range will always be available. Therefore it needs to be verified with the field sales engineer or the internal sales person in charge about the current product availability expectancy before or when the product for application design-in disposal is considered. The approach named above does not apply in the case of individual agreements deviating from the foregoing for customer-specific products.7. Property RightsAll the rights for contractual products produced by Würth Elektronik eiSos GmbH & Co. KG on the basis of ideas, development contracts as well as models or templates that are subject to copyright, patent or commercial protection supplied to the customer will remain with Würth Elektronik eiSos GmbH & Co. KG. Würth Elektronik eiSos GmbH & Co. KG does not warrant or represent that any license, either expressed or implied, is granted under any patent right, copyright, mask work right, or other intellectual property right relating to any combination, application, or process in which Würth Elektronik eiSos GmbH & Co. KG components or services are used.8. General Terms and ConditionsUnless otherwise agreed in individual contracts, all orders are subject to the current version of the “General Terms and Conditions of Würth Elektronik eiSos Group”, last version available at .Würth Elektronik eiSos GmbH & Co. KGEMC & Inductive SolutionsMax-Eyth-Str. 174638 WaldenburgGermanyCHECKED REVISION DATE (YYYY-MM-DD)GENERAL TOLERANCE PROJECTIONMETHODTRi001.0012019-07-17DIN ISO 2768-1mDESCRIPTIONWE-TI Radial Leaded Wire WoundInductor ORDER CODE7447720047SIZE/TYPE BUSINESS UNIT STATUS PAGE。

Honeywell DCS 操作培训绪论从一个完整的Shutdown 上装载系统Honeywell 组合键盘使用本地窗口状态工具条操作入门操作On Off 控制点GUS R600 报警器报警–系统状态使用Trend 显示工艺报警响应操作HPM 程序 (可选)其它•工具•命令•JP/SOP附录X_Plant 缩写列表同Merlion 的接口逻辑符号Honeywell 缩写描述Honeywell 手册报警和状态指示HPM参数参考•Honeywell TPS 综述•HPM 控制功能概观•X6 DCS•DCS 设备布局图•DCS 标签编号系统•点类型•Honeywell DCS系统操作简介 (参考 : HP12500) •X6 Honeywell DCS 系统操作•工艺操作Honeywell TPS 综述•全球用户工作站 (GUS)*DCS 操作控制台*IS Merlion控制台*Windows NT*通过 LCNP 处理机同LCN通信*本地 window⇒操作者和工程师职责(报警系统/控制台状态等等)⇒每个 GUS都有一个*其它windows (显示, 微软官能度)*显示创建者, 站点创建者, 安全综述 (工程功能)*遥控功能•高性能工艺管理(HPM)*M68040 平台⇒通信/控制处理器(冗余)⇒I/O 接口处理器(冗余)*获取数据和控制功能, 对等通信*点数据*顺序控制语言(CL), 联锁操作*每秒钟800个处理单元(PU) (控制,离散逻辑,次序组等等)。

1个PID 控制器使用1个 PU。

*培训系统I/O 模拟。

•通信网络*本地控制网络(LCN)⇒操作网络(历史纪录,软件装载,访问硬盘等等)⇒5兆/秒⇒令牌转交接受协议,每个节点令牌的通过时间大约为30秒。

⇒A和B 电缆线上同时广播。

⇒最多支持64 个节点,网络最远距离为300米。

⇒用于 GUS/PLNM/AM/AxM/HM/NIM/APPNODE*全球控制网络(UCN)⇒工艺网络 (SP, OP, PV, range, alarm generation)⇒5兆/秒⇒令牌总线网络⇒用于HPM•网络接口模块(NIM)*UCN 接到LCN*冗余*使LCN 和 UCN同步*最多支持 32 冗余设备•工厂网络模块 (AppNode)*LCN和以太网 (PIN)的接口*为了下载 SOC 等等•应用模块 (AM / AxM)*运算控制器的补充*管理控制*更先进的计算和控制策略*控制SOC下载语言程序等等 c•历史模块 (HM)*存储系统软件和应用文件(例如硬盘)*存储连续的工艺历史和事件日志*存储图表,节点操作软件,CL 程序HPM 控制功能概观典型的控制回路 :DCS 标签编号系统8 个特征P1****** : polymer POF line 1 tag(P2****** : polymer POF line 2 tag) C1****** : polymer, common areaSA01**TC : spinning machine A cell 01 temperature controller, ** loop no. S1****** : spinning common area (e.g. aspiration gas) R1****** : solvent recovery area P19***** : site specific, polymer areaC19***** : site specific, polymer common area R19***** : site specific, solvent recovery area*G *T analog input (FULL point form)模拟全点analog input (COMPONENT point form) 模拟半点*V *X *R *Z analog output (control valve)模拟输出(控制阀) analog output (micro-motion flow control valve) 模拟输出(流量控制阀)analog output (heater control output) 模拟输出(热量控制输出)analog output (drive control output) 模拟输出(热量控制输出)*C control (控制) FQ totaling (累加器)HC hand controlSC speed control (速度控制) XG Analyzer (分析器) *A digital alarm (数字警报) RC ratio control (比率控制) C E DO calculated value (计算值) digital input (数字输入) digital output (数字输出)PB digital composite / device control 数字组合/控制点HSdigital composite / device control 数字组合/控制点E1SV E2DISolonidPBAPoint Type (点的类型)Point Type 点的类型 Descriptor(描述)Tag Name 点名 Tag Descriptor 点的描述 ANALOG INPUT 模拟输入Perform input processing on all field I/O.(P10312PG) MDI SUPP TK VNT PRESSANALOG OUTPUT 模拟输出Perform output processing on all field I/O. (P10319PV) MDI SUPP PRESS CTRL VLV DIGITAL INPUT 数字输入Perform input processing on all field I/O. (P10315E) MDI SUPP PMP START/STOP DIGITAL OUTPUT 数字输出Perform output processing on all field I/O. (P10315DO) MDI SUPP PMP RUN REGULATORY PV 常规PVProvide an easy to use configurable approach for implementing PV calculations and compensation functions.(P10317PG) MDI FLTR DP REGULATORYCONTROL 常规控制 Perform standard control functions by executing the algorithms that have been configured.(P10319PC) MDI SUPP PRESS CTRLDIGITAL COMPOSITE 数字组合A multi-input/multi-output point provides an interface to discrete devices such as motors, pumps, solenoid valves, and motor-operated valves. It provides built-in structures for handling interlocks, and supports display of the interlock conditions in group, detail, and graphic displays.(P10321HS)MDI ONL/RECIRC VLVDEVICE CONTROL 设备控制 Provide a way to manipulate a device (e.g. motor) and to view the strategy through a single point (help the operator to graphically trace the source of an interlock condition.(P10315PB) MDI SUPP PMPFLAG 状态点A 2 state (On and Off) point is used for storing a Boolean value. The value can be supplied by the operator, sequence program, another point output, etc.(P10322FL) MDI/GLY ONL/RECIRCNUMERIC 数值点 Data point used to store numeric values that can be used for batch/recipe operations, or to store the intermediate results of calculations.(P1CPRCLM) CP RATE CHANGE +/-PROCESS MODULE 过程模块 The resource for execution of user-created programs (CL). (P1CPRTCH) CAPPING RATE CHANGEARRAY 数组点 Provide access to HPM box global variables, or external data from/to serial interface devices.(P1MWTOP) TOP MW ONL DATA TIMER 时间点 Timer data point allows the operator and the sequence program to time the process events.(P1MWRCTM) MW SILO RATE CHANGE TMR LOGIC 逻辑点 Provide a configurable mix of logic capability that provides the basis for integrated logic functions.(P1LOGA) MDI/GLY DIVERT VALVES STRING 字符串点Store descriptive text data, such as the brand name or model etc.--平台 (Point Form)"Full" point form includes alarm-related parameters and sometimes, some other miscellaneous parameters. This information is needed when the point is to be used as the primary operator interface to the point's data."Component" point form should be used for points that provide inputs to the "Full" point, and also for those points that handle the outputs from the "Full" points. Component" points should be used as part of the "Full" point that has been designated a primary operator interface point.NOTE: Full-point form cannot be assigned to DO (digital output) points; they are always component points. Stand-alone digital output points require using a digital composite point that has 0 (zero) inputs and 1 output.Example : Single-LoopExample :Mass FlowExample : Motor ControlHoneywell DCS 系统操作简介(参考: HP12500)登录•Alt-Ctl_+Del组合键用户名: gus密码:键操作•工程键盘•功能键•操作键•通过工程键盘(用于纺丝层)操作键•键锁•其它:*主菜单 (Poly/Spin/Recovery)*Recall tag/schematic name key ...*清屏*故障*Schematic Tagname Toggle*调出最新的图表*相关的显示*组*详述*示意图*标准*系统状态*CONS 状态 (单元显示 / 单元分配 /控制台报警状态/ 系统报警状态) *报警SUMM / UNIT ALM SUMM*MSG SUMM / MSG CONFM / MSG CLEAR*系统菜单⇒概要菜单⇒事件历史⇒组编辑显示 (391~400)显示•改变区域•节点描述•组•图表•详述•趋势改变方式•手动•自动•串联•程序, 包括CL 程序 (例如用于SOC, ...)信号处理•指示或调整控制(带有运算器)模拟/灵敏传感器•用于联锁和顺序控制的数字传感器•驱动通信的串行接口•PV 源选项*所有⇒自动⇒手动⇒SUB, 从程序输入⇒追踪*仅自动Point Exec State•Active•InactiveX6Honeywell DCS 系统操作控制台体系结构•GUS*Deskside GUS 用于纺丝层, ICR, 纺丝 3rd层和培训系统。

NANJING UNIVERSITY OF TECHNOLOGY Honeywell EBI 系统培训教材Teaching Material of Honeywell EBI System主编单位:南京工业大学智能建筑研究所认证单位:美国Honeywell 公司支持单位:南京松普智能系统有限公司2003 年10 月1 日Honeywell EBI 系统培训教材Honeywell EBI Train Documentin NJUT IBINJUT IBI·All rights reserved.For the training of NJUT IBI ONLYNJUT IBI reserves the right to make changes andimprovements to its products without providing notice.南京工业大学智能建筑研究所地址:新模范马路200 号44 号信箱中国·南京邮编:210009电话: or传真:NanJing University of Technology IBIAddress: 44# Xin Mofan StreetLu Weiiang,NanJing 210009CHINATel:086- or 086-Fax:086-目录序 (1)第一章智能建筑概论 (5)一、智能建筑的概念........................................................... .. (5)二、楼宇自动化系统(BAS) (6)三、办公自动化系统(OAS) (8)四、通信与网络系统(CNS)............................................................ .. (9)第二章EXCELCARE 培训教材........................................... (16)第一节.概述 (16)1. 1. C A R E功能 (16)1. 2. C A R E概念 (16)1. 3. C A R E开发步骤 (18)第二节.C A R E工作环境 (19)2. 1. C A R E开发环境总览 (19)第三节.工程和设备 (25)3. 1. 工程................................................................................................ . (25)3. 2. 设备................................................................................................ . (26)3. 3. 举例................................................................................................ . (29)第四节.设备原理图 (30)4. 1. 介绍................................................................................................ . (30)4. 2. 操作................................................................................................ . (31)4. 3. 举例................................................................................................ . (33)第五节.开关逻辑................................................................................................ .. (33)5. 1. 介绍................................................................................................ . (33)5. 2. 操作................................................................................................ . (38)5. 3. 举例................................................................................................ . (40)第六节.控制策略................................................................................................ .. (42)6. 1. 介绍................................................................................................ . (42)6. 2. 操作................................................................................................ . (44)6. 3. 举例................................................................................................ . (48)第七节.控制器........................................................................................ . (49)7. 1. 介绍................................................................................................ . (49)7. 2. 操作................................................................................................ . (49)7. 3. 举例................................................................................................ . (50)第八节.编辑器........................................................................................ . (51)8. 1. 介绍................................................................................................ . (51)8. 2. 操作................................................................................................ . (51)第九节.时间程序.................................................................................... .. (52)9. 1. 介绍................................................................................................ . (52)9. 2. 操作................................................................................................ . (53)9. 3. 举例................................................................................................ . (56)1第十节.编译和仿真................................................................................ .. (57)10. 1. 编译................................................................................................ . (57)10. 2. 仿真................................................................................................ . (57)第十一节.应用实例................................................................................ .. (57)第三章EBI 系统部分............................................................................. .. (58)第一节EBI 概述............................................................................. . (58).EBI 系统丰富的功能................................................................... . (59).EBI 和安防管理................................................................... (59).EBI 和建筑物管理................................................................... . (59).EBI 和火灾报警管理................................................................... . (59).EBI 系统中有什么................................................................... . (59).EBI 如何工作............................................................................. .. (65)第二节安装指南............................................................................ .. (70)第三节配置和管理指南.................................................................. . (74).配置指南................................................................................................ . (76).使用Quick B uilder................................................................. .. (94).配置工作站和打印机............................................................. .. (96).配置控制器............................................................................................. (101).配置点............................................................................................. .. (103).为点配置工作站显示........................................................................ .. (109)第四节南京工业大学IB 所EBI 实验系统 (110).南京工业大学智能建筑研究所(IB 所)介绍 (110).Honeywell EBI 实验系统介绍............................................................ .. (112).设计方法......................................................................................... (117)序前言高效、安全、舒适和便利是智能建筑(IB)的四大优势。

For industrial organizations, it is imperative to increase uptime and improve reliability. Plants seek to boost the effectiveness of their operations teams, and also require faster and more accurate engineering and greater maintenance efficiency. In addition, there is a need for higher speed processing and better control in manufacturing applications. Although Distributed Control System (DCS) technology offers significant advantages for modern industrial operations, the right solution should be purpose-built with the latest technology for your industry and application needs.IntroductionAre These Questions on Your Mind?•H ow do you ensure your plant hasan uninterrupted process execution?•W hat if you could maintainsteady and efficientoperation to ensure productsare manufactured accordingto your customer’s qualityand delivery standards?•H ow do youensure your plantpersonnel have thetools to optimizeproduction?•W hat if you could quicklyrespond to changes in themarket that may requireshifts in production typeor volume, or the start-upof new manufacturingfacilities?FPO If yes, what you’re really looking for is a reliable and flexible DCS with features tailored to your control applications...Five Features to Look for When Choosing a Perfect Fit Distributed Control SystemA DCS should be proven in the most demanding automation environments. It should alsooffer innovative solutions vital to improved plant operations in a fiercely competitive climate. Characteristics of a Proven and Innovative SolutionFeature 1:Proven and Innovative Solutions•S table and time-tested controller and I/O design protecting customer investment•P roven communication networks for fault tolerance, performance and security•V ersatile and robust control environment with proven control algorithm •S88-compliant batch control in controller enables faster, more reliable batch execution •D istributed server architecture optimizing system integrationWith the increasing demand for reliability, safety and production yield, DCS has become the preferred choice of today’s plant manager, thanks to its inherent overall system approach with integrity of process data over a high-performance and deterministic network, minimizing the downtime associated with servers, HMI and applications. Advantages of a Robust Distributed Control SystemFeature 2:Greater Robustness than a PLCBuilt-in Redundancy: True redundancy at all levels of the system from the I/O all the way up through the I/O link, the controller, the network and the servers, no single point of failure. One Data Ownership: Shared singular database across controllers and HMIs, maintaining global data consistency while enabling greater usability and operability. Integrated Station Environment: Allows direct access to controllers for process data, alarms and messages for constant view and control of the process.ASM®-compliant Safe Operator Functions: Provides integrated, interactive instructions to reduce incidents, as well as alarm handling and display layouts to improve overall operator response to abnormal conditions.Purpose-built DCS for Your Specific Requirements• P re-built template and rich function libraries enabling rapid implementation of best practices• B uilt-in function blocks specific for power applications• A dvanced batch control capability supporting chemical manufacturing • C FR21 Part 11 compliant system for pharmaceutical needs • F lexible and compact IO design simplifies project execution and reduces maintenance costT oday, there is a growing demand for a flexible distributed control solution designed to meet the diverse requirements of industrial sites around the world. What this means is a solution enabling users to achieve the performance advantages of a true DCS at a more affordable price than alternative approaches.Feature 3:T echnology to Meet Your Specific RequirementsThe DCS you choose shouldn’t just provide sophisticated process control and SCADA functionality; it should also simplify the use and configuration of these capabilities. This will allow you to elevate your automation performance without disrupting your existing operations or changing your normal work practices.Feature 4:Ease of Configuration and UseKeys to Simplifying Engineering and Operations• S tandardized display library with highest ASM compliance • M ulti-level hierarchy windows with single click navigation • P re-built equipment templates for easy configuration and maintenance• C lass-based recipes for faster implementation• B ulk configuration tools that eliminate repetitive manual tasks • D ynamic alarm suppression that simplifies plant operations.Now, more than ever, your industrial facility needs the confidence of a secure path forward for its process control system. Wouldn’t it make sense to decide the level of automation that’s appropriate for you today, and then expand the system at your own pace as your business grows?Grow to Fit Your NeedsA state-of-the-art DCS should be very flexible, from a single controller, engineering/operator station or server for the system— all residing in one PC or redundant pair of PCs. The system can then expand to many controllers, stations and redundant servers, and even beyond. Deploy Automationon Your T ermsA modern distributed systemarchitecture ensures separate DCSclusters that can be independentlyinstalled and maintained, simplifyingthe overall support. It also providesmaximum flexibility for geographicallydistributed control areas, orcontrol areas in different periodsof construction.Reach FirstProduction SoonerWith the right DCS, your processcontrol personnel can reduce the timespent getting ready for first productionby utilizing features such as drag-and-drop configuration, prebuilt algorithms,a global database, and integrated tagconfiguration. They can also developASM-compliant, preconfigured displaysand objects.Feature 5: Flexibility to Expand ControlDiscover a Perfect FitControl SystemIntroducing PlantCruise by Experion—a Distributed Control System which has beendesigned with all the features mentioned above.This makes it the right DCS for all types of manufacturersand industrial enterprises.Based on Honeywell’s award-winning Experion ProcessKnowledge System (PKS), PlantCruise by Experionefficiently answers the automation demands of differentlysized operations and leverages Honeywell’s track recordas a recognized leader in the field of process control.PlantCruise by ExperionProven. Purpose-Built. Easy-to-Use.Five Features to Look for When Choosing a Perfect Fit Distributed Control System ©2015 Honeywell International Inc.All Rights Reserved.Rely on HoneywellAround the world, Honeywell’s control systems areemployed in the most demanding industrial applicationsto improve process safety, reliability and efficiency.You can rely on our proven, advanced DCS technologyto improve your operational and business performance.For More InformationT o learn more about Honeywell’s PlantCruise by Experionsolution, visit or contact yourHoneywell account manager in your country/region orwrite to us at **************************ASM ® and Experion ® are registered trademarks of Honeywell International Inc.* A ll other trademarks are the property of their respective owners.July 2015。

Honeywell报警产品培训Honeywell是一家全球领先的多元化技术和制造公司,专注于为客户提供创新的解决方案和产品。

在安全领域,Honeywell提供了许多高效可靠的报警产品,包括入侵报警系统、火灾报警系统和气体泄漏报警系统等。

Honeywell报警产品培训将详细介绍这些产品的特点、功能和使用方法,以确保用户能够正确使用和维护这些报警系统。

首先,我们将介绍Honeywell的入侵报警系统。

该系统采用先进的技术,可以有效保护家庭、办公室和商业区等各种场所的安全。

系统由控制器、传感器、报警器和监控设备等组成。

控制器是整个系统的大脑,可以对传感器的输入进行分析,并在检测到入侵事件时触发报警器。

Honeywell的入侵报警系统具有多种防御功能,包括红外传感器、玻璃破碎传感器和震动传感器等,可以有效地检测入侵行为。

此外,报警器可以通过声音和光线等方式发出警报,吸引周围的人们的注意,并起到震慑犯罪的作用。

Honeywell的入侵报警系统还具有远程监控和配对功能,用户可以通过手机或电脑远程监控和控制系统,确保在任何时间和地点都能获得安全的保护。

其次,我们将介绍Honeywell的火灾报警系统。

火灾是一种严重威胁人们生命和财产安全的情况,因此及早发现并采取相应的措施是非常重要的。

Honeywell的火灾报警系统可以及时检测到火灾的迹象,并通过报警器发出声音和光线等信号,警示人们采取相应的逃生措施。

火灾报警系统由控制器、烟雾探测器、温度探测器和手动火灾报警器等组成。

控制器通过烟雾探测器和温度探测器等传感器来监测周围环境的变化,一旦探测到烟雾或温度上升超过设定值,就会触发报警器。

Honeywell的火灾报警系统还具有自动报警和手动报警的功能,用户可以根据实际情况选择相应的报警方式。

此外,火灾报警系统还可以与消防设备和建筑自动化系统等进行集成,为用户提供更全面的保护。

最后,我们将介绍Honeywell的气体泄漏报警系统。