3.西门子S7-1200产品样本

- 格式:pdf

- 大小:2.30 MB

- 文档页数:31

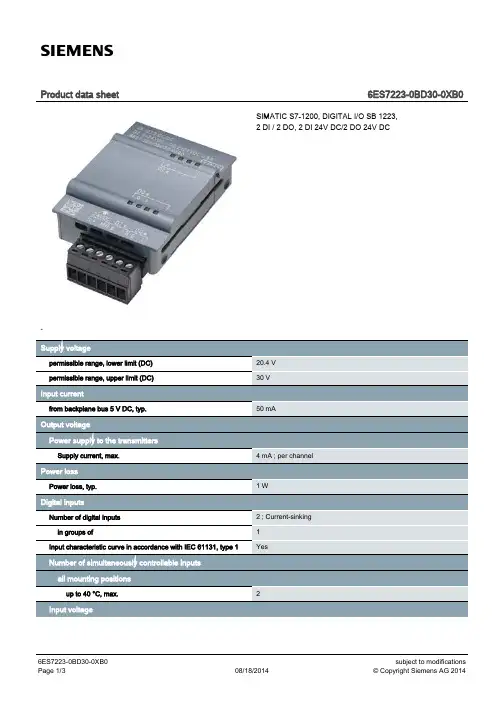

S7-1200的选型与配置(1)本体硬件拓展S7-1211C=本体+1Board+3CM/CPS7-1212C=本体+1Board+3CM/CP+3SMS7-1214C/1215C/1217C=本体+1Board+3CM/CP+8SM相关说明:1Board(信号板):SB-DI/DO AI/AO CB-RS485SM:DI/DO AI/AO 拓展模块CM:RS422/485 RS232 Profibus等通讯模块CP:远程通讯模块(2)本体各类型的接线图相关说明:电源:20.4-28.8VDCPNP(图示)输入自带AI/AO自带24VDC输出电源晶体管24VDC输出端,0.5A/28.8VDC输入接线:PNP/NPN开关,按钮旋钮开关,触电的哇区别以及注意事项。

相关说明:电源:20.4-28.8VDCPNP(图示)输入自带AI/AO自带24VDC输出继电器输出:交直流均可以输出:2.0A/220VAC/30VDC相关说明:电源:85-264VDCPNP(图示)输入自带AI/AO自带24VDC输出继电器输出:交直流均可以输出:2.0A/220VAC/30VDC(3)拓展模块-SM数字量输入模块类型:均支持PNP/NPN逻辑1信号(最小):信号为1时最小电流及电压逻辑0信号(最大):信号为0时最大电流及电压隔离(现场侧与逻辑侧):光电隔离隔离组:通道之间不隔离滤波时间:将输入滤波时间设置为适合的值以避免高速计数器无法正常工作电缆长度:非屏蔽300m;屏蔽500m相关说明:1.24VDC输入接线与本体一样2.滤波时间需要在不同的应用情况下注意调整3.输入信号的电缆长度要注意考虑4.如果遇到交流220VAC的输入信号时建议通过中间继电器转成无源信号,然后用24VDC进行输入(当然,s7-1200PLC系列也有264VAC拓展模块可选)数字量输出模块1.电流:出点输出的最大电流2.通态触电电阻:通道内部电阻值3.每点的测电流:晶体管输出特性,当信号为0时通过的漏电流4.公共端的电流(最大):每个通道组输出的电流综合。

Basic Controller SIMATIC S7-1200Be flexible thanks to networking possibilities Unrestricted / © Siemens AG/s7-1200SIMATIC controllers set new automation scaleTrends Solutions…Ethernet-based field busIT functionality Increased functionality and designflexibilityIncreased Integrated functionalityOptimized usabilityEasy to manage, reduced complexityPROFINET I/O as a standard at all PLCse.g. web server on-board all PLCsFor the same priceMore interfaces, higher performance, memory …e.g. motion control functions / PID controller /Trace / high speed counterse.g. integrated system diagnostics, project upload Simplified commissioning (serial machine building) Reduced, optimized portfolioIncrease of system functionalityHighlight performance•PROFINET Master –decentralized Profinet architectures possible for I/O, HMI, drives, and other Profinet field devices. NO communication module required!•PROFIBUS Master & Slave –decentralized Profinet architectures possible for I/O, drives, and other Profinet devices, including integration into existing system networks.•AS-i Master –The new AS-i-Master is configured in full in the TIA Portal and a new AS-i network can be created very easily with just a few clicks. AS-i networks do not therefore require separate software!•CANopen Master –Enables connection with CANopen devices, as well as with devices running Transparent CAN 2.0A.Highlight performance•Modbus TCP –Enables communication with devices as Modbus master or slave. Only one TCP function block is required for this. •IO-Link Master –Fast and easy integration of the SIRIUS compact starter, M200D starter and SIRIUS soft starter for simple starter control.•GPRS/LTE module –Easy implementation for data recording and control of decentralized computer.•TCP/IP –Via the instructions for open communication you can communicate with other CPUs, other PCs and with devices that use TCP/IP communication protocols as standard. NO communication module required!SIMATIC S7-1200 in the TIA PortalHighlight performance•RS-485, RS-422 & RS-232 –The S7-1200 CPU supports point-to-point (PtP) communication for character-based serial protocols, and this provides maximum freedom and flexibility for the use of PtP communication instructions in the user program.•Modbus RTU –Using the Modbus instructions the Modbus master or slave is able to communicate with devices that use the Modbus RTU protocol.•USS –Using simple USS instructions you can control the operation of drives that support the USS (Universal Serial Interface) protocolS7-1200CPUSMCM CP SM 1278CB 1241 RS485SINAMICS V20USSMODBUS RTUModuleCommunicationCM 1241RS232serial CM 1241RS422/485serialCM 1243-2AS-i master CM 1242-5PROFIBUS DP slave CM 1243-5PROFIBUS DP masterCP 1242-7GPRS Mobile communications telecontrolCP 1243-7LTE Mobile communications telecontrolCP1243-1Ethernet VPN/Firewall, Telecontrol Ethernet (DNP3, IEC 60870)RF120C RFID 1 Reader port; RS422CM CANopenCANopen3rd party: HMS 021620-BS7-1200 integrated PROFINET (Ethernet) interface… with the STEP 7 software•CPU hardware configuration•Loading a project•Monitoring/amending runtime tags•Set runtime I/O statuses•Diagnostics information... with HMI panels•Data from or to the CPU•System diagnostics... from CPU to CPU•Open communication with T-block instructions•Supported protocols: TCP/IP, ISO on TCP, UDP, S7 Com. (PUT/GET)MRP -Media redundancy protocolBased on ring topology (IEC 61158-5-10)Max. 50 nodes in the ring•PROFINET IO-Controller•PROFINET IO-Devices•Components of the network infrastructure (IE switches) 200 ms reconfiguration timeCPU 1215/17 as MRP Client at least FW V4.1 Configuration and diagnostics in STEP7Industrial Ethernet PROFINET•Improved plant availability•More flexibility•Lower costs since less equipment required > V4.1< V4.2S7 routing•Enables a connection between different subnets • A SIMATIC S7-1200 station acts as an S7 router •Based on PROFINET•Actually only with CP 1243-1 at least V2.0 (6GK7243-1BX30-0XE0) andCPU FW V4.2192.168.0.1 192.168.0.3 177.168.0.1192.168.0.2S7 routedConnectionSubnet1Subnet 2CommunicationWebserverIntegrated Web server•Access to system and process reports as well as identification data •System diagnostics for all configured assemblies centrally anddecentralized•Communication diagnostics on parameters, statistics, connection status •Access to process data via tag tables and freely definable tag lists •Pages to be defined by the user•Firmware updateArchive•Access via Webserver using Filebrowser for reciprocal exchanges of data in .csv format•Logging of user-defined tagsStation webserverVarious types of communication access: CPU PN interface, CP 1243-7 LTE,CP1242-7 V2•Central access via CPU page independentlyof the interface•User is then able to browse to the CP-specific webpages from thereuniform, consistent webserverfor entireS7-1200 stationRemote access viaInternet/mobile communicationsPN accessPROFINET i-Device•Simple configuration of S7-1200 CPUsin a master/slave architecture through reading and writing the reciprocal I/O images•Connection of CPUs in different projects•NO PN-PN coupler required (transparent network)IO controllerCPU1IE / PROFINETIO deviceOperational systemApplication / userprogramIO process imageInputaddr.Outputaddr.Operational systemApplication / userprogramIO process imageInputaddr.Outputaddr.PROFINET IOIO controller 1IO device 2IE / PROFINETIO device 1IO device 3i-deviceSavings with costs / installation / wiring of additional hardwareCPU2•Access for up to 2 controllers on S7-1200 as i-device •Rapid exchange of data in real time between S7-1x00 CPUs•Incorporation of 3rd party controllers under PROFINETAs ofV4.1Shared I-DeviceSerial communication•ASCII protocol (character-based serial communication)uses STEP 7 PtP instructions•USS Drive protocol is programmed with STEP 7 USSlibrary instructions•MODBUS protocol is programmed with STEP 7MODBUS library instructions•3964R ProtokollRS232RS485/422USS drivesUpdate rate Array•Fixed update rate (as fast as possible)•Enable instructions in an interrupt alarm OB in order toset a user-defined update rate.Support for drives•Maximum 15 drives per CM (communication module) supported•Non support:•MM3 drives•Deregistration of missing drives•S7-1200 CPU up to 8 IO-Link master modules -centralized•Data rate COM1 (4.8 kbaud), COM2 (38.4 kbaud), COM3 (230.4 kbaud)•Standard IO Mode (SIO Mode)•up to 4 IO-Link devices (3 wire) or 4 standard actuators•Diagnostics configurable for each port •I&M identification•IO-Link parameter allocation with S7-PCT (Port Configuration Tool) V3.2IO-Link supportSM 1278 4xIO-Link master (6ES7 274-1XK30-0XA0)•Point-to-point connection, no bus system•Existing wiring topologies are retained•Standard sensor/actuator cable (three wires with one signal wire), unshielded, 20 m in length,no special-purpose cable / connector•Manufacturer-independent communication standard for the PNO•Non-stop consistent communication•Cyclical, bidirectional process data communication (typ.2 ms cycle)•Non-cyclical service data transmission betweensensors/actuators and the controller as required •Integrated differentiated diagnostics alarms• LinkSwitchingdevices<20 mControl cabinet<20 m3RA6compact starters3RA27function modules for feeders3UG4monitoring relays3RW40soft startersSIMATIC RF120C –Fast communication module for S7-1200RF120CInterface to the applicationInternal S7 busConnection technology S7-1200 setup technology; screw terminals for 24 V supply Interface to the reader RS422 incl. 24 Volt; up to 115.2 KBaud Connection technology Submin-D connectorRFID system RF200, RF300, RF600, MOBY D/U, MV400FB, driver Instructions: Read, Write, Read_EPC-Mem, Write_EPC-Mem, Set_Ant_RF300, Set_Ant_RF600, Reset_Reader; based on FB101Number of readers 1 per RF120C; 3 per S7-1200Degree of protection IP 20Dimensions (W x H x D)30 x 100 x 75•Level measurement in silos and bunkers •Plattform scales•Force and tension measurements •Typical industries: Food & Beverage,Chemicals, Cement, Aggregate•Legal for trade certificate according OIML-R76•CPU 1212C →up to two SIWAREX modules •CPU 1214C orhigher→up to eight SIWAREX modules •Full parameter access from the CPU via free downloadable function block →Complete commissioning andcalibration via CPU/HMISIWAREX WP231 –Basic applications•Up to eight parallel connected analog 350 Ohm load cells per SIWAREX (1mV/V, 2mV/V, 3mV/V or 4mV/V)• 1 SIWAREX = 1 scale• 4 digital inputs / 4 digital outputs • 1 analog output•Ethernet (Modbus TCP & SIWATOOL)•RS485 (Modbus RTU)SIWAREX WP241 –Belt weigherapplications•Belt scales (Cement-, Aggragate plants, Mines, Food & Beverage plants)•Weigh feeder applications (Food & Beverage, Chemical, Steel)•CPU 1212C →up to two SIWAREX modules •CPU 1214C or higher→up to eight SIWAREX modules •Full parameter access from the CPU via free downloadable function block →Complete commissioning andcalibration via CPU/HMI•Up to eight parallel connected analog 350 Ohm load cells per SIWAREX (1mV/V, 2mV/V, 3mV/V or 4mV/V)• 1 SIWAREX = 1 scale• 3 digital inputs / 4 digital outputs / 1 speed sensor input • 1 analog output•Ethernet (Modbus TCP & SIWATOOL)•RS485 (Modbus RTU)SIMATIC S7-1200SIWAREX WP251 –Dosing , Batching and Bagging applications•Dosing and batching scales (Chemical-, Food-, Pharma, Packaging industries)•Bagging machines (Bulk solids industries)•Eichfähig gemäß OIML-R51, R61 und R76•CPU 1212C →up to twoSIWAREX modules •CPU 1214C or higher→up to eight SIWAREX modules •Full parameter access from the CPU via free downloadable function block →Complete commissioning andcalibration via CPU/HMI•Up to eight parallel connected analog 350 Ohm load cells per SIWAREX (1mV/V, 2mV/V, 3mV/V or 4mV/V)• 1 SIWAREX = 1 scale• 4 digital inputs / 4 digital outputs • 1 analog output•Ethernet (Modbus TCP & SIWATOOL)•RS485 (Modbus RTU)•RS485 (Modbus RTU)•A CANopen connection to a S7-1200 systemenables integration between devices and the S7-1200 system •Up to 3 CANopen modules per S7-1200 CPU •Connection type to the CAN: 9-pin DSUB (male)•Up to 16 CANopen nodes per module•256 bytes each for inputs and outputs with the CANopen module•Can be integrated in the hardware catalog of the TIA Portal configuration suite •Ready-made function blocks for simple PLC programming available in the TIA Portal • LinkController Area Network CANopen 021620-BMODBUS communication•Use of a CM or CB 1241 module for serial communication•MODBUS instructions of the communication module for simplified MODBUS RTU operation.•MB_COMM_LOAD for basic initialization of the master and slave operation•MB_MASTER and MB_SLAVE for controlling the report and connection allocations•Modbus addressing supports a maximum of 247 slaves (slave numbers 1 to 247).•Maximum of 32 devices per segment in the Modbus network depending on the loading and drive functions of the RS485 interface•Repeater required if using more than 32 devices to extend to the next segment•Open User Communication MODBUS TCP instructions usethe PROFINET port integrated in the CPUOverview of CP 1243-1 product features•Single-width S7-1200 enclosure (30 x 110 x 75)•Temperature range in operation: -20°C to +70°C•Standard rail mounting•Diagnostic LEDs (overall status and detail)•Power supply using backplane bus•1 x Ethernet Port RJ45 (10/100 Mbit/s) for connectinga modem/router such as SCALANCE M•Integrated security functions (VPN and Firewall)•Integration to Scada Systems via Telecontrol Protokolls(DNP3, IEC 60870)Communication Processor for connecting S7-1200 to Ethernet network withadditional Interface and security features firewall and VPN. Integration toScada Systems via Telecontrol Protokolls (DNP3, IEC 60870, TelecontrolBasic).Overview of CP 1243-7 product features•1 connection to LTE (4G) mobile network(different versions for EU and North America)•Single-width S7-1200 enclosure (30 x 110 x 75)•Temperature range in operation from -20ºC to +70ºC•Standard rail mounting•Diagnostic LEDs (overall status and detail)•Integrated security functions (VPN and Firewall)•Access to the CPU Webserver•Email and SMS Alarms•Process Monitoring and Control via Cellular networkPROFIBUS DP-Master CM 1243-5•Connection for up to 16 DP slaves•PG/OP communication:up to 4 connection for HMI and 1 connection for PG •S7 communication:4 S7 connections to other S7 stations with PUT/GETPROFIBUS DP-Slave CM 1242-5•as an intelligent DP slave for communication for the S7-1200 with any other DP masterCommunication for S7-1200 CPUs according to PROFIBUS standard IEC61158/61784SIMATIC S7-1200PROFIBUS communication DP master CM 1243-5 and DP slave CM 1242-5Challenges need innovative answersIndividualization Globalization Production Logistics •Global alliance ofproduction and suppliers •New business modelsProduction•Customized mass production•Top quality at a competitive priceTime to Market New Technology•Critical to success inhighly competitive industries•Pressure on productivity increases, shortening time for new developmentSustainabilityEnergy Consumption•The efficient use of energy and environmentally safe materialsAlways the appropriate controller with comprehensive functionalities!Innovations across the entire automation life cycle!Engineered in TIA PortalSecurity IntegratedIntegrated system diagnosis Technology Integrated+Design and Handling+Safety IntegratedInnovative system functions for more productivity!Protecting intellectual property and investment Protecting against unauthorized project changesSecurity integratedFor Efficient fault analysis, Uniform display concept and reducing plant downtimesSystem DiagnosticsInvestment protection while replacing S7-1200 with S7-1500 thanks to compatibility of programsScalabilityUser-friendly products, high efficiency and a scalableproduct portfolioFeature / Function BenefitIntegrated PROFINET◆Web server for service-and diagnostic informationTechnology Integrated◆perfect integration of drives through motion control functionalities and PROFIdriveIntegrated Trace functionality◆Program-and application diagnostics at real-time for recognizing even sporadic problemsUse of all TIA Portal advantages◆Efficient programming, commissioning and service toolshighest engineering requirementsEasily adapted to suit your needsFeature / Function BenefitSystem ModularityModular board concept is integrated customization ◆Adding I/O without increasing theCPU footprintExtensive built-in hardwarecapabilitiesEthernet,analog in/out-puts, MC I/O, HSC I/O, SD memory ◆Reduced need for additionalspecialty modules,smaller footprintand lower costOne Engineering SoftwareOne user program for logic, HMI, networking & drives. ◆Reduced engineering time/cost, easier to maintain, easier to reuseSafety IntegratedOne Controller for fail-safe and standard-automation◆reduction of types-and components by single automation system for Standard and SafetyOne Controller for Standard andSafetyNewNewFeature / Function Benefit•Basic Controller with SafetyIntegrated•Connecting ext. devices viaPROFIsafe•CPU 1212CF◆•One Controller, one Network andone Engineering for standardand fail-safe automation tasks•Energy Meter ModuleSM1238 AI ◆•Central Measurement andHandling of energy data •MRP at 2 Port CPUs 1215 / 17as client (FW 4.2)•S7-Routing (FW 4.2)◆•Higher flexibility in network set-up (flexible topology) and highernetwork availability •Userdefined web pages as startpages (FW 4.2)◆•Individual and easy adaption of(CPU) web pages to applications•Backup / Restore with retaindata (FW 4.2)◆•Protection of data loss(incl actual process values)Easy PLC selection thanks to an optimized Portfolio2xTMCPU 1211C-1PN CPU 1212C-1PN CPU 1214C-1PN CPU 1215C-2PN CPU 1217C-2PN CPU 1212FC CPU 1214FC CPU 1215FCCSM PM 13x CM / CP22x I/Q 11x SB 1x CB 1x BBSM 1226 F-DO 2x Relay SM 1226F-DO 4 x 24 V DC SM 1226 F-DI 16 x 24 V DCMarienhöher Milchproduktion Agro Waldkirchen GmbH / Waldkirchen, Germany -S7-1200 and Energy Meter ModuleAllow internal balancingduring operation without high effort and cost1Efficient operation and cost optimization2ReliableSystem Protection3Transparency in energy consumption... through the acquisition of energy data in acompact solutionIncrease of energy efficiency ... through analysisof the reactive power consumptionGuaranteeing plant availability ... by monitoring the current peaksCPU 1212C with SM1238 Energy Meter ModuleCPU 1212C with SM1238 and visualization via KTP 400CPU 1212C with SM1238 and visualization via KTP 400ChallengePreviously Now -CPU 1212CJanitza UMG96SM 1238 Energy Meter -Basic Panel, KTP 400TIA Portal BasicProducts usedCustomer benefitsProducts/solution Energy data acquisition of direct marketing(butcher shop, diary, cheese factory, sales room), transparency and internal balancing in an agricultural enterprise End customer /F&BWaldkirchen/GermanyiProject informationSIMATIC Controller Get more Information…Always up-to-date!•interesting news from and about AS, such as product innovations, success news, best practice information etc.Newsletter/newsletter Detailed product information and related subjects!•Product Websites •Twitter, Youtube..Internet/S7-1200References CenterFrom customer to customer! •Customers gives account to there experiences using our Products for their applicationsGetting Started/automation-tasksEasy Introduction to the new SIMATIC controller generation!•Learn about the new possibilitiesand get to know the new Hardware even betterhttps:///referen zen/#language=enSubject to changes and errors. The information given in this document only contains general descriptions and/or performance features which maynot always specifically reflect those described, or which may undergo modification in the course of further development of the products. The requested performance features are binding only when they are expressly agreed upon in the concluded contract.All product designations, product names, etc. may contain trademarks or other rights of Siemens AG, its affiliated companies or third parties. Their unauthorized use may infringe the rights of the respective owner.。

简介:西门子S7-1200 第三代可编程逻辑控制器选型样本SIMATIC S7-1200 (V3.0) 还提供了以下功能:用户存储器容量增加工作存储器S7-1211C:从25 KB 增加到30 KBS7-1212C:从25 KB 增加到50 KBS7-1214C:从50 KB 增加到75 KB集成装载存储器S7-1211C/S7-1212C 具有1 MB 装载存储器S7-1214C 具有1 MB 至4 MB 装载存储器保持数据S7-1211C/S7-1212C 具有2 KB 至10 KB 的保持数据S7-1214C 具有8 KB 至10 KB 的保持数据性能提高布尔运算的执行时间缩短100ns 至85 ns2 个集成PTO (脉冲串输出)至4 个集成PTO,用于同时控制4 个步进电机通过PROFINET 端口进行固件更新实时时钟的运行储备现在通常为20 天,而不是以前的10 天-20°C 至+60°C 宽温度范围,而不是0°C 至+55°C可与固件版本为V3.0 及更高版本的S7-1200 硬件设计结合使用的附加组件:BB 1297 电池板用于将S7-1200 的实时时钟电源储备延长至一年的电池板。

可插到固件版本为V3.0 及更高版本的所有S7-1200 的信号板插槽中。

用户程序对电池状态进行分析,以指示是否需要更换标准钮扣电池。

供货范围内不包括标准钮扣电池CR1025。

能够使用所述功能的要求:带有V3.0 或更高版本固件的SIMATIC S7-1200STEP7 Engineering System V11 SP2 Update 3 或更高版本S7-1200 FW3.0 的硬件支持包兼容性和必要组件:固件版本为V3.0 创新型S7-1200 CPU 在备件方面与相应的FW2.x 型号兼容。

已交付的固件版本为V2.2 或更低的S7-1200 CPU 不能升级到固件V3.0。

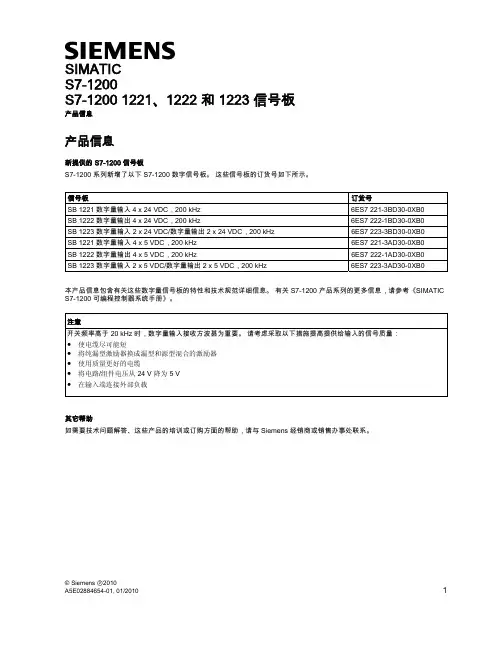

SIMATICS7-1200S7-1200 1221、1222 和 1223 信号板产品信息产品信息新提供的 S7-1200 信号板S7-1200 系列新增了以下 S7-1200 数字信号板。

这些信号板的订货号如下所示。

信号板 订货号SB 1221 数字量输入 4 x 24 VDC,200 kHz 6ES7 221-3BD30-0XB0SB 1222 数字量输出 4 x 24 VDC,200 kHz 6ES7 222-1BD30-0XB0SB 1223 数字量输入 2 x 24 VDC/数字量输出 2 x 24 VDC,200 kHz 6ES7 223-3BD30-0XB0SB 1221 数字量输入 4 x 5 VDC,200 kHz 6ES7 221-3AD30-0XB0SB 1222 数字量输出 4 x 5 VDC,200 kHz 6ES7 222-1AD30-0XB0SB 1223 数字量输入 2 x 5 VDC/数字量输出 2 x 5 VDC,200 kHz 6ES7 223-3AD30-0XB0本产品信息包含有关这些数字量信号板的特性和技术规范详细信息。

有关 S7-1200 产品系列的更多信息,请参考《SIMATIC S7-1200 可编程控制器系统手册》。

注意开关频率高于 20 kHz 时,数字量输入接收方波甚为重要。

请考虑采取以下措施提高提供给输入的信号质量:● 使电缆尽可能短● 将纯漏型激励器换成漏型和源型混合的激励器● 使用质量更好的电缆● 将电路/组件电压从 24 V 降为 5 V● 在输入端连接外部负载其它帮助如需要技术问题解答、这些产品的培训或订购方面的帮助,请与 Siemens 经销商或销售办事处联系。

© Siemens Ⓟ2010S7-1200 SB 1221 数字量输入的规范型号 SB 1221 DI 4 x 24 VDC,200 kHz SB 1221 DI 4 x 5 VDC,200 kHz 订货号 (MLFB) 6ES7 221-3BD30-0XB0 6ES7 221-3AD30-0XB0常规尺寸 W x H x D (mm) 38 x 62 x 21重量 35 g 35 g功耗 1.5 W 1.0 W电流消耗(SM 总线) 40 mA 40 mA电流消耗 (24 VDC) 7 mA/输入 + 20 mA 15 mA/输入 + 15 mA数字量输入输入点数 4类型 源额定电压 7 mA 时 24 VDC,额定值 15 mA 时 5 VDC,额定值允许的连续电压 28.8 VDC 6 VDC浪涌电压 35 VDC,持续 0.5 s 6 V逻辑 1 信号(最小) 2.9 mA 时 L+ - 10 VDC 5.1 mA 时 L+ - 2.0 VDC逻辑 0 信号(最大) 1.4 mA 时 L+ - 5 VDC 2.2 mA 时 L+ - 1.0 VDCHSC 时钟输入频率(最大) 单相:200 kHz正交相位: 160 kHz隔离(现场侧与逻辑侧) 500 VAC,持续 1 min隔离组 1滤波时间 0.2、0.4、0.8、1.6、3.2、6.4 和 12.8 ms;可选择,4 个为一组同时接通的输入数 4电缆长度(米) 50 m 屏蔽双绞线SB 1221 接线图SB 1221 DI 4 x 24 VDC,200 kHzSB 1221 DI 4 x 5 VDC,200 kHz6ES7 221-3BD30-0XB0 6ES7 221-3AD30-0XB0① 仅支持源型输入S7-1200 1221、1222 和 1223 信号板S7-1200 SB 1222 数字量输出的规范型号 SB 1222 DQ 4 x 24 VDC,200 kHz SB 1222 DQ 4 x 5 VDC,200 kHz 订货号 (MLFB) 6ES7 222-1BD30-0XB0 6ES7 222-1AD30-0XB0常规尺寸 W x H x D (mm) 38 x 62 x 21重量 35 g 35 g功耗 0.5 W 0.5 W电流消耗(SM 总线) 35 mA 35 mA电流消耗 (24 VDC) 15 mA 15 mA数字量输出输出点数 4输出类型 固态 - MOSFET 源型和漏型电压范围 20.4 到 28.8 VDC 4.25 到 6.0 VDC最大电流时的逻辑 1 信号 L+ - 1.5 V L+ - 0.7 V最大电流时的逻辑 0 信号 最大 1.0 VDC 最大 0.2 VDC电流(最大) 0.1 A灯负载 --通态触点电阻 最大 11 Ω 最大 7 Ω断态电阻 最大 6 Ω 最大 0.2 Ω每点的漏泄电流 --脉冲串输出频率 最大 200 kHz,最小 2 Hz浪涌电流 0.11 A 0.11 A过载保护 否隔离(现场侧与逻辑侧) 500 VAC,持续 1 min隔离组 1每个公共端的电流 0.4 A 0.4 A电感钳位电压 无开关延迟 上升沿 1.5 μs + 300 ns下降沿 1.5 μs + 300 ns 上升沿 200 ns + 300 ns 下降沿 200 ns + 300 nsRUN 到 STOP 时的行为 上一个值或替换值(默认值为 0) 同时接通的输出数 4电缆长度(米) 50 m 屏蔽双绞线S7-1200 1221、1222 和 1223 信号板SB 1222 接线图SB 1222 DQ 4 x 24 VDC,200 kHzSB 1222 DQ 4 x 5 VDC,200 kHz6ES7 222-1BD30-0XB0 6ES7 222-1AD30-0XB0① 对于源型输出,将“负载”连接到“-”(如图所示)。

西门子S7-1200PLC高速计数器实例及应用详解ABC去学电气技术西门子S7-1200 CPU 提供了最多 6 个(1214C )高速计数器,其独立于 CPU 的扫描周期进行计数。

可测量的单相脉冲频率最高为100KHz ,双相或A/B 相最高为30KHz ,除用来计数外还可用来进行频率测量,高速计数器可用于连接增量型旋转编码器,用户通过对硬件组态和调用相关指令块来使用此功能。

01高速计数器工作模式高速计数器定义为 5 种工作模式1、计数器,外部方向控制。

2、单相计数器,内部方向控制。

3、双相增 /减计数器,双脉冲输入。

4、5A/B 相正交脉冲输入。

5、监控 PTO 输出。

每种高速计数器有两种工作状态。

1、外部复位,无启动输入。

2、内部复位,无启动输入。

所有的计数器无需启动条件设置,在硬件向导中设置完成后下载到 CPU 中即可启动高速计数器,在 A/B 相正交模式下可选择 1X(1 倍) 和 4X(4 倍)模式,高速计数功能所能支持的输入电压为 24V DC, 目前不支持 5V DC 的脉冲输入,表 8-1 列出了高速计数器的硬件输入定义和工作模式。

并非所有的 CPU 都可以使用 6 个高速计数器,如 1211C 只有 6 个集成输入点,所以最多只能支持4 个(使用信号板的情况下)高速计数器。

由于不同计数器在不同的模式下,同一个物理点会有不同的定义,在使用多个计数器时需要注意不是所有计数器可以同时定义为任意工作模式。

高速计数器的输入使用与普通数字量输入相同的地址,当某个输入点已定义为高速计数器的输入点时,就不能再应用于其它功能,但在某个模式下,没有用到的输入点还可以用于其它功能的输入监控PTO 的模式只有 HSC1 和 HSC2 支持,使用此模式时,不需要外部接线,CPU 在内部已做了硬件连接,可直接检测通过PTO 功能所发脉冲。

02高速计数器寻址CPU 将每个高速计数器的测量值,存储在输入过程映像区内,数据类型为 32 位双整型有符号数,用户可以在设备组态中修改这些存储地址,在程序中可直接访问这些地址,但由于过程映像区受扫描周期影响,在一个扫描周期内,此数值不会发生变化,但高速计数器中的实际值有可能会在一个周期内变化,用户可通过读取外设地址的方式,读取到当前时刻的实际值。