聚合物的降解与稳定化

- 格式:doc

- 大小:32.50 KB

- 文档页数:3

聚合物稳定与降解(Polymer stability and degradation)The first chapter, introduction1. the concept of aging (degradation)The storage, processing and use of polymer materials in the process of chemical properties, physical and mechanical properties will gradually become worse, known as aging or degradation. P1Characteristic:The inevitable, irreversible process.The relatively short time scale.2. factors that lead to the degradation of the polymer(a) internalThe composition and structure of A. polymer chain.(1) different composition and degradation of different(2) the activity may be the main cause of the degradation of the matrix(3) the active hydrogen is more likely to be seized(4) head to head (tail tail) structure of polyolefin are more likely to become active points.(5) the effect of molecular weight change: changes in the structure of the molecular weight of the internal rules increases, causing stability. On the contrary, if the irregular structure is reduced, increased stability.(6) effects of the molecular weight distribution: down a wide molecular weight distribution and stability.(7) the degree of branching effect: the degree of branching increases, the weak link in the molecular chain also increased, more prone to degradation.The aggregation state of B. polymersThe stability of amorphous polymer material less than crystalline polymer materialsThe reason: amorphous materials (low density polymer chain irregular arrangement), easy to be oxygen, water, chemical infiltration, degradation.3. impurities in polymersIn the two kinds of polymer impurity:(1) a small amount of impurities mixed in the process of the inevitable;(2) additive.Most of the impurities will accelerate the degradation of polymers.(two) external causes:Effects of A. heat, temperature and heat and oxygen: heat the polymer chain scission, the formation of free radicals (reversible, bidirectional) hot oxygen polymer crosslinking or degradation of the material performance decline.Effect of B. lightEffect of C. oxygen and ozone oxygen to polymer degradation in heat and light effect. The ozone of unsaturated bond (such as rubber) the damage is very serious.Effect of D. water and damp of water dissolving and extraction of components; hydrolysis and chain scission.Effect of E. and other factors: the effect of microorganism; other organisms; effects of various process factors. Often a variety of external synergy.The second chapter, the basic principle of polymer degradation and stability.(a) the type of thermal degradationDepolymerization; random chain scission reaction; small molecular chain breaking elimination reaction;Features: simple caused by heat, no oxygen in.1. the depolymerization reaction (zipper degradation)The depolymerization began or weak molecular chain end point. Only product: monomer.Characteristic:(1) the early change of molecular weight polymer small, great mass loss;(2) to the degradation of polymer quality almost completely lost when the polymer relative molecular weight decreased dramatically.2. random chain scission reaction -- almost all polycondensate and add substantial degradation of polymersIrregular polymer chain scission reaction; the main product is low molecular weight polymer.Characteristic:(1) the initial molecular weight decreased rapidly and the quality of the polymer basically unchanged;(2) degradation to later stage, a large number of low molecular volatile polymer mass quickly disappeared.3. small molecular backbone fracture elimination reactionPolymer degradation caused by the elimination of side groups; and finally caused the main chain scission and comprehensive degradation.Features: from any part of the molecular chain of random elimination(two), the mechanism of degradationThe thermal oxidative degradation of the polymer at a certain temperature and oxygen in the air and the degradation reaction.Auto oxidation is the main feature of thermal oxidative degradation, but also the core of degradation.[heat: Auto oxidation reaction at room temperature to 150 DEG C, thermal oxidation is auto catalytic characteristics in the typical free radical chain mechanism, the. ]Schematic diagram of the polymer thermal oxygen cycleThe polymer thermal oxygen cycle, which represents the thermal oxidation process automatically. Seen from the figure, with each cycle, an initial alkyl radical R - at least 3 into a R, alkyl radical concentration is more and more high, the reaction speed is more and more fast, the formation of auto oxidation reaction.The rate of oxidation1. when the concentration of oxygen concentration in the air reaches or higher, with the rate of R and oxygen is very fast, [R -] < [ROO.Therefore, ROO double dominant coupling termination. The initiation rate is equal to the suspension rate (to reach steady state), available at steady state concentration of ROO.The oxygen concentration is greater than or equal to the oxygen concentration in the air, the oxidation reaction rate and the concentration of oxygen;2. oxygen concentration is very low, [R]>>[ROO, the reaction rate of the oxidation reaction rate depends on R and oxygen.In R, the termination reaction coupling termination dominant base,The oxygen concentration is very low, the oxidation rate of oxygen concentration.(three) the classification and method of adding antioxidant.Two kinds of antioxidants:The main antioxidant (radical scavenger): free radical reaction and auto oxidation process, interrupt the chain reaction.Features: automatic change of oxidation process.The auxiliary antioxidant (preventive antioxidant): can produce automatic decomposition of the oxidation process of ROOH without generating free radicals.Features: only reduce the oxidation rate, does not change the auto oxidation process.Principle: the sooner the better polymer added antioxidants.The type and mechanism of A. primary antioxidantThe main antioxidant can be divided into: hydrogen donor; electron donor; free radical trapping; benzofuran ketones.Hydrogen donor: is the most common secondary aromatic amines and hindered phenolic antioxidant.2,6-di-tert-butyl-4-methylphenolThe electron donor of tertiary amine containing reactive functional group of N-HGenerally, they can be given, generating onium cation.Radical trapping body can capture free radicals, and the product will no longer trigger free radical chain reaction.Benzofuran ketone - dilute oxygen conditions, alkyl radical captureWith B. antioxidantUse a variety of antioxidants, there will be synergistic effect, additive effect and antagonistic effect.Synergy: 1+1>2Two (or more) with antioxidant effect, the sum of more than separately use effect. Can be divided into both synergistic effect and hybrid Association effect.[cases] are synergistic effects of two kinds of hindered phenol.Antagonistic effect: 1+1<2Two (or more) with antioxidant effect, to separately use effect.Additive effect: 1+1 = 2Antioxidants used alone or in conjunction with other antioxidant,The effect of the same.(four) initiation of carbonylThe Norrish type I reaction between carbonyl and alpha carbon atoms bond cleavage.The Norrish type II reaction: only occurred in the gamma ketocarbonyl carbon atoms, at least one hydrogen atom under the condition can occur at room temperature.The Norrish type III reaction: through transfer of beta hydrogen atoms and C - C bond cleavage near the carbonyl side, the formation of aldehydes and alkenes.(five) stabilized light degradation and light degradation of oxygenA commonly used type of light stabilizer: light shielding agent; UV absorber; quenching agent; hindered amine light stabilizerThe 1. light shielding agentThe reflection or absorption of light at the polymer surface, or reduce the amount of transmission to the polymer, the main physical stabilization method.(1) surface protection agent: on the surface of polymer materials for coating or plating metal film protection.(2): carbon black pigment is the most effective light shielding agent.2. UV absorbersA kind of light stabilizer and most strongly and selectively absorb ultraviolet light, with low-energy radiation heat or harmless way to release energy.(1) two o-hydroxyl benzophenone UV absorber is the most importantCarbonyl ortho must contain a hydroxyl group to form hydrogen bonds through the chelate ring, keto enol tautomerism and to absorb and release energy. The intramolecular hydrogen bond strength is greater, more conducive to the process of tautomerism.No ortho hydroxy carbonyl when the compounds become photosensitizer.Six. The reaction of ozone with rubber- double bond addition reactionOzone cracking: the destruction of the ozone stress on the rubber, causing cracking in the direction perpendicular to the stress direction.Crack: rubber cracking caused by oxidative degradation.Seven. Biodegradable polymersNatural polymers are biodegradable, relatively natural polymer, synthetic polymer is difficult to be biodegraded.The third chapterA polyolefin.The structure of the polyolefin and polymer degradation and stability.The thermal stability of various key and group respectively:The thermal stability of order polyolefin as follows: polyethylene polypropylene polyisobutylene > >Main order: Polyolefin oxidation stability of high density polyethylene and low density polyethylene polypropylene > >Two PVC.The thermal stability of PVC is poor, without the stabilizer, cannot be processed into products by melting method.The thermal degradation of PVC 1.(1) the characteristics of degradation of PVC: the release of HCl -- the typical features; the presence of oxygen, accelerated degradation.The mechanism of HCl decomposition 2.PVC:(I) free radical mechanism: (II) ion molecule mechanism: (III) molecular mechanism:The photodegradation of PVC 3.PVC degradation and crosslinking during UV irradiation, the production of conjugated polyene and hydrogen chloride.The fourth chapterThe factors that cause a degradation in the processing andMechanical force, temperature, oxygen, water and other medium, such as trace metal impuritiesThe evaluation method of degradation and stabilization of polymer processing, twoAccording to the processing before and after processing (after different time or several times after processing) a performance test of polymer compared to make a judgment on the polymer degradation degree or stability.OneThe melt flow rate method. 2. the determination of relative molecular mass and its distribution. 3. rheological method. 4. yellow indexTwo. The degradation of PVC in the machining process1. the characteristics of degradation of PVCViscous flow temperature (160 to 212 DEG C) > the decomposition temperature (170 C)De HClThe dark - conjugated polymerThe molecular structure of polyene and intramolecular cyclization - polymer crosslinking and viscosity increase and the decrease of fluidityThe role of oxygen leads to removal of HCl increased;With polyene structure reaction, delay PVC color.Three. The influencing factors of the stability of PVC processingThe performance of the 1. polymer itself: molecular weight; particle morphology of resinInfluence of 2. factors on the degradation of PVC formula in the process ofCan reduce the viscosity of polymer melt.To improve the liquidity, reducing agent -- polymer degradation of PVC in the process of riskTo improve the processing of - PVCThe fifth chapterA polymer stabilizer.1. kinds of polymer stabilizersHeat stabilizer; light stabilizer; antioxidant capacity; chemical stabilizer; fungicideTwo. The mechanism of heat stabilizer1. preventive effect: to prevent the dehydrochlorination reaction, or at least can postpone the reaction.(1) the absorption of HCl, inhibit the auto catalytic role: metal carboxylate, organic tin mercaptide, epoxidized fatty acid esters(2) the replacement of labile chlorine atoms in the molecule of PVC, such as allylic chlorine or a chlorine atom of tertiary carbon, eliminate the trigger: metal soap, organic tin(3) to capture free radicals, prevent the auto oxidation of phenolic antioxidants:2. passivation effect: heat stabilizer can shorten the polyene sequence structure, and can form the PVC damage in the process of heating the carbon onium salt.Only organic tin stabilizer with thiol passivation and prevention functionThree types of heat stabilizers.1. lead heat stabilizer stabilizer2. organic tin stabilizer3. metal carboxylate stabilizer4. other metal stabilizer5.metal free 6. auxiliary stabilizerThe sixth chapterProcessing technology of waste plasticsThe establishment of waste plastics recycling system is feasible to eliminate environmental pollution and ensure waste plastic recycling.The main way of waste plastics recycling1. mechanical regenerationSimple regenerationAdvantages: economical and feasibleDisadvantages: requires relatively clean waste; high separation technology; end use markets products co.;Belongs to labor-intensive processing2. modified regenerationAdvantages: the mechanical property of the product is improved, can be recycled products of high gradeDisadvantages: process is complicated and some specific equipment3.: depolymerization is an advanced technology with the rapid development of recycling4. pyrolysis and gasificationAdvantages: pyrolysis can handle all can not be treated by other ways of waste plastics,Liquefaction condition can be selectedWithout the prior separation of plastic, also do not need to remove the impuritiesDisadvantages: gasification process General requirements for harsh conditionsThe pyrolysis liquid products need to be purified to more hydrocarbon components5. burningAdvantages: energy, fuelDisadvantages: exhaust pollution6. landfillAdvantages: simpleDisadvantages: loss of all available energy; space; exudate pollution; waste plastic refractory; huge investmentThe seventh chapterThe combustion characteristics of polymer materials.1. heat temperature of2.3. high flame burning speed of4. burning poisons released5. in the combustion will produce deformation, softening, melting and dropping phenomenon, which has a great influence on the combustion state, often cause the spread of fire, which makes it difficult to fire.Two. The combustion process of polymer materials3. fire by properties of materials are as follows 1. decomposition of the heating and melting heat: 2. flash temperature, autoignition temperature, limit oxygen index4. burningNet heat of combustion to combustion >0Net heat of combustion <0 stop burning5. flame propagationThree. Combustion process of polymers1. in the combustion of organic matter, the first thermal oxidation degradation reaction of polymer chain, long chain rapid collapse, liquid or solid organic materials into combustible gas (hydrocarbon),Combustion is a free radical chain reaction of 2. small molecule hydrocarbon, eventually forming carbon dioxide and water.3. polymer combustion, the main fuel is hydrogen, instead of carbon; in the polymer structure as the hydrogen molecule from substitutionThe key is to capture the 4. flame retardant free radical and free radical resistance and low energy. The combustion of PVC leaving the fire extinguish, because it generates hydrogen chloride can capture free radicals in the cleavage process.Four. Flame retardant agent and flame retardant mechanism1. basic options: (1) the polymer itself has a certain flame retardance (2) combustion velocity is relatively small(3) (4) good heat resistance and flame retardant filler, good compatibility2. flame retardant flame retardantThe endothermic effect covering effect of dilution effectThe inhibitory effect of enhancement effect3. as a flame retardant with four service conditions:(1) flame retardant is not flammable or low flammable material.(2) have good dispersion in polymer materials.(3) cannot be destroyed by the physical properties of flame retardant material. (4) flame retardant itself or under combustion conditions do not release toxic gases4. kinds of flame retardantsAdd type* easy to use, wide application range,* but there is a certain impact on the performance of polymer,* mainly used in polyethylene, polypropylene, polyvinyl chloride and polystyrene resin.* such as chlorinated paraffin, four Bromethyl, aluminium hydroxide and magnesium hydroxide etc..Reaction type* as a monomer in polymerization, the polymer with flame retardant properties.* operation and processing complex* four phthalic anhydride and two bromine chloride four bisphenol A is a reactive flame retardant.* for the polycondensation reaction, such as polyurethane, unsaturated polyester, epoxy resin, polycarbonate, etc..5. flame retardant mechanism of flame retardantDifferent flame retardant, the flame retardant mechanism is different, but the overall physical effect and chemical effect of.- physical effects of dilution of combustible materials, heat effect and air isolation effect;Chemical interaction in carbonation, eliminate free radicals and phosphorus acylation.The stability and degradation of the eighth chapter of medical polymer materialsOneBiomedical materials can be divided into three categories: medical metal materials, medical ceramic materials and medical polymer materials2.. Various factors in vivo degradation:* after a large number of studies show that the release of inflammatory cells (enzymes and enzyme hydrolase) and oxidant (O2 *, H2O2, OH), acidic substances (such as fatty acids) and substances in body fluids (Ca2+, phospholipid, cholesterol) constitute environmental degradation.* all non endothelialization surfaces of synthetic materialsstimulate certain levels of immune response in vivo, such as inflammatory reactions, and therefore all materials in the body are degraded.* the inflammatory response of the material depends on the interaction of the material surface with the protein in the body fluid. The adsorption and denaturation of the protein is the cause of the biological response to the cell and material interface.3. natural materials: gelatin, chitosan, cellulose, protein, natural coralDegradation of 4.PCL5. polylactic acid (PLA)direct methodThe relative molecular weight of polylactic acid produced by the method is less than 4000, and the strength is low, so the practicability is not strong.indirect method* first, DL- lactic acid was prepared by condensation polymerization with ZnO powder as catalyst* polylactic acid was synthesized by vacuum polymerization under the high temperature with ZnO as catalyst. The synthesized PLA has a molecular weight of 7.3 * 1046. tissue engineeringThe relationship between structure of mammalian tissues using the principle and method of engineering and life sciences to understand the normal and pathological features, biological tissue substitutes and development of live, used to repair, maintain and improve the function of human body.Three major elements of tissue engineering (1)Cell carrier materialThe separation of the cells themselves may not form the organization, they need temporary support material growth, the three-dimensional simulation of the natural counterpart, often in the extracellular matrix, which plays a physical support role, and adhesive substance cell loading in vitro and late implantationThree major elements of tissue engineering (two)Isolation and culture of cellsIndividual cells were collected from healthy parts of the donor tissue and isolated and then transplanted to the site needed by the patient.Three major elements of tissue engineering (three)Cell growth factorIn tissue and organ regeneration, various tissue inducing factors, growth factors and angiogenesis stimulating factors are beneficial to the formation of tissue, but it can not be implanted directly into the body.。

聚合物溶液稳定性在聚合物驱机理中,聚合物通过增加水相黏度,同时降低水相渗透率,改善流度比,提高波及系数。

聚合物分子的任何降解都会导致流度控制的失败。

因此,保持聚合物溶液在地下的强度至关重要,这也是聚合物驱成功的最重要的条件。

保证聚合物溶液的稳定性,也就是要防止聚合物降解。

聚合物降解是指聚合物主链断裂,或主链保持不变而改变了取代基的过程。

聚合物降解主要取决于聚合物本身的化学结构(尤其是化学键键能。

外界因素如应力、温度、含氧量、残余杂质都对聚合物降解有很大影响。

在聚合物驱油中,通常将聚合物的降解分为机械降解、化学降解和微生物降解三个大类。

下面将分别介绍三种降解的原因,影响因素以及保持聚合物溶液黏度所采取的措施。

1.机械稳定性在聚合物驱过程中,聚合物溶液经地面注入(搅拌罐、静混器、闸门和射孔眼进入地层后,其黏度损失主要是由聚合物的机械降解作用引起的。

机械降解是指聚合物分子受到的拉伸应力超过了聚合物分子内化学键所承受的能力时,聚合物分子链断裂的现象。

在常用的聚合物中,部分水解的聚丙烯酰胺(HPAM的机械稳定性较差,而黄胞胶却具有较好的抗剪切性,因此,下面将主要对HPAM机械稳定性进行讨论。

1聚合物驱中的机械降解过程在所有聚合物驱应用中,聚合物都会存在机械降解的可能性。

(1地面设备中流速变化处如闸门、喷嘴、静混器、泵、管线等部位中都有可能降解。

(2在搅拌中,聚合物的降解不仅与转速有关,而且还与搅拌器形状及叶片分布有关。

(3聚合物溶液在地层中尤其是在井筒附近区域的机械降解最为严重。

由于岩石孔隙很小,流速很高,拉伸应力很大,因此降解非常严重。

如果射孔密度不大,射孔炮眼中机械降解也比较严重。

2影响剪切降解因素影响剪切降解的因素有流速、流场应力分布、聚合物相对分子质量、水解度以及地层水矿化度。

流速越高,拉伸应力和拉伸速率越大,分子越容易断链。

拉伸速率为:式中 Q——流速;A——截面积;φ——孔隙度;——岩石颗粒平均半径。

聚合物稳定与降解第一章、绪论1.老化(降解)的概念高分子材料在加工、贮存、使用过程中,物理化学性质和力学性质会逐渐变差,称为老化,或降解。

p1特点:不可避免,不可逆的过程。

时间尺度上相对较短。

2.导致聚合物降解的因素(一)内因A.聚合物的组成及其链结构。

(1)组成不同、降解情况不同(2)活性基体可能是降解的主要内因(3)活泼氢更容易被夺取(4)头-头(尾-尾)结构的聚烯烃更易成为活性点。

(5)分子量变化的影响:分子量的变化使其内部不规则的结构增加,造成稳定性下降。

反之,若不规则结构减少,则稳定性增加。

(6)分子量分布的影响:分子量分布宽、则稳定性下降。

(7)支化度的影响:支化度增加,分子链中的薄弱环节也增加,越容易发生降解。

B. 聚合物的聚集状态非晶聚合物材料稳定性小于结晶聚合物材料原因:非晶材料密度小(高分子链排列不规则),易被氧、水、化学物质渗透、降解。

3. 聚合物中的杂质聚合物中的杂质分两类:(1)加工过程中必然混入的少量杂质;(2)添加剂等物质。

多数杂质会加快聚合物的降解。

(二)外因:A.热、温度和热氧的影响:热使聚合物断链,形成自由基(可逆、双向)热氧作用使聚合物交联或降解,最终使材料性能下降。

B.光的影响C.氧和臭氧的影响:氧易在热、光作用下使聚合物降解。

臭氧对不饱和键(如橡胶)的破坏极为严重。

D. 水和潮湿的影响:对水溶性成分的溶解、抽提;水解、断链。

E.其它因素的影响:微生物的影响;其它生物的影响;加工过程中各种因素的影响。

各种外因往往协同作用。

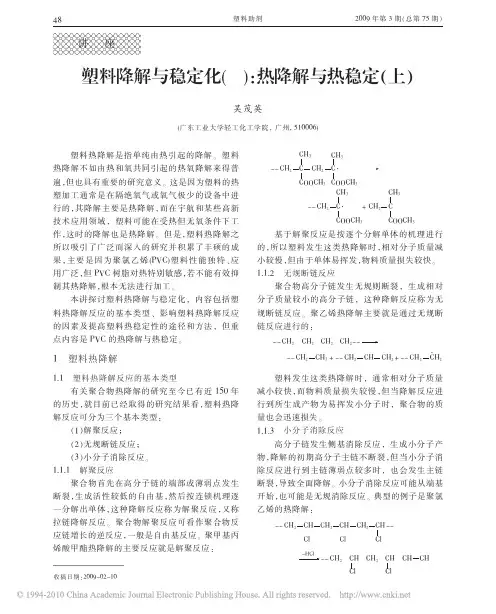

第二章、聚合物降解与稳定化的基本原理(一)热降解的类型解聚反应;无规断链反应;主链不断裂的小分子消除反应;特点:单纯由热引起,没有氧参与。

1. 解聚反应(拉链降解)解聚始于分子链端部或薄弱点。

惟一产物:单体。

特点:(1)初期相对分子质量变化小,聚合物质量损失较大;(2)降解至聚合物质量几乎完全损失时,聚合物相对分子量急剧降低。

2. 无规断链反应——几乎所有缩聚物和大量加聚物的降解方式聚合物无规则断链;反应主要产物为低相对分子量聚合物。

聚合物降解与稳定化

聚合物降解是指聚合物在所受外界条件的作用下,发生化学结构的变化,导致聚合物分子链的破坏和物理性能的下降。

聚合物降解的原因主要有热氧化降解、光辐射降解、机械应力引起的降解等。

降解会导致聚合物材料的拉伸强度、弹性模量等物理性能下降,甚至使其完全失去使用价值。

而聚合物稳定化是为了延缓聚合物降解的过程,提高聚合物材料的耐久性和使用寿命。

常见的聚合物稳定化方法有添加抗氧化剂、紫外吸收剂等。

抗氧化剂可以防止聚合物在高温、氧气和紫外光等环境下发生自由基氧化反应,从而延缓聚合物的降解速度;紫外吸收剂则可以吸收紫外光,减少紫外光对聚合物材料的照射和损伤。

聚合物降解与稳定化是聚合物材料研发和应用中需要重点考虑的问题。

降解会限制聚合物材料的使用寿命和应用范围,稳定化则可以提高聚合物材料的耐久性和可靠性。

因此,在聚合物材料的设计和生产过程中,需要选择合适的降解机理和稳定化方法,以满足不同应用环境和需求。

聚合物的降解与稳定化2011-2012学年上学期聚合物的降解及稳定化复习资料第一章绪论老化(降解):高分子材料在加工、贮存、使用的过程中,物理化学性质和力学性能会逐渐变差。

导致聚合物降解的因素:内因:聚合物的组成及其链结构;聚合物的聚集态结构;杂质。

外因:热、环境温度和热氧的影响;光的影响;氧和臭氧的影响;水和潮湿的影响;其他的因素影响,比如微生物(真菌的活性或酶作用)、某些高级生命体(昆虫)等生物降解。

聚合物再生的意义:保护人类赖以生存的自然环境;充分利用自然资源,变废为宝。

第二章聚合物降解与稳定化的基本定理热降解的三大类:解聚反应(拉链降解);无规断链反应;主链不断裂的小分子消除反应。

热氧降解主要特征以及核心:自动氧化反应。

当氧浓度等于或大于空气中的氧浓度时,氧化反应速率与氧浓度无关;当氧浓度很低时,吸氧速率是氧浓度的函数,即氧化反应速率与氧浓度有关。

抗氧剂的两大类:主抗氧剂(自由基捕获剂):作用——改变自动氧化历程。

辅助抗氧剂(预防型抗氧剂):作用——只能降低氧化速率,而不改变自动氧化历程。

主抗氧剂的分为4类:氢给予体、电子给予体、自由基捕获体、苯并呋喃酮类。

抗氧剂的配合:协同效应、加合效应、对抗效应。

羰基的引发作用:(P42)光稳定剂四大类:光屏蔽剂、紫外光吸收剂、猝灭剂、受阻胺光稳定剂。

邻羟基二苯甲酮类(一类重要的紫外线吸收剂)(P44)臭氧龟裂:具有不饱和键的橡胶,在应力作用的条件下,能和臭氧发生独特的破坏作用,即在垂直与应力方向引起开裂。

第三章聚合物降解各论聚合物分子链中,各种键和基团的热稳定性顺序:(P59、60)对聚丙烯的光氧化而言,氢过氧化物也是主要的起始光引发剂。

由于聚丙烯光氧化的动力学链长大约是聚乙烯的10倍,所以在光氧化的聚丙烯中氢过氧化物浓度比氧化的聚乙烯中高很多。

(P62)聚氯乙烯的降解:典型特征是释放HCl,具有催化作用加速了降解。

厚的试样比薄的试样降解更快,是由于厚的试样中HCl逸出更慢而起到了催化作用。

1、期刊名称:polymer degradation and stability;聚合物降解与稳定化2、出版机构:ELSEVIER-sciencedirect3、刊发周期:月刊4、每期刊发论文数:20-25篇5、期刊检索:SCI,影响因子2.0736、推荐理由:该期刊历史久远,为老牌的聚合物材料类期刊,主要涉及聚合物材料的降解和稳定性问题,如降解反应与控制,包括聚合物的热降解、光降解、生物降解、环境降解等。

还包括各类阻燃材料的设计研究与应用,特种聚合物的合成与应用,聚合物在各类条件下的老化和分解研究,聚合物对环境的影响等。

该期刊发刊速度快,如果顺利,基本上一个月内就可得到回改通知,提交回改后2个星期内即可从网上检索下载。

该期刊很受国内外从事聚合物降解与老化研究的科研人员喜爱,因此大量优秀论文得以在该期刊上发表。

7、给出推荐星级:5星vagrantyang2009-02-13 22:261、期刊名称:Progress in polymer science;聚合物科学进展2、出版机构:ELSEVIER-sciencedirect3、刊发周期:月刊4、每期刊发论文数:8篇以内5、期刊检索:SCI,影响因子12.8696、推荐理由:从影响因子看,就知道它的分量了吧。

本刊专门接受综述文章,一般是主编约稿,论文的作者均是某领域的绝对牛人,我所知道的有复旦大学的江明院士发表过关于自组装的文章。

论述的内容基本上包括高分子相关的所有领域,可以作为了解某一领域研究进展的经典文献。

话不多说,是高分子学科的地球人应该都知道它。

7、给出推荐星级:5星,超5星都不为过吧。

llwang2009-02-17 15:361、期刊名称:高分子学报Acta Polymerica Sinica2、出版机构:中国化学会;中国科学院化学研究所3、刊发周期:月刊4、每期刊发论文数:18篇以内5、期刊检索:SCI,影响因子0.541 ;CA;6、推荐理由:从影响因子看,不是很高,但它是中国化学会、中国科学院化学研究所主办,中国科学院主管,主要刊登高分子化学、高分子合成、高分子物理、高分子物理化学、高分子应用和高分子材料科学等领域中,基础研究和应用基础研究的论文、研究简报、快报和重要专论文章。

有机化学中的聚合物的降解与稳定性聚合物是由连续的重复单元组成的高分子化合物。

它们在各个领域广泛应用,如塑料、纤维、涂料、药物等。

然而,聚合物的降解和稳定性是一个重要的研究领域。

本文将探讨有机化学中聚合物的降解机制以及如何提高其稳定性。

聚合物的降解机制与稳定性密切相关。

降解是指聚合物的分子链发生断裂,导致物理和化学性质的变化。

聚合物的降解可发生在热、光、氧、湿等条件下。

其中,热降解是最为普遍和重要的降解方式。

聚合物在高温下会发生链热解或内聚解。

链热解是指聚合物分子链序列发生断裂,产生自由基和低分子量产物。

内聚解是由于聚合物分子内部有不稳定的键或化学结构,使得整个分子完全分解为小分子。

热降解的温度通常由聚合物材料的玻璃转变温度和熔融温度决定。

除了热降解,光降解也是一个重要的降解方式。

聚合物在长时间的紫外线或可见光照射下,会发生主链裂解或侧链裂解。

主链裂解指的是聚合物的主链发生断裂,导致分子量的减小。

侧链裂解是指聚合物的侧链或取代基发生断裂,引起聚合物结构的改变。

氧降解是指聚合物与氧气接触时发生的降解反应。

氧气中的氧化物能够进一步引发链热解反应,导致聚合物分子链的断裂。

湿降解是指聚合物与水蒸气或溶液中水反应,产生分子链的断裂和水解反应。

为了提高聚合物的稳定性,可以采取一系列措施。

首先,可以通过合适的聚合物设计来提高聚合物的热稳定性。

例如,引入稳定基团来增加分子内的键能,降低链热解的速率。

其次,聚合物的添加剂也可以有效提高聚合物的稳定性。

抗氧化剂、紫外线吸收剂等可以减缓或阻止聚合物的降解反应。

此外,采用适当的包装材料、储存条件和环境控制也能延缓聚合物的降解。

聚合物的降解与稳定性在有机化学中具有重要意义。

深入了解聚合物的降解机制有助于优化聚合物的性能和应用。

通过增加聚合物的稳定性,可以延长其使用寿命,并减少对环境的不良影响。

综上所述,有机化学中的聚合物的降解与稳定性是一个重要的研究领域。

热降解、光降解、氧降解和湿降解是常见的降解方式。

2011-2012学年上学期

聚合物的降解及稳定化

复习资料

第一章绪论

老化(降解):

高分子材料在加工、贮存、使用的过程中,物理化学性质和力学性能会逐渐变差。

导致聚合物降解的因素:

内因:聚合物的组成及其链结构;聚合物的聚集态结构;杂质。

外因:热、环境温度和热氧的影响;光的影响;氧和臭氧的影响;水和潮湿的影响;其他的因素影响,比如微生物(真菌的活性或酶作用)、某些高级生命体(昆虫)等

生物降解。

聚合物再生的意义:保护人类赖以生存的自然环境;充分利用自然资源,变废为宝。

第二章聚合物降解与稳定化的基本定理

热降解的三大类:解聚反应(拉链降解);无规断链反应;主链不断裂的小分子消除反应。

热氧降解主要特征以及核心:自动氧化反应。

当氧浓度等于或大于空气中的氧浓度时,氧化反应速率与氧浓度无关;

当氧浓度很低时,吸氧速率是氧浓度的函数,即氧化反应速率与氧浓度有关。

抗氧剂的两大类:

主抗氧剂(自由基捕获剂):作用——改变自动氧化历程。

辅助抗氧剂(预防型抗氧剂):作用——只能降低氧化速率,而不改变自动氧化历程。

主抗氧剂的分为4类:氢给予体、电子给予体、自由基捕获体、苯并呋喃酮类。

抗氧剂的配合:协同效应、加合效应、对抗效应。

羰基的引发作用:(P42)

光稳定剂四大类:光屏蔽剂、紫外光吸收剂、猝灭剂、受阻胺光稳定剂。

邻羟基二苯甲酮类(一类重要的紫外线吸收剂)(P44)

臭氧龟裂:具有不饱和键的橡胶,在应力作用的条件下,能和臭氧发生独特的破坏作用,即在垂直与应力方向引起开裂。

第三章聚合物降解各论

聚合物分子链中,各种键和基团的热稳定性顺序:(P59、60)

对聚丙烯的光氧化而言,氢过氧化物也是主要的起始光引发剂。

由于聚丙烯光氧化的动力学链长大约是聚乙烯的10倍,所以在光氧化的聚丙烯中氢过氧化物浓度比氧化的聚

乙烯中高很多。

(P62)

聚氯乙烯的降解:典型特征是释放HCl,具有催化作用加速了降解。

厚的试样比薄的试样降解更快,是由于厚的试样中HCl逸出更慢而起到了催化作用。

第四章聚合物在加工过程中的降解

加工过程中引起降解的因素:温度、氧、机械作用力、水、其他介质作用(如稳定剂)。

第五章聚合物的稳定剂

应用于PVC的热稳定剂具有两大功能:

预防作用:(1)吸收HCl,抑制其自动催化作用;

(2)置换聚氯乙烯分子中不稳定的氯原子如烯丙基氯原子或叔碳位氯原子,消除HCL反应的引发点;

(3)捕捉自由基,阻止自动化氧化。

钝化作用:(1)与多烯系列的加成反应;

(2)碳鎓盐发生转化。

第六章塑料的再生及其稳定化

废塑料再生利用途径:机械再生、解聚、热解液化和气化。

(了解各种途径)

第七章聚合物材料的阻燃稳定化

聚合物材料的燃烧过程(5个阶段):加热熔融、热分解、着火、燃烧、火焰传播。

在聚合物燃烧中,最主要的燃料是氢(H2),而不是碳。

聚合物材料分类:

按氧指数(OI)划分:(1)易燃材料:没有助燃性,氧指数在22以下的材料。

如聚乙烯、聚丙烯、PMMA、PS等。

(2)难燃材料:即自熄性,氧指数在22~27之间的材料。

如软质PVC,PV A、PA、PC等。

(3)高难燃材料:氧指数在27以上的材料。

如硬质PVC、PTFE、PI、聚苯醚等。

助燃剂的阻燃作用(了解其含义):吸热效应、覆盖效应、稀释效应、抑制效应、增强效应(协同效应)。

有机磷系阻燃剂的阻燃机理:

在燃烧时,磷化合物分解生成磷酸的非燃性液态膜,其沸点可达300o C。

同时,磷酸又进一步脱水生成偏磷酸,偏磷酸进一步聚合生成聚偏磷酸。

在这过程

中,不仅由磷酸生成的覆盖层起到覆盖效应,而且由于生成的聚偏磷酸是强酸,

是很强的脱水剂,使聚合物脱水而碳化,改变了聚合物燃烧过程的模式并在其表

面形成碳膜以隔绝空气,从而发挥更强的阻燃效果。

第八章稳定化聚合物材料及可降解聚合物材料的设计与应用

化学结构对聚合物耐氧性的影响:(耐氧化性聚合物具有以下特征)

(1)大分子主链饱和、线型;

(2)链含杂原子的结构,如主链含有O、S、N原子;

(3)氯原子对氢的取代;

(4)庞大的侧基;

(5)全芳族和芳杂环结构;

(6)梯形聚合物;

(7)无机主链结构的聚合物。

如硅氧结构;

(8)适度的交联;

(9)结晶对氧化稳定性的影响。

耐高温聚合物的分类及主要特征:(简单了解P316)

附加:医用高分子的稳定与降解

生物医用材料:

是一类用于诊断、治疗或替代人体组织、器官或增进其功能的新型高技术材料。

可分为:医用金属材料、医用陶瓷材料和医用高分子材料。

聚酯分解过程:主要是水解,还有酶解。

可降解的生物医用高分子材料:

是指在生物体内经水解、酶解等过程,逐渐降解成低分子量化合物或单体,降解产物能被排出体外或能够参加体内正常新陈代谢而消失的材料。

按在活体内分解的性质分类:

水解型:低级脂肪族聚酯(如聚乳酸、聚乙醇酸)、聚己内酯、聚酸酐、聚原酸酯等。

酶解型:天然蛋白质、合成多肽、多糖类、核酸、聚羟基丁酸等。

按天然和人工合成分类:

天然材料:明胶、壳聚糖、纤维素、蛋白质、天然珊瑚

合成材料:聚乳酸、聚乙醇酸、聚己内酯、聚酸酐、聚原酸酯等。

组织工程学:

是应用工程学和生命科学的原理和方法来了解正常的和病理的哺乳类组织的结构-功能的关系,并研制活的生物组织代用品,用于修复、维持、改善人体组织的功能。

其三大要素:细胞载体材料、细胞的分离和培养、细胞生长因子。