(整理)ZL-30装载机主变速箱设计 08模具3.

- 格式:doc

- 大小:20.50 KB

- 文档页数:2

ZL30EFB型轮胎式防爆装载机执行标准:Q/***-2014MT990-2006使用说明书***有限公司二O一四年二月安全警告!1.驾驶人员应了解本防爆装载机的基本结构、性能、操作方法、技术保养等,且必须经过培训,持证上岗。

2.必须按本说明书使用、操作防爆装载机并严格遵守本说明书规定的“安全操作规程”。

3.防爆装载机必须定期检修,并经常检查,发现隐患应及时处理。

4.防爆装载机所配防爆部件不得随意更换。

5.当自动保护装置发出警报时,必须停车检查,故障排除前,不允许启动装载机。

6.驾驶人员必须携带有安全标志的便携式瓦斯报警仪,当其发出报警声时必须立即停机。

7.防爆装载机必须配备适宜的灭火器,灭火器应保持良好的在用状态。

8.驾驶人员应配备听力保护装置。

前言为了使用户对ZL30EFB型轮胎式防爆装载机(以下简称装载机)的使用、保养与维护等方面有详细的了解,特编辑本使用维护说明书。

本书简要介绍了ZL30EFB型装载机的主要技术参数、主要部件结构原理、使用、保养和维修等方面的要求,供驾驶人员和维修人员及有关技术管理人员阅读,以便正确的操作和维护,确保安全运行,并提高机器的工效和寿命。

在装载机使用前应详细阅读本说明书,如有疑问请立即向我们厂咨询。

我们殷切希望用户将使用中发现的问题及有关改进意见及时的反馈给我们,以便进一步提高产品质量,更好地为用户服务。

生产制造商:***有限公司地址:邮政编码:电话:传真:目录一、概述················································· (5)二、主要结构特征与工作原理····································· (5)(一)动力系统············································· (5)(二)车架及传动系统········································· (6)(三)制动系统············································· (6)(四)液压系统············································· (7)(五)电气系统············································· (7)三、技术特征 (8)(一)性能参数············································· (8)(二)柴油机 (8)(三)传动系统············································· (9)(四)制动系统············································· (9)(五)转向系统················································ (10)(六)工作装置液压系统·········································· (10)(七)电气系统及仪表··········································· (10)(八)加油容量················································ (10)(九)外形尺寸、重量··········································· (11)四、调试···················································· (11)五、装载机的使用、操作·········································· (12)(一)装载机的使用············································· (12)(二)安全操作规程············································· (14)(三)装载机的用油············································· (16)(四)润滑 (17)六、常见故障及排除方法·········································· (19)七、安全保护装置及处理·········································· (23)八、定期技术保养 (23)(一)每日技术保养············································· (24)(二)每周技术保养············································· (24)(三)每月技术保养············································· (24)(四)每季技术保养············································· (25)(五)每半年技术保养··········································· (25)(六)每年技术保养············································· (25)九、运输及存放················································ (25)十、开箱及检查················································ (26)十一、附表 (27)(一)主要配套件明细表·········································· (27)附图一、概述(一)ZL30EFB型轮胎式防爆装载机(以下简称装载机)是一种以矿用防爆柴油机(以下简称柴油机)为动力、液力机械传动、四轮驱动的煤矿井下无轨式运输装载机械,主要用于巷道坡度不大于25%的煤矿井下的装载、清煤、清渣和排矸等作业。

装载机操作工考试(试卷编号131)1.[单选题]事故处理“四不放过”原则包括事故原因没有查清不放过、事故责任人没有受到处理不放过、事故责任人和广大群众没有受到教育不放过和()。

A)现场没有清理不放过B)没有采取防范措施不放过C)设备没有更新不放过答案:B解析:2.[单选题]港机设备走合时间一般为轻载、低速运转 ()A)50hB)40hC)35h答案:A解析:3.[单选题]耙装机作业时()照明。

A)不需要B)严禁C)必须答案:C解析:4.[单选题]严禁用手触及()中的钢丝绳,装岩中出现故障,要立即断电、停机检查。

A)停止B)运行C)检修答案:B解析:5.[单选题]无论采用何种比例,在图样中标注尺寸时,必须标注( )。

A)零件的实际尺寸B)图样的实际尺寸C)随意尺寸答案:A解析:6.[单选题]侧卸式装载机使用液压油的温度不能过高。

若油温超高,需停止铲装工作,循环冷却使油答案:B解析:7.[单选题]发动机上重要的运动表面如曲轴主轴承采用的润滑方式是()。

A)压力润滑B)飞溅润滑C)综合润滑答案:A解析:8.[单选题]耙装机电动机不能停止,可能的原因是()。

A)耙斗被卡死B)电机过负荷C)接触器动作部分卡住答案:C解析:9.[单选题]有的机油泵上装有( ),当机油压力超过规定压力时,它被压开,多余机油经过它回到机油泵的进油口。

A)机油散热器B)机油滤清器C)机油限压阀D)机油感应器答案:C解析:10.[单选题]液压油缸漂移量检测时,应记录发动机熄火后( )分钟内各活塞杆伸缩量。

A)5B)10C)15D)20答案:B解析:11.[单选题]非作业人员、设备,不得进入()。

A)货场内B)安全防护以外C)车辆内12.[单选题]发动机上的扭转减震器的作用是削减( )。

A)曲轴扭振B)传动轴扭振C)发动机整机振动D)机械整机振动答案:A解析:13.[单选题]柴油机机油压力下降,调压阀再调整无效,同时压力表读数波动,其故障原因可能是( )。

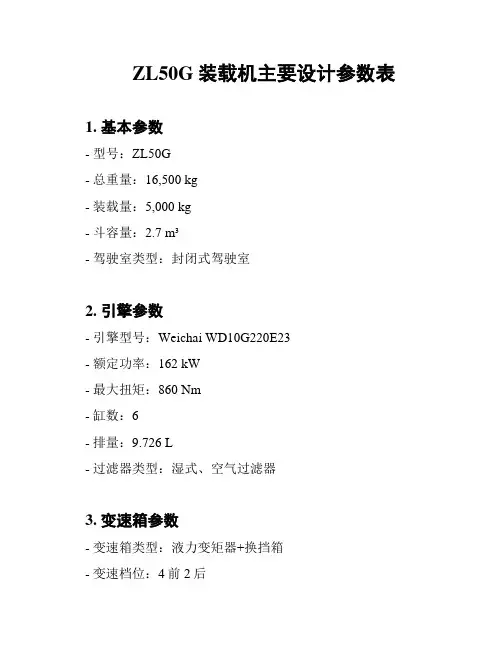

ZL50G装载机主要设计参数表1. 基本参数- 型号:ZL50G- 总重量:16,500 kg- 装载量:5,000 kg- 斗容量:2.7 m³- 驾驶室类型:封闭式驾驶室2. 引擎参数- 引擎型号:Weichai WD10G220E23- 额定功率:162 kW- 最大扭矩:860 Nm- 缸数:6- 排量:9.726 L- 过滤器类型:湿式、空气过滤器3. 变速箱参数- 变速箱类型:液力变矩器+换挡箱- 变速档位:4前2后- 最高速度:38 km/h- 工作液容量:20 L4. 驱动与制动系统参数- 驱动方式:四轮驱动- 制动方式:液压踏板制动- 制动液容量:3.5 L- 制动距离(满载):≤ 8 m - 刹车盘直径:420 mm5. 转向与悬挂系统参数- 转向方式:液压转向- 转向角度:± 35°- 轴距:3,400 mm- 悬挂形式:四轮独立悬挂6. 外形参数- 总长度:7,650 mm- 总宽度:2,800 mm- 总高度:3,480 mm- 接地间隙:400 mm- 接触角:30°7. 操纵参数- 最大转向力矩:9600 Nm- 最大斗杆提升力矩:160.5 kN - 最大刨龙倾矩:290 kN·m- 倾斗倾角:30°- 斗杆倾角:7°8. 燃油与液体容量- 燃油容量:220 L- 液压油容量:160 L- 冷却液容量:24 L9. 轮胎与轮距- 轮胎规格:23.5-25, 16PR- 轮距:2,220 mm10. 其他参数- 最小转弯半径:6,600 mm- 顶升高度:3,440 mm- 铲斗卸载高度:3,170 mm- 最大刨龙深度:130 mm以上是ZL50G装载机的主要设计参数表,仅供参考。

如需更详细的信息,请参阅相关技术手册或与生产厂家联系。

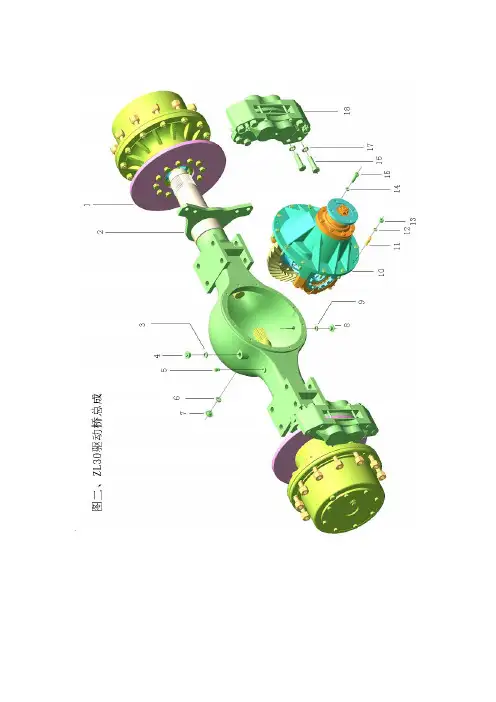

柳工ZL30E装载机专业工程机械技术服务与营销班级姓名2012年03月07日目录绪论 (3)第1章柳工ZL30E装载机概述 (5)1.1、柳工ZL30E轮式装载机简介 (5)1.1.1、装载机的分类及相关参数 (5)1.1.2、柳工ZL30E简介 (6)1.2、柳工ZL30E总体结构 (7)1.3、柳工ZL30E传动系统 (9)1.4、转向系统 (12)1.5、制动系统 (14)1.6、工作装置 (16)1.7、工作液压系统 (18)1.8、散热系统 (22)第2章柳工ZL30E型轮式装载机的常见故障分析及解决措施 (23)2.1、柳工ZL30E型轮式装载机的整机常见故障分类 (23)2.1.1、作业无力问题 (23)2.1.2、功率下降 (23)2.1.3、后桥异响 (24)2.2.柳工ZL30E型轮式装载机的液压系统常见故障分类 (25)2.2.1、动臂举升缓慢,无力或无动作,而转斗翻转正常 (25)2.2.2、动臂工作正常;转斗翻转缓慢、无力或无动作 (27)2.2.3、液压油过热 (28)第3章柳工ZL30E型轮式装载机的主要性能表 (29)第4章装载机国内外主要制造厂商简介 (35)第5章技术发展动态与趋势 (36)结束语 (37)参考文献 (38)致谢 (39)绪论现代轮式装载机起始于20世纪60年代中期的Z435型。

该机为整体机架、后桥转向。

经过几年的努力,在吸收当时世界最先进的轮式装载机技术的基础上,开发成功了功率为162KW的铲接式轮式装载机,定型为Z450(即后来的ZL50),并于1971年12月18日正式通过专家鉴定。

就这样诞生了我国第一台铰接式轮式装载机,从而开创了我国装载机行业形成与发展的历史。

Z450型装载机具有液力机械传动、动力换挡、双桥驱动、液压操纵、铰接式动力转向、气推油加力制动等现代轮式装载机的基本结构,为当时世界先进水平。

也基本上代表了我国第一代轮式装载的基本结构。

2008级工程机械综合课程设计ZL30装载机工作装置设计目录摘要 (I)第一章装载机的发展和应用 (1)1.1装载机概述 (1)1.2装载机的发展 (2)第二章装载机总体参数的确定 (6)2.1装载机阻力的确定 (6)2.1.1插入阻力 (6)2.1.2铲起阻力 (6)2.1.3转斗阻力矩 (7)2.2装载机的总体布置原则 (8)2.3装载机各部件的布置 (9)2.4装载机的总体构造和分类 (11)第三章工作装置设计 (13)3.1工作装置结构分析 (13)3.1.1装载机工作装置 (13)3.1.2结构形式的选择 (14)3.2铲斗设计 (16)3.2.1铲斗结构形式的选择 (16)3.2.2铲斗基本参数的确定 (18)3.3工作机构连杆系统的尺寸参数设计 (22)3.3.1工作装置结构设计 (22)3.3.2动臂设计 (23)3.3.3连杆机构设计 (25)3.4工作装置强度计算 (28)3.4.1确定工作装置的计算位置 (28)3.4.2工作装置载荷分析 (29)3.4.3典型工况分析 (30)3.4.5工作装置受力分析 (31)3.4.6工作装置强度校核 (35)第四章工作装置液压系统设计 (39)4.1液压系统设计要求 (39)4.2油缸作用力的确定 (39)4.3液压系统设计计算 (40)4.4液压系统原理分析 (41)4.5工作装置的限位机构 (42)总结 (44)主要参考文献 (45)摘要装载机主要用来装卸成堆散料,也能进行轻度的铲掘工作。

由于它适用于建筑、矿山、铁道、公路、水电等国民经济各个部门,因此,在国内外,产量与品种的发展都较快,是工程机械中的一个主要机种。

装载机根据不同的使用要求,发展形成了不同的结构类型。

通常,按使用场合的不同,分成露天用装载机和井下用装载机;按行走系统结构不同,分成轮式装载机与履带式装载机;按卸料方式不同,分为前卸式(前端式)、后卸式与回转式装载机。

目前我公司生产的ZL30F装载机,因焊接结构件的变形超差造成的失效已占相当大的比率。

本文主要针对ZL30F装载机前车架焊后变形超差率较高的问题,通过分析该前车架的具体结构形式,制定并采用了合理的焊接工艺,使前车架的焊后变形得到了有效控制。

ZL30F轮式装载机前车架是装载机的重要承载部件,属于空间半箱型的对称焊接结构,其主要组成部件有左、右翼箱,翻斗缸座,前板,上横梁,铰接架,下梁和桥安装板等。

用Solidege 三维软件建立的三维实体模型及其组成部件如图1所示。

前车架所有部件之间的连接均为连续角焊缝连接。

右翼箱1和左翼箱2主要由与前板和上横梁及铰接架相连接的翼板、外翼板、筋板、贴盘等组成。

翼板和外翼板的厚度均为16 mm。

翻斗缸座3主要组成件的厚度为24 mm。

前板4的厚度为10 mm。

上横梁5为折弯件,板厚为24 mm。

铰接架6主要组成件上、下铰接板的厚度为36 mm,4块筋板的厚度为20 mm。

下梁7的厚度为12 mm。

桥安装板8的厚度为30 mm。

材质均为焊接性能良好的低碳合金高强度钢Q345A。

图2所示为前车架主要结构尺寸。

其中宽度方向的3个尺寸810 mm、1015 mm±1.3 mm、 1 244 mm为结构关键尺寸。

1 焊接方法的选择CO2气体保护焊作为一种高效、高质量、低消耗的焊接方法,在国内工程机械行业车架等结构件的焊接中得到广泛应用,我公司装载机前后车架的焊接也采用CO2气体保护焊工艺。

2 ZL30F装载机前车架焊接工艺参数对于ZL30F装载机前车架,其组成工件的板厚大多为12~24 mm,只有上下铰板和桥安装板厚度达到30 mm以上。

由于颗粒过渡焊接的电弧穿透能力强,熔深大,焊接效率高,适合于12~50 mm中厚板焊接,因此该车架的焊接采用颗粒过渡焊接,焊接工艺参数见表1。

3 前车架焊接变形的预防措施据统计,在采用本文介绍的工艺改进措施之前,前车架的最大变形量达到4.5~5.5 mm,集中反映在前车架上部左右翼箱上面两铰接孔横向尺寸的收缩变形上,变形超差率达到20%以上,其中85%的变形量达到4 mm。

修理装载机变速箱的方法和技巧装载机的变速装置,是装载机的一个重要组成部分,它连接着发动机和装载机的行走装置,如果在工作过程中出现了故障那么该怎么进行维修呢?以下是店铺为你整理的修理装载机变速箱的方法,希望能帮到你。

修理装载机变速箱的方法1.变速箱内液压油增多,工作液压油箱内液压油减少故障原因:工作泵或转向泵油封老化,工作泵或转向泵泵轴轴向间隙或径向间障过大排除方法:更换工作泵或转向泵油封,修理校验油泵或更换油泵2.变速箱内液压油减少,工作液压油油箱内液压油增多故障原因:工作油箱进油滤网堵塞或油泵吸油管堵塞排除方法:清洗或更换进油滤网,更换油泵吸油管3.变速箱空挡或挂挡后,变速压力均低整机行走无力故障原因:变速箱内传动油量不够,变速箱油底壳滤网堵塞,行走泵损坏、容积效率低,减压阀或进口压力阀调整压力不当,行走泵吸油管老化或拆弯严重排除方法:加足变速箱内液压油加至怠速时油标中位,更换或清洗滤网,更换行走泵,重新调整压力达到所规定范围内,更换油管。

装载机的维修方法1.装载机某一档位行走无力或不行走,其余档位正常。

判断要点:不行走或行走缓慢时,主传动轴旋转快速有力,提升发动机转速时,主传动轴转速的提升与前后传动轴明显不成比例。

空档及其余档位变速油压正常,挂该挡后压力明显下降。

故障原因:1)轴承盖或尼龙环严重磨损。

2)如轴承盖或尼龙环良好或磨损轻微,则确认该档离合器内外封环密封不良。

排除方法:更换相应损坏零件即轴承盖或尼龙环、内外封封环,重新调整轴套与轴承盖间隙。

故障分析:某一档位行走无力或不行走,可排除变矩器、行走泵、减压阀等各档公用油路和部件的问题,故障发生的部位只能在变速控制阀之后到该档离合器活塞之间的油路上。

轴承盖、尼龙环、内外封封环等薄弱部件磨损后,供往离合器活塞腔的油液从磨损部位大量泄漏,从而造成油压降低。

挂空挡或其余档位由于油液不流经磨损部位,因而油压显示正常。

2.空档自动前行,挂入前进挡也可正常行驶,挂入后退挡时机器停止,不能行走。