电磁有源蜂鸣器规格书(直径9高度4.5)

- 格式:pdf

- 大小:158.42 KB

- 文档页数:1

汽车蜂鸣器技术规范本标准适用于标称电压为6V,12V及24V的各类汽车用触点式报警蜂鸣器。

1 型式和尺寸1.1 蜂鸣器的结构型式为封闭式、电磁触点型。

1.2 蜂鸣器为短时定额工作制。

其使用范围分类如下: A 类:频繁使用的蜂鸣器,加速度警告,转向信号警告,公共汽车门开关警告、自卸车警告等。

B 类:经常使用的蜂鸣器,如发动机油压警告,气压警告,水温警告等。

1.3 蜂鸣器安装尺寸应符合客户规定的要求。

1.4 蜂鸣器分单线制及双线制两种。

2 技术要求2.1 蜂鸣器除符合本标准要求外,还应符合 JB 2261-77《汽车拖拉机用电气设备基本技术条件》的有关规定,并按照规定程序批准的图样及文件制造。

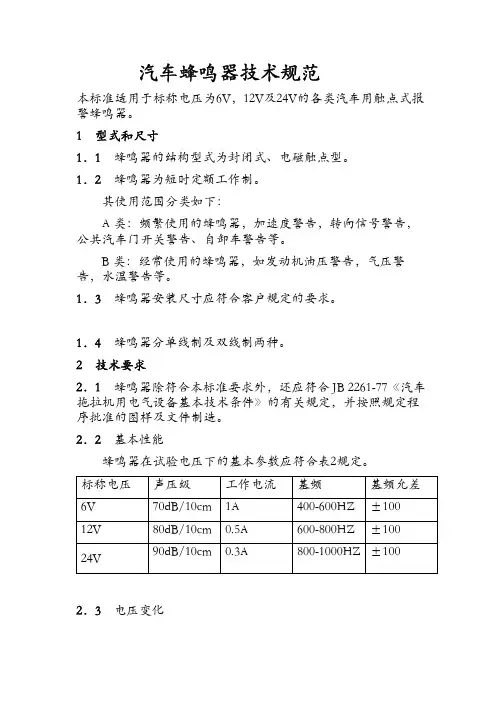

2.2 基本性能 蜂鸣器在试验电压下的基本参数应符合表2规定。

2.3 电压变化2.3.1 蜂鸣器在按表3规定的输入电压范围内工作时,发音应正常不应有尖叫、颤音、振扰、沙哑和声明显不符合这类产品声音特性的声响。

表32.3.2 蜂鸣器输入按表3规定的下限电压时,允许声压级比表2规定的最低值降低5dB(A)。

2.4 绝缘电阻 双线制蜂鸣器的导电引出线与安装支架之间的绝缘电阻应不少于200MΩ。

2.5 耐振性 蜂鸣器按下列规定进行试验后,不应有机械损伤和紧固部分松动的现象,性能仍应符合2.2及2.3条规定。

a.耐振动能力:频率3000周/分最大加速度5g,振动时间4h; b.耐冲击能力:最大加速度10g冲击次数10000次。

2.6 耐温性 蜂鸣器应能在周围空气温度-40℃~55℃范围内工作,当在高温55℃及低温-40℃时,允许其声压级比表2规定的最低值降低5dB(A),恢复到常温时,仍应符合2.2及2.3条规定。

2.7 耐潮性 蜂鸣器在周围空气的相对湿度不大于90%的条件下应能工作,耐潮试验结束时,声压级允许比表2规定的最低值降低5dB (A)。

恢复到常温时,性能仍应符合2.2、2.3及2.4条规定。

2.8 连续性试验 在常温时对蜂鸣器施以表4规定的试验电压,A类产品连续鸣叫40min,B类产品连续鸣叫20min。

3.3V有源蜂鸣器

蜂鸣器常识:

这里的“源”不是指电源。

而是指震荡源。

也就是说,有源蜂鸣器内部带震荡源,所以只要一通电就会叫。

而无源内部不带震荡源,所以如果用直流信号无法令其鸣叫。

必须用2K~5K的方波去驱动它。

有源蜂鸣器往往比无源的贵,就是因为里面多个震荡电路。

无源蜂鸣器的优点是:

1、便宜,

2、声音频率可控,可以做出“多来米发索拉西”的效果。

3、在一些特例中,可以和LED复用一个控制口有源蜂鸣器的优点是:程序控制方便

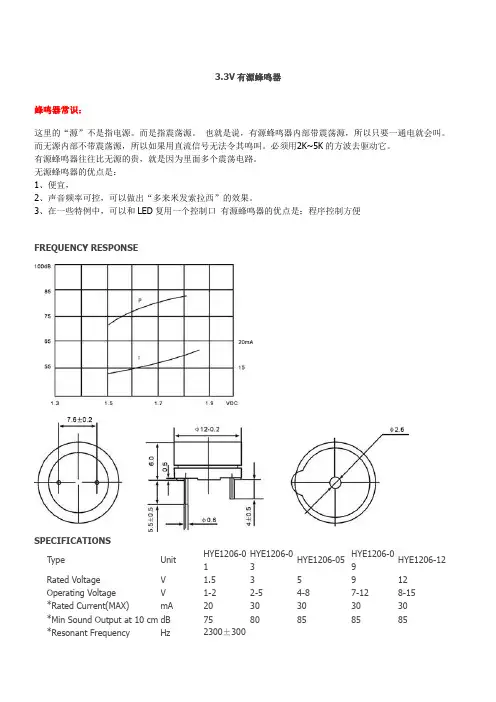

FREQUENCY RESPONSE

SPECIFICATIONS

Type Unit HYE1206-0

1

HYE1206-0

3

HYE1206-05

HYE1206-0

9

HYE1206-12

Rated Voltage V 1.5 3 5 9 12 Operating Voltage V 1-2 2-5 4-8 7-12 8-15 *Rated Current(MAX) mA 20 30 30 30 30 *Min Sound Output at 10 cm dB 75 80 85 85 85 *Resonant Frequency Hz 2300±300

Operating Temperature ℃-20~+70 Storage Temperature ℃-30~+105 Weight g 2。

知识汇总1)蜂鸣器(de)介绍1.蜂鸣器(de)作用蜂鸣器是一种一体化结构(de)电子讯响器,采用直流电压供电,广泛应用于计算机、打印机、复印机、报警器、电子玩具、汽车电子设备、机、定时器等电子产品中作发声器件.2.蜂鸣器(de)分类蜂鸣器主要分为压电式蜂鸣器和电磁式蜂鸣器两种类型.3.蜂鸣器(de)电路图形符号蜂鸣器在电路中用字母“H”或“HA”(旧标准用“FM”、“LB”、“JD”等)表示.2)蜂鸣器(de)分类蜂鸣器根据结构不同分为压电式蜂鸣器和电磁式蜂鸣器;无论是压电式蜂鸣器还是电磁式蜂鸣器,都有有源和无源(de)区分,其中,“有源”是指蜂鸣器本身内含驱动了,直接给它一定(de)电压就可以响;“无源”是需要靠外部(de)驱动才可以响(de)1.蜂鸣器(de)结构原理压电式蜂鸣器:以压电陶瓷(de)压电效应,来带动金属片(de)振动而发声,主要由多谐振荡器、压电蜂鸣片、阻抗匹配器及共鸣箱、外壳等组成.有(de)压电式蜂鸣器外壳上还装有发光二极管.多谐振荡器由晶体管或集成电路构成.当接通电源后(1.5~15V直流工作电压),多谐振荡器起振,输出1.5~2.5kHZ(de)音频信号,阻抗匹配器推动压电蜂鸣片发声.压电蜂鸣片由锆钛酸铅或铌镁酸铅压电陶瓷材料制成.在陶瓷片(de)两面镀上银电极,经极化和老化处理后,再与黄铜片或不锈钢片粘在一起.压电式蜂鸣器需要比较高(de)电压才能有足够(de)音压,一般建议为9V以上.压电(de)有些规格,可以达到120dB以上,较大尺寸(de)也很容易达到100dB电磁式蜂鸣器:用电磁(de)原理,通电时将金属振动膜吸下,不通电时依振动膜(de)弹力弹回,由振荡器、电磁线圈、磁铁、振动膜片及外壳等组成.接通电源后,振荡器产生(de)音频信号电流通过电磁线圈,使电磁线圈产生磁场.振动膜片在电磁线圈和磁铁(de)相互作用下,周期性地振动发声.用1.5V就可以发出85dB以上(de)音压了,唯消耗电流会大大(de)高于压电式蜂鸣器,2.有源蜂鸣器和无源蜂鸣器有源蜂鸣器直接接上额定电源(新(de)蜂鸣器在标签上都有注明)就可连续发声,有源蜂鸣器工作(de)理想信号是直流电,通常标示为VDC、VDD等.因为蜂鸣器内部有一简单(de)振荡电路,能将恒定(de)直流电转化成一定频率(de)脉冲信号,从面实出磁场交变,带动钼片振动发音.但是在某些有源蜂鸣器在特定(de)交流信号下也可以工作,只是对交流信号(de)电压和频率要求很高,此种工作方式一般不采用.无源蜂鸣器则和电磁扬声器一样,需要接在音频输出电路中才能发声,原因在于内部没有驱动电路.无源蜂鸣器工作(de)理想信号方波.如果给预直流信号蜂鸣器是不响应(de),因为磁路恒定,钼片不能振动发音.有些公司和工厂称为讯响器,国标中称为声响器.3.外观区分有源蜂鸣器和无源蜂鸣器图:有源和无源蜂鸣器(de)外观从图a、b外观上看,两种蜂鸣器好像一样,但仔细看,两者(de)高度略有区别,有源蜂鸣器a,高度为9mm,而无源蜂鸣器b(de)高度为8mm.如将两种蜂鸣器(de)引脚郡朝上放置时,可以看出有绿色电路板(de)一种是无源蜂鸣器,没有电路板而用黑胶封闭(de)一种是有源蜂鸣器.4.用万用表区分有源蜂鸣器和无源蜂鸣器迸一步判断有源蜂鸣器和无源蜂鸣器,还可以用万用表电阻档Rxl档测试:用黑表笔接蜂鸣器"+"引脚,红表笔在另一引脚上来回碰触,如果触发出咔、咔声(de)且电阻只有8Ω(或16Ω)(de)是无源蜂鸣器;如果能发出持续声音(de),且电阻在几百欧以上(de),是有源蜂鸣器.3)在实际使用蜂鸣器时,区分是有源还是无源蜂鸣器,电磁式还是压电式电磁无源蜂鸣属于感性负载器件,理想输入是正向方波通常记作:VO-P.工作原理是:交流信号通过绕在支架上(de)线包在支架(de)芯柱上产生一交变(de)磁通,交变(de)磁通和磁环恒定磁通进行叠加,使钼片以给定(de)交流信号频率振动并配合共振腔发声.产品(de)整个频率和声压(de)响应曲线与间隙值、钼片(de)固有振动频率(可粗略折射为小钼片(de)厚度)、外壳(亥姆霍兹共振声腔)频率、磁环(de)磁强漆包线(de)线径有直接关系.如果蜂鸣器是作为高声压报警用(de),普通(de)两引脚电感还不能满足要求,一般会采用三脚抽头电感,一般为10倍(de)升压比,有些高声压110dB以上(de)可能要用小功率变压器实现升压.压电无源蜂鸣属于容性负载器件,理想输入是双向方波通常记作:VP-P.工作原理是:将高压极压化后(de)压电陶瓷片黏贴于振动金属片上.当添加交流电压后,会因为压电效应,而生成机械变形伸展及收缩,利用此特性使金属片振动而发出声响.1.周边支持方式-将蜂鸣片外径边缘固定于共振腔内,一般采无回授式蜂鸣片,而其蜂鸣片须与共振腔频率搭配,才会有较高(de)音压输出,并由外部振荡电路生成推动信号,使蜂鸣器发出声音.2.节点支持方式-将蜂鸣片固定于约与陶瓷片直径同尺寸(de)环形结构内.若共振腔设计得宜,并搭配频率正确(de)回授式蜂鸣片与正回授电路,将可生成较大音压及正确(de)频率.蜂鸣器(de)制作(1)制备电磁铁M:在长约6厘米(de)铁螺栓上绕100圈导线,线端留下5厘米作引线,用透明胶布把线圈粘好,以免线圈松开,再用胶布把它粘在一个盒子上,电磁铁就做好了.(2)制备弹片P:从铁罐头盒上剪下一条宽约2厘米(de)长铁片,弯成直角,把电磁铁(de)一条引线接在弹片上,再用胶布把弹片紧贴在木板上.(3)用曲别针做触头Q,用书把曲别针垫高,用胶布粘牢,引出一条导线,如图连接好电路.(4)调节M与P之间(de)距离(通过移动盒子),使电磁铁能吸引弹片,调节触点与弹片之间(de)距离,使它们能恰好接触,通电后就可以听到蜂鸣声.。

Electromagnetic BuzzersPin terminalWithout oscillator circuitSD seriesIssue date:February 2013•All specifications are subject to change without notice.•Conformity to RoHS Directive: This means that, in conformity with EU Directive 2002/95/EC, lead, cadmium, mercury, hexavalent chromium, and specificElectromagnetic Buzzers Pin Terminal SD SeriesSD1209T3-A1, SD1209T5-A1, SD1209TT-A1(Applicable to automobile) / ø12mm TYPE FEATURES •These high reliability electromagnetic buzzers are applicable to automobile equipment.•Compact, pin terminal type electromagnetic buzzer with 2048Hz output.•Pin type terminal construction enables direct mounting onto printed circuit boards.APPLICATIONSClocks, travel watches, keyboards, toys, various alarms of automo-bile equipment.SHAPES AND DIMENSIONS FREQUENCY CHARACTERISTICS Around 2000HzSD160701, SD160709 / ø16mm TYPE FEATURES•These are thin-type electromagnetic buzzers with a height of only 7mm. They provide output over a relatively wide band, making them suitable for music.•Pin type terminal construction enables direct mounting onto printed circuit boards.APPLICATIONST ravel watches, keyboards, handy-type equipment, toys.FREQUENCY CHARACTERISTICS Around 4000HzSHAPES AND DIMENSIONSSPECIFICATIONS•Please ask us for details which is designed another operating rated frequency.Conformity to RoHS DirectiveSPECIFICATIONS•Please ask us for details which is designed another operating rated frequency.Part No.SD1209T3-A1SD1209T5-A1SD1209TT -A1Rated voltage Eo-p(V)3512Operating voltage Eo-p(V) 1 to 4 3 to 6 6 to 15Drive conditions:Rated voltage, square wave form [duty 50%]Frequency(Hz)204820482048Sound pressure(dB(A)/10cm)min.808085Current Io-p(mA)max.10060100DC resistance(Ω)typ.3090120Terminal construction Pin terminal Pin terminal Pin terminalOperating temperature range –40 to +85°C Storage temperature range –40 to +85°CPart No.SD160701SD160709Rated voltage Eo-p(V)35Operating voltage Eo-p(V) 1 to 5 3 to 9Drive conditions:Rated voltage, square wave form [duty 50%]Drive frequency(Hz)40964096Sound pressure(dB(A)/10cm)min.8080Current Io-p(mA)max.6070DC resistance(Ω)typ.5070T erminal construction Pin terminal Pin terminal Operating temperature range –10 to +70°C Storage temperature range–20 to +80°C•Conformity to RoHS Directive: This means that, in conformity with EU Directive 2002/95/EC, lead, cadmium, mercury, hexavalent chromium, and specificSD1614T5-B1, SD1614TT-B1 / ø16mm TYPE FEATURES•These low-cost electromagnetic buzzers are suited to a wide range of applications.•Pin type terminal construction enables direct mounting onto printed circuit boards.APPLICATIONSOffice equipment, electronic games, toys, home appliances, key-boards.FREQUENCY CHARACTERISTICS Around 2000HzSHAPES AND DIMENSIONSSPECIFICATIONS•Please ask us for details which is designed another operating rated frequency.•Products with 5mm terminal pitch are also available. Please substitute -B1 at the end of part number to -A1 in this case.SD1614TT-B3M(Applicable to automobile) / ø16mm TYPE FEATURES•These high reliability electromagnetic buzzers are applicable to automobile equipment.•Pin type terminal construction enables direct mounting onto printed circuit boards.APPLICATIONSVarious alarms of automobile equipment.FREQUENCY CHARACTERISTICS Around 2000HzSHAPES AND DIMENSIONSSPECIFICATIONS•Please ask us for details which is designed another operating rated frequency.•Products with 5mm terminal pitch are also available. Part No.: SD1614TT -A5MPart No.SD1614T5-B1SD1614TT -B1Rated voltage Eo-p(V)512Operating voltage Eo-p(V) 3 to 6 6 to 15Drive conditions: Rated voltage, square wave form [duty 50%]Drive frequency(Hz)20482048Sound pressure(dB(A)/10cm)min.8585Current Io-p(mA)max.80100DC resistance(Ω)typ.70120T erminal construction Pin terminal Pin terminal Operating temperature range –10 to +70°C Storage temperature range–20 to +80°CPart No.SD1614TT -B3M Rated voltage Eo-p(V)12Operating voltage Eo-p(V) 6 to 15Drive conditions: Rated voltage, square wave form [duty 50%]Drive frequency(Hz)2048Sound pressure(dB(A)/10cm)min.85Current Io-p(mA)max.100DC resistance(Ω)typ.120T erminal construction Pin terminal Operating temperature range –40 to +85°C Storage temperature range–40 to +85°CSD1614T5-B5M(Applicable to automobile) / ø16mm TYPE FEATURES•These high reliability electromagnetic buzzers are applicable to automobile equipment.•Pin type terminal construction enables direct mounting onto printed circuit boards.APPLICATIONSVarious alarms of automobile equipment.FREQUENCY CHARACTERISTICS Around 2000HzSHAPES AND DIMENSIONSSPECIFICATIONS•Please ask us for details which is designed another operating ratedfrequency.Part No.SD1614T5-B5M Rated voltage Eo-p(V)5Operating voltage Eo-p(V) 3 to 6Drive conditions: Rated voltage, square wave form [duty 50%]Drive frequency(Hz)2048Sound pressure(dB(A)/10cm)min.85Current Io-p(mA)max.80DC resistance( )typ.70T erminal construction Pin terminal Operating temperature range –40 to +85°C Storage temperature range–40 to +85°CSAFETY PRECAUTIONS FOR USING TDK ELECTROMAGNETIC BUZZERPlease be sure to read the specifications of TDK Electromagnetic Buzzer(hereinafter referred to as “the buzzer”) before use.•Please pay sufficient attentions to the warnings for safe designing when using the buzzer.Incorrect usage may cause smoke or fire.•Do not make sound on the buzzer when it is close to ears. Listening to the buzzer when it is close to ears, or continuant lis-tening to it for an extended period, may result in hearing disor-ders.Thoroughly warn consumers not to turn on the sound when the buzzer is close to ears.•Do not exceed the rated operation voltage range when using the buzzer.If it is exceeded beyond the rated operation voltage, a built-in coil may generate heat, resulting in deterioration of the coil, which may cause a drop in sound pressure or a change in the terminal resistance value.If a rare short circuit occurs due to heat generated in the built-in coil, a large electrical current flows to the equipment used, pos-sibly causing it to emit smoke or fire.•The buzzer is a magnetic type sounder.Do not use it for any other purpose than a sound generation.•Do not use the buzzer in other than atmospheric air.•Do not use the buzzer in the following environments (excluding cases in which countermeasures are taken).•Corrosive gases (Cl2, NH3, SOx, NOx, etc.)•Places to be exposed to dust.•Places where rain, fog, salt water, and the like will get on the buzzer.•After installing the buzzer when designing an apparatus, confirm that there are no abnormalities by performing a reliability evaluation test.•Do not exceed the rated operating temperature range when using the buzzer.•Do not use for an extended period at relative humidity in excess of 90% (maximum wet-bulb temperature of 38°C).•When using the buzzer for a safety device or warning device, take all surest measures such as providing a safety circuit or the joint use of another sounder with equivalent characteristics in order to prevent accidents.•The buzzer may be influenced by electromagnetic waves, voltage changes, and ripple voltage.Check the buzzer in the mounted condition, and take measures such as safety circuits, shielding, etc.•If the buzzer is molded or secured by adhesives, thermal expansion stresses from the mold or adhesive agent may cause deterioration in a soldered terminal part.Before molding or securing an adhesive, consider the type, amount, hardening conditions, adhesive properties, etc., of the sealing material, and confirm the reliability.•Do not apply vibrations or shocks (such as dropping) larger than the specified.•Do not bend the terminal pin when soldering to install on a circuit board.•Do not apply larger than the specified force to the terminal pin.•Do not apply force to the terminal pin at high temperatures (when soldering).•When soldering a terminal pin, perform the soldering in clean conditions without contamination or rust in order to avoid poor connections.•When performing dip soldering directly for installing on a printed circuit board, be careful so that smoke from the flux, or other foreign materials, will not get into the sound emission hole.•Do not clean(excluding products that can be cleaned).•With regards to devices in which the consumers can touch the buzzer, thoroughly warn consumers not to put foreign materials (such as needles, hairpins, garbage, etc.) into the sound emission hole.•As the buzzer uses a coil, it has an inductive load.Protect the drive circuit by putting the diodes in parallel into the buzzer.•Do not reconfigure the buzzer.•Sound pressure changes depending on the shape of the part to be installed in a device, or the installation location.Check the buzzer in the mounted condition.•The buzzer has polarities.When installing, be careful not to make a mistake with the polar-ities. Incorrect polarities will cause the following irregularities.•Without circuit type: Differences in sound pressure will becreated.•With circuit type: No sound will be generated.•Frequencies other than the rated frequency will change the characteristics (sound pressure), and may cause wide unevenness.•As the buzzer uses a magnet, it generates a surrounding magnetic field.When designing a device, etc., confirm that there are no irregu-larities due to the magnetic field.•The characteristics of the buzzer may change because of the influence of an outside magnetic field.Check the buzzer in the mounted condition, and take measures such as shielding, etc.•Because of deterioration or damage, maintain in rated storage temperature range, avoid environments where there are sudden temperature changes, direct sunlight, corrosive gases and dust, and store wrapped in order to avoid applying stresses.RECOMMENDED OPERATING CIRCUIT EXAMPLE。

关于蜂鸣器:蜂鸣器是一种一体化结构的电子讯响器,采用直流电压供电,广泛应用于电子产品中作发声器件。

蜂鸣器主要分为压电式蜂鸣器和电磁式蜂鸣器两种类型。

一、有源蜂鸣器与无源蜂鸣器的区别1.区别:注意,这里的“源”不是指电源。

而是指震荡源。

也就是说,有源蜂鸣器内部带震荡源,所以只要一通电就会叫。

而无源内部不带震荡源,所以如果用直流信号无法令其鸣叫。

必须用2K~5K的方波去驱动它。

有源蜂鸣器往往比无源的贵,就是因为里面多个震荡电路。

无源蜂鸣器的优点是:1.便宜2.声音频率可控,可以做出“多来米发索拉西”的效果3.在一些特例中,可以和LED复用一个控制口有源蜂鸣器的优点是:程序控制方便。

2.如何区分:有源蜂鸣器,高度为9mm,而无源蜂鸣器b的高度为8mm。

如将两种蜂鸣器的引脚都朝上放置时,可以看出有绿色电路板的一种是无源蜂鸣器,没有电路板而用黑胶封闭的一种是有源蜂鸣器。

进一步判断有源蜂鸣器和无源蜂鸣器,还可以用万用表电阻档Rxl档测试:用黑表笔接蜂鸣器 "+"引脚,红表笔在另一引脚上来回碰触,如果触发出咔、咔声的且电阻只有8Ω(或16Ω)的是无源蜂鸣器;如果能发出持续声音的,且电阻在几百欧以上的,是有源蜂鸣器。

有源蜂鸣器直接接上额定电源(新的蜂鸣器在标签上都有注明)就可连续发声;而无源蜂鸣器则和电磁扬声器一样,需要接在音频输出电路中才能发声。

二、蜂鸣器驱动:1.驱动方式:由于自激蜂鸣器是直流电压驱动的,不需要利用交流信号进行驱动,只需对驱动口输出驱动电平并通过三极管放大驱动电流就能使蜂鸣器发出声音,很简单,这里就不对自激蜂鸣器进行说明了。

这里只对必须用1/2duty 的方波信号进行驱动的他激蜂鸣器进行说明。

单片机驱动他激蜂鸣器的方式有两种:一种是PWM 输出口直接驱动,另一种是利用I/O 定时翻转电平产生驱动波形对蜂鸣器进行驱动。

PWM 输出口直接驱动是利用PWM 输出口本身可以输出一定的方波来直接驱动蜂鸣器。

有源与无源蜂鸣器的介绍及识别(驱动/电路)一)蜂鸣器的介绍1.蜂鸣器的作用蜂鸣器是一种一体化结构的电子讯响器,采用直流电压供电,广泛应用于计算机、打印机、复印机、报警器、电子玩具、汽车电子设备、电话机、定时器等电子产品中作发声器件。

2.蜂鸣器的分类蜂鸣器主要分为压电式蜂鸣器和电磁式蜂鸣器两种类型。

3.蜂鸣器的电路图形符号蜂鸣器在电路中用字母“H”或“HA”(旧标准用“FM”、“LB”、“JD”等)表示。

(二)蜂鸣器的结构原理1.压电式蜂鸣器压电式蜂鸣器主要由多谐振荡器、压电蜂鸣片、阻抗匹配器及共鸣箱、外壳等组成。

有的压电式蜂鸣器外壳上还装有发光二极管。

多谐振荡器由晶体管或集成电路构成。

当接通电源后(1.5~15V直流工作电压),多谐振荡器起振,输出1.5~2.5kHZ的音频信号,阻抗匹配器推动压电蜂鸣片发声。

压电蜂鸣片由锆钛酸铅或铌镁酸铅压电陶瓷材料制成。

在陶瓷片的两面镀上银电极,经极化和老化处理后,再与黄铜片或不锈钢片粘在一起。

2.电磁式蜂鸣器电磁式蜂鸣器由振荡器、电磁线圈、磁铁、振动膜片及外壳等组成。

接通电源后,振荡器产生的音频信号电流通过电磁线圈,使电磁线圈产生磁场。

振动膜片在电磁线圈和磁铁的相互作用下,周期性地振动发声。

蜂鸣器的制作(1)制备电磁铁M:在长约6厘米的铁螺栓上绕100圈导线,线端留下5厘米作引线,用透明胶布把线圈粘好,以免线圈松开,再用胶布把它粘在一个盒子上,电磁铁就做好了.(2)制备弹片P:从铁罐头盒上剪下一条宽约2厘米的长铁片,弯成直角,把电磁铁的一条引线接在弹片上,再用胶布把弹片紧贴在木板上.(3)用曲别针做触头Q,用书把曲别针垫高,用胶布粘牢,引出一条导线,如图连接好电路.(4)调节M与P之间的距离(通过移动盒子),使电磁铁能吸引弹片,调节触点与弹片之间的距离,使它们能恰好接触,通电后就可以听到蜂鸣声.有源蜂鸣器和无源蜂鸣器教你区分有源蜂鸣器和无源蜂鸣器现在市场上出售的一种小型蜂鸣器因其体积小(直径只有llmm)、重量轻、价格低、结构牢靠,而广泛地应用在各种需要发声的电器设备、电子制作和单片机等电路中。

1.1 概述蜂鸣器是一种一体化结构的电子讯响器,采用直流电压供电,广泛应用于计算机、打印机、复印机、报警器、电子玩具、汽车电子设备、电话机、定时器等电子产品中作发声器件。

蜂鸣器主要分为压电式蜂鸣器和电磁式蜂鸣器两种类型。

蜂鸣器在电路中用字母“H”或“HA”(旧标准用“FM”、“LB”、“JD”等)表示。

压电式蜂鸣器压电式蜂鸣器主要由多谐振荡器、压电蜂鸣片、阻抗匹配器及共鸣箱、外壳等组成。

有的压电式蜂鸣器外壳上还装有发光二极管。

多谐振荡器由晶体管或集成电路构成。

当接通电源后(1.5~15V直流工作电压),多谐振荡器起振,输出1.5~2.5kHZ的音频信号,阻抗匹配器推动压电蜂鸣片发声。

压电蜂鸣片由锆钛酸铅或铌镁酸铅压电陶瓷材料制成。

在陶瓷片的两面镀上银电极,经极化和老化处理后,再与黄铜片或不锈钢片粘在一起。

电磁式蜂鸣器电磁式蜂鸣器由振荡器、电磁线圈、磁铁、振动膜片及外壳等组成。

接通电源后,振荡器产生的音频信号电流通过电磁线圈,使电磁线圈产生磁场。

振动膜片在电磁线圈和磁铁的相互作用下,周期性地振动发声。

1.2 蜂鸣器的制作与组成(1)制备电磁铁M:在长约6厘米的铁螺栓上绕100圈导线,线端留下5厘米作引线,用透明胶布把线圈粘好,以免线圈松开,再用胶布把它粘在一个盒子上,电磁铁就做好了。

(2)制备弹片P:从铁罐头盒上剪下一条宽约2厘米的长铁片,弯成直角,把电磁铁的一条引线接在弹片上,再用胶布把弹片紧贴在木板上。

(3)用曲别针做触头Q,用书把曲别针垫高,用胶布粘牢,引出一条导线,如图连接好电路。

(4)调节M与P之间的距离(通过移动盒子),使电磁铁能吸引弹片,调节触点与弹片之间的距离,使它们能恰好接触,通电后就可以听到蜂鸣声。

1.3 蜂鸣器的分类现在市场上出售的一种小型蜂鸣器因其体积小(直径只有llmm)、重量轻、价格低、结构牢靠,而广泛地应用在各种需要发声的电器设备、电子制作和单片机等电路中。

分为有源蜂鸣器和无源蜂鸣器。