磁流体密封ppt课件

- 格式:ppt

- 大小:1.21 MB

- 文档页数:25

■磁性流体密封技术磁性流体密封技术是在磁性流体的基础上发展的,当磁性流体注入具有磁场的间隙中时,它可以充满整个间隙,成为一种液体“O型密封圈”。

磁性流体真空进给装置是一种把旋转运动传入真空容器的装置,其基本构成为一个永久磁场,两个磁极,一个磁性转动轴和磁性流体。

传动轴是一个多级结构,由磁极和转轴组成。

在每级环形间隙中,充满了磁性流体。

在理想状态下,所有磁性流体密封在每一级极间与磁极之间,形成一系列的“磁性流体密封圈”。

每级“磁性流体密封圈”能随的压差0.15-0.2个大气压,整个区域的随能力为密封圈子总的承压能力,为适应真空环境,磁性流体密封圈标准设计压力大于两个大气压,所以说是绝对安全的。

Magnetic fluid Sealing TechniqueSealing techniques of magnetic fluid take advantage ofresponse of Magnetic fluids. When a Magnetic fluid is placed intoa gap between the surfaces of rotating and stationary elementsin the presence of magnetic fluid, it assumes the shape ofa"Liquid O-ring" to comple电话y fill the gap.The magnetic fluid vacuum rotary feed through is a device thattransmits rotary motion into a vacuum chamber. The basiccomponents are permanent magnet, two pole pieces, a magneticallypermeable shaft and Magnetic fluid. The shaft (of pole pieces)contains a multistage structure, completed bye the pole pieces and the shaft, concentrating magnetic flux in the radial gap under each stage. In the ideal situation, all flux lines are confined under each stage, and none are in interstate region. The magnetic fluid is trapped andheld in each-stage, forming a series of " Liquid Oring" with intervening regions that are filled with air. Each stage can typically sustain a pressure differential of 0.15-0.2 atmospheres. All stages act in series to provide a total pressure capability for the seal. For vacuum applications Magnetic fluid seals are normally designed to sustain a pressure differential of greater than two atmospheres, thus allowing a safety margin.■特性密封圈特性:磁性流体包围整个转轴,成为一隔绝空气,水气,烟雾等元素的密封圈,几乎无泄漏的特性,密封圈的泄漏微弱到已无法测量,甚至使用质谱仪也无法测量(1*10-11Torr/e/sec)Hermetic sealing: The Magnetic fluid surrounding the shaft provides a hermetic seal against gas, vapor, mist and other contaminants.长寿命特性:"液体O型密封圈"由一个稳定的磁性流体构成,其装置可长期使用10年无需维修。

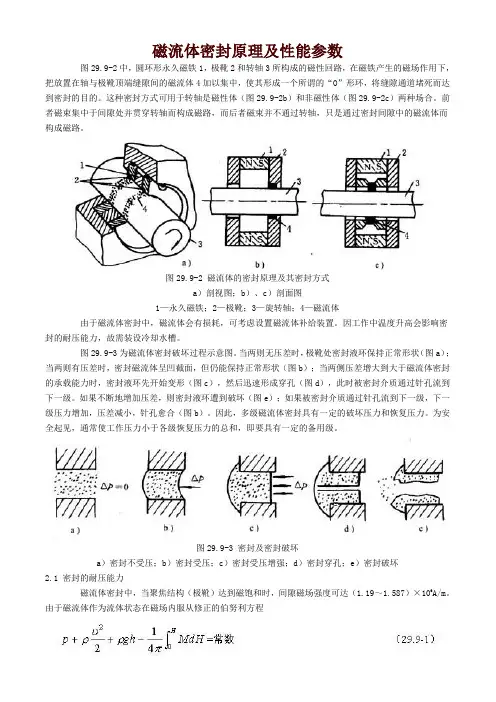

磁流体密封原理及性能参数图29.9-2中,圆环形永久磁铁1,极靴2和转轴3所构成的磁性回路,在磁铁产生的磁场作用下,把放置在轴与极靴顶端缝隙间的磁流体4加以集中,使其形成一个所谓的“O”形环,将缝隙通道堵死而达到密封的目的。

这种密封方式可用于转轴是磁性体(图29.9-2b)和非磁性体(图29.9-2c)两种场合。

前者磁束集中于间隙处并贯穿转轴而构成磁路,而后者磁束并不通过转轴,只是通过密封间隙中的磁流体而构成磁路。

图29.9-2 磁流体的密封原理及其密封方式a)剖视图;b)、c)剖面图1—永久磁铁;2—极靴;3—旋转轴;4—磁流体由于磁流体密封中,磁流体会有损耗,可考虑设置磁流体补给装置。

因工作中温度升高会影响密封的耐压能力,故需装设冷却水槽。

图29.9-3为磁流体密封破坏过程示意图。

当两则无压差时,极靴处密封液环保持正常形状(图a);当两则有压差时,密封磁流体呈凹截面,但仍能保持正常形状(图b);当两侧压差增大到大于磁流体密封的承载能力时,密封液环先开始变形(图c),然后迅速形成穿孔(图d),此时被密封介质通过针孔流到下一级。

如果不断地增加压差,则密封液环遭到破坏(图e);如果被密封介质通过针孔流到下一级,下一级压力增加,压差减小,针孔愈合(图b)。

因此,多级磁流体密封具有一定的破坏压力和恢复压力。

为安全起见,通常使工作压力小于各级恢复压力的总和,即要具有一定的备用级。

图29.9-3 密封及密封破坏a)密封不受压;b)密封受压;c)密封受压增强;d)密封穿孔;e)密封破坏2.1 密封的耐压能力磁流体密封中,当聚焦结构(极靴)达到磁饱和时,间隙磁场强度可达(1.19~1.587)×106A/m。

由于磁流体作为流体状态在磁场内服从修正的伯努利方程式中ρ——磁流体的密度;M——磁流体的磁通密度;H——间隙中的磁场强度;h——高出水平面的高度。

上式中前三项为静压能、动压能和位能之和,第四项为考虑磁特性的附加项。

磁流体密封第1章绪论1.1选题的背景和意义磁流体也叫磁液或铁流体,它是将磁性微粒掺入到载液中是一种对磁场敏感、可流动的液体磁性材料。

磁流体自问世以来,在研磨、抛光、润滑、减振、冷却等领域逐步被人们所认识,磁流体在密封领域的应用也逐渐受到人们的重视。

磁流体密封是借助磁流体在磁场的作用下形成的磁流体密封环对气体、液体进行密封,由于它和密封轴之间是通过磁流体进行接触密封,因而避免了密封轴与密封件之间的直接摩擦,降低了附加载荷。

在旋转轴密封中具有其它密封方式不可比拟的优点:无泄露、无磨损、结构简单、寿命长,受到国内外学者和工程技术人员的重视,在工业、国防等领域具有重要的意义。

磁流体密封在低压气体密封中的应用较为简单,因为密封压力低,所需的密封级数较少、密封间隙也可以选的比较大,所以容易实现。

同时由于密封级数少,故密封装置的轴向尺寸限制较少,密封间隙大,其他诸如转速、磁极齿型等因素对密封装置的密封能力影响也较小,往往可以采用模糊的理论公式或经验公式对密封装置进行设计,就能满足使用的需要。

随着密封压力的升高,磁流体密封耐压公式在磁流体密封装置的设计中越来越重要,它的理论水平直接决定了密封装置的性能。

传统密封理论公式存在一些缺陷,比如密封力的来源不明确,计算复杂,适用范围小等等,这就不能很好的满足磁流体高压密封设计的需要。

因此,应用新的、合理的密封耐压公式对旋转轴高压密封装置的设计是很必要的。

磁流体在气体密封中的应用已经很多,但是在液体密封中的应用较少,本文将磁流体密封技术应用于船舶艉轴密封中,并采用新的耐压公式,计算出密封装置的参数,设计出密封实验装置,进行了具体实验,取得了大量的数据。

最后利用实验数据,分析对船舶艉轴磁流体密封的主要影响因素,可为今后进行磁流体密封装置的设计提供一定的帮助。

1.2国内外磁流体密封技术的发展现状1.2.1磁流体简介磁流体是由超微细磁粉在液体(载体)中稳定分散而形成的能流动、有超顺磁性的胶体,它无剩磁和矫顽力,可通过磁进行控制,在磁场作用下形成具有磁性的流体,其密封膜承压能力与磁场强度成正比。

磁流体密封原理磁流体密封技术是在磁性流体的基础上发展而来的,当磁流体注入磁场的间隙时,它可以充满整个间隙,形成一种“液体的O型密封圈”。

磁流体密封装置的功能是把旋转运动传递到密封容器内,常用于真空密封,其基本原理见下图磁流体密封装置是由不导磁座、轴承、磁极、永久磁铁、导磁轴、磁流体组成,在均匀稳定磁场的作用下,使磁流体充满于设定的空间内,建立起多级“O型密封圈”,从而达到密封的效果;每级密封圈一般可以承受大于0.15~0.2个大气压的压差。

总承压为各级压差之和,一般设计为2.5个大气压,完全满足真空密封的需要;另外经过我公司的研究开发,也可用于高压密封。

2、磁流体密封的特性·长寿命无磨损,具有极佳的工作可靠性。

·高性能极限真空度10-6Pa,泄漏率10-12Pa.m3/sec。

·高适应性:从低速到高速,从低压到高压,从室温到高温,均能满足各种[wiki]设备[/wiki]的要求。

3、磁流体密封的应用近年来,国内外真空设备发展迅猛。

在许多回转动密封装置上,磁流体密封得到了广泛的应用,例如在单晶硅炉、真空钎焊炉、真空熔炼炉、化学气相沉积、离子镀膜、液晶再生等真空设备的密封,以及高温高压设备及对[wiki]环境[/wiki]要求较高的设备的密封。

从而提高产品质量,获得很好的经济效益。

1995年由美国帕佩尔(Papell)发明的磁性流体,是把磁铁矿等强磁性的微细粉末(约100?)在水、油类、酯类、醚类等液体中进行稳定分散的一种胶态液体。

这种液体具有在通常离心力和磁场作用下,既不沉降和凝聚又能使其本身承受磁性,可以被磁铁所吸引的特性。

磁流体由3种主要成分组成:1)固体铁磁体微粒(Fe3O4);2)包覆着微粒并阻止其相互凝聚的表面活性剂(稳定剂);3)载液(溶媒)。

磁流体的特性磁流体是一种叫胶体溶液。

作为密封用的磁流体,其性能要求是:稳定性好,不凝聚、不沉淀、不分解;饱和磁化强度高;起始磁导率大;粘度和饱和蒸气低,其他如凝固点、[wiki]沸点[/wiki]、导热率、比热和表面张力等也有一定的要求。

磁流体密封装置磁流体密封装置是一种新型的密封技术,它利用磁流体的独特性质实现密封。

下面将从以下几个方面详细介绍磁流体密封装置。

一、磁流体的基本特性1. 磁流体的定义磁流体是由微米级的铁粉或其他磁性材料悬浮在液体中形成的一种特殊液态物质。

2. 磁流体的性质(1)粘度可调节:通过改变外加磁场强度,可以改变磁流体的粘度,从而实现对密封效果的调节。

(2)高渗透性:由于磁流体微粒子之间存在空隙,因此其渗透性较高,能够有效地防止气体和液体泄漏。

(3)高耐腐蚀性:由于磁流体中微粒子表面均被包覆有一层保护层,因此具有较好的耐腐蚀性能。

二、磁流体密封装置原理1. 原理概述利用外加电场或者永久磁铁产生一个局部强大的磁场,使磁流体微粒子在磁场的作用下排列成一个密实的磁性密封体,从而实现密封效果。

2. 磁流体密封装置的组成(1)驱动部件:主要由电机和减速器组成,通过驱动磁流体产生旋转运动。

(2)密封部件:由磁极、密封套和磁流体组成。

(3)控制系统:主要控制电机和减速器的运转,以及对磁流体的粘度进行调节。

三、磁流体密封装置的应用1. 应用领域(1)泵类设备:如离心泵、柱塞泵等。

(2)阀门类设备:如球阀、蝶阀等。

(3)传动类设备:如齿轮箱、摆线减速机等。

2. 应用优势(1)高效节能:相比于传统的机械密封,磁流体密封装置具有更高的效率和更低的能耗。

(2)环保安全:由于没有摩擦部件,因此不存在润滑油泄漏问题,同时也避免了因为润滑油污染环境和危害健康的问题。

(3)使用寿命长:由于磁流体密封装置没有摩擦部件,因此使用寿命更长,维护成本更低。

四、磁流体密封装置的发展趋势1. 技术创新磁流体密封装置技术仍处于不断发展之中,未来将会有更多的技术创新和改进。

2. 应用拓展随着磁流体密封装置技术的不断完善和应用领域的拓展,其在各个领域中的应用将会越来越广泛。

3. 市场前景磁流体密封装置具有高效节能、环保安全、使用寿命长等优点,未来市场前景广阔。

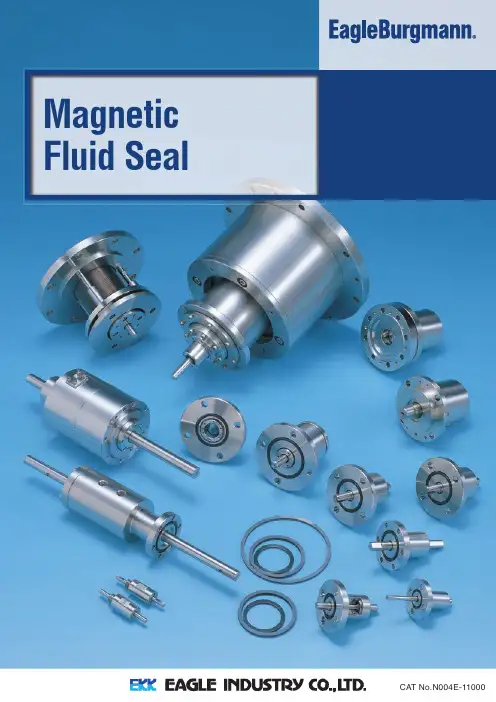

CAT No.N004E-11000Magnetic Fluid Seal1Typical con figurations Multi-axial (two or three shafts) Reciprocating (bellows seal)PressurizedThe NOK group produces the full range of vacuum seal components including O-rings,bellows, bearing lubrication grease and magnetic fluids (see diagram).This enables us to tailor our products to the precise design requirements of individual clients.Welded metal bellows (Eagle Industry)NOK NOK CORPORATION NKL NOK KLÜBER CO.,LTDDesign specifications tailored to client requirements2Magnetic fluid seals from Eagle Industry are employed in a wide range of industrial applications includingmanufacturing (typically semiconductors, LCD panels, solar panels and LED devices) as well as industrial machinery, analyzers and clean robots. Our high-performance and high-reliability seals have been adopted throughout the world.Uses of the magnetic fluid sealEssentially, magnetic fluid is a liquid that is attracted to magnets—in other words, a magnetized liquid.Magnetic fluid consists of three components:(1) magnetic particles, (2) surfactant and (3) a base liquid.The performance of a magnetic fluid seal is largely dependent on the properties of the magnetic fluid.Without surfactant, the very small magnetite (Fe 3O 4) particles (approximately 0.01μm) tend to separate and settle and do not remain evenly mixed with the base liquid. The surfactant envelops the magnetic particles and causes them to oppose one another within the base liquid. This prevents settlement and maintains a uniform distribution of particles (see diagram below).Eagle Industry boasts an extensive understanding of the many parameters of magnetic fluids including particle size, surfactant structure, molecular weight and particle absorption, base liquid purity, surfactant compatibility and dispersion characteristics. These parameters are carefully tailored to produce optimized magnetic fluids for different applications.Base liquids are designed and manufactured within the NOK group.One of the major strengths of Eagle Industry magnetic fluids is that all of the constituent components are designed and manufactured within the NOK group. Our products offers superior high-temperature durability, corrosion resistance, plasma resistance and very low-temperature outgassing performance compared to competitors' products.Magnetic fluid seals from Eagle Industry utilize magnetic fluids that have passed a stringent final qualitytesting process prior to delivery.SpikingWhen a magnet is brought close to magnetic fluid, the magnetic fluid attempts to orient itself with the magnetic force lines. This actsin opposition to interfacial tension, resulting in the phenomenon known asspiking (see photograph).3What is magnetic fluid?4Magnetic fluid selection table* Eagle Industry will be happy to recommend the best process setup and magnetic fluid for your particular operating environment and objectives. To apply, simply fill in the Magnetic Fluid Seal Design Request attached to this catalog (general speci fications are acceptable) and present it to your nearest dealer or distributor.Excellent heat resistance no need toprovide cooling equipment/structures*This also helps to minimize by-products associated with localized cooling of CVD equipment.Allows extremely high vacuum environments to be generated via direct exhaust (i.e. without differential pumping)Low outgassingExcellent corrosion and plasma resistancePa V a p o r p r e s s u r eTemperature Vapor Pressure Chart of Magnetic Fluid* Magnetic fluid is not sold as a stand-alone product.Features of Eagle Industry magnetic fluidsAtmospherePole PieceMagnetMagnetic FluidMagnetic Flux LinesVacuumThe term magnetic fluid seal is a generic term used to describe all seals that employ magnetic fluids.A magnetic fluid seal is filled with magnetic fluid that is oriented with the magnetic force lines created by theshaft, magnet and pole pieces. The sealing action is provided by a sealing skin called the liquid O ring that is formed by the magnetic fluid.Magnetic fluid seals have superior longevity to solid seals as well as lower torque due to the absence of abrasion. However they are not suitable for use with liquids such as water.A magnetic fluid vacuum seal is a special type of magnetic fluid seal used to keep a vacuum.Magnetic fluid vacuum seals are used for delivering rotational power to vacuum chambers, typically in electronic manufacturing systems (such as semiconductors) and analysis equipment.Since pressure resistance of one atmosphere(101.3 kPa) cannot be achieved via a single stage, a multi-stage design is used. Where the pressure differential exceeds the resistance of a stage, gas passes through the magnetic fluid, which then repairs itself. As this process occurs at successive stages, the pressure is apportioned between the stages, creating an equilibrium that maintains theStart of evacuationInitial state Fluid5What is a magnetic fluid seal?About magnetic fluid vacuum sealsMagnetic fluid is a colloidal liquid consisting of nano-sized magnetic particles distributed through a liquid body. As the name suggests, magnetic fluid is attracted to magnetic bodies.Magnetic fluid was originally developed in 1965 by S. S. Papell from NASA (National Aeronautics and Space Administration) as a rocket fuel propulsion technology for weightless environments(1). Subsequent modifications and enhancements have seen magnetic fluids adopted in a wide range of applications from the everyday to the cutting-edge.A magnetic fluid seal is a type of seal that utilizes magnetic fluid.Dust seals and vacuum (or hydraulic) seals generate minimal levels of dust, friction and contamination and provide excellent heat and plasma resistance. As such, they are extensively used in clean production environments, typically for manufacturing semiconductors, LCD panels, solar panels and LED components.19841988 1990 19961999 2002 2009NOK Corporation launches research on in-house production of magnetic fluid products.Commences production and distribution of dust seals.Commences production and distribution of vacuum seals.Develops magnetic fluid 3551 featuring low vapor pressure and high heat resistance. Announces vacuum seals rated to E-8Pa. (see page 4)Announces magnetic fluid 3576, an improved version of 3551. Commences production and distribution of vacuum seals for extremely high vacuum environments (E-13Pa).NOK Corporation transfers production operations to group company Eagle Industry Co., Ltd..Eagle Industry commences production and distribution of magnetic fluid 3576.Eagle Industry announces successful development of newVac Guard® seal featuring magnetic fluid. (see page 11)About magnetic fluid seals67Pressure (vacuum ): E 6Pa (at R.T.) Allowable He leakage:less than 9.9E 11Pa m 3/s Operating temperature: from room temperature to 160°C Usage environment: reactive gases/inert gasesFeaturesTable of dimensions (for reference)* W suf fix on model number denotes water-cooled type. Example: ISF010W* Dimensions subject to change without notice.* W suf fix on model number denotes water-cooled type. Example: IHF010W* Dimensions subject to change without notice.8Pressure (vacuum ): E 9Pa (at R.T.) Allowable He leakage:less than 9.9E 12Pa m 3/s Operating temperature: from room temperature to 220°C Usage environment: reactive gases/inert gasesFeaturesTable of dimensions (for reference)* W suf fix on model number denotes water-cooled type. Example:* Dimensions subject to change without notice.9Pressure differential: 1kPa 10kPaOperating temperature:from room temperature to 160°C (220°C )Circumferential velocity: 3m/s ( 6m/s ) Usage environment:reactive gases/inert gasesFeaturesTable of dimensions (for reference)Dust seals are used to shut out dirt and contaminants from the atmosphere, as well as contaminants generated by bearing grease. A dust seal consists of a magnet, two pole pieces and a shaft, which form a magnetic circuit that holds magnetic fluid in the gaps between the shaftand the pole pieces.Fluid* Dimensions subject to change without notice.Dust seal10Quantity: 500μ3Scale increments: 5μ3Needle (outer x inner diameter):ø0.71×ø0.41mmNeedle length: 51mml Use and handling of dust seals[Option] Magnetic fluid syringe1. Dust seals and magnetic fluids should be stored in a cool location with low humidity and not in direct sunlight.2. Do not mix magnetic fluid with other liquids.3. Take care to avoid oil, grease and magnetic particle spills during use.4. Use a suitable solvent to remove any grease or oil on the shaft surface.5. Attach dust seals to housing using O-rings or adhesive to ensure a secure fit and a good seal.6. Extract magnetic fluid from the container using the magnetic fluid syringe (optional).Take care to prevent air from entering the syringe.Air can affect measurement accuracy, which in turn can compromise the performance of the dust seal. If the magnetic fluid does not draw easily into the syringe, try warming the container first.7. Apply magnetic fluid to the gaps between the shaft and the dust seal (or pole pieces).The correct quantities are indicated on the delivery drawings.8. Use a suitable solvent to clean the syringe.The magnetic fluid syringe (optional extra) provides a clean, easy, accurate and ef ficient means of applying the magnetic fluid.Rotating shaft seals based on the O-ring + vacuum grease design have a relativelyshort maintenance cycle, in the range of several weeks to a few months. Vac Guard ®was developed in response to industry calls for seals with similar performance but alonger life expectancy.The seal is formed with special shaped elastomer, using magnetic fluid as lubricant.The magnetic fluid is the same as that used in magnetic fluid vacuum seals, and hasbeen extensively used in vacuum environments already.Life expectancy: longer than O-ring seal Reduces preventative maintenance (extends MTBF) andcost of ownership.Low-dust design: generates less than 0.05% as muchdust as an O-ring seal (0.1 μm and larger)Low driving torque: 50% lower than O-ring sealFeatures11Vac Guard ®PATENT PENDINGShaft Special shaped elastomer Magnetic Fluid12Test conditions: 25, speed = 300 rpm, vacuum pressure = E-4PaRotation regime: CW for 2 min. rest for 5 sec CCW for 2 min. repeatedTable of dimensions (for reference)Comparison PropertiesNecessary 131.Solvents or other fluids (such as acetone,alcohol, water and oils) or contaminants (such as solids and dust particles) inside a magnetic fluid seal can impact on performance. Take care to protect the seals from contamination. To clean the exterior of the seal, use a clean room wiper impregnated with a small quantity of ethyl alcohol. Note that too much ethyl alcohol on the wiper can cause drips, which could contaminate the seal and affect performance. 2.Leak testing should be performed using an Heleak tester. Never use alcohol or solvents for leak tests. Solvents can contaminate the seal and affect performance.3.Do not exceed the rated pressure (98 kPafor vacuum seals, or for pressurized seals, the maximum pressure stated on the delivery specifications or delivery drawings).4.Magnetic fluid seals designed for inert gasesshould not be used with reactive gases.Reactive gases may affect performance and/ or cause damage to structural components.Similarly, seals designed for use with reactive gases should only be used with the gases listed on the delivery specifications or delivery drawings. Non-listed gases may have an adverse effect on magnetic fluid and sealing performance.5.Magnetic fluid seals must not be subjected toshock, such as being dropped or struck witha hammer, since sudden shock can causedamage to the internal bearings and structural components. If a seal is dropped, check carefully for signs of damage. A damaged seal should be replaced immediately. Remember that internal damage and deformation may not be externally visible.6.When attaching a seal to equipment, centerthe seal first and use a coupling mechanism to connect it. When a seal is poorly centered, load imbalance may affect performance.7.Water-cooled seals should be cooled using 1- 3 liters per minute of ordinary mains water or equivalent coolant at normal temperature, taking care to avoid condensation. Condensation on the seal can affect performance and prevent normal rotation.8.Keep seals away from magnets and magnetizeddevices such as speakers, since magnetism can affect sealing performance.9.When using a vacuum seal for the first time,or when generating a vacuum after a long period of non-use, there may be a slight initial increase in pressure. Also, starting torque and loss torque tends to increase with the length of time that the seal is unused or in storage. These phenomena are associated with partial pressure balance and segmentation of magnetic fluid. For best results, the seal should be acclimatized with at least 20 rotations prior to generating a vacuum.10.Where the chamber of a reactive gasvacuum seal is released to the environment,a cycle purge with N2 gas is recommendedin order to improve the consistency of sealing performance.11.Seals should not be stored in locations thatare humid, dusty, or subject to extremes of temperature. Ideally, seals should be kept in a clean room or other environment with temperature and humidity control. Do not open the vacuum packaging until ready to install the seal.Operating instructions1.Do not touch the product while in operation.2.Where a vacuum seal is suspected of causingabnormal pressure, stop the equipment and perform an He leak test. If the vacuum seal is found to be faulty, remove and replace immediately.3.In the event of bad rotation, stop the equipmentand turn the shaft by hand. If the rotation is found to be faulty, replace the seal.4.If the seal is dropped or otherwise subjectedto a strong external force, stop the device immediately and perform a leak test. Also turn the shaft by hand. If rotation is found to be faulty, replace the seal.Usage and handling tipsUsage and handling tips for magnetic fluid seals14。

磁流体密封磁流体就是以液体形式存在的磁性材料,它是由粒径约为10nm的强磁性粒子,通过表面吸附界面活性剂分子而稳定分散于合适基液中所形成的一种胶态体系。

根据所含的磁性粒子不同,可分为铁氧体系、金属系和氮化铁系3类。

根据基液的不同可为水基、油基、醚基和酯基。

磁流体是功能材料中的一支新秀,它既具有磁性又具有流动性, 在重力和磁力作用下能够保持稳定, 不会出现沉淀或分层现象。

与其他液体相比,磁流体具有以下特点:(1) 在外加磁场下, 有悬浮在载体中的能力。

(2) 既具有液体的流动性, 又具有固体磁性材料的特性, 有感应磁通的能力。

(3) 调节外加磁场强度, 可以改变磁流体的表观比重和粘度, 能使磁性的固体稳定地悬浮在其中。

(4) 超声波在磁流体中传播时, 其速度以及衰减与外磁场有关, 并显示各向异性。

它的介电常数也是各向异性的。

光通过稀释的磁流体时, 或磁流体的薄层时, 会产生光的双折射现象。

当磁化时, 使相对于磁场方向具有光的各向异性, 具有高的折射率。

此外, 在交变磁场中还具有磁粘滞现象。

(5) 在垂直磁场的作用下, 会自发地形成稳定的波峰。

(6) 对外加磁场的响应速度快, 撤去外磁场后,磁流体中的磁性粒子很快呈现无规则分布 ,即在无外加磁场时, 磁流体本身是不显磁性的。

(7) 磁流体在外加磁场的作用中, 将流向并固定在磁场强度高的一方。

对磁流体的研究起源于50 年代,标志是美国的Papell 在1963 年获得的第一个磁流体制备专利,并于1965 年在美国的NASA 航天产品的密封中获得成功应用。

自此引发了对这种新型材料的研究开发和应用,并不断的取得新的进展,一步步的从实验室迈向实用化。

70 年代我国开始进行磁流体的基础研究和应用探索。

磁流体最通常的制备方法是借助于共同沉淀法制得粒度约为10nm 的磁铁矿之类铁氧体之后,吸附以界面活性剂,然后分散于油或水中即制成磁流体。

新近又开发成功了将比铁氧体饱和磁化强应更大的纳米金属铁粉分散于液体中的磁流体,它是在水中添加粒径大的正离子或负离子(取代界面活性剂) 而将铁磁性纳米颗粒分散于液体中的离子性磁流体。