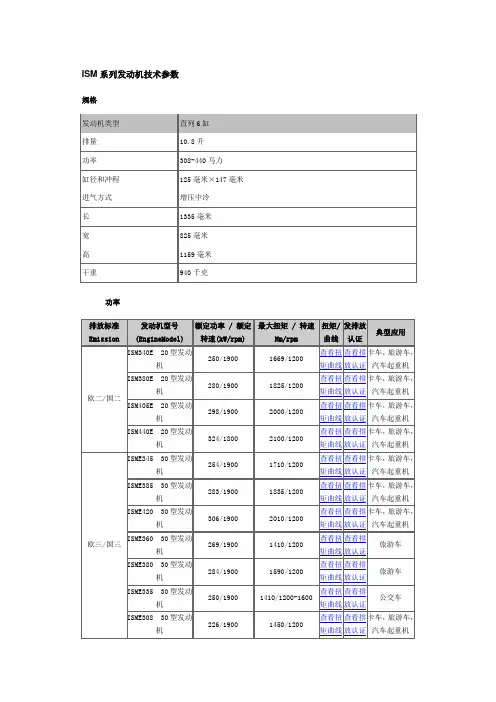

康明斯QSM柴油机主要技术规格

- 格式:docx

- 大小:39.37 KB

- 文档页数:3

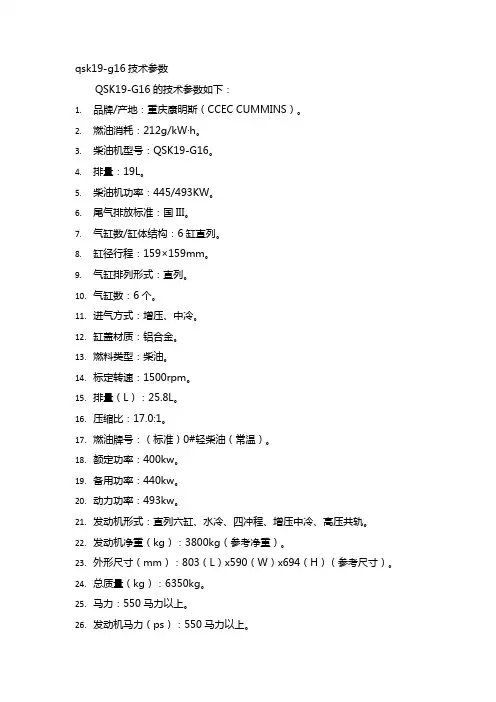

qsk19-g16技术参数QSK19-G16的技术参数如下:1.品牌/产地:重庆康明斯(CCEC CUMMINS)。

2.燃油消耗:212g/kW·h。

3.柴油机型号:QSK19-G16。

4.排量:19L。

5.柴油机功率:445/493KW。

6.尾气排放标准:国III。

7.气缸数/缸体结构:6缸直列。

8.缸径行程:159×159mm。

9.气缸排列形式:直列。

10.气缸数:6个。

11.进气方式:增压、中冷。

12.缸盖材质:铝合金。

13.燃料类型:柴油。

14.标定转速:1500rpm。

15.排量(L):25.8L。

16.压缩比:17.0:1。

17.燃油牌号:(标准)0#轻柴油(常温)。

18.额定功率:400kw。

19.备用功率:440kw。

20.动力功率:493kw。

21.发动机形式:直列六缸、水冷、四冲程、增压中冷、高压共轨。

22.发动机净重(kg):3800kg(参考净重)。

23.外形尺寸(mm):803(L)x590(W)x694(H)(参考尺寸)。

24.总质量(kg):6350kg。

25.马力:550马力以上。

26.发动机马力(ps):550马力以上。

27.电控系统类型:单体泵、电控高压共轨系统、高压共轨系统、国三高压共轨、国三电控单体泵。

28.电控相位器个数:8个电控相位器,但必须确认和原车匹配,否则可能损坏发动机,造成严重后果。

29.适用车型种类:发电机组、发电机组潍柴英致汽车发动机常见配件产品类型使用此配件型号(型号较多)、曲轴动平衡检查、J8试磨装置与J5切向半径检测试验方法应用方向汽摩机械厂家机油要适用保养用品等。

30.其他参数:额定转速为1500rpm,最大扭矩为1736N m,机油容量为88升,带飞轮壳及配重块,采用B系列机体和L系列缸盖等,适用发电机组和汽修学校做磨合及平衡试验设备教学产品演示汽摩学院设计等等配套说明按机型定制各种汽车机械教学用模型配件实训设备柴油机试验台,根据具体要求来配试,为各大院校提供方便易操作的实训设备。

销售热线:137********(李辰)华动牌CUMMINS(康明斯)系列柴油发电机组:华东动力CUMMINS(康明斯)系列机组选用康明斯发动机。

华动与康明斯的合作已有近十年的历程,高可靠性,低使用成本的华动康明斯系列机组,赢得了如军队、交通工程系统、工矿企业等行业用户的钟爱。

康明斯公司创建于1919年,总部位于美国印第安纳州哥伦布市。

康明斯公司在全球137个国家和地区拥有680多家分销商,5000多个服务网点遍布世界各地,作为中国发动机行业最大的外国投资者,康明斯在中国拥有重庆康明斯发动机有限公司(生产M、N和K系列柴油机)及东风康明斯发动机有限公司(生产B、C和L系列柴油机)等制造企业,并以康明斯全球统一的质量标准生产。

通过华动及康明斯公司遍布全国的服务网,为用户提供了最快捷的服务保障。

华动牌柴油发电机组发电机采用英国独资无锡新时代斯坦福发电机和华动牌发电机英国独资无锡新时代斯坦福发电机简介:总部设在英国的新时代国际有限公司是世界交流发电机技术先导和首屈一指的生产商,交流4级5KW—3000KW发电机在世界市场上占有30%以上份额,在英国、印度、美国、印度尼西亚及中国的无锡设有生产厂,斯坦福交流发电机是在国际标准ISO9001要求中按多种国际认可标准完成。

斯坦福电机具有以下几点优越性能:1、四级无刷自励式、防滴漏结构(IP22防护等级)。

H级绝缘,为发电机在恶劣环境中运行提供保障。

2、定子是2/3节距绕制,能有效抑制输出电压的波形畸变,及减少磁场发热。

3、转子装配前经过动平衡,完美的阻尼器绕组帮助减少非恒定负荷下的电压偏差和热量。

4、励磁机转子的输出功率通过三相全波桥式整流器输给主机转子,该整流器由一浪涌抑制器保护,以免由诸如短路或者并联时相位失步而引起的冲击造成损坏。

5、自动电压调节器(AVR)具有保护发动机的自动减荷特性,允许一次性向发电机施加全载,稳态电压调整率可实现±0.5或±1%若选择永磁发电机励磁(PMG)系统,发电机具有输高电动机起动能力并对由非线性负载(如可控硅直流发动机、UPS等)产生的主机定子输出电压波形变具有抗扰性。

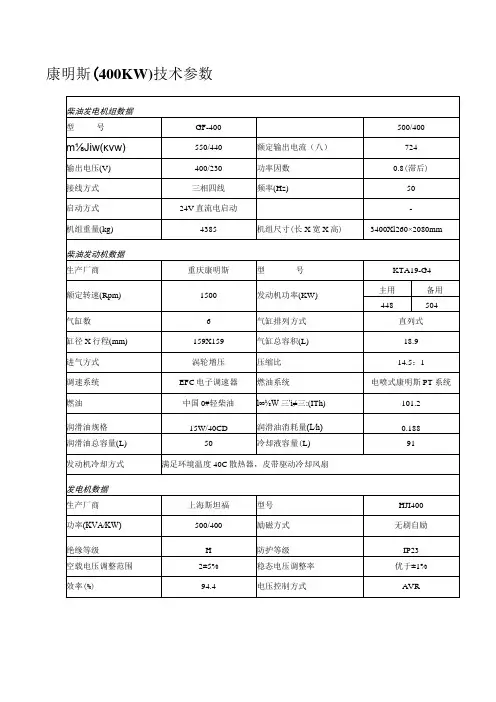

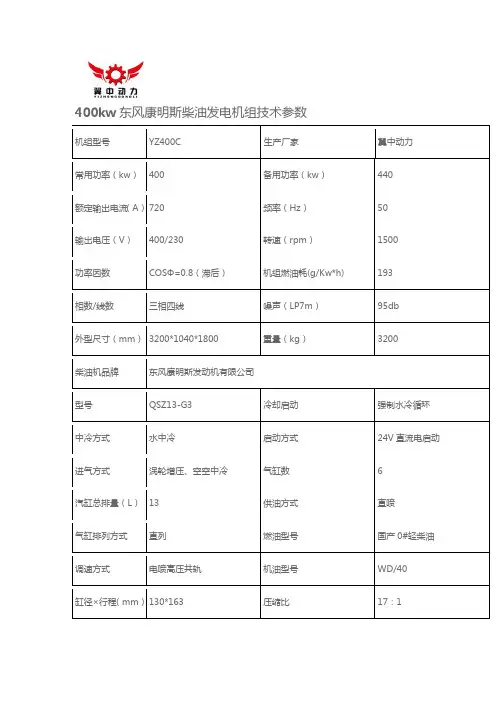

400kw东风康明斯柴油发电机组技术参数

机组型号YZ400C生产厂家翼中动力

常用功率(kw)400备用功率(kw)440

额定输出电流(A)720 频率(Hz)50

输出电压(V)400/230转速(rpm)1500

功率因数COSΦ=0.8(滞后)机组燃油耗(g/Kw*h)193

相数/线数三相四线噪声(LP7m)95db

外型尺寸(mm)3200*1040*1800重量(kg)3200

柴油机品牌东风康明斯发动机有限公司

型号QSZ13-G3 冷却启动强制水冷循环中冷方式水中冷启动方式24V直流电启动进气方式涡轮增压、空空中冷气缸数 6

汽缸总排量(L)13供油方式直喷

气缸排列方式直列燃油型号国产0#轻柴油调速方式电喷高压共轨机油型号WD/40

缸径×行程(mm)130*163压缩比17:1。

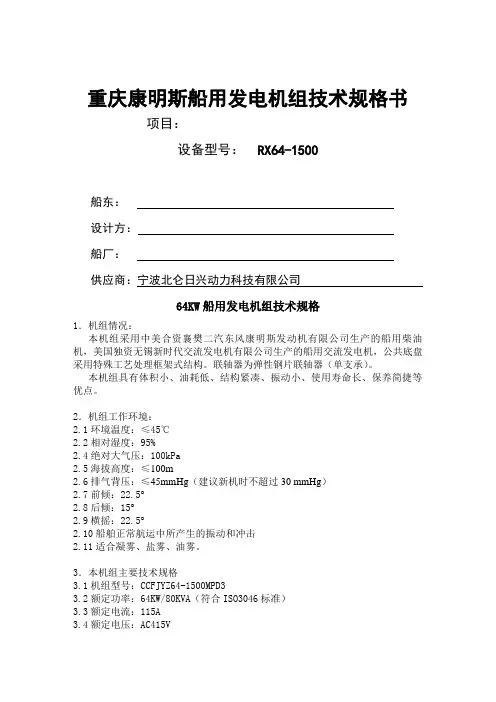

重庆康明斯船用发电机组技术规格书项目:设备型号:RX64-1500船东:设计方:船厂:供应商:宁波北仑日兴动力科技有限公司64KW船用发电机组技术规格1.机组情况:本机组采用中美合资襄樊二汽东风康明斯发动机有限公司生产的船用柴油机,美国独资无锡新时代交流发电机有限公司生产的船用交流发电机,公共底盘采用特殊工艺处理框架式结构。

联轴器为弹性钢片联轴器(单支承)。

本机组具有体积小、油耗低、结构紧凑、振动小、使用寿命长、保养简捷等优点。

2.机组工作环境:2.1环境温度:≤45℃2.2相对湿度:95%2.4绝对大气压:100kPa2.5海拔高度:≤100m2.6排气背压:≤45mmHg(建议新机时不超过30 mmHg)2.7前倾:22.5°2.8后倾:15°2.9横摇:22.5°2.10船舶正常航运中所产生的振动和冲击2.11适合凝雾、盐雾、油雾。

3.本机组主要技术规格3.1机组型号:CCFJYZ64-1500MPD33.2额定功率:64KW/80KVA(符合ISO3046标准)3.3额定电流:115A3.4额定电压:AC415V3.5功率因数:0.8(滞后)3.6频率:50HZ3.7相数:三相三线制(N极留在发电机接线盒内)3.8起动方式:DC24V电起动3.9额定转速:1500r.p.m.3.10机组过载能力:机组每次运行12小时期间允许以额定功率110%负载运行1/2小时。

(110%负载运行每年不超过60小时)3.11机组电气系统相间及相地间的绝缘不低于2兆欧3.12机组重量(净重):约1050KG3.13电压调整率:±1.5%(从空载到100%负载)3.14机组外形尺寸:长×宽×高(高度指到排气弯管)1150×750×1000mm(具体实际尺寸详见正式蓝图)4.机组结构组成4.1柴油机型号:6BT5.9-G3(M)4.1.1柴油机形式:直列、6缸、四冲程废气涡轮增压、中冷。

机组使⽤说明书QSM11+康明斯应急/消防柴油机⽔泵机组使⽤说明书(QSM11机型)编制:任镍校核:黎鹏飞审定:李伟宁中船集团长海⾼新技术有限公司七⼀⼆研究所1. 概述1.1 ⽤途本机组⼴泛应⽤于现代化冶⾦炉或不间断供⽔场所,消防供⽔系统及核反应堆的最后⼀级安全保护装置。

由于使⽤要求不同,应急⽤柴油机⽔泵机组设备的组成也不相同。

1.1组成应急柴油机⽔泵机组由安装在公共底板的柴油机、⽔泵和单独安装的控制柜及电池组组成。

1.1.1柴油机柴油机的安装、使⽤、维护注意事项,详见随机提供的柴油机使⽤说明书等有关⽂件。

操作者必须掌握柴油机的操作规程,并严格按照使⽤说明书中的有关规定进⾏使⽤、维护和保养。

1.1.2⽔泵⽔泵的要求,详见随机组提供的⽔泵安装使⽤说明书,并严格参照执⾏。

1.1.3控制柜控制柜是机组的控制中枢。

在使⽤过程中必须严格按本说明书中有关规定进⾏操作和维护。

1.1.4蓄电池组每套机组配套直流24伏电池组,它是机组启动的动⼒源,因⽽对它的使⽤维护保养的好坏,直接关系到机组的启动性能。

按照电池的使⽤维护说明书中的规定对电池组进⾏维护保养。

2.机组安装详见随机组提供的机组安装说明书。

3.启动、运⾏与停车3.1 ⾸次启动与运⾏(指装配完后,⾸次启动与运⾏)3.1.1 ⾸次启动与怠速运⾏a. 按柴油机使⽤说明书进⾏全⾯准备和对柴油机进⾏检查,按⽔泵使⽤说明书,对⽔泵及管路进⾏全⾯检查,按本使⽤说明书有关规定做好启动前准备⼯作。

检查机组有⽆异常现象。

b.将“速度控制”开关旋⾄“怠速”,“离合器控制”转换开关打到“分”,合上控制柜⾯板上的“直流电源”、断路器,此时准备启动指⽰灯亮。

c.将控制柜板⾯上“操作⽅式选择”转换开关旋⾄“机旁”位置。

d.按下“启动”按钮启动运⾏。

e.启动成功后,运⾏信号灯亮。

f.将“速度控制”开关旋⾄“额定”,柴油机⾃动升到额定转速。

g.观察检查柴油机的运⾏是否正常。

h.如果发现有故障,停机并检查柴油机,同时对照故障闪光代码并查出故障代码含义及故障原因,并及时解决;(故障代码对照表见附录)i.如没有发现问题,正常运⾏5min后按停机按钮,柴油机停机。

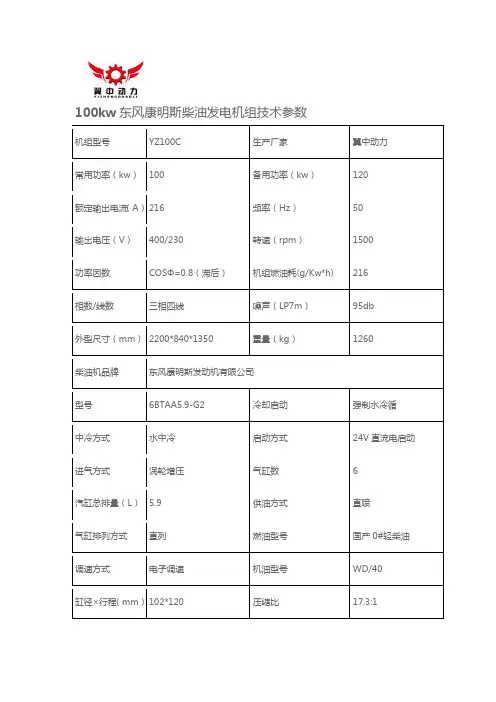

100kw东风康明斯柴油发电机组技术参数

机组型号YZ100C生产厂家翼中动力

常用功率(kw)100备用功率(kw)120

额定输出电流(A)216 频率(Hz)50

输出电压(V)400/230转速(rpm)1500

功率因数COSΦ=0.8(滞后)机组燃油耗(g/Kw*h)216

相数/线数三相四线噪声(LP7m)95db

外型尺寸(mm)2200*840*1350重量(kg)1260

柴油机品牌东风康明斯发动机有限公司

型号6BTAA5.9-G2 冷却启动强制水冷循

中冷方式水中冷启动方式24V直流电启动进气方式涡轮增压气缸数 6

汽缸总排量(L) 5.9供油方式直喷

气缸排列方式直列燃油型号国产0#轻柴油调速方式电子调速机油型号WD/40

缸径×行程(mm)102*120压缩比17.3:1。

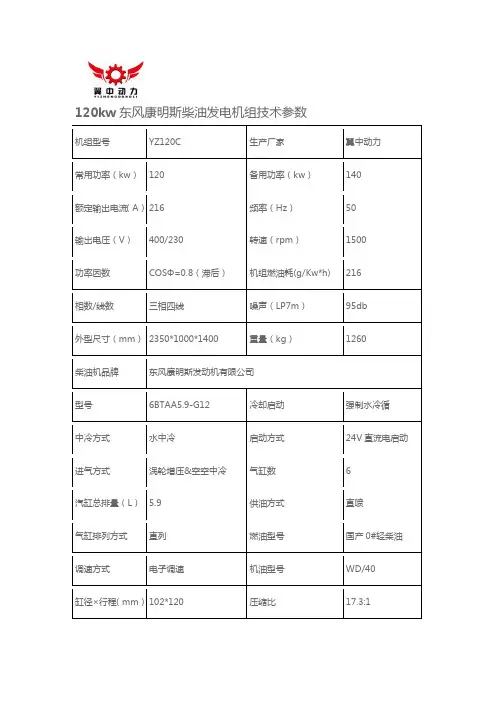

120kw东风康明斯柴油发电机组技术参数

机组型号YZ120C生产厂家翼中动力

常用功率(kw)120备用功率(kw)140

额定输出电流(A)216 频率(Hz)50

输出电压(V)400/230转速(rpm)1500

功率因数COSΦ=0.8(滞后)机组燃油耗(g/Kw*h)216

相数/线数三相四线噪声(LP7m)95db

外型尺寸(mm)2350*1000*1400重量(kg)1260

柴油机品牌东风康明斯发动机有限公司

型号6BTAA5.9-G12 冷却启动强制水冷循

中冷方式水中冷启动方式24V直流电启动进气方式涡轮增压&空空中冷气缸数 6

汽缸总排量(L) 5.9供油方式直喷

气缸排列方式直列燃油型号国产0#轻柴油调速方式电子调速机油型号WD/40

缸径×行程(mm)102*120压缩比17.3:1。

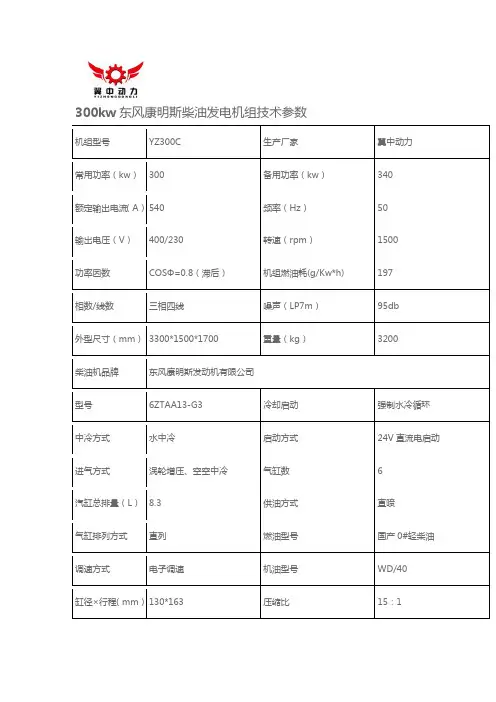

300kw东风康明斯柴油发电机组技术参数

机组型号YZ300C生产厂家翼中动力

常用功率(kw)300备用功率(kw)340

额定输出电流(A)540 频率(Hz)50

输出电压(V)400/230转速(rpm)1500

功率因数COSΦ=0.8(滞后)机组燃油耗(g/Kw*h)197

相数/线数三相四线噪声(LP7m)95db

外型尺寸(mm)3300*1500*1700重量(kg)3200

柴油机品牌东风康明斯发动机有限公司

型号6ZTAA13-G3 冷却启动强制水冷循环中冷方式水中冷启动方式24V直流电启动进气方式涡轮增压、空空中冷气缸数 6

汽缸总排量(L)8.3供油方式直喷

气缸排列方式直列燃油型号国产0#轻柴油调速方式电子调速机油型号WD/40

缸径×行程(mm)130*163压缩比15:1。

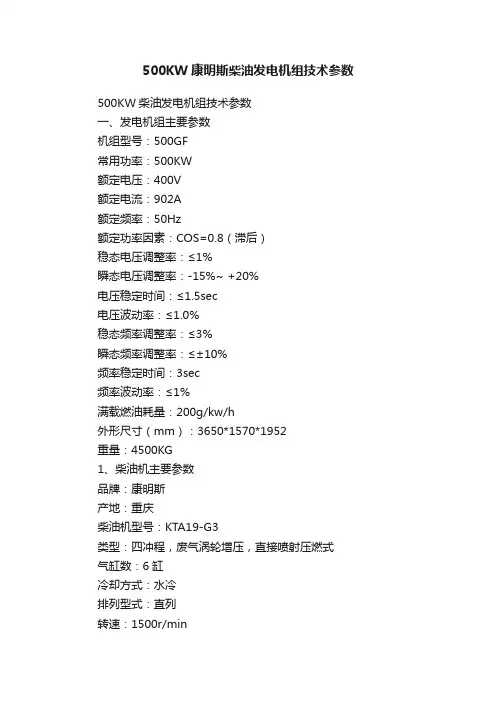

500KW康明斯柴油发电机组技术参数

500KW柴油发电机组技术参数

一、发电机组主要参数

机组型号:500GF

常用功率:500KW

额定电压:400V

额定电流:902A

额定频率:50Hz

额定功率因素:COS=0.8(滞后)

稳态电压调整率:≤1%

瞬态电压调整率:-15%~ +20%

电压稳定时间:≤1.5sec

电压波动率:≤1.0%

稳态频率调整率:≤3%

瞬态频率调整率:≤±10%

频率稳定时间:3sec

频率波动率:≤1%

满载燃油耗量:200g/kw/h

外形尺寸(mm):3650*1570*1952

重量:4500KG

1、柴油机主要参数

品牌:康明斯

产地:重庆

柴油机型号:KTA19-G3

类型:四冲程,废气涡轮增压,直接喷射压燃式

气缸数:6缸

冷却方式:水冷

排列型式:直列

转速:1500r/min

启动方式:DC24V

2、发电机主要参数

发电机品牌:英格

产地:无锡

发电机型号:EG-500KW

类型:无刷(A VR自动调压)

相数接法:三相四线

绝缘等级:H级

二、机组组成部分

1)柴油机

2)发电机

3)控制屏

三、控制屏

该控制屏为普通一体式控制屏。

并带有电压、电流、频率、水温、油压显示,柴油机具有高水温、低油压、超速、停机保护等功能。

四、随机附件:

波纹管、弯管、消声器、电瓶及连接线、减震垫、资料各壹套。

-;HA?DIBasic technical dataNumber of cylinders.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .12 Cylinder arrangement ... ... ... ... ... ... ... ... ... ... ... ... ... ... 60° Vee Cycle. ... ... ... ... ... ... ... ... ... ... ... ..4 stroke, compression ignition Induction system... ... ... ... ... ... ... ... ... ... ... ... ... ...Turbocharged Compression ratio. ... ... ... ... ... ... ... ... ... ... ... ... ..13,6:1 nominal Bore... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 160 mm Stroke ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 190 mm Cubic capacity... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..45.842 litres Direction of rotation... ... ... ... ...Anti-clockwise viewed on flywheel Firing order ... ... ... ... ... ... ...1A,6B,5A,2B,3A,4B,6A,1B,2A,5B.4A,3B Cylinder 1 furthest from flywheelCylinders designated ‘A’ are on the left side of the engine when viewed from the front (opposite end to flywheel)Total weight Electrounit (engine only)4012TAG1A/2A(dry).. ... ... ... ... ... ... ... ... ... ... ... ... ... ... 4400 kg 4012TAG1A/2A(wet) ... ... ... ... ... ... ... ... ... ... ... ... ... ... 4604 kg Overall dimensions ... ... ... ... ... ... ... ... ... ... ... ...Height 2118 mm .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..Length 2731 mm .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ....Width 1723 mm Moment of inertia.. ... ... ... ... ... ... ... ... ... ... ... .Engine 9.73 kgm2 .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ..Flywheel 9.57 kgm2 Cyclic irregularity for engine/flywheel (Prime power):4012TAG1A ... 1500 rev/min ... ... ... ... ... ... ... ... ... ... ... ... 1,714 4012TAG2A ... 1500 rev/min ... ... ... ... ... ... ... ... ... ... ... ... 1,669RatingsSteady state speed stability at constant load. ... ... ... ... ...± 0,25% Electrical ratings are based on average alternator efficiency and are for guidance only (0,8 power factor being used). Operating pointEngine speed. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...1500 rev/min Static injection timing.. ... ... ... ... ... ... ... See engine number plate Cooling water exit temperature.. ... ... ... ... ... ... ... ... ... ... .<98 °C Fuel dataTo conform to BS2869 class A1, A2.PerformanceSound pressure level 1500 rev/min ... ... ... ... ... ... ...106/112 dBA Note:All data based on operation to ISO 3046/1, BS 5514 and DIN 6271 standard reference conditions.Test conditionsAir temperature... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...25 °C Barometric pressure... ... ... ... ... ... ... ... ... ... ... ... ... ... ...100 kPa Relative humidity ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... (30)Air inlet restriction at maximum power (nominal)... ... ... ... 2,5 kPa Exhaust back pressure (nominal)... ... ... ... ... ... ... ... ... ... 3,0 kPa4000 Series 4012TAG1A 4012TAG2AGeneral installation 4012TAG1ADesignation Units50Hz 1500 rev/min60Hz 1800 rev/min ContinuousBaseloadPrimePowerStandbyMaximumContinuousBaseloadPrimePowerStandbyMaximumGross engine power kWb94211781292---Fan power kWm42---Net engine power kWm90011361250---BMEP gross bar1620,522,5---Combustion air flow m3/min7695105---Exhaust gas temperature max (after turbo)°C435460470---Exhaust gas flow max (after turbo)m3/min257---Boost pressure ratio-2,73,223,53---Mechanical efficiency%899192---Overall thermal efficiency%424342---Friction power and pumping losses kWm120---Mean piston speed m/s9,5---Engine coolant flow (min)l/s17---Typical Genset Electrical Output 0,8 pf 25 °C (100 kPa)kVA108013631500---kWe86410911200---Assumed alternator efficiency%96---Diesel Engine - ElectrounitGeneral installation 4012TAG2ANote:Not to be used for CHP design purposes. (Indicative figures only). Consult Perkins Engines Co. Ltd. Assumes complete combustion.Continuous Baseload rating Power available for continuous full load operation. Prime Power rating is available for unlimited hours per year with a variable load of which the average engine load factor is 80% of the published prime power rating, incorporation of a 10% overload for 1 hour in every 12 hours of operation which is permitted. Standby Power rating is for the supply of emergency power at variable load for the duration of the non-availability of the mains power supply. NO OVERLOAD capacity is available at this rating. Engines must not be allowed to have facilities for parallel operation with the mains supply. This rating should be applied only when reliable mains power is available. Should this not be the case then refer to Prime Power rating. A standby rated engine should be sized for an average load factor of 80% based on published standby rating for 500 operating hours per year. Standby ratings should never be applied except in true emergency power failure conditions.DesignationUnits 50Hz 1500 rev/min60Hz 1800 rev/minContinuous BaseloadPrime Power Standby Maximum Continuous BaseloadPrime Power Standby MaximumGross engine power kWb 103712961422---Fan power kWm 42---Net engine power kWm 99512541380---BMEP gross bar 18,122,624,8---Combustion air flowm 3/min 83,6106110---Exhaust gas temperature max (after turbo)°C 442472483---Exhaust gas flow max (after turbo)m 3/min 285---Boost pressure ratio -2,83,533,84---Mechanical efficiency %889292---Overall thermal efficiency%424241---Friction power and pumping losses kWm 120---Mean piston speed m/s 9,5---Engine coolant flowl/s 17---Typical Genset Electrical Output 0,8 pf 25 °C (100 kPa)kVA 119415051656---kWe 95512041325---Assumed alternator efficiency%96---Energy balanceNote:Not to be used for CHP design purposes. (Indicative figures only). Consult Perkins Engines Co Ltd. Assumes complete combustion. 4012TAG1A4012TAG2A Units1500 rev/min1800 rev/min ContinuousBaseloadPrimePowerStandbyMaximumContinuousBaseloadPrimePowerStandbyMaximumEnergy in fuel kWt223827703117---Energy in power output (gross) kWb94211781292---Energy to cooling fan kWm424242---Energy in power output (net)kWm90011361250---Energy to exhaust kWt680760924---Energy to coolant and oil kWt353434465---Energy to radiation kWt4495100---Energy to charge coolers kWt219303336---Units1500 rev/min1800 rev/min ContinuousBaseloadPrimePowerStandbyMaximumContinuousBaseloadPrimePowerStandbyMaximumEnergy in fuel kWt244430783477---Energy in power output (gross) kWb103712961422---Energy to cooling fan kWm424242---Energy in power output (net)kWm99512541380---Energy to exhaust kWt7508771013---Energy to coolant and oil kWt372464511---Energy to radiation kWt4995108---Energy to charge coolers kWt236346423---Cooling systemRecommended coolant: 50% inhibited ethylene glycol or 50% inhibited propylene glycol and 50% clean fresh water. For combined heat and power systems and where there is no likelihood of ambient temperatures below 10 °C then clean ‘soft’ water may be used, treated with 1% by volume of Perkins inhibitor in the cooling system. The inhibitor is available in bottles under Perkins Part No. 21825 735.Nominal jacket water pressure in crankcase. ... ... ... ... ... .1,7 bar The following is a guide based on ambient air conditions of 52 °C on a Perkins supplied radiator.Total coolant capacity:Electrounit (engine only) ... ... ... ... ... ... ... ... ... ... ... ... ... 73 litres ElectropaK (engine/radiator) . ... ... ... ... ... ... ... ... ... ... ..235 litres Pressure cap setting.. ... ... ... ... ... ... ... ... ... ... ... ... ... ...0,69 bar Fan. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...Incorporated in radiator Diameter ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 1524 mm pusher) Ambient cooling clearance (open ElectropaK Prime power) based on air temperature at fan 3 °C above ambient.4012TAG1A4012TAG2ACoolant pump speed andmethod of drive.. ... ... ... ... ... ... ... ... ... ... ... 1,4 x e rev/min gear Maximum static pressure head on pumpabove engine crank centre line.. ... ... ... ... ... ... ... ... ... ... ... ..7 m Maximum external permissible restrictionto coolant pump flow.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... .20 kPa Thermostat operating range... ... ... ... ... ... ... ... ... ... ... ..71-85 °C Shutdown switch setting ... ... ... ... ... ... ... ... ... ... ... 101 °C rising Coolant immersion heater capacity ... ... ... ... ... ... ... ... ..4 kW x 2 *4012TAG2A **4012TAG1A Lubrication systemRecommended lubricating oil to conform with the specification of API CG4 15W/40 .Lubricating oil capacity:Sump maximum.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 159 litres Sump minimum... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 136 litres Lubricating oil temperature maximum to bearings.. ... ... ... 105 °C Lubricating oil pressure:at 80 °C temperature to bearing gallery (minimum) ... ... 0,34 MPa 4012TAG1A4012TAG2A*Typical after 250 hoursSump drain plug tapping size.. ... ... ... ... ... ... ... ... ... ... ... ... ..G1 Oil pump speed and method of drive..1,4 x e rev/min, gear driven Oil pump flow 1500 rev/min. ... ... ... ... ... ... ... ... ... ...6,0 litres/sec Shutdown switch setting.. ... ... ... ... ... ... ... ... ... ...1,93 bar falling Normal operating anglesFore and aft. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...5°Side tilt ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... (10)Maximum additional restriction (duct allowance) to cooling airflow (Prime power) and resultant minimum airflowAmbient clearance 50% glycol Duct allowancemm H20Min airflowm3/minrev/min rev/min rev/min 150018001500180015001800 52 °C52 °20-1872-Maximum additional restriction (duct allowance) to cooling airflow (Prime power) and resultant minimum airflowAmbient clearance 50% glycol Duct allowancemm H20Min airflowm3/minrev/min rev/min rev/min 150018001500180015001800 52 °C52 °20-1872-Jacket cooling water data Units1500rev/min1800rev/minCoolant flow 4012TAG1A/2A l/s17,0-Coolant exit temperature (max)°C98-Coolant entry temperature (min)°C70-Coolant entry temperature (max) *°C85-Coolant entry temperature (max)**°C88-Oil consumptionPrime PowerUnits1500rev/min1800rev/min After running-in*g/kWhr0,50-Oil flow rate from pump I/s6,0-Oil consumptionPrime PowerUnits1500rev/min1800rev/min After running-in*g/kWhr0,51-Oil flow rate from pump I/s6,0-Fuel systemRecommended fuel... ..To conform to BS2869 1998 Class A1, A2 Type of injection system ... ... ... ... ... ... ... ... ... ... ..Direct injection Fuel injection pump... ... ... ... ... ... ... ... ... .Combined unit injector Fuel injector... ... ... ... ... ... ... ... ... ... ... ... .Combined unit injector Fuel injector opening pressure.. ... ... ... ... ... ... ... ... ... ... .234 bar Fuel lift pump. ... ... ... ... ... ... ... ... ... ... ... ... ... .Tuthill TCH 1-089 Delivery/hour at 1500 rev/min... ... ... ... ... ... ... ... ... ... .1020 litres Heat retained in fuel to tank . ... ... ... ... ... ... ... ... ... ... ... ..9,5 kW Temperature of fuel at lift pump to be less than ... ... ... ... ... 58 °C Fuel lift pump pressure.. ... ... ... ... ... ... ... ... ... ... ... ... ... ..3,0 bar Fuel lift pump maximum suction head... ... ... ... ... ... ... ... ... 2,5 m Fuel lift pump maximum pressure head (see Installation Manual) Fuel filter spacing.. ... ... ... ... ... ... ... ... ... ... ... ... ... ..10 microns) Governor type... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .Electronic Torque at the governor output shaft.. ... ... ... ... ... ... ... 1,631 kgm Static injection timing ... ... ... ... ... ... ... .See engine number plate Tolerance on fuel consumption. ... ... ... ... ... .To ISO 8528-1 1993 4012TAG1A4012TAG2A Induction systemMaximum air intake restriction of engine:Clean filter.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 127 mm H20 Dirty filter ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... 380 mm H20 Air filter type... ... ... ... ... ... ... ... ... ... ... ... ... ...4998-00-00 MF&T Exhaust systemMaximum back pressure for total system.Exhaust outlet flange size.. ... ... ... ... ... ... .2 x 254 mm (table ‘D’) For recommended pipe sizes, refer to the Installation Manual. Electrical systemType... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...Insulated return Alternator ... ... ... ... ... ... ... ... ... ... 24 volts with integral regulator Alternator output. ... ... ...40 amps at a stabilised output 28 volts at20 °C ambient Starter motor.. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .. 24 volts Starter motor power ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...16,4 kW Number of teeth on flywheel... ... ... ... ... ... ... ... ... ... ... ... ... ..156 Number of teeth on starter motor... ... ... ... ... ... ... ... ... ... ... (12)Minimum cranking speed at (0 °C). ... ... ... ... ... ... ... .120 rev/min Pull-in current of each starter motor solenoid... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .30 amps at 24 volts Hold-in current of each starter motor solenoid... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...9 amps at 24 volts Engine stop solenoid.. ... ... ... ... ... ... ... ... ... ... ... ... ... ...24 volts Pull-in current of stop solenoid... ... ... ... ... ... .60 amps at 24 volts Hold-in current of stop solenoid.. ... ... ... ... ... 1,1 amps at 24 voltsFuel consumption (gross)Designation g/kWh Litres/hr rev/min1500180015001800 At Standby Max power rating203-309-At Prime Power rating199-276-At Continuous Baseload rating197-218-At 75% of Prime Power rating195-203-At 50% of Prime Power rating194-134-At 25% of Prime power rating207-72-Fuel consumption (gross)Designation g/kWh Litres/hr rev/min1500180015001800 At Standby Max power rating206-345-At Prime Power rating201-306-At Continuous Baseload rating197-240-At 75% of Prime Power rating197-225-At 50% of Prime Power rating195-149-At 25% of Prime power rating207-79-Designation Units1500rev/min1800rev/min 4012TAG1A mmH20949-4012TAG2A mmH20612-Engine mountingPosition of centre of gravity (wet engine) forward from rearface of crankcase .. ... ... ... ... ... ... ... ... ... ... ... ... ... ... ...771 mm Engine vertical centre line above crankshaft centre line ... .38 mm Maximum additional load applied to flywheel due to all rotating components ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... ... .850 kgStarting requirementsNotes:l Battery capacity is defined by the 20 hour rate at 0 °C.lThe oil specification should be for the minimum ambient temperature as the oil will not be warmed by the immersion heater.lBreakaway current is dependent on battery capacity available. Cables should be capable of handling the transient current which may be up to double the steady cranking current.TemperaturerangeRange Down to 0 °C(32 °F)Oil:Starter:Battery:Max breakaway current:Cranking current:Aids:Starter cable size:Maximum length:API CG4 15W/402 x 24V4 x 12 volts x 286 Ah 1600 amps 810 ampsNot necessary 120 mm 26mGA DrawingLoad acceptance (cold)4012TAG1A1500 rev/min4012TAG2A1500 rev/minAbove complies with requirements of Classifications 3 & 4 of ISO 8528-12 and G2 operating limits stated in ISO 8528-5.The above figures were obtained under test conditions as follows:Engine block temperature.. ... ... ... ... ... ..45 °C Alternator efficiency ... ... ... ... ... ... ... ... ... 96%Minimum ambient temperature.. ... ... ... ..10 °C Isochronous GoverningUnder Frequency Roll Off (UFRO) set to 1 Hz below rated frequency Typical alternator inertia. ... ... ... ... ... .50 Kgm 2All tests were conducted using an engine which was installed and serviced to Perkins Engines Company Limited recommendations.Initial load applicationwhen engine reaches rated speed(15 seconds max after engine starts to crank)2nd Load applicationImmediately after engine has recovered to rated speed(5 seconds after initial load application)Prime power%Load kWm/kWe Nett Transient frequency deviation%Frequency recovery time secondsPrime power%Load kWm/kWe Nett Transient frequency deviation%Frequency recovery time seconds63715/686< -10537422/405< -105Initial load applicationwhen engine reaches rated speed(15 seconds max after engine starts to crank)2nd Load applicationImmediately after engine has recovered to rated speed(5 seconds after initial load application)Prime power%Load kWm/kWe Nett Transient frequency deviation%Frequency recovery time secondsPrime power%Load kWm/kWe Nett Transient frequency deviation%Frequency recovery time seconds57715/686< -10543539/518< -105Noise levelsThe figures for total noise levels are typical for an engine running at Prime Power rating in a semi-reverberant environment and measured at a distance of one metre from the periphery of the engine.Octave analysisThe following histograms show an octave band analysis at the position of the maximum noise level.Total noise levelSound pressure level re: -20 x 10-6 paSpeed 1500 rev/min......Ambient noise level 84 dBA.Octave analysis performed at the position of maximum noise.4012TAG1A4012TAG2APOSITION 11500 rev/min 106 - dBA1800 rev/min ------- dBA1500 rev/min 106 - dBA1800 rev/min ------- dBAPOSITION 21500 rev/min 108 - dBA 1800 rev/min ------- dBA 1500 rev/min 108 - dBA 1800 rev/min ------- dBA POSITION 3 1500 rev/min 111 - dBA 1800 rev/min ------- dBA 1500 rev/min 111 - dBA 1800 rev/min ------- dBA POSITION 4 1500 rev/min 111 - dBA 1800 rev/min ------- dBA 1500 rev/min 111 - dBA 1800 rev/min ------- dBA 4012TAG1A 4012TAG2A 4012TAG1A 4012TAG2A 4012TAG1A 4012TAG2A4012TAG1A4012TAG2A POSITION 71500 rev/min 108 - dBA 1800 rev/min ------- dBA 1500 rev/min 108 - dBA 1800 rev/min ------- dBA POSITION 6 1500 rev/min 112 - dBA 1800 rev/min ------- dBA 1500 rev/min 112 - dBA 1800 rev/min ------- dBA POSITION 5 1500 rev/min 112 - dBA 1800 rev/min ------- dBA 1500 rev/min 112 - dBA 1800 rev/min ------- dBA 4012TAG14012TAG24012TAG14012TAG24012TAG1A4012TAG2AFR4012TAG1A4012TAG2AThe information given on technical data sheets are for standard ratings only. For ratings other than shown contact Perkins Engines Company Limited, Stafford.Notes-;HA?DI All information in the document is substantially correct at the time of printing but may be subsequently altered by the company.Distributed by 4000 Series4012TAG1A 4012TAG2A P u bl i c a t i o n N o . T S L 4253, I s s u e 3, J a n u a r y 2003. P r i n t e d i n E n g l a n d . © P e r k i n s E n g i n e s C o m p a n y L i m i t e d .Perkins Engines Company Limited Stafford ST16 3UB United Kingdom Telephone +44 (0)1785 223141Fax +44 (0)1785 。

250kw东风康明斯柴油发电机组技术参数

机组型号YZ250C生产厂家翼中动力

常用功率(kw)250备用功率(kw)292

额定输出电流(A)450 频率(Hz)50

输出电压(V)400/230转速(rpm)1500

功率因数COSΦ=0.8(滞后)机组燃油耗(g/Kw*h)193

相数/线数三相四线噪声(LP7m)95db

外型尺寸(mm)2800*1000*1500重量(kg)2000

柴油机品牌东风康明斯发动机有限公司

型号QSM11-G2 冷却启动强制水冷循环中冷方式水中冷启动方式24V直流电启动进气方式增压中冷气缸数 6

汽缸总排量(L)10.8供油方式电喷

气缸排列方式直列燃油型号国产0#轻柴油调速方式电子调速机油型号WD/40

缸径×行程(mm)125*147压缩比16.3:1。

200kw东风康明斯柴油发电机组技术参数

机组型号YZ200C生产厂家翼中动力

常用功率(kw)200备用功率(kw)220

额定输出电流(A)360 频率(Hz)50

输出电压(V)400/230转速(rpm)1500

功率因数COSΦ=0.8(滞后)机组燃油耗(g/Kw*h)197

相数/线数三相四线噪声(LP7m)95db

外型尺寸(mm)2600*970*1400重量(kg)1700

柴油机品牌东风康明斯发动机有限公司

型号6LTAA8.9-G2 冷却启动强制水冷循环中冷方式水中冷启动方式24V直流电启动进气方式涡轮增压&空空中冷气缸数 6

汽缸总排量(L)8.9供油方式直喷

气缸排列方式直列燃油型号国产0#轻柴油调速方式电子调速机油型号WD/40

缸径×行程(mm)114*145压缩比16.6:1。