日本电产nidec泵介绍概要

- 格式:doc

- 大小:3.43 MB

- 文档页数:15

Precision Gear Technology GuideNidec-SHiMPO cORPORATiONOur companyNIDEC-SHIMPO has established itself as the leading supplier of precision gearing solutions to the industrial automation mar-ketplace. Since 1952, when we introduced the world’s first mechanical variable speed drive, NIDEC-SHIMPO has expanded into a diverse manufacturer of high precision power transmission systems for highly dynamic motion control applications. In 1994, SHIMPO was acquired by the NIDEC Corporation and became formally known as NIDEC-SHIMPO. NIDEC-SHIMPO began to focus on accelerating production volumes as the global market for motion control and mechatronics grew at an acceler-ated rate. We saw a unique opportunity to supply our customer base with the highest variety of transmission technologies, which brought forward strain wave, index table and worm gear products to complement our existing portfolio of planetary and cycloidal gearheads. The result for our customers was a single source drive solutions supplier.Today, our company is shipping over 100,000 gearheads per month out of our manufacturing plants in Kyoto and Shanghai. Our products are used in robotics, machine tools, food packaging, printing, paper converting, material handling, medical, semiconductor and aerospace related systems. Our diverse product portfolio, state-of-the-art equipment, engineering know-how and manufacturing scale allow our customers to compete and expand their businesses globally. NIDEC-SHIMPO has over 2,400 employees strong with a presence across five continents. Our engineering staff, customer support team and dis-tribution partners undergo rigorous product training to ensure the quickest response to our customers’ needs. Our aim is to continue to innovate and provide the highest quality, best-in-class products and services for our customer base.Our Local capabilitiesNIDEC-SHIMPO services the North American marketthrough our Headquarters and 50,000 sq. ft. assembly fa-cility in Glendale Heights, Illinois. This facility houses oursales, design and application engineering and customersupport teams. We assemble over 75% of our productsin North America, most of which can ship within 1 week.Motor adapters are readily available for easy mountingto any servomotor manufacturers’ models. With over$3MM in inventory, next day delivery is available for sev-eral common models and for emergency replacementsfor equipment in the field. We are highly flexible and canfulfill custom requirements such as special output shaftsdimensions, coatings, lubrication, materials of construc-tion and integrated product assemblies.Our products are 100% exit-tested to ensure allperformance specifications are met, giving our cus-tomers security and peace of mind. Each gearboxis inspected for noise, backlash, vibration, no-loadrunning torque, concentricity and input shaft slip-ping using the latest equipment and methods. Our 5Year Standard Warranty is our way of demonstratingNIDEC-SHIMPO’s commitment to quality and durabil-ity over the long term. Local, personal support is aphone call or email away. Each NIDEC-SHIMPO cus-tomer has a dedicated team of customer service andtechnical support professionals, on-standby to assistwith pricing, delivery, sizing, repairs, installation sup-port or other needs. We strive to deliver the highestquality, value and service in the industry.VR Series Inline Planetary GearheadsExceptional value for mid to high end motion controlapplications with demanding accuracy requirementsThe widest range of frame sizes (042-285) and ratios(3-100) available in the marketBest-In-class backlash (≤3 arc-min), with reducedbacklash option availableBroad range of mounting adapters offer a simple,precise attachment to any motorMaintenance-free solution that is lubricated for life.High performance grease allows for flexible mount-ing in any orientationIndustry standard mounting dimensionsAssembled in the USA, with immediate deliveryVR FeaturesCarburized helical gears with proprietary secondaryfinishing process for higher accuracy and smooth,quiet operation. 40% higher tooth surface area thanthe industry standardOne piece output shaft and planet carrier with twobearings straddling the planet gears. Higher stiffness,torque capacity and safety factor, with guaranteedalignment of gearingUncaged needle roller bearings provide excellenttorque density and torsional rigidity. 43% larger bear-ing surface area compared to the rest of the industry Unique labyrinth input seal design greatly reducesheat and increases system efficiency. IP65 protection is available for wash down applicationsOptimized mounting system with active centering on motor pilot diameter guarantees alignment of motor. Motor can be installed in any orientationTrue concentric motor shaft clamping connection,optimized for your specific motor. Reduced inertia for dynamic performance and balanced for highspeed operationRing gear machined directly into the housing, not welded or pressed in. Provides greater concentricityand elimination of speed fluctuation3 2VRSF VRL VRB VRS VRT Inline Inline Inline Inline Inline Helical Planetary Helical Planetary Helical Planetary Helical Planetary Helical Planetary042-220047-285EV Series Right-angle Planetary Gearheads5Compact right-angle design for application where space and clearance are a serious limitation Exceptional value for mid to high end mo-tion control applications with demanding accuracy requirementsThe widest range of frame sizes ( 060-255) and ratios (3-105) available in the marketBroad range of mounting adapters offer a simple, precise attachment to any motorMaintenance-free solution that is lubricated for life. High performance grease allows for mounting in any orientationHollow output shaft available for flexible mounting to machinery Assembled in the USAeV FeaturesRight angle bevel gear configuration allows motor to be mounted at a 90 degree position from the gearbox, saving spaceCarburized helical gears with proprietary secondary finishing process for higher accuracy and smooth, quiet operation. 40% higher tooth surface area than the industry standardOne piece output shaft and planet carrier with two bearings straddling the planet gears. Higher stiffness, torque capacity and safety factor, with guaranteed alignment of gearingUncaged needle roller bearings provide excellent torque density and torsional rigidity. 43% larger bear-ing surface area compared to the rest of the industry Optimized mounting system with active centering on motor pilot diameter guarantees alignment of motor. Motor can be installed in any orientationTrue concentric motor shaft clamping connection, optimized for your specific motor. Reduced inertia for dynamic performance and balanced for high speed operationRing gear machined directly into the housing, not welded or pressed in. Provides greater concentricity and elimination of speed fluctuationNeV eVL eVS eVT Right-angle Right-angle Right-angle Right-angle Spiral Bevel/Planetary Spiral Bevel/Planetary Spiral Bevel/Planetary Spiral Bevel/Planetary070-235060-240064-2553-1004-100EJ Series Servo Worm GearheadsExceptionally quiet, smooth running design. Zero backlash availableNo change in envelope with increase in ratio. Up to 90:1 available in a single stage 300% shock load capacity combined with high overhung load capacityHigh repeatability with exact ratios, beneficial for tuningExcellent fit for continuous duty applications with continuous running speeds as high as 4,000 rpmFlexible mounting options include solidshaft, hollow shaft, dual shaft, ISO flange and shrink discSuperior environmental protection: stainless, black anodized or white epoxy coatings; IP65 orIP69K rated, with double input and output seals3Globoidal gear set – between 3-8 teeth in contact at once, allowing 300% shock load capacityAdapter–bushing connection al-lows simple mounting to virtually any servomotor manufacturerWide range of output mounting styles avail-able – hollow shaft, solid shaft, dual shaft, shrink disc, ISO flangeDouble oil seal and o-ring provide IP65 protectionTapered roller or ball bearings at input side Thermally efficient housings available in an-odized aluminum, cast iron or stainless steeleJ FeatureseJM eJL eJH EJP EJS Right-angle Right-angle Right-angle Right-angle Right-angle Globoidal Worm Globoidal Worm Globoidal Worm Globoidal Worm Globoidal Worm 02-0925-20015-3538-8939-76 5-605-905-605-605-60STH Series Rotary Index TablesSTH Features drive directions85mm pass through hole allows pass through of air lines, wiring or other peripheral components ≤2 arc-min backlash with +- 60 arc-sec indexing accuracyReduction ratios from 12:1 up to 400:15000N radial load capacity, ideal for mid-range index table applicationsBroad range of mounting adapters offer a simple, precise attachment to any motorMaintenance-free solution that is lubricated for life. High performance grease allows flexible mounting in any orientationAssembled in the USA with immediate deliverySTR Series Rotary Index TablesHighest level of positioning accuracy and runout accuracy, difficult to attain with other gearing technologiesZero Backlash Available – a unique preload mecha-nism to completely eliminate backlash and deliver motion that is true to input commandsImpressive dynamics – Exceptional with direction reversing applicationsReduction ratios up to 2000:1 are possible using a planetary primary stageLightweight, compact aluminum alloy housing for minimal footprintExcellent fit for rotary pick and place applications, large dial tables , positioners and transfer systems Maintenance free solution using grease lubrica-tion, can be mounted in any positionWedge-shape ribs on input shaft maintain contact with the roller followers under preload to com-pletely remove backlash.The steel alloy input shaft is made to meet extremely tight toler-ances. These shafts are balanced to suppress vibration under high speed rotation.Roller bearing construction trans-fers torque by the rolling action of the roller followers. Rolling con-tact maintains initial accuracy for extended periods of use.Preloadinput ShaftRoller FollowersSTR FeaturesThe output shaft has an oversized hollow bore that allows easy pas-sage of wiring and air lines, or the shaft of another device, for ex-tended design flexibility.Cross roller bearings are used in-side the output unit for increased rigidity and minimal runout.The motor or gearbox shaft is rig-idly clamped to the input shaft of the rotary unit for a direct transfer of power.Hollow Output Shaftcross Rollersinput clamping System< 1 arc-min backlash with 20-30 arc-sec repeatability High torsional stiffness with minimal hysteresis loss Large e-stop capacity of 5x rated torqueHigh reduction ratios and power density in a com-pact design4 frame sizes with acceleration torque ranging from 613-3185 NmHollow shaft for easy pass thru of wires, cabling or ball screwsFlexible integration into robotic joints, positioners,turntables or other automated machineryEccentricrollerbearings eRP FeaturesWheelseRH FeaturesMounting OptionsBase MountFlange MountRing MountHollow MountHigh efficiency cycloidal design 500% shock load capacity Backlash as low as 6arc-minVarious mounting options: Base, Flange, Ring, Hollow Reduction ratios up to 71:1 offered in a single stage Broad range of mounting adapters offer a simple, precise attachment to any motor Food grade options available Assembled in the USAWP Strain Wave GearsHarmonic gear reduction mechanism that achieves zero backlash, as well as exceptional positioning accuracy, repeatability and high torque densityHigh Reduction Ratios in a single stage. Lightweight, compact designVarious form factors, including component sets, simple contained assemblies and complete gear units. Cup, Silk Hat, solid and hol-low shaft configurations give engineers true design freedom Available in Ultra-Flat and High Torque variations for applications with demanding footprint and performance requirements Industry standard dimensions for simple implementation in legacy equipment designsSuperior choice for Robotics, Machine Tool, Medical, Semiconduc-tor, SatCom and Assembly Automation applicationsWave GeneratorCircular Spline Flexspline 123configure our planetary products with ease. download models.NIDEC-SHIMPO’s Online Product Configurator makes it eas-ier than ever for engineers to incorporate our products into their drive system design. Our configurator allows our cus-tomers to select from wide range of servo motor manufac-turer models to ensure flawless fitment with our products. With over 75 motor manufacturers included, there is a good possibility we have a solution ready to go. The following are just a few examples of motor manufacturers we are fully compatible with:In addition to motor sizing, our configurator also allows our customers to select gearheads based on application. These applications include rotary tables, belt conveyors, rack and pinion drives, lifting and lowering devices, ball screws, drive gears, drive carriages and robot joints. After selecting the application template, customers can then input the application load parameters and motion profile. The proper frame size and reduction ratio are then deter-mined, with motor selection as the final last step.Once sizing is complete, our configurator will then display the full part number, along with gearbox and motor tech-nical specifications. This part number includes the motor mounting adapter, which can be sent directly to our sales support team for pricing & delivery.Drawings and models are also available in PDF, DXF, IG S and STEP formats, making it simple for machine designers to quickly drop them into machine schematics to check for proper fitment. We have seasoned application engineersstanding by to assist with any sizing or selection questions.http://www.nidec-shimpo.co.jp/selection/all/index.phpDrive GearsRack and PinionDrive CarriageRotary TableRobot JointsLifting & Lowering DeviceBall ScrewBelt ConveyorApplication Selection。

672-N4D122501 REVO2005111.11 (2)2 (3)1.21 (4)2 (5)1.31 (7)2“” (7)3“” (8)4 (8)5 (9)22.11 (10)2 (11)3.....................................................................................................12-162.21..................................................................................................17-182.............................................................19-202.31...................................................................................21-222.41 (23)2 (24)3.............................................................................................................25-264 (26)5 (27)2.51..................................................................................................28-312.............................................................................................................32-333.............................................................................................................34-354........................................................................36-371. 11“”“”“”“”“”“”122“”3310m106132O 001011021031039-1039-20480510560630910930951071151~2119120-1~6120-6120-7120-8123123-02124131140-01,02160193-1,2,3205206207245800“”“E F GH……”“”13Cr SUS403SUS420J118-8SUS304S35C••••“”“”“”•[]•••[]1. 31•m3/min l/min•Q-H••P•Hmç%PKw2“”••FS2F FS2G E F G…L3“”••““33•4••“”5•2Q2Q•2Q2Q’•2H2H•2H2H’2 2. 1 1 1FSA 50 Hz 1500 min-1 500 l/min 30 m 80 7.5kW 1 2 3 4 5 6 7652 4 50Hz 1500min-180 65 FS 4KA57.5 _ 10 _30%ReNPSH/2 3MkW FSAmm EVMmm50HzkWkW DSmm50HzkW_11_3• • JIS DIM×mm1 2 • JIS • m3/min Capacity30mm 75mm m3/min l /min l /sec m3/h 1m3 =1000l 1h =60min 1min =60sec 1t =1000kg =1000l 4OC m mAg kgf/cm2 kPa MPa 1kg• •“ 1 2 2 ”• • •m “1kg=10m” Total Head•4OC=1kgf/cm2 =10m =0.1MPa =100kPa• Speed N=120f/ N= 50Hz 4 60Hz 2 • 2 min-1 f Hz Pmin-1 rpmN=120x50/4=1500rpm-1 N=120x60/2=3600rpm-1_12_•kW W Power Out Put 0.75kW” “ “1 = ”S=0.163 x P=1~1.2S S P Q Hx Q x H/kW kg/l m3/min m[]•=1.0•“”3 1 • 50Hz 60Hz “ ” Hz2 • 2 3 3 • 50Hz 200V 220V 220V/ 380V “ ” Voltage Single-phase Three-phase_13_• [] 1/ ODP O:Open D:Drip P:Proof2 TEFC T:Totaly E:Enclosed F:Fan C:Cooled3/45[ 1]2_14_• • M&E • 1M&E•32Star Delta• • •• 7kg 10kgJIS10kg JIS10kg••••_15_Y YY• • 11kW 6••••50•• 100mm60 JIS 100mm• BC• •• “ ” 5%•• 7kg 10kg JIS 10kg JIS 10kg•_16_2. 2 1“”[]FSAIBL_17_[]3ME-LINE_18_2 “ ” 4FSAIBLE-LINEPCD-1 80 4 65 1000l/m 20m 5.5kW 0.2MPa11 FSA 2 3 4 5 6 4 P 0.2MPa 1000l/m 20m 3 380V 1000l/m 20m 3 380V_19_2450Hz1500min-1310080FS4JA55.5•0.7MPaIBL2IBL42P4PFSA2FSA42. 31MS“”MDPAFSAP-1300l/m 60m 7.5kW 3380V11234567EVM 50Hz 300l/m 60m 3380V5.5kW50Hz 300l/m 60m 3380V 7.5kW250Hz3000min-13EVM 16 6F/5.53M EVM2. 41“”40%“”“”10%DS70%DVS2100%DLDSDVSDLDSDVSDLDLDSDVSDSDVSDL10%70%60%70%…•DP-1100l/m 6m0.25kW1220V1234567DDSDSA50Hz100l/m6m3380V50Hz100l/m6m3380V12340DSA5.25A•424EPJ51221112JA12221“”“”“ON”“OFF”FS PS[ ]“ “ ””“”“ ”2[]FS PS_30_13101. 2.12 3_31_2F3100BNF3100BN1 2 3 41 2 3 3m”PB“PB PB3m”“PBF1300B1F1300B1 1 2 3 41 2 3 4 10l/m_32_③定压供水方式•供水机组F1000BD 型F1000BD 型(日本产品示例11- 特点1 使用流量开关控制,供水的压力变动很小。

Hydro Power Synchronous GeneratorsPower range 0.3 to 20 MWOur key word: qualityQuality of products, supported by more than 100 years of know-how and continuous technical and innovative developments.Quality in offering, with comprehensive and detailed proposals supported by a strong evaluation phase.Quality in project management, with top-level technical and logistical support up to commercial operation and for long term service.A trusted partnerAs a historical and recognized player in the field of hydroelectric power generation, Nidec Leroy-Somer develops an approach of commitment and transparency, for your full confidence and satisfaction.Throughout the project life, including design and manufacturing phases, our teams will help you meet technical and environmental specifications ensuring the perfect configuration and implementation.INNOVATION - RELIABLE - FLEXIBLEProduct range overviewA premium industrial & design expertise for your hydro projects.DesignOur highly skilled engineering teams focus on optimization and continuous improvementresulting in the highest performances available on the market (efficiencies, life span and mechanical behaviour).For this purpose, we use the best computation tools relying on Finite element analysis (FEA) and 3D CAD design.Close coordination work with turbinemanufacturers can be performed in order to refine deisgn and ensure a sound behaviour of the turbine-generator system on site.ProductionOur production site (Orléans, France), is equipped with state-of-the-art machinery.We achieve product excellence and reach expectedperformances through controlled high quality components and processes at every step.CNC plasma and laser cutting tools, precision form-woundwinding, vacuum-pressure impregnation are some of the equipment operated by qualified and dedicated workers.Power0.3 to 20 MWVoltage400 to 15,000 VRotation speed 300 to 1500 rpm / 50Hz 360 to 1800 rpm / 60Hz Mountings Vertical or horizontalCoolingIC01, IC21, IC31, IC81W (IEC 60034-6)Insulation class H (medium and high voltage included) Temperature rise classF or BExcitation Self-excited - Brushless rotating excitation RegulationAnalog or digital Leroy-Somer AVRThe right solution• Our products can be coupled to all turbine types, with particular attention to critical speed issues.• Overhung runner assembly on extended shaft end, with turbine load withstanding.• Rigid mechanical assembly coupled todynamical balancing grade G1 (ISO 1940-1), aiming at low vibration levels in all operating conditions.• Compact design aiming at reducing foundation costs.Custom solutions - Ease of integ On-site handlingCombined rotor shaft locking & tilting equipmentFor hard to reach sites and cramped machinerooms, we offer a wide range of solutions& devices that facilitate the alternator lifting& handling.This tool, first introduced by us, allowssafe transport/handling and enablestransfer from horizontal to verticalposition (and vice versa) on site with only one lifting device.Fast opening louvers forpowerhouse heating and/orin case of water supply failure Speed detectionRotor earth fault detectionBrakeOil level detectionHigh -pressure jacking oil systemLow point piping connections forbearing water coolingEasier & quicker integrationIM 3011 mounting arrangement Easy access to the bottom bearing through manholes for inspection & light maintenance operations Vibration monitoring equipmentWater leakage detectionAnchoring equipmentVERTICAL MOUNTINGgration - Comprehensive option rangeCase studyFredet-Bergès Hydro Plant, FranceReducing the acoustic footprint when inhabitants are just across the street:problem solvedProject ID• 3.5 MW • 750 rpmOptimized main terminal box for the integration of:- Current & Voltage transformers - Surge arresters - PD couplersInertia flywheelPossible additional brakeShaft-driven pumpAdapted bearing and shaft endAnchoring equipmentOil lubrication unit with shaft-driven pumpFor safer bearing operationHORIZONTALMOUNTINGTo watch the video, scan the QR code or go to http://lrsm.co/fredetbergeshydroIt combines the proven technologies of a Leroy-Somer designed digital AVRlike the D550 or D700 and a Leroy-Somer Mentor DC drive.The drive provides a continuous direct excitation current up to 900A, controlled by the digital AVR with the following features:- Automatic or manual voltage regulation- Voltage equalization for grid connection- Cos ϕ, Power Factor or kVAR regulation modes- Advanced fault detection and data logging- User-friendly touchscreen interfaceFor more information,scan the QR codeor go to:ServicesWe provide a complete range of services to support you from installation to commissioning and maintenance:• On-site assembly when requested by site contraints • Site erection, installation and commissioning• On-site or in-house operations including repair,maintenance and diagnostic• Long term service agreements with possible remote monitoring• Advanced electrical and mechanical diagnostics,analysis and reports• Parts center ensuring up-time requirementsTrainingOur services and engineering teams have designed courses to address the specific challenges of hydro projects:• Engineering companies: increase or refresh your knowledge, for specification write-up, betterevaluation of proposals and comparison processes • Operating companies: identify key topics to optimize daily and strategic operation activities, includingscheduled controls, monitoring and maintenance,and get the most of Nidec Leroy-SomergeneratorsSupport, Maintenance and Training/company/leroy-somer/Leroy_Somer_en/LeroySomer.Nidec.en/LeroySomerOfficiel© 2022 Moteurs Leroy-Somer SAS. The information contained in this brochure is for guidance only anddoes not form part of any contract. The accuracy cannot be guaranteed as Moteurs Leroy-Somer SAShave an ongoing process of development and reserve the right to change the specification of their productswithout notice.Moteurs Leroy-Somer SAS. Headquarters: Bd Marcellin Leroy, CS 10015, 16915 Angoulême Cedex 9,France. Share Capital: 38,679,664 €, RCS Angoulême 338 567 258.。

面向供应商NIDEC MOBILITY CORPORATIONQuality Planning Department,Quality Management Division,目录1. 前言 (1)2. CAMDS(China Automotive Material Data System)概述 (2)2.1. CAMDS简介 (2)3. CAMDS数据的填报 (2)3.1. 要求事項 (2)3.2. CAMDS数据结构 (3)3.2.1 有效的数据结构 (3)3.2.2 无效的数据结构 (4)3.2.3 简单BOM(FBOM)的报告方式 (5)3.3. 材料的作成 (6)3.3.1 材料分类的选择 (6)3.3.2 材料 (8)3.3.3 基本物质 (10)3.4. 半成品件 (11)3.4.1 添加子节点数据 (12)3.5. 零部件 (14)3.5.1 添加子节点数据 (15)3.5.2 聚合物材质标识 (17)3.5.3 物质应用代码 (18)4. 填报接收人信息 (22)4.1. 发送MDS (23)5. CAMDS的运作方法 (25)5.1. 创建/更新MDS (25)5.2. MDS填报流程 (25)5.3. 数据表被拒绝时 (26)5.4. 包含支给部品的MDS填报流程 (26)5.5. 包含支给材料的MDS填报 (26)6. CAMDS咨询窗口 (27)6.1. CAMDS全面 (27)6.2. 本公司的数据填报 (27)1.前言本手册规定了NIDEC MOBILITY CORPORATION及其集团公司1(以下简称本公司)针对供应商及其制造商提供的部品、材料的CAMDS数据填报时的相关要求。

请依据本手册填报发送给本公司的CAMDS数据。

本手册中的未尽事项,请参照CAMDS管理中心(CATRC)编制的《CAMDS使用手册》2、或《CAMDS填报指南》3等教程。

注**********************************************************************************************12 CAMDS管理中心编制发行的CAMDS运用手册。

潜油电泵介绍第⼀章潜油电泵介绍第⼀节概述随着我国⽯油⼯业的发展和油⽥采油开发的需要,为了提⾼油⽥采油速度和最终采收率,应⽤机械采油⽅法是整个油⽥开发过程的⼀个⼗分重要的步骤。

潜油电泵作为⼀种⽐较常⽤的机械采油设备,由于它⾃⾝的特点,近⼗⼏年来在国内外得到了⼗分⼴泛的应⽤。

尤其是它特别适⽤于海上平台采油。

选⽤潜油电泵⼤排量强采是油⽥长期稳定⽣产的重要⼿段。

⼀、潜油电泵发展概况·1923 年⽩俄罗斯⼈AS 奥托纳夫在世界上⾸先提出潜泣电泵的新概念,并在洛杉机制造出美国第⼀台潜油电泵。

·1930 年奥托纳夫在美国创建了雷达公司。

·50~70年代美国相继出现了三家主要⽣产潜油电泵的制造旖。

它(20世纪)们是森垂列夫特公司、ODI 公司、科贝公司。

·1940 年苏联国家⽯油机械设计院深⽔电机局⽯油⼯业组研制了苏联第⼀台潜油电泵。

开始⼴泛应⽤于油由。

·1953 年中国⽯油部曾在⽟们油⽥对潜油电泵进⾏研究和试验。

·1970 年天津市电机总⼚与⼤庆油⽥联合,成功地开发塞中国鑫⾏设计和制造的第⼀台潜抽电泵并于 1 978 年开始正式投产。

天津市电机总⼚正式获国家批准,引进美雷达公司的潜油电泵制造技术,极⼤地促进了中国电潜泵制造技术和⽣产的发展。

·1989 年随着国内⽯油⼯业和采油技术的不断发展以及引进技术在国内的扩散,相继出现了⼤庆、胜利、虎溪等⼀批电泵制造⼚,形成了中国的潜油电泵制造⾏业。

·2004 年渤海⼯程装备电泵分公司为适应渤海⼆、潜油电泵的应⽤及⽔平近⼗年来,随着潜油电泵在世界范围使⽤的数量不断增加,国内外油⽥在电泵采油⼯艺技术⽅⾯做了⼤量⼯作,因此在潜油电泵⼴泛应⽤的同时,其应⽤⽔平也在不断提⾼,并积累了⼤量丰富的经验。

据统计⽬前先进的国外油⽥在⼀些主要电泵的应⽤指标已达到:电泵系统效率42 %适⽤最⾼井温180 ℃电泵最⼤挂泵深度4500 m平均运⾏寿命600 ~800 天国际⽯油组织1997 年公布,全球油井总数为989908 ⼝〔不含停产油井、注⽔⽤井和辅助油井〕,油井分布情况见表l 。

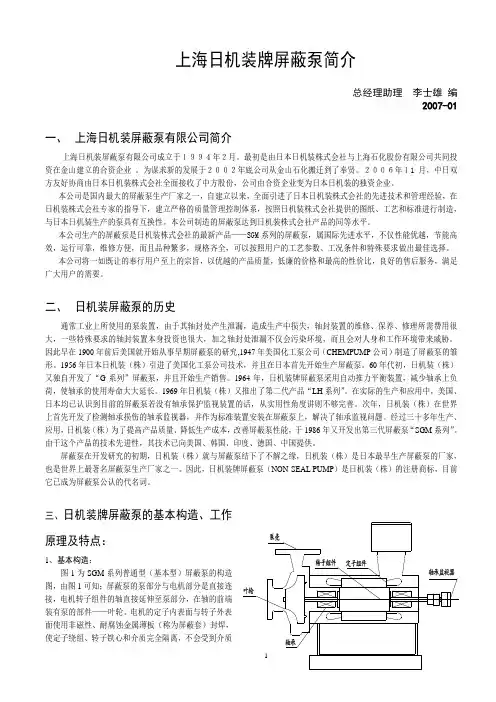

上海日机装牌屏蔽泵简介总经理助理李士雄编2007-01一、上海日机装屏蔽泵有限公司简介上海日机装屏蔽泵有限公司成立于1994年2月。

最初是由日本日机装株式会社与上海石化股份有限公司共同投资在金山建立的合资企业。

为谋求新的发展于2002年底公司从金山石化搬迁到了奉贤。

2006年11月,中日双方友好协商由日本日机装株式会社全面接收了中方股份,公司由合资企业变为日本日机装的独资企业。

本公司是国内最大的屏蔽泵生产厂家之一,自建立以来,全面引进了日本日机装株式会社的先进技术和管理经验,在日机装株式会社专家的指导下,建立严格的质量管理控制体系,按照日机装株式会社提供的图纸、工艺和标准进行制造,与日本日机装生产的泵具有互换性。

本公司制造的屏蔽泵达到日机装株式会社产品的同等水平。

本公司生产的屏蔽泵是日机装株式会社的最新产品——SGM系列的屏蔽泵,属国际先进水平,不仅性能优越,节能高效,运行可靠,维修方便,而且品种繁多,规格齐全,可以按照用户的工艺参数、工况条件和特殊要求做出最佳选择。

本公司将一如既让的奉行用户至上的宗旨,以优越的产品质量,低廉的价格和最高的性价比,良好的售后服务,满足广大用户的需要。

二、日机装屏蔽泵的历史通常工业上所使用的泵装置,由于其轴封处产生泄漏,造成生产中损失,轴封装置的维修、保养、修理所需费用很大,一些特殊要求的轴封装置本身投资也很大,加之轴封处泄漏不仅会污染环境,而且会对人身和工作环境带来威胁。

因此早在1900年前后美国就开始从事早期屏蔽泵的研究,1947年美国化工泵公司(CHEMPUMP公司)制造了屏蔽泵的雏形。

1956年日本日机装(株)引进了美国化工泵公司技术,并且在日本首先开始生产屏蔽泵。

60年代初,日机装(株)又独自开发了“G系列”屏蔽泵,并且开始生产销售。

1964年,日机装牌屏蔽泵采用自动推力平衡装置,减少轴承上负荷,使轴承的使用寿命大大延长。

1969年日机装(株)又推出了第二代产品“LH系列”。

日本油泵操作手册在选择和安装摆线泵之前仔细阅读操作手册。

请安装操作手册正确安装和操作油泵。

此手册包括油泵的选择、安装、操作和故障排除,如果不安装才操作手册操作可能会导致油泵认为损坏或设备损坏。

建议将操作手册保存在一个安全方便的位置,以便将来做为参考。

油泵安全操作事项请在充分理解安全措施的前提下,按照以下预防事项和安全操作条例进行操作。

含有以下标志或标题的事项,可能会造成人员或物品的损伤,请注意。

如果不按照指示进行操作,将会造成人员死亡或者重伤。

如果不按照指示进行操作,可能会发生伤亡事故。

如果不按照指示进行操作,可能会造成人员受伤,或者造成油泵、装置的破损现象。

1.使用液体应该注意该油泵设计适用于油类,虽然它适用于各种条件。

1)商品目录上介绍的油泵,除标记有特别用途的产品之外,设计及性能全部以ISO VG56 40°C为标准。

在使用此种油以外的情况下,性能或耐久性会出现差异。

Trochoid摆线泵采用的是自动润滑方式,根据使用的液体,可以对滑动面或轴承部位进行润滑。

使用不含润滑性的液体、含有腐蚀性的液体以及不含防锈功能的液体(水)会造成油泵破损。

在使用润滑油以外液体的情况下,请咨询本公司。

2)当泵用于燃油时,相对于象煤油这样低粘度的燃油,必须注意,泵的最大使用压力也会受到限制。

不可使用汽油等挥发油。

否则会引起爆炸或火灾事故。

部分燃油含有能让标准油封膨润的性质,当泵用于燃油时,请务必联系本公司以确认规格。

2.使用液体的温度和粘度适用的液体温度范围为-5°C~80°C。

适用液体的粘度范围为10~500mm²/sec。

如果使用过程中超出上述范围,可能会造成泵的使用寿命严重缩短、性能降低以及液体泄露等现象。

使用情况超出上述范围时的特殊规格,请与本公司联系。

使用高温油时,因油泵和泄露的油会引起烧伤事故。

3.适用的环境温度泵适用的环境温度为-20°C~40°C。

从CSR到CSV的跨越作者:屈丽丽来源:《家族企业》2020年第06期从“义利合一”到日本“论语和算盘”的商业价值观,从哈佛商学院教授迈克尔·波特(Micheal Porter)的“创造共享价值”(CSV),到联合国的2030年可持续发展目标(SDGs),从“影响力投资”到国内近几年骤热的商业向善和科技向善的理念,全球几乎在同一时间开始探讨将企业慈善行为作为可持续性发展的商业模式。

而在疫情期间和疫情之后,基于解决社会问题,风险和挑战的商业解决方案的重要性更日益突出。

为此,记者采访了在日本从事CSV研究长达七年之久的日本一桥大学商学院教授名和高司,以及Shibusawa and Company株式会社的董事长涩泽健,而后者的先辈正是被视为日本资本主义之父,提出“论语和算盘”、日本义利合一商业理念、被称为日本近代资本主义之父的涩泽荣一先生。

名和高司教授曾任职于三菱商事,后来在麦肯锡公司担任顾问负责信息化工作,目前还担任迅销集团、电综、NEC 等多家日本知名企业的企业顾问和外部董事。

从2011年开始,名和高司教授和日本最顶尖的25家企业每月进行沟通讨论,创建了适合日本的CSV (Creating Shared Value,创造共享价值)理论。

事实上,早在十多年前迈克尔·波特就提出了CSV理念,人们开始认识到将风险转化成机遇,进而转化成企业可持续的商业模式的重要性,很多企业也开始尝试从CSR(Corporate Social Responsibility,企业社会责任)转向CSV。

日本版CSV:“论语和算盘”2011年迈克尔·波特在《哈佛商业评论》上发表了“创造共享价值”理论,事实上这与日本一直流行着的“论语”和“算盘”理念以及中国儒家提倡的义利合一是一脉相承的。

涩泽荣一将《论语》作为第一经营哲学,“涩泽荣一当时倡导道德与经济相辅相成的思想,换而言之就是‘论语和算盘’。

‘论语’是指孔子思想中重视‘道德’和‘义’的思想,而‘算盘’是经济和商业的代名词。

日本广告语言表达研究引言日本广告业在世界上享有盛誉,其广告文化深受消费者喜爱。

日本广告语言的独特性是其成功的重要因素之一。

本文将从历史、文化和社会背景等方面出发,探讨日本广告语言表达的特点及其对营销的影响,同时分析未来日本广告语言发展的趋势和挑战。

日本广告业的发展经历了多个阶段,从最初的原始商业广告到现代的高科技数字化广告。

在不断的发展过程中,日本广告语言逐渐形成了自己独特的特点。

日本文化强调和谐、礼貌和谦虚,这些文化价值观在广告语言中得到了很好的体现。

此外,日本社会对集体意识的重视也反映在广告语言中,强调团队协作和集体利益。

1、暧昧性:日本广告语言常常采用暧昧、含蓄的表达方式,这种表达方式往往能够让消费者产生更多的想象空间,激发他们的购买欲望。

例如,一些广告会使用比喻、拟人等修辞手法来描述产品特点,而不是直接说明。

2、简洁性:日本广告语言强调简洁明了,避免使用复杂的语言表达。

这有助于提高广告的易读性和可记忆性。

例如,许多日本广告都会采用短句或口号来传达品牌信息,这些短句或口号通常简单易懂,具有强烈的视觉冲击力。

3、情感表达:日本广告语言注重情感表达,通过唤起消费者的情感共鸣来达到营销目的。

许多广告都会利用温馨、感人的场景来打动消费者,让他们对品牌产生好感。

日本广告语言对营销的影响主要体现在以下几个方面:1、提高品牌知名度:通过独特的广告语言,日本广告业能够吸引消费者的注意力,从而提高品牌知名度。

许多经典的日本广告语已经成为流行文化的一部分,如“ora orara”(哦啦哦啦)这一麦当劳的广告语,已经深入人心。

2、建立品牌形象:日本广告语言在塑造品牌形象方面具有很强的作用。

通过使用暧昧、简洁和情感表达的语言,广告能够传达出品牌的个性和价值观,从而让消费者对品牌产生好感。

例如,无印良品的广告语“No brand, good brand”(无品牌,好品牌)就成功地塑造了其简约、自然、环保的品牌形象。

“尼得科Nidec”品牌资质分析报告

尊敬的用户:

随着经济全球化的深入发展,各市场领域的竞争已逐渐表现为品牌竞争。

根据中国互联网络信息中心(CNNIC)公布的最新数据显示,中国网民规模已达8.02亿,互联网普及率57.7%。

而网民规模增长的推动力正是由于互联网商业模式的不断创新以及线上线下服务融合的加速,因此,互联网时代的到来也意味着网络品牌标识的价值提升。

习总书记不断强调知识产权战略的重要性,同时每年5月10日“中国品牌日”的确立也标志着品牌建设与保护已经刻不容缓。

根据您查询的“尼得科Nidec”品牌,及“制造业-机器机械”行业,尼得科Nidec的品牌分析报告如下:

目录

一、尼得科Nidec品牌商标分析

1、行业注册分析

1.1 制造业-机器机械行业注册分析

1.1.1 制造业-机器机械行业品牌注册量

1.1.2 尼得科Nidec品牌在制造业-机器机械行业的主要注册情况

1.1.3 制造业-机器机械行业下尼得科Nidec同名品牌的主要竞争对手

2、尼得科Nidec品牌商标注册分析

2.1 制造业-机器机械行业类别分析

2.2 尼得科Nidec品牌在制造业-机器机械行业的保护现状

3、尼得科Nidec品牌字样在各行业的注册情况表

二、尼得科Nidec品牌域名分析

1、全球知名品牌案例

2、尼得科Nidec品牌域名匹配分析

3、品牌域名注册概况

4、Typo域名

三、品牌保护建议

正文

1.1.2 Nidec-。

日本电产(NIDEC)是全球最大的微电机集团公司.其生产的微型隔膜泵广泛应用于加湿器、微波炉、电饭煲、电冰箱、洗衣机、电暖瓶、咖啡机、美容机、吸乳机、印刷机械、投影仪、医用生化/血球分析装置、智能马桶、测量器械、烹饪器具、香味营销等行业!

微型隔膜气泵及水泵,采用直流无刷电机,具有长寿命,无电磁干扰,噪音小。

直流无刷电机采用内置驱动器,向外输出正反转,FG速度反馈,PWM调速等功能,直接上电工作不需要外接驱动器!膜片采用三膜设计,具有振动小,脉动小,流量重复性好!膜片材质采用EPDM及NBR材质,耐油耐酸耐碱!电机电压有12v,24v,功耗低!功率在3w左右,泵的寿命在连续运行6000h以上!气水两用,水泵流量在330ml左右每分钟,气泵泵水流量在550ml-600ml左右,气泵泵气流量在1L-2L,水泵泵气在500ml左右!

此泵主要应用于医疗行业的临床诊断设备中的液路中,做排废液,进标液,加压,维持负压平衡等。

像全自动生化仪分析仪,全自动电解质分析仪,全自动血液分析仪,全自动血球,全自动蛋白分析仪,全自动尿沉渣分析仪,全自动液基制片机,臂上血压计,碎石机,全自动化学免疫发光仪等。

应用于环保行业的水质气体检测设备,做抽气用。

像手持气体检测仪,在线气体检测仪,水质在线监测仪,大气检测仪等。

应用于家电行业的电饭煲,微波炉,电冰箱,洗衣机,主要用来抽气,抽负压,搅拌等。

应用于扩香机行业,用来作为二流体雾化的气源及提供压力!

应用于医疗行业,影像输出系统打印机中喷墨水!

应用于印刷行业的喷墨打印机中喷墨,膜片耐油墨成份!。