魏德米勒电源产品样本2014

- 格式:pdf

- 大小:11.76 MB

- 文档页数:54

XXXX低压配电柜(箱)采购工程技术规范XXXXXXXX2019年1月8日目录第一节低压配电柜(箱)第二节动力系统低压配电控制柜(箱)第三节低压配电柜(箱)及动力配电控制柜(箱)技术偏离表第四节设备材料建议品牌表第五节配电箱(柜)内明细配置表第一节低压配电柜(箱)1.1总则1.1.1说明1.1.1.1本节说明所有配电装置的供应、安装、测试、试运行和投入使用,如图所示或本章规定。

1.1.1.2为解决电压降问题,若干主线配电电缆选用尺寸过大的电缆。

可能存在着这些电缆不能接到配电装置的情况。

为此,须把电缆接到电缆分盒,再通过截面面积较小的电缆再连接到配电装置上。

投标价格须包括中接。

如需要使用此类电缆分盒,必须在安装前交付电缆尺寸,设备额定值等详细建议供审批用。

1.1.2质量保证1.1.2.1所有设备、材料和工艺须符合相应的国家及行业标准和当地电力公司之规定。

1.1.2.2所有设备材料和附件必须适用于规定的操作条件。

1.1.2.3所有同类型设备和材料必须为同一厂商的产品。

所有相同的部件应能替换使用。

1.1.2.4所规定的每一种设备必须经过测试,并经证明其设计和制造符合相应的国标或IEC 标准。

工程师可独自决定要求提交由享有声誉的独立测试实验室和机构所发出的测试证明书。

1.1.2.5作为一个完整项目的设备,如微型断路器/微型断路器盘须由同一厂制造或在许可下制造(即ABB、施耐德、西门子授权制造商)。

在后一种情况,工程师有权单独决定许可协议的可接受性以及是否接受或拒绝所提供的产品。

1.1.2.6整座低压配电柜(箱)及其部件的设计和制造须符合最新修订的下列标准(但不局限下列标准):A GB7251(1.2.3.4.5)低压成套开关设备及控制设备B GB/T14048.1-1993低压开关设备及控制设备总则C GB/1408(7.8)-1998低压开关设备及控制设备辅助电器,第一第二部分铜导体的接线,端子排D GB14048低压开关设备及控制设备E GB/T16935.1-1997低压系统内设备的绝缘配合F GB/T9466-1998低压成套开关设备基本试验方法G 国际电工标准IEC439-1低压成套开关设备和控制设备H GB503030-2002建筑电气工程施工质量验收规范1.1.3交付1.1.3.1在合同签订后的三星期内和在订货前,交付下列各项供批核用:A 设备、部件和制制造厂商数据的详细投标表。

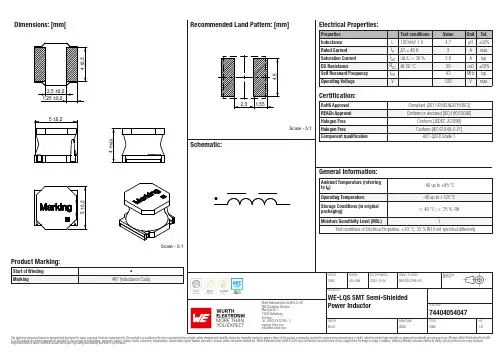

Dimensions: [mm]Scale - 5:174404054047BC74404054047T e m p e r a t u r eT pT L74404054047Cautions and Warnings:The following conditions apply to all goods within the product series of WE-LQS of Würth Elektronik eiSos GmbH & Co. KG:General:•This electronic component is designed and manufactured for use in general electronic equipment.•Würth Elektronik must be asked for written approval (following the PPAP procedure) before incorporating the components into any equipment in fields such as military, aerospace, aviation, nuclear control, submarine, transportation (automotive control, train control, ship control), transportation signal, disaster prevention, medical, public information network etc. where higher safety and reliability are especially required and/or if there is the possibility of direct damage or human injury.•Electronic components that will be used in safety-critical or high-reliability applications, should be pre-evaluated by the customer. •The component is designed and manufactured to be used within the datasheet specified values. If the usage and operation conditions specified in the datasheet are not met, the wire insulation may be damaged or dissolved.•Do not drop or impact the components, the component may be damaged.•Würth Elektronik products are qualified according to international standards, which are listed in each product reliability report. Würth Elektronik does not warrant any customer qualified product characteristics beyond Würth Elektroniks’ specifications, for its validity and sustainability over time.•The responsibility for the applicability of the customer specific products and use in a particular customer design is always within the authority of the customer. All technical specifications for standard products also apply to customer specific products.Product specific:Soldering:•The solder profile must comply with the technical product specifications. All other profiles will void the warranty.•All other soldering methods are at the customers’ own risk.•Strong forces which may affect the coplanarity of the components’ electrical connection with the PCB (i.e. pins), can damage the part, resulting in avoid of the warranty.Cleaning and Washing:•Washing agents used during the production to clean the customer application might damage or change the characteristics of the wire insulation, marking or plating. Washing agents may have a negative effect on the long-term functionality of the product.•Using a brush during the cleaning process may break the wire due to its small diameter. Therefore, we do not recommend using a brush during the PCB cleaning process.Potting:•If the product is potted in the customer application, the potting material may shrink or expand during and after hardening. Shrinking could lead to an incomplete seal, allowing contaminants into the core. Expansion could damage the components. We recommend a manual inspection after potting to avoid these effects.Storage Conditions:• A storage of Würth Elektronik products for longer than 12 months is not recommended. Within other effects, the terminals may suffer degradation, resulting in bad solderability. Therefore, all products shall be used within the period of 12 months based on the day of shipment.•Do not expose the components to direct sunlight.•The storage conditions in the original packaging are defined according to DIN EN 61760-2.•The storage conditions stated in the original packaging apply to the storage time and not to the transportation time of the components. Packaging:•The packaging specifications apply only to purchase orders comprising whole packaging units. If the ordered quantity exceeds or is lower than the specified packaging unit, packaging in accordance with the packaging specifications cannot be ensured. Handling:•Violation of the technical product specifications such as exceeding the nominal rated current will void the warranty.•Applying currents with audio-frequency signals may result in audible noise due to the magnetostrictive material properties.•The temperature rise of the component must be taken into consideration. The operating temperature is comprised of ambient temperature and temperature rise of the component.The operating temperature of the component shall not exceed the maximum temperature specified.These cautions and warnings comply with the state of the scientific and technical knowledge and are believed to be accurate and reliable.However, no responsibility is assumed for inaccuracies or incompleteness.Würth Elektronik eiSos GmbH & Co. KGEMC & Inductive SolutionsMax-Eyth-Str. 174638 WaldenburgGermanyCHECKED REVISION DATE (YYYY-MM-DD)GENERAL TOLERANCE PROJECTIONMETHODChrB.001.0062022-10-01DIN ISO 2768-1mDESCRIPTIONWE-LQS SMT Semi-ShieldedPower Inductor ORDER CODE74404054047SIZE/TYPE BUSINESS UNIT STATUS PAGEImportant NotesThe following conditions apply to all goods within the product range of Würth Elektronik eiSos GmbH & Co. KG:1. General Customer ResponsibilitySome goods within the product range of Würth Elektronik eiSos GmbH & Co. KG contain statements regarding general suitability for certain application areas. These statements about suitability are based on our knowledge and experience of typical requirements concerning the areas, serve as general guidance and cannot be estimated as binding statements about the suitability for a customer application. The responsibility for the applicability and use in a particular customer design is always solely within the authority of the customer. Due to this fact it is up to the customer to evaluate, where appropriate to investigate and decide whether the device with the specific product characteristics described in the product specification is valid and suitable for the respective customer application or not.2. Customer Responsibility related to Specific, in particular Safety-Relevant ApplicationsIt has to be clearly pointed out that the possibility of a malfunction of electronic components or failure before the end of the usual lifetime cannot be completely eliminated in the current state of the art, even if the products are operated within the range of the specifications.In certain customer applications requiring a very high level of safety and especially in customer applications in which the malfunction or failure of an electronic component could endanger human life or health it must be ensured by most advanced technological aid of suitable design of the customer application that no injury or damage is caused to third parties in the event of malfunction or failure of an electronic component. Therefore, customer is cautioned to verify that data sheets are current before placing orders. The current data sheets can be downloaded at .3. Best Care and AttentionAny product-specific notes, cautions and warnings must be strictly observed. Any disregard will result in the loss of warranty.4. Customer Support for Product SpecificationsSome products within the product range may contain substances which are subject to restrictions in certain jurisdictions in order to serve specific technical requirements. Necessary information is available on request. In this case the field sales engineer or the internal sales person in charge should be contacted who will be happy to support in this matter.5. Product R&DDue to constant product improvement product specifications may change from time to time. As a standard reporting procedure of the Product Change Notification (PCN) according to the JEDEC-Standard inform about minor and major changes. In case of further queries regarding the PCN, the field sales engineer or the internal sales person in charge should be contacted. The basic responsibility of the customer as per Section 1 and 2 remains unaffected.6. Product Life CycleDue to technical progress and economical evaluation we also reserve the right to discontinue production and delivery of products. As a standard reporting procedure of the Product Termination Notification (PTN) according to the JEDEC-Standard we will inform at an early stage about inevitable product discontinuance. According to this we cannot guarantee that all products within our product range will always be available. Therefore it needs to be verified with the field sales engineer or the internal sales person in charge about the current product availability expectancy before or when the product for application design-in disposal is considered. The approach named above does not apply in the case of individual agreements deviating from the foregoing for customer-specific products.7. Property RightsAll the rights for contractual products produced by Würth Elektronik eiSos GmbH & Co. KG on the basis of ideas, development contracts as well as models or templates that are subject to copyright, patent or commercial protection supplied to the customer will remain with Würth Elektronik eiSos GmbH & Co. KG. Würth Elektronik eiSos GmbH & Co. KG does not warrant or represent that any license, either expressed or implied, is granted under any patent right, copyright, mask work right, or other intellectual property right relating to any combination, application, or process in which Würth Elektronik eiSos GmbH & Co. KG components or services are used.8. General Terms and ConditionsUnless otherwise agreed in individual contracts, all orders are subject to the current version of the “General Terms and Conditions of Würth Elektronik eiSos Group”, last version available at .Würth Elektronik eiSos GmbH & Co. KGEMC & Inductive SolutionsMax-Eyth-Str. 174638 WaldenburgGermanyCHECKED REVISION DATE (YYYY-MM-DD)GENERAL TOLERANCE PROJECTIONMETHODChrB.001.0062022-10-01DIN ISO 2768-1mDESCRIPTIONWE-LQS SMT Semi-ShieldedPower Inductor ORDER CODE74404054047SIZE/TYPE BUSINESS UNIT STATUS PAGE。

6万吨多晶硅项目低压配电室EPS电源装置技术规范书2021年06目录1 概述 (2)1.1 目的 (2)1.2 范围 (2)2 设计基础 (2)2.1 环境温度 (2)2.2 相对湿度 (2)2.3 海拔高度 (2)2.4 安装位置 (2)3 采用的标准 (2)4 技术要求 (3)4.1 运行方式 (3)4.2 逆变器输出特性 (3)4.3 规格及额定值 (3)4.4 蓄电池 (4)4.5 冷却方式 (4)4.6 噪音 (4)4.7 电池计算 (4)4.8 报警信号 (4)4.9 指示 (4)4.10 附加技术条件 (5)5 性能保证要求 (5)6 成套供货范围 (5)7 界区划分 (5)8 质量保证 (5)9 产品试验、调试及检验 (5)10 提交图纸的编制规定 (6)11 交付资料、图纸 (6)12 培训和服务 (7)13 其它 (7)13.1 运输准备 (7)13.2 备品备件 (7)13.3 铭牌 (7)13.4 涂漆 (7)13 标识 (7)14 附件 (7)15 交货日期 (8)1 概述1.1 目的本规格书为6万吨\年多晶硅项目低压配电室EPS电源装置的通用的设计、选材、制造、检查和试验、装运、存贮和性能保证的最基本要求。

仅对EPS电源装置的通用提出了最低限度的技术要求,未对一切细节做出规定,也未充分引述有关标准规范的条文,制造商应提供符合本规格书要求和有关国家现行标准的优质产品。

1.2 范围本规格书用于6万吨\年多晶硅项目低压配电室EPS电源装置的通用的询价或采购。

2 设计基础EPS电源装置应按在下列条件下使用进行设计:2.1 环境温度极端最高温度45︒C极端最低温度-40.5︒C最热月平均温度30︒C年平均温度7.5︒C2.2 相对湿度相对湿度 52 %2.3 海拔高度海拔高度 499.45~504.11m <1000 m2.4 安装位置安装位置户内3 采用的标准一般来说,EPS应急电源装置及其内部元器件应符合相应的最新版的国家标准( GB )或IEC( 国际电工委员会)标准。

魏德米勒epak-ci-co 技术参数-概述说明以及解释1.引言1.1 概述魏德米勒epak-ci-co是一种先进的技术方案,旨在提高生产效率和产品质量。

该技术参数在生产过程中起到了至关重要的作用。

首先,epak-ci-co技术采用了先进的控制系统,能够精确控制生产过程中的各个环节。

通过实时数据采集和处理,该技术能够对生产线进行智能化管理,确保生产过程的稳定性和可控性。

这种精确的控制系统使得产品的生产过程更加高效,并能够准确把握每个关键的技术参数。

其次,魏德米勒epak-ci-co技术还具备出色的自动化能力。

通过自动化设备的运用,该技术能够减少人工操作对生产过程的干预,从而提高了生产效率和产品质量的稳定性。

自动化的生产线能够实现高速连续生产,大大节约了生产时间和成本。

此外,该技术还具备灵活性和可调性。

魏德米勒epak-ci-co技术的生产线能够根据产品的不同要求进行灵活调整,以满足市场需求的变化。

这种灵活性使得生产线具备了更好的适应性和竞争力。

综上所述,魏德米勒epak-ci-co技术参数在改善生产效率和产品质量方面发挥着重要的作用。

通过先进的控制系统、自动化能力和灵活性,该技术实现了高效、稳定和柔性的生产过程。

对于企业来说,采用魏德米勒epak-ci-co技术是提升竞争力、稳定产品质量和加快产品上市的重要举措。

1.2 文章结构文章结构部分包含以下内容:文章结构本文将按照以下结构来介绍魏德米勒epak-ci-co技术的参数。

首先,我们将在引言部分概述整个文章的内容和目的。

接下来,正文部分将详细介绍魏德米勒epak-ci-co的三个技术参数。

最后,在结论部分,我们将对这些技术参数进行总结,并探讨它们在实际应用中的影响。

此外,我们还将展望魏德米勒epak-ci-co技术在未来的发展方向。

通过这样的结构,我们将全面介绍魏德米勒epak-ci-co技术的参数,并探讨其应用和发展前景。

1.3 目的目的部分旨在明确本篇文章的目标和意义。

魏德米勒各系列接线端子介绍W 系列接线端子W系列端子采用高品质绝缘材料Wemid,阻燃等级V0,不含卤素磷化物,最高工作温度达120°C。

产品品种全面、功能更多。

W系列端子具有如下特点:最大压接导线截面300mm2;仅需两种大小不同的挡板;其中较大的挡板同时可以用作较小魏德米勒接线端子的隔板;W系列接线端子可以轻易地安装在导轨上,这样便可以方便精确地调整接线端子在安装轨上的位置。

相应的固定器可以保证接线端子绝对可靠地固定在正确的位置上。

另外还可以在固定器上安置标记座,以便于分组标记。

W系列的联络组件具有如下特点:1.具有顶部中央螺钉横联和插拔式弹片横联;2.插拔横联最大可至50极;3.本身带绝缘,可以防止接触带电部件;4.螺钉横联件紧固螺钉不会松落,埋头式螺钉便于螺丝刀的操作;5.在400V以下的电压下,切断的联络组件使用于相邻接线端子之间无需挡板或隔板;6.使用联络组件后,不妨碍接线端子通过最大额定电流;7.根据需要剪断某联便可跳过该接线端子;8.可以同时并排交错使用两列联络组件-即可在两种电位下工作;W系列联络组件用于基型接线端子,而且在基型、零线型和接地型接线端子的交叉组合装配时也不受影响,所以能够根据需要方便、经济地组配接线端子!不管接线端子是否装上了联络组件,它都是防触摸的。

此外,直到150mm2的所有接线端子均可安装分组标记牌或带有闪电标志符号图样的盖板。

使用带有闪电标志符号的盖板便于识别带电接线端子;使用分组标记牌便于识别功能组;三种标记系统供你您选择,一块标记上可印十位数字或字符;绝对防止触摸带电部位双层接线端子Weidmüller双层接线端子在不增大接线端子厚度的前提下增大了接线密度。

用双层接线端子代替标准接线端子,可使接线端子数增加一倍,而不必加长安装轨。

魏德米勒双层接线端子具有如下特点:上下两层均可横向联络;上、下两层的导电片可互相连接不必移动相邻接线端子亦可进行更换;可对接线端子做清晰的标记;上、下导电片互连的双层接线端子尤其适合于在空间较小的情况下的电势分配;由接线端子顶端的V型缺口可以识别上下导电片是否互联。