洁净层流车使用说明书

- 格式:docx

- 大小:46.54 KB

- 文档页数:5

J C C-5C型洁净采样车操作规程标准操作规程Standard Operating Procedure1.目的建立JCC-5C型洁净采样车操作规程,确保正确使用。

2.适用范围适用于JCC-5C型洁净采样车的使用。

3.责任者质管部取样人员。

4.操作规程4.1 通电前先检查四只脚轮是否均着地。

否则,请先调整或垫平四只脚轮。

4.2 每次使用前应按如下程序对采样车进行清洁消毒。

4.2.1 清洁用具:抹布;清洗剂:饮用水、纯化水;消毒剂:75%酒精、3%双氧水。

4.2.2 清洁、消毒方法:4.2.2.1 按由上而下、由里至外的顺序进行清洁且清洁每个部位。

4.2.2.2 抹布脏时,用饮用水清洗干净,再继续清洗,直至目测无污迹,再用另一块洁净抹布蘸取纯化水将采样车顶壁及四侧内壁擦洗两次。

4.2.2.3 用洁净抹布蘸取消毒剂对采样车内部进行擦拭消毒后备用。

4.2.3 清洁效果评价:采样车清洁后目测无粉迹,用洁净抹布擦拭无可见污迹即可视为清洁合格。

4.3 采样车经清洁、消毒后,可将待取样物料脱去外包装,然后放进采样车工作区,开启净化风机、紫外灯运行至少半个小时后关闭紫外灯,准备取样。

4.4 用75%酒精棉球消毒手部或带上灭菌手套,自取样口将无菌采样器带入采样车洁净区域内,打开内包装进行取样。

4.5 取样完毕重新封口包装,然后关闭风机,取出物料。

4.6 开启紫外灯照射30分钟后关闭采样车电源。

4.7 作好取样标识及采样车清洁使用记录。

5.采样车日常维护与维修5.1 定期(一般 3个月)用风速仪测试工作区域的平均风速。

用尘埃粒子计数器检测工作区的洁净度以及沉降菌监测。

若发现上述有不符合技术要求者,应调节风机电压,使设备处于最佳状态。

5.2 根据使用环境的洁净程度,定期将预过滤器中的滤料拆下清洗,间隔时间一般为3-6个月为宜。

5.3 当风机电压调至最大,工作区风速仍然达不到技术要求时,则必须更换高效空气过滤器,本设备高效空气过滤器型号为GK-12SA-C,外形尺寸为:600×600×150。

层流床的使用流程及维护1. 层流床简介•层流床是一种常用的实验室设备,用于实现清洁环境下的实验操作。

•通过气流均匀分布,在工作区域内形成无尘、无菌的环境。

•层流床广泛应用于生物实验、微电子制造、医药研发等领域。

2. 使用流程2.1 准备工作•确认实验所需材料及工具已准备齐全。

•检查层流床的运行状态,包括洁净度、风机状态等。

### 2.2 打开层流床•按下电源开关,待指示灯亮起表示设备已启动。

•打开层流床前门,确保工作区域内无杂物。

•关闭其他设备,确保不会产生干扰。

### 2.3 操作层流床•将实验所需材料放置在工作区域内,根据实验要求进行布局。

•打开风机控制开关,调节风速以符合实验要求。

•避免将手臂伸入工作区域内,以免干扰气流分布。

### 2.4 结束实验•关闭风机控制开关,待风速降至安全范围后,再关闭电源开关。

•清理工作区域,将实验所需材料归位。

•关闭层流床前门,确保设备内部干净整洁。

3. 层流床的维护3.1 定期清洁•定期清洁层流床内外表面,使用无粉尘的清洁布进行清洁。

•注意清洁过程中避免对设备造成损坏。

### 3.2 更换过滤器•根据层流床使用情况,定期更换过滤器。

•检查过滤器是否损坏或堵塞,如有需要及时更换。

### 3.3 检查风机状态•定期检查风机的运行状态,确保其正常工作。

•注意检查风机转速、噪音等指标。

### 3.4 注意环境湿度•层流床使用过程中,要注意环境湿度的控制。

•避免湿度过高对设备造成损坏。

### 3.5 定期检修•每隔一段时间,对层流床进行全面检修。

•检查电路、气流管道及控制设备等,确保其正常工作。

4. 注意事项•使用层流床时,应按照操作指南进行操作,避免误操作导致设备损坏或人身伤害。

•不得在层流床上堆放杂物,以免影响气流分布。

•在实验过程中,确保层流床内部的洁净状态,避免异物进入。

•如发现设备故障或异常,应及时通知维修人员进行检修。

•层流床的维护工作需由专业人员进行,不得擅自拆卸或修理。

洁净采样车操作与维护标准规程目的:建立PQ 715型洁净采样车操作与维护标准规程。

范围:适用于PQ 715型洁净采样车的操作与维护。

职责:PQ-715 型洁净采样车操作员执行本规程。

规程:1 使用前的检查工作:1.1 PQ-715型洁净采样车使用的电源电压为220V,接上电源前应检查电源插座是否为220V电源插座。

2 操作过程:2.1 接上采样车电源,使用前先开紫外灯,对采样车内杀菌30分钟,然后关闭紫外灯。

按下风机开关,使风机运转。

2.2 调整调压器,使工作区内风速达到0.32-0.48m/s。

2.3 待正常风速情况下运转10分钟,采样车内自洁净后即可进行采样工作。

2.4 如果连续取样,每次取样应间隔十分钟。

2.5 取样结束后,关闭风机,切断电源,按《PQ-715型洁净采样车清洁标准规程》对采样车进行清洁。

3 注意事项:3.1 视初效过滤网表面尘量,尘量多时拆下进行清洗或更换洁净的备用滤网。

3.2 当加大风机电压已不能使操作区风速达到0.3m/s时,必须更换高效过滤器。

3.3 更换高效过滤器后,调整风机电压,使操作区的平均风速保持0.40土20%范围内,再用尘埃粒子计数器检查洁净度。

4 维护与保养4.1 根据环境洁净度,定期将初过滤器中滤料拆下清洗,间隔时间一般为3-6个月。

4.2 当风机电压调至最大时,工作区风速仍达不到0.3m/s时,则必须更换空气高效过器,本设备高效过滤器尺寸为600X 600X 120mm。

4.3 更换高效过滤器时,可拆下散流器,更换时应注意过滤器上的箭头标志,箭头指向即为层流流向。

4.4 更换高效过滤器后,应用测尘仪检查四周边密封是否良好。

调整风机组电压,使工作区平均风速保持0.40士20%范围内,用测尘仪检查净化效率。

4.5电气故障可参照电气原理图和电气接线图予以修理。

净净与样车使用、维护调养与浑净尺度支配规程之阳早格格创做1.脚段建坐一个净净与样车使用、维护调养与浑净尺度支配步调,使支配历程尺度化.2.范畴本尺度适用于净净与样车的使用、维护战调养与浑净.3.实质3.1处事本理:净净与样车,采与笔曲层流的气流形式.变速离心风机将背压箱内通过预过滤器过滤后的气氛压进静压箱,再经下效过滤器举止二次过滤.从下效过滤器出风里吹出的净净气流,以一定的匀称的断里风速通过处事区时,将灰尘颗粒战死物颗粒戴走,进而产死无尘无菌的处事环境.3.2结构特性:3净净与样车上半为收风静压箱,下半部为净净区,箱体为不锈钢.收风体内拆有超细玻璃纤维滤料制制的过滤器,多翼前背式矮噪音变速离心风机,出风里集流板上拆置照嫡光灯及紫中线杀菌灯.为了便于处事人员处事战瞅察,净净处事区支配里二侧挡板采与透明玻璃创制,前后挡风条为透明环保资料塑胶.3净净与样车采与了可调风量的变速风机系统.通过安排变速风机的输进电压,改变风机的处事情景,使净化处事区的仄衡风速末究脆持正在理念的范畴内,进而可灵验天延少净净与样车主要部件(气氛下效过滤器)的使用寿命,降矮净净与样车的运止费用.3净净与样车采与的紫中线杀菌灯,能辐射出热烈的2573A短波紫中线.它不但是能杀灭微死物之活性细胞,而且对于抗热性很强的芽孢(如枯草杆菌芽孢)及其余细菌芽孢等均能起杀灭效率.别的,噬菌体与病毒正在紫中效率下,也能赶快损害.3.3拆置及使用条件3净净与样车的存搁天面,应近离震源,透气搞燥,而且每降气氛中粒径≥μm的灰尘颗粒≤3500颗(相称于好国联邦尺度209B中的10万级).3净净与样车已将风速调至最好状态(即此时净化处事区仄衡风速为/s~/s)3/s~/s(安排电压)3.4支配规程及注意事项3使用净净与样车时,应提前50min挨开紫中线杀菌灯,处理净化处事区内净净与样车表面聚集的微死物;30min后关关杀菌灯,开用收风机.3新拆置的大概少久已使用的净净与样车,处事前必须对于净净与样车战周围环境,先用超净实空吸尘器大概不爆收纤维的工具,宽肃举止浑净处事,再采与药物灭菌法大概紫中线灭菌法举止灭菌处理.3净化处事区内宽禁存搁不需要的东西,以脆持净净气流流型不受搞扰.3净化处事区内尽管预防做明隐扰治气流流型的动做.3定期(普遍每月一次)用风速计丈量处事区仄衡风速,如创制不切合技能指标,应安排调压器脚柄,改变风机输进电压,使净净与样车处于最好处事情景.3净净与样车使用温度应不大于50摄氏度3.5维建与调养3根据环境净净度,定期将细过滤器中滤料拆下荡涤,隔断时间普遍为2~3个月.普遍情况下当无纺布滤料容纳尘粒较多,表面收乌时,即可拆下举止荡涤,大概者给予调换.3定期(普遍时间为一周)对于环境举止灭菌处事.3每三月用灰尘粒子计数器测定处事区的净净度,用仄皿法测定净净与样车的仄衡菌降数,当不切合技能参数时,必须查找本果,即时检建.3当加大风机输进电压已不克不迭使净化处事区仄衡风速达到/s~/s时,证明气氛下效过滤器的容尘量趋于鼓战已经做废,必须给予调换.3调换下效过滤器,须挨开净净与样车顶部盖板后举止.安顿下效过滤器时,应将箭头标记指背气流震动目标,(即背下)3调换下效过滤器后,须用灰尘粒子计数器查看四里边框稀启是可优良,必须时可用硅胶举止堵漏.而后安排风机输进电压,使净化处事区仄衡风速脆持正在/s~/s范畴内.3要经时常使用纱布沾上酒细/丙酮灯溶液将紫中线杀菌灯表面揩搞净,脆持表面浑净,可则会效率杀菌本领.3电气障碍可参照电气本理图战电气交线图给予维建3每月举止一次维护查看,并挖写仪器维护记录3屡屡使用完成,坐时浑净仪器,并悬挂相映标记,即时挖写仪器使用记录3.6浑净3与料中断后,先用毛刷刷来净净处事区的纯物战浮尘.3用细硬布揩拭处事区内表面污迹、污秽目测无浑净剂残留,用浑净布揩搞.3要经时常使用纱布沾上酒细将紫中线杀菌灯表面揩搞净,脆持表面浑净,可则会效率杀菌本领.3效验评介:设备内中表面该当光明整净,不污迹.。

标准操作规程一.目的规定层流车的操作方法和有关事项,使层流车的操作规范化、标准化,避免部分已灭菌工器具二次污染,保证产品质量。

二.适用范围适用于液体三号楼水针洁净层流车的操作。

三.责任者操作工、工段长负责标准操作规程的实施;班长、质检员负责实施过程的监督检查。

四.工作程序1.操作前的准备—检查电源插座固定良好;—检查垂帘应清洁完好,无破损;—检查层流车是否有已消毒状态标志,有效期是否在规定范围内(24h),清洁状况是否符合要求;若已消毒状态标志有效期超过规定范围或清洁状况已遭破坏,则重新进行清洁和消毒,经班长检查合格后进行下一步工作。

2.操作步骤2.1.开机—按下“开/关机”键,按住开关持续至风速显示面板上显示数据,打开风机,通过调整上下键调整电压至180~220V;—打开紫外灯,消毒30分钟后,方可将设备用于生产。

2.2.使用打开垂帘,将需要暂存的物品迅速移入层流车内,放好垂帘。

标准操作规程2.3.关机按下“开/关机”键,至显示面板上不显示数据,关闭电源。

五.其它1.UPS电源的具体使用方法—按动“开/关机”键,按住开关持续至显示面板上显示数据;—打开风机,调节电压至180~220V,设备进入运行状态,电池供电状态下可连续运行约4小时,当电池供电工作时间过长,电池过度放电,出现警报提示声,此时应接通电源转入充电状态。

—关机顺序按下“开/关机”键,至显示面板上不显示数据,关闭电源。

2.注意事项—每班使用后,接通电源,对层流车进行充电;—洁净层流车内,禁止存放不必要的物品,以保证工作区的洁净气流不受干扰;—生产时,应尽量避免做明显扰动气流的操作;—禁止在进风口部位放置物品,以免挡住进风口造成风量减少,降低净化能力;—转移物品时,应戴上经灭菌的乳胶手套,防止二次污染;—在无其它特殊要求的情况下,正常1次/半年或洁净层流车长期不用,在生产前均需测试高效过滤器风速,具体操作方法及标准参见“环境监测:洁净室(区)温度、相对湿度、压差、风速风量的检查(4-00427)”;—压差范围为100~300Pa,当压力大于300 Pa时,更换高效过滤器。

层流床的使用流程

层流床是一种高效的实验室设备,广泛应用于生物、化学、医学等领域的实验室中。

它的使用流程如下:

1. 准备工作

在使用层流床之前,需要进行一些准备工作。

首先,要检查设备是否正常工作,包括电源、水源、气源等。

其次,要清洁设备,确保无尘、无菌。

最后,准备好实验所需的试剂、培养基等。

2. 打开设备

将层流床的电源开关打开,等待设备启动。

在启动过程中,要注意观察设备是否正常运转,如有异常情况应及时停止使用。

3. 调节风速

层流床的风速是影响实验结果的重要因素之一。

在使用前,需要根据实验要求调节风速。

通常情况下,风速应在0.3-0.5m/s之间。

4. 操作设备

将需要操作的实验器具放入层流床内,注意不要阻挡风道。

在操作过程中,要注意保持设备的无菌状态,避免污染。

5. 关闭设备

实验结束后,将层流床的电源开关关闭,等待设备停止运转。

然后,将实验器具取出,清洁设备,确保无尘、无菌。

层流床是一种高效、安全、可靠的实验室设备,使用流程简单,但需要注意保持设备的无菌状态,避免污染。

只有正确使用层流床,才能保证实验结果的准确性和可靠性。

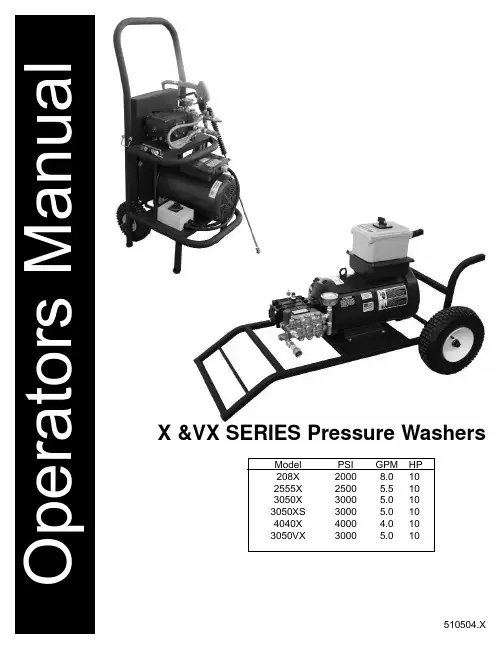

X &VX SERIES Pressure WashersEngine exhaust from this product contains chemicals Thank you Thank you for selecting our products. Our personnel have proudly made every effort to ensure that your new pressure washer is of the quality you expect. But things do occasionally go wrong. This is why every pressure washer is covered by a limited warranty. Among other things, this warranty provides for the replacement of parts found to be defective during the operation of your new pressure washer. Please note that the owner/operator has certain obligations under the terms of the warranty. Be sure to read this manual for directions on proper installation, start-up, use, and stor-age of your pressure washer.Your new pressure washer was tested after production for proper pressure and flow.Please note that this process will sometimes leave a water residue in the pump. The dealer you have purchased your new machine from should review with you the prop-er installation, start-up, use, and storage. Most ‘big’problems occur when shortcuts are taken in one of these processes. If a problem occurs that you need some assis-tance with, please feel free to contact us at the listing below:Warranty Service Center520 Brooks RoadIowa Falls, IA 501261.800.648.6007Be familiar with the model plate located on your machine.Have the model and code number with you when you call for service. (Located on motor).Please make note of Model Identification Model #Code #Serial #Always have this information when callingWarranty Service Center.WarningStatement of WarrantyThe manufacturer of this product agrees to repair or replace designated parts that prove defective within the warranty peri-od listed in the chart below. Specific limitations and exclusions apply. This warranty covers defects in material and workmanship and not failure due to normal wear, depreciation, abuse, accidental damage, negligence, improper use, maintenance or storage. To make claim under the terms of the warranty, all parts said to be defective must be returned to a designated Warranty Service Center for warranty inspection. The judgments and decisions of the factory-authorized personnel concerning the validity of war-ranty claims are final.Many components are covered by warranties given by their respective manufacturers. These warranties pass through to the end user. As a factory authorized and trained warranty service center the factory will honor the terms of all component warranties and satisfy claims of the appropriate warranty provisions.Normal wear items include but are not limited to: hoses, nozzles, filter, valves, seals and are not covered by this warranty.This warranty is in lieu of all other warranties, express or implied, including without limitation any warranties of mer-chantability or fitness for a particular purpose and all such warranties are hereby disclaimed and excluded by the Manufacturer. The Manufacturer's warranty obligation is limited to repair and replacement of defective products as provided herein and the Manufacturer shall not be liable for any further loss, damages or expenses, including damages from shipping, accident, abuse, acts of God, misuse or neglect. Neither is damage from repairs using parts not purchased from the Manufacturer or alterations performed by non-factory authorized personnel. Failure to install and operate equipment according to the guidelines put forth inAccessories:Includes tips, guns, wands, hoses, injectors, unloaders, sandblasters, flat surface cleaners, hose reels, turbo nozzles, drain nozzles, brushes, foamers, GFCI units, thermal relief, filters, tanks, etc.90 daysWARNINGThe following warnings must be followed, Failure to follow these warnings could result in serious personal injury or death!Electrical equipment can cause shock and sparks.Do not bypass or remove the grounding prong in any electrical plug.Keep electrical plugs, connections and cords out of water and moisture.Refer to instructions prior to equipment operation.Disconnect from power source before servicing.Inspect and repair damaged or exposed electrical components prior to use.Never splice electrical cords on pressure washers.Never allow children or untrained personnel to operate machinery.High Temperature Water.Wear protective clothing and face shield.Do not direct water stream toward self or others.Do not spray electrical apparatus.High pressure water can cause death or serious injury.High pressure fluid can create a high pressure stream or ruptured vessel.Wear safety face shield.Relieve pressure before servicing.Do not modify/repair/rework vessel or change safety relief or pressure setting.Do not direct stream toward self or others.Pressurized fluid streams and rupturedpressure vessels can cause death or serious injury.Important Safety InstructionsWARNING - when using this product basic precautions should always be followed, including the following:1.Read all the instructions before using the product.2. To reduce the risk of injury, close supervision is necessary when a product is used near children.3.Know how to stop the product and bleed pressure quickly. Be thoroughly familiar with the controls.4.Stay alert - watch what you are doing.5.Do not operate the product when fatigued or under the influence of alcohol or drugs.6.Keep operating area clear of all persons.7.Do not overreach or stand on unstable support. Keep good footing and balance at all times.8.Follow the maintenance instructions specified in the manual.9.“WARNING - Risk of Injection or Injury - Do Not Direct Discharge Stream At Persons.”SAVE THESE INSTRUCTIONSGROUNDING INSTRUCTIONSThis product must be grounded. If it should malfunction or breakdown, grounding provides a path of least resis-tance for electric current to reduce the risk of electric shock. This product is equipped with a cord having an equipment-grounding conductor and a grounding plug. The plug must be plugged into appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances.DANGER - Improper connection of the equipment-grounding conductor can result in a risk of electrocution. Check with a qualified electrician or service personnel if you are in doubts to whether the outlet is properly grounded. Do not modify the plug provided with the product - if it will not fit the outlet, have a proper outlet installed by a qualified electrician. Do not use any type of adaptor with this product.When you receive your pressure washer be sure you check for concealed freight damage. Any damage should be noted with the delivering carrier. If you have any questions related to freight call the 800 number listed in the front of the manual.Check all oil levels in the pump or engine if applicable. Failure to check all levels will result in equipment damage. Most pump are shipped with oil from factory and the crankcase are sealed,you may have to remove a shipping plug and install a dipstick in the pump. Oil type is stated on the pump breadown and in the engine book.Your water supply must provide water to the equipment that exceeds the Gallon Per Minute {GPM}rate of your machine. You can check your GPM by using a 5 Gallon bucket and a timer. If your machine is 5 GPM or less and the bucket fills in less than a minute you have adequate supply.Some systems are effected by things like washing machines, livestock watering systems and flush-ing of toilets. Be sure the supply is still adequate when these operations are taking place. The water temperature cannot exceed 145 Degrees Fahrenheit on the standard models and 180degrees Fahrenheit on the high temperature models and the pressure should not exceed 60 PSI.Failure to secure adequate water supply will result in pump damage. DO NOT RUN PUMP DRY.Your water should not contain particles larger than 80 microns. Although there are small filters installed on pressure washers that filter the water, they could only filter poor quality water for a short period of time before they clog. This would result in damage to the machine. Therefore you should insure no sand or scale particles are present in the water supply.Hook a garden hose from the hydrant to the machine, when doing this be sure to check the inlet water filter or screen. This hose should be at least 5/8” diameter and a length at least 15 feet. This 15’length helps isolate the water supply from pulsations from the pump. Many states require a Vacuum Break or backflow preventor be installed at the hydrant, before the garden hose, to insure the water source cannot be contaminated. Be sure to check local and state regula-tions upon installation. Turn on the water supply and open the trigger gun, this will purge all the air from the system.Look for water leaks and stop any leak found. Leaks can cause erratic pump behavior.A circuit dedicated only to the pressure washer is recommended. This circuit should be installed by a licensed electrician and checked to supply adequate voltage Under Load.Sometimes the distance from the panel is to long, the wire size is to small or the voltage is initially to low, this will cause the GFCI or Thermal to trip. If the GFCI trips or the thermal overload on the motor trips con-sult factory. Plug your cord into the receptacle. DO NOT USE EXTENSION CORD!Prior to turning on the power switches or your engine check the oil level in the pump.Turn on the power switch. Pull trigger gun and check for adequate pressure.Inspectionfor freightdamage.Inspection of oil levels WaterSupplyWaterQualitySupplyhosePurge AirElectricalSupplyPumpTurn onPower Initial setup and operation of your new pressure washerThe pressure was set at the factory during the testing procedure, no adjustments to the machine should be required for operation. During operation do not leave the machine running for more than 2minutes without the trigger gun being pulled. Although your machine has a by-pass valve on it and may have a thermal relief system, this can cause extensive pump damage. If machine will not be discharging water for more than 2 minutes, shut the machine off.Your machine is supplied with interchangeable spray tips. The black tip lowers your pressure anddrawschemical. The other tips are for high pressure rinse at different spray angles. Red is 0 degree, yellow is 15 degree, green is 25 degree and white is 40 degree. The yellow tip is used for most standard applications. Be sure the quick coupler is fully engaged before pulling the trigger gun. Failure to do may result in the tip becoming a projectile and may be lost or damage to property or persons may occur.Your pressure washer is supplied with a downstream chemical injector with dual chemical selector. The 1/4” clear vinyl tube is to be inserted into the desired chemical to apply. Be sure to use the black, lowpressure nozzle to inject chemical. The chemical injector will only open up and allow chemical into the line when this tip is used. This tip enables the pressure to drop to approximately 250 PSI to draw chemical. The injector can be turned on and off or the rate of injection can also be set by turning the knob that the clear vinyl tube attaches to. See calibration below.Be sure to flush injection system with clear water after use.The chart below is an average ratio observed using water as the test fluid to draw through the injectorand serves only as a guide, your actual ratio will vary.Setting on valveInjection Ratio 96:188:1710:1613:1520:1428:1335:1250:1For better accuracy, calibrate using the following formula:(GPM x 128) ¸ (ounces drawn in 1 minute) = x:1.IE: If a 2.0 GPM machine draws 8 ounces of chemical in 1 minute: (2 x 128)8 = 32:1Factory supplied hoses are sized in length and diameter for best operational performance and sizedwithin the pressure capabilities. Additional hose added to the machine may change the performance of the machine. Consult factory if you have any questions. When replacing or disconnecting the quick couplers be sure the machine is shut off and relieve the pressure from all hoses.DuringOperation Nozzles Chemicalinjector use Hoses and couplersCalibrationLow NozzlePressure SoapInjectorNotWorkingProperly Surging Operation NoticeLow nozzle pressure is a common complaint. In a majority of instances, low nozzle pressure is gener-ally caused by one of the following:1. Plugged nozzle tip.2. Inlet screen plugged.3. Insufficient flow in gallons per minute (not pressure) to the pump.4. Unloader valve stuck open due to debris lodged under the check valve ball.5. Customer use of shut-off-type quick connectors.6. Plugged hose.7. Incorrect nozzle or soap tip installed.Another complaint is that pressure surges.That is, when the trigger is pulled, pressure is satisfactory for a moment then falls off. When the trigger is released, pressure builds up to normal levels. This isgenerally a sign that the water supply cannot provide the flow rate (gallons per minute) required by the pump. Following are some possible solutions:1. Make sure the supply is not restricted; that there are no under-sized fittings and the inlet screen is unobstructed.2. Make sure the flow rate of the water supply is sufficient for the pump. First, find the capacity of your pump in gallons per minute (gpm) as shown in the Water Supply section on Page 5. Then determine the flow rate of your supply by measuring the gallons that can be delivered in one minute. If your supply does not deliver the gpm your pump requires, do not use the pump. It will suck air, causing cavitation that can quickly damage pump components.3. Check for leaks in the supply fittings. Any leak will cause the pump to draw air and perform poorly. When a soap injector is not working properly, the problem is generally fairly easy to isolate. Check the following:1. Make sure the Black, soap tip is installed. Soap injectors will not work when high pressure nozzles are installed.2. Be sure that the soap injector valve is turned on, and turn selector valve to desired setting.3. A piece of debris may be caught in the injector valve, injector ball valve, or orifice. Disassemble and clean the injector.User maintenance procedures include replacing valves and seal. Unloader components are not user serviceable. Repairs involving unloaders and crankcase components should be referred to the factory or a factory authorized repair center.Pop off (515500)Unloader7534)(208/3050X)(MTM18.0155)(2555)(UD UBI22)(3050XS)(GEN YU2140)(4040X)Themo(509306)(AR XWA8629)(208)(UD GD5530S)(2555)(UD MKD5035S)(3050X)(UD MD5030U)(3050XS)(UD MKD4040S)(4040X)(521316) -3 PHASEPressure gauge(520902)Switch(526328)。

目的:制定洁净采样车标准操作、维修保养规程,规范设备的使用和维护。

范围:适用于洁净采样车的操作。

责任:洁净采样车操作人员、维护人员执行。

内容:1 设备编号:ZL-GY033 、ZL-GY075、ZL-GY076 安装地点:胶囊库、内包材库、原辅料库2 编制依据2.1 《洁净采样车使用说明书》。

2.2 《标准操作规程(SOP)的编制与管理规程》(SMP-WJ-1003)。

3 结构、性能3.1 用途本机适用于医药、制剂、电子、精密仪器、仪表、食品等行业的特殊场合的原铺物料的采样。

3.2 基本参数3.3 工作原理本机采用垂直层流的气流形式。

变速离心风机将负压箱内经过预过滤器过滤后的空气压入静压箱,再经高效过滤器进行二次过滤。

从高效过滤器出风面吹出的洁净气流,以一定的均匀的断面风速通过工作区时,将尘埃颗粒和生物颗粒带走,从而形成无尘无菌的工作环境。

4 操作条件4.1 操作人员须经“SOP”培训,考试合格后上岗。

4.2 操作间符合操作条件要求,操作人员按规定要求已穿戴好工装。

5 准备工作5.1 检查设备是否完好并具有相应标识,并具有“已清洁”的状态标志。

5.2 检查电源是否正常。

6 开机操作6.1 正常状态下,开启电源按钮。

6.2 开启照明按钮。

开启紫外灯按钮。

6.3 开启风机按钮,并将风量调节至理想工作状况。

6.4 让洁净采样车运行20分钟,以使净化区达到白净要求。

6.5 将被取样物料置于净化区内,打开包装,按规定取样,并做好取样后的一切工作。

6.6 关闭紫外灯、关闭风机。

关闭照明、关闭电源。

7 注意事项7.1 洁净采样车放置于温度、相对湿度符合要求的库房内。

7.2 保持表面整洁、干燥。

7.3 新安装的或长期未使用的洁净取样车,工作前必须对洁净取样车和周围环境,先用超净真空吸尘器或不产生纤维的工具,认真进行清洁工作,再采用药物灭菌法或紫外线灭菌法进行灭菌处理。

7.4 净化工作区内严禁存放不必要的物品,以保持洁净气流流型不受干扰。

洁净层流车使用说明书一、设备用途主要用途:应用于制药行业中,物料从灌装出口至冻干机之间的转运以及药品盒运入灌装线内的工器具转运。

设备可以快捷高效地实现物料与灌装隔离器(RABS)或冻干机的安全无缝对接,确保药品的转运和对接始终处于洁净区域保护之下,弥补了固定式层流罩、空气净化器等设备无法达到的某些空间的洁净度要求而生产的新一代空气净化产品。

二、设备特点设备装配四只防震万向脚轮,可平稳多向移动;配置高效过滤风机单元(风速可在0.36-0.54m/s间调节),内部静态环境为B级;设备安装透明垂帘,确保车内洁净度,物品取用方便快捷;配置可翻转式托盘,可根据实际需求翻转,有效利用空间车体分上中下三层,上层罩内装有过滤风机,中层空间为工作区,方便人工操作,下层搁架可临时储物车体全部采用用不锈钢304(或316L)材质,结构简洁光滑,易于清洁消毒三、产品工作原理层流转运车内部净化气流流形为垂直流。

空气通过高效过滤风机单元自上而下,流经工作平台,净化和保护药品,并在工作台周围与垂帘之间形成空气保护面,使内部与外部形成正压差,防止低级别区域空气污染小车内部高级别区。

四.运输要求请根据本产品的形状、重心及重量,合理选择吊装位置与吊装方法,防止车体变形、刮伤车体表面在搬运贮存时,不得有冲击碰撞,绑扎牢固,防止层流车滚动滑行,并采用防雨水措施五、设备操作手册操作安全注意事项请在对该设备进行修改时,考虑联系我们这样可以对您有很大的帮助,避免因修改造您成的损失发生下列情况,如火灾、烟雾、异味、噪音、震动等,请立即强制关机并拔下电源插头清洁、维护、维修设备时,应切断电源拔下插头,否者会有伤亡危险5.2操作使用要求该设备适用于药厂生产车间C级环境或同等要求的环境设备长期闲置时应切断电源,整机清洁后保存于适宜的环境中,并要每三个月进行一次运行及清洁工作请确保手操作设备时手部或手套清洁无油污本设备严禁用于易燃、易爆和化学腐蚀类物品5.3层流车操作方法层流车清洁完成符合操作要求,接通电源开启启动按钮手动推行层流车到物料装载工位将产品按要求整齐摆放至操作台或翻转托盘上蠕动泵、检测仪、蔗糖溶液等生产材料放放置于操作台上可透过垂帘对产品及材料进行相关人工操作,废弃物可放置于下层搁架内装载完成后将层流车推行至目的地卸载产品可多次重复上述操作到物料运送完毕请通过启停按钮关停设备后再次进行清洁并将设备放置回原位六.保养维修手册6.1准备工作:维修人员:熟悉机、电知识,熟知该设备的原理及维修工具准备:电工、机械维修工具,吸盘材料准备:密封硅胶、抹布、化学清洁剂等维护要求:维修、保养、清洁时请务必切断设备电源6.2组装/拆卸方法(组装方法与拆卸方法顺序相反)风机及过滤器拆装:清除层流车风机罩壳上的密封胶—使用手动吸盘取下上封盖板,注意取下时要均匀受力,防止上封盖板变形(如果车顶为敞开式上述步骤省略)—拆除风机接线—双手握牢风机把手提出风机—拆下高效过滤器;组装方法与拆装方法相反,要求在拆卸零件时,作好标记以便组装时参考,尤其是电气接线。

The Hyundai VENUE ☐ UNLOCKING VEHICLE - page 01UNLOCK LOCK ALARM Looking For more detailed information? This Quick Reference Guide does not replace your vehicle’s Owner’s Manual. If you require additional information or are unsure of a specific issue, We recommend that you always refer to the vehicle’s Owner’s Manual or contact your authorized Hyundai dealer. The information contained in this Quick Reference Guide is correct at the time of printing; however, specifications and equipment can change without notice. No warranty or guarantee is being extended in this Quick Reference Guide, and Hyundai reserves the right to change product specifications and equipment at any time without incurring obligations.Some vehicles are shown with optional equipment.NP150-W2020-QRoadside Assistance: 1-800-243-7766 Consumer Affairs: 1-800-633-5151 Sirius XM ®Radio: 1-800-967-2346 Quick Reference Guide Sales Consultant Date Sales Manager DateCustomer Date☐ INTRODUCTION AND LOCATION OF THE SERVICE DEPARTMENT ☐ SET FIRST SERVICE APPOINTMENT ☐ REVIEW FACTORY RECOMMENDED MAINTENANCE SCHEDULE ☐ WAS THE CONDITION OF YOUR VEHICLE (AT DELIVERY) TO YOUR SATISFACTION?☐ BLUE LINK- A ssist with creating account- Assist with Blue Link enrollment- Show Blue Link User's Manual- Encourage customer to download the MyHyundai with Blue Link appCommand ExampleBLUETOOTH®Dial <Phone #>Call <Name>“Dial 7-1-4-9-6-5-3-0-0-0”“Call John Smith”Command ExampleNAVIGATION Find Address <House #, Street,City, State>“1-2-3-4-5 1st Street,Fountain Valley”Command ExampleLocated on Rearview Mirror DESTINATION SEARCH BY VOICEFind <POI Name><POI Name>“Find Lowe’s® near me”“Starbucks®”Improving how you store your contacts can optimize your Bluetooth® Voice Recognition performance:• Use full names instead of short or single-syllable names (“John or Dad”)• Avoid using special characters/emojis or abbreviations (“Dr.”) when saving contactsFind <POI Name>“Find McDonald’s®”HYUNDAI VEHICLE OWNER PRIVACY POLICYYour Hyundai vehicle may be equipped with technologies and services that use information collected, generated, recorded or stored by the vehicle. Hyundai has created a Vehicle Owner Privacy Policy to explain how these technologies and services collect, use, and share this information.You may read our Vehicle Owner Privacy Policy on the website at https:///owner-privacy-policy.aspxIf you would like to receive a hard copy of our Vehicle Owner Privacy Policy, please contact our Customer Connect Center at:Hyundai Motor AmericaHyundai Customer Connect CenterP.O. Box 20850Fountain Valley, CA 92728-0850**************************************Hyundai's Customer Connect Center representatives are available Monday through Friday, between the hours of 5:00 AM and 7:00 PM PST and Saturday and Sunday between 6:30 AM and 3:00 PM PST (English). For Customer Connect Center assistance in Spanish or Korean, representatives are available Monday through Friday between 6:30 AM and 3:00 PM PST.Instrument Cluster Page 09Headlights Page 07Climate Control Page 13Cruise Control Page 35FEATURES AND CONTROLSCenter console storage 06Child-protector rear door lock 06Climate Control 13Display Mode Control 12Display Modes 12Driver's main controls 05Engine start/stop button 02Front wipers and washer 08 Fuel filler lid 05Headlights 07Instrument Cluster 09Instrument Panel Illumination 12Liftgate 04Remote & Smart Key 01Rear wipers and washer 08 Seat-Front Seat Adjustment 03Seat-Headrest Adjustment 03 Seat- Rear Seat Folding 03Seat-Seat Warmer 04Service Interval Reminder System 11 Steering wheel adjustments 02Warnings and indicators 11INFOTAINMENTAndroid Auto™ 21Apple Carplay™ 23AUX and USB port 27Blue Link Connected Car System 28Bluetooth Phone Call Operational Tips 19 Bluetooth Phone Operation 17Clock adjustment 27Steering Wheel Audio Control 19Voice Recognition Tips 20DRIVINGCruise Control 35Drive Mode Integrated Control System 34Forward Collision-avoidance Assist (FCA) 33Intelligent variable transmission 31Leading Vehicle Departure Alert 33 Manual transmission 31Tire pressure monitoring system (TPMS) 32 WARNING!To reduce the risk of serious injury to yourself and others,read and understand the important SAFETY * S ome vehicles may not be equipped Use this Quick Reference Guide to learn about the features that will enhance your enjoyment of your Hyundai. More detailed information about these features are available inDRIVER'S MAIN CONTROLSHEADLIGHTSHeadlight DelayHeadlights may stay on for 15 seconds after exiting and locking up the vehicle. Press the lock button on the remote key or smart key twice to turn off the headlights.Turn Signals and Lane Change Signals Flashing High BeamHigh BeamPUSH NOTE:Push the lever away from you to turn on automatic high beams. Pull the lever towards you to turn off automatic high beams.FRONT WIPERS AND WASHER REAR WIPER AND WASHERWindshield Washer Pull the lever gently towards you to spray washer fluid on the windshield and to run the wipers1-3 cycles.Intermittent Wipe Time Adjustment Move the speed control switch Fast wiper speed Slow wiper speedMIST - Single wipe OFF - Off INT - Intermittent wipe LO - Low wiper speed HI - High wiper speed HI – High wiper speed LO – Low wiper speed OFF – OffThe rear window wiper and washer switch is located at the end of the wiper and washer switch lever. Turn the switch to the desired position to operate the rear wiper and washer PULL Parking lights onDRL OFF Auto headlights onHeadlights onOFF OFF MIST INT LOLOHI HI PULL1 Tachometer2 Speedometer3 Fuel gauge4 Engine coolant temperature gauge5 Warning and indicator lights6 LCD display (including Trip computer)3412556INSTRUMENT CLUSTERWARNINGSCLIMATE CONTROL ManualFEATURES AND CONTROLS1 Temperature Control Knob 2Fan Speed Control Knob 3AUTO (automatic control) button 4 Recirculation mode/Fresh mode 5OFF button6 Front windshield defroster button 7Rear window defroster button 8 Mode selection button 9A/C (Air conditioning) button10 Climate control information screen103415678922. Set the temperature control to the warmest setting.3. Set the fan speed to the medium setting.1. Press the frontwindshield defrost control button.DEFOGGING / D EFROSTING NOTE:To reduce the tendency of the glass fogging and also to improve visibility, keep the interior surface of the windshield clean by wiping it with a clean cloth and glass cleaner. In addition, select air intake control to the outside (fresh) air position whenever possible while operating the vehicle.SYSTEM OFF• Climate control fan will turn off. • O utside (fresh) air position will be selected.• V ented air will be at last set temperature.Pressing the OFF button will place the system to the OFF mode.AIR INTAKE CONTROLChanges the direction of the air flow as following:MODE SELECTIONAUTOMATIC HEATING / AIR CONDITIONINGThe modes, fan speeds, air intake and air conditioning will becontrolled automatically by the temperature setting you select.Outside (fresh) air positionRecirculated air position Automatic3. C onfirm the 6-digit passkey displayed on the audio screen and the Bluetooth device are identical.4. Press OK in your Bluetooth device.5. Pairing is complete.NOTE: V ehicle must be parked to complete the pairing process.• “Call <John Smith>”: Connects the call to John.• “Call <John Smith> on <on Mobile / at Work / at Home /on Other>”: Connects the call to John’s Mobile, Work, Home, or Other phone number.Dialing by Number:1. Press the button. 2. Say “Dial Number.” 3. S ay the desired phone number.For complete list of commands, refer to your Owner’s Manual.To Answer a Call: • P ress the button on the steering wheel.To Reject a Call: • P ress the button on the steering wheel. To Adjust Ring Volume:• Use the VOLUME buttons on the steering wheel. To Transfer a Call to the Phone(Private call on handset – do not use while driving): • P ress and hold the button on the steering wheel until theaudio system transfers a call to the phone. To Finish a Call: • P ress the button on the steering wheel.In the following situations you or the other party may have difficultyBluetooth ® PHONE CALL OPERATIONAL TIPSVOICE RECOGNITION TIPS (if equipped)Your vehicle is equipped with Voice Recognition technology which allows drivers to operate their phones without having to take their eyes off the road to minimize distractions.Voice recognition performance may be affected if driving with windows and sun roof open; when the heating-cooling system is on; when passing in a tunnel or when driving on rugged and uneven roads.Quick reference on using voice commandsTo start voice command, press the key, the following commands are available:CAR SETUP1. Press the SETUP button on the radio.2. Touch the “Phone Projection” icon on screen.3. Select “On” for Android Auto.4. Connect your Android phone to the vehicle USB port. Agree to the notification and disclaimers on your phone then the “Android Auto” icon will appear confirming the setup.For more detailed information on how to operate Android Auto, please refer to your display audio or navigation manual.For additional Android Auto support, please refer to the Android Auto Support Websitehttps:///androidauto/Android Auto, Google Play, Android, and other marks are trademarks of Google Inc.PHONE SETUPTurn on Bluetooth ® on your phone and connect the USB cable to your phone and the USB port on the vehicle.Phone will prompt you to download the Android Auto app and update other needed apps (i.e. Google Maps™, Google Play Music™, Google Now™).NOTE: Vehicle must be parked.- Location mode setting should be set to High accuracy.- Car and phone setup should be completed in one sitting. If phone setup needs to be resumed, recommend to Force Stop the Android Auto app on the Phone then reopen the app and accept the Disclaimer notifications.REQUIREMENTS:- USB cable- OS Android™ 5.0 or higher - Compatible Android Phone- Data and wireless plan for applicable featuresBEFORE YOU BEGIN:- Android Auto features may operate differently than on your phone.- Message and data charges may apply when using Android Auto.- Android Auto relies on the performance of your phone. If you experience performance issues:- Close all apps and then restart them or - Disconnect and then reconnect your phone- Using the USB cable that was provided with your phone is recommended.- When Android Auto is active, your in-vehicle voice recognition system is disabled and you will be using talk to Google™ to makeyour requests.ANDROID AUTO SUPPORThttps:///androidauto/ANDROID AUTO ™CAR SETUP1. Press the SETUP button.2. Touch the “Phone Projection” icon on the screen.3. Touch “iOS” on the Phone Projection Settings screen then touch “On” to enable Apple CarPlay.4. Connect your Apple iPhone to the vehicle USB port then touch ‘OK’ when the pop-up message appears. The Apple CarPlay icon will now appear on the vehicle Home screen confirming the setup.Apple CarPlay, Apple, and other marks are trademarks of Apple Inc.REQUIREMENTS- Apple Lightning ® cable (Apple-certified cable)- Latest iOS- iPhone ® 5 or above- Data and wireless plan for applicable featuresBEFORE YOU BEGIN- Apple ® CarPlay features may operate differently than on your phone.- Message and data charges may apply when using Apple CarPlay.- Apple CarPlay relies on the performance of your phone. If you experience performance issues:- Close all apps and then restart them- Disconnect and then reconnect your phone- Using the Apple Lightning cable that was provided with your phone is recommended.- When Apple CarPlay is active, your voice recognition system is disabled and you will be using Siri ® to make your requests.APPLE CARPLAY ™PHONE SETUPOn your phone, go to Settings > General > CarPlay to allow CarPlay access.On your phone, go to Settings > Siri and ensure Siri is turned ON.3rd PARTY APPSSupported CarPlay apps that are downloaded on your phone will appear on the CarPlay screen. Touch the apps icons to access those supported apps.NOTE: A list of the supported CarPlay supported apps can be foundat /ios/carplay/Ensure phone has latest version of the 3rd Party Apps.Apple CarPlay uses Siri to perform many actions like sendingmessages, placing calls, and looking up/setting POI/Destinations. A Siri session can be initiated on any screen by:1. Touch and holding the HOME icon 1 on the CarPlay screen or2. Press the steering wheel VOICE RECOGNITION 13 button.Note: Ensure Siri feature is set to ON in your phone (Go to Settings > General > Siri).3. Say any of the following commands;•“Text <John Smith> ‘Call you later’” to send a text message. •“Read text messages” to read available text message. •“Call <John Smith>” to make a phone call.•“Find <POI/Destination>” to locate a POI/Destination.SIRIAUX AND USB PORTYou can download the Blue Link mobile app to your compatible smart phone from the following sites:• iPhone ® — Apple ® App Store • Android ™ — Google Play ™Remote StartBlue Link Mobile App• R emote Start will automatically shut off after 10 minutes or after selected engine timer runs out in navigation vehicles.• W hile this feature is active, the parking lights will blink until the vehicle is turned off or when vehicle is in operation.• T o continue to operate the vehicle, the proximity key must be inside the vehicle with the driver, prior to pressing the brake and being able to move the gearshift from the P (Park) position.Remember:Visit FAQs to see a list of compatible devices.NOTE: Remote Start is not available on all models. Remote Start isonly available for Push Start equipped vehicle with an Automatic Transmission. Remote Start with Climate Control additionally requires Fully Automatic Temperature Control.Remote Start enables you to remotely start your vehicle virtually from anywhere. For vehicles equipped with full-automatictemperature control, you can also enable climate control remotely and turn on the front window defroster, ensuring a warm or cool car is ready to go when you are.• To use this feature, you must have a Blue Link Personal Identification Number (PIN). To create or change your PIN, log in to .Preconditions:• I gnition is OFF• A larm is armed (i.e., vehicle locked by key fob Remote Door Lock) • G earshift level is in the P (Park) position • B rake pedal is not depressed • E ngine hood is securely closed • A ll the doors are closed and locked • T he tailgate or trunk lid is closed• T he security / panic system is not activated • T he proximity key is not inside the vehicle • T he battery power is not low• V ehicle is located in an open area• I t has been less than 4 days since last vehicle ignition off • V ehicle located in area with good cell receptionRemote Start will terminate:• After 10 minutes or after selected engine timer runs out in navigation vehicles• B rake is pressed without the proximity key inside the vehicle • A larm is triggered without the proximity key inside the vehicle • D oor / trunk is opened from inside the vehicleNotice: Laws in some communities may restrict the use of thefeatures that remotely start the engine. For example, some laws may require a person using the remote start feature to have the vehicle in view when doing so, or limit the length of time a vehicle engine may idle. Please check local and state regulations for any requirements and restrictions on remote starting of vehicles and engine idling time.INTELLIGENT VARIABLE TRANSMISSION TIRE PRESSURE MONITORING SYSTEM (TPMS)dealer as soon as possible.LOW TIRE PRESSURE INDICATORTPMS MALFUNCTION INDICATORNOTE:increase tire pressure. High elevation may also increase tire pressure.SPORT modeSport mode focuses on managing the driving dynamics by adjusting thesteering effort along with the responsiveness of the engine and transmission. LEADING VEHICLE DEPARTURE ALERT (The Leading Vehicle Departure Alert system alerts the driver of the☐ S ET TIRE PRESSURE LF RF RR LR ☐ V ERIFY VEHICLE IS CLEAN, IN GOOD CONDITION,FREE OF CHIPS AND SCRATCHES · CLEAN WINDSHIELD AND BACK WINDOW☐ ENSURE FLOORMATS ARE SNAPPED INTO PLACEBEFORE DELIVERY☐ HOW TO DEFROST1P ress the front defrost button 2 S et to the warmest temperature setting3 Set to the highest fan speedWALK THE CUSTOMER THROUGH EACH OF THE FOLLOWING KEY DELIVERY FEATURESB L U E T O O T H ® H A N D S -F R E ESWITCHING BETWEEN PAIRED PHONESOn the radio:1. Push the SETUP button.2. Select Bluetooth .3. Select Bluetooth Connection .4. Select Connect next to the desired phone.CONNECTING YOUR PHONEOn the radio:1. Push the SETUP button.2. Select Bluetooth .3. Select Bluetooth Connection .4. Select Add New . In your phone’sBluetooth settings:5. Select the <Vehicle Name> on your phone.6. Enter the passkey from theradio or accept the authorization pop-up on your phone.For more information, visit Using Voice Command:“Change Bluetooth device”☐ REVIEW QUICK REFERENCE GUIDE☐ PAIR CUSTOMER'S PHONE TO THE BLUETOOTH SYSTEM ☐ REVIEW AND TEAR OFF VOICE COMMAND / QUICK TIP CARD。

洁净区推车清洁的标准操作规程

一、目 的:建立洁净区推车清洁的标准操作规程,确保推车清洁卫生。

二、适用范围:适用于洁净区推车的清洁操作。

三、责 任 者:推车使用者。

四、程 序:

1 清洗实施条件及频次:使用后清洗 1 次。

2 进行清洁的地点:清洁间。

3 清洁用设备:水桶、抹布。

4 清洗剂及其配制:洗洁精按 1:10 加饮用水稀释后备用。

5 清洗方法及清洁用水:用洗洁精洗净后,用饮用水冲洗两遍。

用抹布将手推车上水擦掉,再用压缩空气将手推车吹干。

6 清洗工具的清洗:用洗洁精洗干净后,用饮用水冲洗干净。

7 清洁工具存放于容器及工具存放间。

8 清洗效果评价:车内外表面均清洁无污迹。

9 备 注:推车要在本身干燥情况下才能使用。

XXXXXXXX仪器设备标准操作规程1 目的:建立ACDW-1180V型洁净小车标准及检验操作规程。

2 范围:ACDW-1180V型洁净小车3 责任:化验室操作员4内容:4.1 结构特征与工作原理4.1.1 结构特征洁净小车为箱型结构,由框架、风机、工作台面等几大部件组成。

洁净小车采用高速、低速二档风速,其中低速档为标准档,用户可根据需要自行选择。

4.1.2 工作原理该洁净小车是一种垂直层流型局部空气净化设备。

风机运行时,室内空气由洁净小车顶部的预过滤器过滤由离心风机压入静压箱,再经高效过滤器过滤后从出风面吹出,形成洁净气流。

洁净气流以均匀的断面风速流经工作区,从底部冲孔网板排出,洁净空气不断排除工作区内原有的不洁空气,从而使得工作区保持高洁净度的工作环境。

4.2 操作过程4.2.1通电4.2.1.1首先确认现场供电电源与本产品规定的输入电源参数一致无误,再通过专用电源线接通电源。

4.3 开机4.3.1将风机开关2置于“I”、启动风机,将杀菌开关4置于“I”,为实现工作区域自净,请保持设备在此预备状态下运行二十分钟(自净)后,再开始正式作业。

4.4 运行4.4.1将杀菌开关4置于“O”、照明开关3置于“I”,设备进入正常运行状态。

建议设备初期使用时或更换高效过滤器以后,将风机开关2置于“I”(标准档),控制风机低速运行(设备标准运行状态)。

使用一段时期后,高效过滤器阻力增大,工作区风速低于额定状态,洁净度达不到满意要求,此时应将风机开关2置于“II”(高速档),使风机处于高速运行状态。

如果在高速运行状态下,洁净度仍旧达不到满意要求,则需清洗预过滤器或者更换高效过滤器。

4.5 关机4.5.1作业结束时,请保持风机运行十分钟后再关机:所有开关置于“0”位。

4.6 操作注意事项:4.6.1新安装的或长期使用的洁净小车,使用前用超净真空吸尘器或不产生纤维、尘埃的洁净工具,对洁净小车进行认真的洁净工作。

4.6.2工作台面上禁止存放无关的物品,以保持工作区的洁净气流不受干扰。

洁净层流车

使

用

说

明

书

一、设备用途

主要用途:应用于制药行业中,物料从灌装出口至冻干机之间的转运以及药品盒运入灌装线内的工器具转运。

设备可以快捷高效地实现物料与灌装隔离器(RABS)或冻干机的安全无缝对接,确保药品的转运和对接始终处于洁净区域保护之下,弥补了固定式层流罩、空气净化器等设备无法达到的某些空间的洁净度要求而生产的新一代空气净化产品。

二、设备特点

设备装配四只防震万向脚轮,可平稳多向移动;

配置高效过滤风机单元(风速可在0.36-0.54m/s间调节),内部静态环境为B级;

设备安装透明垂帘,确保车内洁净度,物品取用方便快捷;

配置可翻转式托盘,可根据实际需求翻转,有效利用空间

车体分上中下三层,上层罩内装有过滤风机,中层空间为工作区,方便人工操作,下层搁架可临时储物

车体全部采用用不锈钢304(或316L)材质,结构简洁光滑,易于清洁消毒

三、产品工作原理

层流转运车内部净化气流流形为垂直流。

空气通过高效过滤风机单元自上而下,流经工作平台,净化和保护药品,并在工作台周围与垂帘之间形成空气保护面,使内部与外部形成正压差,防止低级别区域空气污染小车内部高级别区。

四.运输要求

请根据本产品的形状、重心及重量,合理选择吊装位置与吊装方法,防止车体变形、刮伤车体表面

在搬运贮存时,不得有冲击碰撞,绑扎牢固,防止层流车滚动滑

行,并采用防雨水措施

五、设备操作手册

操作安全注意事项

请在对该设备进行修改时,考虑联系我们这样可以对您有很大的帮助,避免因修改造您成的损失

发生下列情况,如火灾、烟雾、异味、噪音、震动等,请立即强制关机并拔下电源插头

清洁、维护、维修设备时,应切断电源拔下插头,否者会有伤亡危险

5.2操作使用要求

该设备适用于药厂生产车间C级环境或同等要求的环境

设备长期闲置时应切断电源,整机清洁后保存于适宜的环境中,并要每三个月进行一次运行及清洁工作

请确保手操作设备时手部或手套清洁无油污

本设备严禁用于易燃、易爆和化学腐蚀类物品

5.3层流车操作方法

层流车清洁完成符合操作要求,接通电源开启启动按钮

手动推行层流车到物料装载工位

将产品按要求整齐摆放至操作台或翻转托盘上

蠕动泵、检测仪、蔗糖溶液等生产材料放放置于操作台上

可透过垂帘对产品及材料进行相关人工操作,废弃物可放置于下层搁架内

装载完成后将层流车推行至目的地卸载产品

可多次重复上述操作到物料运送完毕

请通过启停按钮关停设备后再次进行清洁并将设备放置回原位

六.保养维修手册

6.1准备工作:

维修人员:熟悉机、电知识,熟知该设备的原理及维修

工具准备:电工、机械维修工具,吸盘

材料准备:密封硅胶、抹布、化学清洁剂等

维护要求:维修、保养、清洁时请务必切断设备电源

6.2组装/拆卸方法(组装方法与拆卸方法顺序相反)

风机及过滤器拆装:清除层流车风机罩壳上的密封胶—使用手动吸盘取下上封盖板,注意取下时要均匀受力,防止上封盖板变形(如果车顶为敞开式上述步骤省略)—拆除风机接线—双手握牢风机把手提出风机—拆下高效过滤器;

组装方法与拆装方法相反,要求在拆卸零件时,作好标记以便组装时参考,尤其是电气接线。

设备维修时要保持清洁,所有组装上的零部件必须是非常清洁的,零部件组装完成并检查合格后,将接缝处用硅胶密封好

6.3设备保养维修

保养:设备整机清洁每月需进行一次,包括车体内外、脚轮每年检查一次密封条,并对硅胶密封进行修补

每年进行风机、过滤器、电气清洁维护

DOP测试每年进行检测评定

维修:风机维修----手动检测电机转动是否轻松灵活、测试电机定转

子电路、风机风叶有无变形、磨损,发现问题可

通过注油或更换电机轴承、风叶进行维修 车脚轮维修---将车抬高或轻轻翻倒,逐一检查脚轮灵活情况,拆下故障脚轮,更换轴承或更换滚轮

6.4故障判断及解决。