H4膜料安全技术说明书

- 格式:pdf

- 大小:107.69 KB

- 文档页数:4

- 1规范信息及安全指南2 -© 2013. 版权所有。

目录 - 3 目录舒适使用产品的技巧和信息 4找对舒适位置 (4)爱护视力 (5)养成好的工作习惯 (5)保护听力 (6)电脑使用的基本保养和建议 7启动/关闭您的电脑 (7)保养您的电脑 (7)常规 (8)安全须知 (8)产品维修 (8)清洁和保养 (9)电池和适配器信息 (9)使用电源 (9)断开电源 (9)使用电源 (9)安全使用电池指南 (11)警告和规范信息 13光驱....................................................... 13电话线安全性.. (13)紧急电话 (14)医疗设备 (14)汽车 (14)易爆环境 (15)废弃处理说明 (15)能源之星 (15)无线适配器规范信息 (16)无线频率干扰 (16)Use on aircraft (17)The wireless adapter and your health (17)USA — FCC and FAA (17)FCC radio frequency interferencerequirements (18)Canada — Industry Canada (IC) (20)European Union (20)符合俄罗斯规范认证 (26)4 - 舒适使用产品的技巧和信息舒适使用产品的技巧和信息重要本指南中的部分信息可能不适用于您的电脑。

长时间使用电脑后,会出现眼睛疲劳和头疼症状。

若一连数小时坐在电脑前工作,身体也可能受到伤害。

长时间工作、不良姿势、不好的工作习惯、力大、不适当的工作条件、个人健康状况和其它因素都会加剧伤害身体。

不正确使用电脑可能导致腕管综合症、肌腱炎、腱鞘炎或其它肌骨失常等不适症状。

以下症状可能出现在手、手腕、臂、肩、颈或背部:•麻木,或灼伤/刺痛的感觉。

•隐痛、酸痛或身体一触即痛。

•疼痛、肿胀或悸痛。

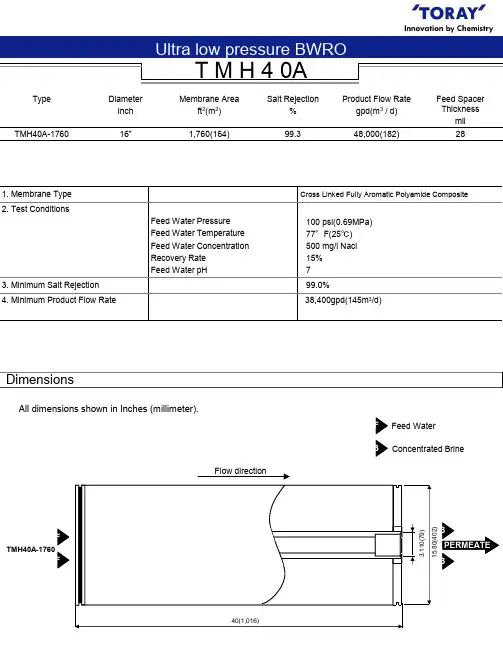

T M H 4 0ATMH40A-176016”1,760(164)99.348,000(182)281. Membrane Type Cross Linked Fully Aromatic Polyamide Composite2. Test ConditionsFeed Water Pressure Feed Water Temperature Feed Water Concentration Recovery Rate Feed Water pH100 psi(0.69MPa)77°F(25℃)500 mg/l Nacl 15%73. Minimum Salt Rejection 99.0%4. Minimum Product Flow Rate38,400gpd(145m 3/d)DimensionsAll dimensions shown in Inches (millimeter).Feed Water Concentrated BrinePERMEATE BBTMH40A-176040(1,016)Flow direction3.110(79)15.80(402)TypeDiameter Inch Membrane Areaft 2(m 2)Salt Rejection%Product Flow Rategpd(m 3/ d)Feed Spacer ThicknessmilOperating Limits1.For the recommended design range, please consult the latest Toray technical bulletin, design guide lines,computer design program, and/ or call an application specialist. If the operating limits given in this Product Information Bulletin are not strictly followed, the Limited Warranty will be null and void.2.All elements are wet tested, treated with a 1% by weight percent sodium bisulfite storage solution, and then vacuum packed in oxygen barrier bags, or treated with tested feed water solution, and then vacuum packed in oxygen barrier bags with deoxidant inside. To prevent biological growth during short term storage, shipment, or system shutdown, it is recommended that Toray elements be immersed in a protective solution containing 500 -1,000 ppm of sodium bisulfite (food grade) dissolved in permeate.3.The presence of free chlorine and other oxidizing agents under certain conditions, such as heavy metals which acts as oxidation catalyst in the feed water will cause unexpected oxidation of the membrane. It is strongly recommended to remove these oxidizing agents contained in feed water before operating RO system.4.Permeate from the first hour of operation shall be discarded.5.The customer is fully responsible for the effects of chemicals that are incompatible with the elements.Their use will void the element Limited Warranty.1.Toray accepts no responsibility for results obtained by the application of this information or the safety or suitability of Toray's products, either alone or in combination with other products. Users are advised to make their own tests to determine the safety and suitability of each product combination for their own purposes.2.All data may change without prior notice, due to technical modifications or production changes.JUL. 2014Maximum Operating PressureMaximum Feed Water Temperature Maximum Feed Water SDI 15Feed Water Chlorine ConcentrationFeed Water pH Range, Continuous Operation Feed Water pH Range, Chemical Cleaning Maximum Pressure Drop per Element Maximum Pressure Drop per Vessel365psi (2.5 MPa)113°F (45℃)5Not Detactable 2-111-1215 psi (0.10 MPa)50 psi (0.34 MPa)Operating InformationNoticeAmericas:Toray Membrane USA, Inc.Sales Office13435 Danielson St,Poway, CA 92064, USA Tel: +1 858 218 2390Fax: +1 858 486 3063Europe, Middle East and Africa:Toray Membrane Europe AGGrabenackerstrasse 8CH-4142 Münchenstein 1, Switzerland Tel: +41 61 415 87 10Fax: +41 61 415 87 20CHINA:Toray BlueStar Membrane Co., Ltd.No.5 Anxiang Street, Area B,Beijing Tianzhu Airport Economic Development Zone,Beijing ,101318 P.R.C.Tel: +86 10 80490552Fax: +86 10 80485217Asia and Oceania:Toray Industries, Inc.RO Membrane Products Department 1-1, Nihonbashi muromachi 2-chome Chuo-ku, Tokyo 103-8666, Japan Tel : +81 3 3245 4540Fax: +81 3 3245 4913http:/ / 。

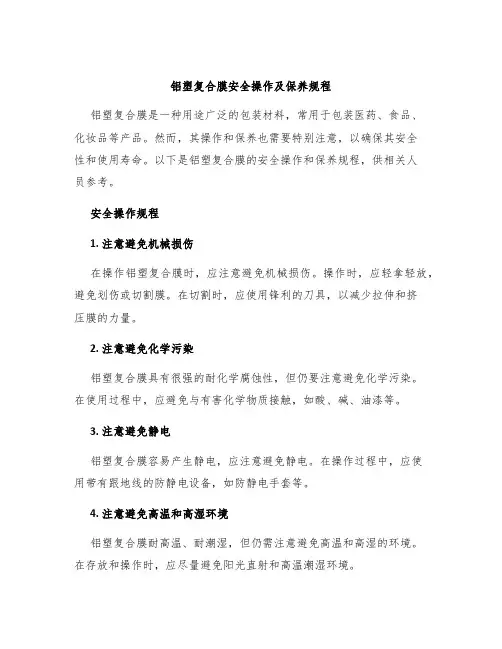

铝塑复合膜安全操作及保养规程铝塑复合膜是一种用途广泛的包装材料,常用于包装医药、食品、化妆品等产品。

然而,其操作和保养也需要特别注意,以确保其安全性和使用寿命。

以下是铝塑复合膜的安全操作和保养规程,供相关人员参考。

安全操作规程1. 注意避免机械损伤在操作铝塑复合膜时,应注意避免机械损伤。

操作时,应轻拿轻放,避免划伤或切割膜。

在切割时,应使用锋利的刀具,以减少拉伸和挤压膜的力量。

2. 注意避免化学污染铝塑复合膜具有很强的耐化学腐蚀性,但仍要注意避免化学污染。

在使用过程中,应避免与有害化学物质接触,如酸、碱、油漆等。

3. 注意避免静电铝塑复合膜容易产生静电,应注意避免静电。

在操作过程中,应使用带有跟地线的防静电设备,如防静电手套等。

4. 注意避免高温和高湿环境铝塑复合膜耐高温、耐潮湿,但仍需注意避免高温和高湿的环境。

在存放和操作时,应尽量避免阳光直射和高温潮湿环境。

5. 注意防火铝塑复合膜具有良好的难燃性能,但仍需注意防火。

在存放和操作时,应远离火源,禁止吸烟等危险行为。

6. 注意保持清洁在操作铝塑复合膜时,应注意保持清洁。

避免污染和污垢的出现,以免影响膜的质量和功能。

在存放前,应先将其清洗干净,包装、密封存放。

保养规程1. 储存和包装铝塑复合膜应存放在干燥、阴凉、通风的环境中,避免阳光直射和高温潮湿环境。

在储存过程中,应注意防潮、防尘、防虫、防鼠。

在包装铝塑复合膜时,应选择质量上乘的材料,以保证产品的完整性和安全性。

包装时应注意使用专业的包装机器和设备,以确保铝塑复合膜的质量和保质期。

2. 清洗和消毒铝塑复合膜在使用后,应及时进行清洗和消毒,以保持卫生和质量。

若膜中出现可疑物质或臭味,应立即停止使用,进行检测和处理。

3. 检查和维护铝塑复合膜在使用过程中,应经常检查和维护,以确保其合格和安全。

检查的内容包括膜的完整性、裂纹、尺寸、颜色和印刷质量等。

如发现问题应及时进行维护和更换。

4. 技术培训铝塑复合膜的安全操作和保养需要相关人员具备相关的技能和知识。

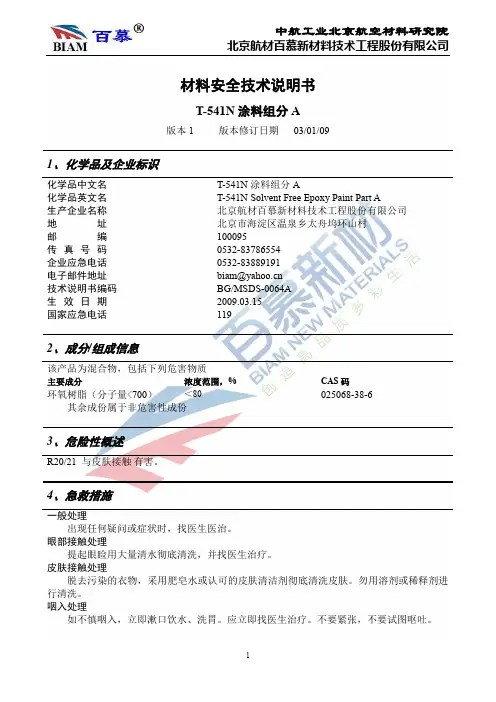

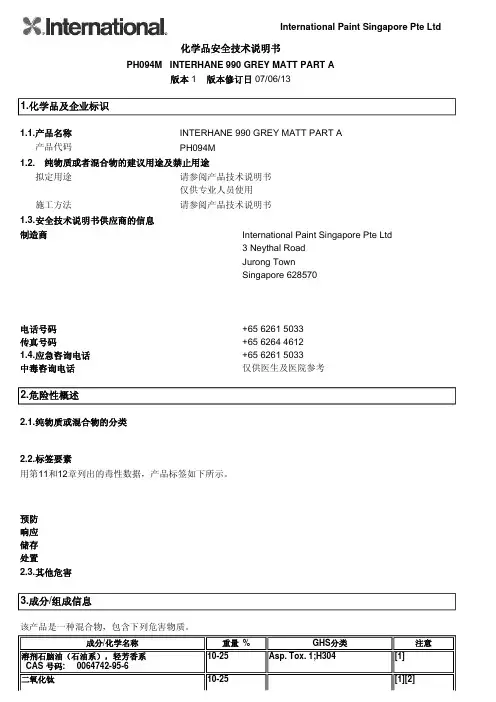

International Paint Singapore Pte Ltd化学品安全技术说明书PH094M INTERHANE 990 GREY MATT PART A版本1 版本修订日 07/06/131.化学品及企业标识1.1.产品名称INTERHANE 990 GREY MATT PART A产品代码PH094M1.2.纯物质或者混合物的建议用途及禁止用途拟定用途请参阅产品技术说明书仅供专业人员使用施工方法请参阅产品技术说明书1.3.安全技术说明书供应商的信息制造商International Paint Singapore Pte Ltd3 Neythal RoadJurong TownSingapore 628570电话号码+65 6261 5033传真号码+65 6264 46121.4.应急咨询电话+65 6261 5033中毒咨询电话仅供医生及医院参考2.危险性概述2.1.纯物质或混合物的分类2.2.标签要素用第11和12章列出的毒性数据,产品标签如下所示。

预防响应储存处置2.3.其他危害3.成分/组成信息该产品是一种混合物,包含下列危害物质。

成分/化学名称重量 %GHS分类注意溶剂石脑油(石油系),轻芳香系10-25Asp. Tox. 1;H304[1]CAS 号码: 0064742-95-6二氧化钛 10-25[1][2]CAS 号码: 0013463-67-7二甲苯CAS 号码: 0001330-20-7 10-25Flam. Liq. 3;H226Acute Tox. 4;H332Acute Tox. 4;H312Skin Irrit. 2;H315[1][2]蓖麻籽油CAS 号码: 0008001-79-42.5-10[1]乙苯CAS 号码: 0000100-41-4 2.5-10Flam. Liq. 2;H225Acute Tox. 4;H332[1][2]醋酸甲氧基丙酯CAS 号码: 0000108-65-61-2.5Flam. Liq. 3;H226[1](1)健康或环境危害物质(2)有工作场所有害因素职业接触限值的物质(3)PBT-物质或vPvB-物质*短语的全文参阅第16章。

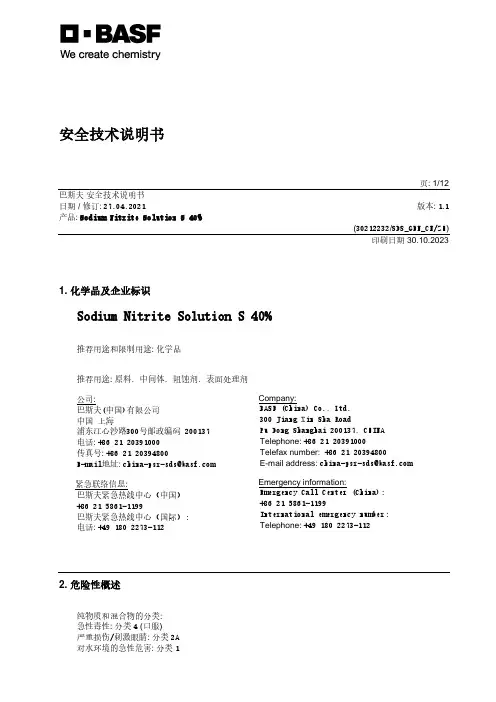

安全技术说明书页: 1/12 巴斯夫安全技术说明书日期 / 修订: 27.04.2021版本: 1.1产品: Sodium Nitrite Solution S 40%(30212232/SDS_GEN_CN/ZH)印刷日期 30.10.20231. 化学品及企业标识Sodium Nitrite Solution S 40%推荐用途和限制用途: 化学品推荐用途: 原料, 中间体, 阻蚀剂, 表面处理剂公司:巴斯夫(中国)有限公司中国上海浦东江心沙路300号邮政编码 200137电话: +86 21 20391000传真号: +86 21 20394800E-mail地址: **********************紧急联络信息:巴斯夫紧急热线中心(中国)+86 21 5861-1199巴斯夫紧急热线中心(国际):电话: +49 180 2273-112Company:BASF (China) Co., Ltd.300 Jiang Xin Sha RoadPu Dong Shanghai 200137, CHINA Telephone: +86 21 20391000Telefax number: +86 21 20394800E-mail address: ********************** Emergency information:Emergency Call Center (China):+86 21 5861-1199International emergency number: Telephone: +49 180 2273-1122. 危险性概述纯物质和混合物的分类:急性毒性: 分类4 (口服)严重损伤/刺激眼睛: 分类2A对水环境的急性危害: 分类1巴斯夫安全技术说明书日期 / 修订: 27.04.2021版本: 1.1产品: Sodium Nitrite Solution S 40%(30212232/SDS_GEN_CN/ZH)印刷日期 30.10.2023 标签要素和警示性说明:警示词:警告危险性说明:H319造成严重眼刺激。

FPU-H4现场处理器폃뮧쫖닡北京瑞赛长城航空测控技术有限公司(原北京长城航空测控技研究所)目录1 FPU-H4现场处理器简介 (1)1.1概述 (1)1.2整体结构 (2)1.3外形尺寸 (3)1.4主要功能 (3)1.5主要技术参数和性能指标 (4)2 FPU系统组成及工作原理 (5)2.1系统组成 (5)2.2工作原理 (6)3 FPU的安装与接线 (7)3.1安装 (7)3.2穿线 (11)3.3接线 (14)4 FPU的通讯设置与基本调试 (15)4.1 通讯设置 (15)4.2 基本调试 (17)5 FPU的验货与组装图示 (18)5.1验货 (18)5.2组装 (19)6 FPU的维护与注意事项 (20)附录:FPU选型图谱 (22)附录1 FPU-H型谱代码注释表 (23)附录2 型号总谱 (28)1FPU-H4现场处理器简介1.1 概述FPU-H4现场处理器(英文名称:Field Process Unit,以下文中简称FPU)是用于储罐计量并具有全部处理功能的智能化系列产品,目前在国内国际具备领先水平。

作为储罐计量系统的通讯与计算、处理中心,FPU可与任何遵守HART(Highway Addressable Remote Transducer)协议的各种有源和无源的现场仪表进行通讯。

它可连接多种遵守HART协议的压力、压差变送器及多种液位、温度仪表,对储罐内液体质量进行检测。

亦可同时连接Rosemount公司、Saab公司、Enraf公司、E+H公司、MTS公司等具有通用HART接口、RS485接口、2FSK调制解调接口的各种液位计;并且具有可连接Saab公司各种雷达液位计的“TR L/2专用接口”、Enraf公司伺服液位计的“Bi-phase mark专用接口”,对储罐内液体液位进行检测。

以及同时连接各种MDT 系列智能单点数字温度变送器、MDT-2型智能多点平均温度计(以上两种产品我公司配套生产,详见相关手册),对储罐内液体温度和环境温度进行检测。

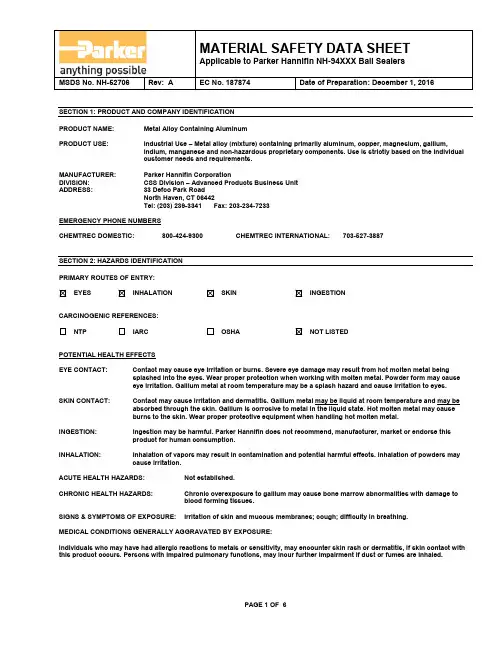

MSDS No. NH-52706 Rev: A EC No. 187874 Date of Preparation: December 1, 2016SECTION 1: PRODUCT AND COMPANY IDENTIFICATIONPRODUCT NAME: Metal Alloy Containing AluminumPRODUCT USE: Industrial Use – Metal alloy (mixture) containing primarily aluminum, copper, magnesium, gallium,indium, manganese and non-hazardous proprietary components. Use is strictly based on the individualcustomer needs and requirements.MANUFACTURER: Parker Hannifin CorporationDIVISION: CSS Division – Advanced Products Business UnitADDRESS: 33 Defco Park RoadNorth Haven, CT 06442Tel: (203) 239-3341 Fax: 203-234-7233EMERGENCY PHONE NUMBERSCHEMTREC DOMESTIC: 800-424-9300 CHEMTREC INTERNATIONAL: 703-527-3887SECTION 2: HAZARDS IDENTIFICATIONPRIMARY ROUTES OF ENTRY:EYES INHALATION SKIN INGESTIONCARCINOGENIC REFERENCES:NTP IARC OSHA NOT LISTEDPOTENTIAL HEALTH EFFECTSEYE CONTACT: Contact may cause eye irritation or burns. Severe eye damage may result from hot molten metal being splashed into the eyes. Wear proper protection when working with molten metal. Powder form may causeeye irritation. Gallium metal at room temperature may be a splash hazard and cause irritation to eyes. SKIN CONTACT: Contact may cause irritation and dermatitis. Gallium metal may be liquid at room temperature and may be absorbed through the skin. Gallium is corrosive to metal in the liquid state. Hot molten metal may causeburns to the skin. Wear proper protective equipment when handling hot molten metal.INGESTION: Ingestion may be harmful. Parker Hannifin does not recommend, manufacturer, market or endorse this product for human consumption.INHALATION: Inhalation of vapors may result in contamination and potential harmful effects. Inhalation of powders may cause irritation.ACUTE HEALTH HAZARDS: Not established.CHRONIC HEALTH HAZARDS: Chronic overexposure to gallium may cause bone marrow abnormalities with damage toblood forming tissues.SIGNS & SYMPTOMS OF EXPOSURE: Irritation of skin and mucous membranes; cough; difficulty in breathing.MEDICAL CONDITIONS GENERALLY AGGRAVATED BY EXPOSURE:Individuals who may have had allergic reactions to metals or sensitivity, may encounter skin rash or dermatitis, if skin contact with this product occurs. Persons with impaired pulmonary functions, may incur further impairment if dust or fumes are inhaled.MSDS No. NH-52706 Rev: A EC No. 187874 Date of Preparation: December 1, 2016SECTION 3: COMPOSITION / INFORMATION ON INGREDIENTS(mg/m3) TLV-STEL(mg/m3) COMPONENT: CAS NO. % WT PEL (mg/m3) TLV-TWAAluminum 7429-90-5 45-85 15 10N.E. N.E. N.E. Gallium 7440-55-30.5-10.50.2-2.0 0.1 0.1 N.E. Indium 7440-74-6Copper 7440-50-82.2-5.4 1 1Magnesium 7439-95-4 0.5-5.5 N.E. 10Manganese 7439-96-5 0.1-1.5 5 0.2 3PROPRIETARY 0.3 MAX. N.E. N.E. N.E.PROPRIETARY 0.2 MAX. N.E. N.E. N.E.SECTION 3 NOTESThis product in not considered to constitute a physical or health hazard in the form it is sold. Subsequent operations such as abrading, melting, welding, cutting or processing in any other fashion may produce potentially hazardous dust or fumes which canbe inhaled, swallowed, or come into contact with skin or eyes.N.E. = Not EstablishedSECTION 4: FIRST AID MEASURESEYE CONTACT: Hold eyelids apart and flush eyes with plenty of water for at least 15 minutes. Seek medical attention if irritation persists.SKIN CONTACT: Remove contaminated clothing. Wash affected area with soap and water. Wash clothing before reuse. If irritation persists, obtain medical attention.INGESTION: If patient is conscious, ONLY induce vomiting as directed by trained personnel. NEVER give anything by mouth to an unconscious person. Seek medical attention immediately.INHALATION: Remove to fresh air. If not breathing, give artificial respiration or oxygen by trained personnel. Seeimmediate medical attention.SECTION 5: FIRE-FIGHTING MEASURESFLASH POINT: Not Applicable FLAMMABLE LIMITS: NonflammableAUTOIGNITION TEMPERATURE: Not EstablishedEXTINGUISHING MEDIA: Product will not burn in the solid state. Product dust and powder may burn under someconditions. Use extinguishers appropriate for the surrounding fire conditions. DO NOTDIRECT WATER AT OR ONTO MOLTEN METAL – IT WILL EXPLODE.SPECIAL FIRE FIGHTING PROCEDURES: Firefighters must wear NIOSH approved self-contained breathing apparatus and fullprotective clothing.MSDS No. NH-52706 Rev: A EC No. 187874 Date of Preparation: December 1, 2016SECTION 6: ACCIDENTAL RELEASE MEASURESSMALL OR LARGE SPILL: In solid form this material poses no special clean-up problems. Use normal clean up procedures; wet sweeping or HEPA vacuum is recommended for cleanup of dust or powder. Do not use compressed airfor cleaning.SECTION 7: HANDLING AND STORAGEHANDLING AND STORAGE: Product should be kept dry.HANDLING PRECAUTIONS: Avoid contact with sharp edges or heated material. Hot and cold material is not visually different and will not present a warning color change. Exercise caution in instances where material may be hot. SECTION 8: EXPOSURE CONTROLS/PERSONAL PROTECTIONVENTILATION : Local exhaust recommended when cutting, grinding or melting or any other operation wheredust or fumes are created.RESPIRATORY PROTECTION: Not normally required. Use an appropriate NIOSH approved respirator if airborne dustconcentrations exceed the OSHA, PEL or ACGIH, TLV.EYE PROTECTION: Safety glasses are recommended.SKIN PROTECTION: Protective gloves are recommended to prevent mechanical irritation.OTHER PROTECTIVE CLOTHING OR EQUIPMENT: Eye wash stations should be readily available in areas of use or handling. WORK HYGIENIC PRACTICES: If the operation generates dust or fumes, exposure to airborne materials should be determinedby having air samples taken in the employees breathing zone and work area.EXPOSURE GUIDELINES: Not established for product as a whole. Refer to Sections 2 & 3.SECTION 9: PHYSICAL AND CHEMICAL PROPERTIESAPPEARANCE: Grey solid metalODOR: Normally none. Slight metallic odor when wet.MELTING POINT: Not established (>850°F)g/cm3DENSITY: 2.70-2.90SOLUBILITY IN WATER: Generally insoluble. Under certain conditions, product may react with water to form aluminumhydroxide and low quantities of evolved hydrogen gas.PERCENT SOLIDS BY WEIGHT: 100%PERCENT VOLATILE BY WEIGHT: Essentially zero.MSDS No. NH-52706 Rev: A EC No. 187874 Date of Preparation: December 1, 2016SECTION 10: STABILITY AND REACTIVITYSTABILITY: Stable in dry air. May tarnish slightly in moist air.CONDITIONS TO AVOID: Conditions which create dust or fumes.INCOMPATIBILE MATERIALS: Reaction with concentrated acids or bases (e.g. sodium hydroxide, potassium hydroxide, sulfuricacid and hydrochloric acid) with a pH less than 5.0 or greater than 11.0 may liberate large quantitieshydrogen gas.HAZARDOUS DECOMPOSITION OR BY-PRODUCTSEvolved hydrogen in confined areas may pose an explosion hazard (see directly above and refer to Section 14). Do not store wet product in confined (i.e. sealed) containers. Potentially hazardous oxides of metals may be produced when product is heated or in a molten state.HAZARDOUS POLYMERIZATION: Will not occur.SECTION 11: TOXICOLOGICAL INFORMATIONTOXICOLOGICAL INFORMATION: There is no information on the toxicity of this alloy. Under normal use of the solid form of this material there are no known health hazards. Welding, grinding or any process creating dust, fumes or oxides may cause hazardous levels of certain elements, as addressed in Sections 2 & 3.SECTION 12: ECOLOGICAL INFORMATIONECOLOGICAL INFORMATION: In solid form this material poses no special environmental problems. Metal powder or dust mayimpact air or water quality. Emissions, spills and releases to the environment should becontrolled immediately.SECTION 13: DISPOSAL CONSIDERATIONSWASTE DISPOSAL METHOD: Due to its high intrinsic value, this material should be reclaimed. Contact a commercial reclaimerfor recycling. Otherwise, dispose of in accordance with all Federal, State and Local environmentalregulations.MSDS No. NH-52706 Rev: A EC No. 187874 Date of Preparation: December 1, 2016SECTION 14: TRANSPORT INFORMATIONGROUND TRANSPORTATIOND.O.T. SHIPPING NAME: Not regulated TECHNICAL SHIPPING NAME: Metal AlloyD.O.T. HAZARD CLASS: None UN SHIPPING NUMBER: NonePRODUCT RQ: None PACKING GROUP: NoneAIR TRANSPORTATIONICAO-TI AND IATA-DGR: Not regulated in solid formA representative sample of this composite metal alloy was selected and tested per Section 33.4 of the UN Manual of Tests and Criteria, 5th Revised Edition - “Substances Which In Contact with Water Emit Flammable Gases”. Test results indicate that reaction of this material with water DOES NOT produce spontaneous ignitable gas and DOES NOT exceed the rate of gas emission required to be considered a hazardous substance in accordance with Class 4, Division 4.3 (refer to Section 2.4.4 of the UN Model Regulations and Parker Hannifin APBU Report No. NH-52695).This metal alloy, having a melting point in excess of 850°F (454°C), will not become liquid during normal transport conditions. In solid form it is considered to be non-corrosive to both aluminum and steel alloys. Therefore, the material is not considered to be a hazardous substance in accordance with Class 8 (refer to sections 2.8.1 and 2.8.2 of the UN Model Regulations).MSDS No. NH-52706 Rev: A EC No. 187874 Date of Preparation: December 1, 2016 SECTION 15: REGULATORY INFORMATIONHMIS Ratings Health = 2 Flammability = 1 Physical Hazard = 0 Personal Protection = E NFPA Ratings Health = 2 Flammability = 1 Instability = 1 Special Notice = N/AOSHA STATUSNo specific regulations. The Hazard Communication Standard of the Occupational Safety and Health Administration, 29 CFR 1910.1200 considers components of this product a Hazardous Substance.TSCA STATUSThis product is an alloy (mixture). Components of this product are listed on the TSCA Chemical Substance Inventory of Existing Chemical Substances.SARA TITLE IIIThe constituents of this alloy (mixture) contain hazardous substances, above one (1) percent, and are subject to the reporting requirements of section 313 of the Emergency Planning and Community Right to Know Act of 1986 and 40CFR372.CANADA – WHMIS DISCLOSURE LISTMaterial does not fall into a Subdivision, or Division as defined by any Section of SOR/DORS/88-66.EUROPEAN UNION – RISK PHRASE: N/ASECTION 16: OTHER INFORMATIONPREPARED BY: Parker Hannifin CorporationComposite Sealing Systems DivisionAdvanced Products Business UnitEnvironmental Health & Safety Department33 Defco Park RoadNorth Haven, CT 06473DISCLAIMERThe information above is believed to be accurate and represents the best information currently available to Parker Hannifin. However, we make no warranty of merchantability or any other warranty, express or implied, with respect to such information, and we assume no liability resulting from its use. Users should make their own investigations to determine the suitability of the information for their particular purposes. In no event shall Parker Hannifin be liable for any claims, losses, or damages of any third party or for lost profits or any special, indirect, incidental, consequential or exemplary damages, howsoever arising, even if Parker Hannifin has been advised of the possibility of such damages.。

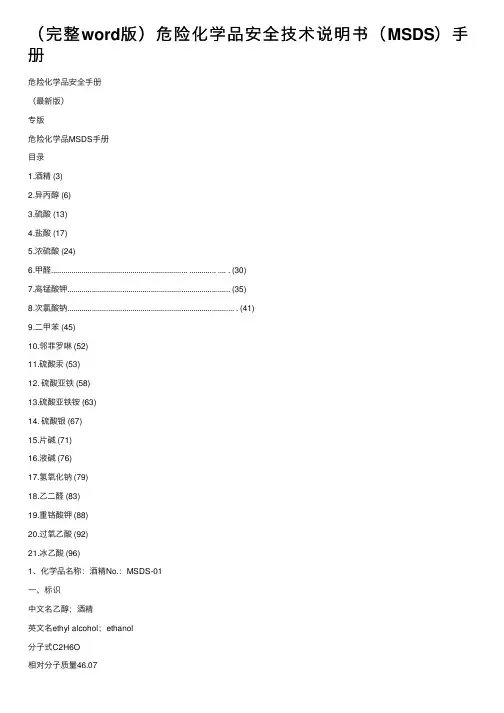

(完整word版)危险化学品安全技术说明书(MSDS)⼿册危险化学品安全⼿册(最新版)专版危险化学品MSDS⼿册⽬录1.酒精 (3)2.异丙醇 (6)3.硫酸 (13)4.盐酸 (17)5.浓硫酸 (24)6.甲醛................................................................... ............. .... . (30)7.⾼锰酸钾 (35)8.次氯酸钠.................................................................................. . (41)9.⼆甲苯 (45)10.邻菲罗啉 (52)11.硫酸汞 (53)12. 硫酸亚铁 (58)13.硫酸亚铁铵 (63)14. 硫酸银 (67)15.⽚碱 (71)16.液碱 (76)17.氢氧化钠 (79)18.⼄⼆醛 (83)19.重铬酸钾 (88)20.过氧⼄酸 (92)21.冰⼄酸 (96)1、化学品名称:酒精No.:MSDS-01⼀、标识中⽂名⼄醇;酒精英⽂名ethyl alcohol;ethanol分⼦式C2H6O相对分⼦质量46.07CAS号64-17-5结构式CH3CH2OH危险性类别第3.2类中闪点易燃液体化学类别醇⼆、主要组成与性状主要成分纯品外观与性状⽆⾊液体,有酒⾹。

主要⽤途⽤于制酒⼯业、有机合成、消毒以及⽤作溶剂。

三、健康危害侵⼊途径:吸⼊、⾷⼊、经⽪吸收。

健康危害:本品为中枢神经系统抑制剂。

⾸先引起兴奋,随后抑制。

急性中毒:急性中毒多发⽣于⼝服。

⼀般可分为兴奋、催眠、⿇醉、窒息四阶段。

患者进⼊第三或第四阶段,出现意识丧失、瞳孔扩⼤、呼吸不规律、休克、⼼⼒循环衰竭及呼吸停⽌。

慢性影响:在⽣产中长期接触⾼浓度本品可引起⿐、眼、粘膜刺激症状,以及头痛、头晕、疲乏、易激动、震颤、恶⼼等。

硅烷(硅烷气体、硅烷气)的MSDS 中文名称硅烷英文名称SILANE英文同义词SILANEINNITROGENSILICONHYDRIDESILICONTETRAHYDRIDECAS号7803-62-5EINECS号232-263-4分子式H4Si分子量32.12储存:1.在通风良好、安全且不受天气影响的地方存储。

钢瓶应直立摆放。

且保持保护性阀盖和输出阀的密封完好。

2.存储区域应远离频繁出入处和紧急出口。

储存区域内不应有火源,储存区内所有电器必须有防爆设施。

易燃物存放区应与氧及氧化物存放区最少相距20ft。

3.或者在中间放置至少5英尺高的非易燃材料作为屏障,以保证能耐火半小时。

储存区和使用区内应有“禁止吸烟和使用明火”的告示牌。

苯基氯硅烷4.存储温度不可高于125℉(52℃)。

将空瓶与满瓶分开存放。

避免过量存储和存储时间过长。

5.使用先进先出系统。

应考虑在储存区内安装测漏器和报警设备。

使用:1.使用防火花工具。

不要试图对装有硅烷的钢瓶进行修理、调节或其他改动。

2.如果出现故障或其他操作问题,请立即与最近的分销商联系。

3.如有可能应避免单独一个人操作钢瓶。

所有的操作都应这样进行——一旦发生泄漏,处理紧急情况的人员可以立即赶到。

4.用氢离子检测器监测硅烷的修理和在空气中的扩散,用红外/紫外监测器监测火灾。

所以的监测器都应有内锁,一旦发现问题立即自动切断硅烷气源。

5.监测系统应装备备用或应急电源。

必须有遥控紧急开关,必要时可关闭硅烷气源。

6.硅烷系统中不允许使用填压阀,只允许使用非填压的膜阀和波纹管阀。

在其分配系统中应安装过流阀或过流开关。

这样可以在下游管线发生爆炸时切断气源。

这个开关阀应安装得离气源越近越好。

7.一定不要拉、滚动或滑动容器。

用合适的手推车来移动容器,不要试图抓住气瓶的盖子来拎起它。

保证气瓶在使用的全过程中为固定状态。

8.用一个减压器或独立的控制阀安全地从气瓶内释放气体。

用单向阀来防止倒流。

1序言序言1内容提要章节标题页码1 .1 手册适用范围1-11 .2 主要内容1-21 .3 功能与特性1-31 .4 总目录1-51 .5 安全的使用1-8感谢您使用中达电通数控产品。

本手册提供中达电通CNC-H4-T全系列车床数控系统的相关资讯。

1.1手册适用范围本手册只适用于下列型号的产品说明,具体型号的差异请参见表1-1和后续相关章节的详细内容。

PUTNC-H4CL-T 10.4”彩色LCD 加强型车床数控系统(电压命令型)PUTNC-H4PL-T 10.4”彩色LCD 加强型车床数控系统(脉冲命令型)PUTNC-H4C-T 5.7”彩色LCD车床数控系统(电压命令型)PUTNC-H4CP-T 5.7”彩色LCD车床数控系统(脉冲命令型)PUTNC-H4-T 5.7”蓝屏LCD车床数控系统(电压命令型)中达电通 CNC-H4系列车床系统操作和编程1-11序言1-2 中达电通 CNC-H4系列车床系统操作和编程10.4寸和5.7寸外观差异H4-T系列车床系统规格表1-1具体型号PUTNC-H4CL-T PUTNC-H4PL -T PUTNC-H4C-T PUTNC-H4CP -T PUTNC-H4-T 显示器规格10.4” 彩色 10.4” 彩色 5.7” 彩色 5.7” 彩色 5.7” 蓝屏 伺服控制方式模拟量电压控制 PULSE 控制 模拟量电压控制 PULSE 控制 模拟量电压控制 辅助操作面板分体设计 分体设计 一体机 一体机 一体机 PLC 、LCD 规划具有车床功能,在标准车床PLC 和LCD 规划基础上,部分开放给机械制造商 控制轴数量最大4路伺服轴+1路主轴 最大3路伺服轴+1路主轴 2路伺服轴+1路主轴 主轴形式伺服/变频器 伺服/变频器 伺服/变频器 变频器 变频器 加减速形式直线/S 可选 反向间隙补正有 有 有 有 有 MPG 手轮接口 有(手轮选配)有(手轮选配)有(手轮选配)有(手轮选配) 有(手轮选配)I/O 24/16 24/16 24/16 24/16 24/16 扩展I/O 可选件16/16 可选件16/16 可选件56/64 可选件56/64 可选件56/64标准刀塔组 8组 (配合PLC 编辑可扩充)刀具、磨耗补正 40组 40组 40组 40组 40组 支持对谈式校刀功能。

膜用杀菌剂化学品名称化学品中文名称:膜用杀菌剂技术说明书编码:001 化学品英文名称: CAS No.: 中文名称2: 分子式:英文名称2:分子量:1000-2000成分/组成信息本品是复合型膜用杀菌剂,以化合物为主剂,复配渗透剂、缓蚀剂,属于新一代安全多功能的杀菌消毒剂。

危险性概述危险性类别: 侵入途径: 健康危害:无 环境危害:无燃爆危险:本品不易燃,不具刺激性,不具致敏性。

急救措施皮肤接触:脱去污染的衣着,用肥皂水和清水彻底冲洗皮肤。

眼睛接触:提起眼睑,用流动清水或生理盐水冲洗。

就医。

吸入:脱离现场至空气新鲜处。

就医。

食入:饮足量温水,催吐。

就医。

消防措施 危险特性:不易燃,不遇明火、高热燃烧。

受高热不分解放出有毒的气体。

有害燃烧产物:无 灭火方法:泄漏应急处理 应急处理:用水冲洗 小量泄漏:用水冲洗 大量泄漏:用大量水冲洗操作处置与储存 操作注意事项:建议操作人员佩戴化学安全防护眼镜。

搬运时要轻装轻卸,防止包装及容器损坏。

储存注意事项:储存于阴凉、通风的库房。

保持容器密封。

储区应备有泄漏应急处理设备和合适的收容材料。

接触控制/个体防护职业接触限值中国MAC(mg/m3):未制定标准 前苏联MAC(mg/m3):未制定标准 TLVTN :未制定标准 TLVWN :未制定标准 监测方法:工程控制:提供良好的自然通风条件。

呼吸系统防护:无要求眼睛防护:一般不需要特殊防护,接触时可戴化学安全防护眼镜。

身体防护:穿一般作业防护服。

手防防护:戴一般作业防护手套。

其他防护:工作现场严禁吸烟。

保持良好的卫生习惯。

理化特性外观与性状:黄色液体 主要用途:杀菌灭藻熔点(℃): 辛醇/水分配系数的对数值:无资料 沸点(℃):100闪点(℃):无 相对密度(水=1):1.05—1.10 引燃温度(℃):无 相对蒸气密度(空气=1):无资料 爆炸上限%(V/V):无 饱和蒸气压(kPa):无资料 爆炸下限%(V/V):无燃烧热(kJ/mol):无资料 溶解性:溶于水,不溶于丙酮、乙醇、甲苯。

第一部分化学品及企业标识化学品中文名:氢氧化锆化学品英文名:Zirconium tetrahydroxideCAS No.:14475-63-9分子式:H4O4Zr产品推荐及限制用途:广泛应用于制备颜料、玻璃、染料等行业,同时也是制备其他锆化合物的重要中间体。

第二部分危险性概述紧急情况概述造成皮肤刺激。

造成严重眼刺激。

可引起呼吸道刺激。

GHS危险性类别皮肤腐蚀 / 刺激类别 2严重眼损伤 / 眼刺激类别 2特异性靶器官毒性一次接触类别 3标签要素:象形图:警示词:警告危险性说明:H315 造成皮肤刺激H319 造成严重眼刺激H335 可引起呼吸道刺激防范说明●预防措施:—— P264 作业后彻底清洗。

—— P280 戴防护手套/穿防护服/戴防护眼罩/戴防护面具。

—— P261 避免吸入粉尘/烟/气体/烟雾/蒸气/喷雾。

—— P271 只能在室外或通风良好处使用。

●事故响应:—— P302+P352 如皮肤沾染:用水充分清洗。

—— P332+P313 如发生皮肤刺激:求医/就诊。

—— P362+P364 脱掉沾染的衣服,清洗后方可重新使用—— P305+P351+P338 如进入眼睛:用水小心冲洗几分钟。

如戴隐形眼镜并可方便地取出,取出隐形眼镜。

继续冲洗。

—— P337+P313 如仍觉眼刺激:求医/就诊。

—— P304+P340 如误吸入:将人转移到空气新鲜处,保持呼吸舒适体位。

—— P312 如感觉不适,呼叫解毒中心/医生●安全储存:—— P403+P233 存放在通风良好的地方。

保持容器密闭。

—— P405 存放处须加锁。

●废弃处置:—— P501 按当地法规处置内装物/容器。

物理和化学危险:无资料。

健康危害:造成皮肤刺激。

造成严重眼刺激。

可引起呼吸道刺激。

环境危害:无资料。

第三部分成分/组成信息√物质混合物第四部分急救措施急救:吸入:如果吸入,请将患者移到新鲜空气处。

皮肤接触:脱去污染的衣着,用肥皂水和清水彻底冲洗皮肤。

安全技术说明书ALUMINIUM WEAR COMPOUND RESIN产品标识产品名称ALUMINIUM WEAR COMPOUND RESIN物质或混合物的推荐用途及限制用途推荐用途粘合剂。

供应商的详细情况供应商ITW Performance PolymersBay 150Shannon Industrial EstateCo. ClareIrelandV14 DF82353(61)771500353(61)471285应急电话应急电话+44(0)1235 239 670 (24h)物质或混合物的分类物理危险非此类健康危害皮肤刺激类别2 - H315 眼刺激类别2A - H319 皮肤致敏物类别1A - H317环境危害危害水生环境-长期危险类别2 - H411人体健康产品含有一种环氧树脂。

可能会导致敏感个体的过敏或过敏性反应。

标签要素象形图警示词警告危险性说明H315 造成皮肤刺激。

H317 可能造成皮肤过敏反应。

H319 造成严重眼刺激。

H411 对水生生物有毒并具有长期持续影响。

防范说明P273 避免释放到环境中。

P280 戴防护手套/ 穿防护服/ 戴防护眼罩/ 戴防护面具。

P302+P352 如皮肤沾染:用大量水清洗。

P305+P351+P338 如进入眼睛: 用水小心冲洗几分钟。

如戴隐形眼镜并可方便地取出,取出隐形眼镜。

继续冲洗。

P333+P313 如发生皮肤刺激或皮疹:求医/ 就诊。

补充的标签信息EUH205 含环氧树脂成分。

可能引起过敏反应。

含有EPOXY RESIN (Number average MW <= 700 )其他危险这种产品不含有任何分类为持久性、生物累积性和有毒(PBT)的物质或高持久性、高累积性(vPvB)的物质。

所有危险性说明的全文会显示在第16部分。

急救措施说明一般信息避免接触皮肤和眼睛。

万一发生事故或感觉不适时, 立即求医咨询(可能时出示标签)。

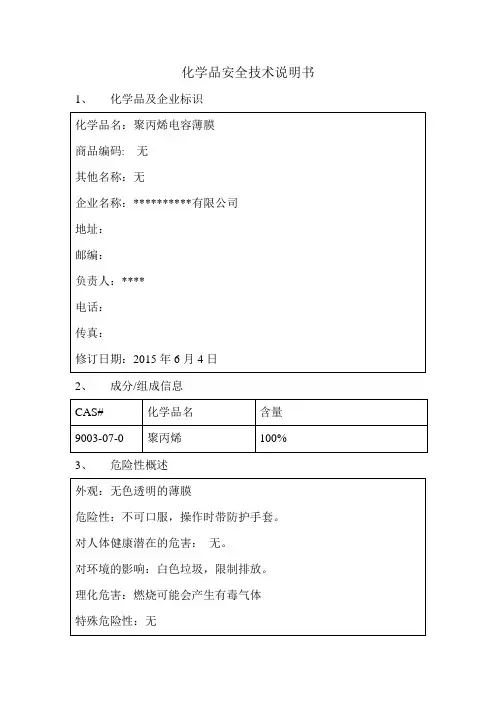

H4膜料安全技术说明书

说明书目录

第一部分 物品与厂商资料 第九部分理化特性

第二部分 成分/组成信息 第十部分稳定性和反应活性 第三部分 危险性概述 第十一部分毒理学资料

第四部分急救措施 第十二部分生态学资料

第五部分消防措施 第十三部分废弃处理

第六部分泄漏应急处理 第十四部分运输信息

第七部分操作处置与储存 第十五部分法规信息

第八部分接触控制/个体防护 第十六部分其他信息

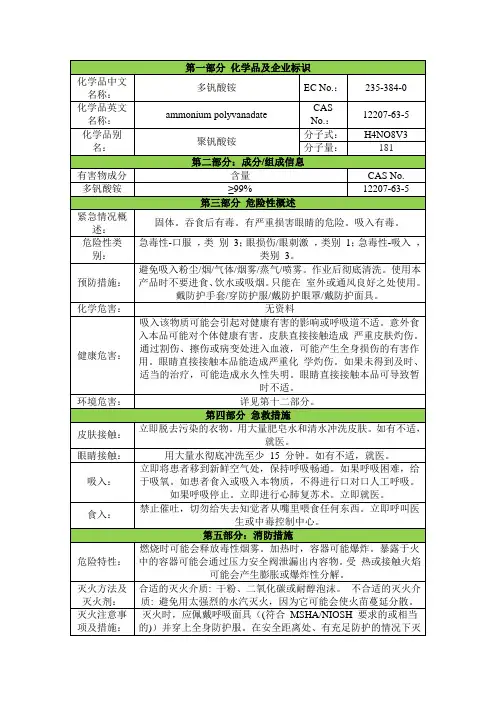

第一部分:物品与厂商资料

物品名称:H4(化合物)

英文名称:lanthanum titanate

分子式:LaTiO3

分子量:234.8

制造商或供应商:南阳利达光电有限公司

地址:中国·南阳

电话:0086-377-63865079

传真:0086-377-63865080

第二部分:成分/组成信息

成分含量CAS No

LaTiO399.95%以上——

第三部分:危险性概述

危险性类别

侵入途径:此固体状态为稳定物质,无发生火灾可能。

健康危害:无

环境危害:无

燃爆危险无

第四部分:急救措施

皮肤接触:对皮肤无任何危害。

眼睛接触:立即撑开眼皮以水冲洗直至完全清除污染物,接受医生处理吸入:万一吸入,立即就医。

食入:万一食入,立即就医

第五部分:消防措施

危险特性:无燃烧可能。

有害燃烧产物:未知。

灭火方法:无需采取措施。

第六部分:泄漏应急处理

应急处理:不需要特别处置。

第七部分:操作处置与储存

操作注意事项:小心操作,防止沾污。

储存注意事项放于干燥的地方,防止吸潮。

第八部分:接触控制/个体防护

工程控制:无资料

呼吸系统防护:戴防护面罩。

眼睛防护:戴安全防护眼镜。

身体防护:可穿着防护衣。

手防护:手套。

其他防护:N/A

第九部分:理化特性

主要成分:LaTiO3

外观与性状:白黑色固体颗粒

pH:无资料

熔点(℃):1800

沸点(℃):2800

相对密度(水=1): 5.9g/cm3

溶解性:不溶于水

主要用途:优良宽带增透膜

其它理化性质:

第十部分:稳定性和反应活性

稳定性:常温下稳定。

禁配物:无

避免接触的条件:高温

聚合危害:无

分解产物:无

第十一部分:毒理学资料

急性毒性:无

亚急性和慢性毒性:无

致突变性:未知

致畸性:未知

致癌性:未知

第十二部分:生态学资料

生态毒理毒性:无

生物降解性:无

非生物降解性:无

生物富集或生物积累性:无

其它有害作用:无

第十三部分:废弃处置

废弃物性质:产品和产品包装物

废弃处置方法:废弃产品回收,严禁浪费,乱弃。

废弃产品包装物依照国家

或地方法规处理。

第十四部分:运输信息

危险货物编号:无资料

UN编号:无资料

包装标志:无资料

包装类别:无资料

包装方法:无资料。

运输注意事项:一般运输,防止包装剥离,防止材料破损。

第十五部分:法规信息

法规信息:化学危险物品安全管理条例 (1987年2月17日国务院发

布),化学危险物品安全管理条例实施细则(化劳发[1992]

677号),工作场所安全使用化学品规定 ([1996]劳部发423

号)等法规,针对化学危险品的安全使用、生产、储存、运

输、装卸等方面均作了相应规定。

第十六部分:其他信息

参考文献:厂商提供MSDS数据

填表时间: 2005年10月20日

填表部门:利达光电股份有限公司光学辅材公司

数据审核单位:利达光电股份有限公司质量管理部

修改说明:

信息:

MSDS修改日期:

填写人编号: FC0203

制作:齐志国审核:张向东批准:杨太礼。