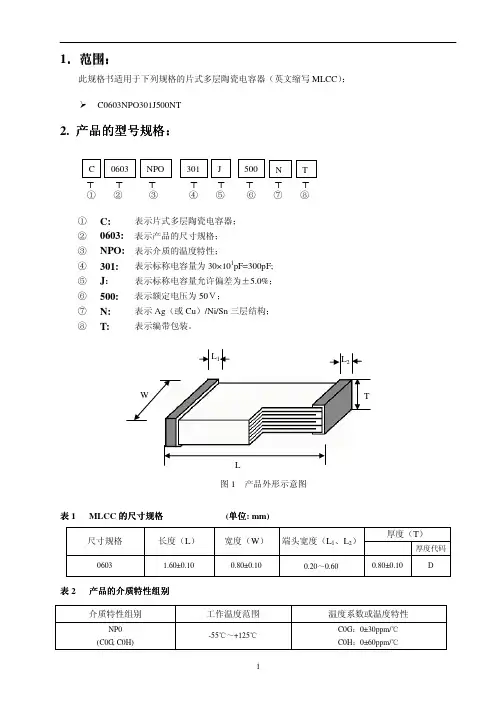

多层陶瓷电容器结构说明图

- 格式:doc

- 大小:440.00 KB

- 文档页数:2

四川华瓷科技有限公司承认书APPROV AL SHEET产品名称:多层片式陶瓷电容器PART NAME :MULTILAYER CERAMIC CAPACITORS 系列:中高压系列(100V~3000V)SERIES :Mid-High Volts Series(100V~3000V)规格:0402 ~ 1812尺寸SPECIFICATION:0402 ~ 1812 Size供应商(SUPPLIER): 四川华瓷科技有限公司发布日期(ISSUE DATE): 20190110批准(APPROVED BY):客户许可(CUSTOMER APPROVAL):1、概述(DESCRIPTION)适合厂家高密度、高效表面贴装的高压陶瓷电容器。

For high density and high efficiency SMT application.产品采用NP0(C0G、C0H), X7R材质制作,具有电气性能优越、可靠性高的特点。

We can provide NP0(C0G/C0H)/X7R capacitors with high reliability and excellent electrical performance.2、产品特点(FEATURES):a、产品尺寸电压高。

High voltage in a given case size.b、高稳定性、高可靠性。

High stability and reliability.3、应用领域(APPLICATIONS):模拟或数字调制解调器。

Analog & Digital Modems局域网/广域网接口界面。

LAN/WAN Interface倍压电器。

V oltage Multipliers直流变送器。

DC-DC Converters背光源驱动电路。

Back-lighting Inverters4 、型号规格表示方法:HOW TO ORDERHHV 1206 R7 102 K 202 N S L JSeries 产品系列HHV 高压型Size尺寸Inch(mm):0402(1005)0603(1608)0805(2012)1206(3216)1210(3225)1808(4520)1812(4532)Dielectric材质R5=X5RR6=X6RS6=X6SR7=X7RS7=X7ST7=X7TR8=X8RG0=C0GH0=C0HCapacitance标称容量R75=0.75pF0R5=0.5pF1R0=1pF100=10pF101=100pF102=1000pF103=10nF104=100nF105=1μF106=10μF107=100μFTolerance精度级别A=±0.05pFB=±0.1pFC=±0.25pFD=±0.5pFF=±1%G=±2%J=±5%K=±10%L=±15%M=±20%S=-20%~+50%Rated voltage额定电压101=100 Vdc201=200 Vdc251=250 Vdc501=500 Vdc631=630 Vdc102=1k Vdc152=1.5k Vdc202=2k Vdc252=2.5k Vdc302=3k Vdc402=4k Vdc502=5k Vdc602=6k VdcTermination端电极类型N=Cu/Ni/SnC=Cu/Resin/Ni/SnPackaging包装方式T=纸带Paper tapingB=散包装BulkS=塑胶带EmbossedtapingSymbol/Thickness(mm)厚度代号A=0.1mmB=0.2mmC=0.3mmD=0.4mmE=0.5mmF=0.6mmG=0.7mmH=0.8mmJ=1.0mmL=1.25mmP=1.6mmS=1.8mmU=2.0mmV=2.5mmW=3.0mmReel Size卷盘规格J=7InchD=13InchK=7Inch12mmwidth tape5、温度系数/特性Temperature Coefficient /Characteristics介质种类Dielectric参考温度点Reference Temperature Point标称温度系数Temperature Coefficient工作温度范围Operation Temperature RangeC0G 20︒C 0±30 ppm/℃-55℃~125℃C0H 20︒C 0±60 ppm/℃-55℃~125℃X7R 20︒C ±15% -55℃~125℃X7S 20︒C ±22% -55℃~125℃备注:Ⅰ类电容器标称温度系数和允许偏差是采用温度在20︒C和85︒C之间的电容量变化来确定的,而Ⅱ类电容器标称温度系数是按照工作范围之间的电容量相对20︒C的电容量变化来确定的。

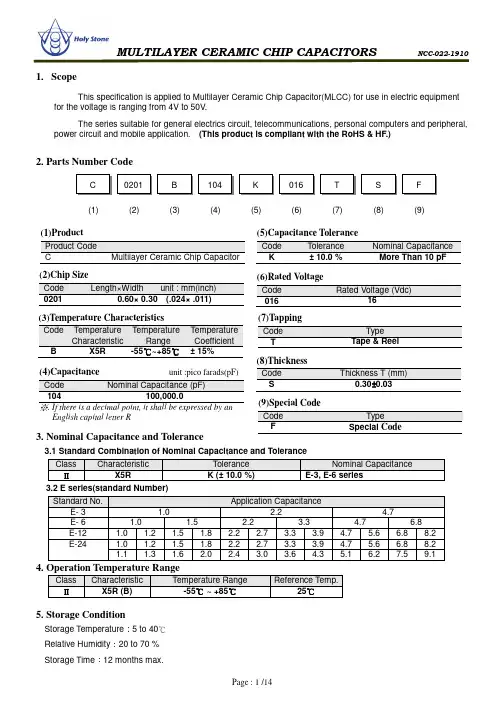

1. ScopeThis specification is applied to Multilayer Ceramic Chip Capacitor(MLCC) for use in electric equipment for the voltage is ranging from 4V to 50V.The series suitable for general electrics circuit, telecommunications, personal computers and peripheral, power circuit and mobile application. (This product is compliant with the RoHS & HF.)2. Parts Number Code3. Nominal Capacitance and Tolerance3.1 Standard Combination of Nominal Capacitance and ToleranceClass CharacteristicTolerance Nominal CapacitanceⅡX5RK (± 10.0 %)E-3, E-6 series3.2 E series(standard Number) Standard No.Application CapacitanceE- 3 1.02.24.7E- 6 1.0 1.52.23.34.76.8E-12 1.0 1.2 1.5 1.8 2.2 2.7 3.3 3.9 4.7 5.6 6.8 8.2 E-241.0 1.2 1.5 1.82.2 2.73.3 3.94.75.66.8 8.2 1.1 1.31.62.02.43.0 3.64.35.16.27.5 9.14. Operation Temperature RangeClassCharacteristic Temperature Range Reference Temp.Ⅱ X5R (B)-55 ~ +85℃℃25℃5. Storage ConditionStorage Temperature :5 to 40℃ Relative Humidity :20 to 70 % (1) (2) (3) (4) (5)(6)(7)(6)Rated VoltageCode Rated Voltage (Vdc)01616(1)ProductProduct Code C Multilayer Ceramic Chip Capacitor (3)Temperature CharacteristicsCode Temperature CharacteristicTemperature Range TemperatureCoefficientB X5R -55℃~+85℃ ± 15%(4)Capacitance unit :pico farads(pF) Code Nominal Capacitance (pF) 104 100,000.0※. If there is a decimal point, it shall be expressed by an English capital letter R(5)Capacitance ToleranceCode Tolerance Nominal Capacitance K± 10.0 %More Than 10 pF(7)TappingCode Type TTape & Reel(2)Chip Size Code Length×Width unit : mm(inch)02010.60× 0.30 (.024× .011)(8)(9)(8)ThicknessCode Thickness T (mm)S0.30±0.03(9)Special CodeCode TypeFSpecial Code6. Dimensions6.1 Configuration and Dimension :Unit:mmTYPE LW TB (min)BW (min) 02010.60± 0.030.30± 0.030.30± 0.030.200.106.2 Termination Type :External Electrodes BarrierInner ElectrodesPolymer Electrodes (If applicable)7. PerformanceFig.1P.C. Board for Bending Strength TestMaterial : Glass Epoxy Substrate: Solder ResistTest SubstrateMaterial : Glass Epoxy Substrate: Copper (Thickness : 0.035mm)Thickness : 1.6 mmUnit:mmType A B C 0201 0.2 0.9 0.4 0402 0.5 1.5 0.6 0603 1.0 3.0 1.0 0805 1.2 4.0 1.6 1206 2.2 5.0 2.0 1210 2.2 5.0 2.9 1808 3.5 7.0 2.5 1812 3.5 7.0 3.7 2208 4.5 8.0 2.5 2211 4.5 8.0 3.0 22204.58.05.68. Packing8.1 Bulk PackingAccording to customer request. 8.2 Chip Capacitors Tape Packing8.3 Material And QuantityTape Material 0201 0402 0603/0805 ≦T 0.33mm ≦T 0.55mm ≦T 1.00mm T >1.00mm Paper 15,000 pcs/Reel 10,000 pcs/Reel 4,000 pcs/Reel NAPlasticNA NA NA 3,000 pcs/ReelTape Material 1206≦T 1.00mm 1.00mm <≦T 1.25mmT >1.25mmPaper 4,000 pcs/ReelNANAPlastic NA3,000 pcs/Reel 2,000 pcs/ReelTape Material 1812/2211/2220 1825/2225 2208 T ≦2.20mm T >2.20mm T ≦2.20mm T >2.20mm T ≦2.20mm Paper NA NA NA NANAPlastic 1,000 pcs/Reel 700 pcs/Reel 700 pcs/Reel400 pcs/Reel 1,000 pcs/Reel NA :Not Available8.4 Cover Tape Reel Off Force8.4.1 Peel-Off Force5 g·≦f Peel-≦Off Force 70 g·f 8.4.2 Measure MethodTape Material 1808/1210≦T 1.25mm1.25mm <≦T2.40mmT >2.40mmPaper NANANAPlastic 3,000 pcs/Reel1,000/2,000 pcs/Reel500/1,000 pcs/Reel8.5 Paper TapeUnit:mm8.6 Plastic TapeUnit:mm TYPE A B C DE 0201 0.37± 0.1 0.67± 0.1 4.00± 0.1 2.00± 0.052.00± 0.10402 0.61± 0.1 1.20± 0.1 0603 1.10± 0.2 1.90± 0.2 4.00± 0.10805 1.50± 0.2 2.30± 0.2 1206 1.90± 0.2 3.50± 0.2 1210 2.90± 0.2 3.60± 0.2 TYPE FG H It0201 1.75± 0.103.50± 0.058.0± 0.30 φ1.50 +0.10/-0 1.10 max.0402 0603 0805 1206 1210Type A B C D E F 0805 1.5±0.2 2.3±0.2 4.0± 0.12.0± 0.054.0± 0.11.75± 0.11206 1.9±0.2 3.5±0.2 1210 2.9±0.2 3.6±0.2 1808 2.5±0.2 4.9±0.2 1812 3.6±0.2 4.9±0.2 8.0± 0.11825 6.9±0.2 4.9±0.2 2208 2.5±0.2 6.1±0.2 2211 3.2±0.2 6.1±0.2 2220 5.4±0.2 6.1±0.2 22256.9±0.26.1±0.28.7 Reel DimensionsReel Material :PolystyreneType G H IJ t O 0805 3.5± 0.058.0± 0.3φ1.5+0.1/-03.0 max.0.3 max.1.0± 0.11206 1210 1808 5.5± 0.05 12.0 ± 0.3 4.0 max. 1.5± 0.11812 1825 2208 2211 2220 2225Type AB C DE W 0201 φ382 max φ50 min φ13± 0.5φ21± 0.82.0±0.510± 0.150402 0603 0805 1206 1210 1808 φ178±2.0 φ60±2.0 13±0.31812 1825 2208 2211 2220 2225Unit:mmPrecautionary Notes:1. StorageStore the capacitors where the temperature and relative humidity don’t exceed 40°C and 70%RH. Werecommend that the capacitors be used within 12 months from the date of manufacturing. Store the products in the original package and do not open the outer wrapped, polyethylene bag, till just before usage. If it is open, seal it as soon as possible or keep it in a desiccant with a desiccation agent.2. Construction of Board PatternImproper circuit layout and pad/land size may cause excessive or not enough solder amount on the PC board. Not enough solder may create weak joint, and excessive solder may increase the potential of mechanical or thermal cracks on the ceramic capacitor. Therefore we recommend the land size to be as shown in the following table: 2.1 Size and recommend land dimensions for reflow soldering2.2 Mechanical strength varies according to location of chip capacitors on the P .C. board.Design layout of components on the PC board such a way to minimize the stress imposed on the components, upon flexure of the boards in depanelization or other processes.Component layout close to the edge of the board or the “depanelization line” is not recommended. Susceptibility to stress is in the order of: a>b>c and d>eEIA Code Chip (mm) Land (mm) L W A B C D E 0201 0.60 0.30 0.2~0.3 0.2~0.4 0.2~0.4 -- -- 0402 1.00 0.50 0.3~0.5 0.3~0.5 0.4~0.6 -- -- 0603 1.60 0.80 0.4~0.6 0.6~0.7 0.6~0.8 -- -- 0805 2.00 1.25 0.7~0.9 0.6~0.8 0.8~1.1 -- -- 1206 3.20 1.60 2.2~2.4 0.8~0.9 1.0~1.4 1.0~2.0 3.2~3.7 1210 3.20 2.50 2.2~2.4 1.0~1.2 1.8~2.3 1.0~2.0 4.1~4.6 1808 4.60 2.00 2.8~3.4 1.8~2.0 1.5~1.8 1.0~2.8 3.6~4.1 1812 4.60 3.20 2.8~3.4 1.8~2.0 2.3~3.0 1.0~2.8 4.8~5.3 1825 4.60 6.35 2.8~3.4 1.8~2.0 5.1~5.8 1.0~4.0 7.1~8.3 2208 5.70 2.00 4.0~4.6 2.0~2.2 1.5~1.8 1.0~4.0 3.6~4.1 2211 5.70 2.80 4.0~4.6 2.0~2.2 2.0~2.6 1.0~4.0 4.4~4.9 2220 5.70 5.00 4.0~4.6 2.0~2.2 3.5~4.8 1.0~4.0 6.6~7.1 2225 5.70 6.354.0~4.62.0~2.2 5.1~5.8 1.0~4.07.1~8.32.3 Layout Recommendation3. Mounting3.1 Sometimes crack is caused by the impact load due to suction nozzle in pick and place operation.In pick and place operation, if the low dead point is too low, excessive stress is applied to component. This maycause cracks in the ceramic capacitor, therefore it is required to move low dead point of a suction nozzle to the higher level to minimize the board warp age and stress on the components. Nozzle pressure is typically adjusted to 1N to 3N (static load) during the pick and place operation.3.2 Amount of Adhesivea0.2mm min. b 70 ~ 100 µm cDo not touch the solder landExample : 0805 & 12064. Soldering4.1. Wave SolderingMost of components are wave soldered with solder at Peak Temperature.. Adequate care must be taken to prevent the potential of thermal cracks on the ceramic capacitors. Refer to the soldering methods below for optimum soldering benefits.Recommend flow soldering temperature ProfileRecommended solder compositions Sn-37Pb (Pb - Sn Solder)Sn-3.0Ag-0.5Cu (Lead Free Solder)To optimize the result of soldering, proper preheating is essential: 1) Preheat temperature is too lowa. Flux flows to easilyb. Possibility of thermal cracks2) Preheat temperature is too higha. Flux deteriorates even when oxide film is removedb. Causes warping of circuit boardc. Loss of reliability in chip and other componentsCooling Condition:Natural cooling using air is recommended. If the chips are dipped into a solvent for cleaning, the temperature difference (ΔT) between the solvent and the chips must be less than 100°C.4.2 Reflow SolderingPreheat and gradualincrease in temperature to the reflow temperature is recommended to decrease the potential of thermal crack on the components. The recommended heating rate depends on the size of component, however it should not exceed 3°C/Sec.Recommend reflow profile for Lead-Free soldering temperature Profile (J-STD-020D)Soldering Method Change in Temp.( )℃1206 and Under Δ≦T 190 ℃1210 and Over Δ≦T 130 ℃Soldering Method Peak Temp.( ℃) / Duration (sec)1206 and Under ∆T ≤ 100~130 max. Pb-Sn Solder 250℃(max.) / 3sec(max.) Lead Free Solder 260℃(max.) / 5sec(max.) ※ The cycles of soldering : Twice (max.)Soldering T e m p e r a t u r e (°C )T e m p e r a t u r e (°C )4.3 Hand SolderingSudden temperature change in components, results in a temperature gradient recommended in the following table, and therefore may cause internal thermal cracks in the components. In general a hand soldering method is not recommended unless proper preheating and handling practices have been taken. Care must also be taken not to touch the ceramic body of the capacitor with the tip of solder Iron.Soldering Method Change in Temp.( )℃1206 and Under Δ≦T 150 ℃1210 and Over Δ≦T 130 ℃How to Solder Repair by Solder Iron1) Selection of the soldering iron tipThe required temperature of solder iron for any type of repair depends on the type of the tip, the substrate material, and the solder land size.2) recommended solder iron conditiona.) Preheating Condition:Board and components should be preheated sufficiently at 150°C or over,and soldering should be conducted with soldering iron as boards and components are maintainedat sufficient temperatures.b.) Soldering iron power shall not exceed 30 W.c.) Soldering iron tip diameter shall not exceed 3mm.d.) Temperature of iron tip shall not exceed 350°C to perform the process within 5 seconds.(refer to MIL-STD-202G)f.) Do not touch the ceramic body with the tip of solder iron. Direct contact of the soldering iron tip to ceramicbody may cause thermal cracks.g.) After soldering operation, let the products cool down gradually in the room temperature.5. Handling after chip mounted5.1 Proper handling is recommended, since excessive bending and twist of the board, depends on the orientationof the chip on the board, may induce mechanical stress and cause internal crack in the capacitor.Temperature(°C)200→Higher potential of crack Lower potential of crack ╳5.3 Mechanical stress due to warping a (a) Crack occurrence ratio will be in (b) Crack occurrence ratio will be in :Tensile Stress ╳6. Handling of Loose Chip Capacitor 6.1 If dropped the chip capacitor may c6.2 In piling and stacking of the P .C. bo may hit the chip capacitor mounted7. Safekeeping condition and period For safekeeping of the products, we re under humidity of 20 to 70% RH. The sing and torsion.be increased by manual separation.be increased by tensile force , rather than compressiv s○ :Compressive Stress tor may crack. .C. boards after mounting for storage or handling, the unted on another board to cause crack.we recommend to keep the storage temperature betwe The shelf life of capacitors is 12 months. ressive force.ess, the corner of the P .C. boardbetween +5 to +40°C and Crack。

MLCCMLCC根底知识•MLCC简介•MLCC根本结构•MLCC分类MLCC可靠性及测试方法•容量•损耗角正切•绝缘电阻•介质耐电强度(口0丫)•可焊性•耐焊接热•抗弯曲强度•端头结合强度•温度循环•潮湿试验•寿命试验MLCC简介通常所说的贴片电容是指MLCC,即多层陶瓷片式电容(Multilayer Cer AMl c Capacitors)o常规贴片电容按材料分为COG(NPO),X7R,丫5丫,其弓|脚封装有201,0402,0603.0805.1206,1210,1812,1825,2225.MLCC根本结构多层陶瓷电^MLCC)是由平行的陶瓷材料和电极材料层叠而成.见下列图:End TarrnifiationsJVlargtn ElectrodesMLCC分类tTOP多层陶瓷电容(MLCC)根据材料分为Class 1和Class 2两类.Class 1是温度补偿型,Class 2是温度稳定型和普通应用的.Class 1- Class 1或者温度补偿型电容通常是由钛酸钡不占主要局部的钛酸盐混合物构成.它们有可预见的温度系数,通常没有老化特性.因此它们是可用的最稳定的电容.最常用的Class 1多层陶瓷电容是COG(NPO)温度补偿型电容(±0 ppm/°C).Class 2- EIA Class 2电容通常也是由钛酸钡化合物组成.Class 2电容有很大的电容容量和温度稳定性. 最普通最常用的Class 2电容电解质是X7R和丫5V.在温度范围-55°C到1250c之间,X7R能提供仅有±15%变化的的中等容量的电容容量.它最适合应用在温度范围宽,电容量要求稳定的场合.Y5V能提供最大的电容容量,常用在环境温度变化不大的地方.在温度范围-30°C to 85°C之间,Y5V电容值的变化是22% to -82%.所有的Class 2电容的电容容量受以下几个条件影响:温度变化、操作电压(直流和交流)、频率.容量tTOP损耗角正切绝缘电阻介质耐电强度(DWV)可焊性耐焊接热抗弯曲强度端头结合强度tTOP工程技术规格测试方法端头结合强度外观无可见损伤施加的力:5N时间:10 ±1S 温度循环fTOP工程技术规格测试方法温度循环△C/C I类:0±2.5%或±0.25pF 取两者中取大的II类:B:0±7.5%E,F:<±20%预处理*〔 2类〕:上限类别温度,1小时恢复:24士1h初始测量循环次数:5次一个循环分以下4步:阶段混度嘴时间?耳钟〕DF同初始标准1IR同初始标准第毋下短混曳3D第£或常混2-3第3步上眼:是度3D第4步常温潮湿试验tTOP工程技术规格测试方法寿命试验。

多层贴片陶瓷电容烧结原理及工艺多层陶瓷电容器(MLCC)的典型结构中导体一般为Ag或AgPd,陶瓷介质一般为(SrBa)TiO3,多层陶瓷结构通过高温烧结而成。

器件端头镀层一般为烧结Ag/AgPd,然后制备一层Ni阻挡层(以阻挡内部Ag/AgPd材料,防止其和外部Sn发生反应),再在Ni层上制备Sn或SnPb层用以焊接。

近年来,也出现了端头使用Cu的MLCC产品。

根据MLCC的电容数值及稳定性,MLCC划分出NP1、COG、X7R、Z5U等。

根据MLCC 的尺寸大小,可以分为1206,0805,0603,0402,0201等。

MLCC 的常见失效模式多层陶瓷电容器本身的内在可靠性十分优良,可以长时间稳定使用。

但如果器件本身存在缺陷或在组装过程中引入缺陷,则会对其可靠性产生严重影响。

陶瓷多层电容器失效的原因分为外部因素和内在因素内在因素主要有以下几种:1.陶瓷介质内空洞(Voids)导致空洞产生的主要因素为陶瓷粉料内的有机或无机污染,烧结过程控制不当等。

空洞的产生极易导致漏电,而漏电又导致器件内部局部发热,进一步降低陶瓷介质的绝缘性能从而导致漏电增加。

该过程循环发生,不断恶化,严重时导致多层陶瓷电容器开裂、爆炸,甚至燃烧等严重后果。

2.烧结裂纹(firing crack)烧结裂纹常起源于一端电极,沿垂直方向扩展。

主要原因与烧结过程中的冷却速度有关,裂纹和危害与空洞相仿。

3.分层(delamination)多层陶瓷电容器的烧结为多层材料堆叠共烧。

烧结温度可以高达1000℃以上。

层间结合力不强,烧结过程中内部污染物挥发,烧结工艺控制不当都可能导致分层的发生。

分层和空洞、裂纹的危害相仿,为重要的多层陶瓷电容器内在缺陷。

外部因素主要为:1.温度冲击裂纹(thermal crack)主要由于器件在焊接特别是波峰焊时承受温度冲击所致,不当返修也是导致温度冲击裂纹的重要原因。

2.机械应力裂纹(flex crack)多层陶瓷电容器的特点是能够承受较大的压应力,但抵抗弯曲能力比较差。

片式多层陶瓷电容器MLCC多层陶瓷电容器MLCC是英文字母Multi-Layer Ceramic Capacitor的首写字母。

在英文表达中又有Chip Monolithic Ceramic Capacitor。

两种表达都是以此类电容器外形和内部结构特点进行,也就是内部多层、整体独石(单独细小的石头)的结构,独石电容包括多层陶瓷电容器、圆片陶瓷电容器等,由于元件小型化、贴片化的飞速发展,常规圆片陶瓷电容器逐步被多层陶瓷电容器取代,人们把多层陶瓷电容器简称为独石电容或贴片电容。

片式多层陶瓷电容器(Multi-layer Ceramic Capacitor 简称MLCC)是电子整机中主要的被动贴片元件之一,它诞生于上世纪60年代,最先由美国公司研制成功,后来在日本公司(如村田Murata、TDK、太阳诱电等)迅速发展及产业化,至今依然在全球MLCC领域保持优势,主要表现为生产出MLCC具有高可靠、高精度、高集成、高频率、智能化、低功耗、大容量、小型化和低成本等特点。

(片式多层陶瓷电容器,独石电容,片式电容,贴片电容) MLCC —简称片式电容器,是由印好电极(内电极)的陶瓷介质膜片以错位的方式叠合起来,经过一次性高温烧结形成陶瓷芯片,再在芯片的两端封上金属层(外电极),从而形成一个类似独石的结构体,故也叫独石电容器。

MLCC除有电容器“隔直通交”的通性特点外,其还有体积小,比容大,寿命长,可靠性高,适合表面安装等特点。

•随着世界电子行业的飞速发展,作为电子行业的基础元件,片式电容器也以惊人的速度向前发展,•每年以10%~15%的速度递增。

目前,世界片式电容的需求量在2000亿支以上,70%出自日本(如MLCC大厂村田muRata),其次是欧美和东南亚(含中国)。

随着片容产品可靠性和集成度的提高,其使用的范围越来越广,•广泛地应用于各种军民用电子整机和电子设备。

如电脑、电话、程控交换机、精密的测试仪器、雷达通信等。

北京芯联科泰电子有限公司贴片叠层瓷介电容器(SMD贴片电容)详细介绍:贴片电容全称:多层(积层,叠层)片式陶瓷电容器,也称为贴片电容,片容。

英文缩写:MLCC。

基本概述贴片电容(多层片式陶瓷电容器)是目前用量比较大的常用元件,就AVX公司生产的贴片电容来讲有NPO、X7R、Z5U、Y5V等不同的规格,不同的规格有不同的用途。

下面我们仅就常用的NPO、X7R、Z5U和Y5V来介绍一下它们的性能和应用以及采购中应注意的订货事项以引起大家的注意。

不同的公司对于上述不同性能的电容器可能有不同的命名方法,这里我们引用的是AVX公司的命名方法,其他公司的产品请参照该公司的产品手册尺寸贴片电容的尺寸表示法有两种,一种是英寸为单位来表示,一种是以毫米为单位来表示,贴片电容的系列型号有0402、0603、0805、1206、1210、1808、1812、2010、2225、2512,是英寸表示法, 04 表示长度是0.04 英寸,02 表示宽度0.02 英寸,其他类同型号尺寸(mm)英制尺寸公制尺寸长度及公差宽度及公差厚度及公差0402 1005 1.00±0.05 0.50±0.05 0.50±0.050603 1608 1.60±0.10 0.80±0.10 0.80±0.100805 2012 2.00±0.20 1.25±0.20 0.70±0.20 1.00±0.20 1.25±0.201206 3216 3.00±0.30 1.60±0.20 0.70±0.20 1.00±0.20 1.25±0.201210 3225 3.00±0.30 2.54±0.30 1.25±0.30 1.50±0.301808 4520 4.50±0.40 2.00±0.20 ≤2.001812 4532 4.50±0.40 3.20±0.30 ≤2.502225 5763 5.70±0.50 6.30±0.50 ≤2.503035 7690 7.60±0.50 9.00±0.05 ≤3.00命名贴片电容的命名所包含的参数有贴片电容的尺寸、做这种贴片电容用的材质、要求达到的精度、要求的电压、要求的容量、端头的要求以及包装的要求。

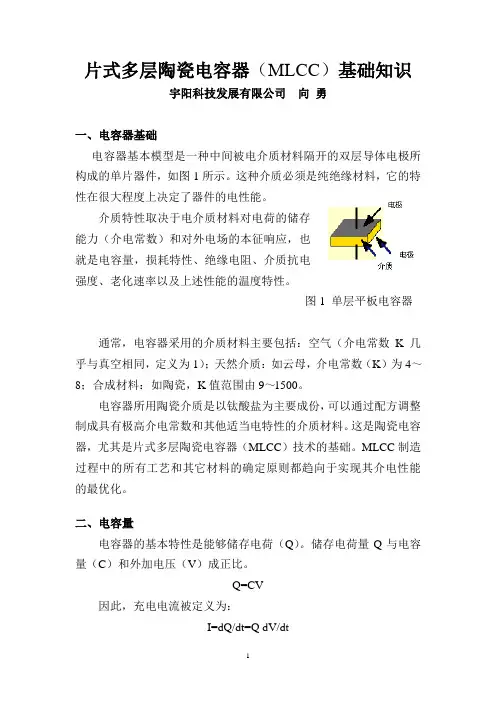

片式多层陶瓷电容器(MLCC)基础知识宇阳科技发展有限公司向勇一、电容器基础电容器基本模型是一种中间被电介质材料隔开的双层导体电极所构成的单片器件,如图1所示。

这种介质必须是纯绝缘材料,它的特性在很大程度上决定了器件的电性能。

介质特性取决于电介质材料对电荷的储存能力(介电常数)和对外电场的本征响应,也就是电容量,损耗特性、绝缘电阻、介质抗电强度、老化速率以及上述性能的温度特性。

图1 单层平板电容器通常,电容器采用的介质材料主要包括:空气(介电常数K几乎与真空相同,定义为1);天然介质:如云母,介电常数(K)为4~8;合成材料:如陶瓷,K值范围由9~1500。

电容器所用陶瓷介质是以钛酸盐为主要成份,可以通过配方调整制成具有极高介电常数和其他适当电特性的介质材料。

这是陶瓷电容器,尤其是片式多层陶瓷电容器(MLCC)技术的基础。

MLCC制造过程中的所有工艺和其它材料的确定原则都趋向于实现其介电性能的最优化。

二、电容量电容器的基本特性是能够储存电荷(Q)。

储存电荷量Q与电容量(C)和外加电压(V)成正比。

Q=CV因此,充电电流被定义为:I=dQ/dt=Q dV/dt当电容器外加电压为1伏特,充电电流为1安培,充电时间为1秒时,电容量定义为1法拉。

C=Q/V=库仑/伏特=法拉由于法拉是一个很大的测量单位,在实用中不会遇到,常用的是法拉的分数,即:微法(μF) = 10-6F毫微法,又称为:纳法(nF) = 10-9F微微法,又称为:皮法(pF) = 10-12F三、影响电容量的因素施加电压的单片电容器如图1,其电容量正比于器件的几何尺寸和相对介电常数:C=KA/f t在这里C=电容量;K=相对介电常数,简称介电常数;A=电极层面积;t=介质厚度;f=换算因子(在基础科学领域:相对介电常数用εr表示。

在工程应用中以K表示,简称为介电常数)在英制度量单位体系中,f=4.452,尺寸A和t用英寸,电容量值用微微法表示。

● Supplier : Samsung Electro-Mechanics CL10B103KA8WPNC● Product : Multi-layer Ceramic CapacitorCAP, 10㎋, 25V, ± 10%, X7R, 0603● AEC-Q200 QualifiedA. Dimension● DimensionB. Samsung Part NumberCL 10B K A 8W P N C ①②③⑤⑥⑦⑧⑨⑩⑪①Series Samsung Multi-layer Ceramic Capacitor ②Size (inch code)L :1.60±0.10 mm W :0.80±0.10 mm ③Dielectric ⑧Inner electrode Ni, Open Mode Design ④Capacitance ㎋Termination Metal-Epoxy ⑤Capacitance ± 10%Plating Sn 100% (Pb Free)tolerance ⑨Product Automotive ⑥Rated Voltage V⑩Special code Normal⑦Thickness0.80±0.10 mm⑪PackagingCardboard Type, 7" ReelTest items High Temperature Appearance : No abnormal exterior appearance Unpowered,1,**********************ExposureCapacitance Change Within ±10 %Measurement at 24±2hrs after test conclusion Tan δ :0.03 max.IR :More than 10,000 ㏁ or 500 ㏁×㎌Initial Measurement 2* Whichever is smallerFinal Measurement 3*Temperature Cycling Appearance : No abnormal exterior appearance1,000CyclesCapacitance Change Within ±10 %Initial Measurement 2* Tan δ :0.03 max.Final Measurement 3*IR :More than 10,000 ㏁ or 500 ㏁×㎌Measurement at 24±2hrs after test conclusionWhichever is smaller1 cycle condition : -55+0/-3℃(30±3min) → Room Temp. (1min)→ 125+3/-0℃(30±3min) → Room Temp. (1min)Destructive Physical No Defects or abnormalities Per EIA 469Analysis Humidity BiasAppearance : No abnormal exterior appearance 1,000hrs 85℃/85%RH, Rated Voltage and 1.3~1.5V,Capacitance Change Within ±12.5 %Add 100kohm resistor Tan δ :0.035 max.Initial Measurement 2* IR :More than 500 ㏁ or 25 ㏁×㎌Final Measurement 4*Whichever is smallerMeasurement at 24±2hrs after test conclusion The charge/discharge current is less than 50mA.High Temperature Appearance : No abnormal exterior appearance 1,000hrs @ 125℃, 200% Rated Voltage,Operating LifeCapacitance Change Within ±12.5 %Initial Measurement 2* Tan δ :0.035 max.Final Measurement 4*IR :More than 1,000 ㏁ or 50 ㏁×㎌Measurement at 24±2hrs after test conclusion Whichever is smallerThe charge/discharge current is less than 50mA.Specification of Automotive MLCC (Reference sheet)103L W T ● Samsung P/N :● Description :0.30±0.20 mmBWSize 0603 inch 1.60±0.10 mm 0.80±0.10 mm 0.80±0.10 mm X7R PerformanceTest condition25④060310External VisualNo abnormal exterior appearance Microscope (´10)Physical Dimensions Within the specified dimensions Using The calipersMechanical ShockAppearance : No abnormal exterior appearance Three shocks in each direction should be applied along Capacitance Change Within ±10 % 3 mutually perpendicular axes of the test specimen (18 shocks)Tan δ, IR :Initial spec.Initial Measurement 2* Final Measurement 5*VibrationAppearance : No abnormal exterior appearance 5g's for 20min., 12cycles each of 3 orientations,Capacitance Change Within ±10 %Use 8"×5" PCB 0.031" Thick 7 secure points on one long side Tan δ, IR :Initial spec.and 2 secure points at corners of opposite sides. Parts mounted within 2" from any secure point. Test from 10~2,000㎐.Initial Measurement 2* Final Measurement 5*Resistance to Appearance : No abnormal exterior appearance preheating : 150℃ for 60~120 sec.Solder HeatCapacitance Change Within ±10 %Solder pot : 260±5℃, 10±1sec.Tan δ, IR :Initial spec.Initial Measurement 2* Final Measurement 3*ESDAppearance : No abnormal exterior appearance AEC-Q200-002 or ISO/DIS10605Capacitance Change Within ±10 %Initial Measurement 2* Tan δ, IR :Initial spec.Final Measurement 4*Solderability95% of the terminations is to be soldered a) Preheat at 155℃ for 4 hours, Immerse in solder for 5s at 245±5℃evenly and continuouslyb) Steam aging for 8 hours, Immerse in solder for 5s at 245±5℃c) Steam aging for 8 hours, Immerse in solder for 120s at 260±5℃solder : a solution ethanol and rosinElectrical Capacitance : Within specified tolerance *A capacitor prior to measuring the capacitance is heat treated at CharacterizationTan δ :0.025 max.150 +0/-10℃ for 1hour and maintained in ambient air for 24±2 hours IR(25℃) :More than 10,000 ㏁ or 500 ㏁×㎌The Capacitance / D.F. should be measured at 25℃,Whichever is smaller1 ㎑ ± 10%,1 ± 0.2 VrmsIR(125℃) More than 1,000 ㏁ or 10 ㏁×㎌I.R. should be measured with a DC voltage not exceeding Whichever is smallerRated Voltage @25℃, @125℃ for 60~120 sec.Dielectric StrengthDielectric Strength : 250% of the rated voltage for 1~5 seconds Board FlexAppearance : No abnormal exterior appearance Bending to the limit,3 ㎜ for 60 seconds 1*Capacitance Change Within ±10 %Initial Measurement 2*Final Measurement 5*Terminal Appearance : No abnormal exterior appearance 10 N, for 60 sec.Strength(SMD)Capacitance Change Within ±10 %Initial Measurement 2* Final Measurement 5*Beam Load Destruction value should be exceed 20 NBeam speed :0.5±0.05 ㎜/secTemperature X7RCharacteristicsFrom -55 ℃ to 125 ℃, Capacitance change should be within ±15%Reflow ( Reflow Peak Temperature : 260 +0/-5℃, 30sec. ), Meet IPC/JEDEC J-STD-020 D Standard*1 : The figure indicates typical specification. Please refer to individual specifications.*2 : Initial measurement : Perform a heat treatment at 150 +0/-10℃ for one hour after soldering process. and then let sit for 24±2 hours at room temperature. Perform the initial measurement.*3 : Final measurement : Let sit for 24±2 hours at room temperature after test conclusion, then measure.*4 : Final measurement : Perform a heat treatment at 150 +0/-10℃ for one hour after soldering process. and then let sit for 24±2 hours at room temperature. Perform the initial measurement.*5 : Final measurement : Let measure within 24 hours at room temperature after test conclusion.Product specifications included in the specifications are effective as of March 1, 2013. Please be advised that they are standard product specifications for reference only.We may change, modify or discontinue the product specifications without notice at any time. So, you need to approve the product specifications before placing an order.Should you have any question regarding the product specifications, please contact our sales personnel or application engineers.0.5msHalf sine4.7m/secPerformance Test conditionPeak value Duration Wave Velocity 1,500G● Disclaimer & Limitation of Use and ApplicationThe products listed in this Specification sheet are NOT designed and manufactured for any use and applications set forth below.Please note that any misuse of the products deviating from products specifications or information provided in this Spec sheet may cause serious property damages or personal injury.We will NOT be liable for any damages resulting from any misuse of the products, specifically including using the products for high reliability applications as listed below.If you have any questions regarding this 'Limitation of Use and Application', you should first contact our sales personnel or application engineers.① Aerospace/Aviation equipment② Medical equipment③ Military equipment④ Disaster prevention/crime prevention equipment⑤ Power plant control equipment⑥ Atomic energy-related equipment⑦ Undersea equipment⑧ Traffic signal equipment⑨ Data-processing equipment⑩ Electric heating apparatus, burning equipment⑪ Safety equipment⑫ Any other applications with the same as or similar complexity or reliability to the applications。