计算结构力学自编平面桁架

- 格式:doc

- 大小:93.00 KB

- 文档页数:7

结构力学实验土木建筑学院实验名称:平面桁架结构的设计实验题号:梯形桁架D2-76姓名:学号:指导老师:实验日期:一、实验目的在给定桁架形式、控制尺寸和荷载条件下,对桁架进行内力计算,优选杆件截面,并进行刚度验算。

①掌握建立桁架结构力学模型的方法,了解静定结构设计的基本过程;②掌握通过多次内力和应力计算进行构件优化设计的方法;③掌握结构刚度验算的方法。

梯形桁架D ;其中结点1到结点7的水平距离为15m;结点1到结点8的距离为2m;结点7到结点14的距离为3m。

选用的是Q235钢,[ɑ]=215MPa。

完成结构设计后按如下步骤计算、校核、选取、设计、优化二、强度计算1)轴力和应力2)建立结构计算模型后,由“求解→内力计算”得出结构各杆件的轴力N(见图3)再由6=N/A得出各杆件应力。

表1内力计算杆端内力值 ( 乘子 = 1)--------------------------------------------------------------------------------------------杆端 1 杆端 2------------------------------------- ------------------------------------------ 单元码轴力剪力弯矩轴力剪力弯矩--------------------------------------------------------------------------------------------1 0.00000000 0.00000000 0.00000000 0.00000000 0.00000000 0.000000002 51.9230769 0.00000000 0.00000000 51.9230769 0.00000000 0.000000003 77.1428571 0.00000000 0.00000000 77.1428571 0.00000000 0.000000004 67.5000000 0.00000000 0.00000000 67.5000000 0.00000000 0.000000005 39.7058823 0.00000000 0.00000000 39.7058823 0.00000000 0.000000006 0.00000000 0.00000000 0.00000000 0.00000000 0.00000000 0.000000007 -54.0000000 0.00000000 0.00000000 -54.0000000 0.00000000 0.000000008 -52.0383336 0.00000000 0.00000000 -52.0383336 0.00000000 0.000000009 -77.3140956 0.00000000 0.00000000 -77.3140956 0.00000000 0.0000000010 -81.1798004 0.00000000 0.00000000 -81.1798004 0.00000000 0.0000000011 -81.1798004 0.00000000 0.00000000 -81.1798004 0.00000000 0.0000000012 -67.6498337 0.00000000 0.00000000 -67.6498337 0.00000000 0.0000000013 -39.7940198 0.00000000 0.00000000 -39.7940198 0.00000000 0.0000000014 -54.0000000 0.00000000 0.00000000 -54.0000000 0.00000000 0.0000000015 66.4939824 0.00000000 0.00000000 66.4939824 0.00000000 0.0000000016 -41.5384615 0.00000000 0.00000000 -41.5384615 0.00000000 0.0000000017 33.3732229 0.00000000 0.00000000 33.3732229 0.00000000 0.0000000018 -21.8571428 0.00000000 0.00000000 -21.8571428 0.00000000 0.0000000019 5.27613031 0.00000000 0.00000000 5.27613031 0.00000000 0.0000000020 -18.0000000 0.00000000 0.00000000 -18.0000000 0.00000000 0.0000000021 19.7385409 0.00000000 0.00000000 19.7385409 0.00000000 0.0000000022 -31.5000000 0.00000000 0.00000000 -31.5000000 0.00000000 0.0000000023 42.0090820 0.00000000 0.00000000 42.0090820 0.00000000 0.0000000024 -47.6470588 0.00000000 0.00000000 -47.6470588 0.00000000 0.0000000025 62.0225709 0.00000000 0.00000000 62.0225709 0.00000000 0.00000000结构轴力图表2桁架四类杆内力与应力计算表3所得各类杆件性质上弦杆 下弦杆 直腹杆 斜腹杆 初选截面 截面D*t (mm )63.5-2 60-2 42-2 45-2.5 截面面积(mm 2)386.4 364.4 251.3 333.8 最大轴力(KN )-81.180 77.143 -54.000 66.494 最大应力(MPa )210.1 211.7 214.9 199.2 调整 截面 截面型号63.5-2 60-2 42-2 45-2.5 截面面积(mm 2)386.4 364.4 251.3 333.8 最大轴力(KN )-81.180 77.143 -54.000 66.494 最大应力(MPa )210.1 211.7 214.9 199.2上弦杆 下弦杆 直腹杆 斜腹杆 EA(KN)77283.1873513.27 50265.48 62046.45 EI(KN*m 2) 36.5814.06 10.0812.15三、强度校核根据0.9[ɑ]≤6≤[ɑ];对于Q235钢,[6]=215MPa;参考公式:A=0.25π[D2+-(D-2t)2];I=π[D4-(D-2t)4]/64.对截面进行强度校核。

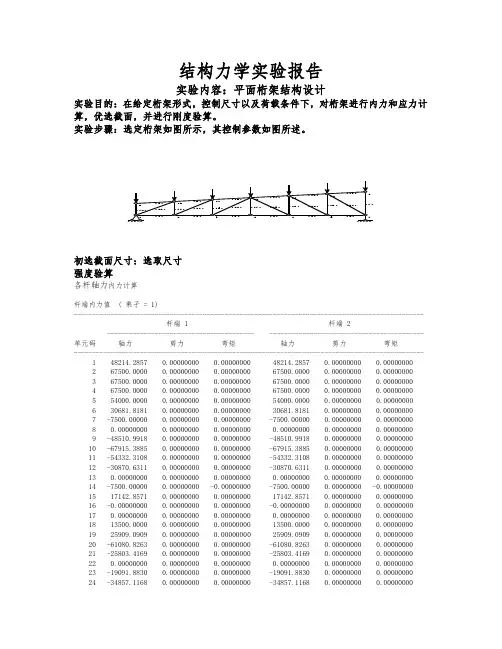

结构力学实验报告实验内容:平面桁架结构设计实验目的:在给定桁架形式,控制尺寸以及荷载条件下,对桁架进行内力和应力计算,优选截面,并进行刚度验算。

实验步骤:选定桁架如图所示,其控制参数如图所述。

1234567891011121314( 1 )( 2 )( 3 )( 4 )( 5 )( 6 )( 7 )( 8 )( 9 )( 10 )( 11 )( 12 )( 13 )( 14 )( 15 )( 16 )( 17 )( 18 )( 19 )( 20 )( 21 )( 22 )( 23 )( 24 )( 25 )初选截面尺寸:选取尺寸 强度验算各杆轴力内力计算杆端内力值 ( 乘子 = 1)-----------------------------------------------------------------------------------------------杆端 1 杆端 2 ---------------------------------------- ------------------------------------------单元码 轴力 剪力 弯矩 轴力 剪力 弯矩 -----------------------------------------------------------------------------------------------1 48214.2857 0.00000000 0.00000000 48214.2857 0.00000000 0.000000002 67500.0000 0.00000000 0.00000000 67500.0000 0.00000000 0.000000003 67500.0000 0.00000000 0.00000000 67500.0000 0.00000000 0.000000004 67500.0000 0.00000000 0.00000000 67500.0000 0.00000000 0.000000005 54000.0000 0.00000000 0.00000000 54000.0000 0.00000000 0.000000006 30681.8181 0.00000000 0.00000000 30681.8181 0.00000000 0.000000007 -7500.00000 0.00000000 0.00000000 -7500.00000 0.00000000 0.000000008 0.00000000 0.00000000 0.00000000 0.00000000 0.00000000 0.000000009 -48510.9918 0.00000000 0.00000000 -48510.9918 0.00000000 0.00000000 10 -67915.3885 0.00000000 0.00000000 -67915.3885 0.00000000 0.00000000 11 -54332.3108 0.00000000 0.00000000 -54332.3108 0.00000000 0.00000000 12 -30870.6311 0.00000000 0.00000000 -30870.6311 0.00000000 0.0000000013 0.00000000 0.00000000 0.00000000 0.00000000 0.00000000 0.0000000014 -7500.00000 0.00000000 -0.00000000 -7500.00000 0.00000000 -0.0000000015 17142.8571 0.00000000 0.00000000 17142.8571 0.00000000 0.0000000016 -0.00000000 0.00000000 0.00000000 -0.00000000 0.00000000 0.0000000017 0.00000000 0.00000000 0.00000000 0.00000000 0.00000000 0.0000000018 13500.0000 0.00000000 0.00000000 13500.0000 0.00000000 0.0000000019 25909.0909 0.00000000 0.00000000 25909.0909 0.00000000 0.0000000020 -61080.8263 0.00000000 0.00000000 -61080.8263 0.00000000 0.0000000021 -25803.4169 0.00000000 0.00000000 -25803.4169 0.00000000 0.0000000022 0.00000000 0.00000000 0.00000000 0.00000000 0.00000000 0.0000000023 -19091.8830 0.00000000 0.00000000 -19091.8830 0.00000000 0.0000000024 -34857.1168 0.00000000 0.00000000 -34857.1168 0.00000000 0.0000000025 -48452.2854 0.00000000 0.00000000 -48452.2854 0.00000000 0.00000000 桁架内力与应力计算在本次计算中直接应用每一杆中的轴力进行应力计算,根据控制应力0.9[σ]进行计算,直接确定各个杆件的最优截面尺寸,避免二次验算,计算结构如表格所示单元尺寸单元尺寸单元尺寸单元尺寸单元尺寸1 34-2.5 6 38-2.5 11 38-2.5 16 30-2 21 30-22 38-3.5 7 38-2.5 12 30-2 17 30-2 22 30-23 38-3.5 8 38-2.5 13 30-2 18 30-2 23 30-24 38-3.5 9 34-2.5 14 30-2 19 30-2 24 30-25 38-2.5 10 38-3.5 15 30-2 20 30-3 25 38-2.5 各个单元计算单元编号杆件轴力杆件应力截面选择截面面积1 48214.29 249.169434-2.5 247.2752 67500 348.837238-3.5 379.1553 67500 348.837238-3.5 380.1554 67500 348.837238-3.5 381.1555 54000 279.069838-2.5 278.6756 30681.82 158.562438-2.5 279.6757 -7500 -38.759738-2.5 280.6758 0.00000004 2.06718E-1038-2.5 281.6759 -48511 -250.703 34-2.5 282.675 10 -67915.4 -350.984 38-3.5 380.155 11 -54332.3 -280.787 38-2.5 278.675 12 -30870.6-159.538 30-2.0 175.84 13 0 0 30-2.0 176.84 14 -7500 -38.7597 30-2.0 177.84 15 17142.86 88.59358 30-2.0 178.84 16 0.0000004 2.06718E-09 30-2 179.84 17 0.000000147.23514E-10 30-2. 180.84 18 13500 69.76744 30-2 181.84 19 25909.09 133.8971 30-2 181.84 20 -61080.8 -315.663 38-3.5 380.155 21 -25803.4 -133.351 30-2.0 181.84 22 -0.00000022-1.137E-09 30-2.0 181.84 23 -19091.9 -98.6661 30-2.0 181.84 24 -34857.1 -180.14 30-2.0 181.84 25-48452.3-250.39938-2.5282.675杆件轴力图1234567891011121314( 1 )( 2 )( 3 )( 4 )( 5 )( 6 )( 7 )( 8 )( 9 )( 10 )( 11 )( 12 )( 13 )( 14 )( 15 )( 16 )( 17 )( 18 )( 19 )( 20 )( 21 )( 22 )( 23 )( 24 )( 25 )48214.2967500.0067500.0067500.0054000.0030681.82-7500.00-48510.99-67915.39-54332.31-30870.63-7500.0017142.8613500.0025909.09-61080.83-25803.42-19091.88-34857.12-48452.29结构变形示意图yx12345678 91011121314 ( 1 )( 2 )( 3 )( 4 )( 5 )( 6 )( 7 ) ( 8 )( 9 )( 10 )( 11 )( 12 )( 13 )( 14 )( 15 )( 16 )( 17 )( 18 )( 19 ) ( 20 )( 21 )( 22 )( 23 )( 24 )( 25 )位移计算以及挠度验算单元挠度验算f MAX<=0.045据此验算各单元的挠度(与下表中的位移进行验算,据此验算得到位移符合要求杆端位移值( 乘子= 1)-----------------------------------------------------------------------------------------------杆端1 杆端2---------------------------------------- ------------------------------------------单元码u -水平位移v -竖直位移-转角u -水平位移v -竖直位移-转角-----------------------------------------------------------------------------------------------1 0.00000000 0.00000000 -0.00794179 0.00179940 -0.01191268 -0.007941792 0.00179940 -0.01191268 -0.00482434 0.00313460 -0.01914918 -0.004824343 0.00313460 -0.01914918 -0.00132530 0.00446981 -0.02113713 -0.001325304 0.00446981 -0.02113713 0.00154073 0.00580502 -0.01882603 0.001540735 0.00580502 -0.01882603 0.00529618 0.00810825 -0.01088176 0.005296186 0.00810825 -0.01088176 0.00725451 0.00941690 0.00000000 0.007254517 0.00941690 0.00000000 0.00470440 0.00000811 -0.00042652 0.004704408 0.00688396 -0.01134398 -0.00742048 0.00564722 -0.00021326 -0.007420489 0.00688396 -0.01134398 -0.00509448 0.00626168 -0.01914918 -0.0050944810 0.00626168 -0.01914918 -0.00122578 0.00512255 -0.02113713 -0.0012257811 0.00512255 -0.02113713 0.00207557 0.00331437 -0.01818625 0.0020755712 0.00331437 -0.01818625 0.00586763 0.00101973 -0.00953110 0.0058676313 0.00101973 -0.00953110 0.00606972 0.00000811 -0.00042652 0.0060697214 0.00000000 0.00000000 -0.00564722 0.00564722 -0.00021326 -0.0056472215 0.00179940 -0.01191268 -0.00435820 0.00688396 -0.01134398 -0.0043582016 0.00313460 -0.01914918 -0.00234530 0.00626168 -0.01914918 -0.0023453017 0.00446981 -0.02113713 -0.00043516 0.00512255 -0.02113713 -0.0004351618 0.00580502 -0.01882603 0.00149439 0.00331437 -0.01818625 0.0014943919 0.00810825 -0.01088176 0.00386647 0.00101973 -0.00953110 0.0038664720 0.00688396 -0.01134398 -0.00693617 0.00000000 0.00000000 -0.0069361721 0.00626168 -0.01914918 -0.00417214 0.00179940 -0.01191268 -0.0041721422 0.00512255 -0.02113713 -0.00132530 0.00313460 -0.01914918 -0.0013253023 0.00512255 -0.02113713 0.00099785 0.00580502 -0.01882603 0.0009978524 0.00331437 -0.01818625 0.00376837 0.00810825 -0.01088176 0.0037683725 0.00101973 -0.00953110 0.00529155 0.00941690 0.00000000 0.00529155 13.绘制材料表材料表构件类型杆件号截面(mm) 长度(mm) 数量重量(KG)每个共计m³合计上弦杆38-2.5281.6751509 3 0.001275 34-2.5282.6751509 1 0.00042738-3.5380.1551509 2 0.00114738-2.5278.675030-2.0176.84030-2.0177.840下弦杆34-2.5247.2751500 1 0.000371 38-3.5379.1551500 3 0.00170638-3.5380.1551500 038-3.5381.1551500 038-2.5278.6751500 2 0.00083638-2.5278.6751500 0直腹杆38-2.5280.6751000 1 0.000281 30-2.0177.841167 6 0.00124530-2.0178.841333 1 0.00023830-2179.841500 1 0.0002730-2.180.841667 1 0.00030130-2181.841833 1 0.00033330-2181.842000 1 0.000364斜腹杆38-3.5380.1551803 1 0.00068530-2.0181.842005 1 0.00036530-2.0181.842121 1 0.00038630-2.0181.842245 1 0.00038630-2.0181.842368 1 0.00040838-2.5282.6752500 1 0.0004310.011776 G=78.5*0.011776=0.92446KN=924.46N=92.446KG实验总结:通过本次试验,对于结构力学求解器有了更好的理解和运用,尤其是对于结构力学求解器进行桁架结构设计有了更加深刻的应用,同时也发现自己在试验中也存在一定的不足和经验的缺乏,比如方程式的应用,函数的应用等等,这些问题都需要自己以后去解决。

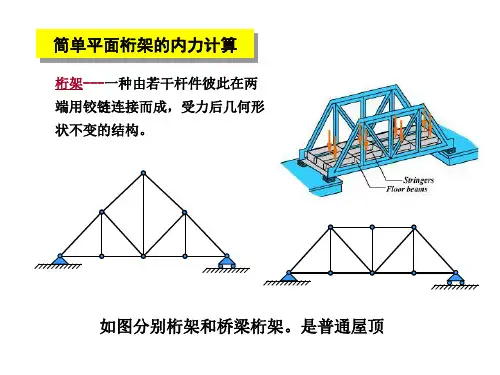

第二节平面静定桁架的内力计算桁架是工程中常见的一种杆系结构,它是由若干直杆在其两端用铰链连接而成的几何形状不变的结构。

桁架中各杆件的连接处称为节点。

由于桁架结构受力合理,使用材料比较经济,因而在工程实际中被广泛采用。

房屋的屋架(见图3-10)、桥梁的拱架、高压输电塔、电视塔、修建高层建筑用的塔吊等便是例子。

图3-10房屋屋架杆件轴线都在同一平面内的桁架称为平面桁架(如一些屋架、桥梁桁架等),否则称为空间桁架(如输电铁塔、电视发射塔等)。

本节只讨论平面桁架的基本概念和初步计算,有关桁架的详细理论可参考“结构力学”课本。

在平面桁架计算中,通常引用如下假定:1)组成桁架的各杆均为直杆;2)所有外力(载荷和支座反力)都作用在桁架所处的平面内,且都作用于节点处;3)组成桁架的各杆件彼此都用光滑铰链连接,杆件自重不计,桁架的每根杆件都是二力杆。

满足上述假定的桁架称为理想桁架,实际的桁架与上述假定是有差别的,如钢桁架结构的节点为铆接(见图3-11)或焊接,钢筋混凝土桁架结构的节点是有一定刚性的整体节点,图3-11 钢桁架结构的节点它们都有一定的弹性变形,杆件的中心线也不可能是绝对直的,但上述三点假定已反映了实际桁架的主要受力特征,其计算结果可满足工程实际的需要。

分析静定平面桁架内力的基本方法有节点法和截面法,下面分别予以介绍。

一、节点法因为桁架中各杆都是二力杆,所以每个节点都受到平面汇交力系的作用,为计算各杆内力,可以逐个地取节点为研究对象,分别列出平衡方程,即可由已知力求出全部杆件的内力,这就是节点法。

由于平面汇交力系只能列出两个独立平衡方程,所以应用节点法往往从只含两个未知力的节点开始计算。

例3-8 平面桁架的受力及尺寸如图3-12a所示,试求桁架各杆的内力。

图3-12 例3-8图解:(1)求桁架的支座反力以整体桁架为研究对象,桁架受主动力2F 以及约束反力YA F 、xB F 、YB F 作用,列平衡方程并求解:1=∑=ni ixF,xB F =0)(1=∑=ni i BmF , 2F ×2l-Y A F l =0, Y A F=F1=∑=ni iyF,YA F +YB F -2F =0,YB F =2F -YA F =F(2)求各杆件的内力设各杆均承受拉力,若计算结果为负,表示杆实际受压力。

结构力学课程设计桁架一、教学目标本节课的学习目标主要包括知识目标、技能目标和情感态度价值观目标。

知识目标要求学生掌握桁架结构的基本概念、类型和受力分析方法;技能目标要求学生能够运用结构力学原理分析和解决桁架结构问题;情感态度价值观目标培养学生的创新意识和团队合作精神。

通过本节课的学习,学生应该能够:1.描述桁架结构的基本概念和特点;2.分析不同类型的桁架结构及其受力特点;3.运用结构力学原理进行桁架结构的受力分析;4.提出桁架结构优化的方法和建议;5.培养创新意识和团队合作精神。

二、教学内容本节课的教学内容主要包括桁架结构的基本概念、类型和受力分析方法。

具体安排如下:1.桁架结构的基本概念:介绍桁架结构的定义、特点和应用领域;2.桁架结构的类型:分析不同类型的桁架结构(如三角形桁架、四边形桁架等)及其受力特点;3.桁架结构的受力分析方法:讲解运用结构力学原理进行桁架结构的受力分析方法,包括节点法、截面法等;4.桁架结构优化:介绍桁架结构优化的方法和建议,如重量减轻、刚度增加等。

三、教学方法为了激发学生的学习兴趣和主动性,本节课将采用多种教学方法,如讲授法、讨论法、案例分析法和实验法等。

具体应用如下:1.讲授法:用于讲解桁架结构的基本概念、类型和受力分析方法;2.讨论法:学生讨论不同类型的桁架结构及其优缺点,促进学生思考;3.案例分析法:分析实际工程中的桁架结构案例,让学生学会将理论知识应用于实际问题;4.实验法:安排实验环节,让学生亲自操作和观察桁架结构的受力现象,增强实践能力。

四、教学资源为了支持教学内容和教学方法的实施,丰富学生的学习体验,我们将选择和准备以下教学资源:1.教材:选用权威、实用的桁架结构力学教材,为学生提供系统理论知识;2.参考书:推荐学生阅读相关参考书籍,拓展知识面;3.多媒体资料:制作精美的PPT、动画和视频,直观展示桁架结构的受力现象;4.实验设备:准备桁架结构实验装置,让学生亲身体验和观察受力现象;5.网络资源:引导学生利用网络资源,了解桁架结构在工程中的应用案例。

平面桁架程序:#include "stdio.h"#include "math.h"#define unitmax 30#define pointmax 30#define matermax 10#define Pmaxnum 20#define bindmax 20main(){int unit[unitmax][4],bind[bindmax][3],number[5];float point[pointmax][2],material[matermax][2],P[Pmaxnum][3];float allarray[pointmax*2][pointmax*2];void readdata(int unit[unitmax][4],float point[pointmax][2],int number[5],int bind[bindmax][3],float material[matermax][2],float P[Pmaxnum][3]);void all(float point[pointmax][2],int unit[unitmax][4],float material[matermax][2], int number[5],float allarray[][pointmax*2]);void equa(float allarray[][pointmax*2],float P[Pmaxnum][3],int bind[][3],int number[]);void result(int unit[unitmax][4],float point[pointmax][2],int number[5],float material[matermax][2],float allarray[][pointmax*2]);readdata(unit,point,number,bind,material,P);all(point,unit,material,number,allarray);equa(allarray,P,bind,number);result(unit,point,number,material,allarray);}/******************************************************************/ void readdata(int unit[unitmax][4],float point[pointmax][2],int number[5],int bind[bindmax][3],float material[matermax][2],float P[Pmaxnum][3]){FILE *fp;int pointnum,unitnum,maternum,Pnum,bindnum,no_use,i,j,k,n,m;if((fp=fopen("data.txt","r"))==NULL){printf("data file can't be opened,please create it");exit(0);return;}for(i=0;i<=4;i++)if(fscanf(fp,"%d",&number[i])==EOF){printf("file error");fclose(fp);}pointnum=number[0];unitnum=number[1] ;maternum=number[2];Pnum=number[3];bindnum=number[4];for(i=0;i<pointnum;i++)fscanf(fp,"%d %f %f",&k,&point[i][0],&point[i][1]);for(i=0;i<unitnum;i++)if(fscanf(fp,"%d %d %d %d\n",&unit[i][0],&unit[i][1],&unit[i][2],&unit[i][3])==EOF) {printf("file error\n");fclose(fp);}for(i=0;i<maternum;i++)if(fscanf(fp,"%d %g %g\n",&k,&material[i][0],&material[i][1])==EOF){printf("file error\n");fclose(fp);}for(i=0;i<Pnum;i++)fscanf(fp,"%d %f %f %f\n",&k,&P[i][0],&P[i][1],&P[i][2]);for(i=0;i<bindnum;i++)if(fscanf(fp,"%d %d %d %d\n",&k,&bind[i][0],&bind[i][1],&bind[i][2])==EOF){printf("file error\n");fclose(fp);}fclose(fp);return;}/*OOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOOO OOOOOOOOOOOOOOOOOOOPPPPPPPPPPPPPPPPP*/void all(float point[pointmax][2],int unit[unitmax][4],float material[matermax][2],int number[5],float allarray[][pointmax*2]){float unitarray[2][2][4],allar[pointmax*2][pointmax*2]; int i,j,ii[2],r,s,v,w,kk;float xi,xj,yi,yj,E,A,L,EAL,SRF,CRF,SS,CC,CS;FILE *wp;wp=fopen("out.txt","w");for(v=0;v<2*number[0];v++)for(w=0;w<2*number[0];w++)allarray[v][w]=0.0;kk=0;for(kk=0;kk<number[1];kk++){i=unit[kk][1];j=unit[kk][2];ii[0]=i;ii[1]=j;xi=point[i-1][0];yi=point[i-1][1];xj=point[j-1][0];yj=point[j-1][1];L=sqrt((xj-xi)*(xj-xi)+(yj-yi)*(yj-yi));E=material[unit[kk][3]-1][0];A=material[unit[kk][3]-1][1];EAL=E*A/L ;SRF=(yj-yi)/L;CRF=(xj-xi)/L;SS=SRF*SRF;CC=CRF*CRF;CS=SRF*CRF;for(r=0;r<=1;r++)for(s=0;s<=1;s++){{if(r==s){unitarray[r][s][0]=EAL*CC;unitarray[r][s][1]=EAL*CS;unitarray[r][s][2]=EAL*CS;unitarray[r][s][3]=EAL*SS;}else{unitarray[r][s][0]=-EAL*CC;unitarray[r][s][1]=-EAL*CS;unitarray[r][s][2]=-EAL*CS;unitarray[r][s][3]=-EAL*SS;}}}for(v=0;v<=1;v++)for(w=0;w<=1;w++){allarray[2*ii[v]-2][2*ii[w]-2]+=unitarray[v][w][0]; allarray[2*ii[v]-2][2*ii[w]-1]+=unitarray[v][w][1];allarray[2*ii[v]-1][2*ii[w]-2]+=unitarray[v][w][2];allarray[2*ii[v]-1][2*ii[w]-1]+= unitarray[v][w][3];}for(v=0;v<number[0]*2;v++)for(w=0;w<number[0]*2;w++)allar[v][w]=0;for(v=0;v<=1;v++)for(w=0;w<=1;w++){allar[2*ii[v]-2][2*ii[w]-2]+=unitarray[v][w][0];allar[2*ii[v]-2][2*ii[w]-1]+=unitarray[v][w][1];allar[2*ii[v]-1][2*ii[w]-2]+=unitarray[v][w][2];allar[2*ii[v]-1][2*ii[w]-1]+= unitarray[v][w][3];}}fclose(wp);return;}/***********************************************************************/void equa(float allarray[][pointmax*2],float P[Pmaxnum][3],int bind[][3],int number[]) {int i,j,k,n,m;float op;FILE *wp;wp=fopen("out.txt","w");for(i=0;i<number[4];i++){ if(bind[i][1]==0){for(j=0;j<2*number[0];j++){allarray[2*bind[i][0]-2][j]=0.0;allarray[j][2*bind[i][0]-2]=0.0;}allarray[2*bind[i][0]-2][2*bind[i][0]-2]=1.0;}if(bind[i][2]==0){ for(j=0;j<2*number[0];j++){allarray[2*bind[i][0]-1][j]=0.0;allarray[j][2*bind[i][0]-1]=0.0;}allarray[2*bind[i][0]-1][2*bind[i][0]-1]=1.0;}}for(i=0;i<2*number[0];i++)allarray[i][2*number[0]]=0.0;for(i=0;i<number[3];i++){allarray[2*(int)P[i][0]-2][2*number[0]]=P[i][1];allarray[2*(int)P[i][0]-1][2*number[0]]=P[i][2];}n=2*number[0];for(k=0;k<n;k++){ op=allarray[k][k];for(m=k;m<=n;m++)allarray[k][m]=allarray[k][m]/op;for(i=k+1;i<n;i++){op=allarray[i][k];for(m=k;m<=n;m++)allarray[i][m]=allarray[i][m]-allarray[k][m]*op;}}for(k=n-1;k>=0;k--){for(i=k-1;i>=0;i--){op=allarray[i][k];for(m=n;m>=0;m--)allarray[i][m]=allarray[i][m]-allarray[k][m]*op;}}return;}/*_____________________________________________________________________________ ___*/void result(int unit[unitmax][4],float point[pointmax][2],int number[5],float material[matermax][2],float allarray[][pointmax*2]){int i,j,k,kk,ii;float disXi,disXj,disYi,disYj,xi,xj,yi,yj,EAL,E,A,L,SRF,CRF,N;FILE *wp;if((wp=fopen("out.txt","a"))==NULL){printf("data file can't be opened,please create it");exit(0);return;}printf("\n");for(kk=0;kk<number[1];kk++){i=unit[kk][1];j=unit[kk][2];xi=point[i-1][0];yi=point[i-1][1];xj=point[j-1][0];yj=point[j-1][1];L=sqrt((xj-xi)*(xj-xi)+(yj-yi)*(yj-yi));E=material[unit[kk][3]-1][0];A=material[unit[kk][3]-1][1];EAL=E*A/L ;SRF=(yj-yi)/L;CRF=(xj-xi)/L;disXi=allarray[2*i-2][2*number[0]];disYi=allarray[2*i-1][2*number[0]];disXj=allarray[2*j-2][2*number[0]];disYj=allarray[2*j-1][2*number[0]];printf("the unit=%d i=%d j=%d\n",unit[kk][0],i,j);printf("disXi=%f disYi=%f disXj=%f disYj=%f \n",disXi,disYi,disXj,disYj);N=-EAL*(CRF*(disXi-disXj)+SRF*(disYi-disYj));printf("the inner force=%f\n",N);fprintf(wp,"the unit=%d i=%d j=%d\n",unit[kk][0],i,j);fprintf(wp,"disXi=%f disYi=%f disXj=%f disYj=%f \n",disXi,disYi,disXj,disYj); fprintf(wp,"the inner force=%f\n",N);}return;}数据:10 17 1 1 21 0.0 0.02 0.0 1.03 1.0 1.04 1.0 0.05 2.0 1.06 2.0 0.07 3.0 1.08 3.0 0.09 4.0 1.010 4.0 0.01 12 12 23 13 1 3 14 1 4 15 3 4 16 3 5 17 3 6 18 4 6 19 5 6 110 5 7 111 6 7 112 6 8 113 7 8 114 7 9 115 7 10 116 8 10 117 9 10 11 2.1e9 0.0025 1 3 0 -501 1 0 02 10 1 0。