PCB专业英语培训教材(2)

- 格式:ppt

- 大小:1.30 MB

- 文档页数:35

pcb生产流程培训英文版Here is the English essay on the topic of "PCB production process training" with a word count of over 1000 words:The production of printed circuit boards (PCBs) is a crucial process in the electronics industry, as these components serve as the backbone for a wide range of electronic devices, from smartphones to industrial equipment. Ensuring the proper training and understanding of the PCB production process is essential for maintaining high standards of quality and efficiency. In this essay, we will delve into the various stages of the PCB production process, providing a comprehensive overview for trainees and professionals alike.The first step in the PCB production process is the design phase. This involves the creation of a digital schematic or layout, which outlines the placement and interconnections of the various components that will be mounted on the board. The design phase requires a thorough understanding of electrical engineering principles, as well as the specific requirements and constraints of the intended application. Designers must consider factors such as component size, heat dissipation, and signal routing to ensure the PCB will function asintended.Once the design is complete, the next step is the fabrication of the PCB itself. This process begins with the creation of the base material, which is typically a thin, rigid substrate made of fiberglass or other insulating materials. The substrate is then coated with a thin layer of copper, which will serve as the conductive pathways for the electronic components. The copper layer is then etched away, leaving behind the desired circuit patterns.After the basic PCB structure has been created, the next step is the drilling process. This involves the use of specialized machinery to create the necessary holes and vias that will allow the components to be mounted and interconnected. The drilling process must be carried out with a high degree of precision, as the placement and size of these holes can have a significant impact on the overall performance and reliability of the PCB.Following the drilling process, the PCB undergoes a series of cleaning and preparation steps to ensure that the surface is ready for the next stage of production. This may include the application of a solder mask, which is a protective coating that helps to prevent short circuits and corrosion, as well as the application of a surface finish, such as gold or tin, to improve the solderability of the board.Once the PCB has been prepared, the next step is the component placement and soldering process. This involves the use of specialized equipment, such as pick-and-place machines, to accurately position the various electronic components on the board. The components are then secured in place using a process called soldering, which involves the melting of a metal alloy to create a strong, conductive bond between the component and the PCB.After the component placement and soldering process, the PCB undergoes a series of quality control checks to ensure that it meets the required standards for performance and reliability. This may include visual inspections, electrical testing, and even more advanced techniques such as automated optical inspection (AOI) and X-ray analysis.Finally, the completed PCB is packaged and prepared for shipment to the end customer. This may involve the addition of protective coatings, the installation of connectors or other hardware, and the labeling and documentation of the PCB.Throughout the entire PCB production process, it is essential that workers and trainees receive comprehensive training on the various techniques and equipment involved. This training should cover not only the practical aspects of the production process, but also the underlying principles and best practices that guide the industry. Byensuring that all personnel involved in the PCB production process are well-trained and knowledgeable, companies can ensure that their products meet the highest standards of quality and reliability.In conclusion, the PCB production process is a complex and multifaceted endeavor that requires a deep understanding of electrical engineering, materials science, and manufacturing techniques. By providing comprehensive training to all personnel involved in the process, companies can ensure that their PCBs are produced to the highest possible standards, helping to drive innovation and advancement in the electronics industry.。

Expedition PCB基础培训教程Copyright(c) Mentor Graphics Corporation 2010All rights reserved本文档记录的信息属于Mentor Graphics公司所有,未经Mentor Graphics公司书面许可,严禁以任何方式复制其中的任何章节或全文内容。

本文档接收者,应当尽力避免对文档信息采取未经授权的使用行为。

目 录第一章 库的使用 (9)第二章 焊盘的创建 (13)第三章 创建Cell (20)第四章 创建Symbol (34)第五章 创建Part (46)第六章 创建Template (56)第七章 DxDesigner的使用 (61)第八章 PCB Editor的使用 (80)第九章 PCB设计设定 (98)第十章 创建Board Geometries (108)第十一章 布局 (117)第十二章 Layout 设定 (127)第十三章 布线 (143)第十四章 测试点 (156)第十五章 生成Plane (160)第十六章 设计检查 (170)第十七章 生成丝印 (177)第十八章 生成Gerber和Drill (185)第十九章 尺寸标注与文件编制设计 (193)关于本书本书是Expedition PCB Introduction的培训教程,书中介绍了熟练使用Mentor Graphics Expedition PCB工具进行印刷电路板的设计需要掌握的相关概念。

读者该培训课程,主要面向使用Mentor Graphics Expedition PCB工具来设计和编辑印刷电路板,并具有以下预备知识的设计师和工程师。

课程特点z本课程关注Expedition PCB在设计流程中的使用,而不是对Expedition PCB的所有功能进行详尽介绍;z阐述印刷电路板技术及其设计方法,也不是本课程的重点。

预备知识●用户应该掌握基本的PCB布局布线设计思想。

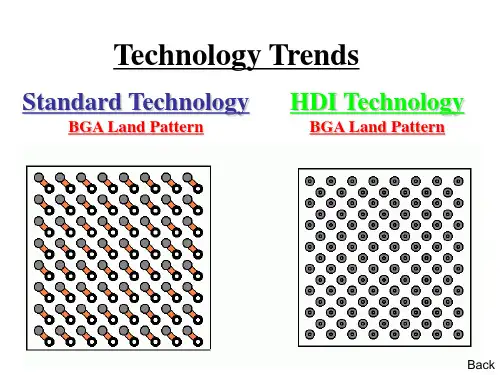

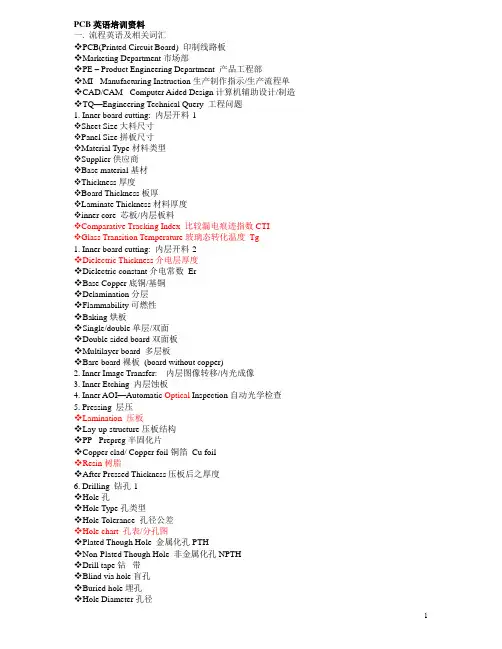

PCB英语培训资料一. 流程英语及相关词汇❖PCB(Printed Circuit Board) 印制线路板❖Marketing Department市场部❖PE – Product Engineering Department 产品工程部❖MI - Manufacturing Instruction生产制作指示/生产流程单❖CAD/CAM - Computer Aided Design计算机辅助设计/制造❖TQ—Engineering Technical Query 工程问题1. Inner board cutting: 内层开料-1❖Sheet Size大料尺寸❖Panel Size拼板尺寸❖Material Type材料类型❖Supplier供应商❖Base material基材❖Thickness厚度❖Board Thickness板厚❖Laminate Thickness材料厚度❖inner core 芯板/内层板料❖Comparative Tracking Index 比较漏电痕迹指数CTI❖Glass Transition Temperature玻璃态转化温度Tg1. Inner board cutting: 内层开料-2❖Dielectric Thickness介电层厚度❖Dielectric constant介电常数Er❖Base Copper底铜/基铜❖Delamination分层❖Flammability可燃性❖Baking烘板❖Single/double单层/双面❖Double sided board双面板❖Multilayer board 多层板❖Bare board裸板(board without copper)2. Inner Image Transfer:内层图像转移/内光成像3. Inner Etching 内层蚀板4. Inner AOI—Automatic Optical Inspection自动光学检查5. Pressing 层压❖Lamination 压板❖Lay-up structure压板结构❖PP - Prepreg半固化片❖Copper clad/ Copper foil铜箔Cu foil❖Resin树脂❖After Pressed Thickness压板后之厚度6. Drilling 钻孔-1❖Hole孔❖Hole Type孔类型❖Hole Tolerance 孔径公差❖Hole chart 孔表/分孔图❖Plated Though Hole 金属化孔PTH❖Non-Plated Though Hole 非金属化孔NPTH❖Drill tape钻带❖Blind via hole盲孔❖Buried hole埋孔❖Hole Diameter孔径6. Drilling 钻孔-2❖Hole location孔位❖Hole Position Tolerance孔位误差❖Hole Position Deviation孔位置偏差❖2nd Drilling 重钻❖Mounting hole安装孔❖Pin hole销定孔❖Target Hole目标孔❖Slot 槽,坑❖No. of holes孔数❖Laser via hole激光穿孔❖Roughness粗糙度7. Plate Through Hole (PTH)沉铜/孔化❖Hole wall copper thick 孔壁铜厚❖Defect缺陷❖Cracking裂缝8. Outer Dry Film 外层干菲林/外光成像-1❖Dry Film干菲林/干膜D/F❖External layer外层❖Internal layer内层❖Component Side 零件面C/S❖Solder Side焊接面S/S❖Top side/ layer 顶层❖Bottom side/layer底层❖Primary side首面❖Secondary side第二面❖(提示: 层的写法尽量按客户的习惯书写)8. Outer Dry Film 外光成像-2❖Power plane电源层❖Ground 接地层❖Layer层❖Dry-film tenting D/F封孔❖Surface mounting Device表面粘贴装置SMD❖Line Width线宽—LW❖Line Space线隙—LS: Line-Line/Line-Pad/Pad-Pad❖Conductor导体❖Circuit线路❖Pattern线路❖Artwork菲林❖Master drawing菲林图形❖Artwork Modification菲林修改❖Outer Dry Film外光成像-3❖Annular ring锡圈❖Min.Annular Ring最小环宽/焊盘宽❖Hole breakout 破环/崩孔❖Pad焊盘❖Round pad圆盘❖Teardrop泪珠❖Clearance/space间距/间隙❖Minimum 最小---Min.❖Maximum 最大---Max.❖Min.Spacing between Line to Line线与线间的最小距离❖Test coupon图样❖Registration Deviation 对位偏差9. Pattern Plating 线路电镀/图形电镀❖Plating电镀❖Chemical corrosion化学腐蚀❖Copper plating电镀铜❖Copper thickness on hole wall 孔内铜厚❖Max.Board Thickness After Plating电镀后总板厚度之上限10. Outer Etching 外蚀板❖Undercut侧蚀11. Solder Resist 湿绿油/阻焊-1❖S/M(Solder Mask) 阻焊❖Solder resist film阻焊菲林❖SM print SM印油菲林❖SM imaging SM曝光菲林❖Solder Mask opening 阻焊开窗/曝光窗❖Solder Mask material/Type 绿油材料/类型❖Color颜色❖Shiny有光泽的,发光的(光亮油,)❖Matte哑光油的❖Matte Green 哑光绿油❖Liquid Photo-Imaginable (LPI)液态光固化剂11. Solder Mask 湿绿油/阻焊-2❖W/F(Wet Film) 湿膜/湿绿油❖Ball Grid Array (BGA) 球栅阵列❖S/M Bridge 绿油桥❖Cover 盖(油入孔)❖Tenting封孔/盖油❖Via Plugging 封孔❖Plug Hole塞孔❖Filled with solder resist 塞孔❖Solder mask on bare copper (SMOBC) 裸铜覆盖阻焊膜❖Encroach 侵占, 蚕食❖Encroach into holes 入孔12. Carbon Ink 印碳油❖Carbon ink碳油❖Carbon Resistance 碳油电阻13. Component Mark 印字符❖Silk Screen丝印❖Component Marking 元件字符C/M❖Legend字符❖Corner mark板角记号❖Logo标记❖Date Code周期代号❖Cust. P/N: customer part number客户型号❖Revision/Version:版本号14. Gold Finger Plating 金手指❖Bevelling斜边❖Gold Finger(G/F) 金手指❖Chamfer倒角❖Key slot槽孔❖Au/Ni 金/镍15. Hot Air Leveling 喷锡❖HAL(Hot Air Leveling) 热风整平❖HASL Hot Air Solder Leveling❖Impedance阻抗IMP❖Surface Treatment表面处理16. Immersion Silver 沉银17. OSP抗氧化处理18. Immersion Tin 沉锡19. Immersion Gold/Imm Au 沉金20. Solder/Tin/Lead Stripping 退锡❖ENIG----Electroless Nickel/Immersion Gold 沉金(工艺) ❖Ag银21. V-Cutting V-坑❖V-Cut V - 坑❖Remain Thickness 保留厚度❖Scoring==V-CUT刻槽❖Scratch划痕❖V-groove V- 坑22. Routing (铣/锣板)/ Punching 啤板❖Profiling外围成型❖Engineering drawing工程图纸❖Fiducial mark基准点❖Dimension尺寸❖Length 长度❖Width 宽度❖Breakaway tab/area板边位❖Datum hole基准参考孔❖Punching die /Punch 啤模❖Offset偏移量❖Outline外形❖Shape 外形23. Electrical Testing 电测试❖E-test fixture E-T 夹具❖Electrical Test Fixture电测试夹具❖V oltage电压❖Open/short开路/短路❖Probe point测试点24. Outer Final QC 最后检查❖Warpage翘曲度❖Bow and twist 板弯曲25. Peelable Mask 印蓝胶❖Peelable Mask/Blue Mask蓝胶❖Peelable可剥性26. Packing&Shipment 包装出货❖Vacunm Pack真空包装❖No.of Pcs Per Bag每包数量❖Packing包装27. Other其它相关-1❖Gerber Data 客户资料打包文件❖Checklist检查表❖production film 生产菲林❖Paste film粘贴/贴键菲林/钢网❖Solder coating上锡❖Reliability可靠性❖Assembly安装性❖Correspondance符合性❖Pin gauge 针规❖Backplane背板❖Customer客户27. Other其它相关-2❖Customer P/N客户产品编号❖Delivery交货❖Description说明❖Golden board金板❖Missing 缺少❖Mother board 主机板❖Ionic cleanliness离子清洁度/离子污染度❖Location位置❖Max. X-out坏板上限/最大允许报废板数❖No.of Array/Panel每个拼板套板数❖Negative反面的❖Positive正的27. Other其它相关-3❖Production生产板❖Sample样板❖Remark备注❖Special requirement特殊要求❖Specification详细说明,制作规范❖Wiring线路❖Square方形的❖View From…观察方向由…❖Lead free process 无铅处理❖Dummy Pad 为圆形或方形的PAD(加在板边位/标位或空白处起平衡电镀作用)❖Dummy copper实心的铜皮❖Thermal Pad 散热盘❖Fibre纤维面二. 问题之基本模式❖Title: Engineering technical question of 021D2002R2 (JOVE P/N: 20LN21119)==On Hold/Go on with suggestion❖Hello Ye jian,❖Nice to contact with you! I'm Jack, an Engineer from Engineering department in Jove.❖For the captioned project, we found some questions need you to confirm with customer.❖Question 1: As there are PTH (plated-hole) between the edge of unit, after doing V-cut, the holes will be scratched, and after customer divide them into two parts along the v-cut line, the copper showing in A part on the hole wall and that on the board may be picked off, which will lead to solder failure. Please refer to fig01❖Suggestion: a)To avoid this potential fault, we will modify the cad data: to add two PTH holes as position B to insure the connection between top and bottom sides. And to add two NPTH holes as position C (use 2nd drill) at the end-point of V-cut line which closed to that big PTH hole to cut the copper off so as to avoid copper being picked off. Please kindly confirm this modification can be acceptable.❖b) Or we will do sample board to let our customer to approve. Please have one, a) or b)? ❖Question 2: Same case as question 1 except that the PTH holes is only on one edge of unit. Please refer to fig02❖Suggestion: a) We will do them NPTH holes and will shave the copper around holes to get about 8 mil clearance.❖ b) We only add two NPTH holes (use 2nd drill) at the end-point of V-cut line whichclosed to that big PTH hole to avoid that potential fault. Please kindly confirm these modification can be acceptable.❖❖Have a nice day!❖B.Regards❖Ding, you de**********************❖Engineering technical question of 021D2002R2 (JOVE P/N: 20LN21119)==On Hold/Go on with suggestion❖Dear John(名字)❖Hello Mr Smith(姓)❖Hi Miss Green❖Nice day John❖Good Morning Jack❖Nice to contact with you! / I’m glad to cooperate with you!❖I'm Jack, an Engineer from Engineering department in Jove.❖1) After checking the captioned new project/updated gerber data, we have some questions as below. Would you please help to settle them. 在检查完此新板后,我们有如下问题。

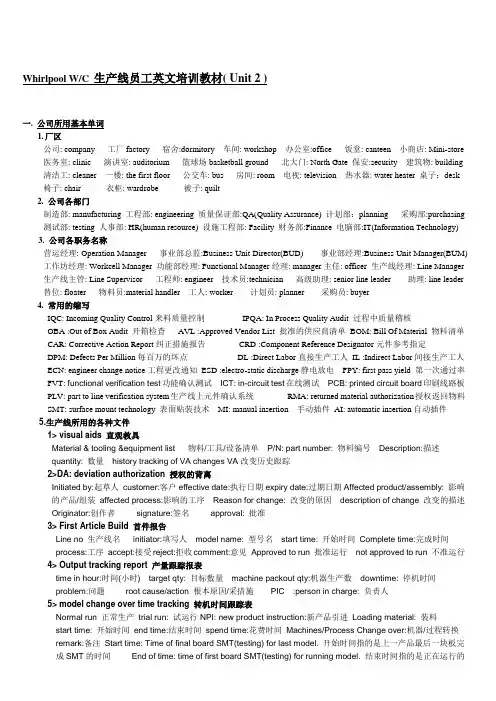

Whirlpool W/C 生产线员工英文培训教材( Unit 2 )一. 公司所用基本单词1.厂区公司: company 工厂factory 宿舍:dormitory 车间: workshop 办公室:office 饭堂: canteen 小商店: Mini-store 医务室: clinic 演讲室: auditorium 篮球场basketball ground 北大门: North Gate 保安:security 建筑物: building 清洁工: cleaner 一楼: the first floor 公交车: bus 房间: room 电视: television 热水器: water heater 桌子:desk 椅子: chair 衣柜: wardrobe 被子: quilt2. 公司各部门制造部: manufacturing 工程部: engineering 质量保证部:QA(Quality Assurance) 计划部:planning 采购部:purchasing 测试部: testing 人事部: HR(human resource) 设施工程部: Facility 财务部:Finance 电脑部:IT(Information Technology)3. 公司各职务名称营运经理: Operation Manager 事业部总监:Business Unit Director(BUD) 事业部经理:Business Unit Manager(BUM) 工作坊经理: Workcell Manager 功能部经理: Functional Manager经理: manager主任: officer 生产线经理: Line Manager 生产线主管: Line Supervisor 工程师: engineer 技术员:technician 高级助理: senior line leader 助理: line leader 替位: floater 物料员:material handler 工人: worker 计划员: planner 采购员: buyer4. 常用的缩写IQC: Incoming Quality Control来料质量控制IPQA: In Process Quality Audit 过程中质量稽核OBA :Out of Box Audit 开箱检查AVL :Approved Vendor List 批准的供应商清单BOM: Bill Of Material 物料清单CAR: Corrective Action Report纠正措施报告CRD :Component Reference Designator元件参考指定DPM: Defects Per Million每百万的坏点DL :Direct Labor直接生产工人IL :Indirect Labor间接生产工人ECN: engineer change notice工程更改通知ESD :electro-static discharge静电放电FPY: first pass yield 第一次通过率FVT: functional verification test功能确认测试ICT: in-circuit test在线测试PCB: printed circuit board印刷线路板PLV: part to line verification system生产线上元件确认系统RMA: returned material authorization授权返回物料SMT: surface mount technology 表面贴装技术MI: manual insertion 手动插件AI: automatic insertion自动插件5.生产线所用的各种文件1> visual aids 直观教具Material & tooling &equipment list 物料/工具/设备清单P/N: part number: 物料编号Description:描述quantity: 数量history tracking of VA changes VA改变历史跟踪2>DA: deviation authorization 授权的背离Initiated by:起草人customer:客户effective date:执行日期expiry date:过期日期Affected product/assembly: 影响的产品/组装affected process:影响的工序Reason for change: 改变的原因description of change 改变的描述Originator:创作者signature:签名approval: 批准3> First Article Build 首件报告Line no 生产线名initiator:填写人model name: 型号名start time: 开始时间Complete time:完成时间process:工序accept:接受reject:拒收comment:意见Approved to run 批准运行not approved to run 不准运行4> Output tracking report 产量跟踪报表time in hour:时间(小时) target qty: 目标数量machine packout qty:机器生产数downtime: 停机时间problem:问题root cause/action 根本原因/采措施PIC :person in charge: 负责人5> model change over time tracking 转机时间跟踪表Normal run 正常生产trial run: 试运行NPI: new product instruction:新产品引进Loading material: 装料start time: 开始时间end time:结束时间spend time:花费时间Machines/Process Change over:机器/过程转换remark:备注Start time: Time of final board SMT(testing) for last model. 开始时间指的是上一产品最后一块板完成SMT的时间End of time: time of first board SMT(testing) for running model. 结束时间指的是正在运行的产品第一块板完成SMT的时间Model change over time:(max of processes’ change over time) 转拉时间指的是在转拉过程中最长工序所花费的时间二.口语训练Nice to Meet You很高兴认识你听下列对话,练习自读跟读。

pcb生产流程培训英文版**Introduction**PCB, short for Printed Circuit Board, is the foundation of any electronic device. It's where all the components are connected and make the device function. Understanding the PCB production process is crucial for engineers, designers, and anyone involved in the electronics industry. In this comprehensive PCB production process training, we'll delve into each step, from concept to completion.**1. PCB Design**The first step is PCB design, which involves converting the electrical schematic into a physical layout. This is done using PCB design software, where components are placed and connected using tracks or wires. The designer needs to consider factors like component size, spacing, and heat dissipation during this stage.**2. Gerber File Generation**Once the design is complete, it's converted into a Gerber file. This is a standard file format used in PCB manufacturing, which contains all the necessary informationabout the board's layers, tracks, and components. TheGerber file is sent to the PCB fabricator for manufacturing. **3. PCB Fabrication**Fabrication involves cutting the PCB board from alarger sheet of copper-clad laminate. This is done using a machine called a router, which follows the patterns in the Gerber file. After cutting, the board goes through various processes like drilling, etching, and plating to create the necessary circuits and connections.**4. Component Placement**The next step is component placement, where the electronic components are soldered onto the PCB. This is done either manually or using automated machines, depending on the complexity and scale of production. Components like resistors, capacitors, and ICs are carefully placed on the board according to the design.**5. soldering and Testing**After component placement, the board goes through a soldering process to ensure secure connections. This is followed by rigorous testing to ensure the board functionsas designed. Tests include visual inspection, continuity checks, and functional testing.**6. Assembly and Final Testing**Once the PCB passes the initial tests, it's assembled with other components and subsystems to form the final product. The assembled product then goes through final testing to ensure it meets all specifications and is ready for market.**Conclusion**The PCB production process is a complex yet fascinating field. It involves multiple stages, each requiring precision and attention to detail. This training has provided a comprehensive overview of the PCB production process, from design to final testing. With this knowledge, you'll be well-equipped to handle any PCB-related task confidently.**PCB生产流程培训中文版****介绍**PCB,即印刷电路板,是任何电子设备的基础。