Poka Yoke 减少失误 防差错技术

- 格式:pdf

- 大小:548.60 KB

- 文档页数:30

防误防错poka yoke百科名片:POKA-YOKE意为“防误防错”,亦即Error & Mistake Proofing。

日本的质量管理专家、著名的丰田生产体系创建人新江滋生(Shingeo Shingo)先生根据其长期从事现场质量改进的丰富经验,首创了POKA-YOKE的概念,并将其发展成为用以获得零缺陷,最终免除质量检验的工具基本理念POKA-YOKE的基本理念主要有如下:⑴不允许哪怕一点点缺陷产品出现,要想成为世界的企业,不仅在观念上,而且必须在实际上达到“0”缺陷。

⑵⑵生产现场是一个复杂的环境,每一天的每一件事都可能出现,poka yoke书籍差错导致缺陷,缺陷导致顾客不满和资源浪费。

⑶我们不可能消除差错,但是必须及时发现和立即纠正,防止差错形成缺陷。

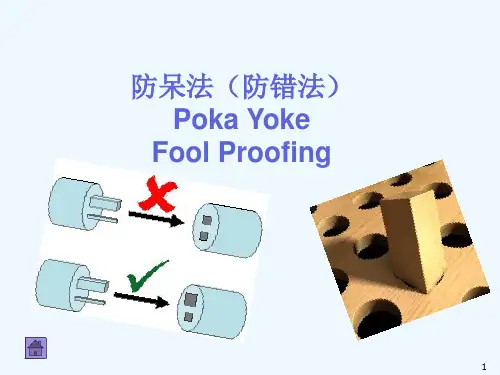

编辑本段基本概念剖析防误- 针对产品及过程设计出一种潜在的失效或导致失效的机理- 错误不可能发生- 前瞻性的- 预防防错- 做出改变,帮助操作人员减少或消除错误检(缺陷)- 防止错误在下游工序继续- 反应性的- 探测防误比防错更高级,更有效,例如十字路口,要避免南北向行驶的车辆与东西向行驶的车辆相撞,有两种办法,一是设置红绿灯,二是建立交桥。

但是设置了红绿灯并不能完全避免南北向行驶的车辆与东西向行驶的车辆相撞,因为有很多的司机会违规驾驶,红绿灯只能起到告警作用,这是防错。

但是如果建造了立交桥,就能完全避免相撞,这就是防误。

POKA YOKE 防错POKA YOKE防错术语过程设计防错产品设计防错零缺陷和POKA YOKE防错FMEA 和防错POKA YOKE实施POKA YOKE防错流程错误的种类人的错误的起因POKA YOKE防错级别和种类过程设计防错案例产品设计防错案例检验中的防错案例POKA YOKE防错技术的分类POKA YOKE防错探测技术的分类编辑本段基本原则消除(Elimination):将可能错误消除在过程和产品被重新设计的过程中;替代(Replacement):是进入更可靠的过程的一个变更;简单化(Facilitation):将过程运行变的更简单化,也更可靠;检测(Detection):使错误在下一步操作前被发现;缓和(Mitigation):是将错误的影响降低到最低。

防错防呆(PokaPoka-yoke)十大原理及其应用案例防呆防错的方法多种多样,智慧的人们总结出主要有如下10大原理:1、自动原理:光、电、力、化学等来进行自动化控制;& 保险丝超过电流,自动断电;& 麦当劳烘干机开启烘干按钮后,10秒钟自动停止;& 商场节能电梯在感应到重力后才会开始工作;& 自动点胶机在启动按钮后,每次自动注射等量的胶量;2、断根原理:从根本上排除可能发生的源头;& 为了祛除狐臭,医生往往采用切断大汗腺的方法;& 为了祛除蚊子,可以进行场地清洁,以除去滋生蚊子的温床;& 为了控制全世界人民,美国孟山都公司逐步控制了世界粮食专利(控制核心);3、保险原理:必须有2个以上的动作同时开动才能继续执行下一步骤;& 操作人员必须双手同时启动2个冲床按钮才能操作,避免工伤事故;& 银行保险箱必须客户与银行工作人员同时打开才能取出物品;4、相符原理:确保两者形状、系统等特性匹配,来避免错误的发生;& 必须用对应的钥匙才能开门;& 登陆QQ或微博必须输入对应的账户和密码;& 规定渔网尺寸来避免鱼苗被打捞;& 医生手术会清点工具(确保工具槽是满的)来避免遗留患者体内;& 产品设计上采用形状匹配来避免操作人员匹配错误;5、隔离原理:远离危险现场,避免可能的错误;& 将危险品锁进柜子或放置高处,避免小孩误食;& 将不良品、嫌疑品进行隔离标识,以避免与良品混淆;& SMT刷锡膏及贴片必须在保护罩关闭以后才能工作;& 所有未校准或待维修的工具必须移除现场,进行隔离;6、顺序原理:避免顺序搞错而进行编号,可减少错误的发生;& 程序文件夹为避免取出后放错而进行斜线编号;& 儿童组装玩具通过编号组装可达到需要的形状;7、复制(确认)原理:也就是确认,可能是对我这辈子影响最大的就是“确认”;& 军队在上级向下级传达指令的时候,下级必须要复述,确保信息的正确传达;& 在信息传递时(如告知电话号码),需进行复述确认;& 在签订合同时,尽量采用一式几份,避免重复手抄出现错误;& 资料传递能够拷贝的尽量拷贝,避免人为手写错误;& 作业指导书可以指导操作员制造出相同品质的产品,并确保工作节拍的一致性;注意:在信息传递时,往往附带着一些隐性要求,需要进一步确认与要求的符合性;8、层别原理:避免将不同的工作做错,而设法加以区分;& 颜色管理,通过不同的颜色来识别对象状态;& 区域划分管理,避免不同区域间的混淆;& 工具按类别或配套管理,以匹配点检或使用;9、警告原理:如有异常发生,会自动以声、光、电提醒报警;& 电梯在超重情况下,会自动报警并停止工作;& 在安全带未系好时,汽车会自动重复报警;& 在出货扫描时,若发现与出货单不符,会自动警报提示;& 产线自动检测发现不良时,发出警报;10、缓和原理:无法排除问题的发生,但可采取措施降低损害程度;& 为了避免笔经常丢失,将笔用绳子绑在桌角;& 用保护膜保护产品,以避免产品被碰伤;所以,防呆防错法是一项非常贴切生活、工作的有效工具,在我看来是一项为人类作出巨大贡献的伟大发明。

PokaYoke防错技术第一部分1. 概述PokaYoke是一种防错技术,其源自日文“poka”(ポカ)和“yokeru”(余計な手間)两个词,意为“避免不必要的失误和麻烦”。

PokaYoke最早应用于生产制造领域,旨在帮助工人在操作过程中不犯错误、不制造废品,提升生产效率,改善产品质量。

如今,这种方法已经被广泛地应用于各个领域,不仅为企业降低了成本、改善了效率和品质,同时也提高了消费者的安全保障和满意度。

2. 原理在制定PokaYoke的方法之前,了解操作人员、流程中可能存在的错误或误操作是首要的步骤。

PokaYoke的目标是通过降低把错误引入产品中的机会,从而降低重新制造产品或改正问题的成本。

因此,根据已有的数据源和其他信息,制定可行的、简单且易于遵循的PokaYoke解决方案是必要的。

PokaYoke的实现通常包括以下几个方面:•设计合理的流程:通过流程设计,明确每个步骤的具体内容和相互关系,避免操作人员在执行不同步骤时出现混淆或误解。

•确定关键环节:在流程中确定容易出错或造成重大问题的关键环节,例如常见的有料或无料、设备的位置等,并进行适当的标记或调整。

•引入检测机制:引入特定的检测机制来确保操作人员能够及时发现并更正错误或产品制造过程中的问题。

这具体包括设备故障警告、必要虚线和特定颜色的警告标识等。

•引入限制机制:在制造的过程中加入特定设计,使其只能进行一种操作,这能够减少错误的发生,例如机械键盘的按键机制。

3. 优点•降低成本:PokaYoke技术能够避免制造废品和重制成本,并且可以减少人力成本。

•提高质量:通过PokaYoke技术可以减少制造的缺陷,提高产品的品质水平。

•提高效率:PokaYoke技术可以减少出现错误的次数,提高生产效率,同时也可以提高工人的满意度和安全性。

•系统化:PokaYoke技术可以制定可行的、重复性的步骤,且可以联动整个生产过程,系统性很高。

•容易实施:PokaYoke技术不需要大量的技术知识和设备,只需要合理的流程设计,就可以很容易的实施。

【可靠性杂谈】防错防呆(POKA-YOKE)十大原理POKA-YOKE意为“防错防呆”,亦即 Error & Mistake Proofing。

日本的质量管理专家、著名的丰田生产体系创建人新江滋生(Shingeo Shingo)先生根据其长期从事现场质量改进的丰富经验,首创了POKA-YOKE的概念,并将其发展成为用以获得零缺陷,最终免除质量检验的工具。

基本理念主要如下:(1)决不允许哪怕一点点缺陷产品出现,要想成为世界的企业,不仅在观念上,而且必须在实际上达到'0'缺陷。

(2)生产现场是一个复杂的环境,每一天的每一件事都可能出现,差错导致缺陷,缺陷导致顾客不满和资源浪费。

(3)我们不可能消除差错,但是必须及时发现和立即纠正,防止差错形成缺陷。

以下所举应用原理,以生活上所常见到的实例列举出来,希望能触类旁通应用于自己的工作上。

1、断根原理将会造成错误的原因从根本上排除掉,使绝不发生错误。

(1)借“排除”的方法来达成例:录音带上若录有重要的资料想永久保存时,则可将侧边防再录孔之一小块塑料片剥下,便能防止再录音。

2、保险原理借用二个以上的动作必需共同或依序执行才能完成工作(1)借“共同”动作必须同时执行来完成例:开银行保险箱时,须以顾客之钥匙与银行之钥匙,同时插入钥匙孔,才能将保险箱打开。

例:操作冲床之工作,为预防操作人员不小心被手夹伤,所以设计一双手必须同时按操作钮下去,才能执行工作。

3、自动原理以各种光学、电学、力学、机构学、化学等原理来限制某些动作的执行或不执行,以避免错误之发生。

目前这些自动开关非常普遍,也是非常简易的“自动化”之应用。

(1)以“浮力”的方式来控制例:抽水马桶之水箱内设有浮球,水升至某一高度时,浮球推动拉杆,切断水源。

(2)以“重量”控制的方式来完成例:电梯超载时,门关不上,电梯不能上下,警告钟也鸣起。

(3)以“光线”控制的方式来完成例:自动照相机,光线若不足时,则快门按不下去。

防错法Poka-Yoke简介防错法Poka-Yoke是一种用于预防和消除错误的技术,最初起源于丰田汽车公司,后逐步被广泛应用于制造业、服务业和医疗行业等领域。

它的意义在于:通过设计和改进生产过程,避免或降低质量问题的发生,从而提高产品和服务的质量水平。

原理Poka-Yoke的思想源于日本的精益生产理念Lean Production,它的核心理念是将生产过程中的误差和浪费降至最低,使生产过程变得高效和精准。

Poka-Yoke技术主要通过以下两种方法实现:1.设计防错:将产品或服务的设计与生产过程同时进行,从而建立一个具有自我验证功能的系统,能够防止人工操作时出现的错误。

例如,在日本某家汽车公司生产线上,零件盒子的颜色与对应的车型颜色相同,这样就可以避免工人错误地安装零件。

2.操作防错:通过在生产过程中加入特殊的检查机构或工具,来帮助工人在工作中正确地执行操作,从而避免人为因素导致的误差。

例如,在某家医院中,医生在给病人进行手术前,必须扫描手术包内的条码,以确保使用正确的工具和药品。

应用Poka-Yoke技术可以应用于各个领域,以下是几个典型的应用案例:1.制造业:在汽车生产线、家电生产线等制造领域,可以通过改进生产系统和工艺流程,设计出具有自我验证能力的产品,加强操作培训,从而防止发生生产缺陷。

2.服务业:在酒店、餐厅等服务领域,可以通过规定服务标准、强化员工培训,以及通过加入检查清单等方式,避免因服务流程混乱、服务环节疏漏,导致服务质量下降。

3.医疗行业:在医疗领域,医院可以引入手术检查清单、术前术后指导等Poka-Yoke技术,从而防止患者术后感染、误用药品等问题。

总结防错法Poka-Yoke是一种重要的生产管理理念和方法,通过改进生产过程、设计具有自我验证功能的产品系统,以及加强操作培训、确定服务标准等方式,可以有效地提高生产质量和服务质量。

Poka-Yoke 技术的应用价值在于避免在服务、生产和工作过程中出现的失误和相关问题,提高员工的效率、减少成本和时间浪费,从而可以使企业更加稳定和有效地运营。

Parker Lean System Poka-YokeObjective•Define Poka-Yoke•Describe the purpose of Poka-Yoke•Given a work scenario, describe examples of how Poka-Yoke could be employed.•Distinguish the difference between mistake proof and fail safe•Describe the ideal approach of Poka-Yoke.•Describe characteristics of Poka-Yoke solutions.•Given examples of Poka-Yoke solutions, identify what is good and what could be improved.Poka Yoke•POKA -inadvertent error•YOKE -proof•Pronounced (POH-kah YOH-kay)In the original Toyoda Loom, Jidoka was the principle of stopping work immediately when a defect occurred. Poka Yoke was the device that made it possible.Original Toyoda Loom -JidokaSources of Defects•Inappropriate process specifications •Excessive process variability •Material properties and variability •Machine performance and variability •Inadvertent errors–Humans or machinesErrors Vs. Defects•Product defects result from errors and mistakes •Errors and mistakes will always be potential issues with operations involving people •Machines can make mistakes tooWe can achieve Zero defects by catching these errors and mistakes and preventing themfrom becoming product defectsErrors Vs. DefectsMistakes (errors) are inevitable“A human is an animal that makesmistakes”--Shingo1001 in 110-11 in 1010-21 in 10010-310-410-510-6(Highest)(Lowest)Crew reaction duringair disasterSimulated militaryemergencyPassive inspections(general walk -arounds )Monitor/inspector fails to recognize initial error by operatorSimple arithmetic errors (without re -doing calculation on separate paper)Missetting largemanual values (nostatus indication except open orclosed)Technician “seeing ”an out of calibration instrument as “intolerance ”General error of omission (no control room display)General error of omission for itemsembedded inprocedureSelection of switch dissimilar in shapeor location todesired switchMissetting large manual valves (controlled by procedure keys, chaining, etc.)Selection of key operated switch rather than non -key switch (does not include error of decision)General errors of commission (e.g., misread label and selected wrongswitch)Upper limit to credibility Two -man team (one do; one check then reverse roles)SOURSE: System Safety 2000, Joe Stephenson (New York: Van Nostrand Reinhold, 1991)Human Error RatesPoka Yoke•Makes permanent changes to equipment,operations, or procedures to eliminateopportunity for error•Provides an immediate signal if a mistakeoccursMistake Proof & Fail Safe Mistake Proof / Fail Safe techniques are partof a Poka-Yoke system•Mistake Proof –Practices and devices thatmake it easy to do it right and difficult orimpossible to do a task wrong.•Fail Safe –If anything does go wrong, itimmediately becomes impossible tocontinue (Jidoka)Ideal Function of Poka-Yoke Linkage to Jidoka and a Zero defect system •Source inspection to detect errors at theirsource•100% inspection for errors/mistakes anddefects using inexpensive sensing devices •Immediate action to stop operations when an error is detectedContact Sensors•Used to physically detect the presence or absence of an object or feature.•Used to physically detect the height orposition of a part or dimension.Impact of Poka YokeState of Defect Source Informative InspectionRegulation Impact Predicted ShutdownAnnunciationLine StopFeedback &Adjust WarningAnnunciationZero Defects (Defect Prevention)Detected Scrap & Rework(Defect Reduction)SameMistake Proof3.5 inch diskette. The diskettecannot be inserted unless it isoriented correctly. This is as faras a disk can be inserted upside-down.The beveled corner of thediskette pushes a stop in the diskdrive out of the way allowing thediskette to be inserted. Thisfeature, along with the fact thatthe diskette is not square,prohibits incorrect orientation.Mistake Proof110 volt outlets in NorthAmerica. All “grounded”items have a thirdprong that only fits oneway in the receptacle.Even two prong /ungrounded items thatare polarity sensitivecan be forced to beplugged in the sameway due to differentsized prongs on boththe plug and outlet.Here is a parts kit for an assembly operation. Can you easilytell if we have all of the right parts? Signed Packing ListMistake ProofMistake ProofThis bathroom sink has asmall hole near the top thathelps prevent overflow.This is a parts kit for an assembly operation that uses a picture. Can youtell which parts have already been installed?Mistake ProofThis automatic coffee pot is equipped with a “pause and serve ”feature. When you remove the pot, the flow isinterrupted by this simple valve.Images from John Grout: /faculty/jgrout/pokayoke.shtml Fail SafeFail SafeA special coupling on gas pumps allows the line to break away and seal if somebody drives away.Mistake Proof & Fail SafeMistake Proof & Fail SafeSki Boots and Bindings.When a skier falls and a skicomes off, a “runaway ski”can cause serious injury. SkiBrakes prevent this fromhappening by automaticallyDowndropping down when the skiboot is no longer in thebinding. They also fold upautomatically when a skiersteps into their skis.RetractedCharacteristic of PokaYoke Solutions •Simple•Inexpensive•Integral part of the process•Placed at the source of errors–Point of transformation (Process Function)•Capable of 100% inspection•Provide quick feedback–(Effective human support system in place)•Ideas generally originate on the shop floor•Prevents process or part from moving forward if errors occur.Poka Yoke Aids•Colors and color-coding •Shapes / sizes •Symbols•Other toolsDegrees of Poka-YokeIs it hard or impossible to do something wrong?•Both meet the definition of Mistake Proof•Example: Color coding doesn’t make it impossible •Impossible to do wrong is always better•Layer techniques for maximum effectLayers of Mistake ProofTrailer plug. This isthe quick disconnectelectrical connectorused to hook up thelights on a trailer to atow vehicle. Thereare two layers of MPhere: color coding(white, green, yellow& brown wires) andthe physical shape ofthe connection.What’s good? How to Improve?This form uses mistake-proofing to help the user fill out the form correctly.ExerciseBreak into teams and develop Poka Yoke devices for:•Getting to this classroom•Making sure the lights are turned off•Making sure the computers are logged off•Making sure the room is locked•Making sure the students arrive on time•Other?Remember, layers are sometimes important!Homework。