武钢汽车用钢使用手册

- 格式:doc

- 大小:2.93 MB

- 文档页数:35

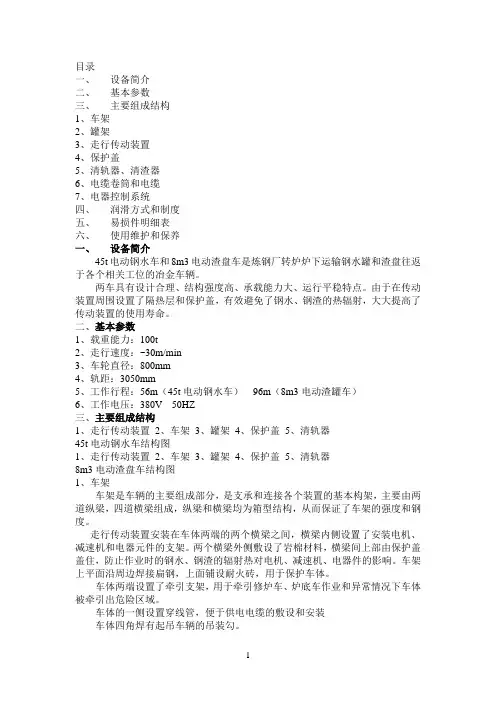

目录一、设备简介二、基本参数三、主要组成结构1、车架2、罐架3、走行传动装置4、保护盖5、清轨器、清渣器6、电缆卷筒和电缆7、电器控制系统四、润滑方式和制度五、易损件明细表六、使用维护和保养一、设备简介45t电动钢水车和8m3电动渣盘车是炼钢厂转炉炉下运输钢水罐和渣盘往返于各个相关工位的冶金车辆。

两车具有设计合理、结构强度高、承载能力大、运行平稳特点。

由于在传动装置周围设置了隔热层和保护盖,有效避免了钢水、钢渣的热辐射,大大提高了传动装置的使用寿命。

二、基本参数1、载重能力:100t2、走行速度:~30m/min3、车轮直径:800mm4、轨距:3050mm5、工作行程:56m(45t电动钢水车)96m(8m3电动渣罐车)6、工作电压:380V 50HZ三、主要组成结构1、走行传动装置2、车架3、罐架4、保护盖5、清轨器45t电动钢水车结构图1、走行传动装置2、车架3、罐架4、保护盖5、清轨器8m3电动渣盘车结构图1、车架车架是车辆的主要组成部分,是支承和连接各个装置的基本构架,主要由两道纵梁,四道横梁组成,纵梁和横梁均为箱型结构,从而保证了车架的强度和钢度。

走行传动装置安装在车体两端的两个横梁之间,横梁内侧设置了安装电机、减速机和电器元件的支架。

两个横梁外侧敷设了岩棉材料,横梁间上部由保护盖盖住,防止作业时的钢水、钢渣的辐射热对电机、减速机、电器件的影响。

车架上平面沿周边焊接扁钢,上面铺设耐火砖,用于保护车体。

车体两端设置了牵引支架,用于牵引修炉车、炉底车作业和异常情况下车体被牵引出危险区域。

车体的一侧设置穿线管,便于供电电缆的敷设和安装车体四角焊有起吊车辆的吊装勾。

渣盘车的车体上面用型钢焊接成支架结构,用来支承渣盘,避免了车体和渣盘直接接触,有效解决了车架因受钢渣传导和辐射热影响而造成的变形。

为提高支架强度又便于传动装置的维修,在传动装置保护盖上部设置了活动支架。

2、罐架45t电动钢水车罐架由钢板焊接而成,调整后焊于车体上,用于支承钢水罐的部件。

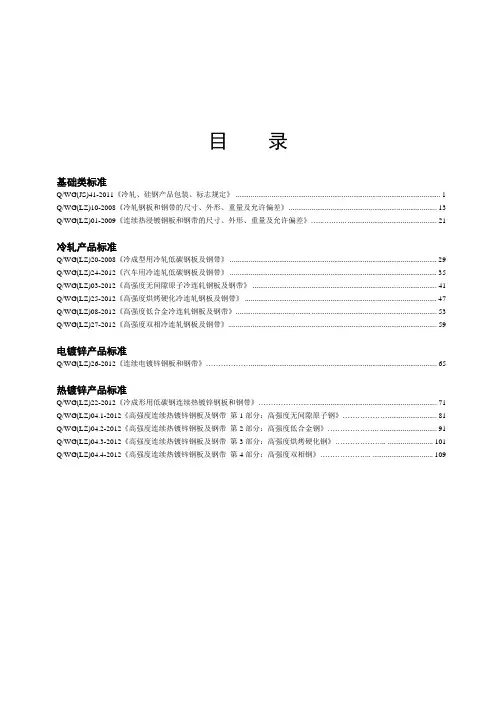

目 录基础类标准Q/WG(JS)41-2011《冷轧、硅钢产品包装、标志规定》 (1)Q/WG(LZ)10-2008《冷轧钢板和钢带的尺寸、外形、重量及允许偏差》 (13)Q/WG(LZ)01-2009《连续热浸镀钢板和钢带的尺寸、外形、重量及允许偏差》................ .. (21)冷轧产品标准Q/WG(LZ)20-2008《冷成型用冷轧低碳钢板及钢带》 (29)Q/WG(LZ)24-2012《汽车用冷连轧低碳钢板及钢带》 (35)Q/WG(LZ)03-2012《高强度无间隙原子冷连轧钢板及钢带》 (41)Q/WG(LZ)25-2012《高强度烘烤硬化冷连轧钢板及钢带》 (47)Q/WG(LZ)08-2012《高强度低合金冷连轧钢板及钢带》........................................ (53)Q/WG(LZ)27-2012《高强度双相冷连轧钢板及钢带》.............................. .. (59)电镀锌产品标准Q/WG(LZ)26-2012《连续电镀锌钢板和钢带》..................... .. (65)热镀锌产品标准Q/WG(LZ)22-2012《冷成形用低碳钢连续热镀锌钢板和钢带》..................... . (71)Q/WG(LZ)04.1-2012《高强度连续热镀锌钢板及钢带第1部分:高强度无间隙原子钢》 (81)Q/WG(LZ)04.2-2012《高强度连续热镀锌钢板及钢带第2部分:高强度低合金钢》..................... (91)Q/WG(LZ)04.3-2012《高强度连续热镀锌钢板及钢带第3部分:高强度烘烤硬化钢》..................... (101)Q/WG(LZ)04.4-2012《高强度连续热镀锌钢板及钢带第4部分:高强度双相钢》..................... .. (109)冷轧、硅钢产品包装、标志规定1 范围本标准规定了武汉钢铁股份有限公司冷轧、硅钢产品的包装、标志技术条件。

汽车车身钢板选用手册(J H)(总14页)本页仅作为文档封面,使用时可以删除This document is for reference only-rar21year.March目次前言 (3)1 范围 (4)2 规范性引用文件 (4)3 定义 (4)4 普通钢与强度钢的分类 (4)5 表面质量分类及代号 (5)6 用途和特点 (5)6.1冷轧板 (5)6.2热轧板 (7)7 材料的选用原则 (7)7.1冷轧板 (7)7.2热轧板 (8)8 优先选用的规格 (8)9 材料表示方法 (9)10 其他 (9)附录A(资料性附录)材料的力学及工艺性能 (10)附录B(资料性附录)本标准与采用标准及有关标准相近牌号对照表 (13)前言车身设计选用“多种钢板”代表了今后车身的发展趋势,通过对多种钢板结构进行优化、即能保证和改进汽车的性能,又能显著的减少质量。

要实现轻量化结构设计,必须强调“合适的板材用在合适的部位”。

考虑到公司目前在车身设计选材时选择的钢板牌号种类规格繁多,不利于生产与成本的控制,为进一步规范车身设计薄板材的选取,制定此标准。

鉴于国标在薄板材料方面相对比较滞后,而多以一些大型钢铁企业标准为事实标准,因此本标准在编写过程充分参考了宝钢公司的企业标准,以及宝钢专家的意见,同时也参考了日本的JIS中相关的材料标准与欧盟的EN标准。

本标准的附录A为资料性附录。

本标准的附录B为资料性附录本标准起草单位:技术中心标准法规部本标准主要起草人:唐小华、徐清魁1 范围本标准确定了车身覆盖件薄板材选用的一般原则,规定了车身薄板材料的牌号和规格范围以及高强度刚的定义,本标准中的材料即车身薄板材。

本标准适用于乘用车、商用车车身设计时薄板材的选取。

2 规范性引用文件下列文件中的条款通过本标准的引用而成为本标准的条款。

凡是注日期的引用文件,其随后所有的修改单(不包括勘误的内容)或修订版均不适用于本标准,然而,鼓励根据标准达成协议的各方研究是否可使用这些文件的最新版本。

五、行车设备操作、维护、检修规程行车设备操作规程一、总则1.行车必须有专人驾驶、保养,使用人员熟悉设备性能。

2.不准超负荷使用,不准斜拉歪拖,不准起吊埋在地下不明重量的物件。

3.禁止在浇钢或吊有重物时调整制动器。

4.禁止用线位开关,作上升停车使用5.禁止突然变更运动方向及变更速度。

6.当行车运行时,禁止人员上下,禁止从事检修,禁止撞车7.当钢丝绳跳出卷筒或轮槽时,应立即停车,检修处理。

8.当降落重物大最低位置时,在卷筒上不少于三圈。

9.吊运接近额定负荷的重物时,应在起吊之后约0.5~1公尺,再行下落(但不得接近地面),检查起升机构制动器得动作情况。

10.不准吊着重物在空中长期停留。

11.水平吊运重物运行时,必须保持重物于地面物件有适当得距离。

12.禁止吊物从人头越过。

13.当行车移动及提升重物,只允许听专人发出信号进行操作,但紧急刹车信号无论谁发出,必须立即停车。

14.电动机的运行温度不超过85。

C 制动器闸衬不得有烧焦的气味。

二、操作顺序开车1.开车前将全部控制器放于零位。

2.推上总电源闸刀,然后揿上电磁开关。

3.必须按喇叭,注意地面和轨道有无行人及障碍物。

停车1.停车应将控制器放于零位。

2.揿脱电磁开关。

3.拉脱总电源闸刀二、操作细则:1.行车在出钢或浇钢时,不得交接班和小调班,浇钢时必须将紧急开关关掉,撑好大车刹车架,思想集中,不得离开驾驶室。

2.满包钢水在对好第一块平板时,严禁作下降动作。

3.钢水浇铸完毕,小车开出前,应将钢包升高一些,避免撞坏总浇口。

4.倒渣时,应听从地面人员指挥,倒进指定的渣包,最先慢后快,防止钢包大翻身,若阿包内渣子结盖严禁用付勾敲清。

5.红钢锭起吊,摆模必须二人领行。

6.吊运帽口,每次最多只准吊七只。

7.平板车卸模子,起步要慢,逐步收紧链条,待领航人员站在安全位置,才能将模子吊起。

8.行车出钢时,相邻行车驾驶员要相互关心,发生故障及时抢修。

9.注钢摆模对准,应先动小车或长路在开降钩子。

钢材使用手册目录▲结构钢的种类、规格、用途 (1)一、碳素结构钢 (1)二、合金结构钢 (5)▲结构钢品种特性 (17)一、板材 (17)二、管材 (23)三、型钢 (25)四、丝 (35)▲钢材重量计算 (37)一、常见金属比重 (37)二、钢材理论重量计算公式 (37)▲各种钢材理论重量表 (40)1.等边角钢理论重量 (40)2.槽钢理论重量 (40)3.工字钢理论重量 (40)4.焊管理论重量 (41)5.热度锌管理论重量 (41)6.扁钢、花纹板、钢板理论重量 (42)7.圆钢理论重量 (42)▲换算单位(中英缩写标符) (42)▲结构钢的种类、规格、用途结构钢是指符合特定强度和可成形性等级的钢。

可成形性以抗拉试验中断后伸长率表示。

结构钢一般用于承载等用途,在这些用途中钢的强度是一个重要设计标准。

结构钢包括碳素结构钢、合金结构钢、低合金结构钢、耐热结构钢等。

一、碳素结构钢碳素结构钢是碳素钢的一种。

含碳量约0.05%~0.70%,个别可高达0.90%。

碳素钢是指碳含量低于2%,并有少量硅、锰以及磷、硫等杂质的铁碳合金。

工业上常指含碳量小于1.35%,除铁、碳和限量以内的硅、锰、磷、硫等杂质外,不含其他合金元素的钢。

碳素钢的性能主要取决于含碳量。

含碳量增加,钢的强度、硬度升高,塑性、韧性和可焊性降低。

与其它钢类相比,碳素钢使用最早,成本低,性能范围宽,用量最大。

(一)分类1.按含碳量分为:(1)低碳钢(碳含量为0.04%~0.25%) (含碳量小于0.04%时称为工业纯铁)。

(2)中碳钢(碳含量为0.25%~0.6%)(3)高碳钢(碳含量为0.6%~1.35%)2.按质量分为:(1)普通碳素钢,其有害杂质磷、硫含量均小于0.05%。

包括:甲类钢:A类钢,保证力学性能乙类钢:B类钢,保证化学成分特类钢:C类钢,保证力学性能和化学成分)如:Q235A,Q235B,Q235C,Q235D,SS400等。

汽车用结构钢SAPH400是结构钢的一种。

结构钢是指符合特定强度和可成形性等级的钢。

可成形性以抗拉试验中断后伸长率表示。

结构钢一般用于承载等用途,在这些用途中钢的强度是一个重要设计标准。

结构钢可以细分为:合金结构钢、碳素结构钢、低合金结构钢、耐热结构钢等等。

SAPH400主要用于要求成型加工性能的汽车构架、车轮等汽车结构件。

主要用于汽车板,汽车构架等产品。

汽车用结构钢SAPH400的化学成分主要如下:C ≤0.21Si ≤0.30Mn ≤1.40P ≤0.030S ≤0.025伸长≥31汽车用结构钢SAPH400按照表面分类主要分为FA和FB两种普通级表面(FA)酸洗表面或轧制表面表面允许有深度(或高度)不超过钢板厚度公差之半的麻点、凹面、划痕等轻微、局部的缺欠,但应保证钢板及钢带允许的最小厚度。

较高级表面(FB)酸洗表面表面允许有不影响成型性的局部缺欠,如轻微划伤、轻微压痕、轻微麻点、轻微辊印及色差等南京和菱贸易有限公司,位于六朝古都南京的鼓楼区中储生产资料市场,为钢材市场诚信单位,公司地理位置优越,交通便利。

我公司资源丰富,价格合理,服务周到,可按照客户要求,加工开平,可待定期货。

材料位于钢厂内,钢厂外仓库为洪申库,方瑞库,中储库,西马船厂库等各大仓库。

公司主要经销:宝钢、涟钢、武钢、马钢、南钢、太钢等大钢厂产品。

产品主要包括:耐磨钢(热处理钢板)、高强度工程机械用钢(单张回火调制钢板)等;汽车大梁钢;搅拌车筒体及叶片用钢;耐候钢,耐酸钢;中高碳钢;双相钢;管线钢等。

公司秉承“诚信服务于广大客户”的经营宗旨,坚持以服务开拓市场,以客户为导向。

在华东地区建立了广泛的客户群,已与多家国企及上市公司建立长期合作关系,并受到了客户的一致好评,在客户和流通行业中树立了良好的企业形象。

汽车用热轧钢板及钢带

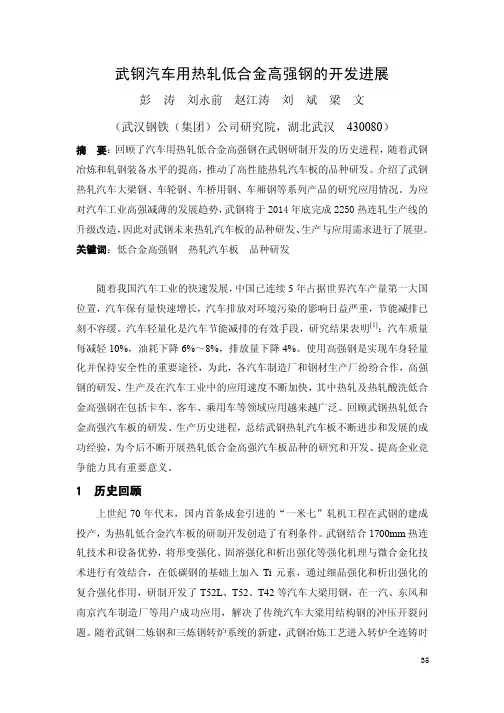

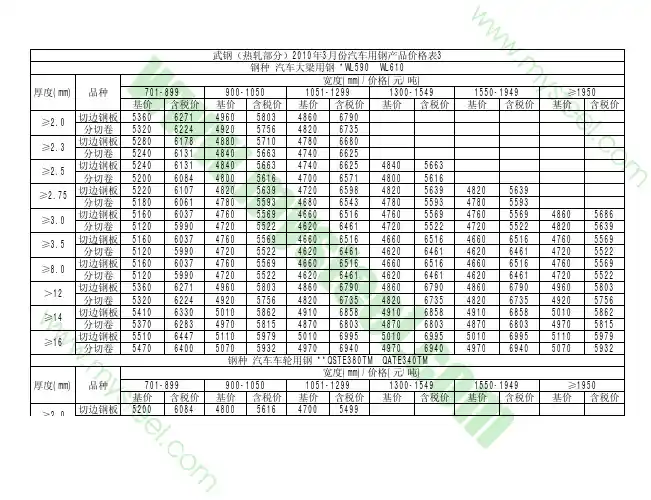

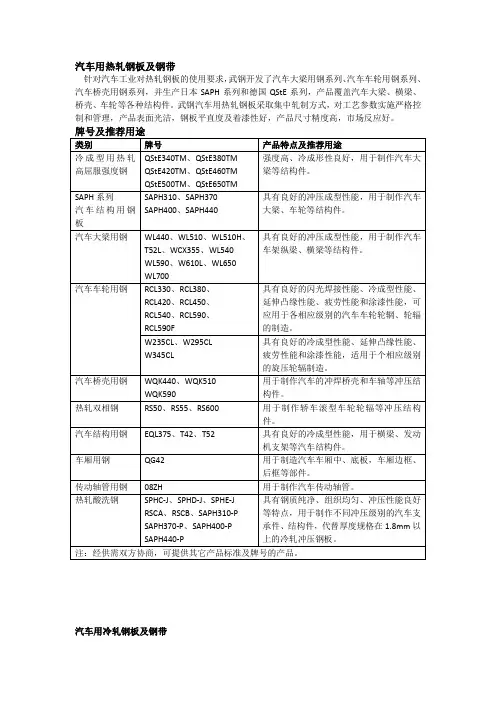

针对汽车工业对热轧钢板的使用要求,武钢开发了汽车大梁用钢系列、汽车车轮用钢系列、汽车桥壳用钢系列,并生产日本SAPH系列和德国QStE系列,产品覆盖汽车大梁、横梁、桥壳、车轮等各种结构件。

武钢汽车用热轧钢板采取集中轧制方式,对工艺参数实施严格控制和管理,产品表面光洁,钢板平直度及着漆性好,产品尺寸精度高,市场反应好。

汽车用冷轧钢板及钢带

武钢冷轧产品表面质量高,尺寸控制精确,生产板宽最大达到2080mm,可以充分满足汽车制造业对板宽的要求,产品种类齐全,包括CQ到SEDDQ全系列的低碳钢产品以及多相钢产品,产品可广泛应用到汽车内部件、外部件、结构件、加强件以及汽车防撞梁等高吸收能量的冲压件。

汽车用热镀锌钢板及钢带

武钢三条镀锌机组均采用目前世界上最先进的热镀锌生产工艺,产品锌层附着力强,耐腐蚀性能好,锌层控制准确,尺寸精度高,产品定位于高档轿车面板,并拥有齐全的钢种,包括低碳钢和超低碳钢镀锌产品系列、烘烤硬化钢、加磷高强度钢以及多相钢产品,产品可广泛应用于制作汽车外部件、内部件、结构件、加强件以及汽车防撞梁等高吸收能量的冲压件。

可供牌号、相应标准及用途(续)。

STEEL UTILITY CARTOWNER’S MANUALWARNING:Read carefully and understand all ASSEMBLY AND OPERATION INSTRUCTIONS before operating. Failure to follow the safety rules and other basic safety precautions may result in serious personal injury.Thank you very much for choosing an Ironton product! For future reference, please complete the owner’s record below:Model: _______________ Purchase Date: _______________Save the receipt, warranty and these instructions. It is important that you read the entire manual to become familiar with this product before you begin using it.This cart is designed for certain applications only. The distributor cannot be responsible for issues arising from modification. Do not modify this cart or use it for any application other than that for which it was designed.For technical questions please call 1-800-222-5381.INTENDED USEThis steel utility cart is perfect for hauling garden supplies, fire wood and more. TECHNICAL SPECIFICATIONSItem DescriptionCapacity Overall maximum 400 lbs. load capacityTires 10 inch Pneumatic TiresDo not inflate the tires more than 30 PSI.Construction SteelDimensions 34 x 18.5 x 21.5GENERAL SAFETY RULESWARNING: Read and understand all instructions. Failure to follow all instructions listed below may result in serious injury.CAUTION:Do not allow persons to operate or assemble this utility cart until they have read this manual and have developed a thorough understanding of how the utility cart works.WARNING:The warnings, cautions, and instructions discussed in this instruction manual cannot cover all possible conditions or situations that could occur. It must be understood by the operator that common sense and caution are factors which cannot be built into this product, but must be supplied by the operator.SAVE THESE INSTRUCTIONSIMPORTANT SAFETY CONSIDERATIONS•Maximum overall load capacity: 400 lbs.•Distribute load evenly over the surface of the bed. Do not load items on the top panels.Lower panel when objects are to be loaded onto the cart.•This cart is not intended for highway use. Do not exceed 5 mph.•Do not use this cart for transporting passengers. Do not allow children to use this cart without supervision. This cart is not a toy.•Do not inflate the tires to more than 30 PSI. Do not use the cart on surfaces or for transporting objects that can cause damage to the pneumatic tires.•Do not modify the cart in any way. Unauthorized modification may impair the function and/or safety and could affect the life of the equipment. There are specific applications for which the cart was designed.•Always check for damaged or worn out parts before using the cart. Broken parts will affect the cart operation. Replace or repair damaged or worn parts immediately.•Store idle. When cart is not in use, store it in a secure place out of the reach of children. Inspect it for good working condition prior to storage and before re-use.ASSEMBLYTools needed for assembly: pliers, adjustable wrenches and/or metric socket set.1. Turn the cart bed upside down. Use the cardboard from the carton to keep from scratching ordamaging the finish.2. Assemble the rear support assembly to the back of the bed using M8x40 bolts (2), M8 washers(2), and M8 lock nuts (2). Hand tighten.Next, attach the left and right rear axle braces using M8x20 bolts (4), M8 washers (4), and M8 lock nuts (4). Tighten all nuts securely.3. The front support assembly is mostly pre-assembled at the factory. Please make sure allbolts and nuts assembled at the factory are tight.Assemble the front axle support by sliding the arms onto the support rod and secure by using a M10 washer and cotter pin.4.5. Install the wheels in the following order:a) Place the wheel spacers onto each axle.b) Place the wheels onto the axles with the valve stems facing out.c) Place the wheel washers and the cotter pin to secure the wheels.6. Turn the cart upright onto the wheels.7. Attach the front, back, left and right panels using the fence assembly pins.8. Attach the handle to the front axle support using M8x60 bolt (1), M8 washer (1) and M8 locknut (1).OPERATIONS•Do not exceed the overall maximum load capacity of 400 lbs. The weight rating is based on an evenly distributed load.•Distribute load evenly over the surface of the bed. Do not load items on the top panels.Lower panel when objects are to be loaded onto the cart. Remove panels before loadingoversized loads.•This cart is not intended for highway use. Do not exceed 5 mph.•Do not use this cart for transporting passengers. Do not allow children to use this cart without supervision. This cart is not a toy.•If any parts become damaged, broken or misplaced, do not use this cart until replacement parts have been obtained.•Do not inflate the tires to more than 30 PSI. Do not use the cart on surfaces or for transporting objects that can cause damage to the pneumatic tires.•Do not modify the cart in any way. Unauthorized modification may impair the function and/or safety and could affect the life of the equipment. There are specific applications for which the cart was designed.•Always check for damaged or worn out parts before using the cart. Broken parts will affect the cart operation. Replace or repair damaged or worn parts immediately.MAINTENANCE•Maintain your cart. It is recommended that the general condition of any cart be examined before it is used. Keep your cart in good repair by adopting a program of conscientious repair and maintenance. Have necessary repairs made by qualified service personnel.DIAGRAM & REPLACEMENT PARTS LISTPart# Description Qty.B. Side Panels 2C. Front Panel 1D. Back Panel 1E. Wheels 4F. Rear Axle Support 1G. Left Rear Axle Brace 1H. Right Rear Axle Brace 1I. Front Axle Support 1J. Handle 1K. Hardware Kit 1For replacement parts and technical questions, please call 1-800-222-5381.WARRANTY1-year limited warrantyDistributed byNorthern Tool + Equipment Co., Inc.Burnsville, Minnesota 55306Made in China。

3048HKD-ATV12 cu ft STEEL ATV DUMP CART2 (x1)1 (x1)3 (x1)4 (x1)5 (x2)6 (x1)7 (x1)8 (x1)9 (x1)25 (x1)20 (x1)11 (x46)12 (x46)24 (x3)10 (x1)21 (x4)22 (x2)TOOLS REQUIRED FOR ASSEMBLY:Large Flat Screwdriver •1/2" Wrench or Socket •Grease Gun•19 (x2)23 (x1)Carton Contents1212119111261211Place body halves on a smooth, flat surface so they are square and fasten together with hardware as shown.Attach front support to body and tighten with hardware as shown.Attach undercarriage to body and tighten with hardware as shown.1322122212419101112BEHIND FLANGESlide axle completely through undercarriage; be sure to catch the drawbar when sliding the axle. Align drawbar with the front support and press down to latch.Slide washers, spacers, and wheels onto axle and secure with hairpins as shown.Attach the support bar to body behind flange loosely.79881112742324Attach corner gussets to rear and sides of body and tighten with hardware as shown.Attach tailgate to body as shown. No hardware is required, tailgate should move freely up or down.Install hitch pin and hairpin to secure to attachment vehicle.101211Before Using Dump Cart:1.Apply grease to wheels using grease gun until grease can be seensqueezing out from both sides of the wheel.2.Check tire pressure and inflate to 24 psi if needed.3.Read all Safety Rules found on page 1.How to Use Dump Cart:1.Attach Dump Cart to your tractor using the supplied hitch pin.2.Do not exceed 1,000 pounds when loading material into the cart body.Distribute the weight of the load as evenly as possible in the cart body for 3.best handling.4.When hauling heavy loads, verify that your vehicle has adequate towing and braking capacity.5.Do not exceed 6 miles per hour when towing Dump Cart.How to Empty Dump Cart:6.Pull hand lever forward to release the latch mechanism.7.Angle cart body as desired to guide the material to preferred location.8.Lower the body and guide the latch into the drawbar and relatch.Periodic Maintenance:•Tighten fasteners as needed before each useCheck tire pressure before each use••Grease wheels annuallyWarrantyIf this product fails due to a defect in material or workmanship within TWO YEARS from the date of purchase, we will at our option repair or replace it free of charge. This warranty excludes tires and wheels, which are expendable and become worn during normal use.This warranty does not cover:•Repairs necessary because of operator abuse or negligence.Equipment used for commercial or rental purposes.•Paint that is worn or faded due to normal use or exposure.•To arrange for product repair call 1-800-652-2321, or return this product to place of purchase for replacement.This warranty gives you specific legal rights, and you may also have other rights which may vary from state to state. This warranty applies only while this product is in use in the United States.In the space below record the purchase date of your Dump Cart.Model Number 3048HKD-ATVPurchase DateKeep this Owner's Manual and your receipt in a safe place for future reference.After the two year warranty period all replacement parts may be ordered by calling 1-800-652-2321.When ordering replacement parts, always give the following information:•Product 12 cu ft STEEL ATV DUMP CART•Model Number 3048HKD-ATV•Part Number•Part DescriptionNotes10 (800) 652-2321DESIGNED AND TESTED IN COLUMBUS, OHIO MANUFACTURED IN THE U.S.A. FROM DOMESTIC AND IMPORTED COMPONENTSMODEL # 3048HKD-ATV2575 Ferris Road Columbus, OH 43224(800) 652-2321。

HIGH-PERFORMANCEIn the serious performance community, there’s moreto intake and exhaust valves than meets the eye.Thanks to the technological advancements madewithin the racing components industry, today we have a mind-boggling array of choices. In this arti-cle, we attempt to explain various materials and de-signs in an effort to better understand today’s valve offerings.Stainless-Steel Valves.Although stainless-steel valves may be offered in varying grades and alloy recipes, high-performance stainless-steel valves are most commonly made of material referred to as EV8 (a more expensive heavy-duty stainless alloy material), and are made from a one-piece forging. In addition, some valve makers offer a stronger stainless-steel formula that offers higher heat re-sistance. Some makers use EV8 only for their exhaust valves, while others utilize this material for both intake and exhaust valves.High-quality performance stainless valves should fea-ture hard stellite tips (since stainless is not hardenable, a hardened tip must be welded onto the stem) and hard chrome-plated stems (not cheap flash chroming) to re-duce guide wear. Undercut stems contribute to a slight weight reduction and benefit flow characteristics. Note : If a particular brand of stainless-steel valves does not fea-ture a hard tip, the use of lash caps will be required.Titanium Valves.Titanium offers the highest strength-to-weight ratio of any known metal. In an unal-loyed condition, titanium is as strong as some steel mate-rials but about 45% lighter. When used to manufacture automotive valves, titanium is alloyed with small percent-ages of various materials, including copper and molybde-num. Titanium can be challenging to machine, as it can gall if tooling isn’t hard and sharp enough, and if the ma-terial isn’t cooled properly during machining.Many titanium valves are produced by starting with a forging, then machined to final shape. But some are pro-duced using a two-piece inertia-welded design. According to Xceldyne Technologies, this process is so effective that inertia-welded valves have been certified as having a su-perior grain structure than a one-piece forged design.The valve is then CNC-machined and in many cases un-dercut in the stem area to allow a bed for the inlay of a coating. The valve is then plasma moly-coated.Specific sections of the valve are further machined and the stem is ground, leaving the plasma moly coating over only the desired stem area. The head, stem and keeper grooves are then final-machined. Stem grinding is finalized to establish dimensional tolerance to within .0002 in. A final precision-polishing reduces the potential for carbon buildup.B YJ IM G IBSONV AL VESThis photo shows a sampling of titanium valves in blank form. Stems have been machined to near-final diameter and the heads are rough-formed, prior to CNC machining.P h o t o c o u r t e s y X c e l d y n e T e c h n o l o g i e sThree styles of valve tips are gener-ally available, which include a hard-ened steel tip or a ceramic-coated tip (ceramic tips are to be used in con-junction with lash caps) and thin-film technology such as a plasma vapor deposition (PVD) coating.Since titanium is a relatively soft material, it requires a protective con-tact surface at the stem tips, usually hardened lash caps. Xceldyne noted that when valves feature stem diame-ters smaller than 5⁄16in. (7mm or less),a specialized hard coating is applied to the stem tip to protect it from lash cap friction.The durable, hard ceramic coating is intended to protect the titanium from the friction caused by the lash cap. Other coatings such as a PVD treatment, a chromium nitride treat-ment, chemical vapor deposition (CVD), diamond-like carbon (DLC)or other highly specialized protective application may be applied to the tips. This hardened feature at the tip prevents material transfer or galling between the tip and lash cap.Hollow titanium valves are also available, either with hollow stems or with a combination of hollow stems and hollow heads. Hollow-stem de-signs reduce valve weight by about10%. The hollow-head design is a proprietary process that removes an additional 6 to 8 grams of weight (de-pending on valve size). As part of the proprietary process, the inside of the valve head may be reinforced to pro-vide a support structure for strength and rigidity.The following precautions should be taken during the handling and use of titanium valves:•Do not touch the valve surface with your bare hands, since finger-print acids may affect the e gloves or coat the valve with oil before handling.•Never use a lapping compound or any abrasive material when the valve is coated with a PVD-style coating.•Replace valve seats during each and every rebuild to ensure a proper valve-to-seat contact. The width of the contact zone (valve face to valve seat) should be at least 1mm.•New valve seats should be a rela-tively soft material, such as bronze or nodular iron (heat-treated to Rock-well RC32 or less).•Unless directed otherwise by the valve maker, always use hardened lash caps on titanium valves. Some makers offer valves built with friction-welded hardened tips. Bare, unprotected titanium tips will mush-room when exposed to rocker arm forces.If the titanium valve features a stellite tip, the tips can be ground dur-ing valve service, but with caution . You should be able to safely remove a maximum of approxi-mately .015 to .020 in.As far as valve seats are concerned, tradi-tional cast or hard seats can wear a groove intothe valve face, so a nick-el-bronze seat material is recommended. Other exotic-metal seats are al-so available.Titanium valves are designed for ap-plications where valve train weight needs to be reduced, for high-rpm and extended high-rpm applications, since titanium valves allow for higher engine speeds and will accommodate highly aggressive camshaft profiles. However,for extreme-temperature situations (blown, turbo and nitro engines), titani-um may not be the ideal choice. Also,for many street applications, titanium may not be a good choice for an engine that doesn’t need to rev as highly, or for an engine that will be buttoned up and not torn down and serviced regularly.In other words, it’s probably best to re-serve the use of titanium for naturally aspirated race or inlet-side forced-induction applications where valve train weight and sustained high-rpm use is paramount.Inconel Valves.Inconel is a regis-tered trademark of Special Metals Corp., and refers to a family of nickel-based superalloys . Inconel alloys are ox-idation- and corrosion-resistant materi-als designed for use in high-heat envi-ronments. Inconel retains strength over a wide range of operating temperatures.As opposed to steel or aluminum,it doesn’t creep as much (change dimen-A variety of specialty coating s can be applied to valves to enhance spe-cific properties such as lubricity,resistance to wear and thermal per-formance to heads, stems or tips.The Pro Stock titanium valve on the left features aPVD-applied diamond-like coating (DLC) for ex-treme hardness and reduction of friction. The Formula 1 titanium valve on the rig ht features a DLC coating on the stem area for a combination of guide wear protection and friction reduction.P h o t o c o u r t e s y X c e l d y n e T e c h n o l o g i e sP h o t o s : J i m G i b s o nsion) under high-heat use.Inconel alloy makeup can include during valve opening cause the liquidsodium to migrate upward inside theHollow-Stem Valves.Hollow-stem stainless-steel or titanium valvesThey may look the same but not all parts are createdequal. Delphi fuel pumps deliver fast-pressure risefor quick engine starts and feature an integrated OEfuel vapor pressure sensor and two-strainer systemfor long-lasting durab ility. What does that mean?Reliab le fuel pumps you, and your customers, cantrust. Providing you with the benefi t of more than 100years of OE heritage, we are the company that makesthe parts cars are born with.High standards.Below the surface.Delphi fuel pumps.IT’S WHAT’S UNDERNEATH THAT SETS DELPHI APARTDelphi Fuel Module // A Integrated Fuel PressureRegulator (1) Maintains pressure at fuel rail (2) Negatesfuel return reducing vehicle EVAP emissions; B Quieter OETurbine Pump Performance matched to OE specifi cationsand lower noise levels – 5 to 10 dB lower – in the cockpit./am©2011 Delphi Automotive Systems, LLC. All rights reserved.ABCircle #2810% as compared to a comparable solid-stem valve.GeneralRecommendationsFor most street engines, a quality stainless-steel valve is recommended.Titanium is generally preferred for most race applications, but some en-gine builders that specialize in tur-bocharged applications prefer a high-nickel Inconel valve. Hollow-stem valves tend to work great on the in-take side, but are much more difficult to manufacture and to inspect for de-fects on the I.D. surface. Many up-per-echelon engine builders shy away from hollow valves for that reason inendurance (NASCAR or 24-hour style) racing.Stainless-steel valves are most com-mon in street and mild-performance racing. Titanium is used when valve weight is important and cost is not a consideration. Inconel is used when exhaust gas temperatures get really high. Stainless steel (for street perfor-mance) has much better durability characteristics than titanium, and the street guys won’t usually see the real benefits of titanium. In racing, use ti-tanium when you want to lose weight…and spend a lot of money.If durability is your customer’s con-cern and he’s already making as much power as he wants and is already turning the engine as high as he wants, then use a stainless-steel mate-rial. If he’s running nitromethane,then an Inconel exhaust valve materi-al will be his best bet if he wants to finish a race.On the exhaust side, sodium-filling is the best way to increase the head capacity of a hollow exhaust valve. Ifstock diameter steel valves are re-Applying a hard coating such as titanium nitride to the stem tip and lock groove (left) protects the titanium valve material from galling damage from a lash cap and retainer locks. Coating the valve face (right) adds protection from heat and deposit buildup to that area.Performance Valve ManufacturersComp Cams Crane Cams, Del West Engineering, Electronic Chrome & Grinding Elgin Industries Ferrea Racing Components KPMI (Kibblewhite Precision Machining) Manley Performance Products Milodon, Inc. Pioneer, Inc. Racing Engine Valves RPM International, SI ValvesSupertech Performance, Xceldyne Technologies Zanzi Spaquired, but a valve weight is not man-dated, going to a hollow intake and only a single groove because it forcesthe lock to grip the valve stem andin the locks, which is fine for streetand low-end performance. BecauseThey may look the same b ut not all parts are created equal. Delphi OE CVCcompressors have proven warranty experience of less than 1 Incident Per ThousandVehicles (IPTV) on major OEM applications. What does that mean? Reliable, highperformance compressors you, and your customers, can trust. Providing you withthe benefi t of more than 100 years of OE heritage, we are the company that makesthe parts cars are born with./amHigh standards.Below the surface.Delphi CVC compressors.ABIT’S WHAT’S UNDERNEATH THAT SETS DELPHI APARTDelphi C C Compressor // A Swash Plate ariableMechanism Patented technology adaptab le to pneumatic andelectronic control for high speed operation at up to 9200 RPM;B Integrated Control Valve Compact packaging and four-port fl owdesign provides a wider range of control set points for improvedfuel economy and emissions.©2011 Delphi Automotive Systems, LLC. All rights reserved.Circle #29。

先进高强度钢应用手册国际汽车钢板研究组织2006.9湖南大学汽车车身设计与制造国家重点试验室译(第1版)2009.1前言近几年来,为了减轻汽车重量和提高汽车安全性,汽车钢板的开发技术、应用技术方面有了许多新的发展。

由国际钢铁公司资助的项目ULSAB (汽车车身轻量化技术)和USLAB-A VC(先进概念车)等,主要在车身上大量采用先进高强度钢,研究汽车的轻量化设计的一些理念。

先进高强度钢的应用,需要新的成形技术和连接技术。

这本指南是汽车钢铁研究组织的多位专家的合作成果。

其中,特别感谢以下专家:Dr Heiko BeenkenMr Willie BernertMr Klaus BlümelDr Björn CarlssonDr Jayanth ChintamaniMr Bart DePompoloMr Daniel ErikssonMr Peter Heidbüche…特别感谢Stuart Keeler博士,他是一位金属成形领域的著名专家。

他负责本书的编辑工作。

国际汽车用钢组织包括全球的下面钢铁公司:宝山钢铁公司……Edward G. Opbroek国际汽车用钢组织主席翻译感言偶然在网上搜索到这本《ADV ANCED HIGH STRENGTH STEEL APPLICA TION GUIDLINES》,当时非常高兴,这本书中包括了一些工厂中常遇到的一些问题,比如,先进高强度钢与传统钢的区别,DP钢与TRIP钢的区别,各种回弹机理。

当时只看了一些感兴趣的章节。

后面继续看这本手册,发现中间还包括很大的信息量,激起了翻译该本手册的兴趣。

翻译过程中,感觉收获比较多,比如局部延伸率,这在国内文献中很少看到。

本手册第一章介绍了先进高强度钢的微观结构、宏观力学性能等;第二章中介绍了先进高强度钢零件的设计、冲压和应用中的一些问题;第三章介绍了先进高强度钢的连接方法;第一章的知识用于解释第二章、第三章中的某些现象。