模德MT-11000皮纹

- 格式:ppt

- 大小:72.00 KB

- 文档页数:4

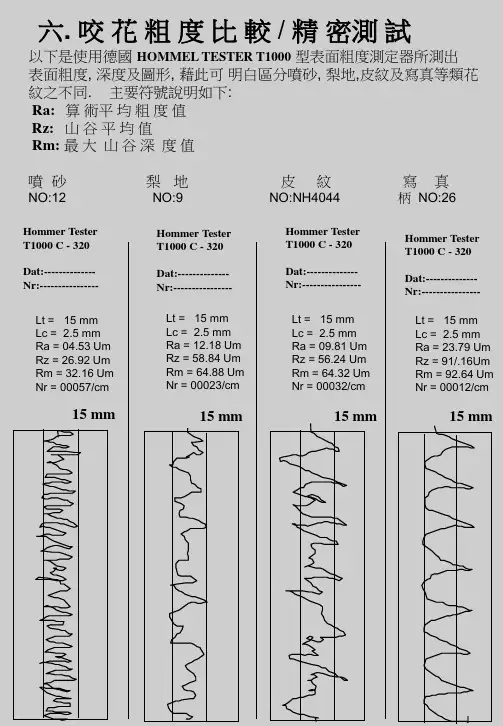

第五节拔模角度的确定原则拔模角度主要帮助从模具中取出成品,为确保产品纹理的准确与成功,正确的脱模角度是至关重要;拔模角度的确定必须考虑产品深度、产品功能、胶料特性(收缩率及韧性)等。

基本原理是每13微米的纹理深度,需要最少1°(500mm高度下);要确保外壁不要因省模不精而产生弧面;要确保靠近分模边线不产生脱模0°的情况出现;如果牵涉到印纹的纹向,其角度更应增大或采取纹理深度渐变效果。

一、拔模角度的确定原则:◎若是可能,拔模角应该要尽可能大。

◎正常的拔模角度为1~2°,而肋则可选择0.5°的拔模角;◎前模(母模、定模)的拔模角度要略大于后模(公模、动模)的拔模角度,为防止产品粘前模。

注意倒装模的拔模角度确定,产品要留在前模,则相反。

◎若骨位深度不超过12.5mm(0.5inch),且将需要拔模角的地方抛光,则可使用很小的拔模角。

◎每咬花13um深时加上1~1.5°的拔模角。

◎咬花时所需的最小拔模角度与产品材料韧性、收缩率、壁厚、咬花种类有关。

◎若是需要完全没有拔模角,则要考虑使用侧向移动开模,如滑块。

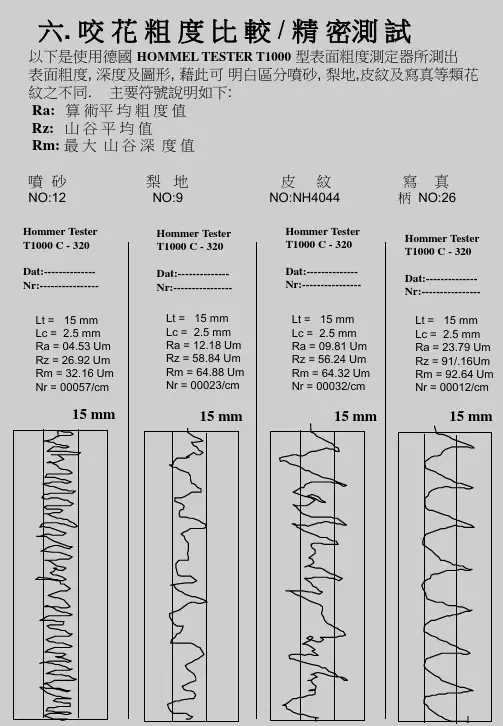

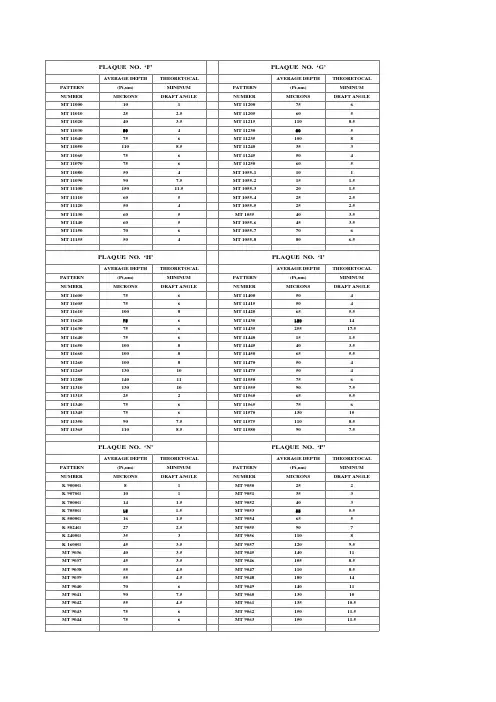

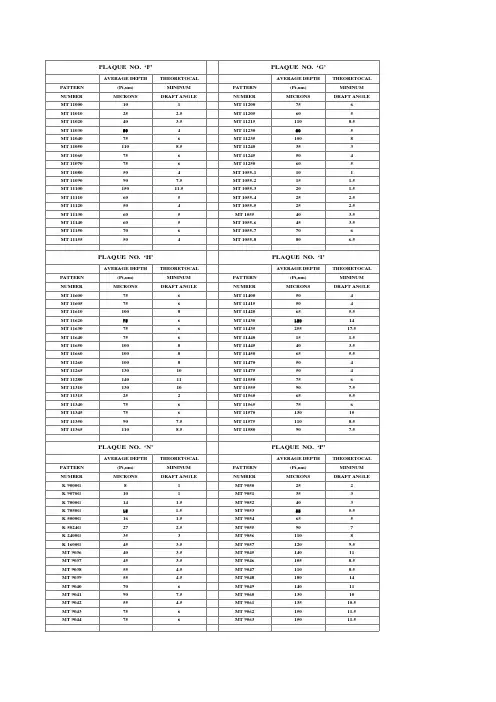

二、常用模德纹号深度及出模角度(附表1):注意单位纹号深度inch脱模角度° 纹号深度inch脱模角度°纹号深度um脱模角度°MT-11000 0.0004 1° MT-11300 0.0025 3.5° MT11600 75 6.5MT-11010 0.001 1.5° MT-11305 0.005 7.5° MT11605 75 6.5MT-11020 0.0015 2.5° MT-11310 0.005 7.5° MT11610 100 8.5MT-11030 0.002 3° MT-11315 0.001 1.5° MT11620 75 6.5MT-11040 0.003 4.5° MT-11320 0.0025 4° MT11630 75 6.5MT-11050 0.0045 6.5° MT-11325 0.003 4.5° MT11640 75 6.5MT-11060 0.003 4.5° MT-11330 0.002 3° MT11650 100 8.5MT-11070 0.003 4.5° MT-11335 0.002 3° MT11660 100 8MT-11080 0.002 3° MT-11340 0.003 4.5° MT9088 80 6.5MT-11090 0.0035 5.5° MT-11345 0.003 4.5° MT9089 30 2.5MT-11100 0.006 9° MT-11350 0.0035 5.5° MT9090 50 4MT-11110 0.0025 4° MT-11355 0.0025 4° MT9091 50 4.5MT-11120 0.002 3° MT-11360 0.0035 5.5° MT9092 70 5.5MT-11130 0.0025 4° MT-11365 0.0045 7° MT9093 155 12MT-11140 0.0025 4° MT-11370 0.004 6° MT9094 85 6.5MT-11150 0.00275 4° MT-11375 0.004 6° MT9095 150 12MT-11160 0.004 6° MT-11380 0.004 6° MT9096 210 16.5MT-11200 0.003 4.5° MT-11400 0.002 3° MT9097 60 6MT-11205 0.0025 4° MT-11405 0.0025 4° MT9098 80 6.5MT-11210 0.0035 5.5° MT-11410 0.0035 5.5° MT9099 70 6.5MT-11215 0.0045 6.5° MT-11415 0.002 3° MT9100 55 5MT-11220 0.005 7.5° MT-11420 0.0025 4° MT9101 50 4.5MT-11225 0.0045 6.5° MT-11425 0.0035 5.5° MT9102 75 5.5MT-11230 0.0025 4° MT-11430 0.007 10° MT9103 90 7.5MT-11235 0.004 6° MT-11435 0.010 15° MT9104 160 13MT-11240 0.0015 2.5° MT-11440 0.0005 1.5° MT9105 90 7.5MT-11245 0.002 3° MT-11445 0.0015 2.5° MT1055-1 10 1.5MT-11250 0.0025 4° MT-11450 0.0025 4° MT1055-2 15 1.5MT-11255 0.002 3° MT-11455 0.003 4.5° MT1055-3 18 1.5MT-11260 0.004 6° MT-11460 0.0035 5.5° MT1055-4 25 2MT-11265 0.005 7° MT-11465 0.005 7.5° MT1055-5 25 2MT-11270 0.004 6° MT-11470 0.002 3° MT1055 40 3.5MT-11275 0.0035 5° MT-11475 0.002 3° MT1055-6 45 3.5MT-11280 0.0055 8° MT-11480 0.003 4.5° MT1055-7 70 5.5MT1055-8 80 6.5 备注:MT11001、MT11002、MT11003、MT11004、MT11005、MT11006、MT11007等,深度为10μm,脱模斜度为1.5°;。

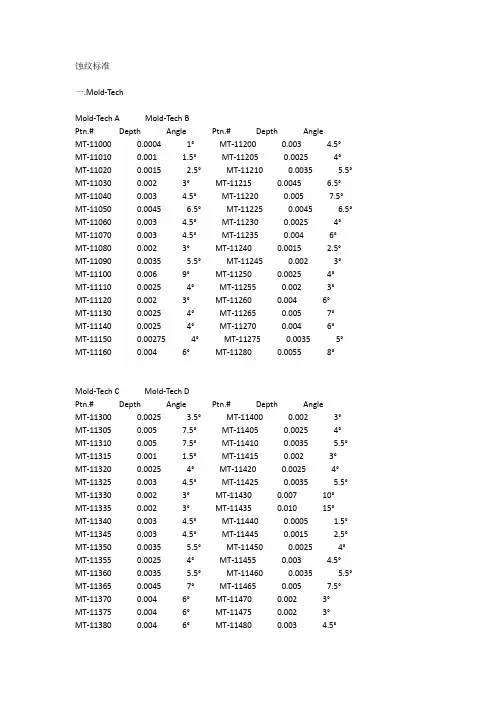

蚀纹标准一.Mold-TechMold-Tech A Mold-Tech BPtn.# Depth Angle Ptn.# Depth AngleMT-11000 0.0004 1°MT-11200 0.003 4.5°MT-11010 0.001 1.5°MT-11205 0.0025 4°MT-11020 0.0015 2.5°MT-11210 0.0035 5.5°MT-11030 0.002 3°MT-11215 0.0045 6.5°MT-11040 0.003 4.5°MT-11220 0.005 7.5°MT-11050 0.0045 6.5°MT-11225 0.0045 6.5°MT-11060 0.003 4.5°MT-11230 0.0025 4°MT-11070 0.003 4.5°MT-11235 0.004 6°MT-11080 0.002 3°MT-11240 0.0015 2.5°MT-11090 0.0035 5.5°MT-11245 0.002 3°MT-11100 0.006 9°MT-11250 0.0025 4°MT-11110 0.0025 4°MT-11255 0.002 3°MT-11120 0.002 3°MT-11260 0.004 6°MT-11130 0.0025 4°MT-11265 0.005 7°MT-11140 0.0025 4°MT-11270 0.004 6°MT-11150 0.00275 4°MT-11275 0.0035 5°MT-11160 0.004 6°MT-11280 0.0055 8°Mold-Tech C Mold-Tech DPtn.# Depth Angle Ptn.# Depth AngleMT-11300 0.0025 3.5°MT-11400 0.002 3°MT-11305 0.005 7.5°MT-11405 0.0025 4°MT-11310 0.005 7.5°MT-11410 0.0035 5.5°MT-11315 0.001 1.5°MT-11415 0.002 3°MT-11320 0.0025 4°MT-11420 0.0025 4°MT-11325 0.003 4.5°MT-11425 0.0035 5.5°MT-11330 0.002 3°MT-11430 0.007 10°MT-11335 0.002 3°MT-11435 0.010 15°MT-11340 0.003 4.5°MT-11440 0.0005 1.5°MT-11345 0.003 4.5°MT-11445 0.0015 2.5°MT-11350 0.0035 5.5°MT-11450 0.0025 4°MT-11355 0.0025 4°MT-11455 0.003 4.5°MT-11360 0.0035 5.5°MT-11460 0.0035 5.5°MT-11365 0.0045 7°MT-11465 0.005 7.5°MT-11370 0.004 6°MT-11470 0.002 3°MT-11375 0.004 6°MT-11475 0.002 3°MT-11380 0.004 6°MT-11480 0.003 4.5°Plaque #6 Plaque #7 Plaque #8 Plaque #10Ptn.# Depth Ptn.# Depth Ptn.# Depth Ptn.# Depth MT229 0.003 MT325 0.003 MT588 0.0085 MT9800.004MT392 0.004 MT964 0.003 MT888 0.013 MT901 0. 003MT585 0.0035 MT1038 0.002 MT1028 0.0035 MT9450.0065MT889 0.004 MT1043 0.002 MT1067 0.013 MT9700.002MT1013 0.003 MT1170 0.0025 MT1149 0.013 MT9720.0025MT1015 0.0055 MT1192 0.0015 MT1153 0.0075 MT9730.0035MT1039 0.003 MT1239 0.003 MT1211 0.0095 MT9740.0025MT1055 0.0055 MT1240 0.003 MT1226 0.0035 MT9780.003MT1068 0.0055 MT1241 0.002 MT1227 0.0035 MT9850.0025MT1070 0.007 MT1242 0.002 MT1228 0.0095 MT1055-10.0001MT1074 0.0055 MT1243 0.002 MT1230 0.013 MT1055-20.0045MT1129 0.003 MT1244 0.0025 MT1232 0.003 MT1055-30.0005MT1159 0.008 MT1250 0.003 MT1233 0.0035 MT1055-40.0075MT1122 0.0015 MT2019 0.0025 MT1234 0.0035 MT1055 -5 0.001MT1125 0.006 MT2020 0.002 MT1235 0.0035 MT10550.0015MT1126 0.0065 MT2028 0.0025 MT1236 0.0035 MT1055 -6 0.0017MT1127 0.0025 23053 0.002 MT1238 0.0045 MT1055-70.0225MT1526 0.0135 23064 0.0015 23031 0.0085二.昵宏咬花番號拔模斜度平均值μ打光程度加工種類HN-DS11 1° 5 ~ 7 800 噴砂咬花HN-DS12 1.5°10 ~ 13 600 ~ 800HN-DS13 2°12 ~ 15 600 ~ 800HN-DS14 2°13 ~ 19 600 ~ 800HN-DS01 3°25 ~ 30 320HN-DS02 4°35 ~ 40 320HN-DS03 4°36 ~ 42 320 化學咬花HN-DS04 4.5°38 ~ 43 320HN-DS05 1.5°9 ~ 13 800HN-DS06 2°14 ~ 19 800HN-DS07 2.5°19 ~ 24 600HN-DS08 3°25 ~ 30 400三.梨地梨地NO. 1 2°8~9 #400梨地NO. 2 2.5°15~16 #400梨地NO. 3 3°15~17 #400梨地NO. 4 3.5°16~18 #400梨地NO. 5 4°20~23 #400梨地NO. 6 4.5°25~30 #400梨地NO. 7 6°40~42 #320梨地NO. 8 6°57~60 #320梨地NO. 9 6°60~66 #320S ---半光澤G ---半光澤NO. 1 1° 1.7 鏡面NO. 2 1° 1 鏡面NO. 3 1° 1.4 鏡面NO. 4 1° 1.8 1000NO. 5 1° 2.9 1000NO. 6 1.5° 4 1000NO. 7 1.5° 6.5 #800NO. 8 2°7 #800NO. 9 2.5°7.7 #800NO. 10 3°10~11 #600NO. 11 3~4°12~15 #600NO. 12 4~5°16~18 #600S ---半光澤G ---半光澤HN20 2.5°12~14 #400HN21 3°15~17 #400HN22 3~4°23~25 #400HN23 4~5°33~37 #320HN24 4°19~21 #320HN25 4°23~25 #320HN26 4°26~30 #320HN27 5°37~40 #320HN28 5~6°41~43 #320HN30 6°58~63 #320 HN31 6°65~73 #320S ---半光澤G ---半光澤HN1000 1°4~5 #800 HN1001 1°5~6 #800 HN1002 1.5°8~ #800 HN1003 1°3~4 #800 HN1004 1°4~5 #800 HN1005 1°5~6 #800 HN1006 2°10~11 #600 HN1007 2.5°12~13 #600 HN1008 3°17~19 #600 HN1009 1.5°6~7 #600 HN1010 2°7~8 #600 HN1011 3°13~14 #600 HN1012 3.5°25~27 #400 HN1013 4°33~37 #400 HN1014 5°43~50 #400 HN1015 3°19~21 #400 HN1016 4°32~~33 #320 HN1017 5°36~~38 #320 S ---半光澤G ---半光澤HN2000 1.5°8~9 #600 HN2001 2°13~15 #600 HN2002 2.5°22~34 #400 HN2003 3.5°40~44 #400 HN2004 4°44~47 #400 HN2005 5.5°61~65 #400 HN2006 5.5°60~63 #400 HN2007 5°61~64 #400 HN2008 5°63~66 #400 HN2009 3°33~35 #400 HN2010 3.5°43~46 #400 HN2011 2°20~21 #400 HN2012 3°28~32 #400 HN2013 3.5°30~35 #400 HN2014 2.5°19~22 #400 HN2015 2.5°25~29 #400 HN2016 3°33~38 #400 HN2017 4°38~41 #400 HN2018 4°50~58 #400 HN2019 5°70~75 #400 HN2020 2°16~23 #400HN2022 3°25~27 #400HN2023 4°30~34 #400HN2024 4.5°42~50 #400HN2025 5°52~56 #400HN2026 5°62~70 #400S ---半光澤G ---半光澤HN3000 1.5°4~5 #800HN3001 1.5°5~6 #800HN3002 1.5°7~9 #800HN3003 2.5°8~11 #800HN3004 3°10~15 #600HN3005 3°16~18 #600HN3006 3.5°17~20 #600HN3007 1.5°7~9 #600HN3008 2°9~11 #600HN3009 2.5°12~14 #600HN3010 2.5°15~18 #600HN3011 3°18~22 #600HN3012 3.5°24~28 #600HN3013 3.5°27~31 #600S ---半光澤G ---半光澤四.相关术语咬花、蚀纹、晒文,其实质就是同一种工艺。

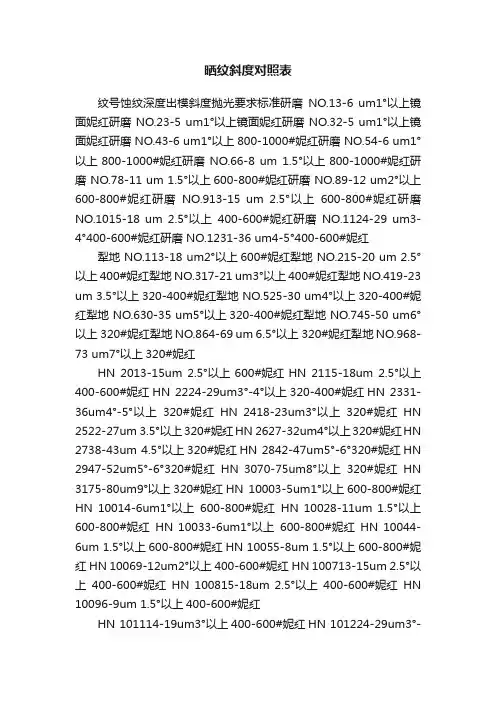

晒纹斜度对照表纹号蚀纹深度出模斜度抛光要求标准研磨NO.13-6 um1°以上镜面妮红研磨 NO.23-5 um1°以上镜面妮红研磨 NO.32-5 um1°以上镜面妮红研磨 NO.43-6 um1°以上800-1000#妮红研磨 NO.54-6 um1°以上800-1000#妮红研磨NO.66-8 um 1.5°以上800-1000#妮红研磨 NO.78-11 um 1.5°以上600-800#妮红研磨 NO.89-12 um2°以上600-800#妮红研磨NO.913-15 um 2.5°以上600-800#妮红研磨NO.1015-18 um 2.5°以上400-600#妮红研磨NO.1124-29 um3-4°400-600#妮红研磨 NO.1231-36 um4-5°400-600#妮红犁地 NO.113-18 um2°以上600#妮红犁地 NO.215-20 um 2.5°以上400#妮红犁地 NO.317-21 um3°以上400#妮红犁地 NO.419-23 um 3.5°以上320-400#妮红犁地 NO.525-30 um4°以上320-400#妮红犁地 NO.630-35 um5°以上320-400#妮红犁地 NO.745-50 um6°以上320#妮红犁地 NO.864-69 um 6.5°以上320#妮红犁地 NO.968-73 um7°以上320#妮红HN 2013-15um 2.5°以上600#妮红HN 2115-18um 2.5°以上400-600#妮红HN 2224-29um3°-4°以上320-400#妮红HN 2331-36um4°-5°以上320#妮红HN 2418-23um3°以上320#妮红HN 2522-27um 3.5°以上320#妮红HN 2627-32um4°以上320#妮红HN 2738-43um 4.5°以上320#妮红HN 2842-47um5°-6°320#妮红HN 2947-52um5°-6°320#妮红HN 3070-75um8°以上320#妮红HN 3175-80um9°以上320#妮红HN 10003-5um1°以上600-800#妮红HN 10014-6um1°以上600-800#妮红HN 10028-11um 1.5°以上600-800#妮红HN 10033-6um1°以上600-800#妮红HN 10044-6um 1.5°以上600-800#妮红HN 10055-8um 1.5°以上600-800#妮红HN 10069-12um2°以上400-600#妮红HN 100713-15um 2.5°以上400-600#妮红HN 100815-18um 2.5°以上400-600#妮红HN 10096-9um 1.5°以上400-600#妮红HN 101114-19um3°以上400-600#妮红HN 101224-29um3°-4°320-400#妮红HN 101335-40um4°-5°320-400#妮红HN 101447-52um5°-6°320-400#妮红HN 101521-26um3°-4°320-400#妮红HN 101636-41um4°-5°320#妮红HN 101745-50um5°-6°320#妮红HN 20008-12um2°以上600#妮红HN 200114-19um3°以上600#妮红HN 200223-28um 3.5°以上400#妮红HN 200336-41um4°以上400#妮红HN 200450-55um 5.5°以上400#妮红HN 200566-71um7°以上400#妮红HN 200671-76um8°以上400#妮红HN 200760-65um7°以上400#妮红HN 200865-70um7.5°以上400#妮红HN 200934-39um4°以上400#妮红HN 201025-45um3°以上400#妮红HN 201120-25um3°以上400#妮红HN 201226-31um 3.5°以上400#妮红HN 201331-36um 3.5°以上400#妮红HN 201419-24um3°以上400#妮红HN 201525-30um4°以上400#妮红HN 201637-42um 4.5°以上400#妮红HN 201742-47um 4.5°以上400#妮红HN 201856-61um6°以上400#妮红HN 201986-90um9°以上400#妮红HN 202015-20um3°以上400#妮红HN 202121-26um 3.5°以上400#妮红HN 202227-32um 3.5°以上400#妮红HN 202336-41u m4°以上400#妮红HN 202454-59um 6.5°以上400#妮红HN 202566-71um7.5°以上400#妮红HN 202684-89um9°以上400#妮红HN 30006-8um 1.5°以上800-1000#妮红HN 30018-11um 1.5°以上600-800#妮红HN 30029-12um2°以上600-800#妮红HN 300313-15um 2.5°600-800#妮红HN 300415-18um 2.5°400-600#妮红HN 300517-22um3°400-600#妮红HN 300624-29um3°-4°400-600#妮红HN 30076-10um 1.5°600-800#妮红HN 30089-14um2°400-600#妮红HN 300913-18um 2.5°400-600#妮红HN 301120-25um3°400-600#妮红HN 301224-29um 3.5°400-600#妮红HN 301331-36um 3.5°400-600#妮红蚀纹型号蚀纹深度in/mm最小出模斜度机器抛光标准MT-110000.0004″ 0.011°模德MT-110100.001″ 0.0251.5°模德MT-110200.0015″ 0.04 2.5°模德MT-110300.002″ 0.053°模德MT-110400.003″ 0.0754.5°模德MT-110500.0045″ 0.116.5°模德MT-110600.003″ 0.0754.5°模德MT-110700.003″ 0.0754.5°模德MT-110800.002″ 0.053°模德MT-110900.0035″ 0.095.5°模德MT-111000.006″ 0.159°模德MT-111100.0025″ 0.064°模德MT-111200.002″ 0.053°模德MT-111300.0025″ 0.064°模德MT-111400.0025″ 0.064°模德MT-111500.00275″ 0.074°模德MT-111600.004″ 0.106°模德蚀纹型号蚀纹深度出模斜度抛光要求标准MT-1100010um1°800#模德MT-1101025um 2.5°800#模德MT-1102040um 3.5°600#模德MT-1103050um4°600#模德MT-1104075um6°400#模德MT-11050110um8.5°400#模德。

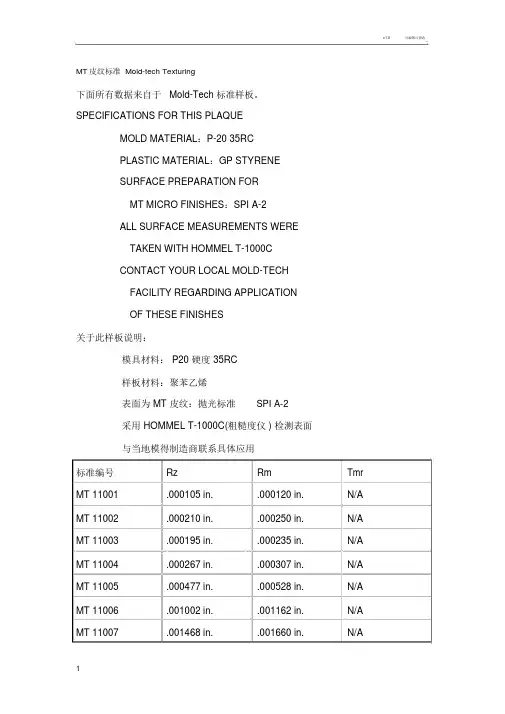

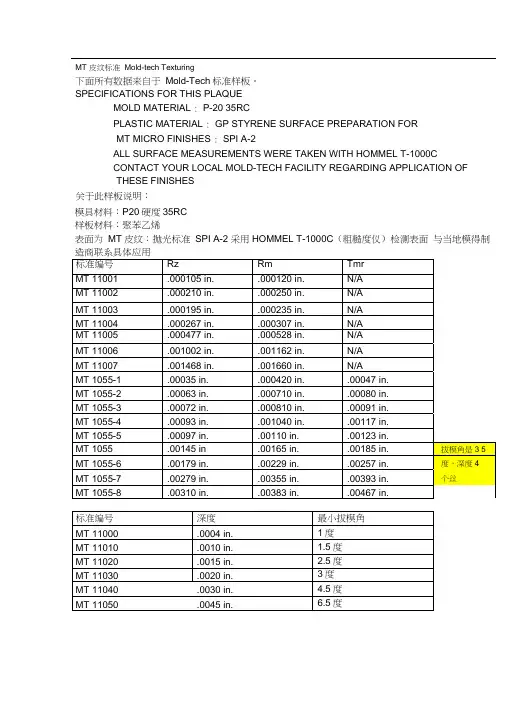

v1.0可编辑可修改MT皮纹标准 Mold-tech Texturing下面所有数据来自于Mold-Tech 标准样板。

SPECIFICATIONS FOR THIS PLAQUEMOLD MATERIAL:P-20 35RCPLASTIC MATERIAL:GP STYRENESURFACE PREPARATION FORMT MICRO FINISHES:SPI A-2ALL SURFACE MEASUREMENTS WERETAKEN WITH HOMMEL T-1000CCONTACT YOUR LOCAL MOLD-TECHFACILITY REGARDING APPLICATIONOF THESE FINISHES关于此样板说明:模具材料: P20 硬度 35RC样板材料:聚苯乙烯表面为 MT 皮纹:抛光标准SPI A-2采用 HOMMEL T-1000C(粗糙度仪 ) 检测表面与当地模得制造商联系具体应用标准编号Rz Rm TmrMT 11001 .000105 in. .000120 in. N/AMT 11002 .000210 in. .000250 in. N/AMT 11003 .000195 in. .000235 in. N/AMT 11004 .000267 in. .000307 in. N/AMT 11005 .000477 in. .000528 in. N/AMT 11006 .001002 in. .001162 in. N/AMT 11007 .001468 in. .001660 in. N/Av1.0可编辑可修改MT 1055-1 .00035 in. .000420 in. .00047 in.MT 1055-2 .00063 in. .000710 in. .00080 in.MT 1055-3 .00072 in. .000810 in. .00091 in.MT 1055-4 .00093 in. .001040 in. .00117 in.MT 1055-5 .00097 in. .00110 in. .00123 in.MT 1055 .00145 in. .00165 in. .00185 in. MT 1055-6 .00179 in. .00229 in. .00257 in. MT 1055-7 .00279 in. .00355 in. .00393 in. MT 1055-8 .00310 in. .00383 in. .00467 in.标准编号深度最小拔模角MT 11000 .0004 in. 1 度MT 11010 .0010 in. 度MT 11020 .0015 in. 度MT 11030 .0020 in. 3 度MT 11040 .0030 in. 度MT 11050 .0045 in. 度MT 11060 .0030 in. 度MT 11070 .0030 in. 度MT 11080 .0020 in. 3 度MT 11090 .0035 in. 度MT 11100 .0060 in. 9 度MT 11110 .0025 in. 4 度MT 11120 .0020 in. 3 度MT 11130 .0025 in. 4 度MT 11140 .0025 in. 4 度拔模角是度,深度 4v1.0可编辑可修改MT 11150 .00275 in. 4 度MT 11160 .0040 in. 6 度。

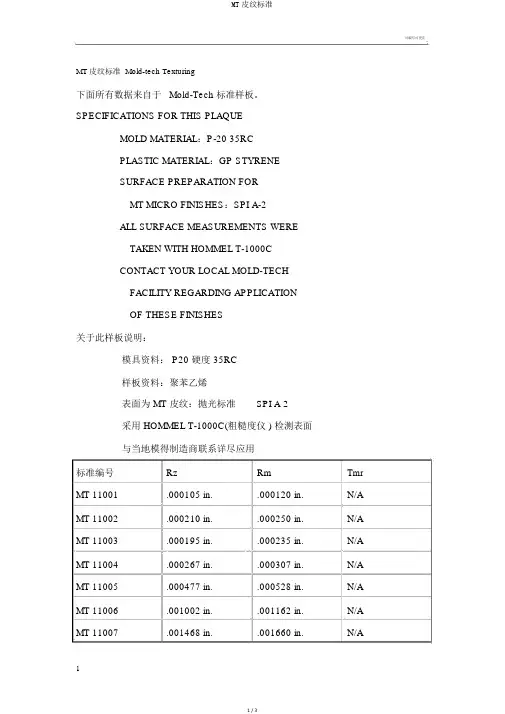

可编写可更正MT皮纹标准 Mold-tech Texturing下面所有数据来自于Mold-Tech 标准样板。

SPECIFICATIONS FOR THIS PLAQUEMOLD MATERIAL:P-20 35RCPLASTIC MATERIAL:GP STYRENESURFACE PREPARATION FORMT MICRO FINISHES:SPI A-2ALL SURFACE MEASUREMENTS WERETAKEN WITH HOMMEL T-1000CCONTACT YOUR LOCAL MOLD-TECHFACILITY REGARDING APPLICATIONOF THESE FINISHES关于此样板说明:模具资料: P20 硬度 35RC样板资料:聚苯乙烯表面为 MT 皮纹:抛光标准SPI A-2采用 HOMMEL T-1000C(粗糙度仪 ) 检测表面与当地模得制造商联系详尽应用标准编号Rz Rm TmrMT 11001 .000105 in. .000120 in. N/AMT 11002 .000210 in. .000250 in. N/AMT 11003 .000195 in. .000235 in. N/AMT 11004 .000267 in. .000307 in. N/AMT 11005 .000477 in. .000528 in. N/AMT 11006 .001002 in. .001162 in. N/AMT 11007 .001468 in. .001660 in. N/A可编写可更正MT 1055-1 .00035 in. .000420 in. .00047 in.MT 1055-2 .00063 in. .000710 in. .00080 in.MT 1055-3 .00072 in. .000810 in. .00091 in.MT 1055-4 .00093 in. .001040 in. .00117 in.MT 1055-5 .00097 in. .00110 in. .00123 in.MT 1055 .00145 in. .00165 in. .00185 in. MT 1055-6 .00179 in. .00229 in. .00257 in. MT 1055-7 .00279 in. .00355 in. .00393 in. MT 1055-8 .00310 in. .00383 in. .00467 in.标准编号深度最小拔模角MT 11000 .0004 in. 1 度MT 11010 .0010 in. 度MT 11020 .0015 in. 度MT 11030 .0020 in. 3 度MT 11040 .0030 in. 度MT 11050 .0045 in. 度MT 11060 .0030 in. 度MT 11070 .0030 in. 度MT 11080 .0020 in. 3 度MT 11090 .0035 in. 度MT 11100 .0060 in. 9 度MT 11110 .0025 in. 4 度MT 11120 .0020 in. 3 度MT 11130 .0025 in. 4 度MT 11140 .0025 in. 4 度拔模角是度,深度 4可编写可更正MT 11150 .00275 in. 4 度MT 11160 .0040 in. 6 度。

通知

C3P中心标准通字[2006]第106 号

为了规范表面皮纹处理的制品的脱模斜度的选择,使在设计表面皮纹处理的制品选择脱模斜度时有据可寻,避免模具脱伤。

现制定制品皮纹处理的外观面脱模斜度设计要求,产品处即日起试行。

特此通知。

附:制品皮纹处理的外观面脱模斜度设计要求

发:产品处

C3P中心

2006.05.19制品皮纹处理的外观面脱模斜度设计要求

1、皮纹处理的外观面脱模斜度设计原则

带皮纹、喷砂等外观处理的塑料件与表面镜面处理的塑料件相比脱模斜度应尽量加大,具体的视皮纹深度而定。

皮纹深度越深,脱模斜度应越大。

对于不同的皮纹图案,在选择脱模斜度时也有不同。

皮纹图案的选择由客户确定,可推荐使用公司内部的皮纹样板类型。

皮纹处理的制品的侧壁的脱模斜度可遵循下面的原则:

对于皮纹深度小于10µ的,脱模斜度可以选择≥2°;

对于皮革纹①,皮纹深度每增加8-10µ,脱模斜度增加1°;

②1°。

3、其它特殊情况

有些制品侧壁要求较小的脱模斜度,但皮纹深度较深,为了保证外观质量,应通过特殊模具结构实现,如:滑块机构。

①表面看起来像皮革一样的图案

②表面看起来像梨皮一样的图案。