刀具参数表1

- 格式:xls

- 大小:2.18 MB

- 文档页数:2

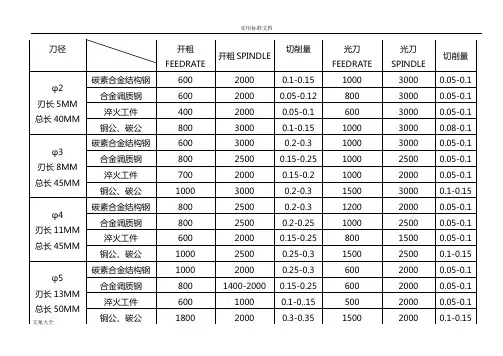

实用标准文档

文案大全

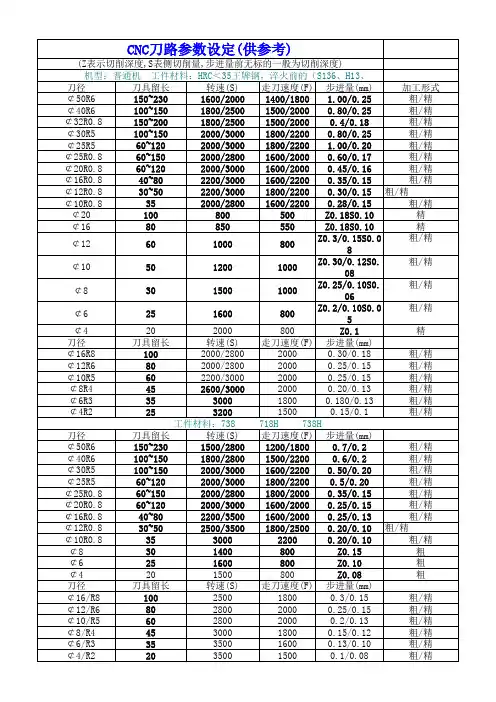

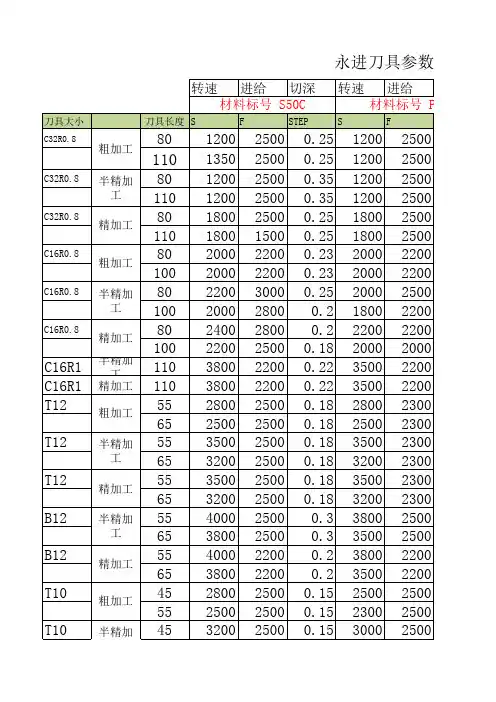

碳素合金结构钢(HRC <20) 合金调质钢(HRC30~40) 淬火工件(HRC46~52) 1

参数 材料

文案大全

碳素合金结构钢(HRC <20= 合金调质钢(HRC30~40) 淬火工件(HRC46~52) 2 碳素合金结构钢(HRC <20) 合金调质钢(HRC30~40) 淬火工件(HRC46~52) 3

材料

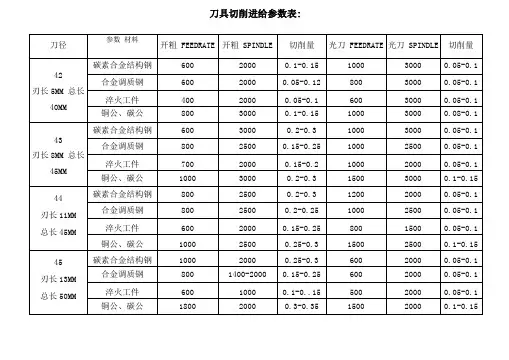

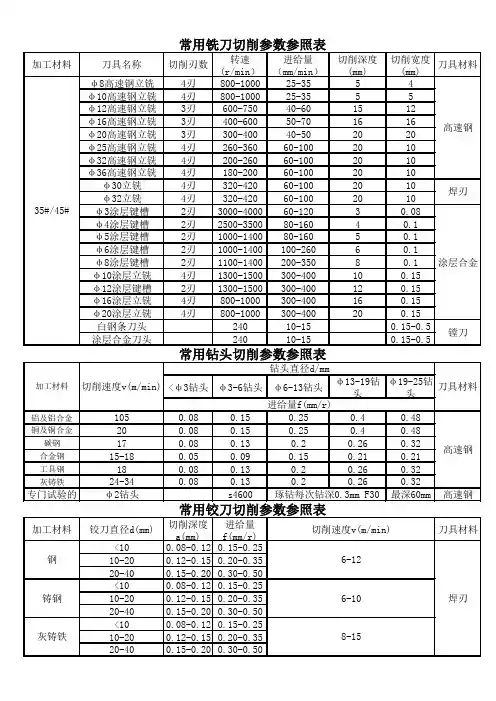

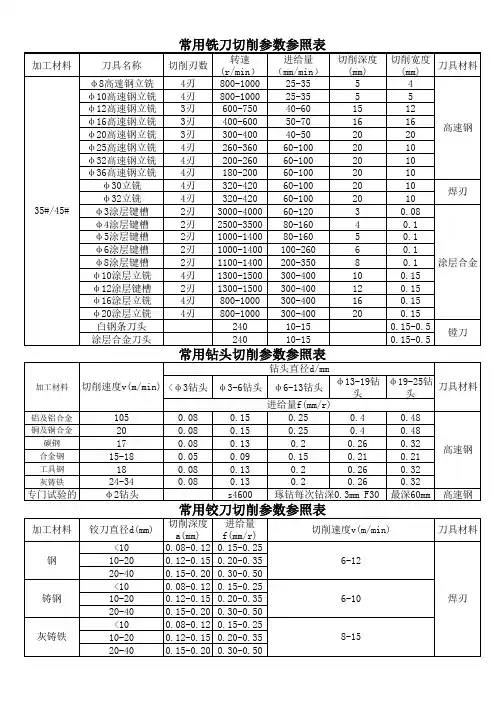

刀具切削进给参数表: 刀具切削进给参数表:

文案大全

碳素合金结构钢(HRC<20=合金调质钢(HRC30~40) 淬火工件(HRC46~52) 4 刀具切削进给参数表:

碳素合金结构钢(HRC<20) 合金调质钢(HRC30~40) 淬火工件(HRC46~52) 5

文案大全

文案大全

实用标准文档

文案大全

碳素合金结构钢(HRC <20) 合金调质钢(HRC30~40) 淬火工件(HRC46~52) 7

刀具切削进给参数表:

实用标准文档

文案大全

碳素合金结构钢(HRC <20) 合金调质钢(HRC30~40) 淬火工件(HRC46~52) 8

刀具切削进给参数表: 刀具切削进给参数表:

碳素合金结构钢(HRC<20) 合金调质钢(HRC30~40) 淬火工件(HRC46~52) 9 文案大全

文案大全

文案大全

文案大全

文案大全。

常用电脑锣加工刀具钢料加工参数表仅供参考刀具名称刀具类型加工类型总长度50R6-1圆鼻刀/刀杆开粗/半精/精27050R6-2圆鼻刀/刀杆开粗/半精/精17050R6-3圆鼻刀/刀杆开粗/半精/精10050R5-1圆鼻刀/刀杆开粗/半精/精1050R5-2圆鼻刀/刀杆开粗/半精/精7550R5-3圆鼻刀/刀杆开粗/半精/精16040R6圆鼻刀/刀杆开粗/半精/精160-25035R6圆鼻刀/刀杆开粗/半精/精160-25035R5圆鼻刀/刀杆开粗/半精/精160-25030R5-1圆鼻刀/刀杆开粗/半精/精25030R5-2圆鼻刀/刀杆开粗/半精/精16025R5圆鼻刀/刀杆开粗/半精/精160-20020R4圆鼻刀/刀杆半精/精16016R4圆鼻刀/刀杆半精/精16012R4圆鼻刀/刀杆半精/精16050R0.8飞刀/刀杆开粗/半精/精40045R0.8飞刀/刀杆开粗/半精/精40035R0.8飞刀/刀杆开粗/半精/精30026R0.8飞刀/刀杆开粗/半精/精25025R0.8飞刀/刀杆开粗/半精/精25021R0.8-1飞刀/刀杆开粗/半精/精20021R0.8-2飞刀/刀杆开粗/半精/精16020R0.8-1飞刀/刀杆开粗/半精/精16017R0.8-1飞刀/刀杆开粗/半精/精16016R0.8飞刀/刀杆开粗/半精/精16013R0.8飞刀/刀杆开粗/半精/精13012R0.8飞刀/刀杆开粗/半精/精13010R0.8飞刀/刀杆开粗/半精/精13025R0白钢刀开粗/半精/精100-160(总长)20R0白钢刀开粗/半精/精100-14018R0白钢刀开粗/半精/精100-15016R0白钢刀开粗/半精/精10012R0钨钢刀开粗/半精/精10010R0钨钢刀开粗/半精/精1008R0钨钢刀开粗/半精/精1006R0钨钢刀开粗/半精/精505R0钨钢刀开粗/半精/精504R0钨钢刀开粗/半精/精403R0钨钢刀开粗/半精/精302.5R0钨钢刀开粗/半精/精302R0钨钢刀开粗/半精/精201R0钨钢刀开粗/半精/精100.5R0钨钢刀开粗/半精/精1020R10球头刀/刀杆开粗/半精/精20016R8球头刀/刀杆开粗/半精/精20012R6钨钢刀/刀杆开粗/半精/精10010R5钨钢刀/刀杆开粗/半精/精1008R4钨钢刀/刀杆开粗/半精/精1006R3钨钢刀开粗/半精/精505R2.5钨钢刀开粗/半精/精504R2钨钢刀开粗/半精/精403R1.5钨钢刀开粗/半精/精302R1钨钢刀开粗/半精/精201R0.5钨钢刀开粗/半精/精10总长度强力立铣刀夹头-1刀头长度70强力立铣刀夹头-2刀头长度70直柄ER加长小刀杆-1总长度200直柄ER加长小刀杆-1总长度200整体加长小刀头-2总长度105整体加长小刀头-3总长度80加工参数表纯属个人常用加工参数表,仅供参考,请根据自己的实际加工情况而定转 速 (S)加工长度最大直径粗半精铣面250-260100010002000150-160100010002000 90100010002000 250-261100010002000150-161100010002000 90100010002000 100-190120012002400100-190150015002200100-190150015002200150-170160016002400 100160016002400 100-1401800180025001002200220095240024006010001000300120012002000300130013002000220170017002000 160-175180018002000 170190019002000 105-12020002000200090-11020002000200085-10021002100200075-902200220020009024002400200070250025002000652600260020006028002800200050-90(刃口)(一刀过)100(一刀过)100 50-70(一刀过)150(一刀过)15050-70(一刀过)200(一刀过)20035-50(一刀过)250(一刀过)25060-65200020002000 50-60220022002200 40-55240024002400 30240024002400 25-30250025002500 20-25260026002600 15280028002800 15280028002800 10350035003500 5400040004000 5400040004000140200020001202100210060-652200220050-602300230040-552400240025-302500250020-252600260020-252700270015280028001035003500540004000最大直径7869加工长度11023加工长度11017加工长度10028加工长度7534实际加工情况而定(S)进 给 (F) 下 刀 量 (精粗半精铣面精粗半精等高/曲面等高/曲面240025002500100025000.5/1.50.5/1240025002500100025000.5/1.50.5/1240025002500100025000.5/1.50.5/1240025002500100025000.5/1.50.5/1240025002500100025000.5/1.50.5/1240025002500100025000.5/1.50.5/1260025002500100025000.5/1.50.5/1270025002500100025000.4/1.50.5/1270025002500100025000.4/1.50.5/1280025002500100025000.4/1.50.5/1280025002500100025000.4/1.50.5/1300025002500100025000.3/1.50.5/1等高/曲面等高/曲面300025002500100025000.2/0.60.4/0.5300025002500100025000.2/0.50.4/0.4300025002500100025000.2/0.40.4/0.3240025002500100025000.40.5250025002500100025000.350.5260025002500100025000.30.25280025002500100025000.250.25280025002500100025000.250.25300025002500100025000.250.25300025002500100025000.250.25300025002500100025000.250.25300025002500100025000.250.25300025002500100025000.250.25320025002500100025000.150.2340025002500100025000.150.2360025002500100025000.10.1(一刀过)100(一刀过)150(一刀过)200(一刀过)25030002500250070025000.150.15 30002500250070025000.150.15 30002500250070025000.150.15 30002500250070025000.150.15 30002500250070025000.150.15 32002000200070020000.150.15 34001800180060018000.10.1 34001800180060018000.10.1 36001500150050015000.050.05 38001500150040015000.030.03 40001500150030015000.010.01等高/曲面等高/曲面26002500250025000.2/0.60.2/0.6 28002500250025000.2/0.60.2/0.6 32002500250025000.2/0.60.2/0.6 33002500250025000.2/0.60.2/0.6 34002500250025000.15/0.50.15/0.5 35002000200020000.15/0.450.15/0.45 36001800180018000.15/0.40.15/0.4 37001500150015000.15/0.350.15/0.35 38001500150015000.1/0.30.1/0.4 39001500150015000.05/0.20.05/0.3 40001500150015000.03/0.10.03/0.2量 (mm)精等高/曲面0.4/0.50.4/0.50.4/0.50.4/0.50.4/0.50.4/0.50.4/0.50.35/0.50.35/0.50.35/0.50.35/0.50.3/0.5等高/曲面0.15/0.150.15/0.150.15/0.150.20.20.20.20.20.20.20.20.20.20.130.120.10.150.150.150.150.150.150.10.10.050.030.01等高/曲面0.15/0.150.15/0.150.15/0.150.15/0.150.13/0.150.12/0.150.10/0.140.08/0.120.05/0.10.03/0.080.01/0.05。

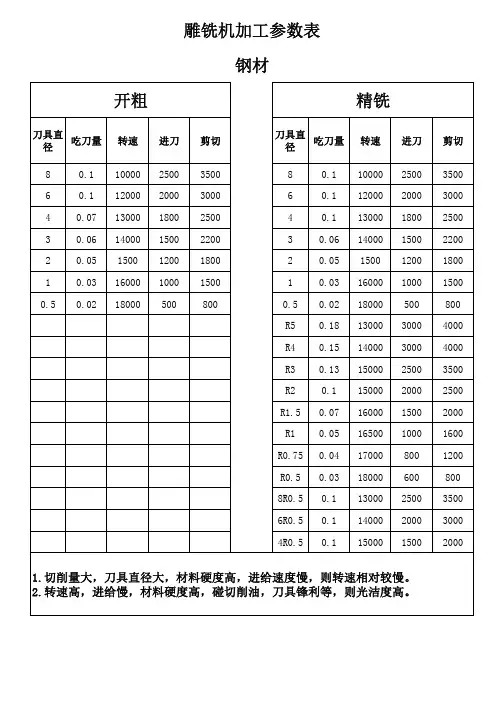

刀具直径吃刀量转速进刀剪切刀具直径吃刀量转速进刀剪切80.1100002500350080.1100002500350060.1120002000300060.1120002000300040.07130001800250040.1130001800250030.06140001500220030.06140001500220020.0515001200180020.0515001200180010.03160001000150010.0316000100015000.50.02180005008000.50.0218000500800R50.181300030004000R40.151400030004000R30.131500025003500R20.11500020002500R1.50.071600015002000R10.051650010001600R0.750.04170008001200R0.50.03180006008008R0.50.113000250035006R0.50.114000200030004R0.50.115000150020001.切削量大,刀具直径大,材料硬度高,进给速度慢,则转速相对较慢。

2.转速高,进给慢,材料硬度高,碰切削油,刀具锋利等,则光洁度高。

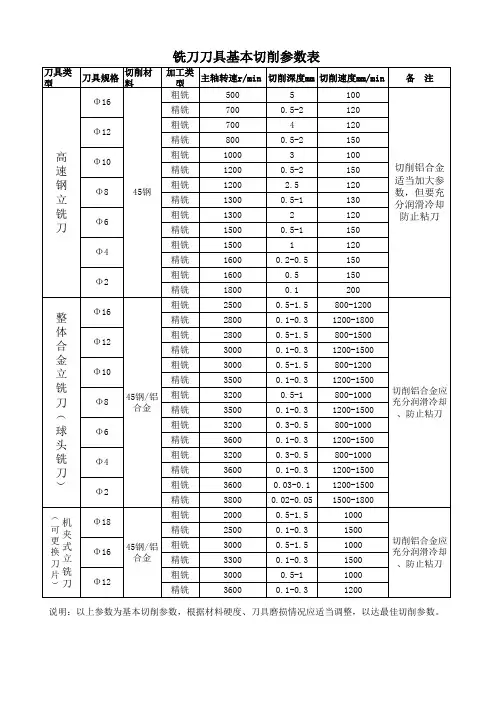

钢材雕铣机加工参数表开粗精铣刀具直径吃刀量转速进刀剪切刀具直径吃刀量转速进刀剪切120.41000035005000120.11000030004000100.351000030004500100.1110003000400080.3100003000450080.1130002500350060..25120003000400060.1140002000300040.2130002200350040.1150001800250030.15150001800250030.08160001500200020.1160001300200020.05170001000150010.05170001000150010.051700080012000.50.02180005008000.50.0218000500800R50.181300030004000R40.151400030004000R30.131500025003500R20.11600020003000R1.50.081700018002500R10.061700015002000R0.750.041800010001500R0.50.03180006008008R0.50.114000200030006R0.50.115000160025004R0.50.116000150020001.切削量大,刀具直径大,材料硬度高,进给速度慢,则转速相对较慢。

各种刀的参数飞刀参数刀具类型加工深度普通长度转速S切削速度F吃刀量ZD100R1.62002505001000 0.2-0.5 D80R1.6 200250500 1000 0.2-0.5 D63R8 180100500-700 1500-1800 0.5-1.5D63R6 140140500-700 1500-1800 0.5-1.5D63R2 300300500-700 1200-1800 0.5-1.5D50R880100500-7001200-1500 0.5-1.5D32R5 1202501200-1500 1000-1500 0.5-1.5D32R2 1002001200-1500 1200-1500 0.5-1D40R0.8 1502501200-1500 1200-1500 0.2-0.5D35R0.8 3003501200-1500 1200-1500 0.2-.5D32R0.8 100-150 2301200-1500 1200-15000.2-0.5D25R4802001000-1500 1000-2000 0.3-0.5D20R0.4 80-120 1501300 15000.3-0.5D16R0.4 60-100 1501200-1500 1000-2000 0.2-0.5D30R15100-160 2301200-1500 1000-1500 0.3-0.6D20R10 80-120 1601000-1200 1000-1500D16R880-120 1601200-1500 1000-1500 0.3-0.5D12R6601001000-15000.-0.5D10R560100>1500100-15000.2-0.5合金刀刀具类型加工深度普通长度普通加长转速S切削速度F 吃刀量125025/7526/100 1800500-1500 0.05-0.5 105022/7025/100 2000 500-1500 0.05-0.5 84519/6015/100 2500 500-1500 0.05-0.5 63013/5015/100 3000500-1500 0.05-0.4 43011/503500 500-1500 0.05-0.3 2258/504000 500-1500 0.05-0.3 1206/50500-1500 0.05-0.15 R67522/7522/100 2000 1000-2000 0.2-17518/7018/00 2000 1000-2000 0.2-1R47514/6014/1002000 1000-2000 0.2-1R37512/5012/100 2500800-1500 0.2-0.8R2.53010/503000 800-1500 0.15-0.6 R2258/50300800-1500 0.15-0.6 R1.5258/503500 800-1500 0.15-0.6R1255/504000 500-800 0.1-0.2 R0.5 252.5/505000500-8000.025白钢刀刀具类型加工深度普通长度普通加长转速S切削速度F3280-120 60/125 106/186 300-400 500-1000 0.1-12580-12090/166 300-400 500-1000 0.1-12012050/110 75/141 500-700 500-10000.1-11612040/9565/123 500-800 500-1000 0.1-11210030/8053/110 500-1000 500-1000 0.1-1108023/7545/95 800-1000500-1000 0.1-0.8 85020/6528/82 800-1200 500-1000 0.1-0.5 65015/60800-1200 500-1000 0.1-0.5 R88032/9235/140 800-1000500-1000 0.2-0.4 R68026/8326/120 800-1000 500-1000 0.2-0.4 R56020/7220/110 800-1000 500-1100 0.2-0.4 R45019/6320/1001000-1500 500-1000 0.2-0.4R33013/5715/90 1000-1500 500-1000 0.2-0.4注:以P20钢材为中间参考值,切削速度取中间值,硬度于P20调低,硬度低于P20调高。