Z155DIII3HD三轴云台用户手册v1.0_cn

- 格式:pdf

- 大小:4.37 MB

- 文档页数:28

目录第1章HD3400L 文本显示器硬件概述 (1)1.1基本描述 (1)1.2产品规格 (1)1.3产品结构及定义 (2)1.4外型尺寸及安装方法 (4)1.5键盘功能列表 (4)第2章HD3000组态软件使用介绍 (6)2.1HD3000画面组态软件基本概述 (6)2.1.1. HD3000 软件的运行要求 (6)2.1.2. 工程文件和人机交互画面 (6)2.1.3. 工程画面内容 (6)2.1.4. HD3000 软件的操作步骤 (6)2.2组态用户监控画面 (6)2.2.1. 组态软件界面说明 (7)2.3菜单“文件” (8)2.3.1. 新建工程 (8)2.3.2. 打开工程 (10)2.3.3. 保存工程 (11)2.3.4. 关闭工程 (11)2.3.5. 工程另存为 (12)2.3.6. 退出 (12)2.4菜单“编辑” (12)2.4.1. 新建画面 (12)2.4.2. 复制画面 (13)2.4.3. 删除画面 (13)2.4.4. 元件复制 (13)2.4.5. 元件粘贴 (13)2.5菜单“工具” (14)2.5.1. 用户设备配置 (14)2.5.2. 系统设置 (14)2.5.3. 报警信息设置与查询 (16)2.5.4. 字动态文本的文本库编辑 (18)2.5.5. 动态图片的图片库编辑 (19)2.5.6. 下载设置 (19)2.5.7. 下载 (19)2.6菜单“元件” (20)2.6.1. 文本 (21)2.6.2. 位动态文本 (22)第3章HD3400L与不同的串口设备的连接方法 (40)3.1和利时 LM 系列 PLC (40)3.2西门子 S7-200 系列 PLC (41)3.3OMRON 全系列 PLC (41)3.4三菱 FX 系列 PLC (43)3.5松下 FP 系列 PLC (44)3.6永宏 FB 系列 PLC (45)3.7光洋 S 系列 PLC (46)3.8施耐德(莫迪康)NEZA/TWIDO 系列 PLC (46)3.9LG Master-K 系列 PLC (48)3.10富士 SPB 系列 PLC (49)3.11台达 DVP 系列 PLC (50)3.12VIGOR 系列 PLC (51)3.13AB Micrologix 系列 PLC (52)3.14GE-FANUC VersaMax 、90-30 系列 PLC (53)3.15Emerson-EC20 系列 PLC (54)3.16DANFOSS 变频器 (55)3.17MODBUS 协议通讯说明 (56)3.18多台串口设备的连接方式 (57)第4章HD3400L操作使用方法 (59)4.1文本显示器和所连串口设备的联机通讯 (59)4.2画面切换 (59)4.3数据输入 (59)4.4状态监控 (60)4.5多状态设定使用说明 (60)第5章HD3400L常见问题解答 (62)5.1上电开机无显示、黑屏 (62)5.2电源灯亮,LCD 屏亮但无显示 (62)5.3不能下载工程文件 (62)5.4为何不能进行数据输入 (62)5.5密码设定无效 (62)5.6如何实现功能键作用 (62)5.7X-Y 曲线图属性如何设置 (62)5.8怎样依次循环查看画面 (62)5.9通讯正常,但有时通讯指示“TxD”灯为何不亮 (62)5.10通讯灯指示慢闪,LCD 屏显示“COM ERR!” (63)5.11与 OMRON PLC 通讯注意事项 (63)第1章 HD3400L 文本显示器硬件概述1.1基本描述HD3400L文本显示器是连接可编程序控制器(PLC)或具有串口通讯能力电气设备的小型人机界面 (HMI) 产品,它能以文字、数据、指示灯、图形、图片等基本元素来完成所连接串口设备的数据显示、状态显示、数据输入等功能,从而使设备的操作人员能够实时监控设备的运行情况。

第一部分概述1.1系统概述非常感谢您使用本公司的点胶控制系统!本系统可以配合多种类型的点胶设备使用,满足您对加工的不同要求。

先进的DSP控制技术,使系统速度更快,同时系统具有友好的人机操作界面,有效的提高了生产效率;控制系统采用平滑曲线调速,使机械运行更平稳,降低整机的噪音,延长机械的使用寿命!在使用之前,请您仔细阅读使用说明书,以确保正确使用本系统。

请妥善保存说明书,以便随时查阅。

因配置不同,有些机器不具备本书所列的部分功能,详情以相应的操作功能为准。

1.2注意事项请不要由非专业人员对电气系统进行维修和调试,这将会降低设备的安全性能,扩大故障,甚至造成人员的伤害和财产损失。

请不要在控制箱周围堆放杂物,并在使用过程中,定期清除控制箱表面和过滤网的灰尘,以保持系统的良好通风,利于散热。

未经授权,请勿擅自改动产品,由此而引起的后果本公司不负任何责任!警告确有必要需打开机箱盖板时,必须在切断电源5分钟后并在专业人员指导下,才允许接触电控箱内的部件!禁止机器在工作时,禁止接触任何运动部件或打开控制设备,否则可能造成人员伤害或导致机器不能正常工作!禁止电器设备在潮湿、粉尘、腐蚀性气体、易燃易爆气体场所工作,否则可能造成触电或火灾!1.3 工作环境通风良好,环境卫生,尘埃少;储存空间温度:0-50°;工作空间温度:5-40°;工作空间相对湿度:30%-90%无结露。

1.4 系统供电及接地1.4-1供电要求本电控系统使用DC24V直流电源供电根据机器配置不同,消耗功率在0.1-0.2KW之间。

1.4-2接地要求为了防止电器设备因漏电、过压、绝缘等原因造成的触电或火灾事故,请您将电控可靠接地。

接地电阻要小于100欧姆,导线长度在20米以内,导线横截面积大于1.0平方毫米。

第二部分系统说明与应用2.1接口及按键说明:(图1)(图2)2.2系统简介硬件接口简介本系统可直接提供,四个轴接口X、Y、Z、U,四个轴各有对应的零位到位信号,其中X、Y轴还分别提供两个硬件限位信号(上限位、下限位)。

三轴运动控制器操作手册目录一与外部驱动器及IO(输入输出)接线图 (4)二用户管理操作 (5)三系统参数设置 (6)四IO(输入输出)设置 (8)五系统自检操作 (10)六手动操作 (12)七编程操作 (14)八自动执行 (16)九指令详解 (18)十电子齿轮计算及公式 (20)十一编程案例 (23)十二常见问题及处理 (28)一与外部驱动器及IO(输入输出)接线图1.控制器与步进驱动器或伺服驱动器的连接(红色线为1号线)2.IO(外接开关及继电器)的接线图(红色线为1号线)注:因输入采用低电平有效,若选用光电开关,则需要选择NPN型。

二用户管理操作注意:所有重要参数只有用户登录以后才可修改保存。

防止他人随意更改参数,影响加工质量。

从主画面进入参数设置,并进入用户管理,进行密码输入。

输入用户密码,按确认键,若输入正确,则提示“用户登陆成功”,否则提示“密码错误,请重新输入”。

用户密码出厂值为“123456”。

用户登录成功后,则可进行加工参数的修改保存。

否则加工参数不可修改保存。

然后直接按退出按键,对系统参数及IO设置进行编辑,编辑完成,再次进入用户管理,并选择用户退出,按确认键,当前参数设置里的内容全部不可更改。

若需要修改,再次进入用户管理进行登录。

注:用户密码可以修改。

但是必须要记忆下新设的密码,否则加工参数将不可修改保存。

三系统参数设置从主界面的参数设置里进入系统参数,通过移动光标,对光标所在位置进行数据修改。

共分5屏,按“上页”“下页”键切换。

控制参数修改完毕可进入速度参数界面进行速度的参数修改,共3屏,修改方式同上。

修改完成后,按参数保存进入参数保存界面,按确认键对当前修改完成的数据进行保存。

若保存成功则提示“参数保存成功”。

注:加工过程中禁止进行参数保存。

按空格键,可将当前参数值清零。

当设定的速度值小于启动速度时,则速度值为启动速度。

当启动速度值设为0时,默认为控制器的最小极限速度。

四IO(输入输出)设置从主界面的参数设置里进入IO设置,对外部输入及输出进行定义,共5屏。

HD Network Mini PT Dome CameraUser’s ManualVersion 1.0.0WelcomeThank you for purchasing our Network camera!This user’s manual is designed to be a reference tool for your system.Please read the following safeguard and warnings carefully before you use this series product! Please keep this user’s manual well for future reference!Important Safeguards and Warnings1.Electrical safetyAll installation and operation here should conform to your local electrical safety codes.The power shall conform to the requirement in the SELV (Safety Extra Low Voltage) and the Limited power source is rated 12V DC or 24V AC in the IEC60950-1. (Refer to general introduction)Please note: Do not connect two power supplying sources to the device at the same time; it may result in device damage! The product must be grounded to reduce the risk of electronic shock. We assume no liability or responsibility for all the fires or electrical shock caused by improper handling or installation.We are not liable for any problems caused by unauthorized modification or attempted repair.2.Transportation securityHeavy stress, violent vibration or water splash are not allowed during transportation, storage and installation.3.InstallationDo not apply power to the camera before completing installation.Please install the proper power cut-off device during the installation connection.Always follow the instruction guide the manufacturer recommended.4.Qualified engineers neededAll the examination and repair work should be done by the qualified service engineers.We are not liable for any problems caused by unauthorized modifications or attempted repair.5.EnvironmentThis series network camera should be installed in a cool, dry place away from direct sunlight, inflammable, explosive substances and etc.Please keep it away from the electromagnetic radiation object and environment.Please make sure the CCD (CMOS) component is out of the radiation of the laser beam device. Otherwise it may result in CCD (CMOS) optical component damage.Please keep the sound ventilation.Do not allow the water and other liquid falling into the camera.Thunder-proof device is recommended to be adopted to better prevent thunder.The grounding studs of the product are recommended to be grounded to further enhance the reliability of the camera.6. Daily MaintenancePlease shut down the device and then unplug the power cable before you begin daily maintenance work.Do not touch the CCD (CMOS) optic component. You can use the blower to clean the dust on the lens surface.Always use the dry soft cloth to clean the device. If there is too much dust, please use the water to dilute the mild detergent first and then use it to clean the device. Finally use the dry cloth to clean the device.Please put the dustproof cap to protect the CCD (CMOS) component when you do not use the camera. Dome enclosure is the optical component, do not touch the enclosure when you are installing the device or clean the enclosure when you are doing maintenance work. Please use professional optical clean method to clean the enclosure. Improper enclosure clean method (such as use cloth) may result in poor IR effect of camera with IR function.7. AccessoriesBe sure to use all the accessories recommended by manufacturer.Before installation, please open the package and check all the components are included.Contact your local retailer ASAP if something is broken in your package.Table of Contents1General Introduction (1)1.1Overview (1)1.2Features (1)1.3Specifications (2)2Structure (4)2.1Components (4)2.2Framework and Dimension (4)3Device Installation (6)3.1Installation Steps (6)3.2Restore Factory Default Setup Introduction (8)4Quick Configuration Tool (9)4.1Overview (9)4.2Operation (9)5Web Operation (11)5.1Network Connection (11)5.2Login and Main Interface (11)6FAQ (13)Appendix Toxic or Hazardous Materials or Elements (14)1General Introduction1.1OverviewThis series network camera integrates the traditional camera and network video technology. It adopts video data collection, transmission together. It can connect to the network directly without any auxiliary device.This series network camera uses standard H.264 video compression technology, which maximally guarantees the video quality.It supports the IR night vision function. In the night environments, the device can use the IR light to highlight the object which is suitable for the surveillance function in the low illumination environments. The waterproof design conforms to the IP 66 level. It has the sound waterproof function suitable for use in the outdoor environments.It can be used alone or used in a network area. When it is used lonely, you can connect it to the network and then use a network client-end. Due to its multiple functions and various uses, this series network camera is widely used in many environments such office, bank, road monitor and etc.1.2Features1.3SpecificationsPlease refer to the following sheet for network camera performance specification.2 Structure2.1 ComponentsYou can refer to the following figure for structure components information. See Figure 2-1.Figure 2-1Sheet 2-1Sheet 2-22.2 Framework and DimensionPlease refer to the following two figures for dimension information. The unit is mm. See Figure 2-2 and Figure 2-3.Figure 2-2 Dimension illustration 1Figure 2-3 Dimension illustration 23Device Installation3.1Installation StepsImportantBefore the installation, please make sure the installation environments can at least support 3x weight of the camera.Figure 3-1Please follow the steps listed below to install the device. Please refer to Figure 3-1 for reference. Step 1Please take the installation position map in the accessories bag, and then paste it on the ceiling or the wall according to your monitor area requirements. Draw and then dig three plastic expansion bolts holes in the installation surface and then insert three expansion bolts in the holes. Secure these three bolts firmly. Please draw the cable out from the cable exit when you install the device.Step 2Adjust the device installation pedestal to the proper position and then line up the three screw holes in the device pedestal to the three plastic expansion bolt holes in the installation position. Put the three self-tapping screws in the three plastic expansion bolts and lock them firmly.Step 3Aim the three slots on the dome body to the three corresponding snaps on the installation pedestal and then push up slowly until you hear a clear sound “KA”.Step4Screw the three M2.5*7 hexagon socket head stainless screws (in figure 2-1) into the corresponding threaded holes of the dome body to tighten the installation pedestal and prevent falling.Note: The device supports bottom cable exit and side cable exit; refer to the following figure for side cable exit.Figure 3-2Please earth the GND port of the device to enhance the device reliability. The GND port is near the cable exit port on the rear of the dome. The GND screw uses the M2X5 pan screw. See Figure 3-3 for more information.Figure 3-3NoteThis series product supports two cable exits. One is from the bottom and the other is from the side. Please refer to the following figure for cable exit from the side information.3.2Restore Factory Default Setup IntroductionImportantPlease use RESET button when device is running.Step1Take down the dome from the installation pedestal.Step2Unscrew two screws.Step3Long press the RESET button to complete the reset function. See Figure 3-4.Figure 3-44 Quick Configuration Tool4.1 OverviewQuick configuration tool can search current IP address, modify IP address. At the same time, you can use it to upgrade the device.Please note the tool only applies to the IP addresses in the same segment.4.2 OperationDouble click the “ConfigTools.exe” icon, you can see an interface is shown as in Figure 4-1.In the device list interface, you can view device IP address, port number, subnet mask, default gateway, MAC address and etc.Figure 4-1 Search interfaceSelect one IP address and then right click mouse, you can see an interface is shown as in Figure 4-2. Select the “Open Device Web” item; you can go to the corresponding web login interface.Figure 4-2 Search interface 2If you want to modify the device IP address without logging in the device web interface, you can go to the configuration tool main interface to set.In the configuration tool search interface (Figure 4-1), please select a device IP address and then double click it to open the login interface. Or you can select an IP address and then click the Login button to go to the login interface. See Figure 4-3.In Figure 4-3, you can view device IP address, user name, password and port. Please modify the corresponding information to login.Please note the port information here shall be identical with the port value you set in TCP port in Web Network interface. Otherwise, you cannot login the device.If you are using device background upgrade port 3800 to login, other setups are all invalid.Figure 4-3 Login promptAfter you logged in, the configuration tool main interface is shown as below. See Figure 4-4.Figure 4-4 Main interfaceFor detailed information and operation instruction of the quick configuration tool, please refer to the Quick Configuration Tool User’s Manual included in the resources CD.5 Web OperationThis series network camera products support the Web access and management via PC.Web includes several modules: Monitor channel preview, system configuration, alarm and etc.5.1 Network ConnectionPlease follow the steps listed below for network connection.●Make sure the network camera has connected to the network properly.●Please set the IP address, subnet mask and gateway of the PC and the network camerarespectively. Network camera default IP address is 192.168.1.108. Subnet mask is 255.255.255.0.Gateway is 192.168.1.1●Use order ping ***.***.***.***(* network camera address) to check connection is OK or not.5.2 Login and Main InterfaceOpen IE and input network camera address in the address bar. See Figure 5- 1.Figure 5- 1 IP addressThe login interface is shown as below. See Figure 5- 2.Please input your user name and password.Default factory name is admin and password is admin.Note: For security reasons, please modify your password after you first login.Figure 5- 2 Web loginAfter you successfully logged in, please install WEB plug-in unit. Please refer to the Web Operation Manual included in the resource CD for detailed operation instruction.See Figure 5- 3.Figure 5- 3 Web monitoring window6FAQAppendix Toxic or Hazardous Materials or ElementsO: Indicates that the concentration of the hazardous substance in all homogeneous materials in the parts is below the relevant threshold of the SJ/T11363-2006 standard.X: Indicates that the concentration of the hazardous substance of at least one of all homogeneous materials in the parts is above the relevant threshold of the SJ/T11363-2006 standard. During the environmental-friendly use period (EFUP) period, the toxic or hazardous substance or elements contained in products will not leak or mutate so that the use of these (substances or elements) will not result in any severe environmental pollution, any bodily injury or damage to any assets. The consumer is not authorized to process such kind of substances or elements, please return to the corresponding local authorities to process according to your local government statutes.Note●This user’s manual is for reference only. Slight difference may be found in user interface.●All the designs and software here are subject to change without prior written notice.●All trademarks and registered trademarks mentioned are the properties of their respectiveowners.●If there is any uncertainty or controversy, please refer to the final explanation of us.●Please visit our website for more information.。

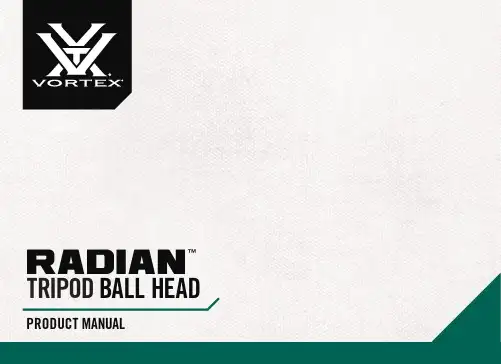

Radian TRIPOD BALL HEAD23Attaching/Removing the Radian ™ Ball HeadTo mount the ball head to the tripod:1. Lift the Quick-Release Locking Latch on the tripod.2. Press and hold the Platform Release Button andfully seat ball head into the tripod. Once seated, the ball head can be oriented in any direction. 3. Rotate the Quick-Release Locking Latch down tothe locked position.4. To remove the ball head, follow these steps inreverse order.NOTE: If needed, the locking latch can be repositioned by shifting the latch to the left and rotating the latch up/down to reposition.Quick-Release PlateQuick-ReleaseBubble LevelDrag Tension KnobPress the Quick-Release Button on the tripod to seat the ball head.Quick-Release Locking LatchBase Panning KnobCounterweight HookTo help stabilize the tripod in windy conditions, hang a weight from the Counterweight Hook.Radian TRIPOD BALL HEAD45Tilt ActionThe ball head’s tilt can be adjusted by unlocking the ball head. This allows you to position your optic at the desired angle. For extreme angle, or full vertical orientation, rotate the head into one of the two cutaways.• To unlock the ball head, rotate the Ball Locking Knob counter-clockwise until the head moves freely. Adjust to your desired position and lock the ball head.• To lock the ball head, rotate the Ball Locking Knob clockwise until you feel tension on the knob.Panning ActionThe Radian ™ Ball Head can be adjusted to allow you to pan across a scene without adjusting the ball head’s angle. This is particularly helpful while glassing wildlife moving across a field, maintaining a flexible shooting position for your mounted rifle.To use the Panning Base Knob:• To unlock the panning base, twist the Panning Base Knob counter-clockwise.• To lock the panning base, twist the Panning Base Knob clockwise. You may also adjust the drag of the panning base by tightening the Panning Base Knob, but not locking it down completely. This will allow you to have more control for smoother panning across a scene.Adjusting Drag TensionThe drag tension can be adjusted on the Radian ™ Ball Head for when the head is in the unlocked position, allowing you to pan and tilt the ball head. This is helpful when viewing fast-paced action scenes. To adjust the drag tension, unlock the ball head by rotating the Ball Locking Knobcounter-clockwise. Turn the Drag Tension Knob clockwise to increase the drag tension, or counter-clockwise to decrease the drag tension.NOTE: Once the drag tension is set, it will stay at this tension no matter how much the Ball Locking Knob is loosened.Rotate the Ball Locking Knob to adjust position or lock in place.Adjust the Drag Tension Knob.Rotate the Panning Base Knob to pan or lock in place.Radian TRIPOD BALL HEAD67Attaching Optics to Ball HeadThe Radian ™ Ball Head uses Arca-Swiss style quick-release plates. To mount your optic to the tripod:1. Twist the Quick-Release Locking Knob counter-clockwise to remove the Quick-Release Plate.2. Attach the plate to your optic. Be sure to tighten the Mount Bolt from the bottom side of theplate and flip the D-ring so it lies flat.3. Place the Quick-Release Plate back into the tripod head and turn the Quick-Release LockingKnob clockwise to securely lock the plate in the head. NOTE: To mount binoculars to the tripod, a binocular adapter is required. Purchase Vortex ® binocular adapters from your local dealers.NOTE: Some optics are designed to be Arca-Swiss compatible and can be mounted to the tripod head without the need for plates.TIP: Purchase additional quick-release plates for your optics so it is easy for you to switch equipment.Quick-Release Plate and Mount BoltQuick-Release Locking KnobVIP WARRANTYOUR UNCONDITIONAL PROMISE TO YOU.We promise to repair or replace the product. Absolutely free.Unlimited UnconditionalLifetime Warranty************************•800-426-0048Note: The VIP Warranty does not cover loss, theft, deliberate damage, or cosmetic damagenot affecting product performance.For additional information, and the most up-to-dateproduct manuals, visit 。

云终端X3————用户手册重要声明首先感谢您使用本公司的云终端设备。

为了让您能够轻松自由地使用本设备,在您开机使用之前,请仔细阅读我们随机提供的说明书,以便您能正确使用本机。

由于产品版本升级或其它原因,本文档内容会不定期进行更新。

除非另有约定,本文档仅作为使用指导,本文档中的所有陈述、信息和建议不构成任何明示或暗示的担保。

本说明书中的资讯资料如有变更,恕不另行通知,且不承担此手册产生的错误或者疏漏引起的任何责任。

注意事项●为保证使用安全,请用本产品专用电源适配器。

●在开机状态,切勿直接拔掉电源,避免突然断电损坏盒子。

●产品使用过程中请勿随意移动设备。

●请勿将产品放在高温、低温环境中,尽量保持工作环境的散热通风、防潮防水。

●请勿投掷、敲击或摇晃机盒,非专业人员的不得擅自拆卸机盒,不当操作可能会导致装置损毁。

●请勿使用刺激性的化学制品、清洁剂或腐蚀性的清洁剂来清洁机体。

关于云终端X3更多资讯欢迎访问华科官网/目录1 部件描述 ........................................................................... 错误!未定义书签。

2 连接 (5)2.1 连接显示器 (5)2.2 连接网线 (5)2.3 连接鼠标和键盘 (6)2.4 连接耳机和麦克风 (6)2.5 连接电源 (6)3 操作指南 (7)3.1 远程连接设置 ...................................................... 错误!未定义书签。

3.1.1 查找主机 (6)3.1.2 配置与快捷方式 (6)3.1.3关机与本机IP (7)3.2 控制面板 (7)3.2.1 网络 (7)3.2.2 显示与声音 (7)3.2.3 外设与启动................................................... 错误!未定义书签。

目录1.导言 (3)2.快速浏览 (4)2.1概要 (4)2.2安装部件 (4)2.3基本内容 (4)3.安装和初始设置 (6)3.1初始安装和接线 (6)3.2主机通讯设置 (7)3.3通讯测试 (8)3.4照相机和其它有效载荷的安装 (8)4.控制指令详解 (10)4.1控制指令格式对照表 (10)4.1.1各个指令的使用范围 (13)4.2 位置控制指令和查询 (14)4.2.1相对位置设置(位置偏移) (14)4.2.2 绝对位置设置和查询 (14)4.2.3查询并设置位置界限 (15)4.2.4 X,Y轴运行控制 (16)4.3 速度控制指令和查询 (17)4.3.1 速度控制和相关术语 (17)4.3.2 速度设置和查询 (18)4.4云台预置点编辑命令 (19)4.4.1 预置点设置 (19)4.4.2 预置点的查询 (20)4.5云台巡航控制指令 (21)4.5.1巡航和直达预置点 (21)4.5.2巡航状态控制 (21)4.5.3查询巡航状态预置点 (22)4.5.4巡航点停留时间控制 (22)4.6系统指令 (23)4.6.1复位控制指令 (23)4.6.2 ID和波特率设制指令 (23)4.6.3其它指令 (24)5 .网络 (25)5.1 基本网络设置步骤 (25)5.2 云台网络接线 (25)5.3网络软件指令 (26)5.3.1 设置云台控制器ID地址 (27)6注意事项 (27)7 云台SDK使用说明 (28)7.1许可协议 (28)17.2 SDK功能简介 (28)7.3 SDK文件概述 (29)7.4系统调用方法 (29)7.4.1系统函数 (29)7.4.2用于云台控制的函数 (30)7.4.3 用于串口控制的函数 (31)7.4.4 用于指令控制的函数 (32)7.5调用过程 (33)7.5.1 GCC (34)7.5.2 Microsoft Visual C++ 6.0 (35)7.6常见问题 (35)7.7实例演示 (35)7.7.1测试工程实例和步骤 (35)7.7.2测试SDK的指令功能 (47)8.常见问题及解决方法 (49)9.保修 (50)21.导言本文所述的高精度数字云台采用计算机串口通讯方式,可以为照相机或其它有效载荷提供低成本,快而准的位置控制。

云台使用说明书本文档描述了DVR里的一个主要功能——云台控制的设置。

主要功能包括:控制云台方向、速度、变倍、聚焦、光圈,预置点、点间巡航、轨迹巡视、边界扫描、旋转、云台复位等通过下列途径找到该设功能设置的界面:直接在预览界面上点击鼠标右键,找到【云台控制】,界面如图1所示:图1前提条件1.操控前,请确认球机的A、B线与硬盘录像机的A、B接口连接正确,连接线上有注明A线和B线,用户进行连接时要先查看线的接口2.云台支持的功能项,由云台协议支持的功能项决定,即由用户所购买的球机的功能决定。

3.操控前,请先右键【主菜单】>左键【摄像机】>选择【云台设置】,设置云台参数,云台设置的界面如下图2(里面的参数是默认值)图2“云台参数”在刚打开球机的时候,预览界面上有显示,显示界面如下图3:图3在云台设置,上图2中首先选择“通道号”,接着设置步骤如下:图2中云台协议对应图3中控制协议,在云台协议的下拉框中选择协议:PELCO_D1图2中云台地址对应图3中的球机地址,在云台地址的文本框中输入球机地址:0图2中的【波特率】、【数据位】、【停止位】、【校验】分别对应图3中的9600、、8、1,N(意思是无),在图2云台设置界面中填写对应下拉框,选择对应的参数。

设置好后按【保存】,对应参数的界面如图4:图4上图4表示已经设置好通道1的云台参数,退出设置界面,右键云台控制就可以控制第一通道的云台了注:1)云台控制的通道须连接云台视频2)球机的A、B线与硬盘录像机的A、B接口连接正确功能细化右键云台控制,进入云台控制界面,如下图5:图5常规选项【控制云台方向】鼠标操控云台转动,支持8个方向控制(前面板只支持4个方向操控),用户直接用鼠标点击界面上云台的方向键,球就会根据用户的点击而转动;用户按住鼠标左键不放,球机会一直转动注意:球机有上下左右的最大限度,不能一直向一个方向转动,出现点击向上云台不会动,点击往下方向查看,排除由于限度原因导致云台不动【变倍】通过/键调节摄像头放大倍数;【聚焦】通过/键调节摄像头进行聚焦;【光圈】通过/键调节摄像头光圈;【进度条】用于设置云台转动的幅度(转动的快慢),数字越大,幅度越大,速度越快,设置范围:0~~15预置点设定某方位为预置点,调用该预置点值,云台自动转动到设定方位。

云智控3.0使用手册快速上手——PC端目录一、登录 (6)1.1 注册系统 (6)1.2 登录系统 (7)二、使用流程 (9)2.1 首页(MoguV) (9)2.1.1 首页概述 (9)2.1.2 MoguV编辑器 (11)2.1.2.1 页面 (11)2.1.2.2 组件 (11)2.2 设备组 (35)2.2.1 设备组列表 (35)2.2.1.1 添加设备组 (35)2.2.1.2 快速配置 (36)2.2.1.3 移动设备组位置 (39)2.2.1.4 删除设备组 (40)2.2.2 基本信息 (40)2.2.3 下属设备 (41)2.2.3.1 编辑下属设备 (41)2.2.3.2 查看设备详情 (42)2.2.4 设备组属性 (42)2.2.4.1 新增设备组属性 (42)2.2.4.2 编辑设备组属性 (43)2.2.4.3 新增自定义属性 (44)2.2.5 实时监测 (44)2.2.5.1 2D实时监测 (44)2.2.5.2 3D实时监测 (46)2.2.5.3 视频监测 (46)2.2.6 边缘智控 (47)2.2.6.1 智控算法 (47)2.2.6.2 智控参数 (54)2.2.6.3 水智控 (57)2.2.7 云端智控 (57)2.2.7.1 智控算法 (57)2.2.7.2 智控参数 (60)2.3 设备 (61)2.3.1 添加设备 (61)2.3.2 删除设备 (62)2.3.3 设备列表 (63)2.3.3.1 设备列表设置 (63)2.3.3.2 导入导出 (63)2.3.4 查看设备详情 (64)2.3.5 远程控制 (68)2.4 统计分析 (68)2.4.1 能源统计 (68)2.4.2 空压站分析 (69)2.4.2.1 效益分析 (69)2.4.2.2 气电分析 (70)2.4.2.3 能效分析 (70)2.4.2.4 浪费分析 (71)2.4.2.5 智控分析 (72)2.4.2.6 智能报告 (72)2.4.3 故障分析 (73)2.4.4 数据查询 (74)2.5 系统管理 (76)2.5.1 用户管理 (76)2.5.1.1 用户账号 (76)2.5.1.2 角色与权限 (77)2.5.1.3 登录日志 (78)2.5.1.4 操作日志 (79)2.5.2 智控管理 (79)2.5.2.1 配置文件同步 (79)2.5.2.2 边缘端控制 (80)2.5.2.3 第三方上位机协议配置 (81)2.5.2.4 智控参数日志 (83)2.5.2.5 边缘智控日志 (83)2.5.2.6 云端智控日志 (84)2.5.3 系统设置 (85)2.5.3.1 能耗单价设置 (85)2.5.3.2 通知设置 (85)2.5.3.3 第三方系统授权 (86)2.5.3.4 费用充值及账单 (87)2.5.3.5 名称与Logo (91)2.6 消息提醒 (92)2.6.1 设备提醒 (92)2.6.2 信息公告 (93)2.7 个人信息 (93)2.8 意见反馈及售后电话 (94)2.9 退出登录 (95)一、登录1.1 注册系统点击【免费注册】,输入手机号码获取验证码,无法收到验证码,点击【查看帮助】获取帮助;点击阅读【云智控使用条约】并勾选同意接受,点击【注册】进入云智控注册页面。

HD-C数控围字机培训说明书第一章设备安装一、设备结构图(1)托料盘(2)机器开关(3)弯弧器(4)接地线(5)接电源线二、设备安装1、接地:设备使用前必须接地(自来水管道、下水道或钢结构上)。

2、清扫:设备使用前必须保证设备内部干净,无铝屑。

设备使用完后必须打扫。

3、随机配件:电源线、控制卡、光盘。

4、将控制卡装入电脑主机内,机器内有两根带插排的线,将其从机器开口处导出,连接在电脑主机控制卡上的两个插口处。

5、电脑主机及显示屏分别接通电源,光盘中是操作软件安装程序,需与供货商联系,由供货商提供序列号给客户完成软件注册。

第二章设备调试出厂设置为设备的基本设置,但由于所用铝型材厚度,硬度及弹性差异,换料时需要对设备的送料长度,弯弧弧度及切割深浅进行重新设置。

操作界面为手动调试操作界面---如图所示:(1)送料:先将型材放在托料盘上,注意要让有折边的面向下,无折边的面向上,然后手动将型材放进进料轨道,接触到送料滚轮,用两个螺丝将型材压好。

退料/进料:在送料选项框里输入相应的数值,点击“退料”/“进料”可退/进相应长度的材料。

连续退料/连续进料/连续快退/连续快进:这4个按钮不需要在送料选项框里输入数值即可实现2个速度(快速、慢速)的送料/退料。

注意:送料主要用于校对设备的进料长度。

参数设置里的“自动计算提前量”和“编码器每毫米脉冲数”是对设备进行长度校正的参数。

方法:第一步:点击“自动计算提前量”出现对话框点击“确定"后,材料会自动进料10次,然后将自动生成的提前量参数值自动保存。

第二部:手动送料500mm或1000mm进行测试(原则上小字用500mm测试,大字用1000mm测试)。

将所测结果按照以下公式修改,并将所得的新脉冲数取代当前脉冲数。

公式:当前编码器每毫米脉冲数×计划走料长度(输入长度)÷实际走料长度举例:当前脉冲数为130.50081,我们以500mm(计划走料长度/输入数值)为测量值,结果设备实际走料499mm(实际走料长度)。

扫描二维码获取电子版产品教程三轴手机稳定器使用说明 V1.0警告&免责声明· 感谢您购买浩瀚iSteady XE。

一旦使用本产品,即视为您已经仔细阅读免责声明与警告,理解、认可和接受本声明全部条款和内容。

您承诺对使用本产品以及可能带来的后果负全部责任。

您承诺仅出于正当目的使用本产品,并且同意本条款以及hohem 浩瀚制定的任何相关条例、政策和指引。

· hohem 浩瀚对于直接或间接使用本产品而造成的损坏、伤害以及任何法律责任不予负责。

用户应遵循包括但不限于本文提及的所有安全指引。

· 本文档及本产品所有相关的文档最终解释权归hohem 浩瀚所有。

如有更新,恕不另行通知。

请访 官方网站以获取最新的产品信息。

电话*************(总机) 400 - 960 - 9206(售后) (周一至周日 9 :00 - 21 :00)邮箱*****************网址制造商深圳市浩瀚卓越科技有限公司地址深圳市南山区西丽路大学城创意园B 栋深圳市浩瀚卓越科技有限公司Hohem Technology Co., Ltd下载全新APP—Hohem Joy体验更多拍摄玩法○ 下载APP 解锁更多功能,注册会员送延保一年权益○ 手机使用 iOS 10.0 及以上系统或 Android 6.0 及以上系统 ○ 请使用浏览器扫描二维码,进入下载页面,或苹果手机前往 App Store,安卓手机前往 “腾讯应用宝” 等各大安卓应用市场,搜索 “Hohem Joy” 下载了解iSteady XE❶ 磁吸补光灯*❷ 手机夹❸ 折叠卡扣A ❹ 折叠卡扣B❺ 模式灯(电量灯)❻ 变焦推杆❷ +号键每单按一次,亮度增加一档❹ 冷/暖光指示灯 C 灯单独亮,表示冷光 W 灯单独亮,表示暖光 C 和W 同时亮,表示自然光❺ 电源指示灯红灯闪烁,表示充电中 红灯常亮,表示充电完成❸-号键每单按一次,亮度降低一档❶M 键(开/关灯键)长按3秒:开启/关闭补光灯单按:切换冷光/暖光/自然光了解XE 磁吸补光灯补光灯支持冷、暖、自然光三色切换,以及十级亮度调节*选配配件,需额外购买❼ 快门键❽ 俯仰电机❾ 臂杆旋钮❿ 航向电机⓫ 蓝牙灯⓬ 四向摇杆*⓭ 功能键⓮ M 键(开/关机键)⓯ Type C 充电口⓰ 底部1/4英寸扩展口⓱ 横滚电机⓲ 手柄(内置电池)⓳ 挂绳孔❹❸❷❺❶如何安装&调平手机?❶ 打开稳定器,伸直臂杆❷ 顺时针旋紧臂杆旋钮❸ 摄像头朝左,卡紧手机夹一侧,拉开手机夹另一侧,推入夹紧手机首次开机使用&蓝牙连接❶ 开机长按M键(开/关机键)3秒开机❷ 进入 Hohem Joy App 连接蓝牙打开手机蓝牙打开 Hohem Joy App,登录进入首页根据提示,点击连接和配对按键有哪些控制操作?❶ M 键(开/关机键)长按3秒:开启/关闭稳定器单按:切换工作模式(首次开机默认PTF 模式,依次切换为PTF-PF-L-POV)双按:稳定器进入休眠模式(单按任意键,可退出休眠)五按:自动校准❷ 摇杆上/下:调整俯仰角度左/右:调整航向角度(APP 内参数设置”摇杆左右控制”中可切换至控制横滚角度)❹ 快门键(确保蓝牙连接成功)单按:拍照/录像双按:切换拍照/录像模式三按:切换前/后置镜头(确保蓝牙已连接,且仅支持Hohem Joy APP,及部分安卓手机)❺ 功能键单按:切换横/竖屏双按:归中三按:180°盗梦空间(自动旋转)七按:进入遥控器*配对模式配对模式中单击功能键:退出遥控器*配对模式双击功能键:清除遥控器*配对信息(清除后原配对遥控器*不可用,需重新配对)长按:查看稳定器电量(*遥控器为选配配件,需额外购买)❸ 变焦推杆(确保蓝牙已连接,且仅支持Hohem Joy APP,及部分安卓手机)上推:画面变大下推:画面缩小❹❺❸❷❶工作模式&拍摄风格有哪些?工作模式稳拍风格(跟随速度)如需切换稳拍风格,请进入Hohem Joy APP—进入拍摄—设置(确保稳定器蓝牙连接成功)PF 航向跟随跟随手柄左/右转动拍摄,俯仰+30°~-30°范围内不跟随,超过该范围跟随俯仰拍摄,横滚锁定不动PTF 俯仰&航向跟随开机默认该模式,当手柄左/右/俯/仰转动拍摄时,镜头将跟随拍摄,横滚锁定L 全锁定俯仰+30°~-30°范围内不跟随,超过该范围跟随俯仰拍摄,横滚和航向锁定不动POV 全跟随第一视角模式航向/俯仰/横滚全域360°跟随拍摄常规速度适中,一般拍摄即可柔顺速度较慢,适合跟随拍摄较慢的移动目标运动速度较快, 跟随拍摄较快的运动目标极速速度极快,适合拍摄极速转场或甩镜头如何收纳折叠稳定器?稳定器不平怎么办?(稳定器校准)3&4当稳定器开机出现水平不平,或静止时航向小角度漂移,此时需要给稳定器进行校准。