HOERBIGER同步器最新技术介绍2013

- 格式:pdf

- 大小:1.36 MB

- 文档页数:30

RT8290®©Copyright 2016 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.Design Tools Sample &BuyGeneral DescriptionThe RT8290 is a high efficiency synchronous step-down DC/DC converter that can deliver up to 3A output current from 4.5V to 23V input supply. The RT8290's current mode architecture and external compensation allow the transient response to be optimized over a wide range of loads and output capacitors. Cycle-by-cycle current limit provides protection against shorted outputs and soft-start eliminates input current surge during start-up. The RT8290 also provides output under voltage protection and thermal shutdown protection. The low current (<3μA) shutdown mode provides output disconnection, enabling easy power management in battery-powered systems. The RT8290is awailable in an SOP-8 (Exposed Pad) package.3A, 23V, 340kHz Synchronous Step-Down ConverterFeatures●4.5V to 23V Input Voltage Range●1.5% High Accuracy Feedback Voltage ●3A Output Current●Integrated N-MOSFET Switches ●Current Mode Control●Fixed Frequency Operation : 340kHz ●Output Adjustable from 0.925V to 20V ●Up to 95% Efficiency●Programmable Soft-Start●Stable with Low-ESR Ceramic Output Capacitors ●Cycle-by-Cycle Over Current Protection ●Input Under Voltage Lockout ●Output Under Voltage Protection ●Thermal Shutdown Protection●Thermally Enhanced SOP-8 (Exposed Pad) Package ●RoHS Compliant and Halogen FreeApplications●Industrial and Commercial Low Power Systems ●Computer Peripherals ●LCD Monitors and TVs●Green Electronics/Appliances●Point of Load Regulation of High-Performance DSPs,FPGAs and ASICs.Ordering InformationNote :Richtek products are :❝ RoHS compliant and compatible with the current require-ments of IPC/JEDEC J-STD-020.❝ Suitable for use in SnPb or Pb-free soldering processes.Pin Configurations(TOP VIEW)SOP-8 (Exposed Pad)SS BOOT VIN GNDSW FBEN COMPTypical Application CircuitOUT V G : Green (Halogen Free and Pb Free)Z : ECO (Ecological Element with Halogen Free and Pb free)RT8290©Copyright 2016 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.RT8290GSP : Product NumberYMDNN : Date CodeFunctional Pin DescriptionRT8290ZSP : Product NumberYMDNN : Date CodeRT8290©Copyright 2016 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.Function Block DiagramAbsolute Maximum Ratings (Note 1)●Supply Voltage, V IN ------------------------------------------------------------------------------------------−0.3V to 25V●Switching Voltage, SW -------------------------------------------------------------------------------------−0.3V to (V IN + 0.3V)●SW (AC) 30ns-------------------------------------------------------------------------------------------------−5V to 30V●BOOT Voltage -------------------------------------------------------------------------------------------------(V SW − 0.3V) to (V SW + 6V)●The Other Pins ------------------------------------------------------------------------------------------------−0.3V to 6V ●Power Dissipation, P D @ T A = 25°CSOP-8 (Exposed Pad)--------------------------------------------------------------------------------------1.333W ●Package Thermal Resistance (Note 2)SOP-8 (Exposed Pad), θJA ---------------------------------------------------------------------------------75°C/W SOP-8 (Exposed Pad), θJC --------------------------------------------------------------------------------15°C/W ●Junction T emperature ----------------------------------------------------------------------------------------150°C ●Lead Temperature (Soldering, 10 sec.)------------------------------------------------------------------260°C●Storage T emperature Range -------------------------------------------------------------------------------−65°C to 150°C ●ESD Susceptibility (Note 3)HBM (Human Body Model)---------------------------------------------------------------------------------2kV MM (Machine Model)----------------------------------------------------------------------------------------200VRecommended Operating Conditions (Note 4)●Supply Voltage, V IN ------------------------------------------------------------------------------------------4.5V to 23V ●Enable Voltage, V EN -----------------------------------------------------------------------------------------0V to 5.5V●Junction T emperature Range -------------------------------------------------------------------------------−40°C to 125°C ●Ambient T emperature Range -------------------------------------------------------------------------------−40°C to 85°CRT8290©Copyright 2016 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.Note 1. Stresses beyond those listed “Absolute Maximum Ratings ” may cause permanent damage to the device. These arestress ratings only, and functional operation of the device at these or any other conditions beyond those indicated in the operational sections of the specifications is not implied. Exposure to absolute maximum rating conditions may affect device reliability.Note 2. θJA is measured at T A = 25°C on a high effective thermal conductivity four-layer test board per JEDEC 51-7. θJC ismeasured at the exposed pad of the package.Note 3. Devices are ESD sensitive. Handling precaution is recommended.Note 4. The device is not guaranteed to function outside its operating conditions.Electrical Characteristics(V = 12V, T = 25°C unless otherwise specified)RT8290©Copyright 2016 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.Typical Operating CharacteristicsReference Voltage vs. Temperature0.9100.9150.9200.9250.9300.9350.940-50-25255075100125Temperature (︒C)R e f e r e n c e V o l t a g e (V)Reference Voltage vs. Input Voltage0.9200.9220.9240.9260.9280.9300.9324681012141618202224Input Voltage (V)R e f e r e n c e V o l t a g e (V )Frequency vs. Temperature300305310315320325330335340345350-50-25255075100125Temperature (︒C)F r e q u e n c y (k H z )Frequency vs. Input Voltage3003053103153203253303353403453504681012141618202224Input Voltage (V)F r e q u e n cy (k H z )Output Voltage vs. Output Current3.3003.3033.3053.3083.3103.3133.3153.3183.32000.511.522.53Output Current (A)O u t p u t V o l t a g e (V)Efficiency vs. Output Current010203040506070809010000.511.522.53Output Current (A)E f f i c i e n c y (%)RT8290©Copyright 2016 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.Current Limit vs. Temperature3.03.54.04.55.05.56.06.57.0-50-25255075100125Temprature ( C)C u r r e n t L i m i t (A)Load Transient ResponseTime (100μs/Div)I OUT (2A/Div)V OUT(200mV/Div)V IN = 12V, V OUT = 3.3V, I OUT = 0A to 3ATime (5ms/Div)Power On from VIN I L (2A/Div)V IN = 12V, V OUT = 3.3V, I OUT = 3AV IN (5V/Div)V OUT (2V/Div)Power Off from VINTime (5ms/Div)I L (2A/Div)V IN (5V/Div)V OUT (2V/Div)V IN = 12V, V OUT = 3.3V, I OUT = 3ASwitching WaveformTime (1μs/Div)V OUT (10mV/Div)V SW (10V/Div)V IN = 12V, V OUT = 3.3V, I OUT = 3AI L (2A/Div)Load Transient ResponseTime (100μs/Div)I OUT (2A/Div)V OUT(200mV/Div)V IN = 12V, V OUT = 3.3V, I OUT = 1.5A to 3ART8290©Copyright 2016 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.Power On from ENTime (10ms/Div)V IN = 12V, V OUT = 3.3V, I OUT = 3AI OUT (2A/Div)V EN (2V/Div)V OUT (2V/Div)Power Off from ENTime (10ms/Div)I OUT (2A/Div)V EN (2V/Div)V OUT (2V/Div)V IN = 12V, V OUT = 3.3V, I OUT = 3ART8290©Copyright 2016 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.Application InformationThe RT8290 is a synchronous high voltage buck converter that can support the input voltage range from 4.5V to 23V and the output current can be up to 3A.Output Voltage SettingThe resistive voltage divider allows the FB pin to sense the output voltage as shown in Figure 1.Figure 1. Output Voltage SettingThe output voltage is set by an external resistive voltage divider according to the following equation :⎛⎫+ ⎪⎝⎭OUT FB R1V = V 1R2where V FB is the feedback reference voltage (0.925V typ.).External Bootstrap DiodeConnect a 10nF low ESR ceramic capacitor between the BOOT pin and SW pin. This capacitor provides the gate driver voltage for the high side MOSFET.It is recommended to add an external bootstrap diode between an external 5V and the BOOT pin for efficiency improvement when input voltage is lower than 5.5V or duty ratio is higher than 65%. The bootstrap diode can be a low cost one such as 1N4148 or BAT54.The external 5V can be a 5V fixed input from system or a 5V output of the RT8290. Note that the external boot voltage must be lower than 5.5V.Figure 2. External Bootstrap DiodeSoft-StartThe RT8290 contains an external soft-start clamp that gradually raises the output voltage. The soft-start timingInductor SelectionThe inductor value and operating frequency determine the ripple current according to a specific input and output voltage. The ripple current ΔI L increases with higher V IN and decreases with higher inductance.OUT OUT L IN V V I =1f L V ⎡⎤⎡⎤∆⨯-⎢⎥⎢⎥⨯⎣⎦⎣⎦Having a lower ripple current reduces not only the ESR losses in the output capacitors but also the output voltage ripple. High frequency with small ripple current can achieve highest efficiency operation. However, it requires a large inductor to achieve this goal.For the ripple current selection, the value of ΔI L = 0.2375(I MAX ) will be a reasonable starting point. The largest ripple current occurs at the highest V IN . To guarantee that the ripple current stays below the specified maximum, the inductor value should be chosen according to the following equation :OUT OUT L(MAX)IN(MAX)V V L =1f I V ⎡⎤⎡⎤⨯-⎢⎥⎢⨯∆⎣⎦⎣⎦Inductor Core SelectionThe inductor type must be selected once the value for L is known. Generally speaking, high efficiency converters can not afford the core loss found in low cost powdered iron cores. So, the more expensive ferrite or mollypermalloy cores will be a better choice.The selected inductance rather than the core size for a fixed inductor value is the key for actual core loss. As the inductance increases, core losses decrease. Unfortunately,increase of the inductance requires more turns of wire and therefore the copper losses will increase.Ferrite designs are preferred at high switching frequency due to the characteristics of very low core losses. So,design goals can focus on the reduction of copper loss and the saturation prevention.can be programmed by the external capacitor between SS pin and GND. The chip provides a 6μA charge current for the external capacitor. If a 0.1μF capacitor is used to set the soft-start, the period will be 15.5ms (typ.).V OUTRT8290©Copyright 2016 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.Ferrite core material saturates “hard ”, which means that inductance collapses abruptly when the peak design current is exceeded. The previous situation results in an abrupt increase in inductor ripple current and consequent output voltage ripple.Do not allow the core to saturate!Different core materials and shapes will change the size/current and price/current relationship of an inductor.T oroid or shielded pot cores in ferrite or permalloy materials are small and do not radiate energy. However, they are usually more expensive than the similar powdered iron inductors. The rule for inductor choice mainly depends on the price vs. size requirement and any radiated field/EMI requirements.C IN and C OUT SelectionThe input capacitance, C IN, is needed to filter the trapezoidal current at the source of the high side MOSFET .To prevent large ripple current, a low ESR input capacitor sized for the maximum RMS current should be used. The RMS current is given by :This formula has a maximum at V IN = 2V OUT , whereI RMS = I OUT /2. This simple worst-case condition is commonly used for design because even significant deviations do not offer much relief.Choose a capacitor rated at a higher temperature than required. Several capacitors may also be paralleled to meet size or height requirements in the design.For the input capacitor, a 10μF x 2 low ESR ceramic capacitor is recommended. For the recommended capacitor, please refer to table 3 for more detail.The selection of C OUT is determined by the required ESR to minimize voltage ripple.Moreover, the amount of bulk capacitance is also a key for C OUT selection to ensure that the control loop is stable.Loop stability can be checked by viewing the load transient response as described in a later section.The output ripple, ΔV OUT, is determined by :RMS OUT(MAX)I = I OUT L OUT 1V I ESR 8fC ⎡⎤∆≤∆+⎢⎥⎣⎦The output ripple will be highest at the maximum input voltage since ΔI L increases with input voltage. Multiplecapacitors placed in parallel may be needed to meet the ESR and RMS current handling requirement. Dry tantalum,special polymer, aluminum electrolytic and ceramic capacitors are all available in surface mount packages.Special polymer capacitors offer very low ESR value.However, it provides lower capacitance density than other types. Although Tantalum capacitors have the highest capacitance density, it is important to only use types that pass the surge test for use in switching power supplies.Aluminum electrolytic capacitors have significantly higher ESR. However, it can be used in cost-sensitive applications for ripple current rating and long term reliability considerations. Ceramic capacitors have excellent low ESR characteristics but can have a high voltage coefficient and audible piezoelectric effects. The high Q of ceramic capacitors with trace inductance can also lead to significant ringing.Higher values, lower cost ceramic capacitors are now becoming available in smaller case sizes. Their high ripple current, high voltage rating and low ESR make them ideal for switching regulator applications. However, care must be taken when these capacitors are used at input and output. When a ceramic capacitor is used at the input and the power is supplied by a wall adapter through long wires, a load step at the output can induce ringing at the input, V IN . At best, this ringing can couple to the output and be mistaken as loop instability. At worst, a sudden inrush of current through the long wires can potentially cause a voltage spike at V IN large enough to damage the part.Checking Transient ResponseThe regulator loop response can be checked by looking at the load transient response. Switching regulators take several cycles to respond to a step in load current. When a load step occurs, V OUT immediately shifts by an amount equal to ΔI LOAD (ESR) and C OUT also begins to be charged or discharged to generate a feedback error signal for the regulator to return V OUT to its steady-state value. During this recovery time, V OUT can be monitored for overshoot or ringing that would indicate a stability problem.RT8290©Copyright 2016 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.Thermal ConsiderationsFor continuous operation, do not exceed the maximum operation junction temperature 125°C. The maximum power dissipation depends on the thermal resistance of IC package, PCB layout, the rate of surroundings airflow and temperature difference between junction to ambient.The maximum power dissipation can be calculated by following formula :P D(MAX) = (T J(MAX) − T A ) / θJAwhere T J(MAX) is the maximum operation junction temperature, T A is the ambient temperature and the θJA is the junction to ambient thermal resistance.For recommended operating conditions specification, the maximum junction temperature is 125°C. The junction to ambient thermal resistance θJA is layout dependent. For SOP-8 (Exposed Pad) package, the thermal resistance θJA is 75°C/W on the standard JEDEC 51-7 four-layers thermal test board. The maximum power dissipation at T A = 25°C can be calculated by following formula :P D(MAX) = (125°C − 25°C) / (75°C/W) = 1.333W for SOP-8 (Exposed Pad) packageThe maximum power dissipation depends on operating ambient temperature for fixed T J(MAX) and thermal resistance θJA . The derating curve in Figure 3 allows the designer to see the effect of rising ambient temperature on the maximum power dissipation.Layout ConsiderationsFollow the PCB layout guidelines for optimal performance of the RT8290.❝Keep the traces of the main current paths as short and wide as possible.❝Put the input capacitor as close as possible to the device pins (VIN and GND).❝SW node is with high frequency voltage swing and should be kept in a small area. Keep sensitive components away from the SW node to prevent stray capacitive noise pick-up.❝Place the feedback components as close to the FB pin and COMP pin as possible.❝The GND pin and Exposed Pad should be connected to a strong ground plane for heat sinking and noise protection.Figure 3. Derating Curve of Maximum Power DissipationInput capacitor must be placed Figure 4. PCB Layout Guide0.00.20.40.60.81.01.21.41.6255075100125Ambient Temperature (°C)M a x i m u m P o w e r D i s s i p a t i o n (W )RT829011DS8290-04 October 2016 ©Copyright 2016 Richtek Technology Corporation. All rights reserved. is a registered trademark of Richtek Technology Corporation.Table 3. Suggested Capacitors for Cand CRT829012DS8290-04 October 2016Richtek Technology Corporation14F, No. 8, Tai Yuen 1st Street, Chupei CityHsinchu, Taiwan, R.O.C.Tel: (8863)5526789Richtek products are sold by description only. Richtek reserves the right to change the circuitry and/or specifications without notice at any time. Customers should obtain the latest relevant information and data sheets before placing orders and should verify that such information is current and complete. Richtek cannot assume responsibility for use of any circuitry other than circuitry entirely embodied in a Richtek product. Information furnished by Richtek is believed to be accurate and reliable. However, no responsibility is assumed by Richtek or its subsidiaries for its use; nor for any infringements of patents or other rights of third parties which may result from its use. No license is granted by implication or otherwise under any patent or patent rights of Richtek or its subsidiaries.Outline DimensionBFHMI(Bottom of Package)8-Lead SOP (Exposed Pad) Plastic Package。

HLP-NV系列变频器是一款高性能矢量型变频器,具有高可靠性和用户友好性,凝聚多种功能,而且调试快捷,体积小巧,安装方便,节省空间。

功率范围:0.18 ~ 2.2kW(单相200-240V),0.25 ~ 3.7kW(三相200-240V),0.37 ~ 22kW(三相380-480V)用户友好面板可热插拔—调试快捷远程安装组件—方便远程控制面板带有电位计或UP、DOWN功能—调速方便全功率范围内使用统一的用户界面—使用更简单F C和MODBUS两种通讯协议—易组成集中控制系统可靠最佳散热设计—使用寿命长防护等级— IP20防护性能高质量的电子元器件和电容器—品质好出厂前经过高温和满负载测试—可靠性高接地故障、过热和短路保护—保护全面带涂层保护的印刷电路板—可靠性高电路板之间全部采用焊接—连接更可靠电机保护功能齐全—安全有保障电子热继电器—替代外部电机保护装置体积小紧凑的笔记本式设计—最少灰尘侵入变频器并排安装—真正节省安装空间性能高独特的VVC+矢量控制—在电动机中产生标准的圆形磁场,没有任何附加的效率损失良好的直流制动功能—可承受频繁的直流制动过载转矩150% 1分钟—无需更大变频器电机自适配—开发全部潜能,保证电机工作状态最佳智能逻辑控制—多数情况下无需PLC功能多带有前馈因数的过程比例积分控制器—无需外部控制器滑差补偿功能—对于冲击性负载,可保证电机的输出转速恒定优异的频率追踪功能—可在极短的时间内捕捉到电机的运行频率并加速到设定值高、低速负载补偿功能—保证电机在不同的负载下平滑、稳定地启动和运行多点V/F曲线控制—最多可设置六点V/F曲线内置制动单元(1.5kW及以上)—节省用户成本HLPB用户友好:⏹具有两个独立的控制菜单,可通过端子或通信方便的切换,且菜单之间可进行参数复制,方便用户在不同场合的应用。

⏹显示界面友好,可以监视电机电流、电机电压、电机频率以及各种输入输出状态,显示各种故障信息。

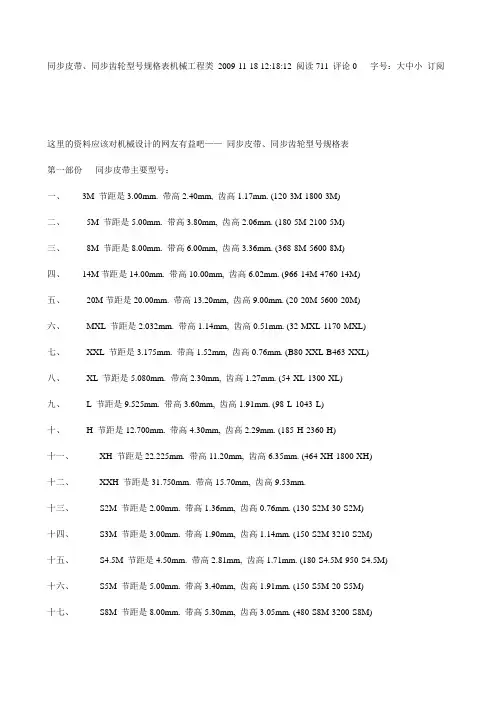

同步皮带、同步齿轮型号规格表机械工程类2009-11-18 12:18:12 阅读711 评论0 字号:大中小订阅这里的资料应该对机械设计的网友有益吧——同步皮带、同步齿轮型号规格表第一部份同步皮带主要型号:一、3M 节距是3.00mm. 带高2.40mm, 齿高1.17mm. (120-3M-1800-3M)二、5M 节距是5.00mm. 带高3.80mm, 齿高2.06mm. (180-5M-2100-5M)三、8M 节距是8.00mm. 带高6.00mm, 齿高3.36mm. (368-8M-5600-8M)四、14M节距是14.00mm. 带高10.00mm, 齿高6.02mm. (966-14M-4760-14M)五、20M节距是20.00mm. 带高13.20mm, 齿高9.00mm. (20-20M-5600-20M)六、MXL 节距是2.032mm. 带高1.14mm, 齿高0.51mm. (32-MXL-1170-MXL)七、XXL 节距是3.175mm. 带高1.52mm, 齿高0.76mm. (B80-XXL-B463-XXL)八、XL 节距是5.080mm. 带高2.30mm, 齿高1.27mm. (54-XL-1300-XL)九、L 节距是9.525mm. 带高3.60mm, 齿高1.91mm. (98-L-1043-L)十、H 节距是12.700mm. 带高4.30mm, 齿高2.29mm. (185-H-2360-H)十一、XH 节距是22.225mm. 带高11.20mm, 齿高6.35mm. (464-XH-1800-XH)十二、XXH 节距是31.750mm. 带高15.70mm, 齿高9.53mm.十三、S2M 节距是2.00mm. 带高1.36mm, 齿高0.76mm. (130-S2M-30-S2M)十四、S3M 节距是3.00mm. 带高1.90mm, 齿高1.14mm. (150-S2M-3210-S2M)十五、S4.5M 节距是4.50mm. 带高2.81mm, 齿高1.71mm. (180-S4.5M-950-S4.5M)十六、S5M 节距是5.00mm. 带高3.40mm, 齿高1.91mm. (150-S5M-20-S5M)十七、S8M 节距是8.00mm. 带高5.30mm, 齿高3.05mm. (480-S8M-3200-S8M)十八、S14M 节距是14.00mm. 带高10.20mm, 齿高5.30mm. (966-S14M-4326-S14M)十九、P3M 节距是3.00mm. 带高1.90mm, 齿高1.15mm. (110-P3M-1569-P3M)二十、P5M 节距是5.00mm. 带高3.50mm, 齿高1.95mm. (225-P5M-2525-P5M)二十一、P8M 节距是8.00mm. 带高5.50mm, 齿高3.20mm. (376-P8M-2800-P8M)二十二、P14M 节距是14.00mm. 带高10.00mm, 齿高.00mm.(966-P14M-4578-P14M)二十三、T2.5 节距是2.50mm. 带高1.30mm, 齿高0.70mm. (145-T2.5-400-T2.5)二十四、T5 节距是5.00mm. 带高2.20mm, 齿高1.20mm. (150-T5-20-T5)二十五、T10 节距是10.00mm. 带高4.50mm, 齿高2.50mm. (340-T10-2800-T10)二十六、T20 节距是20.00mm. 带高8.00mm, 齿高5.00mm. (1240-T20-2760-T20)第二部份同步齿轮主要型号一、AS型(平面式无挡板)二、BS型(有台阶无挡板)三、AF型(平面式有挡板)四、BF型(有台阶有挡板)五、W型(两面凹形无挡板)带及同步带轮的选用同步带传动是一种带齿与带轮齿槽的啮合传动。

K O L L M O R G E N | A K o l l m o r g e n C O M PA N Y欢迎来到科尔摩根官方微信科尔摩根3目录u AKM ™ 同步伺服电机4u AKD ™ 伺服驱动器8u AKM ™ 各种选件12u AKM ™ 防水型和食品级防水型电机13u AKM ™ 系统综述14u AKM ™ 图纸和性能数据AKM1x 16AKM2x 20AKM3x24AKM4x 28AKM5x 34AKM6x 40AKM7x 44AKM8x48u L 10 轴承疲劳寿命和轴负载53u 反馈选件56u 抱闸选件60u 伺服电机连接器选件61u 型号命名67u MOTIONEERING ® Online71科尔摩根A K M 同步伺服电机选型指南克服设计、采购和时间障碍科尔摩根明白:帮助原始设备制造商的工程师克服障碍,可以显著提高其工作成效。

因而,我们主要通过如下三种方式来提供帮助:集成标准和定制产品在很多情况下,理想方案都不是一成不变的。

我们拥有专业应用知识,可以根据全面的产品组合来修改标准产品或开发全定制解决方案,从而为设计奠定良好的基础。

提供运动控制解决方案而不仅仅是部件在各公司减少供应商数量和工程人力的过程中,他们需要一家能够提供多种集成解决方案的全系统供应商。

科尔摩根就采用了全面响应模式,为客户提供全套解决方案,这些方案将编程软件、工程服务以及同类优秀的运动控制部件结合起来。

覆盖全球我们在美洲、欧洲、中东和亚洲拥有众多直销、工程支持单位、生产工厂以及分销商,临近全球各地的原始设备制造商。

这种便利优势可以加速我们的供货过程,根据客户需要随时随地供货。

财务和运营稳定性科尔摩根隶属于Fortive 公司。

Fortive 业务系统是推动Fortive 各部门发展的一个关键力量。

该系统采用“不断改善”(Kaizen )原理。

由高素质人才构成的多学科团队使用世界级的工具对过程进行评估,并制定相关计划以达到卓越的性能。

同步带同步带是以钢丝绳或玻璃纤维为强力层,外覆以聚氨酯或氯丁橡胶的环形带,带的内周制成齿状,使其与齿形带轮啮合。

同步带传动时,传动比准确,对轴作用力小,结构紧凑,耐油,耐磨性好,抗老化性能好,一般使用温度-20℃―80℃,v<50m/s,P<300kw,i<10,对于要求同步的传动也可用于低速传动。

同步带齿有梯形齿和弧齿两类,弧齿又有三种系列:圆弧齿(H系列又称HTD带)、平顶圆弧齿(S系列又称为STPD带)和凹顶抛物线齿(R系列)。

梯形齿同步带梯形齿同步带分单面有齿和双面有齿两种,简称为单面带和双面带。

双面带又按齿的排列方式分为对称齿型(代号DA)和交错齿型(代号DB〕。

梯形齿同步带有两种尺寸制:节距制和模数制。

我国采用节距制,并根据ISO 5296制订了同步带传动相应标准GB/T 11361~11362-1989和GB/T 11616-1989。

弧齿同步带弧齿同步带除了齿形为曲线形外,其结构与梯形齿同步带基本相同,带的节距相当,其齿高、齿根厚和齿根圆角半径等均比梯形齿大。

带齿受载后,应力分布状态较好,平缓了齿根的应力集中,提高了齿的承载能力。

故弧齿同步带比梯形齿同步带传递功率大,且能防止啮合过程中齿的干涉。

弧齿同步带耐磨性能好,工作时噪声小,不需润滑,可用于有粉尘的恶劣环境。

已在食品、汽车、纺织、制药、印刷、造纸等行业得到广泛应用。

方形齿同步带型号节距(mm) 齿高(mm) 带厚(mm) 角度β°MXL 2.032 0.51 1.14 40XL 5.080 1.27 2.30 50L 9.525 1.91 3.60 40H 12.70 2.29 4.30 40XH 22.225 6.35 11.20 40XXH 31.750 9.53 15.70 40T2.5 2.5 0.7 1.30 40T5 5 1.20 2.20 40T10 10 2.50 4.50 40T20 20 5.00 8.00 40AT5 5 1.20 2.70 50AT10 10 2.50 5.00 50AT20 20 5.00 8.00 50圆弧齿同步带(高转矩)齿型代号型号节距(mm) 齿高(mm) 带厚(mm) HTD 2M 2 0.75 1.363M 3 1.17 2.45M 5 2.06 3.88M 8 3.36 6.0014M 14 6.02 10.0020M 20 8.4 13.20半圆弧齿同步带(高转矩)齿型代号型号节距(mm) 齿高(mm) 带厚(mm) STPD/STSS2M 2 0.76 1.36S3M 3 1.14 1.9S4.5M 4.5 1.71 2.81S5M 5 1.91 3.4S8M 8 3.05 5.3S14M 14 5.3 10.2RPP/HPPD2M 2 0.76 1.363M 3 1.15 1.95M 5 1.95 3.58M 8 3.2 5.514M 14 6.00 10万方数据库……《浅谈同步带性能及其在玻璃机械上的设计应用》型号…………周节制同步带轮MXL、XL、L、H、XH、XXH特殊节距制同步带轮T2.5、T5、T1、T2、AT3、AT5A、T10、AT15、AT20圆弧齿同带轮S2M、S3M、S4.5M、S5M、S8M、S14M、S20M、2M、3M、5M、8M14M、20M、2GT、3GT、5GT、8GT、14GT、P5M、P8M、P14M、P20M、8YU/view/961b460b76c66137ee0619e9.html参数/kcms/detail/detail.aspx?dbname=CJFD2009&filename=B LZZ200908006知网同步带的参数及性能买家的参数/ArticleShow.asp?ArticleID=106同步带的种类/ArticleShow.asp?ArticleID=105一些参数/ArticleShow.asp?ArticleID=104/ArticleShow.asp?ArticleID=103/ArticleShow.asp?ArticleID=102/ArticleShow.asp?ArticleID=99/view/50f859858762caaedd33d471.html/esite/szcosate/index.html同步带的厂家的信息/一些同步带的种类的图片各种同步带的参数//橡胶方齿同步带:MXL,XL,L,,H,XH,XXH,双面橡胶方齿同步带:DXL,DL,DH圆弧齿同步带:3M,5M,8M,14M,双面圆弧齿同步带:D5M,D8M,聚氨酯同步带:T5,T10,T2.5,AT5,TAT10 (型号)聚氨酯同步带:DT5,DT10橡胶公制同步带:T10,DT10半圆弧齿同步带:S3M,S4.5M,S5M,S8M,S14M,三星普通三角带:K,M,A,B,C,D三星高速防油窄三角带:SPZ,SPA,SPB,SPC三星多沟带:PJ,PL ,PH,PK,PM三星广角带:3M,5M,7M,14M。

深圳市汇川技术股份有限公司Shenzhen lnovance Technology Co., Ltd.地址:深圳市宝安区宝城70区留仙二路鸿威工业区E栋 总机:(0755)2979 9595传真:(0755)2961 9897 客服:400-777-1260 苏州汇川技术有限公司Suzhou lnovance Technology Co., Ltd.地址:苏州市吴中区越溪友翔路16号 总机:(0512)6637 6666 传真:(0512)6285 6720 客服:400-777-1260 IS620系列伺服本公司通过ISO9001TUV Rheinland Group销售服务联络地址V5.1进取 永不止步Forward, Always Progressing变频器 | 伺服系统 | PLC | 机器人 | 轨道交通 | 新能源巴西长春汇通光电技术有限公司杭州汇坤控制技术有限公司欧洲技术中心汇川技术(印度)有限公司服务网络公司总部设在深圳,同时在苏州、香港、杭州等地建立多家子公司 覆盖全国的67个办事处超过400位一线销售及服务人员 240家授权代理商 128家全国联保中心 8个库存中心保证了响应客户需求的及时性。

汇川技术伺服驱动系统平台公司简介深圳市汇川技术股份有限公司(300124)专注于工业自动化驱动与控制产品的研发、生产和销售,定位服务于中高端设备制造商,以拥有自主知识产权的工业自动化控制技术为基础,以快速为客户提供个性化的解决方案为主要经营模式,实现企业价值与客户价值共同成长。

主要产品有低压变频器、高压变频器、一体化及专机、伺服系统、PLC、HMI、永磁同步电机、电动汽车电机控制器、轨道交通牵引系统等;重点布局智能制造、新能源、工业互联网三大领域,产品广泛应用于电梯、起重、机床、金属制品、电线电缆、塑胶、印刷包装、纺织化纤、建材、冶金、煤矿、市政、汽车、轨道交通等行业。

公司在低压变频器市场的占有率在国产品牌厂商中排名第一,其中一体化及专机产品在多个细分行业处于业内首创或领先地位。

Drilling and hardware insertion technologyMachines and concepts for industrial production.DRILLTEQ C series / DRILLTEQ H series / DRILLTEQ L seriesHOMAG DRILLTEQ Contents 02HOMAG DRILLTEQ ContentsBe on the safe side with HOMAGYou should not experiment with investment in a new machine or plant. Rely on the competence, experience and reliability of a strong partner – rely on HOMAG. YOUR SOLUTIONMORE: CONTENTS04DRILLTEQ | Everything at a glance06DRILLTEQ C-30008DRILLTEQ C-50010DRILLTEQ C-80012DRILLTEQ H-60014DRILLTEQ L-20016DRILLTEQ L-50018DRILLTEQ L-80020Basic concepts34Apps and digital assistants36Life Cycle Services38Technical data 03DRILLTEQ C-300 DRILLTEQ C-500 DRILLTEQ C-800 DRILLTEQ H-600 DRILLTEQ L-200 DRILLTEQ L-500 DRILLTEQ L-800HOMAG Everything at a glanceDRILLTEQ | Everything at a glance 04DRILLTEQ C-300 –Ideal for cross edge processingThe throughfeed machine enables simultaneous processing of the two cross edges of a workpiece. With its modular design, the DRILLTEQ C-300 is the ideal supplement to other machines and can be integrated into machine lines immediately or at a later point in time.The machine is suitable for series production of furniture as well as batch size 1 processing.HOMAG DRILLTEQ DRILLTEQ C-300Drilling·Horizontal drilling with up to 104 drilling spindles Doweling·Dowel insertion with up to 32 doweling units06HOMAG DRILLTEQ DRILLTEQ C-300Up to104 individually accessible drilling spindles in the cross edgeor up to32doweling units enable100%flexible processing in the cross edge2-sided2-sided2-sided2-sided07DRILLTEQ C-500 – A passion for drillingThe focus of the DRILLTEQ C-500 cross throughfeed machine is on drilling workpieces. With the maximum expansion stage of the machine, workpieces can be processed on six sides. The interchangeable drilling gear also allows the product program to be changed quickly and easily.The machine is particularly suitable for a batch size in excess of 250 parts.HOMAG DRILLTEQ DRILLTEQ C-500Clamping bridges·Swivelable or not swivelableHorizontal dowel inserting in the cross edge·Dowel insertion with up to 32 doweling unitsDrilling gear·Easily interchangeable (including retrospectively) ·Customer-specific solutions for 1-cycledrilling gear08HOMAG DRILLTEQDRILLTEQ C-500In a group of2 machines with100% drilling,up to38parts/minute09DRILLTEQ C-800 – Pure dynamicsThe DRILLTEQ C-800, which has been designed for small series, is the answer for dynamic drilling on five sides as well as dowel insertion in the cross edges of a workpiece. Individual drilling patterns can be processed quickly and precisely.The machine is particularly suitable for small series and series production of furniture with a batch size of 20-500 parts or more.Drilling supports from top and bottom·High quality of every drilling operation (example through holes)·Higher productivity·Automatic spindle clamping systemHorizontal drilling and doweling·Separate processing for even more outputFence and guide system·For precise positioning of workpieces·Provides vertical drilling in edge zonefrom topHOMAG DRILLTEQ DRILLTEQ C-80010HOMAG DRILLTEQ DRILLTEQ C-800Up to5,000parts per shiftwith up to32 doweling unitsand up to674individually accessible drilling spindles11HOMAG DRILLTEQ DRILLTEQ H-60012DRILLTEQ H-600 –There's no limit to flexibilityA range of cleverly combined equipment ensures flexible processing options. With an additional unit, even six-sided processingis possible. The DRILLTEQ H-600 offers diverse connection options, from manual feeding to fully automated processes.The machine is particularly suitable for small series up to batch size 1.A B CHOMAG DRILLTEQ DRILLTEQ H-60010413DRILLTEQ L-200 –Ideal for processing carcase sidesStrong heart – strong performance. For our DRILLTEQ L-200 this means more than drilling and hardware insertion. Combined with the HOMAG high-speed drilling gear and the proven hardware components, the machine is the basis for precisely the performance that you need. Professionally designed with fully developed components your individual requirements can be realized.The machine is particularly suitable for batch size 1 production.High-speed drilling gear·Single-head or split-head arrangement ·Automatic spindle clamping system ·Extendable by grooving saws etc.Horizontal drilling aggregate·Special aggregate, e.g. for deep cabledrillsRouting aggregate(left/right hand rotation)·Routing of roller shutter grooves, countersinking of blank-looking fronts or similar·HSK routing aggregate with tool changerpossibleHOMAG DRILLTEQ DRILLTEQ L-200 14HOMAG DRILLTEQ DRILLTEQ L -200Up to4drilling gears processsimultaneously1or2 workpieces and1,2001516HOMAG DRILLTEQ DRILLTEQ L-500DRILLTEQ L-500 –6-Side-processing for universal applicationsComplete processing in one throughfeed. Drilling, routing, grooving, dowel inserting, hardware inserting – at the top, bottom, front, rear, left and right. The DRILLTEQ L-500 offers individual combinations of all processing options. With secure, precise and fast clamped workpiece transport.The machine is particularly suitable for batch size 1 production.4-sided horizontal doweling6-sided routing & drilling2-sided groovingHOMAG DRILLTEQ DRILLTEQ L-500High-speed drilling gear·Vertical drilling aggregates above and below with individually selectable drilling spindles, horizontal drilling spindles in X and Y direction.·Grooving saw aggregates above andbelow·Expandable by routing aggregates ·Automatic spindle clamping systemWorkpiece handling with clamping system·Allows 6-sided processing – also in the edge zone·Depending on processing, the workpieceis positioned with 4 clamps or held with 2 clamps and additional clamped laterally17DRILLTEQ L-800 –Gentle handling of your frontsThe finest pieces of an item of furniture are in good hands here. The DRILLTEQ L-800 treats them exactly as they should be treated – gently, professionally and efficiently. This is irrespective of whether the fronts only need to be drilled or have hardware to be inserted as well.The machine is particularly suitable for batch size 1 production.Inserting hardware·Hinges, sleeve couplers, stop buffers, adapters,...·Press in or screw on·Feeding solutions to meet your requirements: vibration conveyors, bar magazines, pick & place systemAutonomous production cells·Complete solution with automated feedfrom a picking trolley·Also features an automated trolleychangeWorkpiece handling with clampingsystem·Highly dynamic and precise positioningof workpieces with 140 m/min·Permanent workpiece support bysurface-friendly brush systems·Also for profiled frontsHOMAG DRILLTEQ DRILLTEQ L-800 18HOMAG DRILLTEQ DRILLTEQ L -800100% automatic feed of hardwarewith up to2–3parts/minute19Drilling and dowelling plant for small series and serial production with robot handlingPROCESS CONTENTSFeeding station for the subsequent processBrush cleaning from above and belowFeeding by RKR180 robotWorkpiece collectingWorkpiece separationStacking by RKR180 robotRemoval of empty stack supportsStacking position for the previous processProcessing machine DRILLTEQ C-800·Vertical drilling from above and below·Horizontal drilling into the three narrow surfaces (X+/X-/Y+)·Gluing/dowel inserting into the two narrow surfaces (X+/X-)Supply of empty stack supportsHOMAG DRILLTEQ Basic concepts205Batch size 1: Universal cabinet processingPROCESS CONTENTSWorkpiece bufferThroughfeed scannerWorkpiece distributionWorkpiece transportProcessing machine DRILLTEQ H-600·Vertical drilling from above and below·Horizontal drilling into three narrow surfaces(X+/X-/Y-)·Routing from above and below·Grooving (0°/90°) from above and from below·Gluing/dowel inserting into two narrow surfaces(X+/X-)Processing machine DRILLTEQ H-600·Vertical drilling from above and below·Horizontal drilling into four narrow surfaces·Routing from above and below·Grooving (0°/90°) from above and from below·Gluing/dowel inserting into two narrow surfaces(X+/X-)Workpiece buffer (hedgehog buffer)56Batch size 1: High-performance cabinet production PROCESS CONTENTSWorkpiece measurementAngular transferProcessing machine DRILLTEQ L-500·Vertical drilling from above and below·Vertical routing from above and below·Grooving (0°/90°/180°) from above and from below ·Horizontal drilling into two narrow surfaces (Y+/Y-)Processing machine DRILLTEQ C-300·Horizontal drilling into three narrow surfaces (X+/X-)·Gluing/dowel inserting into two narrow surfaces (X+/X-)Angular transfer4Batch size 1:Complete side processing (including hardware inserting)PROCESS CONTENTSProcessing machine DRILLTEQ L-200·Vertical drilling from above·Horizontal drilling into three narrow surfaces (X+/X-) ·Grooving (0°/180°) from above ·Routing from above·Inserting of mounting plates (variant A) from aboveProcessing machine DRILLTEQ L-200·Inserting of mounting plates (variant B) from above·Inserting of glue beads from above·Inserting of top cabinet hangers from above ·Screwing on brackets from above·Screwing on drawer slides (in 4 lengths) from aboveTurning stationMagazine for drawer slidesVibration conveyor for top cabinet hangers Vibration conveyor for mounting plates Vibration conveyor for EURO screws Vibration conveyor for glue beads Vibration conveyor for rear wall brackets13Concepts for series productionPROCESS CONTENTSManual workpiece feedingProcessing machineDRILLTEQ C-500·Vertical drilling from aboveand below·Horizontal drilling into fournarrow surfaces (X+/X-/Y+/Y-)Processing machineDRILLTEQ C-500·Vertical drilling from aboveand below·Horizontal drilling into fournarrow surfaces (X+/X-/Y+/Y-)·Optional dowel insertingManual workpiece stacking PROCESS CONTENTSFEEDTEQ C-500 FeedingProcessing machineDRILLTEQ C-500·Vertical drilling from aboveand below·Horizontal drilling into fournarrow surfaces (X+/X-/Y+/Y-)Processing machineDRILLTEQ C-500·Vertical drilling from aboveand below·Horizontal drilling into fournarrow surfaces (X+/X-/Y+/Y-)·Optional dowel insertingBrush cleaning from above andbelowSTACKTEQ C-500 StackingProcessing machine DRILLTEQ C-500·Vertical drilling from above and below·Horizontal drilling into fournarrow surfaces (X+/X-/Y+/Y-)Processing machine DRILLTEQ C-500·Vertical drilling from above and below·Horizontal drilling into four narrow surfaces (X+/X-/Y+/Y-)·Optional dowel insertingManual workpiece stacking23Concepts for small series production PROCESS CONTENTSProcessing machine DRILLTEQ L-200·Vertical drilling from above·Horizontal drilling into three narrow surfaces (X+/X-/Y+)·Grooving (0°/180°) from above·Optional routing from aboveOptional buffer sectionProcessing machine DRILLTEQ C-300·Horizontal drilling into two narrow surfaces (X+/X-)·Gluing/dowel inserting into two narrow surfaces (X+/X-)Angular transferAngular transfer 1HOMAG DRILLTEQ Basic concepts PROCESS CONTENTSFEEDTEQ C-500 FeedingProcessing machine DRILLTEQ C-800·Vertical drilling from above and below·Horizontal drilling into fournarrow surfaces (X+/X-/Y+/Y-)·Optional dowel insertingBrush cleaning from above and belowSTACKTEQ C-500 Stacking23132HOMAG DRILLTEQ Basic conceptsBatch size 1:Front processing with hardware inserting and robothandlingHOMAG DRILLTEQBasic concepts PROCESS CONTENTSRobot RKR 180Linear conveyor for drawer adaptersProcessing machine DRILLTEQ L-800·Vertical drilling from above and below·Vertical trimming from above·Inserting of hinges (in two variants) from below ·Inserting of drawer adapters (in two variants) from below·Inserting of stop buffers from belowVibration conveyor for drawer adaptersVibration conveyor for hingesVibration conveyor for stop buffersBar magazine for hinges233HOMAGDRILLTEQApps and digital assistantsApps and digital assistants.Quick and easy support in your machine environment.Some people still use pen and paper to create their cutting patterns. But they look at their smartphone if they want to know what the weather is like – instead of looking out of the window. We asked ourselves: why not combine the best of both? Our apps and digital solutions make your everyday work easier: machines, material, tools, cutting patterns, components – you always have everything in your pocket or on your desk.EXCERPTS FROM YOUR FEEDBACK:·Are there simple solutions that can eliminate various obstacles in my day-to-day work(e.g. when organizing materials or sorting parts)?·Is there a way to slowly approach using digital assistants?·Which tools can you try out simply and easily without having to invest huge sums of moneystraight away?OUR ANSWER? SMART AND POWERFUL SOLUTIONS:9Always low investment9Always up to date (no updates necessary) 9Always easy to use (no complex software) 9Always helpful3435HOMAG DRILLTEQ Apps and digital assistantsTHE ADVANTAGES AT A GLANCE·No investment, update or maintenance costsLow starting price, no unplanned financial expense·Licenses are independent of the userAny number of employees can use the application withoutincurring additional costs·Independent of hardware and operating systemCan be used anywhere, anytime·Open system – import possible from almost all systems(ERP, industry software, CAD/CAM, Excel, CSV)No obligation to use specific software systems·Simple, smart operationMinimal training required·More efficient productionJobs completed more quickly, more safely and in higher quality More information atVALOur Mission, Your Performance.TEAM & COVERAGELargest global service network in the industry with over 1,350 personnel. INSTALLATION & COMMISSIONINGFor a smooth start, we only let proven experts manage your setup. OPERATION & CONTROLAfter teaching your personnel the intuitive control system, our clever apps help to make the operator‘s life much easier.MAINTENANCE & SERVICINGTo keep things running, we’re happy to take a preventative approach. You decide how often and how intensively you want the support to be. As we all know, prevention is better than the cure. eSHOP & ONLINE ADVANTAGEA few clicks and it’s fixed. Receiveexclusive advantages by orderingspare parts online, depending onmarket availability. HOTLINE & READINESSWhen there‘s an emergency, we‘rehere. Direct by phone, digitally via appor video, or with on-site support. Weare close to you with over 90 regionalservice organizations worldwide.With more than 35,000 spare partsimmediately available, we can deliver85% of your orders fast.TRAINING & EDUCATIONWith classroom, live online oreLearning training, we offer flexibleoptions to help you get knowledge.We conduct over 4,000 customertraining courses every year, and weeven have our own training centers in19 countriesMODERNIZATION &IMPROVEMENTOur modernization program is tailoredto your machines and processes. Wecan evaluate your data and situationand advise you on the next step.ANALYSIS & SUSTAINABILITYOn request, we analyze all yourprocesses with proven tools andprocedures (LeanSixSigma). We havea large, certified team of experts forthis purpose.FINANCING & CONSULTINGWe offer you tailor-made financingconcepts worldwide. With more than60 years of experience and a closepartner network of prominent banksand insurance companies to help usto find the right solution for you, we’realways transparent and reliable inprocessing.LIFE CYCLE SERVICESImproved performance, more efficient processes, faster help, assurance of availability and smarter working 36HOMAG DRILLTEQ Life Cycle Services37Fast support:94% resolution ratevia our hotlineClose to you:1,350 service experts worldwideWe get things moving:Over 1,000 worldwide spare parts shipments each dayNo one else has that:Electronic documentation on over 150,000 machines, available in 28 languagesHOMAG DRILLTEQ Technical Data38DRILLTEQ | Technical Data Array * Dependent on changeovers and content** 1 shift corresponds to 8 hours production time*** From workpiece to workpieceHOMAG DRILLTEQTechnical Data39S t a t u s 08/23 | T e c h n i c a l c h a n g e s , p r i n t e r r o r s a n d m i s t a k e s r e s e r v e d . P i c t u r e s m a y s h o w s p e c i a l e q u i p m e n t .HOMAG Group AG**************。

HTD8M同步带参数首先,HTD8M同步带具有精密的同步性能。

由于其特殊的齿形设计和编织结构,HTD8M同步带能够准确地传递动力,确保传动系统的各个部分同步运动。

这可以大大提高机械设备的工作效率和稳定性。

其次,HTD8M同步带具有优异的耐磨性能。

由于其制造材料的特殊性质,HTD8M同步带能够承受较大的压力和摩擦力。

这使得HTD8M同步带具有较长的使用寿命,并能在高速运动下保持良好的性能。

此外,HTD8M同步带还具有较低的噪音和振动水平。

相比于其他传动方式,HTD8M同步带的噪音和振动水平较低,使得机械设备在运行过程中更加平稳和安静。

另外,HTD8M同步带的安装和维护也相对较为简单。

由于其特殊的结构和特性,HTD8M同步带不需要润滑剂,减少了设备维护的工作量和成本。

此外,HTD8M同步带的结构紧凑,尺寸小巧,适用于各种空间限制的机械设备。

总的来说,HTD8M同步带是一种高性能的传动方式,具有精密的同步性能、优异的耐磨性能、较低的噪音和振动水平以及简单的安装和维护。

它使用广泛,适用于各种机械设备,为设备的高效、稳定运行提供了可靠的传动保障。

总结起来,HTD8M同步带的参数包括带宽、齿数、带长等。

带宽是指同步带的宽度,一般根据具体的传动需求确定。

齿数是指同步带上的齿的数量,它决定了传动比的大小,一般根据传动系统的要求确定。

带长是指同步带的长度,它与齿数和带宽有关。

在选择HTD8M同步带时,需要根据具体的传动需求,选择合适的带宽、齿数和带长,以确保传动系统的工作正常。

The compact N4603 Series barcode scan engine is an easy-to-integrate, enhanced performance device that fits into tight mobile device designs.The N4603 Series’ dimensions 8,1 mm H x 10,8 mm D [0.32 in H x 0.43 in D],mounting holes and electrical pin-out are the same as the N3603 Series, providing an easy migration path for those customers currently using the N3603 Series. The MIPI interface helps simplify integration into mobile devices that require the most current, as well as traditional, processor interfaces.Based on a VGA global shutter sensor, the N4603 Series scan engine's maximum motion tolerance of 6 m/s [19.7 ft/s] and scan rate of 120 fps maximum, enable increased scanning speed and productivity. The white LED enhances image capture and colored barcode readability and a laser aiming system is available to match application requirements.Using the latest host decoder platform from Honeywell, the N4603 Series supports a wide variety of symbologies, including 1D, 2D and OCR. The device also includes advanced features that support reading poorly printed and on-screen barcodes.The wide operational temperature range (-30°C to 60°C [-22°F to 140°F]) allows expansion into more demanding applications and the lower power consumption increases the battery life provided by a single charge.The N4603 Series is compatible with Honeywell's N660X Series and N670X Series high-performance 2D scan engines. It uses the same connector as these two scan engine families, reducing integration time and design costs while increasing design flexibility and choice.HONEYWELL N4603 SERIESCompact, Undecoded 2D Scan EnginesThe N670X is even slimmer than the N4603 Series and both can fit in compact enclosures. Two differentlevels of barcode scanning performance may be offered to customers without introducing a housing change or additional accessory design.POTENTIAL APPLICATIONSUse in professional-grade, mobile devices such as tablets, wearablescanners, mobile terminals, accessories in retail stores, warehouses andhealthcare facilities, as well as delivery, pick-up/drop-off and field servicing.N4603 Series 2D Scan EngineFEATURES AND BENEFITSCompact size allows use in tight mobile device designs.Improved snappiness with global shutter has much higher motion tolerance of 6 m/s versus 0,1 m/s in rolling shutter.Wide operational temperature range increases potential applications.Supports optionalHoneywell functionalities such as OCR andEasyParse™ for potential use with driving licenses and boarding passes.Compatible with other Honeywell scan engine families for reduced integration time and design costs, as well as increased design flexibility and choice.HONEYWELL N4603 SERIES Technical SpecificationsHoneywell N4603 Series Compact, Undecoded 2D Scan Engines Datasheet | /ast | 2EasyParse™ is a trademark of Honeywell International Inc.007632-2-EN | 2 | 03/21© 2021 Honeywell International Inc. All rights reserved.FOR MORE INFORMATIONTo learn more about Honeywell scan engines and barcode decoding software, visit our website .WARRANTY/REMEDYHoneywell warrants goods of its manufacture as being free of defective materials and faulty workmanship during the applicable warranty period. Honeywell’s standard product warranty applies unless agreed to otherwise by Honeywell in writing; please refer to your order acknowledgment or consult your local sales office for specific warranty details. If warranted goods are returned to Honeywell during the period of coverage, Honeywell will repair or replace, at its option, without charge those items that Honeywell, in its sole discretion, finds defective. The foregoing is buyer’s sole remedy and is in lieu of all other warranties, expressed or implied, including those of merchantability and fitness for a particular purpose. In no event shall Honeywell be liable for consequential, special, or indirect damages.While Honeywell may provide application assistance personally, through our literature and the Honeywell web site, it is buyer’s sole responsibility to determine the suitability of the product in the application.Specifications may change without notice. The information we supply is believed to be accurate and reliable as of this writing. However, Honeywell assumes noresponsibility for its use.HoneywellAdvanced Sensing Solutions 830 East Arapaho Road Richardson, TX 75081 /ast。

ATV13系列经济型小功率变频器用户手册前言首先感谢您购买ATV13系列经济型小功率变频器!本手册介绍了如何正确使用ATV13系列变频器,在进行安装、运行、维护等操作前,请务必认真阅读本手册。

不正确使用变频器可能引致意想不到的事故,请将本手册交给最终用户。

同时,请在正确理解安全注意事项后使用变频器。

注意事项本手册中的图例仅为了用户便于理解而制作,可能和您所订购的产品实物有所不同。

此外,本手册中的图例为卸下外壳或安全覆盖物的状态,请在使用时务必按规定安装好外壳或覆盖物,并严格按本手册进行操作。

当产品升级或规格变更时,本手册内容会及时进行变更。

如果手册丢失、损坏,或在使用时有疑惑,请与本公司服务中心联系:400-159-0088目录前言 (I)安全注意事项 (01)第一章选型指导 (04)1.1产品型号说明 (04)1.2产品名牌说明 (04)1.3选型指导表 (05)1.4键盘托盘与RS485接口.........................06第二章接线. (07)2.1三相380V标准接线图 (07)2.2接线端子及接线说明 (08)第三章操作说明 (09)3.1操作面板说明 (09)3.1.1操作面板图示 (09)3.1.2按键说明 (09)3.1.3功能指示灯说明 (09)3.2操作流程 (10)3.2.1参数设置 (10)3.2.2故障复位 (11)3.2.3电机参数自学习 (11)3.2.4密码设置 (12)第四章功能参数表 (13)第五章故障检查与排除 (30)5.1故障信息及排除方法 (30)5.2常见故障及其处理方法 (33)第六章通讯协议 (34)第七章通讯地址 (45)安全注意事项危险:表示可能会导致死亡或严重人身伤害的状况。

编码器■绝对值型我们是您最理想的全球合作伙伴,为您提供创新产品。

HENGSTLER 产品编码器绝对值型编码器ACURO驱动和ACURO工业型增量型编码器防爆型和不锈钢型总线编码器工业计数器和控制器从微型计数器到大型的控制计数器,多功能计数器,带接口的计数器、位置计数器、计时器、转速计打印机和切纸机打印机解决方案,如信息中心、售票机、自动提款机、POS系统,模块化热式打印机和针式打印机应用,附件如卷纸器和切纸机。

继电器技术主要致力于全球大部分通用安全继电器- 继电器带导向触点组 -其它产品如:双稳继电器,隔离继电器,高电压继电器,微型切换继电器丹纳赫传感器与控制集团的其它品牌编码器 计数器 指示器 继电器 打印机 切纸机Harowe TM Namco TMNorthStar TMPartlow TMVeeder-Root TM West TMDynapar TMEagle Signal TM ENMTM与Hengstler合作的理由位于Aldingen市的Hengstler总部Hengslter总部位于德国西南部的Aldingen市,靠近Black Forest-该地区是德国工业先驱和投资者的聚集地。

其中包括Hengstler公司的创建者Johannes Hengstler,他于1846年所开设的工厂,后来成为Hengstler集团的中心所在地。

工厂最初从事钟表弹簧的制造;现在Hengslte从事从微型计数器到绝对值型空心轴编码器等各种产品的制造。

更具竞争性本产品目录足以见证我们在编码器领域中所具有的竞争性-(所有Hengstler产品)采用最先进技术、最佳设计方案、最高质量和可靠性标准的综合方案。

Hengstler——值得您信赖本手册中的所有技术数据和信息(包括图纸) 经过我们精心地收集和编排。

本手册提供了产品及附件的信息,但并不构成技术数据或功能的任何担保。

产品用户必须自行判断产品的适用性。

我们有权修改所有技术数据。