损伤识别的方法

- 格式:pdf

- 大小:379.99 KB

- 文档页数:18

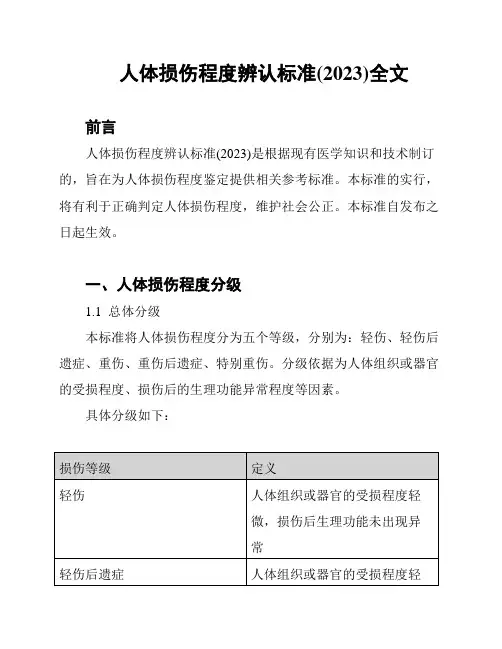

人体损伤程度辨认标准(2023)全文前言人体损伤程度辨认标准(2023)是根据现有医学知识和技术制订的,旨在为人体损伤程度鉴定提供相关参考标准。

本标准的实行,将有利于正确判定人体损伤程度,维护社会公正。

本标准自发布之日起生效。

一、人体损伤程度分级1.1 总体分级本标准将人体损伤程度分为五个等级,分别为:轻伤、轻伤后遗症、重伤、重伤后遗症、特别重伤。

分级依据为人体组织或器官的受损程度、损伤后的生理功能异常程度等因素。

具体分级如下:1.2 分级依据本标准的伤情判断,应该以受伤时的对象体质为基准,考虑如下因素:1.2.1 损伤部位:同等条件下,伤及特定器官或人体部位时应该较其他部位更高一级;1.2.2 损伤程度:包括损伤的面积和深度等因素;1.2.3 年龄、性别、体重等因素。

二、鉴定标准2.1 鉴定程序人体损伤程度的鉴定,需要通过以下程序:2.1.1 现场鉴定:现场可以由就诊医生现场鉴定,或者由专业鉴定机构进行鉴定。

2.1.2 报告提交:将现场鉴定报告提交至相关调查或保险部门,如需要进行评估,需要配合医疗机构提供相关材料;2.1.3 终审:由主管部门进行最后的审核,评估结果对争议解决和诉讼有一定作用,需要确保鉴定过程的公正、合法。

2.2 鉴定标准人体损伤程度的鉴定,应该以现场鉴定报告为依据,结合受伤人的医疗记录,以及其他证明材料综合评估。

具体标准如下:2.2.1 轻伤:不影响正常工作和生活,包括1-2级伤情。

2.2.2 轻伤后遗症:受损组织部位有轻微持续异常,但不影响正常工作和生活,包括1-2级伤情。

2.2.3 重伤:受损组织造成较大影响,需要停止一段时间的正常工作和生活,包括3级以上伤情。

2.2.4 重伤后遗症:受损组织造成的异常较重,持续一段时间反复发作,严重影响正常工作和生活,包括3级以上伤情。

2.2.5 特别重伤:受损组织造成的影响特别严重,短期内危及生命或者造成血管、神经等持久性损伤,如挫伤致颈椎骨折、造成高度色素沉着等。

人体损伤鉴定标准全文

对于人体损伤的鉴定标准,通常是根据法医学的相关知识和法

律法规来进行判断的。

人体损伤鉴定标准主要包括以下几个方面:

1. 外伤的形态特征,法医学鉴定外伤时,需要对外伤的形态特

征进行观察和描述,包括外伤的部位、大小、形状、颜色、溃烂程

度等。

这些特征可以帮助确定外伤的性质和可能的原因。

2. 外伤的组织学改变,法医学鉴定外伤还需要对外伤部位的组

织学改变进行分析,包括皮肤、软组织、骨骼等的损伤情况,以及

可能的愈合情况。

这些改变可以提供外伤的时间、程度和性质等重

要信息。

3. 外伤的致伤机制,通过对外伤造成的致伤机制进行分析,可

以帮助确定外伤的可能原因,比如是意外伤害、自残还是他殴伤等。

4. 外伤与受害者的联系,鉴定人体损伤还需要考虑外伤与受害

者的联系,包括外伤是否与受害者的陈述相符,是否有可能的自卫

行为等。

5. 法律法规的要求,最后,人体损伤的鉴定还需要符合相关的法律法规要求,比如对于家庭暴力、交通事故等特定情况下的鉴定标准。

总的来说,人体损伤的鉴定标准是一个综合性的判断过程,需要结合外伤的形态特征、组织学改变、致伤机制、与受害者的联系以及法律法规的要求等多个方面来进行分析和判断。

同时,鉴定人员需要具备扎实的法医学知识和丰富的实践经验,以保证鉴定结果的准确性和公正性。

基于机器学习的结构损伤识别与评估技术研究随着科技的不断发展,建筑结构的损伤识别与评估变得越来越关键。

传统的损伤检测方法需要大量的人力和时间,而且结果可能不够精确。

然而,近年来,基于机器学习的结构损伤识别与评估技术逐渐成为了研究的热点。

本文将探讨基于机器学习的结构损伤识别与评估技术的原理和应用。

一、机器学习在结构损伤识别中的应用机器学习是一种人工智能的分支,它通过从数据中学习并建立模型,对未知数据进行预测和分类。

在结构损伤识别中,机器学习可以通过分析结构的振动特征,识别和评估结构的损伤情况。

以下是机器学习在结构损伤识别中的几种常见方法:1. 支持向量机(Support Vector Machine,SVM)支持向量机是一种监督学习方法,它通过寻找最佳的超平面,将不同类别的数据点分隔开。

在结构损伤识别中,SVM可以通过分析振动信号的特征参数,如频率和振幅,判断结构的损伤程度。

2. 随机森林(Random Forest)随机森林是一种集成学习方法,它通过构建多个决策树并综合它们的结果来进行预测。

在结构损伤识别中,随机森林可以通过分析结构的振动响应和频谱特征,判断结构的损伤位置和类型。

3. 深度学习(Deep Learning)深度学习是一种基于神经网络的机器学习方法,它模仿人脑神经元的工作方式,通过多层次的神经元网络来提取和学习数据的特征。

在结构损伤识别中,深度学习可以通过分析结构的振动信号和图片信息,实现对结构损伤的自动识别和评估。

二、基于机器学习的结构损伤识别与评估技术的优势基于机器学习的结构损伤识别与评估技术相比传统方法具有以下几个优势:1. 自动化:机器学习可以通过对大量数据的学习和分析,实现对结构损伤的自动识别和评估,大大减少了人力成本。

2. 高效性:机器学习算法可以快速处理大量的数据,并在短时间内给出准确的结果。

3. 精确性:机器学习可以通过建立合适的模型,从大量的数据中提取有用的特征,并实现对结构损伤的精确识别和评估。

钢结构的损伤识别与健康监测方法研究钢结构作为现代建筑领域的重要组成部分,在城市化进程中发挥着重要的作用。

然而,随着时间的推移,钢结构可能会受到不同因素的损伤,例如腐蚀、疲劳、冲击等。

这些损伤如果得不到及时和准确的识别与监测,可能会导致结构的失效风险增加,甚至威胁到人们的生命安全。

因此,钢结构的损伤识别与健康监测方法的研究显得尤为重要。

一、基于传统检验与监测方法的识别与监测传统的检验与监测方法对于钢结构的损伤识别与健康监测提供了一定的参考价值。

例如,视觉检查可以通过观察钢结构表面的裂纹、腐蚀等现象来判断结构是否存在损伤。

此外,还可以利用无损检测技术,例如超声波、X射线等,对结构进行全面的检测。

然而,这些方法存在一定的局限性,无法对结构内部的损伤进行有效的识别与监测。

二、基于结构动态响应的损伤识别与健康监测方法近年来,一种基于结构动态响应的损伤识别与健康监测方法逐渐受到关注。

该方法通过对结构在不同外部激励下的动态响应进行分析,来判断结构是否存在损伤。

其中,振动分析是一个常用的技术手段,可以通过对结构在不同频率下的振动特性进行监测,来获取结构的整体健康状况。

此外,还可以利用应变传感器等设备对结构的应变变化进行监测,从而了解结构的受力状况,并判断是否存在损伤。

三、基于机器学习的损伤识别与健康监测方法随着机器学习技术的不断发展,它在钢结构损伤识别与健康监测中也得到了广泛应用。

机器学习通过对大量的数据进行分析和学习,可以建立起预测模型,并判断结构的损伤状况。

其中,监督学习算法是应用最广泛的一类算法,它通过对已知损伤样本的学习,来对未知损伤样本进行识别和监测。

此外,还可以利用无监督学习算法来进行异常检测,即通过对结构数据的聚类和异常值检测,来发现结构中潜在的损伤。

四、基于传感器网络的损伤识别与健康监测方法传感器网络是一种利用分布在结构各个位置的传感器来实现数据采集、数据传输和数据处理的技术。

通过在结构中布置传感器网络,可以实时获取结构的动态响应、应变分布等信息,从而实现对结构损伤的识别与监测。

诊断外板件损伤的方法有哪些

诊断外板件损伤的方法主要包括以下几种:

1. 观察:通过肉眼观察外板件是否有明显的凹陷、刮擦、裂缝等明显损伤。

2. 打拍:用手指或铁槌等敲击外板件,听声音判断是否有异响或松动现象。

3. 触摸:用手轻轻触摸外板件表面,感受是否有凸起、凹陷等不平整的部分。

4. 摩擦:用手指或抹布等摩擦外板件表面,判断是否有漆面脱落、破损等情况。

5. 使用探针:用探针等工具插入外板件的缝隙中,检测是否有缝隙增大、松动等情况。

6. 检查车辆文件:查看车辆保养记录、维修记录等,判断是否有曾经维修过外板件的记录。

7. X射线检查:使用X射线设备对外板件进行拍片检查,可以较为准确地发现外板件的内部损伤情况。

需要指出的是,以上方法可能需要结合专业人员的经验和技巧进行诊断。

对于严重损伤,最好请专业技师进行全面检查和评估。

变形损伤的判断方法嘿,大家知道吗,变形损伤的判断可是个相当重要的事儿呢!那到底怎么来判断变形损伤呢?别急,听我慢慢道来。

首先呢,要仔细观察物体的外观。

看看有没有明显的弯曲、扭曲、凹陷或者凸起等情况。

这就像是我们看一个人,一眼就能看出他是不是站直了还是歪歪扭扭的。

在观察的时候,可千万不能马虎哦,要像侦探一样敏锐,不放过任何一个小细节。

同时,还可以用手去触摸,感受一下表面是否平整,有没有异常的凸起或凹陷。

这一步看似简单,实则需要极大的耐心和细心呢!接下来咱们说说过程中的安全性和稳定性。

这可太关键啦!就好比走钢丝,要是不安全不稳定,那后果简直不堪设想啊!在进行变形损伤判断时,一定要确保自身安全,不要在危险的环境中操作。

而且操作过程要稳稳当当的,不能毛毛躁躁,不然可能会导致判断失误,甚至对物体造成二次损伤。

所以呀,一定要把安全和稳定放在心上哦!那变形损伤的判断方法都有哪些应用场景和优势呢?哎呀呀,这可多了去啦!在制造业中,它可以帮助我们及时发现产品的缺陷,提高产品质量;在建筑领域,能让我们了解建筑物的结构是否安全可靠;在交通事故中,更是能快速判断车辆的损伤情况。

它的优势就在于能够快速、准确地发现问题,就像给物体做了一次全面的体检一样,让我们对物体的状况了如指掌。

这难道不是超厉害的吗?我给大家讲个实际案例吧。

有一次,在一个工厂里,工人们发现一台机器运行不太正常,但又不知道具体是哪里出了问题。

后来,技术人员通过仔细的变形损伤判断,发现是机器的某个关键部件发生了轻微的变形,及时进行了修复,避免了更大的损失。

你瞧,这就是变形损伤判断的实际应用效果呀,真的是太重要啦!变形损伤的判断方法真的是超级重要的呀,它能帮助我们及时发现问题,解决问题,保障安全和质量呢!大家可一定要重视起来哦!。

损伤程度鉴定标准损伤程度鉴定标准是指根据损伤的性质、程度和范围,对受害人的身体和心理状态进行评估和鉴定的一套标准和方法。

在司法、医学和保险等领域中,损伤程度鉴定标准具有重要的应用价值,可以为相关部门提供科学、客观的依据,保障受害人的合法权益。

下面将从不同角度对损伤程度鉴定标准进行分析和介绍。

首先,从医学角度来看,损伤程度鉴定标准是根据医学知识和临床经验,对受害人的伤情进行评估和判断。

医学上通常将损伤程度分为轻伤、中伤和重伤三个等级,根据伤情的严重程度和对身体功能的影响来确定。

在鉴定过程中,医生会对受害人进行详细的体检和医学检查,包括X光、CT等影像学检查,以及功能评定和病史调查等,从而确定损伤的程度和影响范围。

这样的鉴定标准可以为受害人提供精准的医疗服务和康复方案,保障其身体健康。

其次,从法律角度来看,损伤程度鉴定标准是司法鉴定的一项重要内容。

根据相关法律法规,对于因意外事故或他人过失而受伤的受害人,需要进行损伤程度鉴定,以确定赔偿责任和赔偿金额。

在司法鉴定中,专业的法医医生会根据受害人的伤情和医学证据,进行损伤程度鉴定,包括伤情的轻重、对身体功能的影响、康复期限等,从而为法院提供客观的证据,保障受害人的合法权益。

此外,损伤程度鉴定标准在保险理赔中也具有重要意义。

保险公司通常会要求受害人进行损伤程度鉴定,以确定保险赔偿的范围和金额。

在理赔过程中,保险公司会委托专业的医学鉴定机构对受害人的伤情进行评估和鉴定,根据损伤程度鉴定标准,确定赔偿金额和赔偿方式,保障受害人的合法权益。

总的来说,损伤程度鉴定标准是一项涉及医学、法律和保险等多个领域的重要工作,具有广泛的应用价值。

通过科学、客观的鉴定标准,可以为受害人提供精准的医疗服务和康复方案,保障其合法权益,同时也可以为法院和保险公司提供客观的证据,维护社会公平和正义。

因此,各相关部门应加强对损伤程度鉴定标准的研究和应用,提高鉴定工作的科学性和准确性,为受害人提供更好的保障和服务。

结构损伤识别方法研究对现有的结构损伤识别方法进行概括,并对其进行简要的介绍。

根据每种方法的特点分析其适用条件和优缺点。

标签:结构损伤识别;神经网络;小波变换0、前言随着社会经济的快速发展,现代化建筑物越修越高,越修越复杂,由于各种自然荷载和人为荷载的不断作用,使得构件内部或构件之间连接出现损伤,这间接导致结构承载力下降,而且结构从投入使用开始就面临着损伤累计的问题,并且这些建筑物服役的年限越来越长,一旦发生事故,将会造成不可估量的人身和财产损失。

一般损伤识别研究主要分为两部分:一是对损伤位置的识别;二是对损伤程度的判断。

1、结构损伤识别的研究现状目前,关于结构损伤识别的问题日益成为国内外的热点问题。

对于工程结构进行损伤研究开始于20世纪40年代,近几十年结构损伤识别的理论研究取得了飞速发展,但在实际工程中的应用却很有限。

结构损伤识别技术基本上可以分为两大类:局部损伤识别和整体损伤识别。

1.1 结构损伤识别的局部法目前常用的局部损伤识别方法有目测法、染色法、声发射法、射线法、磁扰动法等,该法是对结构的局部进行定期检查。

局部损伤识别广泛应用于船舶等领域,但也存在着很多限制和弊端,如:该法只适用于小型结构的损伤检测,而对大型复杂的结构损伤识别并不明显,另外,无法对某些结构实施在线及时的检测。

但将传感器固定在一些重要部件上,对这些部件进行远距离在线检测,较好的弥补了这一缺陷。

该技术广泛应用于航空航天、公路桥梁和民用建筑,其优点是可以直接确定构件的裂纹及其位置。

局部损伤识别技术对于压力容器、油箱等小型有规则的结构能有很好的识别效率,但对于大型、复杂的结构,这种技术用来检测结构的每一部分是不可能的。

因此,局部损伤识别技术仅适用于检测结构的特别部件或局部结构。

1.2 结构损伤识别的整体法结构损伤识别的局部法只适用于小型简单结构的损伤识别,因此基于多学科交叉的原理,得出了损伤识别技术的基础理论。

结构可以看作由刚度、质量、阻尼矩阵组成的力学系统,因此寻求物理参数和模态参数之间的对应关系便成为结构损伤识别的核心问题。

√一、损伤、失效及检验方法概述√二、常见损伤模式、案例及检验策略1.腐蚀损伤2.材质劣化3.机械损伤4.其他损伤√三、小结一、损伤、失效及检验方法概述几个概念:损伤损伤模式失效失效分析事故事故调查检验技术=检测技术+评价技术检测技术=无损检测+性能试验——发现和量化缺陷。

——想办法找出缺陷评价技术=应用断裂力学、损伤力学等应用科学,分析设备的安全性。

——能不能用?能用多久?解决方案?关于检验种类及评定方法>>依据法规的检验>>基于失效模式的检验(或针对性检验、预知检验)>>基于风险的检验(RBI)>>在线检验>>基于安全状况等级的评定方法>>基于损伤寿命的评定方法>>可靠性、失效概率评定方法等等二、常见损伤模式、案例及检验策略GB/T30579-2014《承压设备损伤模式识别》(5类73种)第1类:腐蚀减薄(25)①全面腐蚀(均匀腐蚀):盐酸、硫酸、氢氟酸、磷酸、二氧化碳(碳酸)、环烷酸、苯酚、有机酸、高温氧化、大气(有、无隔热层)、冷却水、土壤、苛性碱、氯化铵、胺、高温硫化物、酸性水、甲铵腐蚀等②局部腐蚀(非均匀腐蚀、局部减薄):微生物腐蚀、锅炉冷凝水腐蚀、燃灰腐蚀、烟气露点腐蚀等等第2类:环境开裂(13)氯化物应力腐蚀开裂、碳酸盐、硝酸盐、碱、氨、胺、湿硫化氢破坏(氢鼓包、氢致开裂、应力导向型氢致开裂、硫化物应力腐蚀开裂)、氢氟酸致氢应力开裂、氢氰酸致氢应力开裂、氢脆、高温水、连多硫酸、液体金属脆断等第3类:材质劣化(15)晶粒长大、渗氮、球化、石墨化、渗碳、脱碳、金属粉化、σ相脆化、475°C脆化、回火脆化、辐照脆化、钛氢化、再热裂纹、脱金属腐蚀、敏化—晶间腐蚀等等第4类:机械损伤(11)机械疲劳、热疲劳、振动疲劳、接触疲劳、机械磨损、冲刷、汽蚀、过载、热冲击、蠕变、应变时效等等第5类:其他损伤(9)高温氢腐蚀、腐蚀疲劳、冲蚀、蒸汽阻滞、低温脆断、过热、耐火材料退化、铸铁石墨化腐蚀、微动腐蚀等等1.腐蚀损伤(腐蚀减薄+环境开裂)腐蚀概述金属与周围介质间由于化学或电化学作用而引起的破坏称为腐蚀。

人体损伤鉴定标准人体伤害鉴定,又称人体损伤鉴定或人体伤害比较,是在诊断生理状况、大小、形状、症状、性质、部位、程度、范围、原因等方面去确定任何一种伤害的特征。

伤害可以是某种意外、暴力、健康问题或疾病的结果,由此产生的伤害鉴定也就非常重要。

确定损伤的特征有多种方法,人体损伤鉴定是最常用的方法之一。

主要原理是,对比伤害特征并识别它与其它伤害的不同。

为了得出准确的结论,伤势鉴定工作者需要知道伤害所受的原因以及两个或两个以上损伤情况之间的差异。

一般来说,人体损伤鉴定有三种形式:(1)观察检验,包括视力、听力和触摸等一些以观察伤害特征的方法;(2)体表检验,是检查体表上的伤害、外部和内部的比较,以及整体损伤的特征;(3)解剖检验,是检查人体损伤的组织来诊断伤害的性质、范围和程度。

人体损伤的鉴定需要结合以上技术,因为每种伤害的特征都不同,需要根据具体情况来发现。

在进行伤害鉴定工作时,应尊重受损害者的痛苦,尽量减轻他们心理和身体上的痛苦,同时保护他们的隐私,并遵循相关的专业准则,以确保得出的结论准确可靠。

在很多情况下,人体损伤的保障鉴定需要有权威的法医鉴定专家进行判断。

合格的法医鉴定专家需要具备在医学和法律方面具有扎实基础知识和能力,以及足够丰富的临床经验。

有权威法医鉴定专家可以对客观事实提供可靠的判断,提供科学准确的结论报告。

事实上,人体损伤鉴定不仅是提供准确确定伤害特征的方法,同时也是发现潜在危害的手段,比如发现潜在的肿瘤、病毒感染、血液疾病等。

因此,人体损伤的鉴定是医学技术的重要工作,应给予充分重视。

不仅要提高伤害鉴定的科学性,还要确保安全可靠,以确保鉴定的准确性。

总之,人体损伤鉴定是一项重要的医学任务,是诊断损伤的有效方法,可以有效地排除掉不同伤害之间的差异,也能发现潜在的危害,为临床治疗提供依据。

同时,还有许多伤害鉴定的标准,如医学伤害鉴定解剖学手册、伤害鉴定技术应用规范等,都应严格遵循。

评估漆膜损伤程度的方法漆膜是指涂在物体表面的一层涂料,它不仅能保护物体表面免受外界环境的侵蚀,还能美化物体外观。

然而,随着时间的推移和外界环境的影响,漆膜会出现各种损伤,如划痕、磨损、脱落等。

为了准确评估漆膜的损伤程度,需要采用科学的方法和工具进行检测和分析。

1. 目视检查法目视检查法是最简单也是最常用的评估漆膜损伤程度的方法。

通过肉眼观察漆膜表面,可以初步判断漆膜是否有明显的划痕、磨损或脱落现象。

然而,目视检查法只能提供一个粗略的评估结果,对于一些微小的损伤可能无法准确判断。

2. 手感触摸法手感触摸法是一种常用的评估漆膜损伤程度的方法。

通过用手指触摸漆膜表面,可以感受到漆膜的光滑度和平整度。

如果漆膜表面有明显的凹凸感或粗糙感,就说明漆膜可能存在一定程度的损伤。

3. 摄影检测法摄影检测法是一种较为常用的评估漆膜损伤程度的方法。

通过使用摄影设备拍摄漆膜表面的照片,然后对照片进行放大和分析,可以更清晰地观察漆膜的损伤情况。

此外,可以利用摄影软件对照片进行图像处理,进一步提高图像的清晰度和对比度,以便更准确地评估漆膜的损伤程度。

4. 表面粗糙度测量法表面粗糙度测量法是一种定量评估漆膜损伤程度的方法。

通过使用表面粗糙度测量仪器,可以对漆膜表面的粗糙度进行测量和分析。

粗糙度的值越大,说明漆膜表面越不光滑,可能存在较严重的损伤。

5. 厚度测量法厚度测量法是一种定量评估漆膜损伤程度的方法。

通过使用厚度测量仪器,可以测量漆膜的厚度,并与标准值进行比较。

如果漆膜的厚度明显低于标准值,就说明漆膜可能存在脱落或磨损的情况。

6. 化学分析法化学分析法是一种较为精确的评估漆膜损伤程度的方法。

通过采集漆膜样品,然后进行化学分析,可以确定漆膜中各种成分的含量和比例。

如果漆膜中某种成分的含量明显减少,就说明漆膜可能遭受了一定程度的损伤。

评估漆膜损伤程度的方法有目视检查法、手感触摸法、摄影检测法、表面粗糙度测量法、厚度测量法和化学分析法。

承压设备损伤模式识别 HUA system office room 【HUA16H-TTMS2A-HUAS8Q8-HUAH1688】9承压设备损伤模式识别第01讲承压设备损伤模式识别(一)√一、损伤、失效及检验方法概述√二、常见损伤模式、案例及检验策略1.腐蚀损伤2.材质劣化3.机械损伤4.其他损伤√三、小结一、损伤、失效及检验方法概述几个概念:损伤损伤模式失效失效分析事故事故调查检验技术=检测技术+评价技术检测技术=无损检测+性能试验——发现和量化缺陷。

——想办法找出缺陷评价技术=应用断裂力学、损伤力学等应用科学,分析设备的安全性。

——能不能用能用多久解决方案关于检验种类及评定方法>>依据法规的检验>>基于失效模式的检验(或针对性检验、预知检验)>>基于风险的检验(RBI)>>在线检验>>基于安全状况等级的评定方法>>基于损伤寿命的评定方法>>可靠性、失效概率评定方法等等第02讲承压设备损伤模式识别(二)二、常见损伤模式、案例及检验策略GB/T30579-2014《承压设备损伤模式识别》(5类73种)第1类:腐蚀减薄(25)①全面腐蚀(均匀腐蚀):盐酸、硫酸、氢氟酸、磷酸、二氧化碳(碳酸)、环烷酸、苯酚、有机酸、高温氧化、大气(有、无隔热层)、冷却水、土壤、苛性碱、氯化铵、胺、高温硫化物、酸性水、甲铵腐蚀等②局部腐蚀(非均匀腐蚀、局部减薄):微生物腐蚀、锅炉冷凝水腐蚀、燃灰腐蚀、烟气露点腐蚀等等第2类:环境开裂(13)氯化物应力腐蚀开裂、碳酸盐、硝酸盐、碱、氨、胺、湿硫化氢破坏(氢鼓包、氢致开裂、应力导向型氢致开裂、硫化物应力腐蚀开裂)、氢氟酸致氢应力开裂、氢氰酸致氢应力开裂、氢脆、高温水、连多硫酸、液体金属脆断等第3类:材质劣化(15)晶粒长大、渗氮、球化、石墨化、渗碳、脱碳、金属粉化、σ相脆化、475°C脆化、回火脆化、辐照脆化、钛氢化、再热裂纹、脱金属腐蚀、敏化—晶间腐蚀等等第4类:机械损伤(11)机械疲劳、热疲劳、振动疲劳、接触疲劳、机械磨损、冲刷、汽蚀、过载、热冲击、蠕变、应变时效等等第5类:其他损伤(9)高温氢腐蚀、腐蚀疲劳、冲蚀、蒸汽阻滞、低温脆断、过热、耐火材料退化、铸铁石墨化腐蚀、微动腐蚀等等1.腐蚀损伤(腐蚀减薄+环境开裂)腐蚀概述金属与周围介质间由于化学或电化学作用而引起的破坏称为腐蚀。

土木工程结构检测技术及损伤识别方法探讨摘要:随着社会的不断发展,我国土木工程技术也在不断地更新与进步。

为了确保土木工程质量,应定期进行土木工程结构检测,以确定土木工程的结构是否满足施工要求,是否有必要对其进行维修和加固。

此外,结构损伤识别方法也在不断发展和更新。

它可以及时发现潜在的损伤,并在损伤发生之前对其进行评估。

因此,在实际施工过程中应加强对结构检测技术的重视。

关键词:土木工程;结构检测技术;损伤识别;方法探讨在土木工程施工过程中,经常会受到各种因素的影响,使得其在使用过程中可能会出现结构损伤的情况。

如果出现此类问题,则必须要及时采取有效的措施对其进行处理,以避免结构构件出现进一步的破坏。

土木工程结构检测技术与损伤识别方法是针对土木工程施工过程中可能出现的结构损伤问题而提出的有效解决方法,具有较高的可行性与可靠性。

在实际应用过程中,需要对检测技术与损伤识别方法进行合理运用,以更好地保证土木工程结构施工质量。

文章将结合具体工程实例,对土木工程结构检测技术与损伤识别方法进行详细分析与研究。

1.工程概况某桥梁工程需要对其进行扩建,其实际长度为351m,宽为25m,因此,对其进行扩建施工非常复杂。

为了更好地保证该工程的顺利开展,必须要对其进行结构检测。

在该桥梁工程施工前,对其进行了详细的调查与分析,并制定了详细的检测计划。

具体的检测内容如下:1.对桥梁基础结构状况进行检查与检测。

该桥梁的基础主要为混凝土结构,混凝土的强度等级为C40,并有多处混凝土裂缝。

在对这些裂缝进行检查与分析后发现:该桥梁基础存在不同程度的裂缝、露筋和锈蚀等问题。

2.对桥梁上部结构进行检测与检查。

在该桥梁上部结构中共有12个主梁、13个次梁和14个梁式支撑;主梁平均高度为11.9m;次梁平均高度为12.6m。

在对桥梁上部结构构件进行检测后发现:该桥梁的上部结构存在多处梁板开裂、露筋、锈蚀等问题,因此,必须要对其进行加固处理。

2.混凝土构件质量检测混凝土构件质量检测的内容包括强度、裂缝、缺陷、钢筋保护层厚度等。

主体结构损伤鉴定一、引言主体结构是建筑物的骨架,承担着支撑和保护建筑物的重要功能。

然而,由于各种原因,主体结构可能会遭受损伤,这不仅会影响建筑物的安全性和稳定性,还可能导致其他严重后果。

因此,及时进行主体结构损伤鉴定是至关重要的。

二、主体结构损伤的分类主体结构损伤可以分为静力损伤和动力损伤两类。

1. 静力损伤静力损伤是指由于外力作用或结构自身原因导致的主体结构的损伤。

外力作用包括地震、风力、温度变化等,而结构自身原因主要包括材料老化、设计缺陷等。

静力损伤可以通过目视检查、结构力学分析等方法进行鉴定。

2. 动力损伤动力损伤是指由于振动、冲击等动力载荷作用下的主体结构损伤。

动力载荷可以来自交通运输、机械设备等。

动力损伤的鉴定通常需要借助振动传感器、加速度计等设备进行实时监测和数据分析。

三、主体结构损伤鉴定的方法主体结构损伤鉴定的方法主要包括目视检查、非破坏性检测和结构力学分析等。

1. 目视检查目视检查是最常用的主体结构损伤鉴定方法之一。

通过观察建筑物外观和结构构件的变形、开裂等现象,可以初步判断主体结构是否存在损伤。

然而,目视检查不能提供准确的损伤程度和损伤原因的信息,因此需要结合其他方法进行综合分析。

2. 非破坏性检测非破坏性检测是一种通过对主体结构进行无损检测来获取结构状态信息的方法。

常用的非破坏性检测技术包括超声波检测、磁粉检测、红外热像检测等。

这些技术可以检测主体结构的内部缺陷、裂缝等问题,为损伤鉴定提供重要依据。

3. 结构力学分析结构力学分析是一种基于数学和物理原理的方法,通过建立结构模型和载荷模型,计算和分析主体结构的受力情况,从而判断结构是否存在损伤。

结构力学分析需要借助计算机软件进行模拟和计算,具有较高的准确性和可靠性。

四、主体结构损伤鉴定的意义主体结构损伤鉴定对于建筑物的安全运行和维护具有重要意义。

1. 确保建筑物的安全性通过主体结构损伤鉴定,可以及时发现和修复建筑物的结构问题,保证建筑物的安全性和稳定性。

Wavelet packet based damage identification of beam structuresJian-Gang Han a ,Wei-Xin Rena,b,*,Zeng-Shou SunaaDepartment of Civil Engineering,Fuzhou University,Fuzhou,Fujian 350002,People Õs Republic of ChinabDepartment of Civil Engineering,Central South University,Changsha,Hunan 410075,People Õs Republic of ChinaReceived 1August 2004;received in revised form 6April 2005Available online 8June 2005AbstractMost of vibration-based damage detection methods require the modal properties that are obtained from measured sig-nals through the system identification techniques.However,the modal properties such as natural frequencies and mode shapes are not such a good sensitive indication of structural damage.The wavelet packet transform (WPT)is a mathemat-ical tool that has a special advantage over the traditional Fourier transform in analyzing non-stationary signals.It adopts redundant basis functions and hence can provide an arbitrary time-frequency resolution.In this study,a damage detection index called wavelet packet energy rate index (WPERI),is proposed for the damage detection of beam structures.The mea-sured dynamic signals are decomposed into the wavelet packet components and the wavelet energy rate index is computed to indicate the structural damage.The proposed damage identification method is firstly illustrated with a simulated simply supported beam and the identified damage is satisfactory with assumed damage.Afterward,the method is applied to the tested steel beams with three damage scenarios in the laboratory.Despite the noise is present for real measurement data,the identified damage pattern is comparable with the tests.Both simulated and experimental studies demonstrated that the WPT-based energy rate index is a good candidate index that is sensitive to structural local damage.Ó2005Elsevier Ltd.All rights reserved.Keywords:Damage detection;Wavelet packet transform;Energy rate index;Beam;Dynamic measurement;Signal process1.IntroductionDuring the service of beam structures such as large-scale frames,long-span bridges and high-rise build-ings,local damage of their key positions may continually accumulate,and finally results in sudden failure of0020-7683/$-see front matter Ó2005Elsevier Ltd.All rights reserved.doi:10.1016/j.ijsolstr.2005.04.031*Corresponding author.Address:Department of Civil Engineering,Fuzhou University,523Gongye Road,Fujian Province,Fuzhou 350002,China.Tel.:+8659187892454;fax:+8659183737442.E-mail address:ren@ (W.-X.Ren).URL: (W.-X.Ren).International Journal of Solids and Structures 42(2005)6610–6627/locate/ijsolstrJ.-G.Han et al./International Journal of Solids and Structures42(2005)6610–66276611 structures.One damage identification classification system commonly defines four levels of damage assess-ment(Doebling et al.,1998):(1)the presence of damage;(2)the location of the damage;(3)quantification of the severity of the damage;and(4)prediction of the remaining serviceability of the structure.Basically, damage identification techniques can be classified into either local or global methods.Most currently used techniques,such as visual,acoustic,magneticfield,eddy current,etc.,are effective yet local in nature.They require that the vicinity of the damage is known a priori and the portion of the structure being inspected is readily assessable.The global damage identification methods,on the other hand,quantity the healthiness of a structure by examining changes in its global structural characteristics.It is believed that these two meth-ods should be used in a complementary way to effectively and correctly assess the condition of the health of a complicated structure.One core issue of the global vibration-based damage assessment methods is to seek some damage indices that are sensitive to structural damage(Ren and De Roeck,2002a,b).The damage indices that have been demonstrated with various degrees of success include natural frequencies,mode shapes,mode shape curva-tures,modalflexibility,modal strain energy,etc.Doebling et al.(1998)and Farrar et al.(1999)summarized the comprehensive historic development of damage assessment methodologies based on these indices as well as pointed out their applicability and limitations.Most of vibration-based damage assessment methods re-quire the modal properties that are obtained from the measured signals through the system identification techniques such as the Fourier transform(FT).The structural damage is typically a local phenomenon, which tends to be captured by higher frequency signals.The Fourier analysis transforms the signal from a time-based or space-based domain to a frequency-based one.Unfortunately,the time or space information may be lost during performing such a transform and it is sometimes impossible to determine when or where a particular event took place.To correct this deficiency,the short-time Fourier transform(STFT)was pro-posed by Gabor(1946).This windowing technique analyzes only a small section of the signal at a time. The STFT maps a signal into a2-D function of time or space and frequency.The transformation has the disadvantage that the information about time or space and frequency can be obtained with a limited preci-sion that is determined by the size of the window.A higher resolution in time or space and frequency domain cannot be achieved simultaneously since once the window size is chosen,it is the same for all frequencies.The wavelet transform(WT)is precisely a new way to analyze the signals,which overcomes the problems that other signal processing techniques exhibit.Wavelet functions are composed of a family of basis func-tions that are capable of describing a signal in a localized time(or space)and frequency(or scale)domain (Daubechies,1992).The main advantage gained by using wavelets is the ability to perform local analysis of a signal,i.e.,zooming on any interval of time or space.Wavelet analysis is thus capable of revealing some hidden aspects of the data that other signal analysis techniques fail to detect.This property is particularly important for damage detection applications.Many investigators(Wang and McFadden,1996;Kitada, 1998;Gurley and Kareem,1999;Wang and Deng,1999;Hou et al.,2000;Ovanesova and Suarez,2003) presented applications of wavelet transform to detect cracks in frame structures.One possible drawback of the WT is that the frequency resolution is quite poor in the higher frequency region.Hence,it still faces the difficulties when discriminating the signals containing close high frequency components.The wavelet packet transform(WPT)is an extension of the WT,which provides a complete level-by-level decomposition of signal(Mallat,1989).The wavelet packets are alternative bases formed by the linear com-binations of the usual wavelet functions(Coifman and Wickerhauser,1992).Therefore,the WPT enables the extraction of features from the signals that combine the stationary and non-stationary characteristics withan arbitrary time-frequency resolution.Sun and Chang(2002)developed a WPT-based component energy technique for analyzing structural damage.The component energies werefirstly calculated and then they were used as inputs into the neural network(NN)models for damage assessment.In this paper,a WPT-based method is proposed for the damage detection of beam structures.Dynamic signals measured from structures arefirst decomposed into the wavelet packet components.The wavelet energy rate index is proposed,which is then used to locate damage.Both simulated and tested beams withdifferent damage scenarios are used as the case studies to validate the applicability of proposed damage identification procedure.The results demonstrated that the WPT-based energy index is a good candidate index that is sensitive to structural local damage.2.Theoretical backgroundWavelet packets consist of a set of linearly combined usual wavelet functions.The wavelet packets in-herit the properties such as orthonormality and time-frequency localization from their corresponding wave-let functions.A wavelet packet w ij;k ðtÞis a function with three indices where integers i,j and k are themodulation,scale and translation parameters,respectively,w ij;kðtÞ¼2j=2w jð2j tÀkÞ;i¼1;2;3; (1)The wavelet functions w i can be obtained from the following recursive relationships:w2jðtÞ¼ffiffiffi2p X1k¼À1hðkÞw ið2tÀkÞ;ð2Þw2jþ1ðtÞ¼ffiffiffi2p X1k¼À1gðkÞw ið2tÀkÞ.ð3ÞThefirst wavelet is so-called a mother wavelet function as follows:w1ðtÞ¼wðtÞ.ð4ÞThe discretefilters h(k)and g(k)are the quadrature mirrorfilters associated with the scaling function and the mother wavelet function.There are quite a few mother wavelets reported in the literature.Most of these mother wavelets are developed to satisfy some key properties such as the invertibility and orthogonality. Daubechies(1992)developed a family of mother wavelets based on the solution of a dilation equation. One of these wavelet functions,DB5,is adopted in this study.The WT consists of one high frequency term from each level and one low-frequency residual from the last level of decomposition.The WPT,on the other hand,contains a complete decomposition at every level and hence can achieve a higher resolution in the high frequency region.The recursive relations between the j thand th e(j+1)thlevel components aref i j ðtÞ¼f2iÀ1jþ1ðtÞþf2ijþ1ðtÞ;ð5Þf2iÀ1 jþ1ðtÞ¼Hf ijðtÞ;ð6Þf2i jþ1ðtÞ¼Gf ijðtÞ;ð7Þwhere H and G are thefiltering-decimation operators related to the discretefilters h(k)and g(k)in sucha wayH fÁg¼X1k¼À1hðkÀ2tÞ;ð8ÞG fÁg¼X1k¼À1gðkÀ2tÞ.ð9ÞAfter j level of decomposition,the original signal f(t)can be expressed asfðtÞ¼X2ji¼1f ijðtÞ.ð10Þ6612J.-G.Han et al./International Journal of Solids and Structures42(2005)6610–6627The wavelet packet component signal f ij ðtÞcan be represented by a linear combination of wavelet packetfunctions w ij;kðtÞas follows:f i j ðtÞ¼X1k¼À1c ij;kðtÞw ij;kðtÞ;ð11Þwhere the wavelet packet coefficients c ij;kðtÞcan be obtained fromc i j;k ðtÞ¼Z1À1fðtÞw ij;kðtÞd t;ð12ÞJ.-G.Han et al./International Journal of Solids and Structures42(2005)6610–66276613providing that the wavelet packet functions are orthogonalw m j ;k ðt Þw nj ;k ðt Þ¼0if m ¼n .ð13ÞEach component in the WPT tree can be viewed as the output of a filter tuned to a particular basis func-tion,thus the whole tree can be regarded as a filter bank.At the top of WPT tree (lower level),the WPT yields a good resolution in the time domain but a poor resolution in the frequency domain.At the bottom of WPT tree (higher level),the WPT results in a good resolution in the frequency domain yet a poor res-olution in the time domain.To illustrate the WPT,the following example is given:f ðt Þ¼sin ð2p t Þþsin ð4p t Þþsin ð10p t Þð06t 610s Þ;sin ð1.998p t Þþsin ð4p t Þþsin ð10p t Þð10<t 620s Þ.ð14ÞThis harmonic function as shown in Fig.1(a)basically contains three frequencies:1.0,2.0,and 5.0Hz up to 10s.After 10s,1.0Hz frequency is suddenly reduced to 0.999Hz.Fig.1(b)shows the FT results for the first 10s and the last 10s.As expected,the small perturbation of the 1.0Hz frequency is not visible from the spectral density function by the FT.However,this small change in frequency can be detected by the WPT.Fig.2shows the eight wavelet packet component signals after three levels of wavelet packet decomposition.It can be seen that the suddenly shift at 10s is quit visible in most of the wavelet componentsignals.Fig.2.Signal components of third level wavelet packet transform (WPT).6614J.-G.Han et al./International Journal of Solids and Structures 42(2005)6610–66273.Wavelet packet energy rate indexYen and Lin(2000)investigated the feasibility of applying the WPT to the vibration signals.They de-fined a wavelet packet node energy index and concluded that the node energy representation could provide a more robust signal feature for classification than using the wavelet packet coefficients directly.Sun and Chang(2002)proposed a wavelet packet component energy index which was then used as inputs of neural network models for damage assessment.The numerical simulations were performed using a three-span con-tinuous bridge under impact excitation.Various levels of damage assessment including the occurrence, location,and severity of the damage were studied.In this study,the wavelet packet energy index is pro-posed to identify the locations and severity of damage.To do that,the signal energy E f at j level isfirst defined asE fj ¼Z1À1f2ðtÞd t¼X2jm¼1X2jn¼1Z1À1f mjðtÞf njðtÞd t.ð15ÞSubstituting Eq.(11)into Eq.(15)and using the orthogonal condition Eq.(13)yieldsE fj ¼X2ji¼1E f ij;ð16Þwhere the wavelet packet component energy E f ij can be considered to be the energy stored in the componentsignal f ijðtÞ,E f ij ¼Z1À1f ijðtÞ2d t.ð17ÞIt can be seen that the component signal f ij ðtÞis a superposition of wavelet functions w ij;kðtÞof the samescale as j but translated into the time domain(À1<k<1).This means that the component energy E f ij isthe energy stored in a frequency band determined by the wavelet functions w ij;k ðtÞ.Physically,Eq.(16)illus-trates that the total signal energy can be decomposed into a summation of wavelet packet component ener-gies that correspond to different frequency bands.The component energies for the third level WPT before(denoted E a)and after(denoted E b)the fre-quency shift for the harmonic function Eq.(14)are listed in Table1.Duration of4s is used for computing E a within an interval of2–6s and E b within a interval of14–18s,respectively.For comparison,the third level WT component energies and their changes are also calculated.It is demonstrated that both WT com-ponent energies and WPT component energies are not sensitive to the shift at this level of decomposition.In fact,the signal energy is mainly contributed by thefirst(f13)and the second(f23)components.Thesetwo component energies are nearly close to the original signal energy.To further illustrate,the WT com-ponent energies and thefirst20WPT component energies of thefifth level decomposition are listed in Table 2.It can be observed that the component energies for thefirst two WT components are more sensitive to the original signal energy.The WPT component energies are even more sensitive than those of WT.Also it can be seen that those small-value component energies are more sensitive than the characteristics change,e.g.,the energy change for f45and f55are115.8%and99.74%,respectively.Ideally,these sensitive componentenergies are good candidate indices that can reveal the signal characteristics.So the wavelet packet energy rate index(WPERI)is proposed to indicate the structural damage.The rate of signal wavelet packet energy DðE fjÞat j level is defined asDðE fj Þ¼X2ji¼1ðE f ijÞbÀðE f ijÞaðE f ijÞa;ð18ÞJ.-G.Han et al./International Journal of Solids and Structures42(2005)6610–66276615Table2Component energies for thefifth level wavelet transform(WT)and wavelet packet transform(WPT)(first20terms)before(E a)and after(E b)shift in frequency of the harmonic functionE a(2–6s)E b(14–18s)Change(%)WT f(t) 6.0 6.00870.15f a 5ðtÞ 2.0782 2.1887 5.3153f d 5ðtÞ 1.7523 1.88147.3677f d 4ðtÞ 1.7419 1.74190.00f d 3ðtÞ0.328350.328350.00f d 2ðtÞ0.00143820.00143820.00f d1ðtÞ 2.0371eÀ006 2.0371eÀ0060.00 WPT f(t) 6.0 6.00870.15f1 5ðtÞ 2.0782 2.1887 5.3153f2 5ðtÞ 1.7523 1.88147.3677f3 5ðtÞ 1.5656 1.2371À20.982f4 5ðtÞ0.21570.46548115.8f5 5ðtÞ0.000141720.0002830799.737f6 5ðtÞ0.000287460.00011594À59.668f7 5ðtÞ0.286120.26205À8.4136f8 5ðtÞ0.0519490.0557577.3296f9 5ðtÞ8.2926eÀ007 6.5244eÀ007À21.322f10 5ðtÞ 2.4007eÀ007 4.4744eÀ00786.377f11 5ðtÞ0.0010650.00094255À11.494f12 5ðtÞ0.000184290.0002101214.012f13 5ðtÞ 1.4228eÀ007 1.4148eÀ007À0.5645f14 5ðtÞ 2.8154eÀ008 2.7629eÀ008À1.865f15 5ðtÞ0.000210950.00018344À13.042f16 5ðtÞ 3.6043eÀ005 4.1441eÀ00514.977f17 5ðtÞ 1.1175eÀ0099.657eÀ010À13.587f18 5ðtÞ 1.7835eÀ010 6.4183eÀ010259.87f19 5ðtÞ 1.4005eÀ006 1.4412eÀ006 2.9029f20 5ðtÞ 2.8151eÀ007 2.7678eÀ007À1.6787Table1Component energies for the third level wavelet transform(WT)and wavelet packet transform(WPT)before(E a)and after(E b)shift in frequency of the harmonic functionE a(2–6s)E b(14–18s)Change(%)WT f(t) 6.0 6.00870.15f a 3ðtÞ 5.6702 5.67900.16f d 3ðtÞ0.32840.32840.00f d 2ðtÞ0.00140.00140.00f d1ðtÞ 2.0371eÀ6 2.0371eÀ60.00 WPT f(t) 6.0 6.00870.15f1 3ðtÞ 5.6702 5.67900.16f2 3ðtÞ0.32840.32840.00f3 3ðtÞ0.00120.00120.00f4 3ðtÞ0.00020.00020.00f5 3ðtÞ 1.7014eÀ6 1.7014eÀ60.00f6 3ðtÞ 3.3422eÀ7 3.3422eÀ70.00f7 3ðtÞ 1.224eÀ9 1.224eÀ90.00f8 3ðtÞ 2.4046eÀ10 2.4046eÀ100.006616J.-G.Han et al./International Journal of Solids and Structures42(2005)6610–6627whereðE f ij Þais the component signal energy E f ijat j level without damage,andðE f ijÞbis the component sig-nal energy E f ij with some damage.It is postulated that structural damage would affect the wavelet packetcomponent energies and subsequently alter this damage indicator.It is desirable to select the WPERI that is sensitive to the changes in the signal characteristics.4.Damage identification proceduresA damage identification procedure based on the proposed WPERI is described here.Two assumptions are adopted in this study:(1)the reliable undamaged and damaged structural models are available;(2)the structure is excited by the same impulse load and acts at the same location.Vibration signals measured from the structure by sensors arefirst processed using the WPT.The level of wavelet packet decomposition is determined through a trial and error sensitivity analysis using the undamaged and damaged structural models.Then the wavelet packet energy rates of signals are calculated.It is proposed to establish threshold values for the damage indicators based on the statistical process control(SPC)method(Benffey,1993;Montgomery,1996).For structural health monitoring applications, Sohn et al.(2000)indicated that an X-bar control chart can provide a statistical framework for monitoring future measurements and for identifying abnormality in the new data.The core of the technique is in estab-lishing the lower and upper control limits(LCL and UCL)that can enclose the variation of the extracted damage indicators due to measurement noise witha large probability.Hence,any damage indicator th at falls outside of the enclosure signifies the change of the structural condition with high probability.Sun and Chang(2004)proposed two damage indicators for the purpose of structural health monitoring,which were then formulated to lump the discriminated information from the extracted wavelet packet signature. The thresholds for damage alarming were established using the statistical properties and the one-side con-fidence limit of the damage indicators from successive measurements.If n stands for the total number of all sensors distributing in structure,a total of n WPERIs can be ob-tained after performing the wavelet packet decomposition.When the mean values and the standard devi-ations of these WPERIs are expressed as l WPERI and r WPERI,the one-side(1Àa)upper confidence limit for the WPERI can be obtained from(Ang and Tang,1975)UL aWPERI ¼l WPERIþZ ar WPERIffiffiffin p;ð19Þwhere Z a is the value of a standard normal distribution with zero mean and unit variance such that the cumulative probability is100(1Àa)%.This limit can be considered as a threshold value for alarming of possible abnormality in the damage indicator WPERI.One special advantage of this damage identification is that the setting of the threshold value is based on the statistical properties of the damage indicator mea-sured with sensors.Any indicator that exceeds the threshold would cause damage alarming.So even when the multiple damage occurs,the proposed method can still work well.The location of sensors whose WPERI values exceed the threshold will indicate where possible damage occurs.5.Simulated beamsTo validate the applicability of the proposed wavelet packet based damage identification method,the simulated simply supported beams without damage and with several assumed damage elements are consid-ered.The beam of6m length is discretized with30elements as shown in Fig.3.The mass density and mod-ulus of elasticity of material of beam are2500kg/m3and3.2·104MPa,respectively,while the area and J.-G.Han et al./International Journal of Solids and Structures42(2005)6610–662766176618J.-G.Han et al./International Journal of Solids and Structures42(2005)6610–6627inertia moment of the cross section of simulated beam are0.05m2and1.66·10À4m4,respectively.To emulate a practical impulse load,the force–time history as shown in Fig.4is applied at the distance 0.3m from the left support of the beam.The node displacement responses of the beams under the impulse load are obtained by thefinite element analysis package(ANSYSÒ,1999)at a sampling frequency of 1000Hz.Those displacement responses are regarded as the measured dynamic signals.To simulate damage,four damage scenarios withdifferent levels of severity and location are conceived. The damage severities are implemented by reducing the stiffness of specific elements.The reason to adopt this type of damage is that the damage could be easily emulated and quantified.The undamaged beam is denoted by D0as a reference.The other four different damage scenarios,denoted as D1–D4,are described as follows:(1)D1:stiffness reduced10%in th e15thand16thelements;(2)D2:stiffness reduced20%in th e 15thand16thelements;(3)D3:stiffness reduced10%in th e8th,9th,15thand16thelements;(4)D4:stiff-ness reduced20%in the8th,9th,15th and16th elements.A typical displacement response and its Fourier spectral density for the undamaged beam D0are shown in Fig.5,respectively.It can be shown that the node displacement responses generated by the impulse load are quite small.Thefirst two natural frequencies below200Hz of the undamaged beam are found to be 35.989and143.18Hz by the Fourier spectra.Thefirst two natural frequencies for other four damage cases can also be found from their corresponding Fourier spectral density functions.These frequencies are list in Table3.It is demonstrated that the damage results in the reduction of the beam natural frequencies.How-ever,the changes of both frequencies for all damaged cases are less than1.5%compared to those of undam-aged case D0.Such a small change in natural frequencies indicates that the frequency index is not sensitive to the local structural damage.The displacement responses of all damaged beams at the same node(node10)are shown in Fig.6.It can be observed that damage cannot been seen from the time history responses.As illustrated in the above example of the three-component harmonic function,a sufficiently high level of decomposition is required to obtain the sensitive component energies.For the simulated beams,the decomposition level is set to be4where a total of16component energies are generated.In order to study the effect of decompositionJ.-G.Han et al./International Journal of Solids and Structures42(2005)6610–66276619Table3First two natural frequencies(Hz)for different damage scenariosD0D1D2D3D4First mode35.98935.72635.40635.58335.094 Second mode143.18143.16143.14142.15140.90level,the decomposition level is also set to be5where a total of32component energies are generated.It is found that both results seem very similar,which indicates that4decomposition level is enough.Afterdecomposing the signals,the wavelet packet energy rate indices DðE fj Þof eachnode are calculated usingEq.(18).There are29WPERI DðE fj Þvalues calculated for anyone damaged beam.The statistical analysis is thenimplemented within those29WPERI values.The mean value l WPERI and the standard deviation r WPERIcan be calculated.Assuming that a=0.02,the one sided98%confidence upper limit UL aWPERI for theWPERI can be obtained from Eq.(19).For every damaged beam,the histogram can be drawn whenthe UL aWPERI value is subtracted from the WPERI values.The damage location can be intuitively shownin histograms.Those histograms of four damaged beams are shown in Fig.7.In Fig.7(a),for instance, it can be seen that the wavelet packet energy rate indices appeared between nodes14,15and16,whichare exactly the damage locations of bean D1.In Fig.7(c),it can be observed that the wavelet packet energy rate indices appeared between nodes7,8,9,14,15and16,which are identical to the damage location of beam D3.It is demonstrated that the locations of four damaged beams can be correctly identified.Unfortunately,the damage severity cannot be identified quantificationally.However,for the same dam-age locations but different levels of damage compared with Fig.7(a)and(b)or(c)and(d),the amplitude levels in the histograms are higher for the cases of more severe damage,which can represent the damage severity to some extent.6.Tested beams in laboratoryTo make the damage identification practical,the proposed damage identification procedure should be verified not only withth e simulated data,but also withreal measurement data from dynamic tests on the structures where the noise and measurement errors are present.The damage indices in most ofmodal-based dynamic identification techniques are sensitive to noise and measurement errors,which is the main difficulty for practical applications.Four I -section steel beams withspan lengthof 3m,as sh own in Fig.8,are used to illustrate the proposed damage assessment index.Beam0is an undamaged beam used as the reference.Beam1is a one-damage sce-nario damaged at the middle of beam.Beam2is a two-damage scenario where there are two damage loca-tions.Beam3is a three-damage scenario where there are three damage locations.All beams are dismembered 27segments as shown in Fig.8(b).The properties of the beams are as follows:mass density q =7117kg/m 3,elastic modulus E =210GN/m 2,cross section area A =14.33cm 2,and the inertia moment of cross section I x =245cm 4,I y =32.8cm 4.Dynamic tests and measurements have been carried out on all the beams in the laboratory as shown in Fig.9.The excitation is provided by an impact hammer applied at the center between 1and 2nodes.Twenty-six measurement locations as shown in Fig.8(b)were measured by 3setups.The force-balance accelerometers are used to measure the dynamic responses.The sampling frequency for all signals is 3000Hz.The acceleration responses of all four beams at the same node (node 10)were shown in Fig.10.It is observed that damage cannot been seen from the time historyresponses.Fig.8.Tested beams.(a)Cross section of tested beams.(b)Dimension and damage locations of tested beams.。