西瓦产品培训手册(新)

- 格式:doc

- 大小:488.00 KB

- 文档页数:10

![VAVE活动培训教材[1]](https://uimg.taocdn.com/9baa5e7605087632311212d0.webp)

PARTS LISTand Electrical Diagramsfor GH-1340W/1440W LathesSee manual no. M-321810 for operating and maintenance instructions.WALTER MEIER (Manufacturing) Inc.427 New Sanford RoadLaVergne, Tennessee 37086Part No. M-321810-1 Ph.: 800-274-6848Revision G 08/2010 Copyright © 2010 Walter Meier (Manufacturing) Inc.This .pdf document is bookmarkedTable of ContentsHeadstock Assembly I (3)Headstock Assembly II (6)Headstock Assembly III (8)Gearbox Assembly I (11)Gearbox Assembly II (13)Gearbox Assembly III (15)Apron Assembly I (18)Apron Assembly II (20)Carriage and Cross Slide Assembly (22)Four Way Tool Post and Compound Slide Assembly (25)Tailstock Assembly (27)Bed Assembly (29)Stand Assembly (32)End Gear Assembly (34)Follow Rest (36)Steady Rest (38)Coolant and Work Light Assembly (40)Electrical Components (42)W Series Lathes Electrical Schematic Symbol Glossary (43)Wiring Diagram – 1 Phase (44)Wiring Diagram – 3 Phase (45)To order parts or reach our service department, call 1-800-274-6848, Monday through Friday (see our website for business hours, ). Having the Model Number and Serial Number of your machine available when you call will allow us to serve you quickly and accurately.Index No. Part No. Description Size Qty1 ............... GH1340A-04-06 ............. P lug (1)2 ............... GH1440W-04-60 ............ H eadstock Cover .. (1)3 ............... TS-1503081 ................... H ex Socket Cap Screw .................................M6x35 (6)4 ............... GH1440W-04-61 ............ G asket .. (1)5 ............... GB3452.1-14X2.65 ........ O-Ring .........................................................14x2.65 . (8)6 ............... GH1440W-04-38 ............ G ear.............................................................38T.. (1)7 ............... GH1440W-04-41 ............ S haft .. (3)8 ............... GB75-M6x10 .................. S et Screw ....................................................M6x10 (3)9 ............... GB77-M6x6.................... S et Screw ....................................................M6x6 .. (3)10 ............. GH1440W-04-37 ............ G ear.............................................................48T.. (1)11 ............. GH1440W-04-36 ............ G ear.............................................................43T.. (1)12 ............. GB77-M12x12 ................ S et Screw ....................................................M12x12 . (2)13 ............. GH1440W-04-43 ............ S hift Arm .. (1)14 ............. GB879-5X30 .................. S pring Pin ....................................................5x30 (7)15 ............. GB894.2-12 ................... R etainer Ring ...............................................12 . (3)16 ............. GH1440W-04-45 ............ S hift Fork . (1)17 ............. GH1440W-04-35 ............ S hift Arm .. (2)18 ............. GH1440W-04-44 ............ G ear Shifter. (2)19 ............. GH1440W-04-10 ............ P lug (3)20 ............. GB1096-5X16 ................ K ey ..............................................................5x16 (4)21 ............. GB308-SB8.................... S teel Ball ......................................................8 (5)22 ............. C6240-20018 ................. S pring (5)23 ............. GH1440W-04-49 ............ H andle Body .. (2)24 ............. GB4141.14-BM10X50 .... H andle Cap . (5)25 ............. GH1440W-04-34 ............ H andle Lever .. (5)26 ............. C6240-20001 ................. L ever Name Plate. (3)27 ............. TS-1531012 ................... P an Head Machine Screw ............................M3x6 (14)28 ............. GH1440W-04-59 ............ S crew . (3)29 ............. TS-1503031 ................... S crew ...........................................................M6x12 (6)30 ............. GH1440W-04-50 ............ P osition Plate . (2)31 ............. GB3452.9-19X2.65 ........ O-Ring .........................................................19x2.65 . (3)32 ............. GH1440W-04-40 ............ G ear Shaft....................................................22T.. (1)33 ............. GH1440W-04-42 ............ G ear Shaft....................................................17T.. (1)34 ............. GH1440W-04-51 ............ P osition Plate . (1)35 ............. GH1440W-04-48 ............ H andle Body .. (1)36 ............. TS-1506041 ................... H ex Socket Cap Screw .................................M12x35 . (4)37 ............. GB5782-M10x40 ............ A lignment Bolt ..............................................M10x40 . (2)38 ............. GH1440W-04-62 ............ A lignment Bolt (2)39 ............. GH1440W-04-63 ............ A lignment Block (1)40 ............. GB1160.1-89 ................. O il Sight Glass .............................................20 . (1)................. GHW1160-20A............... O il Sight Glass (serial no. 1002W2659W and higher)...M20x1.5 (1)41 ............. GH1440W-04-01 ............ H eadstock Casting (14”) (1)................. GH1340W-04-01 ............ H eadstock Casting (13”) (1)42 ............. 05-75 ............................. D rain Plug (1)43 ............. GH1440W-04-39 ............ G ear Shaft....................................................27T.. (1)44 ............. GH1440W-04-47 ............ S haft Fork (1)45 ............. GH1440W-04-72 ............ S hifting Crank (1)46 ............. GH1440W-04-71 ............ S haft Fork (1)47 ............. GH1440W-04-56 ............ S hifting Crank (1)48 ............. GB308-SB9.................... S teel Ball ......................................................9 (2)49 ............. GH1440W-49 ................. S pring (2)50 ............. GH1440W-04-52 ............ S haft .. (1)51 ............. GH1440W-04-54 ............ S haft .. (1)52 ............. GH1440W-04-53 ............ S haft .. (1)53 ............. GB1096-4X10 ................ K ey ..............................................................4x10 (1)54 ............. GB3452.9-10.6X2.65 ..... O-Ring .........................................................10.6x2.65 . (1)Index No. Part No. Description Size Qty55 ............. GH1440W-04-55 ............ C ollar . (1)56 ............. TS-1503031 ................... H ex Socket Cap Screw .................................M6x12 . (18)57 ............. GH1440W-04-57 ............ C ollar . (1)58 ............. GH1440W-04-58 ............ H andle Body .. (1)59 ............. 04-62 ............................. W asher . (1)60 ............. 04-90 ............................. I ndicator Disk . (1)142 ........... GB3452.9-25X2.65 ........ O-Ring .........................................................25x2.65 . (3)159 ........... GH1340W-04-02 ............ N ame Plate . (1)................. GH1440W-04-02 ............ N ame Plate . (1)................. GH-1340W-3J.B.S ......... 3-Jaw Chuck (not shown) . (1)................. GH-1340W-4J.B.S ......... 4-Jaw Chuck (not shown) . (1)Index No. Part No. Description Size Qty 56 ............. TS-1503031 ................... H ex Socket Cap Screw .................................M6x12 . (18)61 ............. TS-1504041 ................... H ex Socket Cap Screw .................................M8x20 (1)62 ............. 04-12 ............................. W asher . (1)63 ............. 04-11 ............................. P ulley . (1)64 ............. 11-10 ............................. B reak Block . (1)65 ............. GB879-5X16 .................. P in ...............................................................5x16 (1)66 ............. 11-09 ............................. B rake Actuator Shaft .. (1)67 ............. GB894.2-12 ................... R etainer Ring ...............................................12 . (1)68 ............. GB9877.1-SD25X45X7 .. S pacer .........................................................SD25x45x7 .. (1)69 ............. GB117-A6X26 ................ P in ...............................................................A6x26 . (2)70 ............. GB894.2-8 ..................... R etainer Ring ...............................................8 (1)71 ............. 11-11 ............................. B rake Retainer Stud (1)72 ............. 04-13 ............................. C over . (1)73 ............. 04-14 ............................. G asket .. (1)74 ............. GB894.2-25 ................... R etainer Ring ...............................................25 . (6)75 ............. GB/T276-6205 ............... B all Bearing..................................................6205/p5 . (1)76 ............. GB1096-8X20 ................ K ey ..............................................................8x20 (2)77 ............. GH1440W-04-03 ............ S haft .. (1)78 ............. GB1096-8X72 ................ K ey ..............................................................8x72 (1)79 ............. GH1440W-04-04 ............ G ear.............................................................50T.. (1)80 ............. GH1440W-04-05 ............ G ear.............................................................37T.. (1)81 ............. GH1440W-04-06 ............ G ear.............................................................43T.. (1)82 ............. GB/T276-6204 ............... B all Bearing..................................................6204/p5 . (5)83 ............. GH1440W-04-17 ............ W asher . (1)84 ............. GH1440W-04-12 ............ G ear.............................................................57T.. (1)85 ............. GH1440W-04-11 ............ G ear Shaft....................................................20T.. (1)86 ............. GB893.1-47 ................... R etainer Ring ...............................................47 . (1)87 ............. GB3452.1-40X2.65 ........ O-Ring .........................................................40x2.65 . (1)88 ............. 04-28 ............................. P lug (1)89 ............. 04-53 ............................. B earing Cap (2)90 ............. 04-52 ............................. B earing Cap Gasket (2)91 ............. GH1440W-04-08 ............ G ear.............................................................28T.. (1)92 ............. GB1096-8X38 ................ K ey ..............................................................8x38 (1)93 ............. GH1440W-04-09 ............ G ear.............................................................41T.. (1)94 ............. GH1440W-04-10 ............ G ear.............................................................34T.. (1)95 ............. GB894.2-40 ................... R etainer Ring ...............................................40 . (1)96 ............. GB/T276-6005 ............... B all Bearing..................................................6005/p5 . (4)97 ............. GH1440W-04-07 ............ G ear Shaft....................................................21T.. (1)98 ............. GB894.2-17 ................... R etainer Ring ...............................................17 . (1)99 ............. GB/T276-61803 ............. B all Bearing..................................................61803/p5 .. (2)100 ........... GH1440W-04-15 ............ G ear.............................................................21T.. (1)101 ........... GH1440W-04-14 ............ G ear.............................................................58T.. (1)102 ........... GH1440W-04-16 ............ W asher . (1)103 ........... GB894.2-55 ................... R etainer Ring ...............................................55 . (1)104 ........... GH1440W-04-19 ............ G ear.............................................................59T.. (1)105 ........... GH1440W-04-18 ............ G ear.............................................................31T.. (1)106 ........... GB1096-10X18 .............. K ey ..............................................................10x18 . (1)107 ........... GH1440W-04-13 ............ S pline Shaft. (1)108 ........... GH1440W-04-24 ............ C over . (1)109 ........... TS-1503081 ................... H ex Socket Cap Screw .................................M6x35 (4)157 ........... 11-15 ............................. B rake Shoe Assembly (1)164 ........... VB-A73 .......................... V-Belt (GH-1340W-1/3 & GH-1440W-1). (2)................. VB-A74 .......................... V-Belt (GH-1440W-3) . (2)Index No. Part No. Description Size Qty 56 ............. TS-1503031 ................... H ex Socket Cap Screw .................................M6x12 . (18)74 ............. GB894.2-25 ................... R etainer Ring ...............................................25 . (6)82 ............. GB/T276-6204 ............... B all Bearing..................................................6204/p5 . (5)89 ............. 04-53 ............................. B earing Cap (2)90 ............. 04-52 ............................. B earing Cap Gasket (2)95 ............. GB894.2-40 ................... R etainer Ring ...............................................40 . (1)96 ............. GB/T276-6005 ............... B all Bearing..................................................6005/p5 . (4)102 ........... GH1440W-04-16 ............ W asher . (1)110 ........... TS-1503041 ................... H ex Socket Cap Screw .................................M6x16 (3)111 ........... GH1440W-04-29 ............ C over . (1)112 ........... 04-60 ............................. G asket .. (1)113 ........... TS-1502031 ................... H ex Socket Cap Screw .................................M5x12 (2)114 ........... GH1440W-04-31 ............ N ut .. (1)115 ........... GB/T297-32011 ............. T apered Roller Bearing ................................32011/p5 .. (1)116 ........... GH1440W-04-30 ............ G ear.............................................................38T.. (1)117 ........... GH1440W-04-27 ............ L ock Collar .. (1)118 ........... GH1440W-04-21 ............ G ear.............................................................59T.. (1)119 ........... TS-1504061 ................... H ex Socket Cap Screw .................................M8x30 (1)120 ........... GH1440W-04-23 ............ G ear.............................................................87T.. (1)121 ........... GH1440W-04-25 ............ C ollar . (1)122 ........... GB/T297-30212 ............. T apered Roller Bearing ................................30212/p5 .. (1)123 ........... GH1440W-04-32 ............ G asket .. (1)124 ........... GH1440W-04-28 ............ C over . (1)125 ........... TS-1503051 ................... H ex Socket Cap Screw .................................M6x20 (3)126 ........... GB1096-6X30 ................ K ey ..............................................................6x30 (1)127 ........... GB1096-10X55 .............. K ey ..............................................................10x55 . (1)128 ........... TS-1504031 ................... H ex Socket Cap Screw .................................M8x16 (3)129 ........... 04-31/1 .......................... S pring (3)130 ........... 04-86 ............................. C amlock Set Pin (3)131 ........... 04-85 ............................. C amlock (3)132 ........... GH1440W-04-22 ............ S pindle .. (1)133 ........... GB894.2-20 ................... R etainer Ring ...............................................20 . (4)134 ........... 04-36 ............................. S pacer .. (2)135 ........... 04-35 ............................. G ear.............................................................32T.. (1)136 ........... GB894.2-37 ................... R etainer Ring ...............................................37 . (1)137 ........... 04-54 ............................. G ear.............................................................32T.. (1)138 ........... GB1096-5X16 ................ K ey ..............................................................5x16 (1)139 ........... 04-55 ............................. G ear.............................................................32T.. (1)140 ........... TS-1523041 ................... S et Screw ....................................................M6x12 (1)141 ........... 04-37 ............................. S haft .. (1)142 ........... GB3452.9-25X2.65 ........ O-Ring .........................................................25x2.65 . (3)143 ........... 04-47/1 .......................... K ey ..............................................................6x90 (1)144 ........... 04-46 ............................. G ear ............................................................42T.. (1)145 ........... 04-45 ............................. C ollar . (1)146 ........... 04-44 ............................. G ear ............................................................32T.. (1)147 ........... 04-39 ............................. C ollar . (1)148 ........... 04-41 ............................. G ear.............................................................32T.. (1)149 ........... GB/T276-6004 ............... B all Bearing..................................................6004/p5 . (2)150 ........... GH1440W-04-33 ............ P lug (1)151 ........... 04-47 ............................. S haft (D) .. (1)152 ........... 04-43 ............................. G ear.............................................................38T.. (1)153 ........... 04-42 ............................. S pline Shaft (E) . (1)154 ........... 04-48 ............................. H ousing Gasket . (1)155 ........... 04-49 ............................. H ousing. (1)156 ........... GB9877.1-SD25X40X7 .. S pacer .........................................................SD25x40x7 .. (1)Index No. Part No. Description Size Qty 160 ........... GH1440W-04-66 ............ B alance Space .. (1)161 ........... GH1440W-04-67 ............ B alance Block (1)162 ........... TS-1523041 ................... S et Screw ....................................................M6x12 (1)163 ........... TS-1524031 ................... S et Screw ....................................................M8x12 (1)Index No. Part No. Description Size Qty1 ............... 05-73 ............................. P lug (1)2 ............... GH1440W-05-06 ............ G earbox Casting .. (1)3 ............... 05-07 ............................. F ront Cover . (1)4 ............... TS-1532032 ................... F lat Head Machine Screw.............................M4x10 (8)5 ............... GH1440W-05-26 ............ O il Cover (14”) (1)................. GH1340W-05-26 ............ O il Cover (13”) (1)6 ............... GH1440W-05-07/1 ......... C over (14”) .. (1)................. GH1340W-05-07/1 ......... C over (13”) .. (1)7 ............... GH1440W-05-08 ............ T op Cover (1)8 ............... GH1440W-05-09 ............ B racket.. (1)9 ............... TS-1531012 ................... P an Head Machine Screw ............................M3x6 .. (4)10 ............. GH1440W-05-11 ............ E lectrical Plate .. (1)11 ............. 05-61 ............................. G earbox Gasket (1)12 ............. TS-1504081 ................... H ex Socket Cap Screw .................................M8x40 (2)13 ............. TS-1504051 ................... H ex Socket Cap Screw .................................M8x25 (3)14 ............. GH1440W-14 ................. P in ...............................................................5x20 (2)15 ............. GH1440W-15 ................. P in ...............................................................5x28 (2)16 ............. 05-75 ............................. P lug (2)33 ............. GB118-A8X30 ................ P in ...............................................................A8x30 . (2)121 ........... GB867-2X4 .................... R ivet ............................................................2x4 .. (4)122 ........... GH-1440W-05-12/1 ........ S peed Chart (1)Index No. Part No. Description Size Qty17 ............. 05-49 ............................. G ear.............................................................16T.. (1)18 ............. GH893.1-19 ................... R etainer Ring ...............................................19 . (1)19 ............. GB/T276-6198 ............... B earing ........................................................6198/p5 . (1)20 ............. 05-51 ............................. S haft .. (1)21 ............. TS-1523021 ................... S et Screw ....................................................M6x8 .. (4)22 ............. 05-03 ............................. S hifter (1)23 ............. 05-02 ............................. S haft .. (1)24 ............. TS-1503051 ................... H ex Socket Cap Screw .................................M6x20 (2)25 ............. 05-13 ............................. R ack .. (1)26 ............. 05-01 ............................. S hift Key .. (3)27 ............. 05-12 ............................. S hift Fork . (1)28 ............. TS-1523021 ................... S et Screw ....................................................M6x8 .. (2)29 ............. 05-15 ............................. S haft .. (1)30 ............. 05-05 ............................. L ocating Plate (1)31 ............. 05-04 ............................. C ontrol Plate .. (1)32 ............. TS-1503031 ................... H ex Socket Cap Screw .................................M6x12 (4)33 ............. GB118-A8X30 ................ P in ...............................................................A8x30 . (2)34 ............. 05-60 ............................. S hift Hub .. (1)35 ............. GB1096-4X10 ................ K ey ..............................................................4x10 (3)36 ............. GH1440W-05-02 ............ S haft .. (1)37 ............. GB879-5X20 .................. P in ...............................................................5x20 (1)38 ............. 05-14 ............................. G ear.............................................................26T.. (1)39 ............. 05-55 ............................. S hift Fork . (1)40 ............. 05-56 ............................. S hift Lever (1)41 ............. GB879-5X20 .................. P in ...............................................................5x20 (1)42 ............. GH1440W-05-03 ............ S haft .. (1)43 ............. GH1440W-05-01 ............ C over . (1)44 ............. 05-58 ............................. L ocating Disk . (1)45 ............. GB819-M5X10 ............... F lat Head Machine Screw.............................M5x10 (8)46 ............. GB4141.14-BM10X50 .... K nob .. (1)47 ............. GH1440W-05-15 ............ H andle Shaft .. (1)48 ............. GH14440W-05-14 .......... S hift Hub .. (1)49 ............. 05-08 ............................. W asher . (3)50 ............. TS-1503041 ................... H ex Socket Cap Screw .................................M6x16 . (14)51 ............. 04-90 ............................. I ndicator Disk . (1)52 ............. TS-1531012 ................... P an Head Machine Screw ............................M3x6 (12)53 ............. 05-70 ............................. I ndicator Disk . (2)54 ............. TS-1524011 ................... S et Screw ....................................................M8x8 .. (4)55 ............. GH1440W-05-72 ............ S pring (4)56 ............. GB308-SB6.5 ................. S teel Ball ......................................................6.5 (4)57 ............. 05-10 ............................. L ocating Disk . (1)58 ............. GH1440W-05-27 ............ O il Sight Glass .. (1)................. GHW1160-16A............... O il Sight Glass (serial no. 1007W2720W and higher)......M16x1.5 . (1)59 ............. 05-59 ............................. L ocating Disk . (1)60 ............. GH1440W-05-13 ............ S hift Hub .. (2)61 ............. TS-1503081 ................... H ex Socket Cap Screw .................................M6x35 (7)123 ........... GH1440W-05-10-1 ......... N ame Plate (1 Phase) (1)................. GH1440W-05-10-3 ......... N ame Plate (3 Phase) (1)................. GH1340W-05-10-1 ......... N ame Plate (1 Phase) (1)................. GH1340W-05-10-3 ......... N ame Plate (3 Phase) (1)Index No. Part No. Description Size Qty 50 ............. TS-1503041 ................... H ex Socket Cap Screw .................................M6x16 . (14)62 ............. 05-42 ............................. W asher . (1)63 ............. 05-41 ............................. G ear.............................................................50T.. (1)64 ............. TS-1503051 ................... H ex Socket Cap Screw .................................M6x20 (3)65 ............. 05-39 ............................. F lange (1)66 ............. 05-38 ............................. G asket .. (1)67 ............. GB/T276-6004 ............... B all Bearing..................................................6004/P5 . (1)68 ............. GB1096-5X14 ................ K ey ..............................................................5x14 (1)69 ............. 05-40 ............................. G ear Shaft Assembly . (1)70 ............. GB/T276-6002 ............... B all Bearing..................................................6002/p5 . (1)71 ............. 05-36 ............................. S haft Collar . (1)72 ............. GB1096-5X75 ................ K ey ..............................................................5x75 (1)73 ............. 05-27 ............................. S haft .. (1)74 ............. 05-67 ............................. S haft Collar . (1)75 ............. GB/T276-6003 ............... B all Bearing..................................................6003/p5 . (2)76 ............. GB894.1-20 ................... R etainer Ring ...............................................20 . (3)77 ............. 05-21 ............................. G ear.............................................................16T/32T . (1)78 ............. GB/T276-6202 ............... B all Bearing..................................................6202/p5 . (4)79 ............. 05-48 ............................. G asket .. (2)80 ............. 05-47 ............................. F lange (2)81 ............. 05-35 ............................. G ear.............................................................28T.. (1)82 ............. GH1440W-05-19 ............ W asher . (1)83 ............. 05-34 ............................. G ear.............................................................26T.. (1)84 ............. GH1440W-05-20 ............ W asher . (1)85 ............. 05-33 ............................. G ear.............................................................24T.. (1)86 ............. GH1440W-05-21 ............ W asher . (1)87 ............. 05-32 ............................. G ear.............................................................23T.. (1)88 ............. GH1440W-05-22 ............ W asher . (1)89 ............. 05-31 ............................. G ear.............................................................22T.. (1)90 ............. GH1440W-05-23 ............ W asher . (1)91 ............. 05-30 ............................. G ear.............................................................20T.. (1)92 ............. GH1440W-05-24 ............ W asher . (1)93 ............. 05-29 ............................. G ear.............................................................18T.. (1)94 ............. GH1440W-05-25 ............ W asher . (1)95 ............. 05-28 ............................. G ear.............................................................16T.. (1)96 ............. 05-37 ............................. G ear.............................................................26T.. (1)97 ............. 05-52 ............................. S pline Shaft. (1)98 ............. GB1096-5X14 ................ K ey ..............................................................5x14 (2)99 ............. GB1096-6X14 ................ K ey ..............................................................6x14 (1)100 ........... GB893.1-32 ................... R etainer Ring ...............................................32 . (2)101 ........... GB/T276-61804 ............. B earing ........................................................61804/p5 .. (2)102 ........... 05-49 ............................. G ear.............................................................16T.. (1)103 ........... GH1340A-05-66 ............. W asher . (1)104 ........... 05-25 ............................. G ear.............................................................21T.. (1)105 ........... GB896-15 ...................... R etainer Ring ...............................................15 . (1)106 ........... 05-19 ............................. G ear.............................................................36T.. (1)107 ........... 05-53 ............................. G asket .. (1)108 ........... 05-17 ............................. F lange (1)109 ........... GB3452.1-15X2.65 ........ O-Ring .........................................................15x2.65 . (1)110 ........... GB301-8104 .................. B all Bearing..................................................8104 (3)111 ........... GB1096-5X20 ................ K ey ..............................................................5x20 (1)112 ........... GH1440W-05-04 ............ S haft .. (1)113 ........... GH1440W-05-05 ............ S haft .. (1)114 ........... 05-18 ............................. F lange (1)115 ........... 05-53 ............................. G asket .. (1)116 ........... 05-20 ............................. N ut .. (2)。

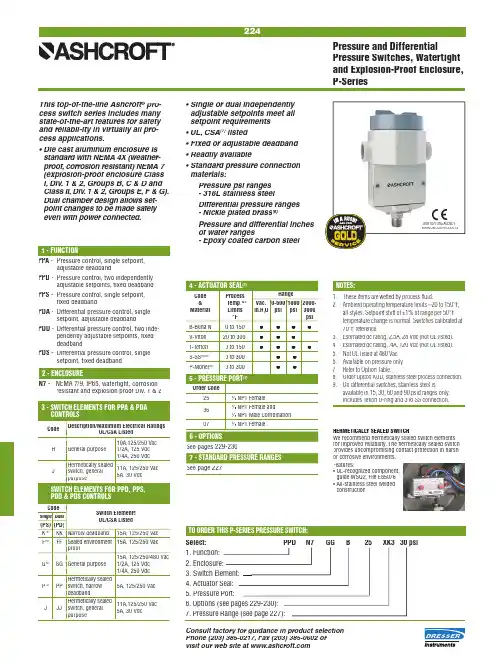

224Consult factory for guidance in product selection Phone (203) 385-0217, Fax (203) 385-0602 or visit our web site at Process Code R ange & Temp.(2) Vac. 0-600 1000 2000- Material Limits in.H 2O psi psi 3000 °F psi B-Buna N 0 to 150 ● ● ● ●V-Viton 20 to 300 ● ● ●T-Tefl on 0 to 150● ● ● ●S-SS (6)(9)0 to 300 ● ● P -Monel (6)0 to 300 ● ●D escription/Maximum Electrical Ratings Code UL/CSA Listed10A,125/250 VacH General purpose 1/2A, 125 Vdc 1/4A, 250 VdcHermetically sealed J switch, general 11A, 125/250 Vac purpose5A, 30 VdcCodeSwitch ElementsSingle D ual UL/CSA Listed(PS) (PD) K (4) KK Narrow deadband 15A, 125/250 Vac F (4)FF Sealed environment 15A, 125/250 Vacproof15A, 125/250/480 VacG (5) GG General purpose 1/2A, 125 Vdc 1/4A, 250 VdcHermetically sealedP (3) PP switch, narrow 5A, 125/250 VacdeadbandHermetically sealedJ JJ switch, general 11A,125/250 Vacpurpose 5A, 30 Vdc Select: PPD N7 GG B 25 XK3 30 psi 1. Function: 2. Enclosure: 4. Actuator Seal: 5. Pressure Port: 6. Options (see pages 229-230): 7. Pressure Range (see page 227):Pressure and Differential Pressure Switches, Watertight and Explosion-Proof Enclosure, P-Series • S ingle or dual independently adjustable setpoints meet all setpoint requirements • U L, CSA listed lis (7)• Fixed or adjustable deadband • Readily available • S tandard pressure connection materials:Pressure psi ranges - 316L stainless steel Differential pressure ranges - Nickle plated brass (8)Pressure and differential inches of water ranges - Epoxy coated carbon steel This top-of-the-line Ashcroft oft pro- pr ®cess switch series includes many state-of-the-art features for safety and reliabil-ity in virtually all pro-cess applications.• D ie cast aluminum enclosure is standard with NEMA 4X (weather-proof, corrosion resistant) NEMA 7 (explosion-proof enclosure Class I, Div. 1 & 2, Groups B, C & D and Class II, Div. 1 & 2, Groups E, F & G). Dual chamber design allows set-point changes to be made safely even with power connected.PPA - Pressure control, single setpoint, adjustable deadband PPD - Pressure control, two independently adjustable setpoints, fi xed deadband PPS - Pressure control, single setpoint, fi xed deadband PDA - Differential pressure control, single setpoint, adjustable deadbandPDD - Differential pressure control, two inde- pendently adjustable setpoints, fi xed deadband PDS - Differential pressure control, single setpoint, fi xed deadbandN7 - N EMA 7/9, IP65, watertight, corrosionresistant and explosion proof Div. 1 & 2 See pages 229-230 See page 227 Order Code 25 14⁄ NPT Female 1⁄4 NPT Female and 06 12⁄ NPT Male Combination 07 12⁄ NPT Female 3. Switch Element: HERMETICALLY SEALED SWITCH We recommend hermetically sealed switch elements for improved reliability. The hermetically sealed switch provides uncompromising contact protection in harsh or corrosive environments. Features:• U L-recognized component, guide WSQ2, File E85076• A ll-stainless steel welded construction LOOK FOR THIS AGENCY MARK ON OUR PRODUCTS 1. These items are wetted by process fl uid.2. A mbient operating temperature limits –20 to 150°F , all styles. Setpoint shift of ±1% of range per 50°F temperature change is normal. Switches calibrated at 70°F reference.3. Estimated dc rating, 2.5A, 28 Vdc (not UL listed).4. Estimated dc rating, .4A, 120 Vdc (not UL listed).5. Not UL listed at 480 Vac.6. Available on pressure only.7. Refer to Option Table.8. O rder Option XUD, stainless steel process connection.9. On differential switches, stainless steel is available in 15, 30, 60 and 90 psid ranges only. Includes Tefl on O-ring and 316 SS connection.。

贝加莱培训指南2021by B&R Automation Academy目录1概述 (3)1.1典型的培训过程 (3)1.2特别提示 (4)1.3如果你。

(4)2培训路径 (5)3培训课程介绍 (6)3.1基础培训 - PLC控制基础课程 (6)3.2基础培训 - PLC控制中级课程 (7)3.3基础培训 - 运动控制基础课程 (7)3.4专题培训 - 多轴运动控制 (8)3.5基础培训 - 人机界面之mappView (9)3.6基础培训 - 可视化界面之VC4 (10)3.7专题培训 - 终端用户诊断 (10)3.8定制化培训 (11)4 2021年课程计划 (12)4.1上海培训中心课程计划 (12)4.2 西安培训中心课程计划 (12)4.3北京培训中心课程计划 (13)4.4广州培训中心课程计划 (13)5培训报名流程 (14)5.1 标准培训报名流程 (14)5.2 定制化培训报名流程 (18)6流程和报名注意事项 (18)7附录 (19)贝加莱软件下载地址 (19)贝加莱培训手册和培训视频 (20)贝加莱上海培训中心周边住宿推荐 (20)贝加莱大中华区培训中心地址 (20)1 概述您好!首先十分感谢贵司对贝加莱一直的支持,基于增强双方技术交流的考虑,以下介绍贝加莱2021培训报名流程,欢迎您的参与。

贝加莱自动化学院是一个快速,高效的推进生产的方式。

为员工提供入职基础培训以及持续的专题培训为公司的成功做出来巨大的贡献。

我们的课程设计目标是为您建立并且拓宽自动化领域的专业技术能力。

学会如何在贝加莱体系中高效工作,并且开拓属于你自己的全球等级的自动化解决方案。

确保你有决定性的竞争优势,让你能够在全球不断变化的市场中快速响应。

自动化学院的全部课程都是基于培训手册的。

这些紧凑的培训模块遵循了统一,结构清晰的概念,在这些培训手册中,我们一步一步为你理解复杂的系统概念。

我们将培训手册模块化成独立的话题单元,使得培训手册能够同时完美的符合不同的培训客户的需求和自学者的需求。

西开GIS产品培训资料第⼀章西开G I S产品简介⼀、概述⽓体绝缘⾦属封闭开关设备(简称GIS),⾃开发以来,经历了三⼗多年历史.由于它将断路器、隔离开关、接地开关母线、互感器、避雷器等主要元件均装⼊密封的⾦属容器,内充以绝缘⽓体,故具有体积⼩、占地⾯积少、不受外界环境影响、运⾏安全可靠、维护简单和检修周期长等优点。

因此倍受⽤户欢迎,发展⾮常迅速,现已被⼴泛的运⽤于各类变电站。

⼆、GIS的称谓GIS国外称之为1、Gas Insulated metal-enclosed Switchgear⽓体绝缘⾦属封闭开关设备2、Gas Insulated Switchgear⽓体绝缘开关设备3、Gas Insulated Substation⽓体绝缘电站GIS国内俗称全封闭组合电器H-GIS国外称之为1、Half GIS 半个GIS2、Hybrid GIS 混合型GISH-GIS国内俗称复合电器四、GIS 的构成三、GIS 的分类按电压:o 72.5kV GIS126kV GIS 145kV GISo 252kV GIS o 275kV GIS363kV GISo 550kV GIS 按结构:全三相共箱型主母线三相共箱;其余分箱型全三相分箱型G I S间隔元件及系统辅助设备备件/⼯具等间隔元件及系统间隔元件及系统组成元件CB—断路器DS—隔离开关ES/FES—检修/故障关合接地开关BUS—母线CT—电流互感器总装内导DS/ES连接机构接地系统SF6系统压缩空⽓系统电器控制系统系统组成总体布置形式主要取决于安装现场条件和主接线的要求,同时也与进出线配置及元件结构等有关。

总体布置设计的任务是根据主接线要求在限定的安装场地和空间范围内使所有组成元件布置的合理、稳固、便于运⾏维护、经济美观。

五、GIS 的⼀次主接线及总体布置GIS 可满主各种主接线的要求,主要⼀次主接线类型:单母线接线形式双母线接线形式 ? 桥形接线形式 ? ⼀倍半接线形式126/145kVGIS 主要布置形式有单母、双母分段、桥形、双桥、双母、变压器直联等多种接线⽅式,以桥形接线为多。

{产品名称}产品使用手册Versio n:编号:WD PA PUM关于此文档{产品名称} (1)产品使用手册 (1)第1章简介 (3)1.1 目的和范围 (3)1.2 术语和缩略语 (3)1.3 参考资料 (3)第2章产品介绍 (4)2.1 产品背景 (4)2.2 产品定位 (4)2.3 版本说明 (4)2.4 运行环境 (4)第3章安装与部署 (5)3.1 服务端环境 (5)3.2 客户端环境 (5)3.3 安装步骤1 (5)3.4 安装步骤2 (5)第4章子系统1/模块1 (6)4.1 分解模块1 (6)4.1.1 下层分解模块1 (6)4.1.2 下层分解模块2 (6)4.2 分解模块2 (6)第5章常见问题与解答 (7)第1章简介1.1目的和范围说明文档描述的主要内容(一句话),文档编制的背景、针对的读者1.2术语和缩略语说明文档中涉及的业务术语和缩略语的含义,方便读者理解。

1.3参考资料第2章产品介绍2.1产品背景描述产品的研发过程2.2产品定位以尽量简洁的语言概述产品的主要功能和用途2.3版本说明描述产品的当前版本、历史版本、知识产权2.4运行环境描述产品支持的运行环境,需要的硬件和软件设施。

第3章安装与部署列出为运行本产品所需要的硬件环境和软件环境,支持软件注意标明版本号说明产品安装完成后,初始化过程中的全部操作命令以及表征安装工作完成的测试实例3.1服务端环境3.2客户端环境3.3安装步骤13.4安装步骤2第4章子系统1/模块1将每个子系统/功能模块按照功能逐层分解进行描述,建议拆分层次最好不要超过3层4.1分解模块14.1.1下层分解模块14.1.2下层分解模块24.2分解模块2第5章常见问题与解答。

因专业而领先瓦工项目施工培训培训师:钛马赫中国技术中心培训项目1.砌块隔墙砌筑施工 2.砌块包管道施工工艺 3.墙面抹灰施工工艺 4.地面垫层施工工艺 5.防水工程施工工艺 6.薄贴法施工工艺 7.地下室防潮保温处理(略)因专业而领先钛马赫中国技术中心1.1 隔墙砌筑施工概念: 用轻体砌块、砂浆按要求砌筑隔墙。

作用: A.分隔各功能间。

B.隔音、保温。

适用范围: 室内隔断。

因专业而领先钛马赫中国技术中心1.2施工流程因专业而领先1.放位置线2.砌筑干粉搅拌、铺灰3.砌筑墙体钛马赫中国技术中心1.3施工要点A.砌筑墙体时,墙底部应 现浇混凝土坎台等,其高 度不宜小于200mm。

因专业而领先200mm地枕基施工钛马赫中国技术中心1.3施工要点B.隔墙控制点:施工范围关键点控制2Ф6拉结筋,每500mm高度一 长度<3米 道,长度1000mm,100mm有效结合。

3米<长度 2×Ф6拉结筋拉通筋,每 <4米,高 500mm高度一道, 要求通筋 度<3米 处理,100mm有效结合。

2条水平拉结带,1条构造 长度>4米, 柱,2×Ф6拉结筋拉通筋, 高度>3米 每500mm高度一道,长度1000mm,100mm有效结合。

因专业而领先钛马赫中国技术中心因专业而领先1.3施工要点C.砌块搭砌长度不应小于砌块长度的1/3;轻骨料混 凝土小型空心砌块搭砌长度不应小于90mm 。

钛马赫中国技术中心1.3施工要点混凝土承重墙 轻体墙2φ6钢筋101000因专业而领先新建隔墙与承重墙交接处结构新建隔墙转角构造钛马赫中国技术中心1.3施工要点D.门窗洞口上方设置过梁, 现浇90-120mm厚的C20混 凝土过梁,内设钢筋网 片,过梁伸入墙内每边长 250mm。

E.对于原结构墙体须新建门 垛的部位,小于150mm的砌 体结构柱或墙,使用混凝 土现浇。

250mm因专业而领先90-120mm钛马赫中国技术中心因专业而领先1.4验收标准砂浆饱满度检验方法:砌体分类灰缝饱满度及要求检验方法空心砖砌块加气混凝土砌块 和轻骨料混凝 土小砌块砌体水平 垂直 水平垂直≥90%填满砂浆,不得有透明缝 采用百格网检查块材≥90%底面砂浆的粘结痕迹 面积≥90%一般尺寸允许偏差:项次 项 目允许偏差 (mm)位置偏移51垂直度52表面平整 度5检验方法用尺量检查 用2m托线板或吊线、尺量检查 用2m靠尺和楔形塞尺检查钛马赫中国技术中心1.5常见问题分析及预防常见问题一:过梁搭接长度不规范。

强化地板产品知识培训手册强化地板产品知识培训手册一.地面装饰材料分类及特点常用地面装饰材料包括:实木地板,多层实木地板,竹地板,软木地板,强化木地板,塑胶地板,瓷砖,大理石,地毯等。

(见附表)二.强化木地板知识1.强化木地板的定义。

强化木地板(Laminate floor covring)也叫复合地板,其学名:浸责纸饰面层压木质地板。

它市以一层或多层专用纸浸责热固性氨基树脂,铺装在刨花板,中密度纤维板(MDF),高密度纤维板(HDF)等人造板基材表层,背面加平衡层,正面加耐磨层,热和贴面(热压)而成的地板。

1.早期的强化木地板是以中密度纤维板(MDF),刨花板为基材,以装饰用防火板为面层和平衡用防火板为地层的三层复合板(防火板是一种全部以浸责纸压层而成的板材)。

因而生产时需要热压较高(大于70kg/cm),这种生产方式属高压法,即HPL?(hight Pressure Laminate),也叫连续层压法,即CPL(Continuous Pressure Laminate),也叫连续层压法,即CPL(Continuous Pressure Laminate).高压法或连续层压法的生产成本较高,现在已较少使用.新型强化木地板90年代初,以高密度基材(HDF),耐磨层,装饰层,平衡层为生产材料的新型强化木地板研制成功,因其生产时所需的热压较低(30KG/CM),这种生产方式属于低压法,即LPL(Low Pressure Laminate),也叫直接压层法,即DPL(Diyect Pressure Laminate)正因为强化木地板对基材的要求很高,所以其基材大部分是由专业的高密度纤维板(HDF)生产企业生产,由于其基材层是采用人工速生材制造,不会造成对天然林的威胁和破坏,所以符合绿色环保的国际潮流,对于保护全球生态平衡,天然林保护工程可以起到积极的作用,从发展的角度,长远的眼光预测,强化木地板的主要原料因为是人造速生材和其加工剩余物,且木材的利用率极高,从资源可持续发展性战略来看是最有前途的. 二.强化地板发展史1985年有奥地利的刨花板生产商和瑞典的生厂商联合研制而成.自研制成功之日起,就显示出了强大的生命力,以其独特的综合优点受到了越来越多的顾客青睐.1998年欧美地区产销量已经突破一亿平方米,1999年全球销量为2.22亿平方米,2000年则为3.51亿平方米增长58%.1995年强化地板进入中国市场,作为起步阶段截至1997年年销量约为600万平方米,而老百姓大多不知何为强化地板,从事生产的企业少于10家,销售品牌少于30个,无特别系统的品牌推广策略,也没有成熟的大规模的生产企业出现.第一片国企强化地板诞生上海中远汇丽,,民企是湖南康派.1998年-2000年为强化地板高速发展阶段,3年间强化地板市场由600平方米增长4800平方米,增长7,5倍.从事生产的企业迅速增至50家之多,品牌达100多个,随着强化木地板的强势企业和品牌的浮现,产品平均销售价格下降,产品出现低价竞争,国际的跨国集团产品多方渗透到市场.2000-2005年为强化地板的成熟阶段,2000年销售4800万平方米,增长50%,2001年6500万平方米,增长35%,2002年8500万平方米增长31%,2003年12000万平方米,增长25%,2005年16000万平方米增长7%.三.强化木地板的结构强化的板一般分为四层::表层(耐磨层),装饰层,基材层以及底层—亦叫平衡层.第一层:强化米地板的表层,又叫耐磨层.它是采用三氧化二铝(金属氧化物,蓝宝石成分,钻石硬度)或碳化硅覆盖在透明纸上,要求用于表面涂层的三氧化铝极细,在工艺上既不遮盖装饰层上的花纹和色彩,又要均匀而细密的附着在装饰层的表面.常说的强化木地板的耐磨转数(耐磨系数)直接取决于其表层三氧化二铝或碳化硅的用量.适宜于普通家庭使用的,表层三氧化二铝的用量的多为38g/m2(AC2级欧标)或为(欧洲标准AC3级即加家用顶级商用末级),而表面涂层使用三氧化二铝的量达到49g/m2或62g/m2的地板,常用于人流量较大的公共场所.第二层:装饰层,也就是电脑仿真制作的印刷纸.由于是电脑模仿,可仿真制作各类材种的木材花纹,甚至可以模仿石材的纹路以及创造出一些独特的图案.利用三聚氰胺浸过的电脑图案装饰纸,具有强抗紫外光的优点,经过长期照射不会引起褪色.第三层也就是基础层,,多采用高密度纤维板(HDF),中密度纤维板(MDF)或特殊形态的优质刨花板.高密度纤维板的密度应该在0.82g/m3以上,由于强化木地板品质的优劣很大程度上取决于基材层的质量,所以一般对基材的要求很高,主要有以下几点:(1)基材的胶合强度要高(2)表层平整,密度均匀(3)游离甲醛的含量较少(4)基材的静曲强度高(5)弹性模量高(6)防潮性能好,由于强化木地板对基材的要求很高,所以目前国内的强化木地板生产企业有近百条生产线,但真正能够自己生产基材层的企业并不多,仅有可数的十几家,大部分是从专业的中高密度纤维板生产企业订制,如今,我国的中高密度纤维板生产能力达到277万m3以上,仅次于美国,是世界排名第二的生产国家.由于强化木地板的基材层是采用人工速生材制造,不会造成天然林威胁和破坏,人工速生林,也为广大农民提供了更多的就业机会.第四层底层也叫防潮平衡层一般采用一定强度的厚纸在三聚氰胺中浸责,可以阻隔来自地面的潮气与水分,从而保护地板不受地面的潮湿影响,进一步强化了底层的防潮功能.同时,底层也起到了平衡的作用.这种设计面不仅提高了木地板的强韧度,外观平整度和尺寸稳定性,而且在耐磨,阻燃,防潮等方面有了很大突破,使用强化木地板已成了当今世界的半的发展潮流.强化地板现状及发展趋势中国是一个森林资源相对贫乏的国家,人均森林占有面积仅为0.13hm3,为世界人均占有量的1/5,人均森林蓄积量也仅有9.048m3,仅为世界人均蓄量的1/8.因此,按照科学发展观的要求,大力发展循环经济,发展速生产林,提高林木综合利用率,加快建立资源节约型社会,就显得尤为重要,尤为迫切.强化木地板是一种利国利民的绿色的环保产品,也是符合国家可持续发展战略的产品.经过十年的发展,中国强化木地板产业呈现了十分喜人的景象,形成了一批令世界瞩目的生产基地,出现了一批与国外着名企业实力相当的民族的企业,造就了一批国外知名的着名品牌,建立和完善了一套具有中国特色的产品质量标准,培育起一个潜力巨大的消费市场 .强化地板的特性强化木地板具有以下特点:耐磨,款式丰富,抗冲击,抗变形,耐污染,阻燃 ,防潮,环保,不褪色,安装简便,易打理,可用于地采暖地面等.强化地板的产品发展优势强化木地板作为一种新型环保建材产品,在市场竞争中显示出其它建材类产品不可比拟的竞争优势:1.政策优势: 强化木地板符合国家可持续发展的产业政策,符合国家环境保护相关政策,因此,强化木地板是国家重点支持的产业.2.产品优势: 强化木地板将继续以耐磨,美观,环保,防潮,阻燃,防蛀,安装便捷,易清洁护理,经济实用等诸多优点而获得更多消费者的青睐 ;强化木地板品质不断提高,产品更加艺术化,个性化,更时尚,美观,更环保,表面处理技术更趋先进和多样化,更能满足不同市场的需求.3.市场优势: 国家扩大内需的政策将进一步推动中国经济持续稳定地发展;申奥成功带来新的经济发展机遇 ;强化木地板消费市场因此进一步扩大,将由大,中城市逐步进入小城市,甚至乡镇;强化木地板正成为大众化家装消费品,它将在整个铺地材料中取得更多的市场份额;目前,国内已经形成了几个较具生产规模和综合实力的强化木地板企业,并引领着这个行业继续发展;更多跨国企业和国外品牌进入中国市场,将催化中国强化木地板行业的迅速发展.4.品牌优势: 强化木地板企业历来重视品牌培育,已经形成一些强势品牌;强势品牌的配送,销售服务,市场研发,促销推广等系统将逐步以高效率,低成本,专业化的信息流,物流,资金流而在竞争中取得优势.推广品牌营销概念与当前中国百姓逐步成熟的消费心理相吻合,品牌形象良好与绿色环保的地板将受到更多消费者的欢迎.5.成本优势: 强化木地板规模化,集约化的生产带来了价格和成本上的优势,更大程度地满足了广大消费者不同层次的需求.三. 强化地板的分类强化地板断代明细(见附表)1.静音地板软木吸音型底层软木吸音层脚感更软,更静,软木的多层性能使地板更防潮保湿;EPE吸音型底层EPE吸音层,脚感更软,更静,软木的多层性能是地板更防潮保湿;2.户外地板化学防腐,物理防腐,木塑地板(挤出)塑胶,纯塑(中空)地板.3. 卫浴地板松木(桑那板),小规格(实木)地板,防水强化地板(塑封,蜡封),中空纯塑及户外地板.4. 抗菌地板光触媒经过光的照射后,发挥其触媒的特性,将四周的能量转换,使其细胞质流失死亡.凝固细菌的蛋白质,使其失去活性从而达到捕捉,杀除空气中的浮游细菌,杀菌能力极高,光触媒(二氧化钛)超氧化能力(氢氧自由基),能对有机物和有害物进行氧化还原反应,将其转化为无害的水和二氧化碳,从而达到净化环境和空气的功效.银系纳米地板多层涂附技术纳米银系抗菌系统—通过微量银粒子与菌体接触后,穿透细胞壁进入细胞内并与疏基(-SH)反应,使蛋白质凝固,破坏细胞合成酶的活性,细胞丧失分裂增殖能力而死亡;银离子还能破坏微生物电子传输系统,呼吸系统和物质传输系统,当菌体失去活性后,银离子又会从菌体中游离出来,重复进行杀菌活动,因此其抗菌效果持久,在光的作用下,银离子起到催化活性中心的作用,激活水和空气中的氧,产生羚基自由基(-OH)和活性氧离子(02),活性氧离子具有很强的氧化能力,在短时间内破坏细菌的增殖能力而使细菌不再生长.什么是纳米物质?纳米是一个长度单位,指10-9米,纳米物质是采用纳米科学技术及用单个原子,分子制造的物质,一般是指尺寸在1~100mm间的粒子,纳米材料又称为超微颗粒材料,有纳米离子组成.纳米离子也叫超微颗粒,处在原子簇和宏观物体交界过渡区域.纳米科学的概念是什么?纳米科学技术是以许多现代先进科学技术为基础的科学技术,它是现代科学(混屯物理,量子力学,介观物理,分子生物学)结合的产物,纳米科学技术又将引发一系列新的科学技术,例如纳米电子学,纳米材料学,纳米机械学等,纳米科学技术被认为是世界之交出现的一项高科技.纳米材料又何奇异性质?从通常关于微观和宏的观点看,这样的系统既非典型的微观系统亦非典型的宏观系统,它具有表面的效应,小尺寸效应和宏观量子隧道相应.当人们将宏观物体系分成超微量颗粒(纳米级)后,它将显示出许多奇异的特性,即它的光学,热学,电学,磁学,力学以及化学方面的性质和大块固体时相比将会有显着的不同.5.地热地板此外还有:DIY花样拼装地板,巴洛克复古风格地板(洛可可)流派设计派系列艺术地板,保健地板(BIO),静音地板(胶,软木),防水地板.(两种),真木地板(皮真木),防腐地板,秸秆地板,均质地板,镜面地板,漆面地板,高光两面(Lg质喷粉),设计派实木地板,三层两层实木地板,侧压地板(立木实木多层),护条地板,视觉V形槽地板(幻影)(雕饰面分类,倒角型分类),积木地板,真木(同步对花),软木地板,石纹地板,抗菌地板,特种基材地板(陶瓷石膏,)曲线地板(大小边),模压花边地板,猎醛地板(AF,FCF),铝铂地板,亚麻地板.第二部分产品基础知识强化木地板的主要指标强化木地板主要有以下十项技术指标:1. 密度(g/cm2),这是指强化木地板基材质量强化木地板的基材是中高密度板,这种板是由木纤维经高温,高压压制而成.密度越高,基材的抗冲击,抗压能力等质量就越好.2表面耐磨(R)::利用专用砂纸来磨设计地板表层,并以地板出现磨损时的砂轮转数值来衡量地板的耐磨性能。

SUNGROW NextGen Product Training Lecturer: Graham SmithDate: June 2018DisclaimerThe following presentation is intended as a guide to the benefits, and the install and commission of the New Generation Sungrow Crystal and PowCube 4.8 systems.It is not a statement or advice on any of the Electrical or Solar Industry standards or guidelines.Please observe all OH&S regulations when working on Sungrow equipment.Contents010203 NextGen Crystal Series NextGen ESSService & Warranty01Crystal SeriesNextGen Crystal Series Overview - Improvements- Built-in LCD- Easy set-upWi-Fi monitoringOptional Export Controlwith single and 3 phaseEnergy Meters- 98.2% Max efficiencyfor single tracking- 98.4% Max efficiencyPlug & Play connectionWhy NextGen Crystal Series?Easy to install and commission Flexible configuration with single phase or three phase meter solutions Optional ‘Export Control’Easy troubleshooting for installers, with smart monitoring solutionsElectrical ConnectionSimply plug in the DC and AC connectors and switch on:Easy Connection of the Energy Meter (single phase shown) Connection in the switchboard side Connection on the inverter sideCommissioning Overview• Commissioning is simple• Switch the inverter on and allow to go through start-up• Enter into the menu and make any changes as necessaryCommissioning – a few simple stepsStep 1: Set the date and time (important if loggingvia Solarinfo Bank)Step 2: Check/Set the country (AU Default) – AS4777Step 3 (optional): Set the network parametersExport Setting (Only if Sungrow energy meter installed)• Enter the settings• Password 111• Select Zero Export function:– Off: All power will be exported to the grid– On: No power will be exported to the grid.– Partial: Select percentage of total power tobe exported to the grid.• Press ‘Enter’ to save.Monitoring Solutionsª App and web portal solutions for end users and installers (free) ª Local access and online monitoring via App (SolarInfo Home)ª Easy set up of account on ‘SolarInfo Bank’Router CloudWebInverter Wi-FiModule RS485Wi-Fi Net/4G/Wi-FiSmartphoneAPPMonitoring for CustomersMonitoring for Troubleshooting (Installers)NextGen ESS02Why NextGen ESS? Outstanding featuresEasy to install and commissionFlexible configuration for different installation applicationsEasy troubleshooting for installers, with smart monitoring solutions• New look SH5K-20 Hybrid Inverter plusan Energy Meter (single phase or threephase (optional))• The STB5K - 20 EPS Box• Up to 3 SBP4K8 Batteries (3*4.8=14.4kWh)• Modular - Allows flexible install optionsThe PowCube System – ComponentsThe PowCube System – Features• Suitable for retrofit with existing systems • Can run in EPS (off-grid) mode• True Hybrid – AC and DC charging• Single or 3 phase installation• Flexible installation options• Up to 14.4 kWh storageFlexible ConfigurationStandard Energy Storage System AC Charger System Retrofit Solar System 1 (without solar) Retrofit Solar System 2 (with solar)PowCube 4.8 SystemThe PowCube 4.8 is not just a battery storage system, it can also run in ‘EPS’ mode.PowCube 4.8 SpecificationsHybrid inverterMax. PV input power 6500 W Nominal AC output power 5000 W EPS output5000 W EPS output (with battery only) 3000 W Max. efficiency > 97.7 % Weight22 kg Ingress protection ratingIP65 BatteryBattery type Li-ion (NMC) Energy capacity 4.8 kWh ScalabilityUp to 14.4 kWhDepth of discharge (DOD) > 95% Weight48 kg Key ComponentsSH5K-20Batteries Compatible with the SH5K-20v Sungrow / Samsung SBP4K8 Li-ion v LG Chem Li-ion (LV) v BYD Li-ion (LV) v Pylon Li-ion v GCL Li-ion v Lead Acid 48VPylon/GCLLG ChemSungrow SamsungBYDLead Acid• 5 kW from PV + Battery • 3 kW from Battery only • ‘Reserve Capacity’ function available EPS in Off-Grid modeAt zero grid, EPS box decouples from grid.EPS box sends a signal over control wires and invertergoes into 'Off-Grid' mode.Grid presence signals also come from the Energy Meter.When grid re-establishes, EPS box couples with grid andinverter resumes grid-connected modeDCAutomatic changeoverswitchACNo Grid!ACDCHouse loads i.e. Power, StoveEmergency Loads i.e. Fridge, LightsFeatures - Emergency Power Supply (EPS)A “Reserve Capacity” can be setfor EPS use.Reserve capacity set at for eaxmple 10%+-*Reserve capacity only available in 'Off-Grid' mode and w ill not be used for day-to-day battery cycling.Total capacity 4.8 kWh Reserve Capacity @ 10%Daily cycle availableUsable Capacity 4.56 kWh95% DODFeatures - Easy to Connect Battery• Power and data connections at both sides Array allow flexible install options• Also allows daisy chain connection• No DIP switches• 48 kg• Free standing or wall mount with optionalshelf• SH5K-20 will automatically detect battery type (Li-ion)Features - Retrofitting System• No need to upgrade the existing system • Can be installed with or without new solar PV• Will allow AC charging from existing systemFeatures - Three-phase meter (optional)ª Increase Self-consumption of a three-phase property with a three-phase meter for net meterThe new SH5K+ Inverter is simple to connect with new spring-clip connectors for the Data cables.Spring-clipRemovable coverInstallation - BatteryC A N L* Communication cableincluded in the packageInstall the communication cableInstall electrical cablesConnection with Sungrow Samsung Battery• Modular design of the inverter and battery• Suitable for both free-standing and wall-mountable installations • Simple setup for multiple battery packsConnection with LG Chem Batteryv LG Chem RESU Gen II (range from 3.3 kWh to 19.6 kWh )v LG Chem RESU Gen I (range from 6.4 kWh to 12.8 kWh )Connection with BYD Batteryv Compatible with 8 BYD batteries(2.5 kWh U3A1-50P-A) up to 20kWh• Automatically senses Li-ion battery type during setup• Inverter automatically ‘wakes up’ battery Easy Battery Setup• Lead Acid 48 Volts – Manual parameter setup by accredited installerCase StudiesMonitoring featuresInformationSystemPVBatteryGridHouseSolarInfo MoniAccess to Data and AlarmsMonitor Import Power to assist battery up-sellService &Warranty03Service NetworkCall centerremotely assist customers throughout Australia Service c ontractors located in major capital cities for field service supportRepair workshoptest and repair faultyinvertersSpare parts warehouse manage backup inverters, spare parts and outbound & inbound logistics 43Warranty Process – On Line44• Technical support hotline• • Sydney based training centre • capitals• and training centreHotline+61 1800 786 476 Email************************.au*********************.au Sungrow has an extensive knowledge base available on the web page.Visit .au© 2018SUNGROW Confidential。

A GREAT ALTERNATIVE FOR THE HEALTHY WORKFORCEThe Workrite Sierra HXL Crank is engineered to enable manual adjustability requiring minimal amounts of human force, making it a good alternative for the healthy workforce or for areas where frequent adjustments are not required.The HXL Crank adjusts from 25.5"– 43" and will accommodate the average male or female worker, making it a good solution for companies seeking limited height adjustability. It adjusts at a rate of 5.6 turns per inch even with up to 125 pounds of equipment on the worksurface.Sierra HXL Crank is available in silver with two foot design options that can be selected to build the best workcenter for each specific application.Easily raise height 1" for every 5.2 turns.ADJUSTABLE HEIGHT WORKCENTERS SIERRA HXL™ CRANKFlat Foot25.5"–43"1.44"Sierra HXL Crank Frame SetSpecifications• Frame options: 2-leg frames • 24" or 30" depths• Widths from 36" to 72" depending on shape • Finish options: silver, black, and white • Height range: 25.5" to 43" • Payload capacity: 125 pounds •Travel speed: 1 inch = 5.6 turns•• • ADJUSTABLE HEIGHT WORKCENTERSSIERRA HXL ™ CRANK FRAME SETSierra HXL Front Crank Base SetsFoot Size Model # Color Weight US $ List CAN $ List 2-Leg Worksurfaces 36" wide 24" deep SCFHXL36-F24-☐45 $974 $1,249 30" deep SCFHXL36-F30-☐48 $985 $1,263 42" wide 24" deep SCFHXL42-F24-☐45 $980 $1,256 30" deep SCFHXL42-F30-☐48 $990 $1,269 48" wide 24" deep SCFHXL48-F24-☐46 $985 $1,263 30" deep SCFHXL48-F30-☐49 $995 $1,276 54" wide 24" deep SCFHXL54-F24-☐46 $990 $1,269 30" deep SCFHXL54-F30-☐49 $1,000 $1,282 60" wide 24" deep SCFHXL60-F24-☐47 $995 $1,276 30" deep SCFHXL60-F30-☐50 $1,005 $1,288 66" wide 24" deep SCFHXL66-F24-☐47 $1,000 $1,282 30" deep SCFHXL66-F30-☐50 $1,010 $1,295 72" wide24" deep SCFHXL72-F24-☐48 $1,005 $1,288 30" deepSCFHXL72-F30-☐51$1,016$1,303Frame Set colors: S :Silver, B :Black, W :WhiteSierra HXL T op Crank Base Sets2-Leg Worksurfaces 42" wide 24" deep SCTHXL42-F24-☐45 $980 $1,256 30" deep SCTHXL42-F30-☐48 $990 $1,269 48" wide 24" deep SCTHXL48-F24-☐45 $985 $1,263 30" deep SCTHXL48-F30-☐49 $995 $1,276 54" wide24" deep SCTHXL54-F24-☐46 $990 $1,269 30" deepSCTHXL54-F30-☐49$1,000$1,282Frame Set colors: S :Silver, B :Black, W:WhiteProducts listed on this page are available through GSA ContractGS-28F-0030S SIN #711-2 (Schedule 71)ADJUSTABLE HEIGHT WORKCENTERSSIERRA HXL ™ CRANK FRAME SETSierra HXL Accessories & Replacement Parts WorksurfaceDepth Model #Weight US $ List CAN $ ListFlat Foot Kit Reinforced steel construction for added stabilitySold as a pair for a single workstation24"FFK24-❒15$79 $10130"FFK30-❒18$90 $115Dual Depth FFK2430-❒17$85 $109Foot colors: S:Silver, B:Black, W:WhiteFour casters required for 2-leg work centers, fivecasters required for 3-leg work centersPremium PolyurethaneCastersCompatible with carpet and hard flooringLocking casters with smooth rolling 1"W × 3"Htranslucent polyurethane wheelsCasters raise work centers by 3.5"Use with all Styled Foot and Flat Foot Kits (notavailable on Cascade Work centers)Four casters for 2-leg work centers, 400 lb. grossload capacityFive casters for 3-leg work centers, 500 lb. grossload capacity4ACC-CASTER-4PK3IN-CP2$153$1965ACC-CASTER-5PK3IN-CP2$184$236 SIERRA HXL CRANK FRAME SETLaminate Price Tier 1White* SW811SD Folkstone Gray*SG241SDSlate*SG228SDHardrock MapleWM791SDMillwork CherryWC431SDFormal MahoganyWY031SDWalnut GroveWW050SDLaminate Price Tier 2078506007937380799238079253807054600798938Shadow Zephyr*0485760Misted Zephyr*0484360 Laminate Price Tier 3Grey Elm8201K12Fawn Cypress8208K16Veranda Teak8209K28Phantom Cocoa8213K28Studio Teak7960K18Phantom Charcoal8214K28Skyline Walnut7964K12Walnut Heights7965K12Figured Mahogany7040K78Black Velvet*1550531STANDARD LAMINATE AND EDGEBAND COLOR SELECTIONSApplies to: Sit-Stand Desk Worksurfaces, Sonoma Table Worksurfaces, Laminated Modesty Panels, Laminated Mobile &Hanging PedestalsWorkrite's standard laminate selections includes many popular colors from Pionite and Wilsonart. Starting with our Tier 1 selection for greatest value, through our premium Tier 2 wood grains and patterns, ending with our Tier 3 embossed and special finishes round out our offering. Our tops feature color coordinated matching 3 mm edgeband. For more accurate color selection we recommend reviewing our laminate sample chain when making selections.Note: Due to printing limitations, these colorsare not guaranteed to be accurately reproduced.For best results order actual Laminate MaterialSamples by calling (800) 959-9675.*These laminates are not available for mobile or hanging pedestal collectionSPECIAL ORDER LAMINATESWorkrite has access to many laminate manufacturers. We can quote special order laminates on request from Wilsonart, Pionite, Nevamar, Formica, and Abet Laminati. If you don't see the brand, give us a call.Please note for special order laminate colors: based on laminate brand, color requested, and specific color matching edgeband requirements, minimum order requirements and special order upcharges may apply.Flexible Solutions for the Ergonomic Workplace.©2019 Workrite Ergonomics, 2277 Pine View Way, Suite 100, Petaluma, CA 94954 800.959.9675WORKSURFACES0919 Subject to change without notice.ExploreLaunch website。

西瓦产品培训手册编制单位:佛山市荣冠玻璃建材有限公司市场部目录<一>西瓦产品简介 .................................... - 2 -1、什么是西瓦..................................... - 2 -2、西瓦的优点..................................... - 2 -3、西瓦的来历以及国内外发展情况................... - 2 -4、西瓦的发展前景................................. - 3 -<二>产品知识 ........................................ - 4 -1、生产状况....................................... - 4 -2、西瓦产品分类、标识和规格....................... - 4 -3、西瓦的施工方法................................. - 7 -<三>西瓦销售的计件算法 .............................. - 8 -<四>西瓦销售特点及注意事项........................... - 9 -<一>西瓦产品简介1、什么是西瓦西瓦,是西班牙瓦的简称(英文名 Spanish Roofing tile),因其外型象英文字母“S”,所以俗称又叫S瓦(市面上还有其他俗称,如川渝等地叫大波瓦,江浙等地叫曲瓦)。

西瓦是一种以红坭、黄坭、岗砂按比例来配备原料(或按客户的要求成色来配比),经过陈腐加工、挤出冲压成型、干燥施釉(有釉产品) 、二次干燥后,进窑炉煅烧而成的烧结彩瓦。

它是一种现代流行的具有欧洲风格的健康环保的屋面装饰瓦。

※什么是烧结瓦?烧结瓦是由粘土或其他无机非金属原料,经成型、烧结等工艺处理,用于建筑物屋面覆盖及装饰用的板状或块状烧结制品。

通常根据形状、表面状态及吸水率不同来进行分类和具体产品命名。

注:根据吸水率不同分为Ⅰ类瓦(≦6%)、Ⅱ类瓦(6%~10%)、Ⅲ类瓦(10%~18%)、青瓦(≦21%)。

西瓦属于Ⅱ类瓦。

2、西瓦的优点西瓦与其他烧结彩瓦对比,有以下优点:A.起源早,流行广泛。

2000多年前起源于欧洲,广泛流行于世界各地。

B.色彩丰富,自然。

可根据个性需要调色,达到人性化与自然化的结合。

C.设计简单,安装便利。

设计上达到简单实用,安装比琉璃瓦方便高效。

3、西瓦的来历以及国内外发展情况西瓦最早是在西班牙等西欧国家出现并流行而得名,是一种用于屋顶装饰效果并具有朴素典雅、风韵别致的西欧风格的屋面装饰建材。

古典西瓦是最传统的瓦型,是传统陶瓦中轮廓尤其丰润的瓦型。

2000多年以来古典西瓦伴随着人类的发展。

而现代科技赋予这一传统瓦全新的内涵。

在地中海周边尤其受欢迎,古典西瓦追求将其传统坚持到底,紧凑的线条颇具时尚品位,丰富的色彩满足不同国度和地区的需求。

全新的别墅,古宅的翻新都有上佳表现。

同时,西瓦的屋面装饰效果慢慢得到世界各国建筑设计师的追捧和广大人们的认可,并于上世纪80年代末逐渐传入到亚洲的韩国,日本和中国。

它与国内的琉璃瓦相似,并别具一格,所以在国内得以认可和流行起来,成为一种具有欧洲风格的装饰瓦。

西瓦是属于瓦类中的烧结彩瓦,它从普通瓦类的遮风挡雨的功能转变为主要以装饰功能为主,装饰效果古朴自然、经典怀旧、风韵雅致。

它是各种中高档酒店别墅、楼宇亭台、大型商业中心、市政工程等建筑的首选屋面装饰材料。

目前我国瓦产品主要有三大品种,一是烧结黏土瓦,二是水泥彩瓦,三是烧结彩瓦(琉璃瓦、亚光瓦)。

其中:烧结黏土瓦色调单一不均匀,直接影响建筑工程的外观质量,吸水率较高,在下雨时增加了屋面的重量和基础建设投资,其市场占有率会逐渐减少。

水泥彩瓦的表层颜色是由有机的粘接剂和无机颜料组成,其耐久性和保持稳定色彩的能力令人担忧,而且抗折强度和抗渗性能低、抗化学侵蚀(如酸雨)能力及耐侯性(如抗紫外线)差,并且易碎,运输极不方便。

烧结彩瓦则具备了隔热好、耐久性、成本低和色彩鲜艳等诸多功能和特色,已逐渐成为高档屋面装饰的主流产品。

国内生产西瓦较早的企业有佛山红狮、广州嘉泰、佛山华联、永大等。

但大多数企业生产设备落后,技术不高,产品质量不稳定,产能较底。

随着国内需求市场的不断扩大,产品供给出现不平衡。

荣冠公司作为国内规模较大的一家装饰建材企业,引进日本先进设备,专业生产“荣冠”牌西班牙瓦,年产西班牙瓦达1300多万件。

“荣冠”牌西班牙瓦具有质量稳定、色均质优、尺寸一致等特点,物理性能各项指标均达到国家烧结瓦GB/T 21149--2007标准。

4、西瓦的发展前景随着国内居民生活水平的提高,人们追求亲近自然、环保的居住环境,对住房风格要求多样化、个性化和人性化。

西瓦作为一种健康环保的装饰瓦将得到更多建筑设计师的追捧的广大人们的认可,市场对西瓦产品的的需求呈不断的上升趋势。

同时,人们对产品质量的要求也更加严格,对花色品种的追求也呈现多样化、自然化和搭配的自由化。

良好的市场前景和发展状况对西瓦生产企业来说是一种机遇也是一种挑战,作为荣冠销售人员,要好好把握住这个机会并愿意接受任何挑战。

我们将以优异的品质和良好的服务来满足客户的需求。

<二>产品知识1、生产状况(1)生产设备:主要生产设备从日本进口,如挤出机、冲压机、施釉机等。

其他西瓦配件生产设备及原料加工设备均比其他厂家先进。

喂料机、搅拌机、对辊机、圆盘机、球磨机、皮带机等原料加工设备齐全并且布局合理高效运作,实现一次成料(其他厂家要两次成料)。

另外有130米干燥窑一座,140米烧结窑一座(其他厂家一般为85~100米),烧制产量比同行高出一半。

(2)生产工艺流程:原料配备——→一次原料加工——→陈腐——→二次原料加工——→挤出冲压成型——→干燥——→施釉(有釉产品) ——→装窑车——→二次干燥——→窑炉煅烧——→卸窑车产品——→检验分级——→包装——→进仓.原料可以按用户的要求呈色来配比,一般采用红坭,黄坭,岗砂按比例来配备,烧成温度在1070---1100℃之间.烧成应该呈较鲜艳砖红色(烟熏除外还原火焰).烧成后吸水率不大于12%(内控为5%--10%),配方要求干燥和烧成后总收缩为10%--10.5%.(3)品质标准:荣冠西瓦按国家标准(烧结瓦) GB/T 21149—2007。

内控检验应为优等品和合格品,对出窑每一件产品进行外观检验,把不合格产品分验出来,如有变形,开裂,崩缺,缺釉或杂釉等。

在进行品质检验时,首先检查瓦面外观的色泽一致,没有碰崩,釉粘,缺釉和裂纹,人工敲击声音清响,表面光滑,无缺陷等。

(4)包装要求:打包人员把经过检验合格的产品进行分种类,分级别包扎或包装。

主瓦S1:用包装带包扎:每扎4件;配件S2,S5:用包装带包扎:每扎5件;S3,S4,S7,S8,S9,S10,S16,S四叉等,装长方竹笠按发货数量发放;正盾瓦和斜盾瓦:装纸箱,每箱50件;如装车发货时瓦件每层和每行都用纸皮铺垫,以免碰崩损坏。

(5)产能情况:按目前设备产能为4万件/每天,(不包括配件),在备好原料的情况下,生产周期(以4万件/天的产能为单位算)是一个星期。

2、西瓦产品分类、标识和规格(1)、西瓦的分类①按瓦件的使用功能及外观形状来分,荣冠西瓦分为主瓦和配件两大类。

主瓦叫S1,配件有:S2、S3、S4、S5、S7、S8、S9、S10、S11、S12、S13、S16、S四叉、S正盾、S斜盾、宝顶等,可参照产品图片介绍:S1:又叫主瓦,用于天面铺贴主要使用的瓦件,使用量占80%以上。

S2:又称半瓦、沟瓦,主要用于两平面交角间水沟铺底。

S3:又称左收边瓦,用于大瓦面的左边(没有栅墙)收口。

S4:又称右收边瓦,用于大瓦面的右边(没有柵墙)收口(要加配S2)。

S5:又称筒瓦、脊瓦,用作正脊或斜脊,是配件中用量最多的一种。

S7:又称斜脊收口,用于斜脊下端收口。

S8:又称二叉、阴沟转角,用于正脊直角弯连接S5用。

S9:又称三叉,用于正脊与斜脊连接S5用。

S10:大飘角瓦,用于斜脊下端S7下飘角用,现被S16代替。

S11:又称半筒,当大瓦面有柵墙时左边用(不建议使用)。

S12:又称正脊左收口,正脊左端(没有有柵墙)收口用。

S13:又称正脊右收口,正脊右端(没有有柵墙)收口用。

S16:小飘角瓦,又称翘角,与S10同样使用。

S四叉:用于四个三角面交汇脊顶连接S5用。

S正盾瓦:又称正挡板,用于正脊与S1间封闭面用。

S斜盾瓦:又称斜挡板,用于斜脊与S1间封闭面用(不建议使用)。

宝顶:用于屋面的最高点。

②按西瓦的表现风格来分,荣冠西瓦分为质朴无光系列(SW系列)、古朴亚光系列(SY系列)、亮丽釉面系列(SL系列)。

质朴无光系列,由红胎和其他无光色料土上色烧成。

红胎,就是粘土原料所具有的颜色不上任何色料烧成的瓦,我司编号是SW84。

质朴无光系列代表的是大自然最纯朴、至真至美的风格,是崇尚简约、回归自然、追求淡泊的现代智者所青睐的装饰效果。

古朴亚光系列,由胚体上亚光色釉后烧成。

这一系列的产品既有古老而质朴的内涵又有现代文明时尚的气息,是满怀激情的现代人对经典的美好内涵的一种怀旧,但又割舍不了对现代亮丽时尚的热衷。

它表现的是古典美与现代美的强烈碰撞和亲密结合。

亮丽釉面系列,由胚体上釉面后烧成。

这一系列的产品彰显的是一种完全时尚亮丽的风格,鲜艳的色彩,亮丽的外表,无不流露出追求个性完美,表现前卫的现代完美主义风格。

其张扬的外表似乎诉说着对古典美的一种进步,但无论如何却摆脱不了古典美的永久熏陶,因为经典的才是永恒的。

(2)西瓦的规格:西瓦的主瓦及配件的规格如下.S1:主瓦有三种规格:310*310mm(厚度为15mm)S2:310*245mmS3:310*180mmS4:310*180mmS5:285*185mmS7:265*185mmS8:250*250*185mmS9:380*355*185mmS10:400*370mmS12:240*185mmS13:310*185mmS16:380*310mmS四叉:400*400*185mmS正盾瓦:265*90mmS斜盾瓦:265*75mm宝顶:530*○290mm3、西瓦的施工方法3.1材料瓦的固定方式主要有钉钢钉、扎线及灰浆垫底三种,可依屋面情况配合选用,其材料规定如下:①瓦钉:使用直径约3.5mm钢钉,长度足以深入挂瓦条的厚度大约3/4的尺寸。

檐口瓦、边瓦每片均应钉钢钉。

②挂瓦条:使用宽30mm、高15mm直纹杉木经防腐处理为佳。