GMS通用汽车全球制造系统

- 格式:ppt

- 大小:10.40 MB

- 文档页数:156

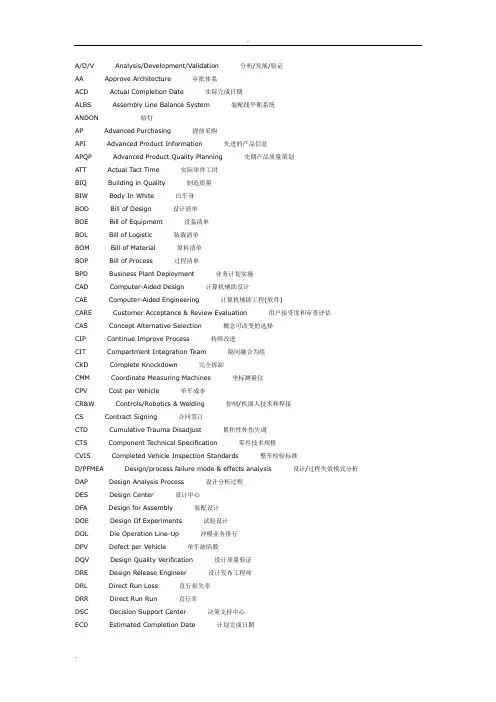

A/D/V Analysis/Development/Validation 分析/发展/验证AA Approve Architecture 审批体系ACD Actual Completion Date 实际完成日期ALBS Assembly Line Balance System 装配线平衡系统ANDON 暗灯AP Advanced Purchasing 提前采购API Advanced Product Information 先进的产品信息APQP Advanced Product Quality Planning 先期产品质量策划ATT Actual Tact Time 实际单件工时BIQ Building in Quality 制造质量BIW Body In White 白车身BOD Bill of Design 设计清单BOE Bill of Equipment 设备清单BOL Bill of Logistic 装载清单BOM Bill of Material 原料清单BOP Bill of Process 过程清单BPD Business Plant Deployment 业务计划实施CAD Computer-Aided Design 计算机辅助设计CAE Computer-Aided Engineering 计算机辅助工程(软件)CARE Customer Acceptance & Review Evaluation 用户接受度和审查评估CAS Concept Alternative Selection 概念可改变的选择CIP Continue Improve Process 持续改进CIT Compartment Integration T eam 隔间融合为组CKD Complete Knockdown 完全拆缷CMM Coordinate Measuring Machines 坐标测量仪CPV Cost per Vehicle 单车成本CR&W Controls/Robotics & Welding 控制/机器人技术和焊接CS Contract Signing 合同签订CTD Cumulative Trauma Disadjust 累积性外伤失调CTS Component Technical Specification 零件技术规格CVIS Completed Vehicle Inspection Standards 整车检验标准D/PFMEA Design/process failure mode & effects analysis 设计/过程失效模式分析DAP Design Analysis Process 设计分析过程DES Design Center 设计中心DFA Design for Assembly 装配设计DOE Design Of Experiments 试验设计DOL Die Operation Line-Up 冲模业务排行DPV Defect per Vehicle 单车缺陷数DQV Design Quality Verification 设计质量验证DRE Design Release Engineer 设计发布工程师DRL Direct Run Loss 直行损失率DRR Direct Run Run 直行率DSC Decision Support Center 决策支持中心ECD Estimated Completion Date 计划完成日期EGM Engineering Group Manager 工程组经理ELPO Electrode position Primer 电极底漆ENG Engineering 工程技术、工程学EOA End of Acceleration 停止加速EPC&L Engineering Production Cntrol &Logistics 工程生产控制和后勤EQF Early Quality Feedback 早期质量反馈EWO Engineering Work Order 工程工作指令FA Final Approval 最终认可FE Functional Evaluation 功能评估FEDR Functional Evaluation Disposition Report 功能评估部署报告FFF Free Form Fabrication 自由形态制造FIN Financial 金融的FL 听FMEA Failure Mode and Effects Analysis 失效形式及结果分析FPS Fixed Point Stop 定点停FTP File Transfer Protocol 文件传送协议FTQ First Time Quality 一次送检合格率GA General Assembly 总装GA Shop General Assembly Shop 总装车间Paint Shop 涂装车间Body Shop 车身车间Press Shop 冲压车间GCA Global Customer Audit 全球顾客评审GD&T Geometric Dimensioning & Tolerancing 几何尺寸及精度GDS Global Delivery Survey 全球发运检查GM General Motors 通用汽车GMAP GM Asia Pacific 通用亚太GME General Motors Europe 通用汽车欧洲GMIO General Motors International Operations 通用汽车国际运作GMIQ General Motors Initial Quality 通用汽车初始质量GMPTG General Motors Powertrain Group 通用汽车动力组GMS Global Manufacturing System 通用全球制造系统GP General Procedure 通用程序GQTS Global Quality Tracking System 全球质量跟踪系统GSB Global Strategy Board 全球战略部HVAC Heating, Ventilation ,and Air Conditioning 加热、通风及空调I/P Instrument Panel 仪表板IC Initiate Charter 初始租约ICD Interface Control Document 界面控制文件IE Industrial Engineering 工业工程IEMA International Export Market Analysis 国际出口市场分析ILRS Indirect Labor Reporting System 间接劳动报告系统IO International Operations 国际业务IOM Inspection Operation Mathod 检验操作方法IOS Inspection Operation Summary 检验操作概要IPC International Product Center 国际产品中心IPTV Incidents Per Thousand Vehicles 每千辆车的故障率IQS Initial Quality Survey 初始质量调查IR Incident Report 事故报告ISP Integrated Scheduling Project 综合计划ITP Integrated Training Process 综合培训方法ITSD Interior T echnical Specification Drawing 内部技术规范图IUVA International Uniform Vehicle Audit 国际统一车辆审核JES Job Element Sheet 工作要素单JIS Job Issue Sheet 工作要素单JIT Just in Time 准时制JPH Job per hour 每小时工作量KCC Key Control Characteristics 关键控制特性KCDS Key Characteristics Designation System 关键特性标识系统KPC Key product Characteristic 关键产品特性LT Look at 看MFD Metal Fabrication Division 金属预制件区MFG Manufacturing Operations 制造过程MIC Marketing Information Center 市场信息中心MIE Manufacturing Integration Engineer 制造综合工程师MKT Marketing 营销MLBS Material Labor Balance System 物化劳动平衡系统MMSTS Manufacturing Major Subsystem Technical Specifications 制造重要子系统技术说明书MNG Manufacturing Engineering 制造工程MPG Milford Proving Ground 试验场MPI Master Process Index 主程序索引MPL Master Parts List 主零件列表MPS Material Planning System 原料计划系统MRD Material Required Date 物料需求日期MSDS Material Safery Data Sheets 化学品安全数据单MSE Manufacturing System Engineer 制造系统工程MSS Market Segment Specification 市场分割规范MTBF Mean Time Between Failures 平均故障时间MTS Manufacturing T echnical Specification 生产技术规范MVSS Motor Vehicle Safety Standards 汽车发动机安全标准NAMA North American Market Analysis 北美市场分析NAO North American Operations 北美业务NAOC NAO Containerization NAO货柜运输NC Numerically Controlled 用数字控制NOA Notice of Authorization 授权书NSB NAO Strategy Board 北美业务部OED Organization and Employee Development 组织和员工发展OSH Occupational Safety & Health 职业安全健康OSHA Occupational Safety & Health Act 职业安全与健康法案OSHMS Occupational Safety & Health Management System 职业安全健康管理体系OSHS Occupational Safety & Health Standards 职业安全标准PA Production Achievement 生产结果PAA Product Action Authorization 产品临时授权PAC Performance Assessment Committee 绩效评估委员会PACE Program Assessment and Control Environment 项目评估和控制条件PAD Product Assembly Document 产品装配文件PARTS Part Readiness Tracking System 零件准备跟踪系统PC Problem Communication 问题信息PCL Production Control and Logistics 生产控制和支持PCM Process Control Manager 工艺控制负责人PCR Problem Communication Report 问题交流报告PDC Portfolio Development Center 证券发展中心PDM Product Data Management 产品资料管理PDS Product Description System 产品说明系统PDT Product Development Team 产品发展小组PED Production Engineering Department 产品工程部PEP Product Evaluation Program 产品评估程序PER Personnel 人员PET Program Execution T eam 项目执行小组PGM Program Management 项目管理PI People Involement 人员参与PIMREP Project Incident Monitoring and Resolution Process 事故方案跟踪和解决过程PLP Production Launch Process 生产启动程序PMI Process Modeling Integration 加工建模一体化PMM Program Manufacturing Manager 项目制造经理PMR Product Manufacturability Requirements 产品制造能要求PMT Product Management Team 产品车管理小组POMS Production Order Management System 产品指令管理小组POP Point of Purchase 采购点PP Push - Pull 推拉PPAP Production Part Approval Process 生产零部件批准程序PPE 个人防护用品PPH Problems Per Hundred 百辆车缺陷数PPM Problems Per Million 百万辆车缺陷数PPS Practical Problem Solving 实际问题解决PR Performance Review 绩效评估PR/R Problem Reporting and Resolution 问题报告和解决PRTS Problem Resolution and Tracking System 问题解决跟踪系统PSC Portfolio Strategy Council 部长职务策略委员会PST Plant Support T eam 工厂支持小组PTO Primary Tryout 第一次试验PTR Production Trial Run 生产试运行PUR Purchasing 采购PVD Production Vehicle Development 生产汽车发展PVM Programmable Vehicle Model 可设计的汽车模型QA Quality Audit 质量评审QAP Quality Assessment Process 质量评估过程QBC Quality Build Concern 质量体系构建关系QC Quality Characteristic 质量特性QCOS Quality Control Operation Sheets 质量风险控制QE Quality Engineer 质量工程师QET Quality Engineering T eam 质量工程小组QFD Quality Function Deployment 质量功能配置QRD Quality, Reliability,andDurability 质量、可靠性和耐久力QS Quality System 质量体系QUA Quality 质量RC Review Charter 评估特许RCD Required Completion Date 必须完成日期RFQ Request For Quotation 报价请求RGM Reliability Growth Management 可靠性增长小组RONA Return on Net Assets 净资产评估RPO Regular Production Option 正式产品选项RQA Routing Quality Assessment 程序安排质量评定RT&TM Rigorous Tracking and Throughout Managment 严格跟踪和全程管理SDC Strategic Decision Center 战略决策中心SF Styling Freeze 造型冻结SIL Single Issue List 单一问题清单SIP Stansardized Inspection Process 标准化检验过程SIU Summing It All Up 电子求和结束SL System Layouts 系统规划SLT Short Leading T eam 缩短制造周期SMARTSMBP Synchronous Math-Based Process 理论同步过程SME Subject Matter Expert 主题专家SMT Systems Management Team 系统管理小组SNR 坏路实验SOP Start of Production 生产启动SOP Safe Operating Practice 安全操作规程SOR Statement of Requirements 技术要求SOS Standardization Operation Sheet 标准化工作操作单SOW Statement of Work 工作说明SPA Shipping Priority Audit 发运优先级审计SPC Statistical Process Control 统计过程控制SPE Surface and Prototype Engineering 表面及原型工程SPO Service Parts Operations 配件组织SPT Single Point T eam 专一任务小组SQA Supplier Quality Assurance 供应商质量保证(供应商现场工程师)SQC Supplier Quality Control 供方质量控制SQD Supplier Quality Development 供应方质量开发SQE Supplier Quality Engineer 供方质量工程师SQIP Supplier Quality Improvement Process 供应商质量改进程序SSF Start of System Fill 系统填充SSLT Subsystem Leadership T eam 子系统领导组SSTS Subsystem Technical Specification 技术参数子系统STD Standardization 标准化STO Secondary Tryout 二级试验SUI 安全作业指导书SUW Standard Unit of Work 标准工作单位SWE Simulated Work Environment 模拟工作环境TAG Timing Analysis Group 定时分析组TBD To Be Determined 下决定TCS Traction Control System 牵引控制系统TDC Technology Development Centre 技术中心TDMF Text Data Management Facility 文本数据管理设备TG Tooling 工具TIMS Test Incident Management System 试验事件管理系统TIR Test Incident Report 试验事件报告TMIE Total Manufacturing Integration Engineer 总的制造综合工程TOE Total Ownership Experience 总的物主体验TPM Total Production Maintenance 全员生产维护TSM Trade Study Methodology 贸易研究方法TT Tact Time 单件工时TVDE Total Vehicle Dimensional Engineer 整车外型尺寸工程师TVIE Total Vehicle Integration Engineer 整车综合工程师TWS Tire and Wheel System 轮胎和车轮系统UAW United Auto Workers 班组UCL Uniform Criteria List 统一的标准表UDR Unverified Data Release 未经核对的资料发布UPC Uniform Parts Classification 统一零件分级VAE Vehicle Assembly Engineer 车辆装配工程师VAPIR Vehicle & Progress Integration Review T eam 汽车发展综合评审小组VASTD Vehicle Assembly Standard Time Data 汽车数据标准时间数据VCD Vehicle Chief Designer 汽车首席设计师VCE Vehicle Chief Engineer 汽车总工程师VCRI Validation Cross-Reference Index 确认交叉引用索引VDP Vehicle Development Process 汽车发展过程VDPP Vehicle Development Production Process 汽车发展生产过程VDR Verified Data Release 核实数据发布VDS Vehicle Description Summary 汽车描述概要VDT Vehicle Development Team 汽车发展组VDTO Vehicle Development Technical Operations 汽车发展技术工作VEC Vehicle Engineering Center 汽车工程中心VIE Vehicle Integration Engineer 汽车综合工程师VIN Vehicle Identification Number 车辆识别代码VIS Vehicle Information System 汽车信息系统VLE Vehicle Line Executive 总装线主管VLM Vehicle Launch Manager 汽车创办经理VMRR Vehicle and Manufacturing Requirements Review 汽车制造必要条件评审VOC Voice of Customer 顾客的意见VOD Voice of Design 设计意见VS Validation Station 确认站VSAS Vehicle Synthesis,Analysis,and Simulation 汽车综合、分析和仿真VSE Vehicle System Engineer 汽车系统工程师VTS Vehicle T echnical Specification 汽车技术说明书WBBA Worldwide Benchmarking and Business Analysis 全球基准和商业分析WOT Wide Open Throttle 压制广泛开放WPO Work Place Organization 工作场地布置WWP Worldwide Purchasing 全球采购COMMWIP Correction 纠错浪费Overproduction 过量生产浪费Material Flow 过度物料移动浪费Motion 过度移动浪费Waiting 等待浪费Inventory 过度库存浪费Processing 过度加工浪费。

车辆工程技术96车辆技术0 前言 BIQS涉及五大原则,一共29+2个条款,其中*2*是指的安全和WPO(工作现场有序),用红、黄、绿评价每一个评审条款的审核结果。

通过计算评价结论为绿色的模块的百分占比得出BIQS应用评审评分结果。

目前GM评价是评审29+2,SGM评审为29+1,其中“1”是指安全,SGM要求Lever3供应商是大于18个条款为绿色,也就是大于等于62%,Lever4供应商是大于22个条款为绿色,也就是大于等于75%。

BIQS实际就是汽车行业推行的IATF16949的细化,供应商在推行中无须另起炉灶专搞BIQS,它是与供应商内部质量管理体系IATF16949宗旨要求相一致的,只是具体到31个条款,有更加具体细化的要求。

如何才能使BIQS在工厂一线有效落地并实施,达到从被动到主动,质量缺陷不出制造工位的效果, 需要经过四步过程:意识到位、能力到位、执行到位、标定到位,具体操作如下:1 意识到位 (1)建立推进小组。

高层领导在推进初期设立推进小组,任命推进组长和组员,按照五大原则分解为五个不同职能部门推进负责人,成立BIQS团队发展矩阵,分别推进分解的各自条款(BIQ原则21个条款,STD原则2个条款,PI原则3个条款,SLT原则2个条款,CI原则3个条款)。

(2)文化宣贯。

将BIQS理念植入企业文化,通过企业文化宣贯来倡导、普及BIQS知识,最终达到全员自主践行BIQS的目的。

(3)例会制度。

建立定期例会制度,向领导层汇报展示推进效果和发现的问题,在例会上向汇报整改关闭情况,快速有效的推动问题整改。

2 能力到位 通过案例剖析、各原则轮训等专项培训对全员进行培训,搭建BIQS共享交流平台,多轮考试验证学习效果,提升各层级人员能力。

3 执行到位 通过前面的全员培训,按各条款要求执行,开展TPM/PM推进、班组建设、标准化等工作,以点带面推动现场的执行。

4 标定到位 (1)定期内部评价机制。

OEM生产,即贴牌生产,也称为定牌生产,俗称“贴牌”,由于其英文表述为Original Equipment/Entrusted Manufacture(译为原始设备制造商或原产地委托加工),因此简称为OEM。

基本含义为品牌生产者不直接生产产品,而是利用自己掌握的关键的核心技术负责设计和开发新产品,控制销售渠道,具体的加工任务通过合同订购的方式委托同类产品的其他厂家生产。

之后将所订产品低价买断,并直接贴上自己的品牌商标。

这种委托他人生产的合作方式简称OEM,承接加工任务的制造商被称为OEM厂商,其生产的产品被称为OEM产品。

可见,贴牌生产属于加工贸易中的“代工生产”方式,在国际贸易中是以商品为载体的劳务出口。

OEM的特征就是:技术在外,资本在外,市场在外,只有生产在内。

ODM是英文Original Design Manufacturer (原始设计制造商)的缩写,指一家厂家根据另一家厂商的要求,为其生产产品和产品配件,亦称为定牌生产或授权贴牌生产.即可代表外委加工,也可代表转包合同加工.国内习惯称为协作生产,三来加工。

ODM的厂商设计方案分为买断或不买断的方式供应:1.买断方式:有品牌拥有方买断ODM厂商现成的某型号产品的设计,或品牌拥有方单独要求ODM厂商为自己设计产品方案。

2.不买断方式:品牌拥有方不买断ODM厂商某型号产品的设计,ODM厂商可将同型号产品的设计采取不买断的方式同时卖给其它品牌。

当这两个或多个品牌共享一个设计时,两个品牌产品的区别主要在于外观。

SOP (small-outline package,批量生产,为上市积累一定的库存)SOP =Standard Operating Procedure 标准操作程序OBD是英文On-Board Diagnostics的缩写,中文翻译为“车载自动诊断系统”。

这个系统将从发动机的运行状况随时监控汽车是否尾气超标,一旦超标,会马上发出警示。

当系统出现故障时,故障(MIL)灯或检查发动机(Check Engine)警告灯亮,同时动力总成控制模块(PCM)将故障信息存入存储器,通过一定的程序可以将故障码从PCM中读出。

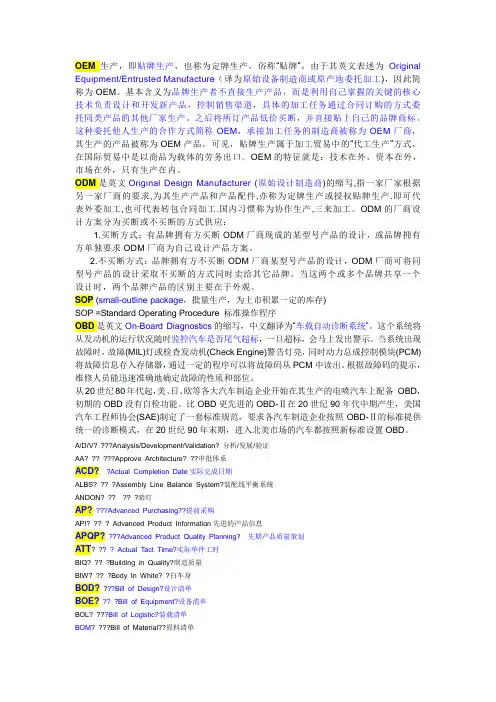

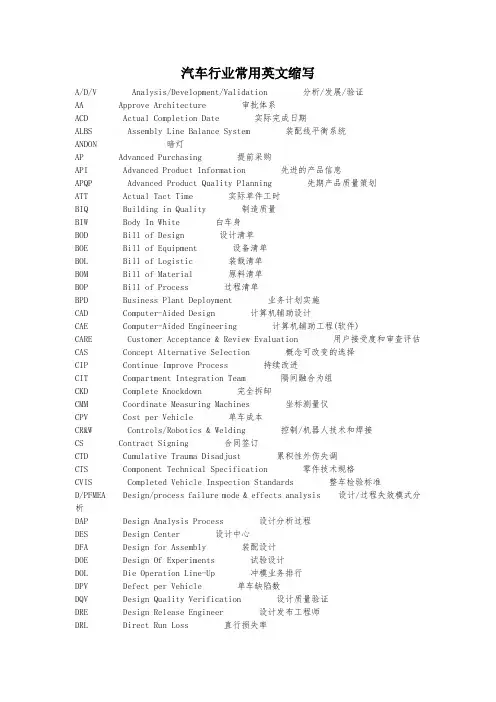

汽车行业常用英文缩写A/D/V Analysis/Development/Validation 分析/发展/验证AA Approve Architecture 审批体系ACD Actual Completion Date 实际完成日期ALBS Assembly Line Balance System 装配线平衡系统ANDON 暗灯AP Advanced Purchasing 提前采购API Advanced Product Information 先进的产品信息APQP Advanced Product Quality Planning 先期产品质量策划ATT Actual Tact Time 实际单件工时BIQ Building in Quality 制造质量BIW Body In White 白车身BOD Bill of Design 设计清单BOE Bill of Equipment 设备清单BOL Bill of Logistic 装载清单BOM Bill of Material 原料清单BOP Bill of Process 过程清单BPD Business Plant Deployment 业务计划实施CAD Computer-Aided Design 计算机辅助设计CAE Computer-Aided Engineering 计算机辅助工程(软件)CARE Customer Acceptance & Review Evaluation 用户接受度和审查评估CAS Concept Alternative Selection 概念可改变的选择CIP Continue Improve Process 持续改进CIT Compartment Integration Team 隔间融合为组CKD Complete Knockdown 完全拆缷CMM Coordinate Measuring Machines 坐标测量仪CPV Cost per Vehicle 单车成本CR&W Controls/Robotics & Welding 控制/机器人技术和焊接CS Contract Signing 合同签订CTD Cumulative Trauma Disadjust 累积性外伤失调CTS Component Technical Specification 零件技术规格CVIS Completed Vehicle Inspection Standards 整车检验标准D/PFMEA Design/process failure mode & effects analysis 设计/过程失效模式分析DAP Design Analysis Process 设计分析过程DES Design Center 设计中心DFA Design for Assembly 装配设计DOE Design Of Experiments 试验设计DOL Die Operation Line-Up 冲模业务排行DPV Defect per Vehicle 单车缺陷数DQV Design Quality Verification 设计质量验证DRE Design Release Engineer 设计发布工程师DRL Direct Run Loss 直行损失率DRR Direct Run Run 直行率DSC Decision Support Center 决策支持中心ECD Estimated Completion Date 计划完成日期EGM Engineering Group Manager 工程组经理ELPO Electrode position Primer 电极底漆ENG Engineering 工程技术、工程学EOA End of Acceleration 停止加速EPC&L Engineering Production Cntrol &Logistics 工程生产控制和后勤EQF Early Quality Feedback 早期质量反馈EWO Engineering Work Order 工程工作指令FA Final Approval 最终认可FE Functional Evaluation 功能评估FEDR Functional Evaluation Disposition Report 功能评估部署报告FFF Free Form Fabrication 自由形态制造FIN Financial 金融的FL 听FMEA Failure Mode and Effects Analysis 失效形式及结果分析FPS Fixed Point Stop 定点停FTP File Transfer Protocol 文件传送协议FTQ First Time Quality 一次送检合格率GA General Assembly 总装GA Shop General Assembly Shop 总装车间Paint Shop 涂装车间Body Shop 车身车间Press Shop 冲压车间GCA Global Customer Audit 全球顾客评审GD&T Geometric Dimensioning & Tolerancing 几何尺寸及精度GDS Global Delivery Survey 全球发运检查GM General Motors 通用汽车GMAP GM Asia Pacific 通用亚太GME General Motors Europe 通用汽车欧洲GMIO General Motors International Operations 通用汽车国际运作GMIQ General Motors Initial Quality 通用汽车初始质量GMPTG General Motors Powertrain Group 通用汽车动力组GMS Global Manufacturing System 通用全球制造系统GP General Procedure 通用程序GQTS Global Quality Tracking System 全球质量跟踪系统GSB Global Strategy Board 全球战略部HVAC Heating, Ventilation ,and Air Conditioning 加热、通风及空调I/P Instrument Panel 仪表板IC Initiate Charter 初始租约ICD Interface Control Document 界面控制文件IE Industrial Engineering 工业工程IEMA International Export Market Analysis 国际出口市场分析ILRS Indirect Labor Reporting System 间接劳动报告系统IO International Operations 国际业务IOM Inspection Operation Mathod 检验操作方法IOS Inspection Operation Summary 检验操作概要IPC International Product Center 国际产品中心IPTV Incidents Per Thousand Vehicles 每千辆车的故障率IQS Initial Quality Survey 初始质量调查IR Incident Report 事故报告ISP Integrated Scheduling Project 综合计划ITP Integrated Training Process 综合培训方法ITSD Interior Technical Specification Drawing 内部技术规范图IUVA International Uniform Vehicle Audit 国际统一车辆审核JES Job Element Sheet 工作要素单JIS Job Issue Sheet 工作要素单JIT Just in Time 准时制JPH Job per hour 每小时工作量KCC Key Control Characteristics 关键控制特性KCDS Key Characteristics Designation System 关键特性标识系统KPC Key product Characteristic 关键产品特性LT Look at 看MFD Metal Fabrication Division 金属预制件区MFG Manufacturing Operations 制造过程MIC Marketing Information Center 市场信息中心MIE Manufacturing Integration Engineer 制造综合工程师MKT Marketing 营销MLBS Material Labor Balance System 物化劳动平衡系统MMSTS Manufacturing Major Subsystem Technical Specifications 制造重要子系统技术说明书MNG Manufacturing Engineering 制造工程MPG Milford Proving Ground 试验场MPI Master Process Index 主程序索引MPL Master Parts List 主零件列表MPS Material Planning System 原料计划系统MRD Material Required Date 物料需求日期MSDS Material Safery Data Sheets 化学品安全数据单MSE Manufacturing System Engineer 制造系统工程MSS Market Segment Specification 市场分割规范MTBF Mean Time Between Failures 平均故障时间MTS Manufacturing Technical Specification 生产技术规范MVSS Motor Vehicle Safety Standards 汽车发动机安全标准NAMA North American Market Analysis 北美市场分析NAO North American Operations 北美业务NAOC NAO Containerization NAO货柜运输NC Numerically Controlled 用数字控制NOA Notice of Authorization 授权书NSB NAO Strategy Board 北美业务部OED Organization and Employee Development 组织和员工发展OSH Occupational Safety & Health 职业安全健康OSHA Occupational Safety & Health Act 职业安全与健康法案OSHMS Occupational Safety & Health Management System 职业安全健康管理体系OSHS Occupational Safety & Health Standards 职业安全标准PA Production Achievement 生产结果PAA Product Action Authorization 产品临时授权PAC Performance Assessment Committee 绩效评估委员会PACE Program Assessment and Control Environment 项目评估和控制条件PAD Product Assembly Document 产品装配文件PARTS Part Readiness Tracking System 零件准备跟踪系统PC Problem Communication 问题信息PCL Production Control and Logistics 生产控制和支持PCM Process Control Manager 工艺控制负责人PCR Problem Communication Report 问题交流报告PDC Portfolio Development Center 证券发展中心PDM Product Data Management 产品资料管理PDS Product Description System 产品说明系统PDT Product Development Team 产品发展小组PED Production Engineering Department 产品工程部PEP Product Evaluation Program 产品评估程序PER Personnel 人员PET Program Execution Team 项目执行小组PGM Program Management 项目管理PI People Involement 人员参与PIMREP Project Incident Monitoring and Resolution Process 事故方案跟踪和解决过程PLP Production Launch Process 生产启动程序PMI Process Modeling Integration 加工建模一体化PMM Program Manufacturing Manager 项目制造经理PMR Product Manufacturability Requirements 产品制造能要求PMT Product Management Team 产品车管理小组POMS Production Order Management System 产品指令管理小组POP Point of Purchase 采购点PP Push - Pull 推拉PPAP Production Part Approval Process 生产零部件批准程序PPE 个人防护用品PPH Problems Per Hundred 百辆车缺陷数PPM Problems Per Million 百万辆车缺陷数PPS Practical Problem Solving 实际问题解决PR Performance Review 绩效评估PR/R Problem Reporting and Resolution 问题报告和解决PRTS Problem Resolution and Tracking System 问题解决跟踪系统PSC Portfolio Strategy Council 部长职务策略委员会PST Plant Support Team 工厂支持小组PTO Primary Tryout 第一次试验PTR Production Trial Run 生产试运行PUR Purchasing 采购PVD Production Vehicle Development 生产汽车发展PVM Programmable Vehicle Model 可设计的汽车模型QA Quality Audit 质量评审QAP Quality Assessment Process 质量评估过程QBC Quality Build Concern 质量体系构建关系QC Quality Characteristic 质量特性QCOS Quality Control Operation Sheets 质量风险控制QE Quality Engineer 质量工程师QET Quality Engineering Team 质量工程小组QFD Quality Function Deployment 质量功能配置QRD Quality, Reliability,andDurability 质量、可靠性和耐久力QS Quality System 质量体系QUA Quality 质量RC Review Charter 评估特许RCD Required Completion Date 必须完成日期RFQ Request For Quotation 报价请求RGM Reliability Growth Management 可靠性增长小组RONA Return on Net Assets 净资产评估RPO Regular Production Option 正式产品选项RQA Routing Quality Assessment 程序安排质量评定RT&TM Rigorous Tracking and Throughout Managment 严格跟踪和全程管理SDC Strategic Decision Center 战略决策中心SF Styling Freeze 造型冻结SIL Single Issue List 单一问题清单SIP Stansardized Inspection Process 标准化检验过程SIU Summing It All Up 电子求和结束SL System Layouts 系统规划SLT Short Leading Team 缩短制造周期SMARTSMBP Synchronous Math-Based Process 理论同步过程SME Subject Matter Expert 主题专家SMT Systems Management Team 系统管理小组SNR 坏路实验SOP Start of Production 生产启动SOP Safe Operating Practice 安全操作规程SOR Statement of Requirements 技术要求SOS Standardization Operation Sheet 标准化工作操作单SOW Statement of Work 工作说明SPA Shipping Priority Audit 发运优先级审计SPC Statistical Process Control 统计过程控制SPE Surface and Prototype Engineering 表面及原型工程SPO Service Parts Operations 配件组织SPT Single Point Team 专一任务小组SQA Supplier Quality Assurance 供应商质量保证(供应商现场工程师)SQC Supplier Quality Control 供方质量控制SQD Supplier Quality Development 供应方质量开发SQE Supplier Quality Engineer 供方质量工程师SQIP Supplier Quality Improvement Process 供应商质量改进程序SSF Start of System Fill 系统填充SSLT Subsystem Leadership Team 子系统领导组SSTS Subsystem Technical Specification 子系统技术规范STD Standardization 标准化STO Secondary Tryout 二级试验SUI 安全作业指导书SUW Standard Unit of Work 标准工作单位SWE Simulated Work Environment 模拟工作环境TAG Timing Analysis Group 定时分析组TBD To Be Determined 下决定TCS Traction Control System 牵引控制系统TDC Technology Development Centre 技术中心TDMF Text Data Management Facility 文本数据管理设备TG Tooling 工具TIMS Test Incident Management System 试验事件管理系统TIR Test Incident Report 试验事件报告TMIE Total Manufacturing Integration Engineer 总的制造综合工程TOE Total Ownership Experience 总的物主体验TPM Total Production Maintenance 全员生产维护TSM Trade Study Methodology 贸易研究方法TT Tact Time 单件工时TVDE Total Vehicle Dimensional Engineer 整车外型尺寸工程师TVIE Total Vehicle Integration Engineer 整车综合工程师TWS Tire and Wheel System 轮胎和车轮系统UAW United Auto Workers 班组UCL Uniform Criteria List 统一的标准表UDR Unverified Data Release 未经核对的资料发布UPC Uniform Parts Classification 统一零件分级VAE Vehicle Assembly Engineer 车辆装配工程师VAPIR Vehicle & Progress Integration Review Team 汽车发展综合评审小组VASTD Vehicle Assembly Standard Time Data 汽车数据标准时间数据VCD Vehicle Chief Designer 汽车首席设计师VCE Vehicle Chief Engineer 汽车总工程师VCRI Validation Cross-Reference Index 确认交叉引用索引VDP Vehicle Development Process 汽车发展过程VDPP Vehicle Development Production Process 汽车发展生产过程VDR Verified Data Release 核实数据发布VDS Vehicle Description Summary 汽车描述概要VDT Vehicle Development Team 汽车发展组VDTO Vehicle Development Technical Operations 汽车发展技术工作VEC Vehicle Engineering Center 汽车工程中心VIE Vehicle Integration Engineer 汽车综合工程师VIN Vehicle Identification Number 车辆识别代码VIS Vehicle Information System 汽车信息系统VLE Vehicle Line Executive 总装线主管VLM Vehicle Launch Manager 汽车创办经理VMRR Vehicle and Manufacturing Requirements Review 汽车制造必要条件评审VOC Voice of Customer 顾客的意见VOD Voice of Design 设计意见VS Validation Station 确认站VSAS Vehicle Synthesis,Analysis,and Simulation 汽车综合、分析和仿真VSE Vehicle System Engineer 汽车系统工程师VTS Vehicle Technical Specification 汽车技术说明书WBBA Worldwide Benchmarking and Business Analysis 全球基准和商业分析WOT Wide Open Throttle 压制广泛开放WPO Work Place Organization 工作场地布置WWP Worldwide Purchasing 全球采购COMMWIP Correction 纠错浪费Overproduction 过量生产浪费Material Flow 过度物料移动浪费Motion 过度移动浪费Waiting 等待浪费Inventory 过度库存浪费Processing 过度加工浪费转载请注明出自六西格玛品质论坛。

最全最实用汽车行业英文缩写汽车行业词汇缩写A-DA/D/V Analysis/Development/Validation 分析/发展/验证AA Approve Architecture 审批体系ACD Actual Completion Date 实际完成日期ALBS Assembly Line Balance System 装配线平衡系统ANDON 暗灯AP Advanced Purchasing 提前采购API Advanced Product Information 先进的产品信息APQP Advanced Product Quality Planning 先期产品质量策划ATT Actual Tact Time 实际单件工时ABS Anti lock Braking SystemAIAG 美国汽车联合会ANPQP Alliance New Product Quality Procedure Apportionment 分配APQP Advanced Product Quality PlanBIQ Building in Quality 制造质量BIW Body In White 白车身BOD Bill of Design 设计清单BOE Bill of Equipment 设备清单BOL Bill of Logistic 装载清单BOM Bill of Material 原料清单BOP Bill of Process 过程清单BPD Business Plant Deployment 业务计划实施Backlite Windshield 后窗玻璃Benchmark Data 样件资料BMW Bavarian Motor WorksCAD Computer Aided Design 计算机辅助设计CAE Computer Aided Engineering 计算机辅助工程(软件)CARE Customer Acceptance & Review Evaluation 用户接受度和审查评估CIP Continue Improve Process 持续改进CIT Compartment Integration Team 隔间融合为组CKD Complete Knockdown 完全拆缷CMM Coordinate Measuring Machines 坐标测量仪CPV Cost per Vehicle 单车成本CR&W Controls/Robotics & Welding 控制/机器人技术和焊接CS Contract Signing 合同签订CTD Cumulative Trauma Disadjust 累积性外伤失调CTS Component T echnical Specification 零件技术规格CVIS Completed Vehicle Inspection Standards 整车检验标准C.P.M Certified Purchasing manger 认证采购经理人制度CB Confirmation Build 确认样车制造CC Change CutOff 设计变更冻结CC\SC critical/significant characteristicCCR Concern & Countermeasure RequestCCT Cross Company TeamCharacteristics Matrix 特性矩阵图COD Cash on Delivery 货到付现预付货款(T/T in advance) CP1 Confirmation Prototype 1st第一次确认样车CP2 Confirmation Prototype 2nd 第二次确认样车Cpk Cpk=Zmin/3 过程能力指数CPO Complementary Parts OrderCraftsmanship 精致工艺Cross functional teams 跨功能小组CUV Car Based Ultility VehicleDAP Design Analysis Process 设计分析过程DES Design Center 设计中心DFA Design for Assembly 装配设计DOE Design Of Experiments 试验设计DOL Die Operation Line Up 冲模业务排行DPV Defect per Vehicle 单车缺陷数DQV Design Quality Verification 设计质量验证DRE Design Release Engineer 设计发布工程师DRL Direct Run Loss 直行损失率DRR Direct Run Run 直行率DSC Decision Support Center 决策支持中心DCC Design Change ControlDOE Design Of Examination 试验设计DQES Delivery Quality Evaluation SystemDTL Direct To LineDVP&R Design Validate Plan&Report 设计验证计划报告ECD Estimated Completion Date 计划完成日期3 lEGM Engineering Group Manager 工程组经理ENG Engineering 工程技术、工程学EOA End of Acceleration 停止加速EPC&L Engineering Production Control &Logistics 工程生产控制和后勤EQF Early Quality Feedback 早期质量反馈EWO Engineering Work Order 工程工作指令EDI electronic data interchange 电子数据交换ERP Enterprise Resource PlanningES Engineering Specification 工程规格ESI Early Supplier Involvement 供应商先期参与Ex Work(工厂交货)、FOB(船上交货)、FAS(船边交货)或CIF(运保费在内交货)FA Final Approval 最终认可FE Functional Evaluation 功能评估FEDR Functional Evaluation Disposition Report 功能评估部署报告FFF Free Form Fabrication 自由形态制造FIN Financial 金融的FPS Fixed Point Stop 定点停FTP File Transfer Protocol 文件传送协议FTQ First Time Quality 一次送检合格率FEU Field Evaluation Units 用户市场实际体验与评估first gear 一档Flow Chart 流程图FMEA Failure Mode and Effects AnalysisFRG Ford Reliability Guideline 福特可靠性指导Front Windshield 前挡风玻璃FSS Full service supplier 全服务供应商FTA Fault Tree AnalysisGA General Assembly 总装GA Shop General Assembly Shop 总装车间Paint Shop 涂装车间Body Shop 车身车间Press Shop 冲压车间GCA Global Customer Audit 全球顾客评审GD&T Geometric Dimensioning & T olerancing 几何尺寸及精度GDS Global Delivery Survey 全球发运检查GM General Motors 通用汽车GMAP GM Asia Pacific 通用亚太GME General Motors Europe 通用汽车欧洲GMIO General Motors International Operations 通用汽车国际运作GMIQ General Motors Initial Quality 通用汽车初始质量GMPTG General Motors Powertrain Group 通用汽车动力组GMS Global Manufacturing System 通用全球制造系统GP General Procedure 通用程序GQTS Global Quality Tracking System 全球质量跟踪系统GSBGlobal Strategy Board 全球战略部GD&T Geometric Dimensioning & Tolerancing 标准公差GR&R Guage Repeatability&reproducibility 量具的重复性和再现性HV AC Heating, Ventilation ,and Air Conditioning 加热、通风及空调HTFB Hard Tooling Functional Build 工装集成调试与验证IC Initiate Charter 初始租约ICD Interface Control Document 界面控制文件IE Industrial Engineering 工业工程ILRS Indirect Labor Reporting System 间接劳动报告系统IO International Operations 国际业务IOM Inspection Operation Method 检验操作方法IOS Inspection Operation Summary 检验操作概要IPC International Product Center 国际产品中心IPTV Incidents Per Thousand Vehicles 每千辆车的故障率IQS Initial Quality Survey 初始质量调查IR Incident Report 事故报告ISP Integrated Scheduling Project 综合计划ITP Integrated Training Process 综合培训方法ITSD Interior Technical Specification Drawing 内部技术规范图IUV A International Uniform Vehicle Audit 国际统一车辆审核IPO Individual Parts OrderISIR Initial Sample Inspection ReportJES Job Element Sheet 工作要素单JIS Job Issue Sheet 工作要素单JIT Just in Time 准时制JPH Job per hour 每小时工作量KCC Key Control Characteristics 关键控制特性KCDS Key Characteristics Designation System 关键特性标识系统KPC Key product Characteristic 关键产品特性KD knocked down/ Semi Knock Down(SKD) /Completely Knock Down(CKD) KO Kick offLT Look at 看Laminated glass 夹层玻璃LP-Lean Production 精益生产LR Launch Readiness 启动准备LVPM Local Vendor Packaging MethodMFD Metal Fabrication Division 金属预制件区MFG Manufacturing Operations 制造过程)MIE Manufacturing Integration Engineer 制造综合工程师MLBS Material Labor Balance System 物化劳动平衡系统MNG Manufacturing Engineering 制造工程MPG Milford Proving Ground 试验场MPI Master Process Index 主程序索引MPL Master Parts List 主零件列表MPS Material Planning System 原料计划系统MRD Material Required Date 物料需求日期MSDS Material Safety Data Sheets 化学品安全数据单MSE Manufacturing System Engineer 制造系统工程MTBF Mean Time Between Failures 平均故障时间MTS Manufacturing Technical Specification 生产技术规范MVSS Motor Vehicle Safety Standards 汽车发动机安全标准MPV Multi PurposeVehicle 多用途汽车MRD Material Required DateMRO Maintenance,Repair,and OperationMTP Make to print supplier 照图加工供应商NAMA North American Market Analysis 北美市场分析NAO North American Operations 北美业务NAOC NAO Containerization NAO货柜运输NC Numerically Controlled 数字控制NOA Notice of Authorization 授权书NSB NAO Strategy Board 北美业务部N/A Not ApplicableNCDR Non Conforming Delivery ReportNCMAR Non Conforming Material Action ReportNDA Non Disclosure Agreement 保密协定NDS Nissan Design SpecificationNML Nissan Motor LtdNVH System Noise, Vibration & Harshness 系统噪音,振动及粗糙性OED Organization and Employee Development 组织和员工发展OSH Occupational Safety & Health 职业安全健康T OSHA Occupational Safety & Health Act 职业安全与健康法案OSHMS Occupational Safety & Health Management System职业安全健康管理体系OSHS Occupational Safety & Health Standards 职业安全标准OSM Outside of MaterialPA Production Achievement 生产结果PAA Product Action Authorization 产品临时授权PAC Performance Assessment Committee 绩效评估委员会PACE Program Assessment and Control Environment 项目评估和控制条件PAD Product Assembly Document 产品装配文件PARTS Part Readiness Tracking System 零件准备跟踪系统PC Problem Communication 问题信息PCL Production Control and Logistics 生产控制和支持PCM Process Control Manager 工艺控制负责人PCR Problem Communication Report 问题交流报告PDM Product Data Management 产品资料管理PDS Product Description System 产品说明系统PDT Product Development Team 产品发展小组PED Production Engineering Department 产品工程部PEP Product Evaluation Program 产品评估程序PER Personnel 人员PET Program Execution Team 项目执行小组PGM Program Management 项目管理PI People Involvement 人员参与PLP Production Launch Process 生产启动程序PMI Process Modeling Integration 加工建模一体化PMM Program Manufacturing Manager 项目制造经理PMR Product Manufacturability Requirements 产品制造能要求POMS Production Order Management System 产品指令管理小组POP Point of Purchase 采购点PP Push Pull 推拉PPAP Production Part Approval Process 生产零部件批准程序PPE Personal Protective Equipment 个人防护用品PPH Problems Per Hundred 百辆车缺陷数PPM Problems Per Million 百万辆车缺陷数PPS Practical Problem Solving 实际问题解决PR Performance Review 绩效评估PR/R Problem Reporting and Resolution 问题报告和解决PRTS Problem Resolution and Tracking System 问题解决跟踪系统PSC Portfolio Strategy Council 部长职务策略委员会PST Plant Support Team 工厂支持小组PTO Primary Tryout 第一次试验PTR Production Trial Run 生产试运行PUR Purchasing 采购PAT Program Attributes Team 产品属性小组PDL Product Design LetterPH Proportions&HardpointsPIPC Percentage of Indexes with Process Capability 能力指数百分比PIST Percentage of Inspection points Satisfying Tolerance 检测点满意工差百分比PMT Program Moudle Team 产品模块小组PO Purchase OrderPPAP Production Part Approval Process 生产件批准程序PPSR Production Preparation Status ReportPQA Process Quality AssurancePR Program ReadinessPre Launch 试生产price driven costing 价格引导成本Production Preparation Final Nissan PT2/Renault PP Production Preparation Initial Nissan PT1/Renault PPP3 Production Trial Run 试生产Prototype 样件QA Quality Audit 质量评审QAP Quality Assessment Process 质量评估过程QBC Quality Build Concern 质量体系构建关系QC Quality Characteristic 质量特性QCOS Quality Control Operation Sheets 质量风险控制QE Quality Engineer 质量工程师QET Quality Engineering Team 质量工程小组QFD Quality Function Deployment 质量功能配置QRD Quality, Reliability and Durability 质量、可靠性和耐久力QS Quality System 质量体系QUA Quality 质量QFTT Quality Functional Task TeamQR Quality Reject 质量拒收RC Review Charter 评估特许RCD Required Completion Date 必须完成日期RFQ Request For Quotation 报价请求RGM Reliability Growth Management 可靠性增长小组RONA Return on Net Assets 净资产评估RPO Regular Production Option 正式产品选项RQA Routing Quality Assessment 程序安排质量评定RT&TM Rigorous Tracking and Throughout Management 严格跟踪和全程管理RAN Release Authorisation Number reverse 倒车档RFQ Request For Quotation 询价RKD Reverse Knock DownRLQ Receiving Lot QuantityROC Rate of ClimbROI return on investment 报酬率ROP Re Order PointRTO Required To OperateSDC Strategic Decision Center 战略决策中心SF Styling Freeze 造型冻结SIL Single Issue List 单一问题清单SIP Standardized Inspection Process 标准化检验过程SL System Layouts 系统规划SLT Short Leading Team 缩短制造周期SMBP Synchronous Math Based Process 理论同步过程SMT Systems Management Team 系统管理小组SNR 坏路实验SOP Start of Production 生产启动SOP Safe Operating Practice 安全操作规程SOR Statement of Requirements 技术要求SOS Standardization Operation Sheet 标准化工作操作单SOW Statement of Work 工作说明SPA Shipping Priority Audit 发运优先级审计SPC Statistical Process Control 统计过程控制SPE Surface and Prototype Engineering 表面及原型工程SPO Service Parts Operations 配件组织SPT Single Point Team 专一任务小组SQA Supplier Quality Assurance 供应商质量保证(供应商现场工程师)SQC Supplier Quality Control 供方质量控制SQD Supplier Quality Development 供应方质量开发SQE Supplier Quality Engineer 供方质量工程师SQIP Supplier Quality Improvement Process 供应商质量改进程序SSLT Subsystem Leadership Team 子系统领导组SSTS Subsystem Technical Specification 技术参数子系统STD Standardization 标准化STO Secondary Tryout 二级试验SUI 安全作业指导书SUW Standard Unit of Work 标准工作单位SWE Simulated Work Environment 模拟工作环境SAIS Supplier Assessment & Improvement SystemSC Strategic Confirmation/significant Charac''teristicsSDS System/ Design Specifications 系统/设计说明Shipping Date 出货日、Invoice Date 发票日或On Board Date 装船日Side Windshield 侧窗玻璃SJ Strategic IntentSNP Standard Number of PartsSOW state of work 工作申明SPC Statistical Process ControlSQA Supplier Quality AssuranceSREA Supplier Request for Engineering Approval 供应商工程设计更改申请ST Surface TranferSTRS Supplier Test Report SystemSubcontractor 分承包商Sunroof Windshield 天窗玻璃SUV Sports Utility VehicleTAG Timing Analysis Group 定时分析组TBD To Be Determined 下决定TCS Traction Control System 牵引控制系统TDC Technology Development Centre 技术中心TDMF Text Data Management Facility 文本数据管理设备TG Tooling 工具TIMS Test Incident Management System 试验事件管理系统TIR Test Incident Report 试验事件报告TMIE Total Manufacturing Integration Engineer 总的制造综合工程TOE T otal Ownership Experience 总的物主体验TPM Total Production Maintenance 全员生产维护TSM Trade Study Methodology 贸易研究方法TT Tact Time 单件工时TVDE T otal Vehicle Dimensional Engineer 整车外型尺寸工程师TVIE Total Vehicle Integration Engineer 整车综合工程师TWS Tire and Wheel System 轮胎和车轮系统TAG Test Aptitude GraphiqueTCO Total Cost of Ownership 总持有成本TCRA Total Cost Reduction ActivityTGR Things Gone RightTGW Things Gone WorstTM Techinical ManualTPM Total Preventive MaintenanceTTO T ool Try Out 工装验证UAW United Auto Workers 班组UCL Uniform Criteria List 统一的标准表UDR Unverified Data Release 未经核对的资料发布UPC Uniform Parts Classification 统一零件分级V AE Vehicle Assembly Engineer 车辆装配工程师VCD Vehicle Chief Designer 汽车首席设计师VCE V ehicle Chief Engineer 汽车总工程师CVCRI Validation Cross Reference Index 确认交叉引用索引VDR Verified Data Release 核实数据发布VDS V ehicle Description Summary 汽车描述概要VDT Vehicle Development Team 汽车发展组VEC V ehicle Engineering Center 汽车工程中心VIE Vehicle Integration Engineer 汽车综合工程师VIN Vehicle Identification Number 车辆识别代码VIS Vehicle Information System 汽车信息系统VLE Vehicle Line Executive 总装线主管VLM Vehicle Launch Manager 汽车创办经理VOC V oice of Customer 顾客的意见VOD V oice of Design 设计意见VS Validation Station 确认站VSAS Vehicle Synthesis Analysis and Simulation 汽车综合、分析和仿真VSE V ehicle System Engineer 汽车系统工程师VTS V ehicle Technical Specification 汽车技术说明书VO Vehicle Operation 主机厂VPP Vehicle Program Plan 整车项目计划VQA Vehicle Quality AssuranceVTTO Vendor Tool Try Out 供应商工装验证WOT Wide Open Throttle 压制广泛开放WPO Work Place Organization 工作场地布置WWP Worldwide Purchasing 全球采购WERS World Wide Engineering Release SystemWVTA Whole Vehicle Type Approval其他相关词汇招聘IQC解聘OQC岗位说明书SOP(标准作业程序)绩效考核SPC部门管理TQM人力资源会议MRB(MaterialReviewBoard)物料评审会议人员流失要进行5W2H(what、why、where、when、who、how、howmuch)人才要先编写FMEA任用要进行PFMEA招聘要进行DFMEA岗位设计才是DFMEA工作流分析就是流程再造岗位职责要求就是SIP(StandardInspectionProcedure标准检验程序)KPI权重就是AQL权重CP是岗位工作手册绩效标准、考评、面谈、反馈和改善计划就是APQP流程节点规划、岗位需求测量、价值流和工作流分析、岗位分析、绩效改善计划、绩效管制就是DMAIC(六西格玛项目推进流程)每日考勤和工作报表是查检表质量目标要用SMART员工关系是亲和度人员招聘委托书是CEM人事档案是DCC中介公司考察就是SSQA花名册明细名单BOM人员照片就是DWG人事招聘控制就是PCC人事招聘顾问QE绩效专员就是QA人资开发就是R&D人员招聘策划DQA招聘计划SQA关键特性就是KPI1PP First Phase of Production Prove Out 第一次试生产3C Customer(顾客导向)、Competition(竞争导向)、Competence(专长导向)4S Sale, Sparepart零配件, Service, Survey信息反馈5S 整理,整顿,清理,清洁,素养8D 8 DisciplineD1:信息收集;D2:建立8D小组;D3:制定临时的围堵行动措施,避免不良品流出;D4:定义和证实根本原因,避免再发;D5:根据基本原因制定永久措施;D6:执行和确认永久措施;D7:预防再发,实施永久措施;D8:认可团队和个人的贡献。

生产制造管理中常用英文单词A/D/V Analysis/Development/Validation 分析/发展/验证AA Approve Architecture 审批体系ACD Actual Completion Date 实际完成日期ALBS Assembly Line Balance System 装配线平衡系统 ANDON 暗灯(安腾灯)AP Advanced Purchasing 提前采购API Advanced Product Information 先进的产品信息 APQP Advanced Product Quality Planning 先期产品质量策划 ATT Actual Tact Time 实际单件工时BIQ Building in Quality 制造质量BIW Body In White 白车身BOD Bill of Design 设计清单BOE Bill of Equipment 设备清单BOL Bill of Logistic 装载清单BOM Bill of Material 原料清单BOP Bill of Process 过程清单BPD Business Plant Deployment 业务计划实施CAD Computer-Aided Design 计算机辅助设计CAE Computer-Aided Engineering 计算机辅助工程(软件) CARE Customer Acceptance & Review Evaluation用户接受度和审查评估 CAS Concept Alternative Selection 概念可改变的选择 CIP Continue Improve Process 持续改进CIT Compartment Integration Team 隔间融合为组CKD Complete Knockdown 完全拆缷CMM Coordinate Measuring Machines 坐标测量仪CPV Cost per Vehicle 单车成本CR&W Controls/Robotics & Welding 控制/机器人技术和焊接 CS Contract Signing 合同签订CTD Cumulative Trauma Disadjust 累积性外伤失调CTS Component Technical Specification 零件技术规格CVIS Completed Vehicle Inspection Standards 整车检验标准 D/PFMEA Design/process failure mode & effects analysis设计/过程失效模式分析DAP Design Analysis Process 设计分析过程DES Design Center 设计中心DFA Design for Assembly 装配设计DOE Design Of Experiments 试验设计DOL Die Operation Line-Up 冲模业务排行DPV Defect per Vehicle 单车缺陷数DQV Design Quality Verification 设计质量验证DRE Design Release Engineer 设计发布工程师DRL Direct Run Loss 直行损失率DRR Direct Run Run 直行率DSC Decision Support Center 决策支持中心ECD Estimated Completion Date 计划完成日期EGM Engineering Group Manager 工程组经理ELPO Electrode position Primer 电极底漆ENG Engineering 工程技术、工程学EOA End of Acceleration 停止加速EPC&L Engineering Production Cntrol &Logistics 工程生产控制和后勤EQF Early Quality Feedback 早期质量反馈EWO Engineering Work Order 工程工作指令FA Final Approval 最终认可FE Functional Evaluation 功能评估FEDR Functional Evaluation Disposition Report 功能评估部署报告FFF Free Form Fabrication 自由形态制造FIN Financial 金融的FL 听FMEA Failure Mode and Effects Analysis 失效形式及结果分析 FPS Fixed Point Stop 定点停FTP File Transfer Protocol 文件传送协议FTQ First Time Quality 一次送检合格率GA General Assembly 总装GA Shop General Assembly Shop 总装车间Paint Shop 涂装车间Body Shop 车身车间Press Shop 冲压车间GCA Global Customer Audit 全球顾客评审GD&T Geometric Dimensioning & Tolerancing 几何尺寸及精度 GDS Global Delivery Survey 全球发运检查GM General Motors 通用汽车GMAP GM Asia Pacific 通用亚太GME General Motors Europe 通用汽车欧洲GMIO General Motors International Operations 通用汽车国际运作 GMIQ General Motors Initial Quality 通用汽车初始质量 GMPTG General Motors Powertrain Group 通用汽车动力组GMS Global Manufacturing System 通用全球制造系统GP General Procedure 通用程序GQTS Global Quality Tracking System 全球质量跟踪系统 GSB Global Strategy Board 全球战略部HVAC Heating, Ventilation ,and Air Conditioning 加热、通风及空调 I/P Instrument Panel 仪表板IC Initiate Charter 初始租约ICD Interface Control Document 界面控制文件IE Industrial Engineering 工业工程IEMA International Export Market Analysis 国际出口市场分析 ILRS Indirect Labor Reporting System 间接劳动报告系统 IO International Operations 国际业务IOM Inspection Operation Mathod 检验操作方法IOS Inspection Operation Summary 检验操作概要IPC International Product Center 国际产品中心 IPTV Incidents Per Thousand Vehicles 每千辆车的故障率 IQS Initial Quality Survey 初始质量调查IR Incident Report 事故报告ISP Integrated Scheduling Project 综合计划ITP Integrated Training Process 综合培训方法ITSD Interior Technical Specification Drawing 内部技术规范图IUVA International Uniform Vehicle Audit 国际统一车辆审核 JES Job Element Sheet 工作要素单JIS Job Issue Sheet 工作要素单JIT Just in Time 准时制JPH Job per hour 每小时工作量KCC Key Control Characteristics 关键控制特性KCDS Key Characteristics Designation System 关键特性标识系统KPC Key product Characteristic 关键产品特性LT Look at 看MFD Metal Fabrication Division 金属预制件区MFG Manufacturing Operations 制造过程MIC Marketing Information Center 市场信息中心MIE Manufacturing Integration Engineer 制造综合工程师 MKT Marketing 营销MLBS Material Labor Balance System 物化劳动平衡系统 MMSTS Manufacturing Major Subsystem TechnicalSpecifications 制造重要子系统技术说明书MNG Manufacturing Engineering 制造工程MPG Milford Proving Ground 试验场MPI Master Process Index 主程序索引MPL Master Parts List 主零件列表MPS Material Planning System 原料计划系统MRD Material Required Date 物料需求日期MSDS Material Safery Data Sheets 化学品安全数据单MSE Manufacturing System Engineer 制造系统工程MSS Market Segment Specification 市场分割规范MTBF Mean Time Between Failures 平均故障时间MTS Manufacturing Technical Specification 生产技术规范 MVSS Motor Vehicle Safety Standards 汽车发动机安全标准NAMA North American Market Analysis 北美市场分析NAO North American Operations 北美业务NAOC NAO Containerization NAO货柜运输NC Numerically Controlled 用数字控制NOA Notice of Authorization 授权书NSB NAO Strategy Board 北美业务部OED Organization and Employee Development 组织和员工发展 OSH Occupational Safety & Health 职业安全健康OSHA Occupational Safety & Health Act 职业安全与健康法案 OSHMS Occupational Safety & Health Management System 职业安全健康管理体系OSHS Occupational Safety & Health Standards 职业安全标准 PA Production Achievement 生产结果PAA Product Action Authorization 产品临时授权PAC Performance Assessment Committee 绩效评估委员会 PACE Program Assessment and Control Environment 项目评估和控制条件PAD Product Assembly Document 产品装配文件PARTS Part Readiness Tracking System 零件准备跟踪系统PC Problem Communication 问题信息PCL Production Control and Logistics 生产控制和支持PCM Process Control Manager 工艺控制负责人PCR Problem Communication Report 问题交流报告PDC Portfolio Development Center 证券发展中心PDM Product Data Management 产品资料管理PDS Product Description System 产品说明系统PDT Product Development Team 产品发展小组PED Production Engineering Department 产品工程部PEP Product Evaluation Program 产品评估程序PER Personnel 人员PET Program Execution Team 项目执行小组PGM Program Management 项目管理PI People Involement 人员参与PIMREP Project Incident Monitoring and ResolutionProcess 事故方案跟踪和解决过程PLP Production Launch Process 生产启动程序PMI Process Modeling Integration 加工建模一体化PMM Program Manufacturing Manager 项目制造经理PMR Product Manufacturability Requirements 产品制造能要求 PMT Product Management Team 产品车管理小组POMS Production Order Management System 产品指令管理小组 POP Point of Purchase 采购点PP Push - Pull 推拉Production Part Approval Process 生产零部件批准程序PPE 个人防护用品PPH Problems Per Hundred 百辆车缺陷数PPM Problems Per Million 百万辆车缺陷数PPS Practical Problem Solving 实际问题解决PR Performance Review 绩效评估PR/R Problem Reporting and Resolution 问题报告和解决 PRTS Problem Resolution and Tracking System 问题解决跟踪系统PSC Portfolio Strategy Council 部长职务策略委员会PST Plant Support Team 工厂支持小组PTO Primary Tryout 第一次试验PTR Production Trial Run 生产试运行PUR Purchasing 采购PVD Production Vehicle Development 生产汽车发展PVM Programmable Vehicle Model 可设计的汽车模型QA Quality Audit 质量评审QAP Quality Assessment Process 质量评估过程QBC Quality Build Concern 质量体系构建关系QC Quality Characteristic 质量特性QCOS Quality Control Operation Sheets 质量风险控制QE Quality Engineer 质量工程师QET Quality Engineering Team 质量工程小组QFD Quality Function Deployment 质量功能配置QRD Quality, Reliability,andDurability 质量、可靠性和耐久力QS Quality System 质量体系QUA Quality 质量RC Review Charter 评估特许RCD Required Completion Date 必须完成日期RFQ Request For Quotation 报价请求RGM Reliability Growth Management 可靠性增长小组RONA Return on Net Assets 净资产评估RPO Regular Production Option 正式产品选项RQA Routing Quality Assessment 程序安排质量评定RT&TM Rigorous Tracking and Throughout Managment 严格跟踪和全程管理SDC Strategic Decision Center 战略决策中心SF Styling Freeze 造型冻结SIL Single Issue List 单一问题清单SIP Stansardized Inspection Process 标准化检验过程SIU Summing It All Up 电子求和结束SL System Layouts 系统规划SLT Short Leading Team 缩短制造周期SMARTSMBP Synchronous Math-Based Process 理论同步过程SME Subject Matter Expert 主题专家SMT Systems Management Team 系统管理小组SNR 坏路实验Start of Production 生产启动Safe Operating Practice 安全操作规程SOR Statement of Requirements 技术要求SOS Standardization Operation Sheet 标准化工作操作单 SOW Statement of Work 工作说明SPA Shipping Priority Audit 发运优先级审计SPC Statistical Process Control 统计过程控制SPE Surface and Prototype Engineering 表面及原型工程 SPO Service Parts Operations 配件组织SPT Single Point Team 专一任务小组SQA Supplier Quality Assurance 供应商质量保证(供应商现场工程师)SQC Supplier Quality Control 供方质量控制SQD Supplier Quality Development 供应方质量开发SQE Supplier Quality Engineer 供方质量工程师SQIP Supplier Quality Improvement Process 供应商质量改进程序SSF Start of System Fill 系统填充SSLT Subsystem Leadership Team 子系统领导组SSTS Subsystem Technical Specification 技术参数子系统 STD Standardization 标准化STO Secondary Tryout 二级试验SUI 安全作业指导书SUW Standard Unit of Work 标准工作单位SWE Simulated Work Environment 模拟工作环境TAG Timing Analysis Group 定时分析组TBD To Be Determined 下决定TCS Traction Control System 牵引控制系统TDC Technology Development Centre 技术中心TDMF Text Data Management Facility 文本数据管理设备TG Tooling 工具TIMS Test Incident Management System 试验事件管理系统 TIR Test Incident Report 试验事件报告TMIE Total Manufacturing Integration Engineer 总的制造综合工程TOE Total Ownership Experience 总的物主体验TPM Total Production Maintenance 全员生产维护TSM Trade Study Methodology 贸易研究方法TT Tact Time 单件工时TVDE Total Vehicle Dimensional Engineer 整车外型尺寸工程师TVIE Total Vehicle Integration Engineer 整车综合工程师 TWS Tire and Wheel System 轮胎和车轮系统UAW United Auto Workers 班组UCL Uniform Criteria List 统一的标准表UDR Unverified Data Release 未经核对的资料发布UPC Uniform Parts Classification 统一零件分级VAE Vehicle Assembly Engineer 车辆装配工程师VAPIR Vehicle & Progress Integration Review Team 汽车发展综合评审小组VASTD Vehicle Assembly Standard Time Data 汽车数据标准时间数据VCD Vehicle Chief Designer 汽车首席设计师VCE Vehicle Chief Engineer 汽车总工程师VCRI Validation Cross-Reference Index 确认交叉引用索引 VDP Vehicle Development Process 汽车发展过程VDPP Vehicle Development Production Process 汽车发展生产过程VDR Verified Data Release 核实数据发布VDS Vehicle Description Summary 汽车描述概要VDT Vehicle Development Team 汽车发展组VDTO Vehicle Development Technical Operations 汽车发展技术工作VEC Vehicle Engineering Center 汽车工程中心VIE Vehicle Integration Engineer 汽车综合工程师VIN Vehicle Identification Number 车辆识别代码VIS Vehicle Information System 汽车信息系统VLE Vehicle Line Executive 总装线主管VLM Vehicle Launch Manager 汽车创办经理VMRR Vehicle and Manufacturing Requirements Review 汽车制造必要条件评审VOC Voice of Customer 顾客的意见VOD Voice of Design 设计意见VS Validation Station 确认站VSAS Vehicle Synthesis,Analysis,and Simulation 汽车综合、分析和仿真VSE Vehicle System Engineer 汽车系统工程师VTS Vehicle Technical Specification 汽车技术说明书WBBA Worldwide Benchmarking and Business Analysis 全球基准和商业分析WOT Wide Open Throttle 压制广泛开放WPO Work Place Organization 工作场地布置WWP Worldwide Purchasing 全球采购COMMWIP Correction 纠错浪费Overproduction 过量生产浪费Material Flow 过度物料移动浪费Motion 过度移动浪费Waiting 等待浪费Inventory 过度库存浪费Processing 过度加工浪费什么是TPM(Total Productive Maintenance)?Description:TPM是Total Productive Maintenance 第一个字母的,本意是"全员参与的生产保全",也翻译为"全员维护",即通过员工素质与设备效率的提高,使企业的体质得到根本改善。

汽车行业词汇缩写A-DA/D/VAnalysis/Development/Validation分析/发展/验证AAApproveArchitecture审批体系ACDActualCompletionDate实际完成日期ALBSAssemblyLineBalanceSystem装配线平衡系统ANDON暗灯APAdvancedPurchasing提前采购APIAdvancedProductInformation先进的产品信息APQPAdvancedProductQualityPlanning先期产品质量策划ATTActualTactTime实际单件工时ABSAntilockBrakingSystemAIAG美国汽车联合会CSContractSigning合同签订CTDCumulativeTraumaDisadjust累积性外伤失调CTSComponentTechnicalSpecification零件技术规格CVISCompletedVehicleInspectionStandards整车检验标准C.P.MCertifiedPurchasingmanger认证采购经理人制度CBConfirmationBuild确认样车制造CCChangeCutOff设计变更冻结CC\SCcritical/significantcharacteristic CCRConcern&CountermeasureRequest CCTCrossCompanyTeamCharacteristicsMatrix特性矩阵图CODCashonDelivery货到付现预付货款(T/Tinadvance)CP1ConfirmationPrototype1st第一次确认样车CP2ConfirmationPrototype2nd第二次确认样车CpkCpk=Zmin/3过程能力指数CPOComplementaryPartsOrderCraftsmanship精致工艺Crossfunctionalteams跨功能小组CUVCarBasedUltilityVehicleDAPDesignAnalysisProcess设计分析过程DESDesignCenter设计中心DFADesignforAssembly装配设计ExWork(工厂交货)、FOB(船上交货)、FAS(船边交货)或CIF(运保费在内交货)FAFinalApproval最终认可FEFunctionalEvaluation功能评估FEDRFunctionalEvaluationDispositionReport功能评估部署报告FFFFreeFormFabrication自由形态制造FINFinancial金融的FPSFixedPointStop定点停FTPFileTransferProtocol文件传送协议FTQFirstTimeQuality一次送检合格率FEUFieldEvaluationUnits用户市场实际体验与评估firstgear一档FlowChart流程图FMEAFailureModeandEffectsAnalysis FRGFordReliabilityGuideline福特可靠性指导FrontWindshield前挡风玻璃FSSFullservicesupplier全服务供应商FTAFaultTreeAnalysisGAGeneralAssembly总装GAShopGeneralAssemblyShop总装车间PaintShop涂装车间BodyShop车身车间PressShop冲压车间IOSInspectionOperationSummary检验操作概要IPCInternationalProductCenter国际产品中心IPTVIncidentsPerThousandVehicles每千辆车的故障率IQSInitialQualitySurvey初始质量调查IRIncidentReport事故报告ISPIntegratedSchedulingProject综合计划ITPIntegratedTrainingProcess综合培训方法ITSDInteriorTechnicalSpecificationDrawing内部技术规范图IUVAInternationalUniformVehicleAudit国际统一车辆审核IPOIndividualPartsOrder ISIRInitialSampleInspectionReportJESJobElementSheet工作要素单JISJobIssueSheet工作要素单JITJustinTime准时制JPHJobperhour每小时工作量KCCKeyControlCharacteristics关键控制特性KCDSKeyCharacteristicsDesignationSystem关键特性标识系统KPCKeyproductCharacteristic关键产品特性KDknockeddown/SemiKnockDown(SKD)/CompletelyKnockDown(CKD) KOKickoffLTLookat看Laminatedglass夹层玻璃LP-NAONorthAmericanOperations北美业务NAOCNAOContainerizationNAO货柜运输NCNumericallyControlled数字控制NOANoticeofAuthorization授权书NSBNAOStrategyBoard北美业务部N/ANotApplicableNCDRNonConformingDeliveryReport NCMARNonConformingMaterialActionReport NDANonDisclosureAgreement保密协定NDSNissanDesignSpecificationNMLNissanMotorLtdNVHSystemNoise,Vibration&Harshness系统噪音,振动及粗糙性OEDOrganizationandEmployeeDevelopment组织和员工发展OSHOccupationalSafety&Health职业安全健康T OSHAOccupationalSafety&HealthAct职业安全与健康法案OSHMSOccupationalSafety&HealthManagementSystem职业安全健康管理体系OSHSOccupationalSafety&HealthStandards职业安全标准OSMOutsideofMaterialPAProductionAchievement生产结果PAAProductActionAuthorization产品临时授权PACPerformanceAssessmentCommittee绩效评估委员会PACEProgramAssessmentandControlEnvironment项目评估和控制条件PPMProblemsPerMillion百万辆车缺陷数PPSPracticalProblemSolving实际问题解决PRPerformanceReview绩效评估PR/RProblemReportingandResolution问题报告和解决PRTSProblemResolutionandTrackingSystem问题解决跟踪系统PSCPortfolioStrategyCouncil部长职务策略委员会PSTPlantSupportTeam工厂支持小组PTOPrimaryTryout第一次试验PTRProductionTrialRun生产试运行PURPurchasing采购PATProgramAttributesTeam产品属性小组PDLProductDesignLetterPHProportions&Hardpoints PIPCPercentageofIndexeswithProcessCapability能力指数百分比PISTPercentageofInspectionpointsSatisfyingTolerance检测点满意工差百分比PMTProgramMoudleTeam产品模块小组POPurchaseOrderPPAPProductionPartApprovalProcess生产件批准程序PPSRProductionPreparationStatusReportPQAProcessQualityAssurancePRProgramReadinessPreLaunch试生产pricedrivencosting价格引导成本ProductionPreparationFinalNissanPT2/RenaultPPRT&TMRigorousTrackingandThroughoutManagement严格跟踪和全程管理RANReleaseAuthorisationNumberreverse倒车档RFQRequestForQuotation询价RKDReverseKnockDownRLQReceivingLotQuantityROCRateofClimbROIreturnoninvestment报酬率ROPReOrderPointRTORequiredToOperateSDCStrategicDecisionCenter战略决策中心SFStylingFreeze造型冻结SILSingleIssueList单一问题清单SIPStandardizedInspectionProcess标准化检验过程SLSystemLayouts系统规划SLTShortLeadingTeam缩短制造周期SMBPSynchronousMathBasedProcess理论同步过程SMTSystemsManagementTeam系统管理小组SNR坏路实验SOPStartofProduction生产启动SOPSafeOperatingPractice安全操作规程SORStatementofRequirements技术要求SOSStandardizationOperationSheet标准化工作操作单SUISOWstateofwork工作申明SPCStatisticalProcessControlSQASupplierQualityAssurance SREASupplierRequestforEngineeringApproval供应商工程设计更改申请STSurfaceTranferSTRSSupplierTestReportSystemSubcontractor分承包商SunroofWindshield天窗玻璃SUVSportsUtilityVehicleTAGTimingAnalysisGroup定时分析组TBDToBeDetermined下决定TCSTractionControlSystem牵引控制系统TDCTechnologyDevelopmentCentre技术中心TDMFTextDataManagementFacility文本数据管理设备TGTooling工具TIMSTestIncidentManagementSystem试验事件管理系统TIRTestIncidentReport试验事件报告TMIETotalManufacturingIntegrationEngineer总的制造综合工程TOETotalOwnershipExperience总的物主体验TPMTotalProductionMaintenance全员生产维护TSMTradeStudyMethodology贸易研究方法TTTactTime单件工时TVDETotalVehicleDimensionalEngineer整车外型尺寸工程师VINVehicleIdentificationNumber车辆识别代码VISVehicleInformationSystem汽车信息系统VLEVehicleLineExecutive总装线主管VLMVehicleLaunchManager汽车创办经理VOCVoiceofCustomer顾客的意见VODVoiceofDesign设计意见VSValidationStation确认站VSASVehicleSynthesisAnalysisandSimulation汽车综合、分析和仿真VSEVehicleSystemEngineer汽车系统工程师VTSVehicleTechnicalSpecification汽车技术说明书VOVehicleOperation主机厂VPPVehicleProgramPlan整车项目计划VQAVehicleQualityAssurance VTTOVendorToolTryOut供应商工装验证WOTWideOpenThrottle压制广泛开放WPOWorkPlaceOrganization工作场地布置WWPWorldwidePurchasing全球采购WERSWorldWideEngineeringReleaseSystem WVTAWholeVehicleTypeApproval其他相关词汇招聘IQC解聘OQC岗位说明书SOP(标准作业程序)绩效考核部门管理评审会议who、how(KPICP析、花名册明细名单BOM人员照片就是DWG人事招聘控制就是PCC人事招聘顾问QE绩效专员就是QA人资开发就是R&D人员招聘策划DQA招聘计划SQA关键特性就是KPI1PPFirstPhaseofProductionProveOut第一次试生产3CCustomer(顾客导向)、Competition(竞争导向)、Competence(专长导向)4SSale,Sparepart零配件,Service,Survey信息质量保证验认可Nullserie零批量Bias偏差DBDurabilityBuild样车阶段leadtimen.订货至交货的时间sinkmark缩痕LRRlaunchreadinessreviewYC(PotentialCriticalCharacteristic)潜在关键特性YS(PotentialSignificantCharacteristic)潜在重要特性RestrictionofHazardousSubstances简称RoHSBVBureauVeritas法国国际检验局Frontbumper前保险杠Rearbumper后保险杠Radiatorgrille格栅Headlamp前大灯Taillampliftgate尾灯行李箱盖上Taillampquarter尾灯后侧围上Frontdoortrimpanel前门内饰板Reardoortrimpanel后门内饰板Interiorreleasehandlebezel内开手把手框ConsoleClusterCarpet前地毯Trunkcarpet后地毯Frontseat前座椅2ndrowseat第二排座椅burr(金属)flash(塑件)毛边gap间隙defectiveproducts不良品finishedproducts成品disposedproducts处理品bandaid创可贴scratch刮伤dents压痕凹坑concave车床lathe抽查试验spotchecktest出厂试验deliverytest次品defectiveproduct调幅amplitudemodulation(AM)调频FrequencyModulation断差offset对讲机interphone法平面normalplane翻车rollover选料上乘、做工精细besuperiorinmaterialandexcelllentinworkmans hip仪表板dashboard油门throttle褶皱crimple整车运输transportationoftruckload总装finalassembly阻流板step,reflectro,baffle最大扭矩转速speedatmaximumtorque左对齐leftjustify报废scrapping皮纹grain缩水Shrinkage缩水SinkMark顶白StressMark首检Firstarticleinspection 自检Selfinspection全检100%inspection巡检processaudit开箱检验outofboxaudit出货检验outgoinginspection 进货检验incominginspection 例行检验确认检验在线检验线下检验。

A/D/V Analysis/Development/Validation 分析/发展/验证AA Approve Architecture 审批体系ACD Actual Completion Date 实际完成日期ALBS Assembly Line Balance System 装配线平衡系统ANDON 暗灯AP Advanced Purchasing 提前采购API Advanced Product Information 先进的产品信息APQP Advanced Product Quality Planning 先期产品质量策划ATT Actual Tact Time 实际单件工时BIQ Building in Quality 制造质量BIW Body In White 白车身BOD Bill of Design 设计清单BOE Bill of Equipment 设备清单BOL Bill of Logistic 装载清单BOM Bill of Material 原料清单BOP Bill of Process 过程清单BPD Business Plant Deployment 业务计划实施CAD Computer-Aided Design 计算机辅助设计CAE Computer-Aided Engineering 计算机辅助工程(软件)CARE Customer Acceptance & Review Evaluation 用户接受度和审查评估CAS Concept Alternative Selection 概念可改变的选择CIP Continue Improve Process 持续改进CIT Compartment Integration Team 隔间融合为组CKD Complete Knockdown 完全拆缷CMM Coordinate Measuring Machines 坐标测量仪CPV Cost per Vehicle 单车成本CR&W Controls/Robotics & Welding 控制/机器人技术和焊接CS Contract Signing 合同签订CTD Cumulative Trauma Disadjust 累积性外伤失调CTS Component Technical Specification 零件技术规格CVIS Completed Vehicle Inspection Standards 整车检验标准D/PFMEA Design/process failure mode & effects analysis 设计/过程失效模式分析DAP Design Analysis Process 设计分析过程DES Design Center 设计中心DFA Design for Assembly 装配设计DOE Design Of Experiments 试验设计DOL Die Operation Line-Up 冲模业务排行DPV Defect per Vehicle 单车缺陷数DQV Design Quality Verification 设计质量验证DRE Design Release Engineer 设计发布工程师DRL Direct Run Loss 直行损失率DRR Direct Run Run 直行率DSC Decision Support Center 决策支持中心ECD Estimated Completion Date 计划完成日期EGM Engineering Group Manager 工程组经理ELPO Electrode position Primer 电极底漆ENG Engineering 工程技术、工程学EOA End of Acceleration 停止加速EPC&L Engineering Production Cntrol &Logistics 工程生产控制和后勤EQF Early Quality Feedback 早期质量反馈EWO Engineering Work Order 工程工作指令FA Final Approval 最终认可FE Functional Evaluation 功能评估FEDR Functional Evaluation Disposition Report 功能评估部署报告FFF Free Form Fabrication 自由形态制造FIN Financial 金融的FL 听FMEA Failure Mode and Effects Analysis 失效形式及结果分析FPS Fixed Point Stop 定点停FTP File Transfer Protocol 文件传送协议FTQ First Time Quality 一次送检合格率GA General Assembly 总装GA Shop General Assembly Shop 总装车间Paint Shop 涂装车间Body Shop 车身车间Press Shop 冲压车间GCA Global Customer Audit 全球顾客评审GD&T Geometric Dimensioning & Tolerancing 几何尺寸及精度GDS Global Delivery Survey 全球发运检查GM General Motors 通用汽车GMAP GM Asia Pacific 通用亚太GME General Motors Europe 通用汽车欧洲GMIO General Motors International Operations 通用汽车国际运作GMIQ General Motors Initial Quality 通用汽车初始质量GMPTG General Motors Powertrain Group 通用汽车动力组GMS Global Manufacturing System 通用全球制造系统GP General Procedure 通用程序GQTS Global Quality Tracking System 全球质量跟踪系统GSB Global Strategy Board 全球战略部HVAC Heating, Ventilation ,and Air Conditioning 加热、通风及空调I/P Instrument Panel 仪表板IC Initiate Charter 初始租约ICD Interface Control Document 界面控制文件IE Industrial Engineering 工业工程IEMA International Export Market Analysis 国际出口市场分析ILRS Indirect Labor Reporting System 间接劳动报告系统IO International Operations 国际业务IOM Inspection Operation Mathod 检验操作方法IOS Inspection Operation Summary 检验操作概要IPC International Product Center 国际产品中心IPTV Incidents Per Thousand Vehicles 每千辆车的故障率IQS Initial Quality Survey 初始质量调查IR Incident Report 事故报告ISP Integrated Scheduling Project 综合计划ITP Integrated Training Process 综合培训方法ITSD Interior Technical Specification Drawing 内部技术规范图IUVA International Uniform Vehicle Audit 国际统一车辆审核JES Job Element Sheet 工作要素单JIS Job Issue Sheet 工作要素单JIT Just in Time 准时制JPH Job per hour 每小时工作量KCC Key Control Characteristics 关键控制特性KCDS Key Characteristics Designation System 关键特性标识系统KPC Key product Characteristic 关键产品特性LT Look at 看MFD Metal Fabrication Division 金属预制件区MFG Manufacturing Operations 制造过程MIC Marketing Information Center 市场信息中心MIE Manufacturing Integration Engineer 制造综合工程师MKT Marketing 营销MLBS Material Labor Balance System 物化劳动平衡系统MMSTS Manufacturing Major Subsystem Technical Specifications 制造重要子系统技术说明书MNG Manufacturing Engineering 制造工程MPG Milford Proving Ground 试验场MPI Master Process Index 主程序索引MPL Master Parts List 主零件列表MPS Material Planning System 原料计划系统MRD Material Required Date 物料需求日期MSDS Material Safery Data Sheets 化学品安全数据单MSE Manufacturing System Engineer 制造系统工程MSS Market Segment Specification 市场分割规范MTBF Mean Time Between Failures 平均故障时间MTS Manufacturing Technical Specification 生产技术规范MVSS Motor Vehicle Safety Standards 汽车发动机安全标准NAMA North American Market Analysis 北美市场分析NAO North American Operations 北美业务NAOC NAO Containerization NAO货柜运输NC Numerically Controlled 用数字控制NOA Notice of Authorization 授权书NSB NAO Strategy Board 北美业务部OED Organization and Employee Development 组织和员工发展OSH Occupational Safety & Health 职业安全健康OSHA Occupational Safety & Health Act 职业安全与健康法案OSHMS Occupational Safety & Health Management System 职业安全健康管理体系OSHS Occupational Safety & Health Standards 职业安全标准PA Production Achievement 生产结果PAA Product Action Authorization 产品临时授权PAC Performance Assessment Committee 绩效评估委员会PACE Program Assessment and Control Environment 项目评估和控制条件PAD Product Assembly Document 产品装配文件PARTS Part Readiness Tracking System 零件准备跟踪系统PC Problem Communication 问题信息PCL Production Control and Logistics 生产控制和支持PCM Process Control Manager 工艺控制负责人PCR Problem Communication Report 问题交流报告PDC Portfolio Development Center 证券发展中心PDM Product Data Management 产品资料管理PDS Product Description System 产品说明系统PDT Product Development Team 产品发展小组PED Production Engineering Department 产品工程部PEP Product Evaluation Program 产品评估程序PER Personnel 人员PET Program Execution Team 项目执行小组PGM Program Management 项目管理PI People Involement 人员参与PIMREP Project Incident Monitoring and Resolution Process 事故方案跟踪和解决过程PLP Production Launch Process 生产启动程序PMI Process Modeling Integration 加工建模一体化PMM Program Manufacturing Manager 项目制造经理PMR Product Manufacturability Requirements 产品制造能要求PMT Product Management Team 产品车管理小组POMS Production Order Management System 产品指令管理小组POP Point of Purchase 采购点PP Push - Pull 推拉PPAP Production Part Approval Process 生产零部件批准程序PPE 个人防护用品PPH Problems Per Hundred 百辆车缺陷数PPM Problems Per Million 百万辆车缺陷数PPS Practical Problem Solving 实际问题解决PR Performance Review 绩效评估PR/R Problem Reporting and Resolution 问题报告和解决PRTS Problem Resolution and Tracking System 问题解决跟踪系统PSC Portfolio Strategy Council 部长职务策略委员会PST Plant Support Team 工厂支持小组PTO Primary Tryout 第一次试验PTR Production Trial Run 生产试运行PUR Purchasing 采购PVD Production Vehicle Development 生产汽车发展PVM Programmable Vehicle Model 可设计的汽车模型QA Quality Audit 质量评审QAP Quality Assessment Process 质量评估过程QBC Quality Build Concern 质量体系构建关系QC Quality Characteristic 质量特性QCOS Quality Control Operation Sheets 质量风险控制QE Quality Engineer 质量工程师QET Quality Engineering Team 质量工程小组QFD Quality Function Deployment 质量功能配置QRD Quality, Reliability,andDurability 质量、可靠性和耐久力QS Quality System 质量体系QUA Quality 质量RC Review Charter 评估特许RCD Required Completion Date 必须完成日期RFQ Request For Quotation 报价请求RGM Reliability Growth Management 可靠性增长小组RONA Return on Net Assets 净资产评估RPO Regular Production Option 正式产品选项RQA Routing Quality Assessment 程序安排质量评定RT&TM Rigorous Tracking and Throughout Managment 严格跟踪和全程管理SDC Strategic Decision Center 战略决策中心SF Styling Freeze 造型冻结SIL Single Issue List 单一问题清单SIP Stansardized Inspection Process 标准化检验过程SIU Summing It All Up 电子求和结束SL System Layouts 系统规划SLT Short Leading Team 缩短制造周期SMARTSMBP Synchronous Math-Based Process 理论同步过程SME Subject Matter Expert 主题专家SMT Systems Management Team 系统管理小组SNR 坏路实验SOP Start of Production 生产启动SOP Safe Operating Practice 安全操作规程SOR Statement of Requirements 技术要求SOS Standardization Operation Sheet 标准化工作操作单SOW Statement of Work 工作说明SPA Shipping Priority Audit 发运优先级审计SPC Statistical Process Control 统计过程控制SPE Surface and Prototype Engineering 表面及原型工程SPO Service Parts Operations 配件组织SPT Single Point Team 专一任务小组SQA Supplier Quality Assurance 供应商质量保证(供应商现场工程师)SQC Supplier Quality Control 供方质量控制SQD Supplier Quality Development 供应方质量开发SQE Supplier Quality Engineer 供方质量工程师SQIP Supplier Quality Improvement Process 供应商质量改进程序SSF Start of System Fill 系统填充SSLT Subsystem Leadership Team 子系统领导组SSTS Subsystem Technical Specification 技术参数子系统STD Standardization 标准化STO Secondary Tryout 二级试验SUI 安全作业指导书SUW Standard Unit of Work 标准工作单位SWE Simulated Work Environment 模拟工作环境TAG Timing Analysis Group 定时分析组TBD To Be Determined 下决定TCS Traction Control System 牵引控制系统TDC Technology Development Centre 技术中心TDMF Text Data Management Facility 文本数据管理设备TG Tooling 工具TIMS Test Incident Management System 试验事件管理系统TIR Test Incident Report 试验事件报告TMIE Total Manufacturing Integration Engineer 总的制造综合工程TOE Total Ownership Experience 总的物主体验TPM Total Production Maintenance 全员生产维护TSM Trade Study Methodology 贸易研究方法TT Tact Time 单件工时TVDE Total Vehicle Dimensional Engineer 整车外型尺寸工程师TVIE Total Vehicle Integration Engineer 整车综合工程师TWS Tire and Wheel System 轮胎和车轮系统UAW United Auto Workers 班组UCL Uniform Criteria List 统一的标准表UDR Unverified Data Release 未经核对的资料发布UPC Uniform Parts Classification 统一零件分级VAE Vehicle Assembly Engineer 车辆装配工程师VAPIR Vehicle & Progress Integration Review Team 汽车发展综合评审小组VASTD Vehicle Assembly Standard Time Data 汽车数据标准时间数据VCD Vehicle Chief Designer 汽车首席设计师VCE Vehicle Chief Engineer 汽车总工程师VCRI Validation Cross-Reference Index 确认交叉引用索引VDP Vehicle Development Process 汽车发展过程VDPP Vehicle Development Production Process 汽车发展生产过程VDR Verified Data Release 核实数据发布VDS Vehicle Description Summary 汽车描述概要VDT Vehicle Development Team 汽车发展组VDTO Vehicle Development Technical Operations 汽车发展技术工作VEC Vehicle Engineering Center 汽车工程中心VIE Vehicle Integration Engineer 汽车综合工程师VIN Vehicle Identification Number 车辆识别代码VIS Vehicle Information System 汽车信息系统VLE Vehicle Line Executive 总装线主管VLM Vehicle Launch Manager 汽车创办经理VMRR Vehicle and Manufacturing Requirements Review 汽车制造必要条件评审VOC Voice of Customer 顾客的意见VOD Voice of Design 设计意见VS Validation Station 确认站VSAS Vehicle Synthesis,Analysis,and Simulation 汽车综合、分析和仿真VSE Vehicle System Engineer 汽车系统工程师VTS Vehicle Technical Specification 汽车技术说明书WBBA Worldwide Benchmarking and Business Analysis 全球基准和商业分析WOT Wide Open Throttle 压制广泛开放WPO Work Place Organization 工作场地布置WWP Worldwide Purchasing 全球采购COMMWIP Correction 纠错浪费Overproduction 过量生产浪费Material Flow 过度物料移动浪费Motion 过度移动浪费Waiting 等待浪费Inventory 过度库存浪费Processing 过度加工浪费。

汽车行业用缩写汇总File modification on June 16, 2021 at 16:25 pmA/D/V Analysis/Development/Validation 分析/发展/验证AA Approve Architecture 审批体系ACD Actual Completion Date 实际完成日期ALBS Assembly Line Balance System 装配线平衡系统ANDON 暗灯AP Advanced Purchasing 提前采购API Advanced Product Information 先进的产品信息APQP Advanced Product Quality Planning 先期产品质量策划ATT Actual Tact Time 实际单件工时BIQ Building in Quality 制造质量BIW Body In White 白车身BOD Bill of Design 设计清单BOE Bill of Equipment 设备清单BOL Bill of Logistic 装载清单BOM Bill of Material 原料清单BOP Bill of Process 过程清单BPD Business Plant Deployment 业务计划实施CAD Computer-Aided Design 计算机辅助设计CAE Computer-Aided Engineering 计算机辅助工程软件CARE Customer Acceptance & Review Evaluation 用户接受度和审查评估CAS Concept Alternative Selection 概念可改变的选择CIP Continue Improve Process 持续改进CIT Compartment Integration Team 隔间融合为组CKD Complete Knockdown 完全拆缷CMM Coordinate Measuring Machines 坐标测量仪CPV Cost per Vehicle 单车成本CR&W Controls/Robotics & Welding 控制/机器人技术和焊接CS Contract Signing 合同签订CTD Cumulative Trauma Disadjust 累积性外伤失调CTS Component Technical Specification 零件技术规格CVIS Completed Vehicle Inspection Standards 整车检验标准D/PFMEA Design/process failure mode & effects analysis 设计/过程失效模式分析DAP Design Analysis Process 设计分析过程DES Design Center 设计中心DFA Design for Assembly 装配设计DOE Design Of Experiments 试验设计DOL Die Operation Line-Up 冲模业务排行DPV Defect per Vehicle 单车缺陷数DQV Design Quality Verification 设计质量验证DRE Design Release Engineer 设计发布工程师DRL Direct Run Loss 直行损失率DRR Direct Run Run 直行率DSC Decision Support Center 决策支持中心ECD Estimated Completion Date 计划完成日期EGM Engineering Group Manager 工程组经理ELPO Electrode position Primer 电极底漆ENG Engineering 工程技术、工程学EOA End of Acceleration 停止加速EPC&L Engineering Production Cntrol &Logistics 工程生产控制和后勤EQF Early Quality Feedback 早期质量反馈EWO Engineering Work Order 工程工作指令FA Final Approval 最终认可FE Functional Evaluation 功能评估FEDR Functional Evaluation Disposition Report 功能评估部署报告FFF Free Form Fabrication 自由形态制造FIN Financial 金融的FL 听FMEA Failure Mode and Effects Analysis 失效形式及结果分析FPS Fixed Point Stop 定点停FTP File Transfer Protocol 文件传送协议FTQ First Time Quality 一次送检合格率GA General Assembly 总装GA Shop General Assembly Shop 总装车间Paint Shop 涂装车间Body Shop 车身车间Press Shop 冲压车间GCA Global Customer Audit 全球顾客评审GD&T Geometric Dimensioning & Tolerancing 几何尺寸及精度GDS Global Delivery Survey 全球发运检查GM General Motors 通用汽车GMAP GM Asia Pacific 通用亚太GME General Motors Europe 通用汽车欧洲GMIO General Motors International Operations 通用汽车国际运作GMIQ General Motors Initial Quality 通用汽车初始质量GMPTG General Motors Powertrain Group 通用汽车动力组GMS Global Manufacturing System 通用全球制造系统GP General Procedure 通用程序GQTS Global Quality Tracking System 全球质量跟踪系统GSB Global Strategy Board 全球战略部HVAC Heating, Ventilation ,and Air Conditioning 加热、通风及空调I/P Instrument Panel 仪表板IC Initiate Charter 初始租约ICD Interface Control Document 界面控制文件IE Industrial Engineering 工业工程IEMA International Export Market Analysis 国际出口市场分析ILRS Indirect Labor Reporting System 间接劳动报告系统IO International Operations 国际业务IOM Inspection Operation Mathod 检验操作方法IOS Inspection Operation Summary 检验操作概要IPC International Product Center 国际产品中心IPTV Incidents Per Thousand Vehicles 每千辆车的故障率IQS Initial Quality Survey 初始质量调查IR Incident Report 事故报告ISP Integrated Scheduling Project 综合计划ITP Integrated Training Process 综合培训方法ITSD Interior Technical Specification Drawing 内部技术规范图IUVA International Uniform Vehicle Audit 国际统一车辆审核JES Job Element Sheet 工作要素单JIS Job Issue Sheet 工作要素单JIT Just in Time 准时制JPH Job per hour 每小时工作量KCC Key Control Characteristics 关键控制特性KCDS Key Characteristics Designation System 关键特性标识系统KPC Key product Characteristic 关键产品特性LT Look at 看MFD Metal Fabrication Division 金属预制件区MFG Manufacturing Operations 制造过程MIC Marketing Information Center 市场信息中心MIE Manufacturing Integration Engineer 制造综合工程师MKT Marketing 营销MLBS Material Labor Balance System 物化劳动平衡系统MMSTS Manufacturing Major Subsystem Technical Specifications 制造重要子系统技术说明书MNG Manufacturing Engineering 制造工程MPG Milford Proving Ground 试验场MPI Master Process Index 主程序索引MPL Master Parts List 主零件列表MPS Material Planning System 原料计划系统MRD Material Required Date 物料需求日期MSDS Material Safery Data Sheets 化学品安全数据单MSE Manufacturing System Engineer 制造系统工程MSS Market Segment Specification 市场分割规范MTBF Mean Time Between Failures 平均故障时间MTS Manufacturing Technical Specification 生产技术规范MVSS Motor Vehicle Safety Standards 汽车发动机安全标准NAMA North American Market Analysis 北美市场分析NAO North American Operations 北美业务NAOC NAO Containerization NAO货柜运输NC Numerically Controlled 用数字控制NOA Notice of Authorization 授权书NSB NAO Strategy Board 北美业务部OED Organization and Employee Development 组织和员工发展OSH Occupational Safety & Health 职业安全健康OSHA Occupational Safety & Health Act 职业安全与健康法案OSHMS Occupational Safety & Health Management System 职业安全健康管理体系OSHS Occupational Safety & Health Standards 职业安全标准PA Production Achievement 生产结果PAA Product Action Authorization 产品临时授权PAC Performance Assessment Committee 绩效评估委员会PACE Program Assessment and Control Environment 项目评估和控制条件PAD Product Assembly Document 产品装配文件PARTS Part Readiness Tracking System 零件准备跟踪系统PC Problem Communication 问题信息PCL Production Control and Logistics 生产控制和支持PCM Process Control Manager 工艺控制负责人PCR Problem Communication Report 问题交流报告PDC Portfolio Development Center 证券发展中心PDM Product Data Management 产品资料管理PDS Product Description System 产品说明系统PDT Product Development Team 产品发展小组PED Production Engineering Department 产品工程部PEP Product Evaluation Program 产品评估程序PER Personnel 人员PET Program Execution Team 项目执行小组PGM Program Management 项目管理PI People Involement 人员参与PIMREP Project Incident Monitoring and Resolution Process 事故方案跟踪和解决过程PLP Production Launch Process 生产启动程序PMI Process Modeling Integration 加工建模一体化PMM Program Manufacturing Manager 项目制造经理PMR Product Manufacturability Requirements 产品制造能要求PMT Product Management Team 产品车管理小组POMS Production Order Management System 产品指令管理小组POP Point of Purchase 采购点PP Push - Pull 推拉PPAP Production Part Approval Process 生产零部件批准程序PPE 个人防护用品PPH Problems Per Hundred 百辆车缺陷数PPM Problems Per Million 百万辆车缺陷数PPS Practical Problem Solving 实际问题解决PR Performance Review 绩效评估PR/R Problem Reporting and Resolution 问题报告和解决PRTS Problem Resolution and Tracking System 问题解决跟踪系统PSC Portfolio Strategy Council 部长职务策略委员会PST Plant Support Team 工厂支持小组PTO Primary Tryout 第一次试验PTR Production Trial Run 生产试运行PUR Purchasing 采购PVD Production Vehicle Development 生产汽车发展PVM Programmable Vehicle Model 可设计的汽车模型QA Quality Audit 质量评审QAP Quality Assessment Process 质量评估过程QBC Quality Build Concern 质量体系构建关系QC Quality Characteristic 质量特性QCOS Quality Control Operation Sheets 质量风险控制QE Quality Engineer 质量工程师QET Quality Engineering Team 质量工程小组QFD Quality Function Deployment 质量功能配置QRD Quality, Reliability,andDurability 质量、可靠性和耐久力QS Quality System 质量体系QUA Quality 质量RC Review Charter 评估特许RCD Required Completion Date 必须完成日期RFQ Request For Quotation 报价请求RGM Reliability Growth Management 可靠性增长小组RONA Return on Net Assets 净资产评估RPO Regular Production Option 正式产品选项RQA Routing Quality Assessment 程序安排质量评定RT&TM Rigorous Tracking and Throughout Managment 严格跟踪和全程管理SDC Strategic Decision Center 战略决策中心SF Styling Freeze 造型冻结SIL Single Issue List 单一问题清单SIP Stansardized Inspection Process 标准化检验过程SIU Summing It All Up 电子求和结束SL System Layouts 系统规划SLT Short Leading Team 缩短制造周期SMARTSMBP Synchronous Math-Based Process 理论同步过程SME Subject Matter Expert 主题专家SMT Systems Management Team 系统管理小组SNR 坏路实验SOP Start of Production 生产启动SOP Safe Operating Practice 安全操作规程SOR Statement of Requirements 技术要求SOS Standardization Operation Sheet 标准化工作操作单SOW Statement of Work 工作说明SPA Shipping Priority Audit 发运优先级审计SPC Statistical Process Control 统计过程控制SPE Surface and Prototype Engineering 表面及原型工程SPO Service Parts Operations 配件组织SPT Single Point Team 专一任务小组SQA Supplier Quality Assurance 供应商质量保证供应商现场工程师SQC Supplier Quality Control 供方质量控制SQD Supplier Quality Development 供应方质量开发SQE Supplier Quality Engineer 供方质量工程师SQIP Supplier Quality Improvement Process 供应商质量改进程序SSF Start of System Fill 系统填充SSLT Subsystem Leadership Team 子系统领导组SSTS Subsystem Technical Specification 技术参数子系统STD Standardization 标准化STO Secondary Tryout 二级试验SUI 安全作业指导书SUW Standard Unit of Work 标准工作单位SWE Simulated Work Environment 模拟工作环境TAG Timing Analysis Group 定时分析组TBD To Be Determined 下决定TCS Traction Control System 牵引控制系统TDC Technology Development Centre 技术中心TDMF Text Data Management Facility 文本数据管理设备TG Tooling 工具TIMS Test Incident Management System 试验事件管理系统TIR Test Incident Report 试验事件报告TMIE Total Manufacturing Integration Engineer 总的制造综合工程TOE Total Ownership Experience 总的物主体验TPM Total Production Maintenance 全员生产维护TSM Trade Study Methodology 贸易研究方法TT Tact Time 单件工时TVDE Total Vehicle Dimensional Engineer 整车外型尺寸工程师TVIE Total Vehicle Integration Engineer 整车综合工程师TWS Tire and Wheel System 轮胎和车轮系统UAW United Auto Workers 班组UCL Uniform Criteria List 统一的标准表UDR Unverified Data Release 未经核对的资料发布UPC Uniform Parts Classification 统一零件分级VAE Vehicle Assembly Engineer 车辆装配工程师VAPIR Vehicle & Progress Integration Review Team 汽车发展综合评审小组VASTD Vehicle Assembly Standard Time Data 汽车数据标准时间数据VCD Vehicle Chief Designer 汽车首席设计师VCE Vehicle Chief Engineer 汽车总工程师VCRI Validation Cross-Reference Index 确认交叉引用索引VDP Vehicle Development Process 汽车发展过程VDPP Vehicle Development Production Process 汽车发展生产过程VDR Verified Data Release 核实数据发布VDS Vehicle Description Summary 汽车描述概要VDT Vehicle Development Team 汽车发展组VDTO Vehicle Development Technical Operations 汽车发展技术工作VEC Vehicle Engineering Center 汽车工程中心VIE Vehicle Integration Engineer 汽车综合工程师VIN Vehicle Identification Number 车辆识别代码VIS Vehicle Information System 汽车信息系统VLE Vehicle Line Executive 总装线主管VLM Vehicle Launch Manager 汽车创办经理VMRR Vehicle and Manufacturing Requirements Review 汽车制造必要条件评审VOC Voice of Customer 顾客的意见VOD Voice of Design 设计意见VS Validation Station 确认站VSAS Vehicle Synthesis,Analysis,and Simulation 汽车综合、分析和仿真VSE Vehicle System Engineer 汽车系统工程师VTS Vehicle Technical Specification 汽车技术说明书WBBA Worldwide Benchmarking and Business Analysis 全球基准和商业分析WOT Wide Open Throttle 压制广泛开放WPO Work Place Organization 工作场地布置WWP Worldwide Purchasing 全球采购COMMWIP Correction 纠错浪费Overproduction 过量生产浪费Material Flow 过度物料移动浪费Motion 过度移动浪费Waiting 等待浪费Inventory 过度库存浪费 Processing 过度加工浪费。

汽车行业词汇缩写A-DA/D/VAnalysis/Development/Validation分析/发展/验证AAApproveArchitecture审批体系ACDActualCompletionDate实际完成日期ALBSAssemblyLineBalanceSystem装配线平衡系统ANDON暗灯APAdvancedPurchasing提前采购APIAdvancedProductInformation先进的产品信息APQPAdvancedProductQualityPlanning先期产品质量策划ATTActualTactTime实际单件工时ABSAntilockBrakingSystemAIAG美国汽车联合会CSContractSigning合同签订CTDCumulativeTraumaDisadjust累积性外伤失调CTSComponentTechnicalSpecification零件技术规格CVISCompletedVehicleInspectionStandards整车检验标准C.P.MCertifiedPurchasingmanger认证采购经理人制度CBConfirmationBuild确认样车制造CCChangeCutOff设计变更冻结CC\SCcritical/significantcharacteristic CCRConcern&CountermeasureRequest CCTCrossCompanyTeamCharacteristicsMatrix特性矩阵图CODCashonDelivery货到付现预付货款(T/Tinadvance)CP1ConfirmationPrototype1st第一次确认样车CP2ConfirmationPrototype2nd第二次确认样车CpkCpk=Zmin/3过程能力指数CPOComplementaryPartsOrderCraftsmanship精致工艺Crossfunctionalteams跨功能小组CUVCarBasedUltilityVehicleDAPDesignAnalysisProcess设计分析过程DESDesignCenter设计中心DFADesignforAssembly装配设计ExWork(工厂交货)、FOB(船上交货)、FAS(船边交货)或CIF(运保费在内交货)FAFinalApproval最终认可FEFunctionalEvaluation功能评估FEDRFunctionalEvaluationDispositionReport功能评估部署报告FFFFreeFormFabrication自由形态制造FINFinancial金融的FPSFixedPointStop定点停FTPFileTransferProtocol文件传送协议FTQFirstTimeQuality一次送检合格率FEUFieldEvaluationUnits用户市场实际体验与评估firstgear一档FlowChart流程图FMEAFailureModeandEffectsAnalysis FRGFordReliabilityGuideline福特可靠性指导FrontWindshield前挡风玻璃FSSFullservicesupplier全服务供应商FTAFaultTreeAnalysisGAGeneralAssembly总装GAShopGeneralAssemblyShop总装车间PaintShop涂装车间BodyShop车身车间PressShop冲压车间IOSInspectionOperationSummary检验操作概要IPCInternationalProductCenter国际产品中心IPTVIncidentsPerThousandVehicles每千辆车的故障率IQSInitialQualitySurvey初始质量调查IRIncidentReport事故报告ISPIntegratedSchedulingProject综合计划ITPIntegratedTrainingProcess综合培训方法ITSDInteriorTechnicalSpecificationDrawing内部技术规范图IUVAInternationalUniformVehicleAudit国际统一车辆审核IPOIndividualPartsOrder ISIRInitialSampleInspectionReportJESJobElementSheet工作要素单JISJobIssueSheet工作要素单JITJustinTime准时制JPHJobperhour每小时工作量KCCKeyControlCharacteristics关键控制特性KCDSKeyCharacteristicsDesignationSystem关键特性标识系统KPCKeyproductCharacteristic关键产品特性KDknockeddown/SemiKnockDown(SKD)/CompletelyKnockDown(CKD) KOKickoffLTLookat看Laminatedglass夹层玻璃LP-NAONorthAmericanOperations北美业务NAOCNAOContainerizationNAO货柜运输NCNumericallyControlled数字控制NOANoticeofAuthorization授权书NSBNAOStrategyBoard北美业务部N/ANotApplicableNCDRNonConformingDeliveryReport NCMARNonConformingMaterialActionReport NDANonDisclosureAgreement保密协定NDSNissanDesignSpecificationNMLNissanMotorLtdNVHSystemNoise,Vibration&Harshness系统噪音,振动及粗糙性OEDOrganizationandEmployeeDevelopment组织和员工发展OSHOccupationalSafety&Health职业安全健康T OSHAOccupationalSafety&HealthAct职业安全与健康法案OSHMSOccupationalSafety&HealthManagementSystem职业安全健康管理体系OSHSOccupationalSafety&HealthStandards职业安全标准OSMOutsideofMaterialPAProductionAchievement生产结果PAAProductActionAuthorization产品临时授权PACPerformanceAssessmentCommittee绩效评估委员会PACEProgramAssessmentandControlEnvironment项目评估和控制条件PPMProblemsPerMillion百万辆车缺陷数PPSPracticalProblemSolving实际问题解决PRPerformanceReview绩效评估PR/RProblemReportingandResolution问题报告和解决PRTSProblemResolutionandTrackingSystem问题解决跟踪系统PSCPortfolioStrategyCouncil部长职务策略委员会PSTPlantSupportTeam工厂支持小组PTOPrimaryTryout第一次试验PTRProductionTrialRun生产试运行PURPurchasing采购PATProgramAttributesTeam产品属性小组PDLProductDesignLetterPHProportions&Hardpoints PIPCPercentageofIndexeswithProcessCapability能力指数百分比PISTPercentageofInspectionpointsSatisfyingTolerance检测点满意工差百分比PMTProgramMoudleTeam产品模块小组POPurchaseOrderPPAPProductionPartApprovalProcess生产件批准程序PPSRProductionPreparationStatusReportPQAProcessQualityAssurancePRProgramReadinessPreLaunch试生产pricedrivencosting价格引导成本ProductionPreparationFinalNissanPT2/RenaultPPRT&TMRigorousTrackingandThroughoutManagement严格跟踪和全程管理RANReleaseAuthorisationNumberreverse倒车档RFQRequestForQuotation询价RKDReverseKnockDownRLQReceivingLotQuantityROCRateofClimbROIreturnoninvestment报酬率ROPReOrderPointRTORequiredToOperateSDCStrategicDecisionCenter战略决策中心SFStylingFreeze造型冻结SILSingleIssueList单一问题清单SIPStandardizedInspectionProcess标准化检验过程SLSystemLayouts系统规划SLTShortLeadingTeam缩短制造周期SMBPSynchronousMathBasedProcess理论同步过程SMTSystemsManagementTeam系统管理小组SNR坏路实验SOPStartofProduction生产启动SOPSafeOperatingPractice安全操作规程SORStatementofRequirements技术要求SOSStandardizationOperationSheet标准化工作操作单SUISOWstateofwork工作申明SPCStatisticalProcessControlSQASupplierQualityAssurance SREASupplierRequestforEngineeringApproval供应商工程设计更改申请STSurfaceTranferSTRSSupplierTestReportSystemSubcontractor分承包商SunroofWindshield天窗玻璃SUVSportsUtilityVehicleTAGTimingAnalysisGroup定时分析组TBDToBeDetermined下决定TCSTractionControlSystem牵引控制系统TDCTechnologyDevelopmentCentre技术中心TDMFTextDataManagementFacility文本数据管理设备TGTooling工具TIMSTestIncidentManagementSystem试验事件管理系统TIRTestIncidentReport试验事件报告TMIETotalManufacturingIntegrationEngineer总的制造综合工程TOETotalOwnershipExperience总的物主体验TPMTotalProductionMaintenance全员生产维护TSMTradeStudyMethodology贸易研究方法TTTactTime单件工时TVDETotalVehicleDimensionalEngineer整车外型尺寸工程师VINVehicleIdentificationNumber车辆识别代码VISVehicleInformationSystem汽车信息系统VLEVehicleLineExecutive总装线主管VLMVehicleLaunchManager汽车创办经理VOCVoiceofCustomer顾客的意见VODVoiceofDesign设计意见VSValidationStation确认站VSASVehicleSynthesisAnalysisandSimulation汽车综合、分析和仿真VSEVehicleSystemEngineer汽车系统工程师VTSVehicleTechnicalSpecification汽车技术说明书VOVehicleOperation主机厂VPPVehicleProgramPlan整车项目计划VQAVehicleQualityAssurance VTTOVendorToolTryOut供应商工装验证WOTWideOpenThrottle压制广泛开放WPOWorkPlaceOrganization工作场地布置WWPWorldwidePurchasing全球采购WERSWorldWideEngineeringReleaseSystem WVTAWholeVehicleTypeApproval其他相关词汇招聘IQC解聘OQC岗位说明书SOP(标准作业程序)绩效考核部门管理评审会议who、how(KPICP析、花名册明细名单BOM人员照片就是DWG人事招聘控制就是PCC人事招聘顾问QE绩效专员就是QA人资开发就是R&D人员招聘策划DQA招聘计划SQA关键特性就是KPI1PPFirstPhaseofProductionProveOut第一次试生产3CCustomer(顾客导向)、Competition(竞争导向)、Competence(专长导向)4SSale,Sparepart零配件,Service,Survey信息质量保证验认可Nullserie零批量Bias偏差DBDurabilityBuild样车阶段leadtimen.订货至交货的时间sinkmark缩痕LRRlaunchreadinessreviewYC(PotentialCriticalCharacteristic)潜在关键特性YS(PotentialSignificantCharacteristic)潜在重要特性RestrictionofHazardousSubstances简称RoHSBVBureauVeritas法国国际检验局Frontbumper前保险杠Rearbumper后保险杠Radiatorgrille格栅Headlamp前大灯Taillampliftgate尾灯行李箱盖上Taillampquarter尾灯后侧围上Frontdoortrimpanel前门内饰板Reardoortrimpanel后门内饰板Interiorreleasehandlebezel内开手把手框ConsoleClusterCarpet前地毯Trunkcarpet后地毯Frontseat前座椅2ndrowseat第二排座椅burr(金属)flash(塑件)毛边gap间隙defectiveproducts不良品finishedproducts成品disposedproducts处理品bandaid创可贴scratch刮伤dents压痕凹坑concave车床lathe抽查试验spotchecktest出厂试验deliverytest次品defectiveproduct调幅amplitudemodulation(AM)调频FrequencyModulation断差offset对讲机interphone法平面normalplane翻车rollover选料上乘、做工精细besuperiorinmaterialandexcelllentinworkmans hip仪表板dashboard油门throttle褶皱crimple整车运输transportationoftruckload总装finalassembly阻流板step,reflectro,baffle最大扭矩转速speedatmaximumtorque左对齐leftjustify报废scrapping皮纹grain缩水Shrinkage缩水SinkMark顶白StressMark首检Firstarticleinspection 自检Selfinspection全检100%inspection巡检processaudit开箱检验outofboxaudit出货检验outgoinginspection 进货检验incominginspection 例行检验确认检验在线检验线下检验。

OEM生产,即贴牌生产,也称为定牌生产,俗称“贴牌〞,由于其英文表述为Original Equipment/Entrusted Manufacture〔译为原始设备制造商或原产地委托加工),因此简称为OEM。

根本含义为品牌生产者不直接生产产品,而是利用自己掌握的关键的核心技术负责设计和开发新产品,控制销售渠道,具体的加工任务通过合同订购的方式委托同类产品的其他厂家生产。

之后将所订产品低价买断,并直接贴上自己的品牌商标。

这种委托他人生产的合作方式简称OEM,承接加工任务的制造商被称为OEM厂商,其生产的产品被称为OEM产品。

可见,贴牌生产属于加工贸易中的“代工生产〞方式,在国际贸易中是以商品为载体的劳务出口。

OEM的特征就是:技术在外,资本在外,市场在外,只有生产在内。

ODM是英文Original Design Manufacturer (原始设计制造商)的缩写,指一家厂家根据另一家厂商的要求,为其生产产品和产品配件,亦称为定牌生产或授权贴牌生产.即可代表外委加工,也可代表转包合同加工.国内习惯称为协作生产,三来加工。

ODM的厂商设计方案分为买断或不买断的方式供给:1.买断方式:有品牌拥有方买断ODM厂商现成的某型号产品的设计,或品牌拥有方单独要求ODM厂商为自己设计产品方案。

2.不买断方式:品牌拥有方不买断ODM厂商某型号产品的设计,ODM厂商可将同型号产品的设计采取不买断的方式同时卖给其它品牌。