单管晶闸管模块MT500A

- 格式:pdf

- 大小:971.55 KB

- 文档页数:3

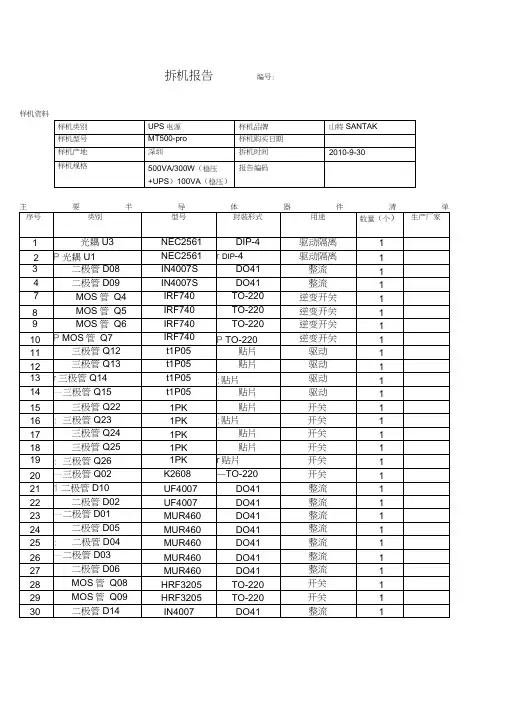

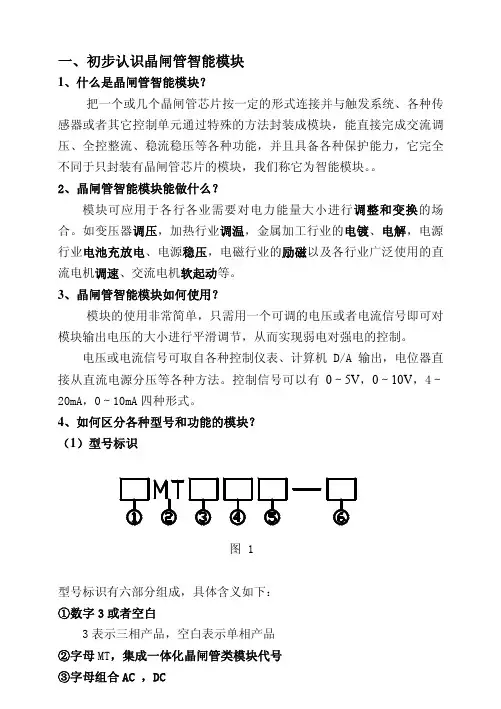

拆机报告编号: 样机资料电源开关控制 电路及指示灯 控制电路 瓶充电控制 IC :U3843BN、整机照片图 图一:电源主体 逆变电路 电瓶 I R RS232接口可以与计算 连进行通讯模式转 F74 0 .............― 换控制 电路MOS 管 K2608 TX1电瓶充电 控制电路防雷击浪涌 保护电路电容后侧有 一稳压管: 7805 逆变电路双运算放大器LM358市电检测蜂S |稳压输蜂鸣器电路电源启动控制 稳压.PWM 控制RF32C四Q27:蜂鸣器驱动三极管充电控制辅 助电路2个HLM358双运放反馈5电路:市电检测电 路IC : SG3525AN1020=二 可编程 升压电路C68HC908市电异常时市电正常时五、工作原理1、 市电正常时,市电经 EMI 电路滤波后,一路经继电器与负载连接,由市电直接为负载供电;另一路在电池充电控制电路作用下,经充电电路为电 池充电,其电路主体由充电控制 IC UC3848BN MOS 管 K2608以及外围电路组成。

同时,市电经采样电路输入给市电检测电路进行市电检测,检测电路主要由双运放LM358及外围电路组成。

2、 当市电异常时,市电检测电路将信号传递给处理器U01,由U01发出指令,继电器断开市电通路,切换到电池供电状态。

电池电源经 PWM 控制ICSG3525AN 进行PW 碉制后的信号,经两只 MOS 管HRF3205组成的推挽电路和 TX1、D04、D05组成它激式逆变电源电路升压到约 330V 后,经Q04~Q07组成 的逆变电路转换为交流市电为负载供电。

输出为方波交流。

3、 该电源逆变部分使用 4支MOS 管IRF740组成全桥逆变电路,逆变电源部分升压前级使用两支MOS 管HRF3205组成推挽电路,充电控制部分使用 1支 MOS 管 K2608。

4、 该UPS 电源带有防雷击浪涌保护电路,采用瞬变抑制二极管和压敏电阻组成突波抑制电路。

技术协议供方:需方:2018年7月、高压无功自动补偿装置1、产品遵循的主要标准GB50227-95《并联电容器装置设计规范》SD205-87《高压并联电容器技术条件》DL492.9-91《电力系统油质试验方法绝缘油介电强度测定法》DL462-92《高压并联电容器用串联电抗器订货技术条件》DL/T653-1998《高压并联电容器用放电线圈订货技术条件》JB7111-93《高压并联电容器装置》GB11032-89《交流无间隙金属氧化锌避雷器》GB10229-88《电抗器》GB50150《电气装置安装工程电气设备交接试验标准》GB/T5882《高压电力设备外绝缘污秽等级》GB3983.2《高压并联电容器》GB311.1-97《高压输变电设备的绝缘配合》GB/T16927《高电压试验技术》GB763《交流高压电器在长期工作时的发热》GB11025《并联电容器用内熔丝和内部压力隔离器》DL442《高压并联电容器单台保护用熔断器定货技术条件》DL/T604《高压并联电容器成套装置定货技术条件》JB/T8970《高压并联电容器用放电线圈》GB/T11024.1-2001《高压并联电容器耐久性试验》GB50062-92《电力装置的继电保护和自动装置设计规范》2、设备主要技术性能参数2.1环境条件2.1.1安装地点:户内2.1.2安装形式:柜式2.1.3海拔:<1000米2.1.4环境温度:一25°C/+55°C最大日温差:25K2.1.5环境湿度:月平均相对湿度(25C)不大于95%日平均相对湿度(25C)不大于95%2.1.6耐受地震能力:地震烈度:W8度地面水平加速度:2.5m/s2地面垂直加速度:1.25m/s22.1.7污秽等级:III级泄露比距不小于25mm/Kv(相对与系统最高电压)2.1.8安装环境无有害气体和蒸汽,无导电或爆炸性尘埃,无剧烈震动。

2.2系统运行条件2.2.1额定电压:10KV2.2.2最高运行电压:12KV2.2.3额定频率:50HZ2.2.4谐波情况:电抗率6%,能抑制五次及以上谐波2.2.5电容器组接线方式:单星形开口三角形电压保护2.2.6进线方式:电缆下进线2.3设备名称及型号:2.3.1设备名称:高压无功自动补偿装置2.3.2设备型号:GGZB10-1800(300+600+900)AK2.3.3设备数量:1套3、设备要求:装置补偿总容量为1800kvar,分三组自动投切,每组投切容量分别为300Kvar、600Kvar、900Kvar。

SEMIPACK ®6SKETThyristor ModulesSKET 741/22 EFeatures•Precious metal pressure contacts for high reliability•Thyristor with amplifying gate •UL recognized, file no. E 63 532Typical Applications*•DC motor control (e. g. for machine tools)•Temperature control (e. g. for ovens, chemical processes)•Softstart applicationAbsolute Maximum Ratings SymbolConditions Values UnitChip I T(AV)sinus 180°T c =85°C 819A T c =100°C 564A I TRMS continuous operation 1500A I TSM 10ms T j =25°C 30000A T j =125°C 26500A i 2t 10msT j =25°C 4500000A²s T j =125°C3500000A²s V RSM2300V V RRM 2200V V DRM 2200V (di/dt)cr 200A/µs (dv/dt)cr 1000V/µs T j -40...125°C Module T stg -40 (130)°C V isola.c.; 50 Hz; r.m.s.1min 3000V 1s3600VCharacteristics SymbolConditions min.typ.max.UnitChip V T T j =125°C, I T =3000A 1.51V V T(TO)T j =125°C 0.82V r T T j =125°C0.17m ΩI DD ;I RD T j =125°C,V DD = V DRM ; V RD = V RRM 150mA t gd T j =25°C,I G =1A, di G /dt =1A/µs4µs t q 350µs I H T j =25°C500mA I L T j =25°C,R G =33Ω2500mA V GT T j =25°C,d.c. 2.2V I GT T j =25°C,d.c.250mA V GD T j =125°C, d.c.0.25V I GD T j =125°C, d.c.10mA R th(j-c)cont.per chip 0.0405K/W per module 0.0405K/W R th(j-c)sin. 180°per chip 0.042K/W per module 0.042K/W R th(j-c)rec. 120°per chip 0.043K/W per module0.043K/WModule R th(c-s)chip 0.015K/W module 0.015K/W M s to heatsink M6 5.1 6.9Nm M t to terminal M1216.219.8Nm a 5 * 9,81m/s²w1950gThis is an electrostatic discharge sensitive device (ESDS), international standard IEC 60747-1, chapter IX.*IMPORTANT INFORMATION AND WARNINGSThe specifications of SEMIKRON products may not be considered as guarantee or assurance of product characteristics("Beschaffenheitsgarantie"). The specifications of SEMIKRON products describe only the usual characteristics of products to be expected inSKETtypical applications, which may still vary depending on the specific application. Therefore, products must be tested for the respective application in advance. Application adjustments may be necessary. The user of SEMIKRON products is responsible for the safety of their applications embedding SEMIKRON products and must take adequate safety measures to prevent the applications from causing a physical injury, fire or other problem if any of SEMIKRON products become faulty. The user is responsible to make sure that the application design is compliant with all applicable laws, regulations, norms and standards. Except as otherwise explicitly approved by SEMIKRON in a written document signed by authorized representatives of SEMIKRON, SEMIKRON products may not be used in any applications where a failure of the product or any consequences of the use thereof can reasonably be expected to result in personal injury. No representation or warranty is given and no liability is assumed with respect to the accuracy, completeness and/or use of any information herein, including without limitation, warranties of non-infringement of intellectual property rights of any third party. SEMIKRON does not assume any liability arising out of the applications or use of any product; neither does it convey any license under its patent rights, copyrights, trade secrets or other intellectual property rights, nor the rights of others. SEMIKRON makes no representation or warranty of non-infringement or alleged non-infringement of intellectual property rights of any third party which may arise from applications. Due to technical requirements our products may contain dangerous substances. For information on the types in question please contact the nearest SEMIKRON sales office. This document supersedes and replaces all information previously supplied and may be superseded by updates. SEMIKRON reserves the right to make changes.。

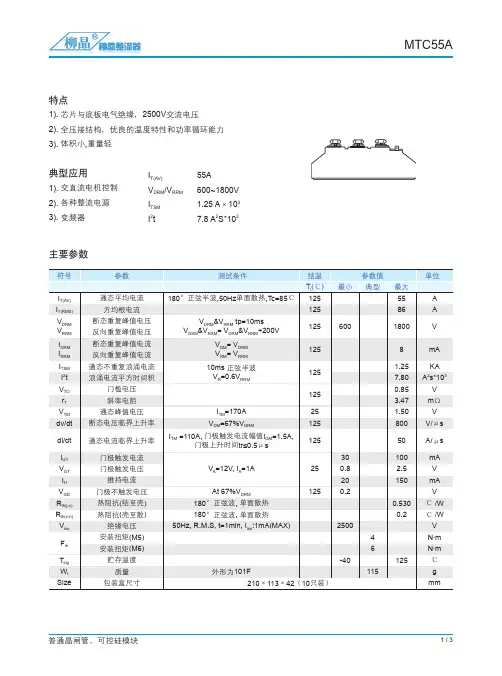

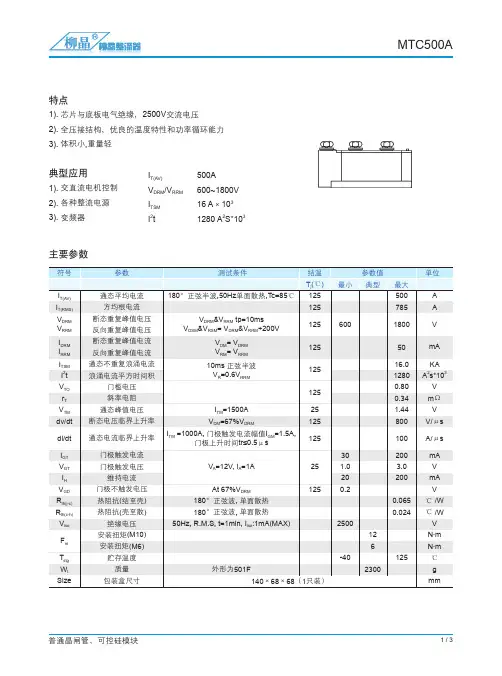

杭州国晶电子科技有限公司杭州国晶电子科技有限公司杭州国晶电子科技有限公司 模块典型电路 电联结形式(右图)模块外型图、安装图M220M225使用说明:一、使用条件及注意事项:1、使用环境应无剧烈振动和冲击,环境介质中应无腐蚀金属和破坏绝缘的杂质和气氛。

2、模块管芯工作结温:可控硅为-40℃∽125℃;环境温度不得高于40℃;环境湿度小于86%。

3、模块在使用前一定要加装散热器,散热器的选配见下节。

散热可采用自然冷却、强迫风冷或水冷。

强迫风冷时,风速应大于6米∕秒。

二、安装注意事项:1、由于MTC可控硅模块是绝缘型(即模块接线柱对铜底板之间的绝缘耐压大于2.5KV有效值),因此可以把多个模块安装在同一散热器上,或装置的接地外壳上。

2、散热器安装表面应平整、光滑,不能有划痕、磕碰和杂物。

散热器表面光洁度应小于10μm。

模块安装到散热器上时,在它们的接触面之间应涂一层很薄的导热硅脂。

涂脂前,用细砂纸把散热器接触面的氧化层去掉,然后用无水乙醇把表面擦干净,使接触良好,以减少热阻。

杭州国晶电子科技有限公司模块紧固到散热器表面时,采用M5或M6螺钉和弹簧垫圈,并以4NM力矩紧固螺钉与模块主电极的连线应采用铜排,并有光滑平整的接触面,使接触良好。

模块工作3小时后,各个螺钉须再次紧固一遍。

模块散热器选择用户选配散热器时,必须考虑以下因素:①模块工作电流大小,以决定所需散热面积;②使用环境,据此可以确定采取什么冷却方式——自然冷却、强迫风冷、还是水冷;③装置的外形、体积、给散热器预留空间的大小,据此可以确定采用什么形状的散热器。

一般而论,大多数用户会选择铝型材散热器。

为方便用户,对我公司生产的各类模块,在特性参数表中都给出了所需散热面积。

此面积是在模块满负荷工作且在强迫风冷时的参考值。

下面给出散热器长度的计算公式:模块所需散热面积=(散热器周长)×(散热器长度)+(截面积)×2其中,模块所需散热面积为模块特性参数表中给出的参考值,散热器周长、截面积可以在散热器厂家样本中查到,散热器长度为待求量。

MT-500S系列保护装置技术手册长沙铭泰电力科技有限公司济南华电东工科技有限公司目录1系统综述 (1)1.1适用范围 (1)1.2系统特点 (1)1.3技术指标 (1)1.3.1额定数据 (1)1.3.2功耗 (2)1.3.3环境条件 (2)1.3.4抗干扰性能 (2)1.3.5绝缘性能 (3)1.3.6机械性能 (3)1.3.7各整定元件工作范围及误差 (3)1.3.8延时元件整定范围及误差 (3)1.3.9测量精度 (3)1.4结构和安装 (4)1.4.1机箱结构 (4)1.4.2接线端子示意图 (4)2人机接口操作说明 (6)2.1面板指示灯说明 (6)2.2液晶显示及键盘操作 (6)2.2.1按键介绍 (6)2.2.2主菜单 (7)2.2.3浏览菜单 (8)2.2.4调试操作 (10)2.2.5整定操作 (12)3微机线路保护测控装置 (15)3.1概述 (15)3.2功能配置 (15)3.3保护原理 (15)3.3.1起动元件 (15)3.3.2三段过流保护 (15)3.3.3接地告警 (16)3.3.4三相一次重合闸 (16)3.3.5加速保护 (17)3.3.6过负荷保护 (17)3.3.7TV断线检测 (18)3.3.8装置告警 (18)3.3.9对时功能 (18)3.3.10网络通信 (18)3.4保护定值 (19)3.5装置接线端子定义 (19)3.5.1接线端子示意图(后视图) (19)3.5.2接线端子定义说明 (19)3.6附图 (22)附图3-1MT-L542S系列装置直流操作二次接线示意图 (22)附图3-3MT-L542S系列装置交流操作二次接线示意图 (22)附图3-4MT-L542S系列装置交流操作回路接线示意图 (22)4微机配电变保护测控装置 (27)4.1概述 (27)4.2功能配置 (27)4.3保护原理 (28)4.3.1起动元件 (28)4.3.2两段过流保护 (28)4.3.3高压侧零序过流保护 (28)4.3.4低压侧零序反时限过流保护 (29)4.3.5低压侧零序过流保护 (29)4.3.6低电压保护 (29)4.3.7过负荷保护 (29)4.3.7TV断线检测 (30)4.3.8装置告警 (30)4.3.9对时功能 (31)4.3.10网络通信 (31)4.4保护定值 (31)4.5接线端子定义 (32)4.5.1接线端子示意图(后视图) (32)4.5.2接线端子定义说明 (32)4.6附图 (34)附图4-1MT-T543S系列装置直流二次接线示意图 (34)附图4-2MT-T543S系列装置直流操作回路接线示意图 (35)附图4-3MT-T543S系列装置直流二次接线示意图 (35)附图4-4MT-T543S系列装置直流操作回路接线示意图 (35)5微机电容保护测控装置 (40)5.1概述 (40)5.2功能配置 (40)5.3保护原理 (40)5.3.1起动元件 (40)5.3.2两段过流保护 (40)5.3.3小电流接地告警 (40)5.3.4不平衡电压保护 (41)5.3.5过电压保护 (41)5.3.6低电压保护 (41)5.3.7TV断线检测 (42)5.3.8装置告警 (42)5.3.9对时功能 (43)5.3.10网络通信 (43)5.4保护定值 (43)5.5装置接线端子定义 (44)5.5.1接线端子示意图(后视图) (44)5.5.2接线端子定义说明 (44)5.6附图 (46)附图5-2MT-C541S系列装置直流操作回路接线示意图 (46)附图5-3MT-C541S系列装置交流操作二次接线示意图 (46)附图5-4MT-C541S系列装置交流操作回路接线示意图 (46)6微机电动机保护测控装置 (51)6.1装置简介 (51)6.2功能配置 (51)6.3保护原理 (51)6.3.1电流速断保护 (51)6.3.2不平衡保护 (52)6.3.3接地保护 (53)6.3.4堵转保护 (53)6.3.5起动时间过长保护及其合闸回路闭锁 (53)6.3.6过热保护及其合闸回路闭锁 (54)6.3.7过负荷保护 (55)6.3.8低电压保护 (55)6.3.9F-C闭锁 (56)6.3.10装置告警 (56)6.3.11对时功能 (56)6.3.12网络通信 (56)6.4保护定值 (57)6.5装置接线端子定义 (58)6.5.1接线端子示意图(后视图) (58)6.5.2接线端子定义说明 (58)6.6附图 (60)附图6-1MT-E541S系列装置直流操作二次接线示意图 (60)附图6-2MT-E541S系列装置直流操作操作回路接线示意图 (60)附图6-3MT-E541S系列装置交流操作二次接线示意图 (60)附图6-4MT-E541S系列装置交流操作操作回路接线示意图 (60)7现场安装和调试 (65)7.1调试资料及试验仪器准备 (65)7.2通电前检查 (65)7.3通电试验 (65)7.4模拟量刻度校验 (66)7.5异常处理 (66)8投运说明及注意事项 (67)8.1投运前的设置、检查 (67)8.2运行注意事项 (68)8.3正常运行模拟量参考 (68)9存储及保修 (68)10供应成套性 (69)11订货须知 (69)1系统综述1.1适用范围MT-500S配电站自动化系统集保护、测量、控制、监控于一体,适用于10kV及以下电压等级的城市电网、楼宇及厂矿企业的供电系统。

MTC/MTX 晶闸管模块三、产品外形、安装尺寸符合标准:JB /T 3283-4-注:(单位mm )90%。

温度下限为-30℃,温度上限为+75℃。

七、开箱及检查八、订货须知品合格证。

用户在订货时,请注明产品的型号、规格。

如有特殊要求,请与制造商协商。

打开外包装纸盒,检查包装盒内应有使用说明书,产九、公司承诺自产品生产日期起二十四个月内,在客户正常的储运、保养、使用条件下,因产品的制造质量问题而不能正常使用时,提供“三包”服务。

-3-本产品执行JB /T3283标准经检验合格,准予出厂。

检 验 员:检验日期:名称:型号:晶闸管模块MTC/MTX 系列检 01见内盒标签××××××××321K2G2G1K1×321K2G2G1K1×400A 、500A 晶闸管模块70A 、90A 、110A 晶闸管模块25A 、40A 、55A 晶闸管模块250A 、300A 晶闸管模块250A 、300A 水冷晶闸管模块400A 、500A 水冷晶闸管模块600A 晶闸管模块600A 水冷晶闸管模块800A 、1000A 晶闸管模块800A 、1000A 水冷晶闸管模块×130A 、160A 、200A 晶闸管模块地址: 浙江省乐清市柳市镇电器城3单元 邮编: 325604电话: (86-577)6177 8888传真: (86-577)6177 8000客服热线: 400-826-8008本使用说明书自2021年03月 第一版生产厂:表一:(产品不包含散热器,如需要请另外购买)。