Fisher阀门

- 格式:ppt

- 大小:4.37 MB

- 文档页数:87

FISHER防喘阀使用指南引言:一、FISHER防喘阀的安装:1.确定安装位置:首先需要确定FISHER防喘阀的安装位置。

一般来说,应选择一个离流体压力源较近,流体流速较高,且能方便进行维护和检修的地方安装。

应注意避免将防喘阀安装在有过多弯曲、支座或其他阻碍流体正常流动的地方。

2.安装固定支架:根据阀门的尺寸和重量,选择合适的支架进行安装。

支架应牢固可靠,能够承受阀门本身的重量。

3.连接管道:连接喘阀的进出口与管道系统,注意确保连接的密封性。

可使用法兰、螺纹或焊接等方式进行连接。

4.安装附件:根据实际需要,可能还需要安装一些附件,如温度传感器、压力传感器等。

这些附件能够通过监测流体的温度和压力,提供实时的监控和反馈。

二、FISHER防喘阀的使用:1.进行压力调节:使用工具将阀门的调节杆旋转,调节阀门的开启程度,以改变管道系统中的流体压力。

调节过程中应逐步进行,小幅度调整,以避免剧烈的压力波动。

2.监测阀门状态:使用监测设备对阀门状态进行实时监测。

通过观察监测设备上的数据,可以判断阀门是否正常工作,是否需要进一步调整或维护。

3.定期维护:定期对阀门进行检查和维护,以保证其正常运行。

可以通过清洗阀门内部的零部件,更换磨损的密封件等方式来维护阀门。

4.注意安全:使用FISHER防喘阀时,应注意安全操作。

禁止任何人员在阀门附近站立,以防止意外发生。

阀门开启和关闭时,避免过度用力,以免损坏阀门。

三、FISHER防喘阀的故障排除和维修:1.处理阀门漏气:如果阀门存在漏气现象,首先检查阀门周围的密封件是否完好。

如果需要更换密封件,应使用原厂配件进行更换。

2.处理阀门卡死:如果阀门出现卡死现象,可能是由于阀门内部的零部件损坏或腐蚀。

此时需要拆卸阀门,并对内部的零部件进行检查和维修。

3.处理阀门无法调节:如果阀门无法调节流量或压力,可能是由于阀门的调节杆松动或损坏。

此时需要拆卸阀门,并对调节杆进行检查和修复。

总结:FISHER防喘阀的安装和使用需要注意一些关键的步骤和细节。

浅谈FISHER调压阀常见故障分析FISHER调压阀是一种在工业自动化控制系统中广泛使用的自动控制装置。

它可以对液体或气体的压力进行精确控制,并保持压力在一定范围内稳定不变。

不过,由于长时间的使用和各种外部因素的影响,FISHER调压阀常常会出现一些故障,影响着其正常工作,下面我们就来简单了解一下FISHER调压阀的常见故障分析。

第一种故障是FISHER调压阀漏气。

FISHER调压阀不管是该气体时还是液体时,在正常工作过程中,都不应该出现气体或液体泄漏的现象。

如果发现FISHER调压阀存在泄漏现象,很可能是由于密封圈磨损或松动引起的。

此时,我们需要对整个阀进行检修,检查和更换阀门密封部分上的密封圈,以解决漏气问题。

第二种故障是FISHER调压阀启动延迟。

FISHER调压阀在正常工作状态下应该能够及时启动和关闭,确保被控制的气体或液体的压力稳定在设定的范围内。

如果发现 FISHER调压阀启动延迟,很可能是由于内部的灵敏度调整不当或者阀门部分的接触不良导致的。

这时,我们需要通过调整阀门部分的接触以及重新设置灵敏度,来确保调压阀能够在最短时间内启动。

第三种故障是FISHER调压阀无法保持稳定压力。

FISHER调压阀的主要作用是维持被调整气体或液体的压力在稳定范围内,因此FISHER调压阀无法保持稳定压力就成了明显的故障。

当调压阀无法保持稳定压力时,很可能是由于弹簧力不足或者阀门孔道堵塞导致的。

此时,我们需要彻底清洗阀门内部,以消除孔堵塞;如果是弹簧力不足的问题,我们则需要更换弹簧来解决。

通过以上分析,我们可以发现FISHER调压阀的故障原因多种多样。

在实际使用过程中,我们需要仔细观察调压阀的工作状态,并及时对其进行维护和维修,以确保调压阀能够持续稳定地工作。

同时,我们还需要定期检查和更换调压阀的部件,以确保其在正常工作压力范围内稳定不变。

FISHER阀门定位器介绍FISHER阀门定位器是一种用于控制和调节阀门位置的装置。

它能够准确测量和控制阀门的开度,实时调整阀门位置,以达到所需的流量控制和压力调节。

FISHER是一家知名的工业自动化公司,其阀门定位器被广泛应用于石油化工、电力、水处理、制药等行业。

1.高精度测量:FISHER阀门定位器采用先进的传感器技术,能够实时准确地测量阀门的开度,并反馈给控制系统。

其测量精度可达到高达0.1%。

2.宽工作范围:FISHER阀门定位器适用于各种类型的阀门,包括蝶阀、球阀、蜗轮蜗杆阀等。

无论是小型阀门还是大型阀门,都能够实现精确的位置控制。

3. 快速反应速度:FISHER 阀门定位器能够快速响应控制系统的指令,实时调整阀门的位置。

其响应时间通常在10ms以内,确保流程控制的灵活性和高效性。

4.可远程控制:FISHER阀门定位器支持远程控制,可以通过现场总线或无线通信等方式进行远程监控和操作。

这使得操作人员可以方便地调整阀门位置,减少了人工干预的复杂性和风险。

5.易于安装和维护:FISHER阀门定位器采用模块化设计,安装和维护便捷。

其具有自动校准和自学习功能,能够自动适应阀门的特性,减少了调试和维护的工作量。

6.高可靠性和耐用性:FISHER阀门定位器采用高品质的材料和先进的制造工艺,具有良好的耐腐蚀性和耐高温性能。

其设计经过严格的耐久性测试,能够在恶劣的工作环境下长时间稳定运行。

除了以上的特点和优势,FISHER阀门定位器还具有一些附加功能,以满足不同行业和应用的需求。

例如,它可以支持多种通信协议,实现与其他设备的无缝集成;它可以提供诊断和报警功能,监测阀门的运行状态和故障情况;它还可以记录和存储阀门的运行数据,便于分析和优化流程控制。

总之,FISHER阀门定位器是一种高精度、高性能的阀门控制装置,广泛应用于各个领域的流程控制和压力调节。

它能够提高流程的稳定性和可靠性,降低能耗和运行成本。

与传统的手动调节方法相比,FISHER阀门定位器具有更高的自动化水平和精确度,为工业生产带来更多的便利和效益。

浅谈FISHER调压阀常见故障分析FISHER调压阀是一种常用的调压装置,广泛应用于石油、化工、电力、冶金等工业领域。

它能够有效地稳定管道内的压力,保证管道系统的安全稳定运行。

随着使用时间的增长和环境条件的变化,FISHER调压阀也会出现一些常见故障。

本文将就FISHER调压阀的常见故障进行分析,并提出相应的解决方案。

1. 调压阀漏气FISHER调压阀在使用过程中可能出现气体泄漏的情况,这种情况可能是由于密封件磨损、腐蚀或者安装不当所引起的。

此时需要先检查密封件是否完好,如发现密封件有磨损或者腐蚀的情况,需要及时更换密封件。

还需要仔细检查调压阀的安装情况,确保安装正确,密封良好。

2. 调压阀堵塞调压阀可能会因为管道内部杂物堵塞而导致调压阀无法正常工作。

这种情况可能是由于管道内部杂物进入调压阀引起的。

解决这一问题需要定期清理管道,排除杂物,保持管道畅通。

如果出现频繁堵塞的情况,需要考虑增加过滤器或者净化设备来保护调压阀。

3. 调压阀通气不良调压阀通气不良可能会导致调压阀内部空气堆积,影响调压阀的正常工作。

在发现调压阀通气不良的情况时,需要先检查通气口是否被堵塞,清理通气口。

如果通气口正常,还需要检查是否有泄漏或者损坏的密封件,及时更换损坏的密封件。

4. 调压阀压力不稳定FISHER调压阀在使用过程中可能出现压力不稳定的情况。

这可能是由于调压阀内部零部件磨损、松动或者污染所引起的。

解决这一问题需要定期对调压阀进行检查、维护和保养,及时更换磨损严重的零部件,清理污染的部件,保持调压阀的正常运行。

FISHER调压阀作为管道系统中的重要设备,其正常运行对保障管道系统的安全稳定运行至关重要。

在使用过程中,我们要定期对调压阀进行检查、维护和保养,及时排除故障,确保调压阀的正常工作。

也要注意加强对调压阀的安装和使用管理,保证调压阀在使用过程中能够发挥最大的作用。

【来源:百度百科】。

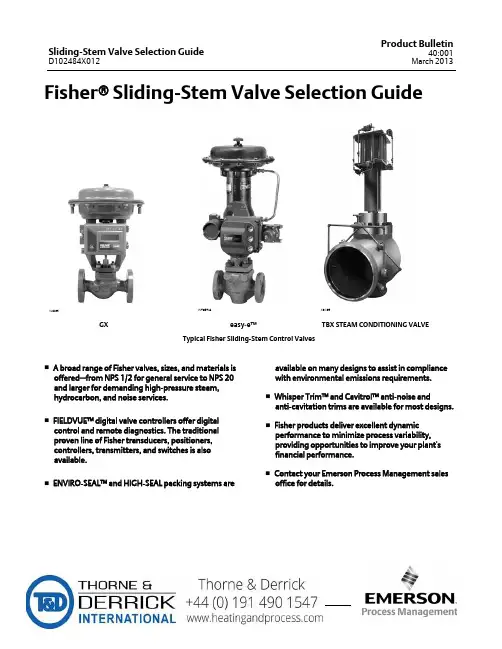

Fisher r Sliding -Stem Valve Selection GuideTypical Fisher Sliding-Stem Control ValvesW8861W7957-2easy -e™GXTBX STEAM CONDITIONINGVALVEX0165⏹A broad range of Fisher valves,sizes,and materials is offered–from NPS 1/2for general service to NPS 20and larger for demanding high -pressure steam,hydrocarbon,and noise services.⏹FIELDVUE™digital valve controllers offer digital control and remote diagnostics.The traditional proven line of Fisher transducers,positioners,controllers,transmitters,and switches is also available.⏹ENVIRO -SEAL™and HIGH -SEAL packing systems areavailable on many designs to assist in compliance with environmental emissions requirements.⏹Whisper Trim™and Cavitrol™anti -noise andanti -cavitation trims are available for most designs.⏹Fisher products deliver excellent dynamic performance to minimize process variability,providing opportunities to improve your plant's financial performance.⏹Contact your Emerson Process Management sales office for details.Sliding-Stem Valve Selection GuideD102484X0122EZW2966B ESW3421-3GX CONTROL VALVE AND ACTUATORSYSTEMW8486-3Table 1.General Service and Heavy -Duty Valves (GX,EZ,and ES)GXEZ ESApplicationsCompact,state -of -the -art control valve and actuator system designed to control a wide range of process liquids,gases,and vapors.Capable of air supply pressures to 6.0barg (87psig),allowingvalve shutoff at high pressure drops.Heavy -duty general service for controlling liquidsand gases,including viscous and other hard -to -handle fluids.UOP applicationsHeavy -duty,general -service valve for clean liquidsand gases.Positive shutoff at seatStyleSingle port,flow up globe style valveStem -guided or port -guided Balanced or unbalanced Screwed -in seat ringSingle -seated,post -guided globe or angle valveUnbalancedSeat ring retained by spacerMetal or soft seatsCage -guided globe or angle valveUnbalanced Cage -retained seatSizesDN 15,20,25,40,50,80,and 100NPS 1/2,3/4,1,1-1/2,2,3,and 4DN 15,20,25,40,50,80,and 100NPS 1/2,3/4,1,1-1/2,2,3,and 4ES:DN 15through 200(NPS 1/2through 8)EWS:DN 100x 50through 600x 500(NPS 4x 2through 24x 20)RatingsPN 10to 40,CL150and 300PN 16,25,40,63and 100and CL125,150,300,and 600PN 10,16,25,40,63,or 100andCL150,300,or 600End ConnectionsFlanged raised -face per EN 1092-1andASME B16.5Screwed NPT internal,flat -or raised -face flanged,ring -type joint,socket -weld,and buttwelding endsScrewed NPT internal,flat -or raised -face flanged,ring -type joint,socket -weld and buttwelding endsValve Body MaterialsEN:1.0619steel,1.4409stainless steel,or CW2M ASME:SA216WCC steel,SA351CF3M stainlesssteel,or CW2MSteel,alloy steel,stainless steel (to EN,ASME,orASTM specifications)Steel,alloy steel,stainless steel (to EN,ASME,orASTM specifications)Valve Plug and Seat Ring (Trim)MaterialsStainless steel (316L)with optional alloy 6hardfacing or PTFE soft seatStainless steel with or without alloy 6on seat orseat and guide Soft seat is PTFE Stainless steel with or without alloy 6on seat orseat and guide Soft seat is PTFE Flow Characteristics and Maximum Flow CoefficientsEqual percentage or linear Maximum C v from 0.0389to 183.5Quick opening,linear,or equal percentageMaximum C v from 4.47to 190Quick opening,linear,or equal percentageMaximum C v from 6.53to 1110Shutoff Class (IEC 60534-4and ANSI/FCI 70-2)Class IV (standard with metal seats),Class V (optional with metal seats),or Class VI (optionalwith PTFE seats)Class IV (standard with metal seats),Class V (optional with metal seats),or Class VI (optionalwith soft or metal seats)Class IV (standard with metal seats),Class V (optional with metal seats),or Class VI (optionalwith soft or metal seats)Available Actuators (see section on Sliding -Stem Valve Actuators)GX multi -spring,pneumatic diaphragm657or 667spring and diaphragm;585C piston657or 667spring and diaphragm;585C piston3ED W3162-3ETW0451-3HP AND EHW5815-1Table 2.Heavy -Duty and Severe -Service Valves (ED,ET,HP,and EH)EDET HP and EHApplicationseasy -e heavy -duty,general -and severe -service valve for clean liquids and gases with higher pressure drops but where tight shutoff is notrequiredeasy -e heavy -duty,general -and severe -servicevalve for tight shutoff with clean liquids and gaseswith higher pressure drops and temperatures to232_C [450_F](to 316_C [600_F]with optional sealmaterials)For high -pressure and severe -service applications.Available with special trim to combat noise andcavitation.Often used in power generationapplicationsStyleCage -guided globe or angle valveBalanced trim Cage -retained seat Cage -guided globe or angle valveBalanced trim Cage -retained seatCage -guided globe or angle valve Balanced or unbalanced trimSizesDN 25through 200and NPS 1through 8(ED)DN 100x 50through 600x 500and NPS 4x 2through 24x 20(EWD)DN 25through 200and NPS 1through 8(ET)DN 100x 50through 600x 500and NPS 4x 2through 24x 20(EWT)DN 25through 500and NPS 1through 20RatingsPN 10,16,25,40,63,or 100,andCL150,300,or 600PN 10,16,25,40,63,or 100,andCL150,300,or 600DIN PN 160,250,420andCL900,1500,2500,or intermediate ASME ratingsEnd ConnectionsScrewed NPT internal,flat -or raised -face flanged,ring -type joint,socket -weld and buttwelding endsScrewed NPT internal,flat -or raised -face flanged,ring -type joint,socket -weld and buttwelding endsRaised -face flanged,ring -type joint,socket -weldand buttwelding ends Expanded ends Valve Body MaterialsSteel,alloy steel,stainless steel (to EN,ASME,orASTM specifications)Steel,alloy steel,stainless steel (to EN,ASME,orASTM specifications)Steel,alloy steel,stainless steel (to EN,ASME,orASTM specifications)Valve Plug and Seat Ring (Trim)Materials Stainless steel with or without alloy 6on seat orseat and guide Stainless steel with or without alloy 6on seat orseat and guide.Soft seat is PTFE Stainless steel with or without alloy 6on seat orseat and guide Flow Characteristics and Maximum Flow CoefficientsQuick opening,linear,or equal percentageMaximum C v from 17.2to 6500Quick opening,linear,or equal percentageMaximum C v from 17.2to 6500Linear,equal percentage or characterizedMaximum C v from 0.354to 2600Shutoff Class (IEC 60534-4and ANSI/FCI 70-2)Class II (standard)Class III or IV (optional depending on size)Class IV (standard with metal seats),Class V (optional with soft or metal seats),or Class VI(optional with soft or metal seats)Class II,III,IV or V (depending on size andconstruction)Available Actuators (see section on Sliding -Stem Valve Actuators)657or 667spring and diaphragm;585C piston657or 667spring and diaphragm;585C piston657or 667spring and diaphragm;585C piston4Figure 3.Three-Way,Cryogenic,and Lined Valves (YD and YS,ET-C and EZ-C,and RSS)YD AND YS W0665-3ET -C &EZ -CW6396RSSW4521-2Table 3.Three -Way,Cryogenic,and Lined Valves (YD and YS,ET -C and EZ -C,and RSS)YD and YSET -C and EZ -C RSSApplicationsThree -way valves for flow -mixing or flow -splitting service.The YS unbalanced,and the YD is balanced.easy -e stainless steel cryogenic valves for liquefiednatural gas and other special chemical and hydrocarbon applications with temperatures to-198_C (-325_F)Lined valve for severely corrosive or toxic process fluids.An economic alternative to alloy bodies.Limited in pressure and temperatureStyle Cage -guided three -way globe valvesBalanced or unbalanced trim Single -seated post -guided (EZ -C)or cage -guided(ET -C)globe valveUnbalanced (EZ -C)or balanced (ET -C)Metal seatsFully lined,single -seated,unbalanced globe valveIncludes bellows stem sealSizesNPS 1/2through 6DN80through 250x 200or NPS 3through10x 8(ET -C)DN 15through 100or NPS 1through 4(EZ -C)NPS 1through 4(face -to -face dimensions to DIN orANSI/ISA specifications)RatingsCL125,150,250,300,or 600PN 10,16,25,40,63,100and CL150,300,600CL150or 300End Connections Screwed NPT internal,flat -or raised -face flanged,ring -type joint,socket -weld and buttwelding ends Raised -face flanges Raised -face flanges Valve Body MaterialsCast iron,steel,alloy steel,stainless steel (to ASMEor ASTM specifications)Stainless steel (to ASME or ASTM specifications)Ductile iron with PFA liner Valve Plug and Seat Ring (Trim)MaterialsStainless steelStainless steel with or without alloy 6hardfacing onseatValve Plug and Seat Ring:Pure modified(reinforced)PTFEBellows:Heavy -duty PTFE (TFM1705)with 304L SSTsupport rings [Bellows is PTFE for NPS 1/2and 3/4valves]Flow Characteristics and Maximum Flow CoefficientsLinearMaximum C v 8.42to 567Quick opening,linear,or equal percentageMaximum C v from 13.2to 924Equal percentageMaximum C v from 0.212to 145Shutoff Class (IEC 60534-4and ANSI/FCI 70-2)Class II or IV (YD)Class IV or V (YS)Class IV (standard)0.05mL/min/psid/inch of port diameter (optionalfor ET -C)or Class V (optional for EZ -C)Class VI (soft seat)Available Actuators (see section on Sliding -Stem Valve Actuators)657or 667spring and diaphragm;585C piston657or 667spring and diaphragm;585C piston657or 667spring and diaphragm;585C piston5TBX (FLOWUP)TBX (FLOW DOWN)CVXTable 4.Steam Conditioning Valves (TBX Flow Up,TBX Flow Down,and CVX)TBX Flow UpTBX Flow Down CVXApplicationsHP,HRH,IP,LP Turbine BypassProcess steam Steam Let DownStyleFlow up design,hung trim configuration to thermally compensate rapid changes intemperature,incorporates a spraywater manifold of variable geometry AF nozzles that produce an optimized spray pattern over a wide operatingrange.Flow down design,hung trim configuration to thermally compensate rapid changes intemperature,incorporates a spraywater manifold of variable geometry AF nozzles that produce an optimized spray pattern over a wide operatingrange.Flow down design,hung trim configuration to thermally compensate rapid changes intemperature,incorporates a spraywater manifold of variable geometry AF nozzles that produce an optimized spray pattern over a wide operatingrange.SizesInlet Sizes:NPS 4-24Outlet Sizes:NPS 8-36Orifice TypeWelded or BoltedBolted Welded or BoltedEnd ConnectionsASME Buttweld or ASME Raised Face FlangeFlow CharacteristicsWhisper Trim III:Linear or WhisperFlo™:LinearWhisper Trim III:LinearStandard Drill Hole:LinearShutoff Class (IEC 60534-4and ANSI/FCI 70-2)Class V:Standard Class IV:OptionalValve Body and Bonnet Material and ConstructionSA105(Carbon Steel),SA182Grade F22(2.25Cr -1Mo),SA182Grade F91(9Cr -1Mo -V)Available ActuatorsSee Section on Sliding-Stem Valve Actuators6657and667585CW0363-1W6304-1585CLSW2795Table5.Sliding-Stem Valve Actuators(657,667,585C,and585CLS)657and667585C and585CLSFeaturesHeavy-duty actuators585C:Heavy-duty actuators585CLS:Heavy-duty actuators for large valves and valves with long travel StyleSpring-return pneumatic diaphragm 585C:Double-acting piston or spring-bias piston 585CLS:Double-acting pistonTypical Maximum Thrust,Lbf(Varies with Operating Pressure,Spring,and Construction)45,000585C:5890@125psig operating pressure585CLS:25,000@125psig operating pressure AccessoriesPneumatic or electro-pneumatic valve positioners,FIELDVUE digital valve controller,limit switches,position transmitters,handwheels,travel stops,and supply pressure filter-regulator 585C:I/P transducers,pneumatic or electro-pneumatic valve positioners, FIELDVUE digital valve controller,limit switches,position transmitters, handwheels,travel stops,and67CFR supply pressure filter-regulator 585CLS:I/P transducers,pneumatic valve positioners,limit switches, position transmitters,handwheels,travel stops,and supply pressurefilter-regulator76551008W0446BW0590Table 6.Sliding -Stem Valve Actuators (655and 1008)6551008FeaturesActuators for pressure regulation applicationsManual handwheel for applications that requirea throttling type of control valve that can be manually operated and setStylePressure -actuated,spring -and -diaphragmManual handwheel actuatorTypical Maximum Thrust,Lbf (Varies with Operating Pressure,Spring,and Construction)17,000AccessoriesTravel indicator,top -mounted handwheel/adjustable travel stop,stem sealand drain tapping for leakoffHandwheel lock,Tejax valve stem position indicatorOther actuators available are...⏹Full range of self -operated control valves,1B,643,644,645Alloy Valve Guidelines⏹Emerson Process Management expertise has combined its knowledge of metals and foundry techniques with valve user experience in creating high alloy valves that fight corrosion successfully.⏹Guidelines have been developed to help the valve user specify alloy valves correctly.Techniques have also been implemented that verify a foundry's ability to cast alloy valves properly and has established stringent specifications that guide the foundry in providing quality results.⏹Valve user guidelines include–Avoid the use of alloy tradenames,Don't specify wrought for cast,Forego non -destructive testing⏹Steps used to qualify a foundry include–Weldability tests to gauge the foundry's ability to pour alloy materials,Dedicating casting patterns solely to high -alloy service⏹Stringent specifications developed by Emerson Process Management include–Raw Material Composition and Quality,Heat Qualification,Visual Inspection,Weld Repair,Heat Treatment,and Nondestructive TestingSliding-Stem Valve Selection GuideD102484X012 Product Bulletin40:001March2013FIELDVUE DIGITAL VALVE CONTROLLERMOUNTED ON667ACTUATOR ANDeasy-e VALVEGX CONTROL VALVE AND ACTUATORSYSTEM W6307-1846ELECTRO-PNEUMATICTRANSDUCER MOUNTED ON A667ACTUATOR W7957-2W8861⏹A complete line of actuators and accessories for Fisher sliding-stem valves are offered that meet yourprice/performance expectations⏹FIELDVUE digital valve controllers are communicating,microprocessor-based controllers that utilize HART t andF OUNDATION t fieldbus protocols.Through digital communications,the controllers give easy access to actuator,valve,and instrument information that is critical to process operation.⏹AMS ValveLink t Software and AMS Suite:Intelligent Device Manager allow you to care for and maintain equipmentassets–such as valves,transmitters,analyzers,motors,pumps,etc.and plant unit equipment such as pipes, vessels,tanks,columns,reactors,digesters,etc.–to improve yields and minimize downtime of industrialmanufacturing processes.⏹Contact your Emerson Process Management sales office for detailsEmerson Process ManagementMarshalltown,Iowa50158USASorocaba,18087BrazilChatham,Kent ME44QZ UKThe contents of this publication are presented for informational purposes only,and while every effort has been made to ensure their accuracy,they are not to be construed as warranties or guarantees,express or implied,regarding the products or services described herein or their use or applicability.All sales are governed by our terms and conditions,which are available upon request.We reserve the right to modify or improve the designs or specifications of such products at any time without notice.Fisher,ValveLink,easy-e,Cavitrol,ENVIRO-SEAL,FIELDVUE,Whisper Trim,and WhisperFlo are marks owned by one of the companies in the Emerson Process Management business unit of Emerson Electric Co.Emerson Process Management,Emerson,and the Emerson logo are trademarks and service marks of Emerson Electric Co.All other marks are the property of their respective owners.Neither Emerson,Emerson Process Management,nor any of their affiliated entities assumes responsibility for the selection,use or maintenanceof any product.Responsibility for proper selection,use,and maintenance of any product remains solely with the purchaser and end user.。

Fisher气动阀1.工作原理电气转换器接收4~20mADC的电流指令信号,相应的输出3~15psi的气压作为气动定位器的输入信号。

定位器输入信号的变化,使它的喷嘴背压发生变化,定位器的放大器输出气压也相应变化,带动阀门动作。

同时,与阀门门杆相连的定位器反馈杆带动定位器的凸轮转动,从而改变了定位器喷嘴挡板的位置,使喷嘴背压发生改变,达到一个新的力平衡状态,阀门停在于指令信号相应的位置。

2.气压降落保位主要由保位阀实现。

将保位阀的动作压力调整在250~350psi的某个值上。

当保位阀控制气压高于调定值时,打开保位阀输出气路,使通往阀门气室的气路相通,即正常自动工作状态。

当气压低于调定值时,保位阀闭锁切换气路,切断通往阀门气室的气路,维持负载的原有位置,实现断气自锁保护。

3.结构Fisher气动阀的执行机构主要由气动定位器、电气转换器、位置变送器、断气保位装置及薄膜腔室构成。

4.基本误差及回程误差校准电气转换器检查校准(检查电气转换器的气源压力应为140psi左右。

)将信号电流分为4、8、12、16、20mA五个校准点,电气转换器的输出气压应与之对应为3、6、9、12、15psi,其误差应在±5%以内,回程误差小于2%,否则应进行调整。

调整时先将信号电流调至4mA,调零位螺母;再将电流调至20mA,调量程螺母使输出在额定值。

反复进行调整直至合格,应尽量使其准确。

5.执行机构检查校准检查气动定位器的气源压力应为35±2psi左右。

将校准后的电气转换器输出作为气动定位器的输入信号;全开全关的确认先应与本体专业进行联系确认全开及全关的位置,并将刻度盘固定,在调试定位器时应以刻度盘为基准。

6.不灵敏区校准:校准点应在25%、50%、75%、位置进行,方法为:将阀门操作在一定开度(如25%),稳定一会后,当阀位在30秒内不变化时,再缓慢加指令/或减指令,直到执行机构的位变产生变化为止,此时的指令变化的值就在阀门的不灵敏区。

FISHER控制阀的使用和维修一、FISHER控制阀的基本原理FISHER控制阀是一种用来控制流体介质流量、压力或温度的装置,其基本原理是通过调节阀芯位置,改变阀门的流通面积,从而控制介质的通量。

FISHER控制阀可以分为直线型和等百分比型两种,直线型控制阀的流量特性随阀芯位置的改变线性变化,而等百分比型控制阀的流量特性随阀芯位置的改变不是线性变化的。

二、FISHER控制阀的使用1.控制阀的选型:根据需要控制的介质参数、工作温度和压力等条件,选择合适的FISHER控制阀型号。

关键的选型参数包括阀门大小、流量特性、密封材料等。

2.安装调试:将FISHER控制阀安装在管道上,根据需要连接管件和附件。

在安装之前,要进行阀门、阀体和密封表面的清洁,避免杂质对阀门正常使用的影响。

安装完成后,进行阀门的调试,包括调整阀芯位置、检查阀门是否泄漏,确保阀门能够正常工作。

3.操作维护:根据控制系统的需要,通过操作电磁阀、行程开关等装置,实现对FISHER控制阀的远程控制。

在操作过程中,要注意避免阀门过度开启或关闭,避免给阀门带来不必要的压力和负荷。

此外,还需要定期对阀门进行检查、润滑和维护,确保阀门的正常运行。

三、FISHER控制阀的维修1.维修前的准备工作:在进行维修前,要做好相应的准备工作,包括关闭阀门上下游的介质流动、排空阀门内部介质等。

此外,还要准备好所需的工具和备件,以便于维修操作。

2.维修阀芯和阀座:阀芯和阀座是FISHER控制阀的核心部件,如果发现阀芯和阀座磨损或密封不严,就需要进行维修或更换。

操作时要将阀芯取出来,检查其表面的磨损情况,并对阀座进行清洁和修复,以恢复阀门的密封性能。

3.维修阀体和密封表面:如果阀体存在损坏或密封表面出现磨损,就需要进行维修或更换。

维修阀体时,要检查阀体的连接处和焊接处是否有裂纹或破损,并做相应的修复。

对密封表面进行处理时,可以采用打磨或涂覆的方式,以保证阀门的密封性能。

FISHER防喘阀使用指南(气动)FISHER防喘阀使用指南(气动)1.引言1.1 本文档旨在提供关于FISHER防喘阀(气动)的详细使用指南。

1.2 本指南适用于使用FISHER防喘阀(气动)的操作员和维护人员。

2.产品概述2.1 FISHER防喘阀是一种气动控制装置,用于控制流体介质中的喘振和脉动。

2.2 FISHER防喘阀具有优异的稳定性和可靠性。

2.3 FISHER防喘阀适用于各种工业领域,包括石油、化工、能源等。

3.安装要求3.1 在安装FISHER防喘阀之前,确保设备和管道系统处于合适的工作状态。

3.2 按照FISHER防喘阀的安装图纸进行正确的安装。

3.3 检查阀门的密封性能,确保无泄漏。

4.使用方法4.1 操作员使用前应仔细阅读使用说明书。

4.2 在操作FISHER防喘阀之前,请确保气源正常并连接稳定。

4.3 使用控制系统控制FISHER防喘阀的开启和关闭。

4.4 定期检查FISHER防喘阀的工作状态并进行维护。

5.维护保养5.1 每隔一段时间,对FISHER防喘阀进行清洁和润滑。

5.2 定期检查FISHER防喘阀的密封性能,并进行相应的调整和更换。

5.3 如遇到故障或异常情况,及时联系厂家或维修人员进行处理。

6.注意事项6.1 在操作FISHER防喘阀时,务必严格按照使用说明书进行操作。

6.2 请勿强行打开或关闭FISHER防喘阀,以免损坏设备。

6.3 在维护和更换零部件时,使用原配件或厂家建议的零部件。

7.附件本文档涉及的附件包括:附件1:FISHER防喘阀使用说明书附件2:FISHER防喘阀安装图纸8.法律名词及注释8.1 本文档中使用的法律名词及注释详见附件1.8.2 FISHER防喘阀的使用涉及到一些相关法律名词和定义,这些内容包含在附件1中,并提供了相应的注释。