Robcad 9.0安装文档

- 格式:pdf

- 大小:421.72 KB

- 文档页数:7

安装准备

0.到此基本完场安装过程,安装过程中,需要注意,第一,在自己设定安装路径时,不能出现空格,中划线,或者中文字样,并且不允许电脑插着U盘或者移动硬盘,电脑配置较低,建议不安装本软件,安装前关闭各种防护软件。

整个过程在30分钟以上,请安心等待。

1.首先对电脑进行简单设置。

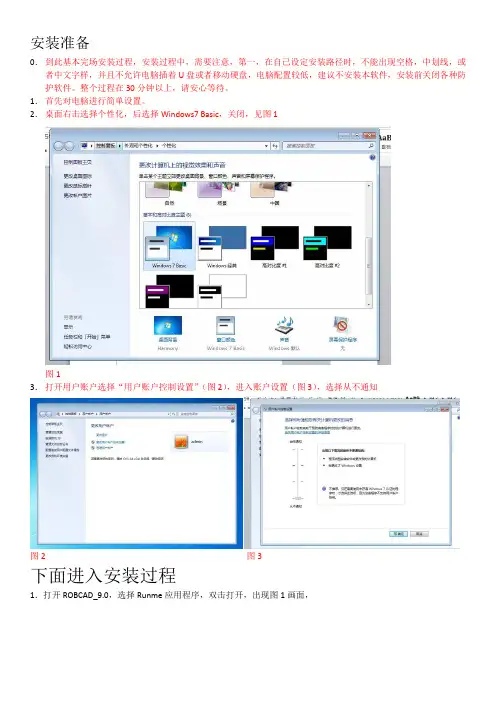

2.桌面右击选择个性化,后选择Windows7 Basic,关闭,见图1

图1

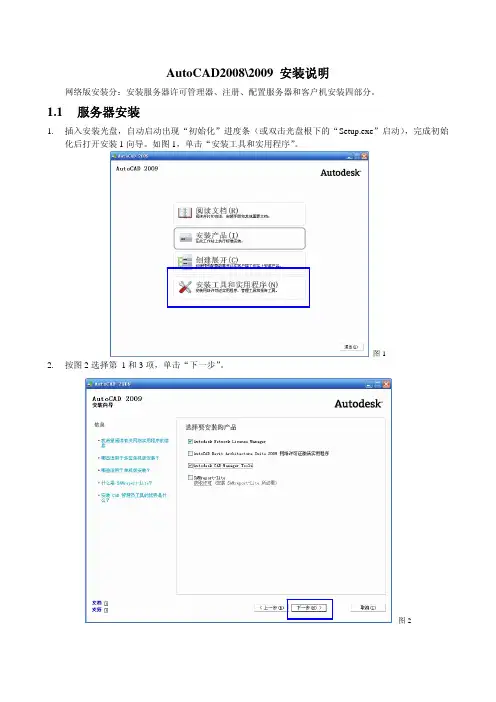

3.打开用户账户选择“用户账户控制设置”(图2),进入账户设置(图3),选择从不通知

图2 图3

下面进入安装过程

1.打开ROBCAD_9.0,选择Runme应用程序,双击打开,出现图1画面,

图1

2.选择箭头所指,等待程序安装,过程中出现“next”,选择“next”,直到安装成功出现图2画面,选择不立刻重启,然后选择“Finish”。

图2

3.选择安装文件夹ROBCAD_9.0.1r_PC并打开,选择文件ROBCAD_9.0.1r_PC文件夹打开后选择Robcad901r文件,双击打开安装等待,中途出现“下一步”则点击“下一步”。

安装完成后出现图3,点击“finish”等待计算机重启。

图3

4.开机后出现图4,选择ok

图4

5.进入安装程序ROBCAD_9.0,选择bin文件夹中的roblms文件并复制,粘贴至文件安装位置C:\Robcad\bin\lm,(此路径为默认安装路径,如果安装文件位置变化,需要自己做出调整)。

6.进入安装程序ROBCAD_9.0,选择bin文件夹中.robcad并复制,粘贴至C:\Robcad\usr,(同样的不是默认的安装路径时,自己做出调整),到此基本完场安装过程,安装过程中。

![[vip专享]2020软件9.0安装手册](https://uimg.taocdn.com/455a01732f60ddccda38a059.webp)

20-20 Design9.0 安装手册一.2020软件的安装(1)打开2020v9.0的安装文件夹。

(2)找到setup图标:。

(3)双击setup图标,如果是win7系统,右击图标选择“以管理员身份运行”。

进入2020v9.0设计软件的安装过程:(4)出现安装Quicktime界面:单击按钮。

(5)出现Quicktime许可证协议界面:单击按钮。

(6)出现选择安装路径界面:默认安装位置是C:\Program Files\QuickTime\,选择路径后点击按钮:(7)出现正在安装Quicktime界面:(8)安装好之后会自动弹出安装完成界面:单击按钮。

(9)出现询问是否升级Quicktime界面:点击按钮,Quicktime就安装完成了。

(10)Quicktime安装完成后会自动弹出安装2020V9.0界面:单击按钮。

20-20家具设计软件 V9.0 (11)出现软件许可证协议界面:选择“我接受许可证协议中的条款”,单击按钮。

(12) 出现输入客户信息界面:将用户名、公司名称、序列号(加密狗的号)输入完成后,单击按钮。

(注20-20家具设计软件 V9.0意在点击“下一步”按钮之前要把加密狗插在电脑上)(13) 出现选择度量标准界面:选择“公制”默认选项,单击按钮。

(14) 出现选择安装路径界面:默认的是在C盘下,我们可以更改安装路径。

点击按钮,选择安装路径。

选择好路径后单击按钮:(15) 出现准备安装界面单击按钮。

(16) 出现正在安装界面:(17) 最后出现安装完毕界面:二.数据库的安装20-20家具设计软件 V9.0 (1)将2020公司传来的数据库保存在电脑的硬盘上。

(2)点击2020快捷方式栏上的第三个图标:。

(3)出现2020型录工具界面:单击图标。

(4) 出现型录安装指南界面:20-20家具设计软件 V9.0单击按钮。

(5)出现选择将要安装的压缩型录界面:点击选择按钮。

(6)出现打开对话框:选中需要安装的数据库,并点击“打开”按钮。

AutoCAD2008\2009 安装说明网络版安装分:安装服务器许可管理器、注册、配置服务器和客户机安装四部分。

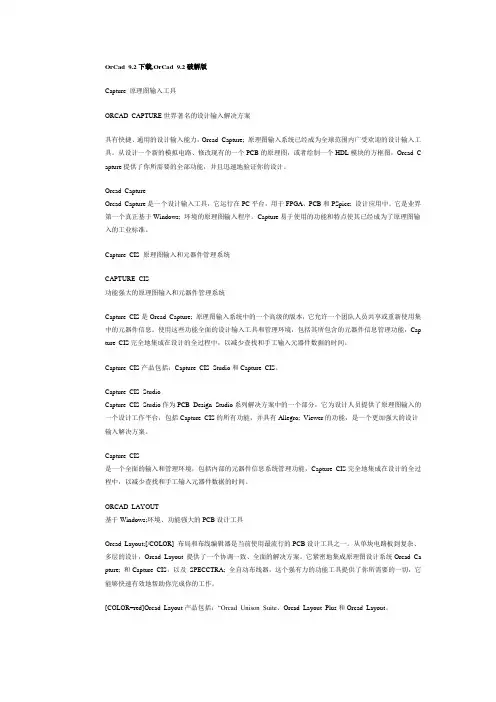

1.1服务器安装1.插入安装光盘,自动启动出现“初始化”进度条(或双击光盘根下的“Setup.exe”启动),完成初始化后打开安装1向导。

如图1,单击“安装工具和实用程序”。

图12.按图2选择第1和3项,单击“下一步”。

图23.在图3中选择“我接受”,单击“下一步”。

图3 4.在图4中单击“配置”打开许可管理器配置对话框。

图45.在图5中确认选择顶部的“Autodesk Network License Manager”(许可管理器),设置安装路径,单击“下一步”。

图56.至此许可管理器配置完成。

在图6中选择顶部的“Autodesk CAD Manager Tools”。

图67.在图7中设置安装路径,单击“下一步”。

图7 8.至此配置完成。

在图8中单击“配置完成”。

图89.在图9中确认刚才的设置,单击“安装”开始安装,如图10。

图9图1010.在图11中单击“完成”结束安装。

图111.2软件注册服务器安装完成后首先要配置服务器,并向Autodesk注册,获得授权文件后才能使用。

1.在桌面上双击“LMTOOLS”图标,或从Windows的“开始 - 所有程序– Autodesk - Autodesk NetworkLicense Manager - LMTOOLS”命令,如图1,启动许可管理器。

图12.如图2设置,单击顶部的“System Settings”选项卡。

图2 3.在图3拷贝服务器机器名和网卡物理地址,如下图所示。

粘贴到下一步的邮件中。

图3 4.按下列格式发邮件给Autodesk公司注册部:prod.reg.chn@注册软件。

使用者信息:联系人:XXX 职务:XXX单位: XXXXXXX设计院地址:XXXXXXXXXXXXXXXX 邮编:XXXXXXXXXXX电话: XXXXXXXX 传真: XXXXXXXXX电子邮件: XXXXX@经销商:北京北纬华元软件科技有限公司东北办事处_沈阳软件信息:产品名称:AutoCAD Revit Architevture 2009许可数量:50服务器机器名:RNL-QJ网卡物理地址: 0019d2903411系列号:349-12345678(原软件序列号:343-23456781 如果是升级版本,才需要填写老版本序列号)5.注册部收到邮件后会自动发送收条,如图4,并将在 2 个小时后回复。

Sony Vegas Pro 9.0C安装说明一、 概述 (2)二、 系统要求 (2)三、 软件下载地址 (2)1. 原版安装下载地址 (2)2. 汉化包下载地址 (2)3. 注册机下载地址(注册机不分32BIT和64BIT) (2)四、 软件安装说明(以32BIT为例) (2)1. 原版(英文版)软件安装截图说明 (2)2. 汉化包安装截图说明 (8)3. 打补丁、注册激活截图说明 (15)一、 概述Sony Vegas Pro 90C是一款专业影像编辑软件,它的安装遵循的原则是,首先进行原版安装,其次是汉化,最后打补丁、注册激活,在下载原版安装和汉化软件时有32bit(32位)和64bit(64位)两种情况,所以,在下载之前应首先确定自己的计算机是32位的还是64位的,以便选择对应的原版安装文件和汉化包文件。

下面以在32位操作系统上安装32bit的Sony Vegas Pro 90C为例进行截图说明,由于每台计算机已经安装的软件不尽相同,所以安装过程可能会略有差别。

二、 系统要求Microsoft® Windows® XP 32-bit SP2 (SP3 recommended) or Windows Vista™ 32-bit or 64-bit (SP1 recommended)1 GHz processor (multicore or multiprocessor CPU recommended for HD)200 MB hard-disk space for program installation1 GB RAM (2 GB recommended)OHCI-compatible i.LINK® connector*/IEEE-1394DV card (for DV and HDV capture and print-to-tape) USB 2.0 connection (for importing from AVCHD, XDCAM EX, or DVD camcorders)Windows-compatible sound cardDVD-ROM drive (for installation from a DVD only)Supported CD-recordable drive (for CD burning only)Supported DVD-recordable drive (for DVD burning only)Supported Blu-ray recordable drive (for Blu-ray Disc burning only)Microsoft .NET Framework 3.0QuickTime® 7.1.6 or later三、 软件下载地址1.原版安装下载地址32位:/current/vegaspro90c_32bit.exe64位:/current/vegaspro90c_64bit.exe2.汉化包下载地址32位汉化包:/space/file/mvip/share/2009/11/20/Sony_VegasPro9.0c-002d32bit-6c49-5 316-5b89-88c5-5305.rar/.page64位汉化包:/space/file/mvip/share/2009/11/20/Sony_VegasPro9.0c-002d64bit-6c49-5 316-5b89-88c5-5305.rar/.page3.注册机下载地址(注册机不分32bit和64bit)/training/OldDocuments/Keygen1_7_en.rar四、 软件安装说明(以32bit为例)1.原版(英文版)软件安装截图说明1)运行vegaspro90c_32bit.exe,解压缩向导会提取安装Vegas Pro 9.0c所需的文件,需要等上一会儿;2)出现选择语言对话框,选择“英语”,点“确定”;3)根据各自计算机已安装软件的不同,接下来有可能会出现提示下载Microsoft .NET Framework 3.0等所需软件,点“Download”;4)下载过程需要一些时间,请耐心等候;5)下载完成后,点“Install”;6)随后出现配置组件对话框,这个过程也需耐心等候7)Microsoft .NET Framework 3.0等软件安装完成后,点“OK”;8)出现Vegas Pro 9.0c软件安装向导,点“Next”;9)出现最终用户许可协议,勾选“I have read the End User License Agreement and the Privacy Policies andagree to their terms”后,点“Next”;10)确认主程序安装目录和插件安装目录,建议使用默认,不要修改,点“Next”;11)可根据个人喜好决定是否勾选“Install shortcut on the desktop”,即桌面快捷方式,点“Install”;12)Vegas Pro 9.0c软件安装进行中,稍等片刻;13)Vegas Pro 9.0c软件安装完成,点“Finish”;2.汉化包安装截图说明1)在进行汉化包安装之前(包括后面第六步的打补丁、注册激活之前),须将以下两个文件拷贝至C:\ProgramFiles\Sony\Vegas Pro 9.0目录,两个文件如下(文件可从下载的压缩包中得到):¾Sony VegasPro9.0c-32bit汉化安装包.exe¾Keygen.exe2)运行Sony VegasPro9.0c-32bit汉化安装包.exe,需要注意的是,Vista或Win7系统需要以管理员身份去运行,方法是点右键,选“以管理员身份运行”;3)出现汉化安装包安装向导,点“下一步”;4)出现Vegas Pro汉化包许可协议,等待10秒钟后,点“我同意”;5)在汉化责任说明界面,点“下一步”;6)输入用户名、公司名称和序列号,用户名和公司名称可以随便输入,序列号(这里的序列号是指汉化安装包的序列号,而并非是Sony Vegas Pro 90C软件的序列号)如下,四个序列号中任选一个即可,序列号也可从下载的汉化压缩文件中的“说明.txt”中得到,点“下一步”;7)确认汉化安装包的安装路径为C:\Program Files\Sony\Vegas Pro 9.0目录后,点“下一步”;8)勾选“全部汉化”和“原版备份”后,点“下一步”;9)出现选择程序文件夹界面,直接点“下一步”;10)不要勾选“是否把DV驿站论坛作为IE首页”,点“下一步”;11)确认以上信息后,点“安装”;12)安装进行中,稍等片刻;13)信息页面,无关紧要,点“下一步”;14)取消勾选“访问DV驿站论坛”和“访问MV论坛”后,点“完成”,至此,汉化包安装完毕。

OrCad 9.2下载,OrCad 9.2破解版Capture 原理图输入工具ORCAD CAPTURE世界著名的设计输入解决方案具有快捷、通用的设计输入能力,Orcad Capture; 原理图输入系统已经成为全球范围内广受欢迎的设计输入工具。

从设计一个新的模拟电路、修改现有的一个PCB的原理图,或者绘制一个HDL模块的方框图,Orcad C apture提供了你所需要的全部功能,并且迅速地验证你的设计。

Orcad CaptureOrcad Capture是一个设计输入工具,它运行在PC平台,用于FPGA、PCB和PSpice; 设计应用中。

它是业界第一个真正基于Windows; 环境的原理图输入程序。

Capture易于使用的功能和特点使其已经成为了原理图输入的工业标准。

Capture CIS 原理图输入和元器件管理系统CAPTURE CIS功能强大的原理图输入和元器件管理系统Capture CIS是Orcad Capture; 原理图输入系统中的一个高级的版本,它允许一个团队人员共享或重新使用集中的元器件信息。

使用这些功能全面的设计输入工具和管理环境,包括其所包含的元器件信息管理功能,Cap ture CIS完全地集成在设计的全过程中,以减少查找和手工输入元器件数据的时间。

Capture CIS产品包括:Capture CIS Studio和Capture CIS。

Capture CIS StudioCapture CIS Studio作为PCB Design Studio系列解决方案中的一个部分,它为设计人员提供了原理图输入的一个设计工作平台,包括Capture CIS的所有功能,并具有Allegro; Viewer的功能,是一个更加强大的设计输入解决方案。

Capture CIS是一个全面的输入和管理环境,包括内部的元器件信息系统管理功能,Capture CIS完全地集成在设计的全过程中,以减少查找和手工输入元器件数据的时间。

安装准备0.安装过程中,需要注意,第一,在自己设定安装路径时,不能出现空格,中划线,或者中文字样,并且不允许电脑插着U盘或者移动硬盘,电脑配置较低,建议不安装本软件,安装前关闭各种防护软件。

整个过程在30分钟以上,请安心等待。

1.首先对电脑进行简单设置。

2.桌面右击选择个性化,后选择Windows7 Basic3.打开用户账户选择“用户账户控制设置”(图2),进入账户设置(图3),选择从不通知。

重启电脑设置才能生效。

下面进入安装过程1.打开ROBCAD_9.0,选择Runme应用程序,双击打开,出现图示画面,点击Install Robcad9.0进入安装界面。

安装过程中,一直点击NXET,直至程序安装完成,直到安装成功,出现下图画面,选择不立刻重启,然后选择“Finish”,退出Runme 安装程序。

2.选择安装文件夹ROBCAD_9.0.1r_PC并打开,选择文件ROBCAD_9.0.1r_PC文件夹打开后选择Robcad901r文件,双击打开安装等待,中途出现“下一步”则点击“下一步”。

安装完成后出现下图,点击“finish”等待计算机重启。

3.开机后出现图,选择ok4.进入安装程序ROBCAD_9.0,选择bin文件夹中的roblms文件并复制,粘贴至文件安装位置C:\Robcad\bin\lm,(此路径为默认安装路径,如果安装文件位置变化,需要自己做出调整)。

5.进入安装程序ROBCAD_9.0,选择usr文件夹中.robcad并复制,粘贴至C:\Robcad\usr,(同样的不是默认的安装路径时,自己做出调整),到此基本完成安装过程。

6.再安转换插件(jt文件转换为co)7.装cad translater安装完成后,不需重启电脑,即可打开Robcad了。

AutoCAD 2012官方简体中文正式版安装说明:1.启动安装 Autodesk AutoCAD 20122.输入AutoCAD安装序列号: 666-69696969, 667-98989898,400-454545453.输入AutoCAD密匙: 001D14.完成安装,重启AutoCAD。

5.点击激活按钮之前你有两个选择:a)禁用您的网络或拔掉网线;b)点击激活后它会告诉您,您的序列号是错误的,这时点击上一步等一会再点击激活即可。

选择了a或b后看下一步。

6.在激活界面中选择我拥有一个Autodesk激活码7.一旦到了激活屏幕:启动注册机如果你是32位的请启用32位的注册机如果是64位的请启动64位的注册机。

8.先粘贴激活界面的申请号至注册机中的Request中,9.点击Generate算出激活码,在注册机里点Mem Patch键,否则无法激活,提示注册码不正确。

10.最后复制Activation中的激活码至“输入激活码”栏中,并点击下一步,即会提示激活成功。

AutoCAD 2012官方简体中文正式版(含注册机)下载页面其他AutoCAD版本autocad 2006/2008/2010/2011全功能龙幻简化版合集Autodesk??AutoCAD 2012软件介绍CAD是Computer Aided Design的缩写,指计算机辅助设计,美国Autode sk公司的AutoCAD是目前应用广泛的CAD软件。

Autodesk于二十世纪八十年代初为微机上应用CAD技术而开发了绘图程序软件包AutoCAD,经过不断的完美,现已经成为国际上广为流行的绘图工具。

具有完善的图形绘制功能、强大的图形编辑功能、可采用多种方式进行二次开发或用户定制、可进行多种图形格式的转换,具有较强的数据交换能力,同时支持多种硬件设备和操作平台。

AutoCAD可以绘制任意二维和三维图形,并且同传统的手工绘图相比,用AutoCAD绘图速度更快、精度更高、而且便于个性,它已经在航空航天、造船、建筑、机械、电子、化工、美工、轻纺等很多领域得到了广泛应用,并取得了丰硕的成果和巨大的经济效益。

Robcad 9.0安装说明一、系统需求硬件配置:●Intel Core 2 CPU 6600 @ 2.40 GHz or higher●RAM 2GB or higher●Graphic card nVidia GeForce or Quadro FX series 256MB or higher操作系统Windows XP SP2 is required.二、软件安装2.1 卸载旧版本Robcad如果电脑上安装有旧的版本,请先卸载旧的版本,将下图3项均选中卸载。

卸载完旧版本之后重新启动电脑2.2 安装Robcad 9.0①运行RunMe.exe,点击Install Robcad 9.0②点击Next③选则安装路径,然后点击Next④继续点击next安装过程中会自动安装下面的两个软件⑤安装完毕,选择Yes,点击finish。

重启电脑后点击确定即可完成安装。

2.3 安装Robcad Online help运行RunMe.exe,点击Install online help2.4 安装Robcad CAD Translators①运行RunMe.exe,点击Install CAD Translators,一直选择Next即可2.5 配置license①开始→所有程序→tecnomatix→license→lmtools.exe,在对话框中选择config serviers,按照步骤1-5进行操作。

②切换到start/stop/reread ,1、点击strart server ,2、然后点击reread license file ,确定对话框下方提示栏中提示信息为reread server license file completed③开始→所有程序→tecnomatix→license→license setup,在弹出对话框中选择license server/redundant license server,点击next,在first中填写服务器计算机名称(或者服务器的IP地址),port为默认的27006,然后点击finish。

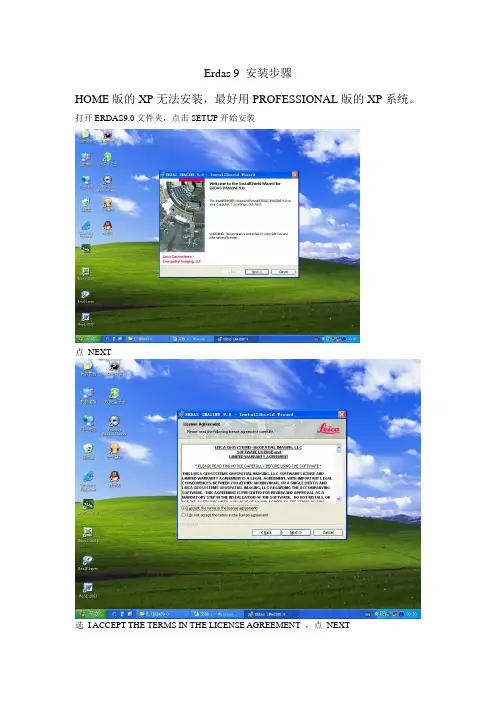

Erdas 9 安装步骤HOME版的XP无法安装,最好用PROFESSIONAL版的XP系统。

打开ERDAS9.0文件夹,点击SETUP开始安装点NEXT选I ACCEPT THE TERMS IN THE LICENSE AGREEMENT ,点NEXTNEXTNEXTINSTALL点FINISH打开E:\ERDAS9.0\crack ,运行lps9lic.exe 将此处的“勾”去掉点GO出现ENJOY!TEAM FCN 后点EXIT 退出。

打开E:\ERDAS9.0\crack ,将license9.DA T拷贝到C:\Program Files\LeicaGeosystems\Shared\bin\ntx86 下。

使用记事本打开license9.DAT文件此处改为你的计算机名计算机名改好后是这样然后保存关闭license9.DA T。

点开始——程序——LEICA GEOSYSTEMS——LICENSE TOOLS——FLEXLM TOOLS点 CONFIG SERVICES 选项卡将SERVICE NAME 改为ERDAS LICENSE MANAGER点BROWSE 选择LMGRD文件的路径:C:\Program Files\Leica Geosystems\Shared\bin\ntx86选择Lmgrd.exe文件点BROWSE 选择LICENSE文件的路径:C:\Program Files\LeicaGeosystems\Shared\bin\ntx86 选择license9.DAT点BROWSE 选择LOG文件的路径:C:\Program Files\Leica Geosystems\Shared\bin\ntx86 文件名处添LOGG按上图选好后点SA VE SERVICE点“是”点START/STOP/RETEAD 选项卡,先点STOP SERVER再点START SERVER,关闭LMTOOLS。

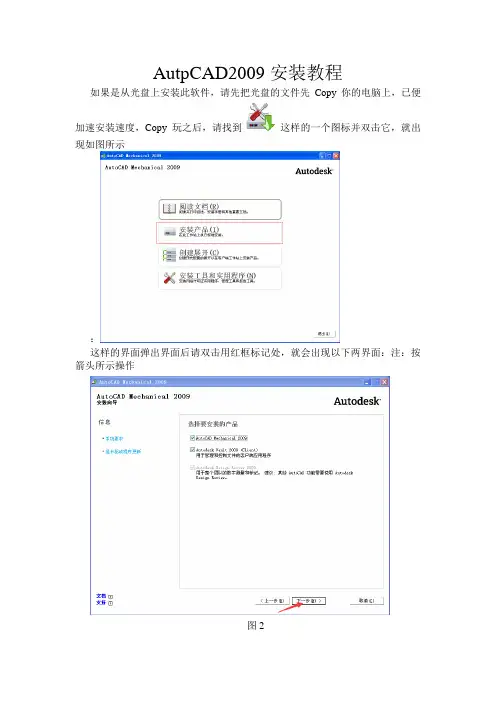

AutpCAD2009安装教程

如果是从光盘上安装此软件,请先把光盘的文件先Copy你的电脑上,已便

加速安装速度,Copy玩之后,请找到这样的一个图标并双击它,就出现如图所示

:

这样的界面弹出界面后请双击用红框标记处,就会出现以下两界面:注:按箭头所示操作

图2

这样就在初始化,初始化好后就会弹出下图:

选择我同意在点击下一步出现如图5所示:

在图5中填写你的序列号,姓氏等;再点击下一步,弹出图6

图6

图6中要注意的是这里有两种配置:默认配置和自定义配置,默认配置就是选择单机许可,我选择的是自定义配置

首先点击图中的配置选项,会出现图7所示:

图7

这样就在自定义配置,(注意:这里许可类型要选择下)自定义配置完后就会出现图8所示:

图8

在点击图8中安装就弹出图9所示

到这里所有的安装进程就玩了,等图9中安装完就以了。

autocad2009怎么安装?autocad2009安装方法发布时间:2022-09-09 作者:郑琦希很多刚学CAD的朋友都会遇到软件的安装问题,今天小编就带大家来共同学习autocad2009安装方法,希望可以帮助到有需要的小伙伴哦,下面就是详细完整的操作步骤。

autocad2009怎么安装?...很多刚学CAD的朋友都会遇到软件的安装问题,今天小编就带大家来共同学习autocad2009安装方法,希望可以帮助到有需要的小伙伴哦,下面就是详细完整的操作步骤。

autocad2009怎么安装?autocad2009安装方法第一步:解压下载的CAD2009文件包右键点击解压文件。

解压文件保持默认就好。

但是要注意我们解压出来的文件不能放在有中文字的文件夹里。

2第二步:开始安装在解压出来的文件里面找到“setup”安装程序双击运行。

3第三步:确认安装CAD2009 32/64位中文版点击“安装产品”开始安装如图三。

4第四步:选择自己要安装的产品第一个必选第二个看个人的需要自行安装点击“下一步”继续如图四。

5第五步:进入协议界面国家地区选择“China”勾选“我同意”点击“下一步”继续。

6第六步:CAD2009 32/64中文版的产品信息输入CAD2009 32/64位中文版的用户信息自己随意填写即可点击“下一步”继续。

7第七步:CAD2009 32/64位中文版的安装目录及属性点击“配置”可以修改CAD2009 32/64位中文版的配置确定后点击“安装”开始安装CAD2009 。

8第八步:正在安装CAD2009 32/64位安装CAD2009 32/64位中文版中请耐心等待一下......9第九步:安装完成。

开始激活点击“完成” 这样CAD2009 32/64文中文版就安装完成了以上这里为各位分享了autocad2009安装方法。

有需要的朋友赶快来看看本篇文章吧!郑重声明:本文版权归原作者所有,转载文章仅为传播更多信息之目的,如作者信息标记有误,请第一时间联系我们修改或删除,多谢。

Table of ContentsChapter 1. Introduction to eM-Workplace1.1Basics of Robcad operation 1.2View Control in e-M Workplace 1.3Entity and component conceptChapter 2. Modeling2.1 Setup World2.2 Display tool 2.3 Files2.4 Modeling Basics2.5 Opening and editing of direct models in rob cadChapter 3. Fundamentals of Kinematics3.1 Assigning Kinematics 3.2 Creating Devices3.3 Reading the States Command 3.4 DataChapter 4. Processing4.1 Creation of Library and project,4.2 Project and library setting.4.3 Placement of Robots and tools ( Work cell buildup)4.4 Tool V alidation (Static Collision)4.5 Auto placeChapter 5. Paths generations5.1 Creation of locations5.2 Robot path Creation. (Path editor)5.3 Attribute Assignment 5.4 Robot motions setting 5.5 Tcp settingChapter 6. Simulation6.1 Simulation of motion function: Move Commands 6.2 Path Finalizing and Dynamic collision detection 6.3 Interference checkingChapter 7. eM–Spot Worldw.d oc u -t r a c k.cwo7.1 Generation of weld location7.2 Different options to create weld location 7.3 Creation of weld tcp and remote tcp 7.4 Weld path editor 7.5 Spot setupChapter 8. eM OLP.8.1 Olp editor8.2 assigning attributes and different aux data 8.3 Assigning a simple sequence of operationChapter 9. Other applications9.1 Layer Menu 9.2 Tree Menu 9.3 Mc Rose9.4 View Manager 9.5 Note Editor 9.6 Report Creator 9.7 Program Editorw.d oc u -t r a c k.cwoChapter 1. Introduction to eM-Workplace :The eM-Workplace Workcell product enables the user to arrange graphically the components in a robotic workcell, and to verify the feasibility of the arrangement by simulating the operations which these components are intended to perform in the actual workcell. The user can customize the working environment individually for each robot controller with which the eM-Workplace system is intended to function. In addition, optional, special-purpose applications supplied with the eM-Workplace workstation, are utilized from within Workcell.Workcell facilitates designing a workcell by enabling the user to:Position and orient components in the workcell.Duplicate components.Attach components to each other.Write task files for use in simulations.Execute task files by means of an interpreter, without first compiling them.Move mechanisms or individual joints by motion commands and panels.To verify both the workcell and its tasks, Workcell notifies of:Violations of the limits of joint movements.Violations of speed and acceleration limits.Collisions and near misses.1.1 Basics of Robcad operationRobcad is a simulation software from which we can Create devices, assign kinematics, path creation and design validation, writing program to the robot etc. And mainly used to atomize the manufacturing industry .The basic Robcad window is a GUI, Looks as shown below.This is a main Menu Bar containing eMpower, Setup, Display etc.The above menu bar shows us the version of the Software ,work cell menu,cell name,project rootdirectory and pick instance.1.2: Layout:This is the Main menu of the workcell mode of the Robcad, from these options we can build up the workcell as per the given standard layout. And also this commands which arrange a station or workcell. These commands bring components to the workcell and change their placements. They permit storing modified workcells in the database as desired.The store command is deactivated until load cell is issued to load a workcell.The cell description window allows users to enter textual identifying descriptions for cells, and manually generate a cell preview. By using these options to create a text description and graphic thumbnail, users can then more accurately and quickly identify cells for loading, by viewing the description, graphic preview or using the Thumbnails option to view multiple cells in the directory.1.2.1:Load Cell:Mainly to load ie. to open the cell this option is used. The dialog displays an icon cell preview, if one was created, to enable accurate selection of the desired workcell. The Thumbnails options allows displaying thumbnail graphic previews of all cells in the directory, if previews were created.After selecting a cell, loads and displays a workcell in the database, replacing any previously displayed workcell. Beginning an eM-Workplace operating session opens a new workcell named noname. This command enables replacing that workcell with a specified workcell. If the workcell contains a single robot, that robot is selected as the active mechanism; its parameters appear in the data window. The workcell is loaded with its working frame situated at the origin of the graphics space.1.2.2:Get Cell:This option is used to Merge the no of cells and to make one big cell Merges a workcell with the displayed workcell. Brings to the graphics display the contents of a workcell in the database, constituting it as a group within the currently displayed workcell. The location of the merged workcell is specified as described for the create frame command, and a name for the merged workcell can be specified. This command is intended especially to merge with the existing workcell a component or group of another workcell that had been stored by means of the store as command. Selecting this command displays a browser window for finding the workcell directory: the window displays directories in the left scrollable region,and workcells in the right scrollable region. But the workcell must be located in the currentdirectory: the left scrollable region is deactivatedw.d oc u -t r a c k.cwo1.2.3:Get Component:It is the most commonly used option by which we can retrivethe component from the prescribed library to buildup the work cell.Which Brings from the database a specified component model, and locates it as describedfor the create frame command.w.d oc u -t r a c k.cwoSelecting get component displays a browser window for finding and locating the component:the window displays components in the right scrollable region. Selecting current project displays directories in the left scrollable region, but that region is deactivated to require that the component be taken from the current project. If libraries is selected, the left scrollable region displays libraries : special directories located under the root library directory the name of which the $LIB_ROOT environment variable holds. Each library contains components which many workcells can include, without the need to duplicate the components for each workcell. Any library may be selected: the left scrollable region is activated.1.2.4:Robot Envolope:Generates the work envelope of a robot.Generates and displays the work envelope of a specified robot, as an entity pertaining to the robot. This command produces the work envelope by using only joints 1, 2 and 3 to move the robot TOOLFRAME, where joint 1 is the joint attached to the base link; the base link is the link whose frame has been constituted as the BASEFRAME. The movement ofthese joints remains within their limits. A work envelope is illustrated below.w.d oc u -t r a c k.cwoThe robot must meet five criteria:1.The robot is articulated , having only rotational joints without any prismatic joint.2.The axes of joints 2 and 3 are parallel.3.The axis of joint 1 is perpendicular to the axes of joints 2 and 3.4.The axis of joint 1 lies on the extension of the plane that the TOOLFRAME describes when it is moved by varying only joints 2 and 3.5.The robot does not have “overhead” reach capability, i.e., the limits for joints 2 and 3render the robot incapable of bringing the TOOLFRAME to intersect the extended axis of joint 1.The work envelope is shown in light shading, but its display can be changed like that of any other entity. Except for modifying its display, however, other eM-Workplace commands do not affect the work envelope.The precision of the work envelope depends on a specified tolerance ; a specified clearance permits increasing the size of the computed envelope beyond the actual, maximum reach of the robot. If the system is unable to produce the work envelope itself, it generates and displays a closed curve showing the outline of the work envelope. This curve can be modified by eM-Workplace commands applicable to curves.Apart from these some of the other commands which are used to edit or create the entities in the workcells, which are like delete, create frame,working frame Group and ungroup and attach, detach.1.3:Setup:c ommands that define units and other parameters needed for variouseM-Workplacecommands.Color: Determines the color of eM-Workplace items. Selecting the command displays a color editing window listing the command parameters and showing four color bars. The three leftmost bars determine the values of the red, green and blue components in the resultant color. The numerical value corresponding to the height of each bar is displayed below the bar; the range is 0–255. The rightmost bar shows the resultant color. To modify the color of a eM-Workplacew.d oc u -t r a c k.cwoConfiguration:This is a very important command used in robcad, that facilitate setting many parameters for eM-Workplace workcells and applications. They permit storing the parameters in the database and then applying them to any workcell as desired. The parameters enable presetting most of the commands in the Setup menu, many of the commands in the Display menu, and other parameters. The values are assigned automatically by issuing corresponding eM-Workplace commands, and then by issuing the Configuration/store command.The configuration parameters are stored in a special robcad_config.xml file. When a workcell is loaded, the system searches for a file by that name in five locations, in the order as listed below,and presets the configuration parameters according to the contents of the first file it encounters:1.working_directory/robcad_config_<userLoginName>.xml.2.working_directory /robcad_config.xml. This file permits preparing custom configurations to meet the exigencies of a specific application. To produce this file, prepare a $HOME/robcad_config.xml file as described for 2, below, and then copy it to the working directory by means of the copy command in the Data/File Utilities submenu.3.$HOME/robcad_config.xml, where $HOME represents the home directory of the current user.This file permits each user to prepare a configuration file to meet specific needs or to express personal preferences. To produce this file, prepare the configuration as desired, and issue the store command with the user parameter.4./usr/local/robcad/usr/robcad_config.xml. This file enables establishing a standard for all users of the eM-Workplace workstation. To produce this file, first prepare a $HOME/robcad_config.xml file as described for 2, above, and then copy it to the /usr/local/robcad/usr directory by means of the copy command in the Data/File Utilities submenu.5.$ROOT/dat/robcad_config.xml, where $ROOT is the eM-Workplace installation directory:the default installation directory is /usr/local/robcad. This file is the default supplied with the eM-Workplace system;it should not be modified .In addition to the five robcad_config.xml files listed above, a file having any desired name with a .xml suffix can be placed in the $HOME/ROBCAD directory; the load command can then use this file to modify the configuration of the current workcell as desired. The store command produces both this file and also the file described in 2, above.If the Cell View/store command under the Viewing header in the Display menu has been invoked for a particular workcell, it overrides corresponding configuration parameters.Hot Key viewer:All possible user hot key combinations are organized and displayed in a ers may configure hot key combinations to match those they commonly use in their preferred CAD systems (e.g., display all =Ctrl+A ). The setup file robcad.hotkeys contains the default settings and is stored in the /$ROBCAD/dat directory. Users may not modify hot key shortcuts that use function keys, or that enable viewing controlled by the mouse or keyboard (e.g.,Ctrl+Arrow up for zooming in). The setup file is loaded together with eM-Workplace only once, preventing users from editing the values during a working session in a similar way to the loading of the .robcad file.w.d oc u -t r a c k.cwoThe following table lists the hot key combinations that users can customize:Operation description Blank paths Shift p Blank locations Shift l Blank local locations Shift x Blank global locations Sh Blank local paths Shift v Blank global paths Shift b Toggle display Ctrl a Display all Ctrl t Display paths Ctrl p Display locations Ctrl l Display local locations Ct Display global locations Ctrl gDisplay local paths Ctrl v Display global paths Ctrl b Open Setup menu Alt s Open Display menu Alt d Open Layout menu Alt l Open Sop menu Alt o Open Query menu Alt q Open Data menu Alt a Save cellCtrl s Status window menubar Ctrl mStatus window update Ct Undo Ctrl u w CenterAlt vw.d oc u -t r a c k.cwoThe following table lists the hot key combinations that may not be modified:Operation description Shortcut Graphic window local setup F5Graphic window display mode F10Graphic window full view F3Graphic window global setup F6Graphic window pick intent F11Graphic window pick level F12Keyboard viewing zoom in Alt arrow up Keyboard viewing zoom out Alt arrow down Keyboard viewing pan up Shift arrow up Keyboard viewing pan down Shift arrow down Keyboard viewing pan left Shift arrow left Keyboard viewing pan right Shift arrow right Keyboard viewing rotate up Arrow up Keyboard viewing rotate down Ar Keyboard viewing rotate left Arrow left Keyboard viewing rotate right Arrow rightMouse viewing zoom in Middle button drag left Mouse viewing zoom outMiddle button drag rightMouse viewing zoom window in CtMouse viewing zoom window out Shift&Alt left button Mouse viewing pan Right buttonRotate around viewcenter Middle&right buttons Rotate around viewpoint Ctrl middle&right buttons Online help F1 / Help (on Sun)UI form copy list F7UI form paste list Shift F7 / F8UI form okF9Window output menuF4Apart from these some simple commands are floor, motion, project and units.w.d oc u -t r a c k.cwo1.4:Display:This command is same for all the pages. Mainly used to change thedisplay property of the cell and the entities.And which affect in various ways the display in the graphics windows. If more than one graphics window is open, these commands affect allof them.w.d oc u -t r a c k.cwo1.6:DATA: MENU of submenus containing commands that enhance the flexibility of the eM-Workplace system by providing a means for displaying and manipulating data in the database.The eM-Workplace system uses data comprising workcells, components, and various files not included as part of the workcells and components. A workcell is constituted as a directory containing the various data files needed to describe the workcell; its name has a .ce suffix. A component is similarly constituted as a directory containing the various data files needed to describe the component; its name has a .co suffix. A directory containing workcell and component directories, together with task, connection, simulation and other files as needed for a complete eM-Workplace work session, is designated a project .w.d oc u -t r a c k.cwoThe pack and go is utilized toseparate the cell and its respective library from the main library. And other options are like cad import and cad export and project,& library utilities.Views Control in eM-Workplace.(Mouse Right click Menus.)Chapter: 2 Modeling And Kinematics:In order to use the eM-Workplace system to simulate a workcell, or car-parts station, the workcell must be equipped with components either supplied with eM-Workplace or designed by the user. One example of a component is a fixture unit , a mechanical system that uses force to hold two car parts together. Its objective is to remove all degrees of freedom before welding occurs, and to ensure that movement does not occur during welding.It must be designed to avoid collision with adjacent units and with the welding gun, and to minimize the cost of manufacture. The eM-Fixtures product constitutes components as fixture units.The eM-Workplace Modeling and eM-Fixtures products enable designing units as well as all of the other components that a station may require, and also facilitates modifying existing designs. The components can range from simple production workpieces to functioning mechanisms.Units can be modeled either individually or as part of a station; if the latter, the stationremains displayed as desired throughout the use of the Modeling and eM-Fixtures products.The component being modeled is always an instance of the component prototype that occurs in the database as a directory with a .co suffix appended to its name. A station can contain one or more instances of a component prototype; the component being modeled can be one of these instances, or it can be an instance of an existing component not present in the station, or it can be an instance of a new component.The Modeling and eM-Fixtures products utilize advanced CAD techniques for three basic operations:1.Constructing primitive and composite bodies.2.Producing mechanisms, i.e., kinematic components.3.Utilizing viewing and placement functions.Solid bodies are constructed in four different ways:üSweeping or revolving surfaces into solid entities.üGenerating 3D primitive bodies.üCombining 3D primitive bodies by means of Boolean operations.üCombining 3D primitive bodies by means of assembly operations.üDesigning a mechanism includes defining its joints, specifying for each joint:The type of the joint:rotational or prismatic (linear).The parent (controlling)link and the child (controlled)link .The position and orientation of the axis of each joint.The limits of the motion, speed and acceleration of each joint.Whether or not motion depends on other joints.If the joint is part of a closed loop constituting a four-bar linkage.Apart from this we can also directly open the modeled component and modify etc.w.d oc u -t r a c k.cwo2.1: Files:This initiate, conclude, and otherwise affect the current modeling session. Ifthe open command has initiated a modeling session for a component, the load cell command is deactivated . To activate the load cell command, issue close to terminate the modeling session.Load Cell: Loads and displays a workcell in the database, replacing any previously displayed workcell. Beginning a Modeling operating session opens a new workcell named noname. This command enables replacing that workcell with a specified new or existing workcell.Open: Brings a component to the display and initiates a modeling session.Initiates a modeling session for a component, and loads an instance of a component prototype. The instance can be selected from a component instance present in the currently displayed workcell, or it can be an instance of an existing component prototype, or it can be an instance of a new component that does not yet occur in the database as a prototype. The component instance can be edited either independently or as part of a currently displayed workcell. If it is a new component instance being edited as part of a workcell, its location in the workcell can be specified as described for the create frame command in the Workcell Layout menu. If it is edited independently, the workcell is unloaded.Close: Terminates a modeling session with a component. If the component loaded by the open command has been modified by means of Toolbox commands, either its prototype in the database can be updated accordingly, the same as issuing the save command, or thechanges can be discarded.w.d oc u -t r a c k.cwoGet Subcomponent:Brings from the database a specified component model, andlocates it as described for the Workcell Layout/create frame command. The component is constituted as a subcomponent of the component being modeled.Current Library: Specifies the current library for the component. and used to load the component from the appended library. Specifies either a library or the working directory (“current project”) for use during the current operating session. A library is a special directory located within the library root directory: either the default /usr/Robcad/LIBRARIES directory, or another directory as specified by the Setup/Projects/set library root command.Save as New Component:By this option the entity of a component can be saved separately in a different name. Constitutes as an eM-Workplace prototype component a list of specified entities in the graphics space. The component that results from the operation is placed in the current project, and is independent of the root component (unit) being modeled.The origin frame of the new component is superimposed on the working frame.Apart form these some of the direct modeling tools are explained and shown in tool bar manager.2.2: Features:PIPES: This will generate and edit various and sundry pipes . To generate a pipe, specify first the name of a new or existing pipe, then the cross section of the pipe, and finally the curve that determines the run of the pipe. Duly specifying these parameters activates the accept item; the successfully produced pipe is displayed both in the main graphics window and also in a separate graphics window that opens to display exclusively the pipe.BEAM: This will create beams . To generate a beam, specify first the name of a new or existing beam, and then the cross-sectional profile that is swept to produce the beam.Finally specify either the starting and end points, or else the starting point and the direction and length, to determine the direction and distance to sweep the profile: unlike pipes, beams are always straight. Duly specifying these parameters activates the accept item; selectingaccept generates the beam and displays it in the main graphics window.This menu containing three submenus. The Pipes submenu contains commands for producing various kinds of pipes; the commands in the Beams submenu create beams; the commands in the NC Blocks submenu produce various kinds of numerical-control (NC) blocks.w.d oc u -t r a c k.cwoNCBLOCKS: create and evaluate NC block s . NC blocks are the only parts of a unit that contact the car-part surface; they are positioned at the end of clamps. To prevent possible damage to the car part, the NC blocks should conform to the shape of the car-part surface.To ensure the accuracy of the contact surface of the NC blocks,numerical control (NC)machines fabricate them. Three numerical-control machine manufacturing processes areused to fabricate NC blocks: Five-Axis Milling, Three-Axis Milling, and Electric-Discharge Machine (EDM). eM-Workplace currently supports only Five-Axis Milling and EDM. The Five-Axis Milling process fabricates the NC block by cutting its contact surface in three dimensions. This process is used when the NC block is generated by means of the NC Block/cut command. The EDM process fabricates the NC block by cutting its contact surface in “two and a half”dimensions: a 2D contour is swept along the normal to its plane to produce a 3D NC block. This process is used when the NC block is generated by using the NC Block/sweep or ruled nc block command. It is a less expensive process than Five-Axis Milling, and can be used when the car-part shape varies only in the two dimensions of the contour.Before creating an NC block, perform two steps from within eM-Line:1.Issue the read or assign option of the eM-Line Prepare/Import/PLPs command to create a PLP on the car part at the desired clamping location for each NC block to be created. Assign to the PLPs a function of clamping or resting.w.d oc u -t r a c k.cwow.d o cu-t r a c k.cw o2.3: Tool Box Manager:It is Combination of all tools which includes 2-D,3-D and Surface editing tools.PANEL of icons (toolboxes) that represent commands and submenus, located at the lower-right corner of the eM-Workplace display. This document describes only the toolboxes that constitute part of the Modeling product. The remaining toolboxes are separate applications and are described separately.2.3.1General tool:123 4 5 6This tool is divided in to threesection like EDIT,FRAME andGROUPS, that edit in various waysa unit, component or other entity;that generate frames, move theworking frame, and displayself-origin frames; and create andedit groups and assembliesw.d o cu-t r a ck.cw o2.3.2: 2-D Sketcher:If solid creation specifies polyhedral approximation, these solids are represented as polyhedral approximations with a specified number of sides.These commands can be used with a 2D graphics window as opened by the 2D Window/open command, in order to produce a umerical-control (NC)block for holding a workpiece. The modifications can be effected, however, either in the 2D graphics window or in the main graphics window; the results appear simultaneously in both windows.2.3.3: 3-D Sketcher:This is a command by which we can generate and edit solidentities in the graphics space. They generate various solid primitives, and combine these primitives by means of three Boolean operations. The solid creation command specifies whether the system generates solids that are represented exactly, or as polyhedrons with a specified polyhedral approximation: it specifies the number of sides for the approximation.We can also create the primitive objects like cube, box, wedge, cylinder, cone, sphere, torus and ring commands each generates a solid either with its frame superimposed on a specified frame , or such that the origin of its frame is placed on a point and its Z axis is parallel to a line, with the other two axes of its frame having an arbitrary orientation. The frame can be specified by selecting any individual frame, or by selecting an entity for which to use its frame, or it by picking anywhere in the graphics space. The last option places the origin of the frame of the solid at the projection of the picked point onto the working plane, the X-Y plane of the working frame; and orients the frame parallel to the working frame. The Subtool is shown below.This is a special 2-D tool used to create may geometrical features in the modeling world.The created geometries are used either in the 3-D operation or in the kinematics. And these are the simple 2-d tool options which are created same as in the other engineering tools like Auto cad, CA TIA etc. which generate and edit entities in the graphics space. These entities have fewer than three dimensions; they include points, lines, polylines, arcs, circles,and curves. The Edit commands produce polylines from curves and polygons from polylines; the sweep commands produce solids from curves. If the solid creation command in the 3D Sketcher submenu specifies exact, the solids are exact representations.w.d oc u -t r a c k.cwo3-D Sketcher.2.3.4: Surface:which generate and edit surfaces in the graphics space. All of thesesurfaces are true surfaces, but no planar surfaces are displayed as faceted.The frame of the surface that the revolution, ruled through curves, surface by border, sweep along direction and offset surface commands produce, is superimposed on the origin frame of the component being modeled. The frame of the surfaces that the rectangle by diagonal,polygon, polygon by points, and polygon from curve commands produce, is located at the center of the surface with the Z axis normal to the surface and the X axis pointing to a system-determined first vertex .2.3.5: Query:This command is used to know the information of the component,measurethe entity,and to know the unit etc,,like wise to enquire regarding the entity mainly this command is applicable.And the Placement editor is extensively used to move place or put and many moreoptions, is explained seperatly in the other chapterw.d oc u -t r a c k.cwo。

Robcad9.0.1在win10 64位下安装教程一、用虚拟光驱加载Robcad_9.0.1.isz文件。

请按照文件夹中的顺序进行安装。

二、安装Robcad 9.01.打开01_ROBCAD 9.0文件夹,双击“RunMe.exe”文件进行安装2.出现下面画面中点击“Install Robcad 9.0”3.安装地址不能有空格,所以一般选择默认就好01 Robcad 9.0安装文件02 Robcad 9.0.1升级文件03 破解文件04 转co的插件05 Robcad 9.0.1插件4.一路点击“Next”直到安装成功,选择“否,我稍后重启电脑”,然后点击“Finish”。

三、升级到Robcad 9.0.11.打开02_ROBCAD_9.0.1r_PC文件夹,右键单击Robcad901r.exe文件,选择“以管理员身份运行”2.点击“Next”直到安装完成,这次选择“现在重启”,然后点击“Finish”后重启电脑3.重启后会自动进入下面界面4.在下面红框的图标中点击右键,选择“Exit”退出Exceed。

四、破解1.复制03_Crack\bin\lm文件夹下面的roblms.exe,替换到“C:\Robcad\bin\lm”下面2.复制03_Crack\dat文件夹下面的“.robcad”文件到“C:\Users”下面(中文系统显示“C:\用户”)五、安装Translators_3.0转换插件(此插件可以将catia文件转换成co文件)1.打开“04_CAD_Translators_3.0_x64_PC”文件夹,双击“setup.exe”文件进行安装2.点击“Next”,直到安装结束,点击“Finish”结束安装。

六、安装补丁1.解压05_ROBCAD9.0.1_Patch.rar到任意文件夹,双击其中Patch_setup.bat安装补丁文件。

2.等待安装完成:在setup.log文件最后可以看到如下的信息,就说明安装成功。

QC9。

0的安装前准备与安装一、QC的安装前准备1。

安装环境:windows xp/window 20032.安装sql server2005并下载sp3补丁包安装/Oracle 数据库(也可以不安装数据库,但需要知道一个数据库服务器的名字和管理员的登录名和密码)二、QC的安装1。

在QC安装文件中找到qc9.0\Installation\setup.exe,双击后进行安装2.点击下一步3、出现如下界面,然后导入QC9。

0的破解lincese文件,点击“下一步”说明,license文件如下,把下面的红色字体内容粘贴在文本文件中,然后后缀名改为qc90.txt即可(文件名自己任意命名,只要保证后缀名是txt即可)〈?xml version=”1。

0" encoding=”UTF—8”?〉〈license〉〈terms><issued_to〉rapidhorse。

com。

cn</issued_to〉〈license_identifier>SN732563653〈/license_identifier〉〈edition〉enterprise〈/edition〉<evaluation>N</evaluation〉〈start_date〉12/13/2007〈/start_date><expiration〉5/29/2099〈/expiration>〈full_test_director>500</full_test_director〉〈additional_defects>500〈/additional_defects〉<tolerance>0%</tolerance>〈requirements〉Y</requirements〉〈advanced_reports〉Y</advanced_reports〉〈business_process_testing〉500〈/business_process_testing〉<version_control〉Y</version_control><dashboard〉Y</dashboard〉〈/terms〉〈Signature〉lA0FAVrF+UTDW2qVIDjVPCSpPKRUpKcoTO8/GI95D1RLIzQAq/8mv+HnIGQ0Grv9am8QK HfncRsARR153QxqKw==</Signature〉</license〉4。

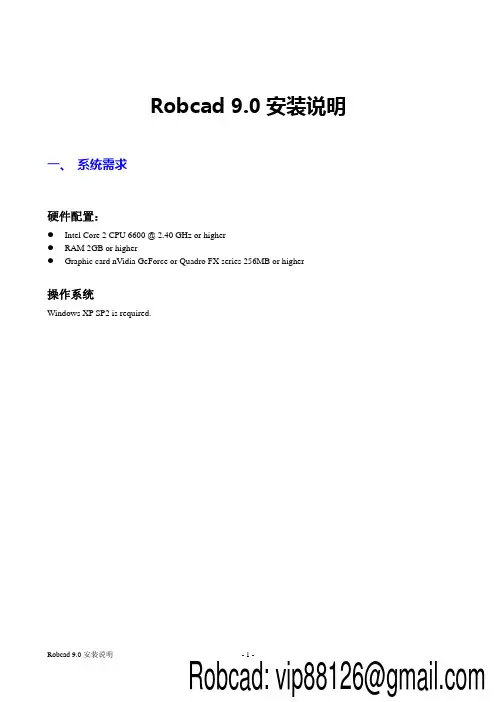

Robcad 9.0安装说明

一、系统需求

硬件配置:

●Intel Core 2 CPU 6600 @ 2.40 GHz or higher

●RAM 2GB or higher

●Graphic card nVidia GeForce or Quadro FX series 256MB or higher

操作系统

Windows XP SP2 is required.

二、软件安装

2.1 卸载旧版本Robcad

如果电脑上安装有旧的版本,请先卸载旧的版本,将下图3项均选中卸载。

卸载完旧版本之后重新启动电脑

2.2 安装Robcad 9.0

①运行RunMe.exe,点击Install Robcad 9.0

②点击Next

③选则安装路径,然后点击Next

④继续点击next

安装过程中会自动安装下面的两个软件

⑤安装完毕,选择Yes,点击finish。

重启电脑后点击确定即可完成安装。

2.3 安装Robcad Online help

运行RunMe.exe,点击Install online help

2.4 安装Robcad CAD Translators

①运行RunMe.exe,点击Install CAD Translators,一直选择Next即可

2.5 配置license

①开始→所有程序→tecnomatix→license→lmtools.exe,在对话框中选择config serviers,按照步骤1-5进行操作。

②切换到start/stop/reread ,1、点击strart server ,2、然后点击reread license file ,确定对话框下方提示栏中提示信息为reread server license file completed

③开始→所有程序→tecnomatix→license→license setup,在弹出对话框中选择license server/redundant license server,点击next,在first中填写服务器计算机名称(或者服务器的IP地址),port为默认的27006,然后点击finish。