FDA最新版-药物分析程序及方法验证指导原则-中文翻译版

- 格式:docx

- 大小:22.21 KB

- 文档页数:8

药品及生物制品的分析方法和方法验证指导原则目录1.介绍 (1)2.背景 (2)3.分析方法开发 (3)4.分析程序内容 (3)A.原则/范围 (4)B.仪器/设备 (4)C.操作参数 (4)D.试剂/标准 (4)E.样品制备 (4)F. .................................................................................................................... 标准对照品溶液的制备 (5)G.步骤 (5)H.系统适应性 (5)I.计算 (5)J.数据报告 (5)5.参考标准和教材 (6)6 分析方法验证用于新药,仿制药,生物制品和DMF (6)A.非药典分析方法 (6)B.验证特征 (7)C.药典分析方法 (8)7.统计分析和模型 (8)A.统计 (8)B.模型 (8)8.生命周期管理分析程序 (9)A.重新验证 (9)B.分析方法的可比性研究 (10)1.另一种分析方法 (10)2.分析方法转移的研究 (11)C.报告上市后变更已批准的新药,仿制药,或生物制品 (11)9.美国FDA 方法验证 (12)10.参考文献前言本指导原则草案,定稿后,将代表美国食品和药物管理局(FDA)目前关于这个话题目前的想法。

它不会创造或赋予或任何人的任何权利,不约束FDA 或公众。

您可以使用另一种方法,如果该方法符合适用的法律和法规的要求。

如果你想讨论一个替代方法,请与FDA 工作人员负责实施本指南。

如果你不能确定适当的FDA 工作人员,请拨打本指南的标题页上所列的电话号码。

介绍:该修订指南草案将取代行业2000 年的指导分析方法和方法验证草案,并最终确定后,也将取代1987 年美国FDA 行业指南《提交的样品和分析数据的方法验证》。

该草案提供了有关申请人如何提交分析程序和方法验证数据来支持说明原料药和制剂具有强度、质量、纯度和效用的文件。

FDA指导原则(中文)目录仿制药晶型研究的技术指导原则.pdf口服固体制剂溶出度试验技术指导原则.pdf口服缓释制剂体内外相关性研究技术指导原则.pdf改变制剂处方和变更药物给药途径的非临床安全性评价技术指导原则.pdf 终端灭菌产品实施参数放行的相关申报资料要求.pdf制剂注册申请对所附原料药生产工艺资料的要求.pdf药用辅料的非临床安全性评价技术指导原则.pdf原料药、药用辅料及包材申报资料的内容及格式要求(DMF).pdf无菌制剂生产质量管理规范.pdf无菌工艺验证资料的申报要求.pdf工艺验证的一般原则和方法.pdf药物临床安全性评价审评报告撰写指导原则.pdf药品审评质量管理规范.pdf生物利用度和生物等效性试验生物样品的处理和保存要求.pdf群体药代动力学研究技术指导原则.pdf食物对生物利用度的影响以及餐后生物等效性研究技术指导原则.pdf临床试验中人种和种族数据收集的技术指导原则.pdf因临床研究者失职叫停临床试验的相关规定.pdf药物上市前风险评估的技术指导原则.pdf药物警戒管理规范和药物流行病学评估技术指导原则.pdf药物肝毒性评价技术指导原则.pdf药物代谢产物安全性试验技术指导原则.pdf现有治疗手段的界定及对新治疗手段的评估技术指导原则.pdf人体首剂最大安全起始剂量的估算.pdf新药临床试验用样品制备技术指导原则.pdf新药Ⅱ期和Ⅲ期临床试验药学申报资料的内容及格式要求.pdf新药Ⅰ期临床试验申报资料的内容及格式要求.pdf临床研究进程中沟通交流会的药学资料准备要求.pdf临床试验中应用计算机系统的技术指导原则.pdf临床试验数据监查委员会的建立与工作技术指导原则.pdf紧急临床研究免除知情同意的相关规定.pdf风险最小化执行方案的制定和完善的技术指导原则.pdfⅡa期临床试验结束后沟通交流会的有关要求.pdfⅠ期临床试验用样品的生产质量管理规范.pdf获得药品临床研究有效性证据的技术指导原则.pdf已上市药品和生物制品增加新的抗肿瘤适应症的技术指导原则.pdf已上市抗肿瘤药物开展新的临床试验豁免申请的相关要求.pdf预防和治疗糖尿病药物研究技术指导原则.pdf血脂调节药物临床评价技术指导原则.pdf对抗肿瘤药物上市申请临床数据的相关要求.pdfⅡ型糖尿病新药研发中的心血管风险评价技术指导原则.pdf抗肿瘤药物临床试验终点的技术指导原则.pdf抗逆转录病毒药物进行HIV耐药性检测的技术指导原则.pdf 抗病毒药物病毒学研究的申报资料要求.pdf抗菌药物采用非劣效性临床研究技术指导原则.pdf。

项目调试和确认指南1.简介2.本指南的目的、关键概念及定义3.影响评估4.GEP (工程质量管理规范)MISSIONING(项目调试)6.QULIFICATION PRACTICES(确认操作管理规范)7.ENHANCED DESIGN REVIEW(进一步设计审核)8.安装确认9.运行确认10.性能确认11.相关程序1、简介和以前出版的指南一样,Commissioning(项目调试)和Qualification(项目确认)由国际制药工程协会的医药咨询理事会发布,在Commissioning(项目调试)和Qualification(项目确认)指南中所有的方案、指南及技术指导由指导委员会提供。

本指南应用范围本规程适用于药厂建造符合FDA或其他卫生部门规范的生产设施的设计、建造、调试移交及确认,该指南既不是一种标准也不是GMP的规定,它不能取代法定标准、准则、规程。

该指南只是有助于建造符合cGMP要求的公共设施、设备等。

该指南需要谨慎应用。

本指南重点在于工程方法和工程施使,以及及时地提供满足预计要求的经济实用的生产设施,具体来说,使设施、设备和公用设施的设计、建造、调试及确认符合FDA或其他卫生部门要求。

本指南不是为了解决工艺或产品验证的问题,本指南得到FDA和其他权威部门的认定。

Commissioning(项目调试)和Qualification(项目确认)是工序验证的基础,进一步讲,这些操作在提供有效、安全、高效率的设施、设备和公用设施运作起着至关重要作用。

因此,在Commissioning(项目调试)和Qualification(项目确认)操作中实施综合、全面的方案是非常重要的,一套较好的构思和实施Commissioning(项目调试)和Qualification(项目确认)防范能达到及时地、经济实用的验证效果。

本指南只提出了一些对Commissioning(项目调试)和Qualification(项目确认)程序有影响的非工程方面的软件问题,例如,系统支持,文档问题,决定程序等,这些软件对于项目工程师来说比较重要。

E6(R2)人用药品注册技术要求国际协调会ICH协调指导原则ICH指导委员会2016年11月9日当前版本:第四阶段中文编译:中国GCP联盟 & 临床研究大汇E6(R1)译者序公元1996年,ICH-GCP正式发布R1版,彼时之中国,了解GCP的人仅限于当时中国卫生部培养的数百名医学专家,规范的临床试验法规与体系还在起草中。

1998年3月卫生部而发布了中国第一部GCP(试行),同年5月实施;1998年国务院机构改革成立了国家药品监督管理局,1999年9月1日实施的《药品临床试验管理规范》(局令13号,已废止),在整整4年之后的2003年9月1日,我国的GCP,《药物临床试验质量管理规范》(局令第3号)颁布实施并持续至今。

受制于起步阶段的能力所限,我们的GCP法规只有70条款共计12998字,而对比ICH-GCP则有383条款共计27936单词。

R1版的ICH-GCP,2003年国家药监局中国药品生物制品检定所获权组织专家翻译,才有过中文版(未曾公开发布),陆续有过多个版本的企业/组织发布版本,而以国家药品审评中心(CDE)发布的官译稿件,时间却很明确,是在2016年8月5日才得以发布(如下图)。

可以说,无论是标准的水平高低还是时代的步伐快慢,我们都曾落后了太多太多。

人生如梦,岁月如歌,春去秋来,夏行冬至。

二十载岁月匆匆而过。

2016年11月30日,ICH正式颁布了GCP的增补件R2,标志着全球药物临床试验进入到了一个崭新的时代,无独有偶,仅仅过去了2天,2016年12月2日,中国国家食品药品监督管理总局发布了《药物临床试验质量管理规范》的第二次征求意见稿,大量新内容参考了ICH-GCP R1甚至R2,意见稿直接以超30000字的信息量向全中国全世界展现它的雄心:今天的和未来的中国药物临床试验,在经历了蹒跚学步与青春期的躁动之后,正大幅度的向着国际先进水平看齐。

天行健,君子当自强不息,“中关村玖泰药物临床试验技术创新联盟/中国药物临床试验机构联盟”携手“临床研究大汇”,有志于协助我国临床研究行业在这次革新中及时跟上时代潮流,我们在R2发布后的7日内,参考借鉴CDE的R1中文版,完成了中文版的翻译与校对工作,在此时正式向全球华语用户推送,由于时间紧,我们的工作可能有不足之处,在此虚心并诚恳的接受所有批评意见。

药物分析专业词汇中英文对照绪论释药系统(drug delivery system,DDS)中国药典(Chinese Pharmacopoeia,ChP)美国药典(The United States Pharmacopoeia,USP)美国国家处方集(The National Formulary,NF)英国药典(British Pharmacopoeia,BP)欧洲药典(European Pharmacopoeia,Ph.Eup)国际药典(The International Pharmacopoeia,Ph.Int)良好药品实验研究规范(Good Laboratory Practice,GLP)良好药品生产规范(Good Manufacture Practice,GMP)良好药品供应规范(Good Supply Practice,GSP)良好药品临床试验规范(Good Clinical Practice,GCP)分析质量管理(Analytical Quality Control,AQC)第1章药物的鉴别试验药物的鉴别试验identification test一般鉴别试验general identification test专属鉴别试验specific identification test灵敏度sensitivity最低检出量minimum detectable quantity最低检出浓度minimum detectable concentration第2章药物的杂质检查巯基醋酸mercaptoacetic acid古蔡氏Gutzeit二乙基二硫代氨基甲酸银siliver diethyldithio-carbamate硫酸灰分sulphated ash炽灼残渣residue on ignition热重分析法thermogravimetric analysis,TGA差示热分析法differential thermal analysis,DTA差示扫描量热法differential scanning calorimetry,DSC碱性酒石酸铜试验Fehling’s reagent异红紫酸盐isopurpurate2,3-二氨基萘2,3-diaminonaphthalene4,5-苯并苯硒二唑4,5-benzopiazselenol第3章定量分析样品前处理与测定方法的效能指标汞齐化法amalgamation method氧瓶燃烧法oxygen flask combustion method葡萄糖醛酸甙glucuronides硫酸酯sulphates血浆plasma血清serum全血whole blood治疗药物浓度监测therapeutic drug monitoring,TDM结合bound游离free缀合物conjugate l液-液提取法liquid-liquid extraction,LLE离子对试剂ion pair reagent离子对提取法ion pair extraction method反离子counter液-固提取法liquid-solid extraction LSE半自动样品制备系统advanced automated sample processor,AASP 烷基化alkylations酰基化acylations L硅烷化silylations精密度precision标准差standard deviation,SD orS相对标准差relative standard deviation变异系数coefficient of variation,批内精密度within-run precision日内精密度within-day precision批间精密度between-run precision日间精密度day to day precision准确度accuracy定量限limit of quantitation,LOQ检测限limit of detection,LOD选择性selectivity专属性specificity线性与范围linearity and range重现性ruggedness耐用性robustness散布图scatter diagram+y r:L!z7\9^'T3l'h*M荧光偏振免疫测定法fluorescence polarization immunoassay第4章巴比妥类药物的分析溴化十六烷基三甲基苄铵cetyltrimethylbenzylammonium bromide,CTMA 氯化四癸基二甲基苄铵T etradacyldimethybenzylammonium chloride,TDBA第5章芳酸及其酯类药物的分析苯甲酸及其钠盐benzoic acid and sodium benzoate布美他尼bumetanide羟苯乙酯ethylparoben丙磺舒probenecid酚黄乙胺etamsylate第6章胺类药物的分析第7章杂环类药物的分析二硝基氯苯反应Vongerichten反应戊烯二醛反应反应第8章生物碱类药物的分析生物碱alkaloids阿片gum opium扫尾剂tailing-suppressing reagent蒂巴因thebaine诺司卡品noscapine竞争离子competing ions亲脂性lipophicity拖尾因子tailing factor金刚烷adamantane第9章维生素类药物的分析维生素vitamin去氢维生素A dehydroretinol去水维生素A anhydroretinol鲸醇kitol三氯化锑反应Carr-Price反应维生素B1 thiamine hydrochloride;盐酸硫胺2,3,5-三苯基氯化四氮唑2,3,5-triphenyltetrazolium chlorid,TTC红四氮唑red tetrazoline,RT蓝四氮唑blue tetrazoline,BT3,3’-二甲基氧苯基-双-4,4’-(3,5-二苯基)氯化四氮唑{3,3’-dianisole-bis[4,4’-(3,5-dipheny)tetrazolium chloride]}有色甲……formazan铁-酚试剂iron-phenol reagente铁-柯柏试剂iron-Kober reagent南药07药理复试题一、名词解释(5分*10)1、一级动力学消除;2、非竞争性拮抗剂;3、动作电位时程;4、前致癌物;5、初次接触效应;6、synergism;7、mutation;8、GLP;9、acute toxicity;10、uptake1。

ICH指导原则全套ICH指导原则全套指的是国际药品注册与研发领域的一系列指导原则,由国际药品注册与安全性评价协调委员会(International Council for Harmonisation of Technical Requirements for Pharmaceuticals for Human Use, 简称ICH)制定和发布。

ICH是一个由欧洲、美国和日本的药品监管机构以及研发与注册领域的药企组成的国际组织,通过制定统一的指导原则和标准,以促进国际间药品注册的协调与一致。

1. ICH Q1A(R2) Stability Testing of New Drug Substances and Products(新药物物质和产品的稳定性测试)这个指导原则规定了对新药物物质和产品进行稳定性测试的方法和要求,以确保其在存储和使用期间的稳定性和一致性。

2. ICH Q1B Photostability Testing of New Drug Substances and Products(新药物物质和产品的光稳定性测试)这个指导原则规定了对新药物物质和产品进行光稳定性测试的方法和要求,以评估其在光照条件下的稳定性。

3. ICH Q2(R1) Validation of Analytical Procedures: Text and Methodology(分析方法验证:文本和方法)这个指导原则规定了药物分析方法的验证要求,确保这些方法的准确性、精确性和可靠性。

4. ICH Q3A(R2) Impurities in New Drug Substances(新药物物质中的杂质)这个指导原则规定了新药物物质中可能存在的杂质的评估和控制要求,以保证药物物质的纯度和质量。

5. ICH Q3C(R6) Impurities: Guideline for Residual Solvents(杂质:残留溶剂指南)这个指导原则规定了药物制剂中可能存在的残留溶剂的评估和控制要求,以保证药物制剂的安全性。

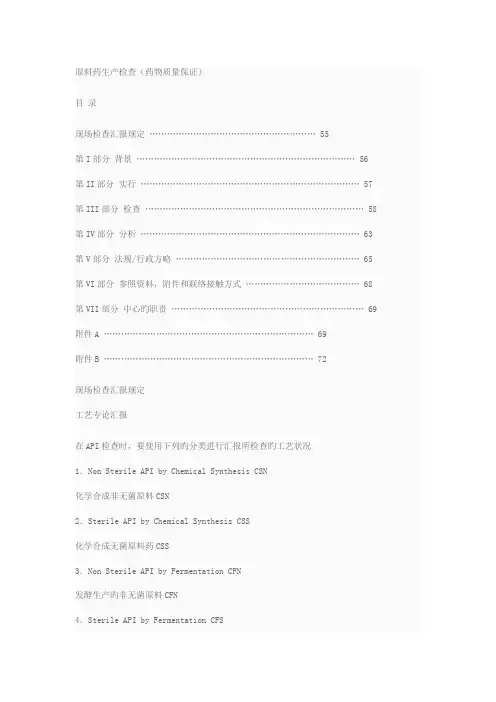

原料药生产检查(药物质量保证)目录现场检查汇报规定 (55)第I部分背景 (56)第II部分实行 (57)第III部分检查 (58)第IV部分分析 (63)第V部分法规/行政方略 (65)第VI部分参照资料,附件和联络接触方式 (68)第VII部分中心旳职责 (69)附件A (69)附件B (72)现场检查汇报规定工艺专论汇报在API检查时,要使用下列旳分类进行汇报所检查旳工艺状况1.Non Sterile API by Chemical Synthesis CSN化学合成非无菌原料CSN2.Sterile API by Chemical Synthesis CSS化学合成无菌原料药CSS3.Non Sterile API by Fermentation CFN发酵生产旳非无菌原料CFN4.Sterile API by Fermentation CFS发酵生产旳无菌原料CFS5.Plant/Animal Extraction API CEX植物/动物提取原料药CEX6.Biotechnology API CBI生物技术生产旳原料药CBI第I部分――背景至八十年代后期以来,美国食品与药物管理局以强化了其对原料药(API)生产企业旳检查内容。

从部分方面来说,这归咎于对原料药质量在制剂旳质量、效力、和安全面所起旳重要作用认识旳提高。

例如,在配制成固体口服制剂,混悬剂和局部用药时原料药旳化学特性会对制剂旳溶出度/生物运用度产生不利影响。

此外,原料中旳少许没有鉴别出旳杂质或其特性未知旳杂质会给病人导致旳严重不良反应。

FDA长期以来一直认为,收载在制剂药物生产质量管理规范规定(21 CFR 210 and 211)中旳CGMP概念对原料药生产工艺同样有效。

这些概念包括,与其他一起,产品质量是生产出来旳,雇佣可以胜任和通过培训旳员工,建立合适旳书面程序和管理规定,建立一套在线测试和产品测试系统,工艺验证,和保证原料药在预期旳有效期内质量稳定。

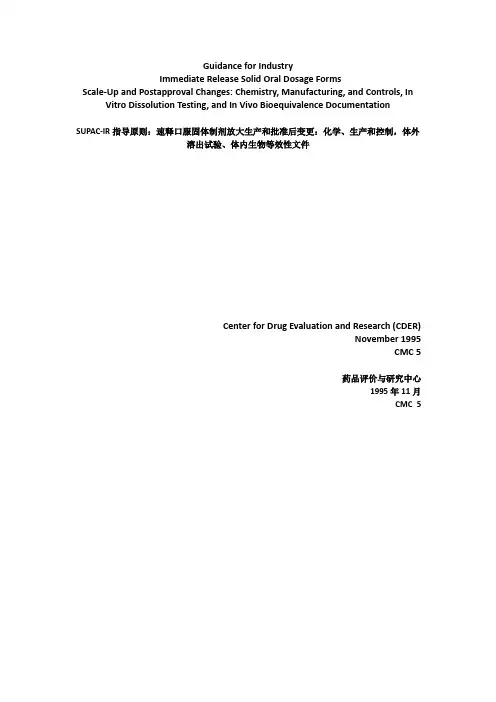

Guidance for IndustryImmediate Release Solid Oral Dosage FormsScale-Up and Postapproval Changes: Chemistry, Manufacturing, and Controls, In Vitro Dissolution Testing, and In Vivo Bioequivalence DocumentationSUPAC-IR指导原则:速释口服固体制剂放大生产和批准后变更:化学、生产和控制,体外溶出试验、体内生物等效性文件Center for Drug Evaluation and Research (CDER)November 1995CMC 5药品评价与研究中心1995年11月CMC 5TABLE OF CONTENTS目录I. PURPOSE OF GUIDANCE (本指导原则的目的). . . . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . 1 II. DEFINITION OF TERMS(术语定义). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 3 PONENTS AND COMPOSITION(辅料成分或组成的变更). . . . . . . . . . . . . . . . . . . . . . . . .. 6 IV. SITE CHANGES(地点变更). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .. 13 V. CHANGES IN BATCH SIZE (SCALE-UP/SCALE-DOWN)(批量大小(放大/缩小)的变更). .. . . . 16 VI. MANUFACTURING(生产变更). . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 VII. IN VITRO DISSOLUTION (体外溶出试验). . . . .. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 VIII. IN VIVO BIOEQUIVALENCE STUDIES (体内生物等效性). . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 IX. REFERENCES(参考文献). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 APPENDIX A: NARROW THERAPEUTIC RANGE DRUGS(附录A:治疗窗狭窄药物). . . . . . . . . A-1GUIDANCE FOR INDUSTRY 1IMMEDIATE RELEASE SOLID ORAL DOSAGE FORMS SCALE-UP AND POSTAPPROVAL CHANGES: CHEMISTRY, MANUFACTURING, AND CONTROLS, IN VITRO DISSOLUTION TESTING, AND IN VIVO BIOEQUIVALENCE DOCUMENTATION速释口服固体制剂放大生产和批准后变更:化学、生产和控制,体外溶出试验、体内生物等效性文件I. PURPOSE OF GUIDANCE(本指导原则的目的)This guidance provides recommendations to sponsors of new drug applications (NDA's), abbreviated new drug applications (ANDA's), and abbreviated antibiotic applications (AADA's) who intend, during the postapproval period, to change: 1) the components or composition; 2) the site of manufacture; 3) the scale-up/scale-down of manufacture; and/or 4) the manufacturing (process and equipment) of an immediate release oral formulation.本指导原则所提供的的建议适用于新药申请(NDA's)、仿制药申请(ANDA's)和抗生素仿制药申请(AANA’S)的企业的批准后变更,内容包括:1)成分或组分的变更;2)生产地点的变更;3)放大/缩小生产规模的变更;和/或4)生产过程(工艺和设备)的变更This guidance is the result of: 1) a workshop on the scale-up of immediate release drug products conducted by the American Association of Pharmaceutical Scientists in conjunction with the United States Pharmacopoeial Convention and the Food and Drug Administration (FDA); 2) research conducted by the University of Maryland at Baltimore on the chemistry, manufacturing and controls of immediate release drug products under the FDA/University of Maryland Manufacturing Research Contract; 3) the drug categorization research conducted at the University of Michigan and the University of Uppsala on the permeability of drug substances; and 4) the Scale-Up and Post Approval Changes (SUPAC) Task Force which was established by the Center for Drug Evaluation and Research (CDER) Chemistry, Manufacturing and Controls Coordinating Committee to develop guidance on scale-up and other postapproval changes.本指导原则是以下工作的成果:1)在美国药学科学家协会与美国药典委员会和FDA的指导下,进行速释药品放大生产的车间;2)在位于巴尔的摩的马里兰大学指导下,并在FDA/马里兰大学生产研究合同下的速释药品的化学、生产和控制的研究;3)在密歇根大学和乌普萨拉大学指导下的药品分类学研究中关于药物渗透性的研究;4)由药品评价和研究中心(CDER)化学、生产和控制协调委员会成立的放大生产和批准后变更(SUPAC)特别小组,来制定关于放大生产和其它的批准后变更的指导原则。

Analytical Procedures and Methods Validation for Drugsand BiologicsDRAFT GUIDANCEThis guidance document is being distributed for comment purposes only. Comments and suggestions regarding this draft document should be submitted within 90 days of publication in the Federal Register of the notice announcing the availability of the draft guidance. Submit electronic comments to . Submit written comments to the Division of Dockets Management (HFA-305), Food and Drug Administration, 5630 Fishers Lane, rm. 1061, Rockville, MD 20852. All comments should be identified with the docket number listed in the notice of availability that publishes in the Federal Registe r.For questions regarding this draft document contact (CDER) Lucinda Buhse 314-539-2134, or (CBER) Office of Communication, Outreach and Development at 800-835-4709 or 301-827-1800.U.S. Department of Health and Human ServicesFood and Drug AdministrationCenter for Drug Evaluation and Research (CDER)Center for Biologics Evaluation and Research (CBER)February 2014CMCAnalytical Procedures and Methods Validation for Drugsand BiologicsAdditional copies are available from:Office of CommunicationsDivision of Drug Information, WO51, Room 2201Center for Drug Evaluation and ResearchFood and Drug Administration10903 New Hampshire Ave., Silver Spring, MD 20993Phone: 301-796-3400; Fax: 301-847-8714druginfo@/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/default.htmand/orOffice of Communication, Outreach andDevelopment, HFM-40Center for Biologics Evaluation and ResearchFood and Drug Administration1401 Rockville Pike, Rockville, MD 20852-1448ocod@/BiologicsBloodVaccines/GuidanceComplianceRegulatoryInformation/Guidances/default.htm(Tel) 800-835-4709 or 301-827-1800U.S. Department of Health and Human ServicesFood and Drug AdministrationCenter for Drug Evaluation and Research (CDER)Center for Biologics Evaluation and Research (CBER)Febr uary 2014CMCTABLE OF CONTENTSI.INTRODUCTION (1)II.BACKGROUND (2)III.ANALYTICAL METHODS DEVELOPMENT (3)IV.CONTENT OF ANALYTICAL PROCEDURES (3)A.Principle/Scope (4)B.Apparatus/Equipment (4)C.Operating Parameters (4)D.Reagents/Standards (4)E.Sample Preparation (4)F.Standards Control Solution Preparation (5)G.Procedure (5)H.System Suitability (5)I.Calculations (5)J.Data Reporting (5)V.REFERENCE STANDARDS AND MATERIALS (6)VI.ANALYTICAL METHOD VALIDATION FOR NDA, ANDAs, BLAs, AND DMFs (6)A.Noncompendial Analytical Procedures (6)B.Validation Characteristics (7)pendial Analytical Procedures (8)VII.STATISTICAL ANALYSIS AND MODELS (8)A.Statistics (8)B.Models (8)VIII.LIFE CYCLE MANAGEMENT OF ANALYTICAL PROCEDURES (9)A.Revalidation (9)B.Analytical Method Comparability Studies (10)1.Alternative Analytical Procedures (10)2.Analytical Methods Transfer Studies (11)C.Reporting Postmarketing Changes to an Approved NDA, ANDA, or BLA (11)IX.FDA METHODS VERIFICATION (12)X.REFERENCES (12)Guidance for Industry11Analytical Procedures and Methods Validation for Drugs and2Biologics345This draft guidance, when finalized, will represent the Food and Drug Administration’s (FDA’s) current 6thinking on this topic. It does not create or confer any rights for or on any person and does not operate to 7bind FDA or the public. You can use an alternative approach if the approach satisfies the requirements of 8the applicable statutes and regulations. If you want to discuss an alternative approach, contact the FDA9staff responsible for implementing this guidance. If you cannot identify the appropriate FDA staff, call 10the appropriate number listed on the title page of this guidance.11121314I. INTRODUCTION1516This revised draft guidance supersedes the 2000 draft guidance for industry on Analytical17Procedures and Methods Validation2,3 and, when finalized, will also replace the 1987 FDA18guidance for industry on Submitting Samples and Analytical Data for Methods Validation. It19provides recommendations on how you, the applicant, can submit analytical procedures4 and20methods validation data to support the documentation of the identity, strength, quality, purity,21and potency of drug substances and drug products.5It will help you assemble information and 22present data to support your analytical methodologies. The recommendations apply to drug23substances and drug products covered in new drug applications (NDAs), abbreviated new drug 24applications (ANDAs), biologics license applications (BLAs), and supplements to these25applications. The principles in this revised draft guidance also apply to drug substances and drug 26products covered in Type II drug master files (DMFs).2728This revised draft guidance complements the International Conference on Harmonisation (ICH) 29guidance Q2(R1)Validation of Analytical Procedures: Text and Methodology(Q2(R1)) for30developing and validating analytical methods.3132This revised draft guidance does not address investigational new drug application (IND) methods 33validation, but sponsors preparing INDs should consider the recommendations in this guidance.34For INDs, sufficient information is required at each phase of an investigation to ensure proper35identity, quality, purity, strength, and/or potency. The amount of information on analytical36procedures and methods validation will vary with the phase of the investigation.6 For general371 This guidance has been prepared by the Office of Pharmaceutical Science, in the Center for Drug Evaluation andResearch (CDER) and the Center for Biologics Evaluation and Research (CBER) at the Food and DrugAdministration.2 Sample submission is described in section IX, FDA Methods Verification.3 We update guidances periodically. To make sure you have the most recent version of a guidance, check the FDADrugs guidance Web page at/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/default.htm.4Analytical procedure is interchangeable with a method or test procedure.5The terms drug substance and drug product, as used in this guidance, refer to human drugs and biologics.6 See 21 CFR 312.23(a)(7).guidance on analytical procedures and methods validation information to be submitted for phase 38one studies, sponsors should refer to the FDA guidance for industry on Content and Format of39Investigational New Drug Applications (INDs) for Phase 1 Studies of Drugs, Including40Well-Characterized, Therapeutic, Biotechnology-Derived Products. General considerations for 41analytical procedures and method validation (e.g., bioassay) before conduct of phase three42studies are discussed in the FDA guidance for industry on IND Meetings for Human Drugs and 43Biologics, Chemistry, Manufacturing, and Controls Information.4445This revised draft guidance does not address specific method validation recommendations for46biological and immunochemical assays for characterization and quality control of many drug47substances and drug products. For example, some bioassays are based on animal challenge48models, and immunogenicity assessments or other immunoassays have unique features that49should be considered during development and validation.5051In addition, the need for revalidation of existing analytical methods may need to be considered 52when the manufacturing process changes during the product’s life cycle. For questions on53appropriate validation approaches for analytical procedures or submission of information not54addressed in this guidance, you should consult with the appropriate FDA product quality review 55staff.5657If you choose a different approach than those recommended in this revised draft guidance, we58encourage you to discuss the matter with the appropriate FDA product quality review staff before 59you submit your application.6061FDA’s guidance documents, including this guidance, do not establish legally enforceable62responsibilities. Instead, guidances describe the Agency’s current thinking on a topic and should 63be viewed only as recommendations, unless specific regulatory or statutory requirements are64cited. The use of the word should in Agency guidances means that something is suggested or65recommended, but not required.666768II.BACKGROUND6970Each NDA and ANDA must include the analytical procedures necessary to ensure the identity, 71strength, quality, purity, and potency of the drug substance and drug product.7 Each BLA must 72include a full description of the manufacturing methods, including analytical procedures that73demonstrate the manufactured product meets prescribed standards of identity, quality, safety,74purity, and potency.8 Data must be available to establish that the analytical procedures used in 75testing meet proper standards of accuracy and reliability and are suitable for their intended76purpose.9 For BLAs and their supplements, the analytical procedures and their validation are77submitted as part of license applications or supplements and are evaluated by FDA quality78review groups.79807 See 21 CFR 314.50(d)(1) and 314.94(a)(9)(i).8 See 21 CFR 601.2(a) and 601.2(c).9 See 21 CFR 211.165(e) and 211.194(a)(2).Analytical procedures and validation data should be submitted in the corresponding sections of 81the application in the ICH M2 eCTD: Electronic Common Technical Document Specification.108283When an analytical procedure is approved/licensed as part of the NDA, ANDA, or BLA, it84becomes the FDA approved analytical procedure for the approved product. This analytical85procedure may originate from FDA recognized sources (e.g., a compendial procedure from the 86United States Pharmacopeia/National Formulary (USP/NF)) or a validated procedure you87submitted that was determined to be acceptable by FDA. To apply an analytical method to a88different product, appropriate validation studies with the matrix of the new product should be89considered.909192III.ANALYTICAL METHODS DEVELOPMENT9394An analytical procedure is developed to test a defined characteristic of the drug substance or95drug product against established acceptance criteria for that characteristic. Early in the96development of a new analytical procedure, the choice of analytical instrumentation and97methodology should be selected based on the intended purpose and scope of the analytical98method. Parameters that may be evaluated during method development are specificity, linearity, 99limits of detection (LOD) and quantitation limits (LOQ), range, accuracy, and precision.100101During early stages of method development, the robustness of methods should be evaluated102because this characteristic can help you decide which method you will submit for approval.103Analytical procedures in the early stages of development are initially developed based on a104combination of mechanistic understanding of the basic methodology and prior experience.105Experimental data from early procedures can be used to guide further development. You should 106submit development data within the method validation section if they support the validation of 107the method.108109To fully understand the effect of changes in method parameters on an analytical procedure, you 110should adopt a systematic approach for method robustness study (e.g., a design of experiments 111with method parameters). You should begin with an initial risk assessment and follow with112multivariate experiments. Such approaches allow you to understand factorial parameter effects 113on method performance. Evaluation of a method’s performance may include analyses of114samples obtained from in-process manufacturing stages to the finished product. Knowledge115gained during these studies on the sources of method variation can help you assess the method 116performance.117118119IV.CONTENT OF ANALYTICAL PROCEDURES120121You should describe analytical procedures in sufficient detail to allow a competent analyst to 122reproduce the necessary conditions and obtain results within the proposed acceptance criteria. 123You should also describe aspects of the analytical procedures that require special attention. An 124analytical procedure may be referenced from FDA recognized sources (e.g., USP/NF,12510 See sections 3.2.S.4 Control of Drug Substance, 3.2.P.4 Control of Excipients, and 3.2.P.5 Control of DrugProduct.Association of Analytical Communities (AOAC) International)11 if the referenced analytical126procedure is not modified beyond what is allowed in the published method. You should provide 127in detail the procedures from other published sources. The following is a list of essential128information you should include for an analytical procedure:129130A.Principle/Scope131132A description of the basic principles of the analytical test/technology (separation, detection, etc.); 133target analyte(s) and sample(s) type (e.g., drug substance, drug product, impurities or compounds 134in biological fluids, etc.).135136B.Apparatus/Equipment137138All required qualified equipment and components (e.g., instrument type, detector, column type, 139dimensions, and alternative column, filter type, etc.).140141C.Operating Parameters142143Qualified optimal settings and ranges (allowed adjustments) critical to the analysis (e.g., flow144rate, components temperatures, run time, detector settings, gradient, head space sampler). A145drawing with experimental configuration and integration parameters may be used, as applicable. 146147D.Reagents/Standards148149The following should be listed:150151•Grade of chemical (e.g., USP/NF, American Chemical Society, High152Performance or Pressure Liquid Chromatography, or Gas153Chromatography and preservative free).154•Source (e.g., USP reference standard or qualified in-house reference material). 155•State (e.g., dried, undried, etc.) and concentration.156•Standard potencies (purity correction factors).157•Storage controls.158•Directions for safe use (as per current Safety Data Sheet).159•Validated or useable shelf life.160161New batches of biological reagents, such as monoclonal antibodies, polyclonal antisera, or cells, 162may need extensive qualification procedures included as part of the analytical procedure.163164E.Sample Preparation165166Procedures (e.g., extraction method, dilution or concentration, desalting procedures and mixing 167by sonication, shaking or sonication time, etc.) for the preparations for individual sample tests. 168A single preparation for qualitative and replicate preparations for quantitative tests with16911 See 21 CFR 211.194(a)(2).appropriate units of concentrations for working solutions (e.g., µg/ml or mg/ml) and information 170on stability of solutions and storage conditions.171172F.Standards Control Solution Preparation173174Procedures for the preparation and use of all standard and control solutions with appropriate175units of concentration and information on stability of standards and storage conditions,176including calibration standards, internal standards, system suitability standards, etc.177178G.Procedure179180A step-by-step description of the method (e.g., equilibration times, and scan/injection sequence 181with blanks, placeboes, samples, controls, sensitivity solution (for impurity method) and182standards to maintain validity of the system suitability during the span of analysis) and allowable 183operating ranges and adjustments if applicable.184185H.System Suitability186187Confirmatory test(s) procedures and parameters to ensure that the system (equipment,188electronics, and analytical operations and controls to be analyzed) will function correctly as an 189integrated system at the time of use. The system suitability acceptance criteria applied to190standards and controls, such as peak tailing, precision and resolution acceptance criteria, may be 191required as applicable. For system suitability of chromatographic systems, refer to CDER192reviewer guidance on Validation of Chromatographic Methods and USP General Chapter <621> 193Chromatography.194195I.Calculations196197The integration method and representative calculation formulas for data analysis (standards,198controls, samples) for tests based on label claim and specification (e.g., assay, specified and199unspecified impurities and relative response factors). This includes a description of any200mathematical transformations or formulas used in data analysis, along with a scientific201justification for any correction factors used.202203J.Data Reporting204205A presentation of numeric data that is consistent with instrumental capabilities and acceptance 206criteria. The method should indicate what format to use to report results (e.g., percentage label 207claim, weight/weight, and weight/volume etc.) with the specific number of significant figures 208needed. The American Society for Testing and Materials (ASTM) E29 describes a standard209practice for using significant digits in test data to determine conformance with specifications. For 210chromatographic methods, you should include retention times (RTs) for identification with211reference standard comparison basis, relative retention times (RRTs) (known and unknown212impurities) acceptable ranges and sample results reporting criteria.213214215V.REFERENCE STANDARDS AND MATERIALS216217Primary and secondary reference standards and materials are defined and discussed in the218following ICH guidances: Q6A Specifications: Test Procedures and Acceptance Criteria for 219New Drug Substances and New Drug Products: Chemical Substances (ICH Q6A), Q6B220Specifications: Test Procedures and Acceptance Criteria for Biotechnological/Biological221Products, and Q7 Good Manufacturing Practice Guidance for Active Pharmaceutical222Ingredients. For all standards, you should ensure the suitability for use. Reference standards for 223drug substances are particularly critical in validating specificity for an identity test. You should 224strictly follow storage, usage conditions, and handling instructions for reference standards to225avoid added impurities and inaccurate analysis. For biological products, you should include226information supporting any reference standards and materials that you intend to use in the BLA 227and in subsequent annual reports for subsequent reference standard qualifications. Information 228supporting reference standards and materials include qualification test protocols, reports, and 229certificates of analysis (including stability protocols and relevant known impurity profile230information, as applicable).231232Reference standards can often be obtained from USP and may also be available through the233European Pharmacopoeia, Japanese Pharmacopoeia, World Health Organization, or National 234Institute of Standards and Technology. Reference standards for a number of biological products 235are also available from CBER. For certain biological products marketed in the U.S., reference 236standards authorized by CBER must be used before the product can be released to the market.12 237Reference materials from other sources should be characterized by procedures including routine 238and beyond routine release testing as described in ICH Q6A. You should consider orthogonal 239methods. Additional testing could include attributes to determine the suitability of the reference 240material not necessarily captured by the drug substance or product release tests (e.g., more241extensive structural identity and orthogonal techniques for purity and impurities, biological242activity).243244For biological reference standards and materials, we recommend that you follow a two-tiered 245approach when qualifying new reference standards to help prevent drift in the quality attributes 246and provide a long-term link to clinical trial material. A two-tiered approach involves a247comparison of each new working reference standard with a primary reference standard so that it 248is linked to clinical trial material and the current manufacturing process.249250251VI.ANALYTICAL METHOD VALIDATION FOR NDA, ANDAs, BLAs, AND 252DMFs253254A.Noncompendial Analytical Procedures255256Analytical method validation is the process of demonstrating that an analytical procedure is257suitable for its intended purpose. The methodology and objective of the analytical procedures 258should be clearly defined and understood before initiating validation studies. This understanding 25912 See 21 CFR 610.20.is obtained from scientifically-based method development and optimization studies. Validation 260data must be generated under an protocol approved by the sponsor following current good261manufacturing practices with the description of methodology of each characteristic test and262predetermined and justified acceptance criteria, using qualified instrumentation operated under 263current good manufacturing practices conditions.13 Protocols for both drug substance and264product analytes or mixture of analytes in respective matrices should be developed and executed. 265266ICH Q2(R1) is considered the primary reference for recommendations and definitions on267validation characteristics for analytical procedures. The FDA Reviewer Guidance: Validation of 268Chromatographic Methods is available as well.269270B.Validation Characteristics271272Although not all of the validation characteristics are applicable for all types of tests, typical273validation characteristics are:274275•Specificity276•Linearity277•Accuracy278•Precision (repeatability, intermediate precision, and reproducibility)279•Range280•Quantitation limit281•Detection limit282283If a procedure is a validated quantitative analytical procedure that can detect changes in a quality 284attribute(s) of the drug substance and drug product during storage, it is considered a stability285indicating assay. To demonstrate specificity of a stability-indicating assay, a combination of286challenges should be performed. Some challenges include the use of samples spiked with target 287analytes and all known interferences; samples that have undergone various laboratory stress288conditions; and actual product samples (produced by the final manufacturing process) that are289either aged or have been stored under accelerated temperature and humidity conditions.290291As the holder of the NDA, ANDA, or BLA, you must:14 (1) submit the data used to establish292that the analytical procedures used in testing meet proper standards of accuracy and reliability, 293and (2) notify the FDA about each change in each condition established in an approved294application beyond the variations already provided for in the application, including changes to 295analytical procedures and other established controls.296297The submitted data should include the results from the robustness evaluation of the method,298which is typically conducted during method development or as part of a planned validation299study.1530013 See 21 CFR 211.165(e); 21 CFR 314.50 (d), and for biologics see 21 CFR 601.2(a), 601.2(c), and 601.12(a).14 For drugs see 21 CFR 314.50 (d), 314.70(d), and for biologics see 21 CFR 601.2(a), 601.2(c), and 601.12(a). For aBLA, as discussed below, you must obtain prior approval from FDA before implementing a change in analyticalmethods if those methods are specified in FDA regulations15 See section III and ICH Q2(R1).pendial Analytical Procedures302303The suitability of an analytical procedure (e.g., USP/NF, the AOAC International Book of304Methods, or other recognized standard references) should be verified under actual conditions of 305use.16 Compendial general chapters, which are complex and mention multiple steps and/or306address multiple techniques, should be rationalized for the intended use and verified. Information 307to demonstrate that USP/NF analytical procedures are suitable for the drug product or drug308substance should be included in the submission and generated under a verification protocol.309310The verification protocol should include, but is not limited to: (1) compendial methodology to 311be verified with predetermined acceptance criteria, and (2) details of the methodology (e.g.,312suitability of reagent(s), equipment, component(s), chromatographic conditions, column, detector 313type(s), sensitivity of detector signal response, system suitability, sample preparation and314stability). The procedure and extent of verification should dictate which validation characteristic 315tests should be included in the protocol (e.g., specificity, LOD, LOQ, precision, accuracy, etc.). 316Considerations that may influence what characteristic tests should be in the protocol may depend 317on situations such as whether specification limits are set tighter than compendial acceptance318criteria, or RT or RRT profiles are changing in chromatographic methods because of the319synthetic route of drug substance or differences in manufacturing process or matrix of drug320product. Robustness studies of compendial assays do not need to be included, if methods are 321followed without deviations.322323324VII.STATISTICAL ANALYSIS AND MODELS325326A.Statistics327328Statistical analysis of validation data can be used to evaluate validation characteristics against 329predetermined acceptance criteria. All statistical procedures and parameters used in the analysis 330of the data should be based on sound principles and appropriate for the intended evaluation.331Reportable statistics of linear regression analysis R (correlation coefficient), R square332(coefficient of determination), slope, least square, analysis of variance (ANOVA), confidence 333intervals, etc., should be provided with justification.For information on statistical techniques 334used in making comparisons, as well as other general information on the interpretation and335treatment of analytical data, appropriate literature or texts should be consulted.17336337B.Models338339Some analytical methods might use chemometric and/or multivariate models. When developing 340these models, you should include a statistically adequate number and range of samples for model 341development and comparable samples for model validation. Suitable software should be used for 342data analysis. Model parameters should be deliberately varied to test model robustness.34334416 See 21 CFR 211.194(a)(2) and USP General Chapter <1226> Verification of Compendial Procedures.17 See References section for examples including USP <1010> Analytical Data – Interpretation and Treatment.。

XXFDA分析方法验证指南中英文对照I. INTRODUCTION This guidan ___ provides remendations to applicants on submitting ___ytical pro ___dures, validation data, and samples to support the documentation of the identity, strength, quality, purity, and potency of drug substan ___s and drug products. 1. 绪论本指南旨在为申请者提供建议,以帮助其提交分析方法,方法验证资料和样品用于支持原料药和制剂的认定,剂量,质量,纯度和效力方面的文件。

This guidan ___ is intended to assist applicants in assembling infor ___tion, submitting samples, and presenting data to support ___ytical methodologies. The remendations apply to drug substan ___s and drug products covered in new drug applications (NDAs), abbreviated new drug applications (ANDAs), biologics li ___nse applications (BLAs), product li ___nse applications (PLAs), and supplements to these applications. 本指南旨在帮助申请者收集资料,递交样品并资料以支持分析方法。

这些建议适用于 NDA,ANDA,BLA,PLA 及其它们的补充中所涉及的原料药和制剂。

全版最新中文版ICH指导原则国际卫生规范和指南(ICH)是一个由包括美国、欧洲和日本在内的制药监管机构共同组成的组织,致力于制定和推动国际间药品监管的一致性和标准化。

以下是ICH《指导原则:药品质量发展》的最新中文版全文,共计1200字以上:【目录】导言1.适用范围2.引用资料3.术语和定义4.质量原则4.1质量原则的适用4.2制订质量目标4.3实施全面质量管理4.4建立质量风险管理体系4.5进行质量风险评估4.6引入持续改进措施4.7知识管理5.因变更和变更控制引发的质量的影响5.1引言5.2变更管理5.3因变更和变更控制引发的质量把控5.4因变更和变更控制引发的质量评估5.5因变更和变更控制引发的质量的报告附录导言本《指导原则:药品质量发展》为指导其它ICH指南和规范的质量管理原则,旨在提供一个整体性框架,以确保药物的优质和稳定性。

1.适用范围本指导原则适用于所有药品(包括化学药品和生物制品),并可以适用于 diagnOSTICS。

2.引用资料本指导原则参考了ICH其他指南和规范,并鼓励读者在需要的时候参考其他国家规定和准则。

3.术语和定义本章节提供了本指南中使用的一些关键术语和定义的阐释。

4.质量原则4.1质量原则的适用质量原则适用于产品周期的各个阶段,包括药品的研发、生产和销售过程。

符合质量原则的实施将有助于确保产品的质量和安全性。

4.2制订质量目标药品的制订新的质量目标应基于注册文件的要求,并考虑药品的用途和可行性。

公司应根据国家和国际要求,确保其制定的质量目标符合相关标准。

4.3实施全面质量管理全面质量管理是质量保证方面的一个重要原则,涵盖了贯穿药品生命周期的风险管理、变更控制和报告、审计和持续改进等方面。

4.4建立质量风险管理体系质量风险管理体系是确保药品质量的关键环节之一、企业应根据可能的风险,采取有效的措施进行预防和响应,并对其风险管理的有效性进行评估。

4.5进行质量风险评估质量风险评估是企业在制订质量管理计划和决策过程中的一个重要工具。

【2020药典】分析方法确认、转移指导原则(新增)盛会汇聚国内外质量领域最具经验的实践专家和法规专家,基于国内外最新法规指南理念和监管形势解读,聚焦质量保证关键点,深耕关键技术细节。

篇首语《中国药典》2020版较2015版新增分析方法确认指导原则和分析方法验证指导原则。

在本版指导原则发布之前,国内还没有关于分析方法转移和确认的指导原则或法规。

9099分析方法确认指导原则分析方法确认(analytical method verification)是指首次使用法定分析方法时,由现有的分析人员对分析方法中关键的验证指标进行有选择性的考察,以证明方法对所分析样品的适用性,同时证明分析人员有能力使用该法定分析方法。

《分析方法验证指导原则》中提供了建立分析方法需要验证的指标,分析方法的确认并不是重复验证过程。

本指导原则不涉及微生物分析方法的确认。

一、确认过程(verification process)分析方法的确认过程,是指应用法定方法对药物及其制剂进行测定时,评价该方法能否达到预期的分析目的。

分析人员应具备一定的药物分析经验和知识,经培训后能够理解和执行法定方法。

分析方法确认应当由上述分析人员开展,以确保法定方法能够按预期顺利实施。

如果法定方法确认失败,并且相关工作人员(或起草人员)未能协助解决失败的问题,也可能是该方法不适用于在该实验室测定待分析的样品。

二、确认要求(verification requirements)1. 确认原则分析方法确认无需对法定方法进行完整的再验证,但是需要将《分析方法验证指导原则》表1 中列出的分析方法验证的指标用于方法的确认。

分析方法确认的范围和需验证的指标取决于实验人员的培训和经验水平、分析方法种类、相关设备或仪器、具体的操作步骤和分析对象等。

分析方法确认需验证的指标和检验项目(鉴别、杂质分析、含量测定等)有关,不同的检验项目,方法确认所需验证的指标也不同。

2. 考察指标分析方法确认应包含对影响方法的必要因素的评估。

Guidance for Industry 行业指南Process Validation: General Principles and Practices工艺验证:一般原则与规范U.S. Department of Health and Human ServicesFood and Drug AdministrationCenter for Drug Evaluation and Research (CDER)Center for Biologics Evaluation and Research (CBER)Center for Veterinary Medicine (CVM)January 2011Current Good Manufacturing Practices (CGMP)Revision 1美国卫生与人类服务部食品药品管理局药物评价和研究中心(CDER)生物制品评价和研究中心(CBER)兽药中心(CVM)2011年1月现行药品质量生产管理规范(CGMP)修订版1包含不具约束力的建议中文译稿:北京大学药物信息与工程研究中心************** Guidance for Industry 行业指南Process Validation: General Principles and Practices工艺验证:一般原则与规范Additional copies are available from:Office of CommunicationsDivision of Drug Information, WO51, Room 220110903 New Hampshire Ave.Silver Spring, MD 20993Phone: 301-796-3400; Fax: 301-847-8714****************.gov/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/default.htmand/orOffice of Communication, Outreach and Development, HFM-40Center for Biologics Evaluation and ResearchFood and Drug Administration1401 Rockville Pike, Rockville, MD 20852-1448(Tel) 800-835-4709 or 301-827-1800/BiologicsBloodVaccines/GuidanceComplianceRegulatoryInformation/Guidances/default.htm and/orCommunications Staff, HFV-12Center for Veterinary MedicineFood and Drug Administration7519 Standish Place,Rockville, MD 20855(Tel) 240-276-9300/AnimalVeterinary/GuidanceComplianceEnforcement/GuidanceforIndustry/default.htm包含不具约束力的建议中文译稿:北京大学药物信息与工程研究中心**************另外的副本可从以下部门得到:马里兰州银泉市新罕布什尔大道10193号2201室药品信息处,对外信息办公室,邮政编码:20993电话:301-796-3400; 传真:301-847-8714****************.gov/Drugs/GuidanceComplianceRegulatoryInformation/Guidances/default.htm和/或马里兰州洛克维尔市洛克维尔大道1401号HFM-40 FDA生物制品评价和研究中心对外信息、外联与发展办公室邮政编码:20852-1448电话:800-835-4709 或301-827-1800/BiologicsBloodVaccines/GuidanceComplianceRegulatoryInformation/Guidances/default.htm和/或马里兰州洛克维尔市Standish Place 7519号食品药品管理局兽药中心HFV-12通讯处,邮政编码:20885电话:240-276-9300/AnimalVeterinary/GuidanceComplianceEnforcement/GuidanceforIndustry/default.htmU.S. Department of Health and Human ServicesFood and Drug AdministrationCenter for Drug Evaluation and Research (CDER)Center for Biologics Evaluation and Research (CBER)Center for Veterinary Medicine (CVM)January 2011Current Good Manufacturing Practices (CGMP)Revision 1美国卫生与人类服务部食品药品管理局药物评估和研究中心(CDER)生物制品评估和研究中心(CBER)兽药中心(CVM)2011年1月现行药品质量生产管理规范(CGMP)修订版 1包含不具约束力的建议中文译稿:北京大学药物信息与工程研究中心**************Table of Contents目录I. INTRODUCTION (1)一. 简介 (1)II. BACKGROUND (3)二. 背景 (3)A. Process Validation and Drug Quality (4)A. 工艺验证与药品质量 (4)B. Approach to Process Validation (5)B. 工艺验证方法 (5)III. STATUTORY AND REGULATORY REQUIREMENTS FOR PROCESS VALIDATION (7)三. 对工艺验证的法规和监管要求 (7)IV. RECOMMENDATIONS (9)四. 建议 (9)A. General Considerations for Process Validation (9)A. 对工艺验证的总体考虑 (9)B. Stage 1 - Process Design (10)B. 第一阶段- 工艺设计 (10)1. Building and Capturing Process Knowledge and Understanding (11)1. 建立和捕获工艺知识与理解 (11)2. Establishing a Strategy for Process Control (12)2. 建立工艺控制策略 (12)C. Stage 2 - Process Qualification (14)C. 第二阶段- 工艺确认 (14)1. Design of a Facility and Qualification of Utilities and Equipment (14)1. 厂房设施设计以及公用设施与设备确认 (14)2. Process Performance Qualification (16)2. 工艺性能确认 (16)3. PPQ Protocol (17)3. 工艺性能确认方案 (17)4. PPQ Protocol Execution and Report (19)4. 工艺性能确认执行与报告 (19)D. Stage 3 - Continued Process Verification (20)D. 第三阶段- 持续工艺验证 (20)V. CONCURRENT RELEASE OF PPQ BATCHES (22)五. 工艺性能确认批次的同时放行 (22)VI. DOCUMENTATION (24)六. 文件记录 (24)VII. ANALYTICAL METHODOLOGY (24)七. 分析方法 (24)GLOSSARY (26)术语表 (26)REFERENCES (28)参考资料 (28)包含不具约束力的建议中文译稿:北京大学药物信息与工程研究中心**************1Guidance for Industry1行业指南1Process Validation: General Principles and Practices工艺验证:一般原则与实施This guidance represents the Food and Drug Administration’s (FDA’s) current thin king on this topic. It does not create or confer any rights for or on any person and does not operate to bind FDA or the public. You can use an alternative approach if the approach satisfies the requirements of the applicable statutes and regulations. If you want to discuss an alternative approach, contact the FDA staff responsible for implementing this guidance. If you cannot identify the appropriate FDA staff, call the appropriate number listed on the title page of this guidance.本指南体现了食品药品管理局(FDA)关于这一主题的最新见解。

药品及生物制品的分析方法和方法验证指导原则目录1.介绍 (1)2.背景 (2)3.分析方法开发 (3)4.分析程序内容 (3)A.原则/范围 (4)B.仪器/设备 (4)C.操作参数 (4)D.试剂/标准 (4)E.样品制备 (4)F. .................................................................................................................... 标准对照品溶液的制备 (5)G.步骤 (5)H.系统适应性 (5)I.计算 (5)J.数据报告 (5)5.参考标准和教材 (6)6 分析方法验证用于新药,仿制药,生物制品和DMF (6)A.非药典分析方法 (6)B.验证特征 (7)C.药典分析方法 (8)7.统计分析和模型 (8)A.统计 (8)B.模型 (8)8.生命周期管理分析程序 (9)A.重新验证 (9)B.分析方法的可比性研究 (10)1.另一种分析方法 (10)2.分析方法转移的研究 (11)C.报告上市后变更已批准的新药,仿制药,或生物制品 (11)9.美国FDA 方法验证 (12)10.参考文献前言本指导原则草案,定稿后,将代表美国食品和药物管理局(FDA)目前关于这个话题目前的想法。

它不会创造或赋予或任何人的任何权利,不约束FDA 或公众。

您可以使用另一种方法,如果该方法符合适用的法律和法规的要求。

如果你想讨论一个替代方法,请与FDA 工作人员负责实施本指南。

如果你不能确定适当的FDA 工作人员,请拨打本指南的标题页上所列的电话号码。

介绍:该修订指南草案将取代行业2000 年的指导分析方法和方法验证草案,并最终确定后,也将取代1987 年美国FDA 行业指南《提交的样品和分析数据的方法验证》。

该草案提供了有关申请人如何提交分析程序和方法验证数据来支持说明原料药和制剂具有强度、质量、纯度和效用的文件。

它会帮你收集信息和现有数据来支持你的分析方法。

该指导原则适用于原料药和制剂产品涵盖新药申请(NDA),简化新药申请(仿制药),生物制品许可申请(BLA),以及这些申请的补充申请。

在这个修订草案指导原则也适用于原料药和制剂产品涵盖二类药物主文件(DMFs)。

该修订指南草案补充了国际协调会议(ICH)Q2(R1)指导原则《分析程序的验证:开发和验证的分析方法Q2(R1)和方法的文本。

该修订指南草案不涉及研究性新药申请(IND)方法验证,但研究者在准备研究性新药申请时应考虑该指导原则中的建议。

研究性新药申请需要在研究的每个阶段有足够的信息,以确保正确鉴别性,质量,纯度,强度和/或效力。

对分析方法和方法验证的信息量将随研究中不同阶段而变化。

有关分析程序和需提交的阶段方法验证资料方面的指导意见的研究中,申请者可以参考FDA 的指导原则《Ⅰ期研究药物的IND 的内容和格式,包括性状、疗效和生物技术衍生产品》。

一般考虑在第三阶段的研究进行之前,分析方法和分析方法验证(例如,生物测定)是在FDA 行业指导原则《人类药物和生物制剂、化学、制造、控制信息会议》。

该修订指南草案不涉及生物和免疫化学检测的表征和许多原料药和制剂产品质量控制的具体方法验证的建议。

例如,一些基于动物模型的生物测定,并且免疫原性评估或其它免疫测定具有独特的特征,应开发和验证过程中予以考虑。

此外,需要对现有的分析方法再验证时可能需要在制造过程中产品的生命周期的变化予以考虑。

有关适当的验证方法的分析程序或者提交本指南中未提及的信息的问题,您应该向用FDA 产品质量评审人员咨询。

如果您选择了与本指导草案中不同的方式,我们建议您在提交申请前与相应的FDA 产品质量评审人员讨论。

FDA 的指南文件,包括本指导原则,不具有法律强制性的责任。

相反,指南描述的是FDA 对某个主题目前的想法,并应仅作为建议,除非有明确的法律或法规要求的引用。

使用“应该”这个词在FDA 指南意味着什么建议或推荐,但不是必需的。

II.BACKGROUND 背景每个NDA 和ANDA 都必需包括必要的分析程序,以确保原料药和制剂的鉴别,强度,质量,纯度和效果.每个BLA 必须包括完整的制造方法描述,包括能够确保产品身份、质量、安全、纯度和有效的分析程序。

数据必须能够用于建立满足精度和可靠性标准的分析方法并适合与拟定目的.对于BLAs 及补充补充,分析方法和方法验证是许可证申请或补充申请必须提交的一部分,并通过美国FDA质量评审小组进行评估。

分析方法和验证资料应当按照ICH M2 eCTD 的相应部分提交。

当一个分析程序作为NDA,ANDA 或者BLA 的一部分被批准时,它就变成了FDA 获批药品的获批分析程序。

这个分析程序可能源于FDA 认可来源(如源于USP/NF 的药店程序)或者是一个提交的已被认定通过美国FDA 可以接受的经验证的程序。

应用一个分析方法到不同的产品,需要考虑对新产品进行适当的验证研究。

III.ANALYTICAL METHODS DEVELOPMENT 分析方法开发分析方法的开发是为了一个定义药物原料药与制剂产品特性的检测标准。

新方法开发初期,应当基于分析项目与方法适用范围选择检测仪器和检测方法。

该方法可在开发过程中进行专属性,线性,检测限(LOD)和定量限(LOQ),范围,精度和准确度的评估。

在方法开发过程的早期阶段,方法的稳定性应进行评估,因为这个特性可以帮助您确定哪一种方法您将提交审批。

在发展的早期阶段分析程序最初开发基于基本方法和以往的经验机理认识的结合。

早期程序的实验数据可用于指导进一步发展。

你应该在方法验证部分中提交支持该方法的有效性的发展数据。

要充分认识在变化在分析过程方法参数的影响,你应该采取的方法的稳定性研究(例如,实验方法参数设计)的系统方法。

你应该从风险评估开始,并跟进多因素实验。

这些方法能让你了解到方法性能参数因子的影响。

检测方法的性能评价贯穿了样品生产的整个过程。

在研究专属性过程中获得的知识可以帮助你评估方法的性能。

IV.CONTENT OF ANALYTICAL PROCEDURES 分析程序内容你应该说明分析过程中足够的细节,让主管分析师重现的必要条件,并提出验收标准范围内得到结果。

您还应该说明需要特别注意的分析程序问题。

如果所参考的分析方法未经过修改超出了已发布方法的允许,需引用FDA 认可的来源(如:USP / NF,分析师协会(AOAC)国际)。

你应提供详细的从其他出版来源的程序。

以下是重要的信息,你应该包括一个分析程序的列表:A.原则/范围分析测试/技术(分离,检测等)的基本原理的说明;目标分析物和样品(S)型(如,药物,药品,生物体液等杂质或化合物)。

B.仪器/设备所有需要的合格的设备和部件(例如,仪器类型,检测器,柱子类型,尺寸,过滤器类型等)。

C.操作参数合格的最佳设置和范围(可予以调整)对分析至关重要(比如,流速,组件的温度,运行时间,顶空进样器、检测器的设置)。

如果适用实验配置和集成参数的绘图也可以使用。

D.试剂/标准以下应列出:•化学的等级(例如,USP / NF,美国化学学会,高效液相色谱级,或气相色谱级)。

•来源(例如,参照美国药典标准或合格的内部参考材料)。

•状态(例如,干燥,未干燥等)及浓度。

•标准纯度(纯度校正因子)。

•存储控制。

•安全使用说明书(按目前的安全数据)。

•验证或可用的保质期。

生物试剂,如单克隆抗体,多克隆抗体,或细胞,资格审查程序中队新的批次有一定的资格限制。

E.样品制备样品制备过程(例如,萃取法,稀释或浓缩,混合超声脱盐过程,振摇或超声处理的时间等)单方和复方检测时的溶解浓度(如,微克/毫升或毫克/毫升),以及溶液储存的稳定性信息。

F.标准对照品溶液的制备所有标准对照品溶液的配制方法和储存条件,包括校准标准,内部标准,系统适用性标准等。

G.程序一步一步的描述分析方法(例如,平衡时间,空白对照,安慰剂,样本,控制,灵敏度溶液(杂质的方法)和样品分析的系统适用性),以及工作范围的调整。

H.系统适用性确证试验(次)的程序和参数,以确保系统(分析设备,电子及操作)将作为一个系统在使用的时候正常工作。

适用于标准和控制,如峰拖尾,精密度和分离度。

对于色谱系统的系统适用性,是指在色谱方法的验证和USP通则<621>色谱评审指导。

I.计算用于基于标签要求和测试(例如,检测,指定和非指定杂质和相对影响因子)的积分方法和有代表性的计算公式进行数据分析(标准品,质控,样品)。

这包括用于数据分析的数学转换或公式的描述,以及使用一个科学的校正因子。

J.数据报告一个演示数字数据是与仪器的功能和验收标准是一致的。

该方法应说明什么格式来与所需显著数字的具体数量报告结果(例如,百分比标签要求,重量/体重,重量/体积等)。

在美国测试和材料协会(ASTM)E29描述了使用显著位数的测试数据,以确定是否符合规范的标准做法。

对于色谱方法,你应该包括保留时间(RT)识别与参考标准比较的基础上,相对保留时间(RRTS)(已知和未知杂质)可接受的范围和样本结果报告标准。

V.参考标准和教材一级和二级参考标准和材料的定义,并讨论以下ICH指导原则:Q6A规格:新原料药和新制剂的测试程序和验收标准:化学原料(ICH Q6A ),Q6B规格:生物技术/生物制品的测试程序和验收标准,活性药物成分和Q7优良制造规范指南。

对于所有的标准,应该确保适用性。

原料药的标准建立中验证专属性的鉴别试验尤为关键,要严格按照存储,使用条件的参考标准操作,以避免增加杂质导致分析处理不准确。

对于生物制品,应当包括支持您打算在以后的年度报告参考的参考标准资格和材料的信息。

支持参考标准和材料包括鉴定试验方案,报告和分析证书(如果可以,应包括协议和相关的已知杂质的信息)。

参考标准通常可以从美国专利获得,也可以通过欧洲药典,日本药典,世界卫生组织,或标准和技术研究所提供。

我们可以从美国药品与生物制品中心找到关于生物制品的参考标准。

对于在美国销售的生物制品,在上市之前必须参考美国药品与生物制品中心的标准。

其他来源的参考资料,必须以ICH Q6A常规与非常规测试结果为参考。

你应该考虑正交方法,进一步的测试可以包括材料的属性来确定其适应性(例如,更广泛的结构同一性和纯度和杂质的正交技术,生物活性)。

对于生物参考标准和材料,我们建议您遵循两个层次的方法检验的新参考标准,可以帮助防止不稳定的质量属性,并提供长期的链接,临床试验材料。

一个两层的方法涉及用一个基本参考标准与每个新的工作参照标准进行比较,因此它是临床试验材料和当前的制造工艺的链接。

VI.分析方法验证用于新药,仿制药,生物制品,和药物主文件A.非药典分析方法分析方法验证是论证某一分析方法适用于其预期目的的过程。