一汽大众汽车物流.

- 格式:ppt

- 大小:156.00 KB

- 文档页数:14

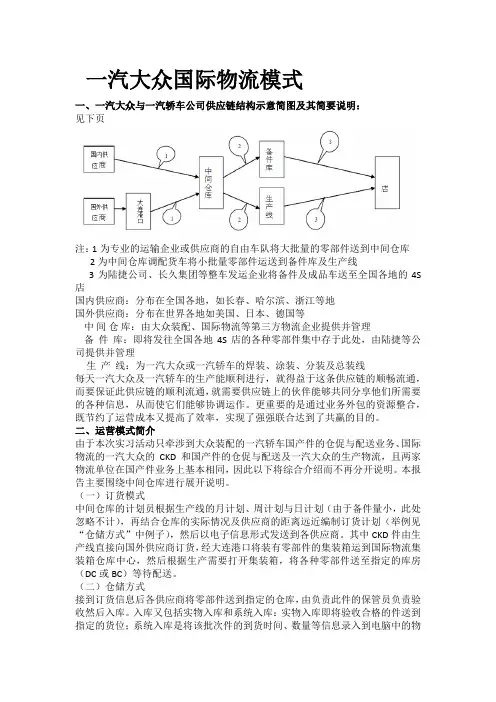

一汽大众国际物流模式一、一汽大众与一汽轿车公司供应链结构示意简图及其简要说明:见下页注:1为专业的运输企业或供应商的自由车队将大批量的零部件送到中间仓库2为中间仓库调配货车将小批量零部件运送到备件库及生产线3为陆捷公司、长久集团等整车发运企业将备件及成品车送至全国各地的4S 店国内供应商:分布在全国各地,如长春、哈尔滨、浙江等地国外供应商:分布在世界各地如美国、日本、德国等中间仓库:由大众装配、国际物流等第三方物流企业提供并管理备件库:即将发往全国各地4S店的各种零部件集中存于此处,由陆捷等公司提供并管理生产线:为一汽大众或一汽轿车的焊装、涂装、分装及总装线每天一汽大众及一汽轿车的生产能顺利进行,就得益于这条供应链的顺畅流通,而要保证此供应链的顺利流通,就需要供应链上的伙伴能够共同分享他们所需要的各种信息,从而使它们能够协调运作。

更重要的是通过业务外包的资源整合,既节约了运营成本又提高了效率,实现了强强联合达到了共赢的目的。

二、运营模式简介由于本次实习活动只牵涉到大众装配的一汽轿车国产件的仓促与配送业务、国际物流的一汽大众的CKD和国产件的仓促与配送及一汽大众的生产物流,且两家物流单位在国产件业务上基本相同,因此以下将综合介绍而不再分开说明。

本报告主要围绕中间仓库进行展开说明。

(一)订货模式中间仓库的计划员根据生产线的月计划、周计划与日计划(由于备件量小,此处忽略不计),再结合仓库的实际情况及供应商的距离远近编制订货计划(举例见“仓储方式”中例子),然后以电子信息形式发送到各供应商。

其中CKD件由生产线直接向国外供应商订货,经大连港口将装有零部件的集装箱运到国际物流集装箱仓库中心,然后根据生产需要打开集装箱,将各种零部件送至指定的库房(DC或BC)等待配送。

(二)仓储方式接到订货信息后各供应商将零部件送到指定的仓库,由负责此件的保管员负责验收然后入库。

入库又包括实物入库和系统入库:实物入库即将验收合格的件送到指定的货位;系统入库是将该批次件的到货时间、数量等信息录入到电脑中的物料管理系统中去。

一汽大众应用物流系统纪实一汽大众汽车有限公司目前仅捷达车就有七八十个品种、十七八种颜色,而每辆车都有2000多种零部件需要外购。

从1997年到2000年年末,公司捷达车销售从43947辆一路跃升至94150辆,市场兑现率已高达95—97%。

与这些令人心跳的数字形成鲜明对比的是公司零部件居然基本处于“零库存”状态,而制造这一巨大反差的就是一整套较为完整的物流控制系统。

一个占地9万多平方米、可同时生产三种不同品牌的亚洲最大的整车车间,它的仓库也一定非常壮观吧?可这里没有仓库,只有入口。

一汽大众的零部件送货形式有三种:第一种是电子看板,即公司每月把生产信息用扫描的方式通过电脑网络传递到各供货厂,对方根据这一信息安排自己的生产,然后公司按照生产情况发出供货信息,对方则马上用自备车辆将零部件送到公司各车间的入口处,再由入口处分配到车间的工位上;第二种叫作“准时化(Just-in-time)”,即公司按过车顺序把配货单传送到供货厂,对方也按顺序装货直接把零部件送到工位上,从而取消了中间仓库环节;第三种是批量进货,供货厂每月对于那些不影响大局又没有变化的小零部件分批量地送一到两次。

在一汽公司流行着这样一句话:“在制品是万恶之源”,用以形容大量库存带来的种种弊端。

在生产初期,捷达车的品种比较单一,颜色也只有蓝、白、红三种。

公司的生产全靠大量的库存来保证。

随着市场需求的日益多样化,传统的生产组织方式面临着严峻的挑战。

1997年,“物流”的概念进入了公司决策层。

考虑到应用德方的系统不仅要一次性投入1500万美元,每年的咨询和维护费用也需要数百万美元,中方决定自己组织技术人员和外国专家进行物流管理系统的研究开发。

1998年年初,公司开发的物流控制系统获得成功并正式投入使用。

如今,这套用了不足300万元人民币的系统经受住了十几万辆车的考验。

在整车车间,生产线上每辆车的车身上都贴着一张生产指令表,零部件的种类及组装顺序一目了然。

一汽大众入厂物流模式第3章一汽-大众入厂物流现状分析一汽-大众零件供应主要通过两种途径:进口件(CKD件)和国产件。

从国外进口,在德国汉堡港装船,经海运抵达中国大连等地,再经国内公路或铁路运输到达长春,即CKD零件。

主要供应商在一汽-大众公司附近,一部分在东北地区,采用铁路运输、公路运输和水运,即国产化零件。

3.1总装车间物料供应模式一汽-大众汽车有限公司在长春建有两个总装生产厂,分别是一厂和二厂。

总装一厂于1997年8月投产;总装二厂于2004年12月建成并投产。

总装二厂在总装车间的物料供应模式及物流规划思路上都是对一厂的继承、发展和提高。

依据零件来源方式,总装车间物料主要来源于自制件、外协件及CKD件三种。

自制件是指本一汽自己加工、组装的零部件,如车身、发动机等。

外协件是指公司以外生产,通过采购使用的零件。

根据具体的物料看板、交接、结算不同,在一汽-大众又分为JIT供货和看板供货两种方式。

CKD件是主要指在德国生产,通过采购使用的零配件。

总装车间三种不同来源的物料,具体的实物运输方式有所不同。

3.2自制件物流过程如图3.1所示,本厂件运输可以利用悬挂运输和汽车短途运输。

一般来说,如果物料转移仅考虑成本中心,不考虑利润中心,自制件不必考虑企业内部的单据交接,简化了自制件实物流。

一汽-大众三种物料来源如图3.1所示。

(1)悬挂运输。

在一汽-大众,当喷漆车间完成车身喷涂工作,放置到悬挂上,由悬挂经过封闭通道运输到总装车间。

汽车零部件悬挂运输在运输设计上封闭通道能完全杜绝外界环境对于金属零部件的各种物理和化学影响,密闭通道保证了零部件不与外部接触,很大程度上减少了货物的缺失等现象。

但悬挂运输的成本较高、投资相对较大;需要规划出响应的空间,并且对于信息系统的依赖大。

(2)短距离运输。

在一汽-大众总装车间,本厂件的发动机和传动器主要采用短距离运输。

在动力总成工段,用户的订单决定工人选取的发动机和传动器型号。

物流一般标准一汽-大众汽车生产管理部适用于一汽-大众汽车供应生产零件和材料的一次配套国供应商Version:Jan.2006目录前言31.原则42.供货方式43.结算依据44.供应商的地理位置45.供货物流方案56.运输要求57.中转仓储要求58.包装要求69.零件需求计划710.要货信息系统811.处罚原则812.技术更改913.工作时间914.联系人915.应急预案916.安全管理917.物流费用报价10附件1 供货信息系统投资与费用11附件2 一汽-大众生产管理部组织机构与物流联系人员12附件3 零件费用定义13前言此《物流一般标准》是根据一汽-大众生产管理部的要求结合在日常工作中实际发生和存在的情况而制定,其目的是为了能够在新件定点前明确其物流要求,使预选供应商能够更准确的完成物流费用报价,为今后批量供货时实施物流要求提供基础和保证。

在新零件开始实施时,一汽-大众生产管理部将按照零件定点时所确定的物流标准进一步进行明确和调整。

在日常的供货和操作过程中,所有供应商必须遵照此《物流一般标准》和其它一汽-大众书面提出的具体物流要求,履行供应商与一汽-大众合同所规定的各项义务和责任,杜绝所有不符合现象,从而提高整个物流环节的操作效率和控制能力。

一汽-大众生产管理部拥有本《标准》的最终解释权。

随着一汽-大众的发展和有关法规新要求的提出,一汽-大众将予以更新并与时重新发布。

1.原则1.1.预选供应商必须按一汽-大众的物流要求组织、规划自己的物流过程,并按此完成报价,在一汽-大众的报价单中明确各项物流费用。

1.2.供应商在供货过程中不仅须遵守本《标准》所述物流要求,亦须遵守在本《标准》未着重或未提与的一汽-大众规定的其它方面的物流标准和要求。

1.3.供应商在物流供货过程上对报价、操作方案有任何变化均须获得一汽-大众生产管理部的认可、同意后方可实施,否则将由供应商承担由此引起的后果。

2.供货方式原则上,零件供应到一汽-大众指定地点有三种供货方式:2.1.看板供货(KANBAN):供应商按照一汽-大众以电子看板(或)形式发出的要货需求送货到一汽-大众入口。

一汽大众公司汽车物流业务优化方案研究第三章一汽大众物流现状分析一汽大众汽车有限公司是由中国第一汽车集团公司和德国大众汽车股份公司、奥迪汽车股份公司及大众汽车(中国)投资有限公司合资经营的大型轿车生产企业,是我国第一个按经济规模起步建设的现代化轿车工业基地。

一汽大众于1991年2月6日正式成立,1997年8月正式通过国家验收。

2004年12月7日,一汽大众轿车二厂正式建成投产。

一汽大众采用先进技术和设备制造当今世界名牌产品—捷达、宝来、高尔夫、开迪、速腾、迈腾、奥迪系列轿车。

一汽大众的建成,使我国轿车工业进入了大规模生产的新时期,一汽大众已成为成熟的A、B、C全系列汽车生产制造基地。

从1991年生产第一批捷达轿车至今,一汽大众公司从一个注册资本只有37.12亿元人民币的企业发展到现在拥有总资产276亿元人民币的大型汽车企业。

目前,一汽大众公司累计向国家上缴的税金达到400多亿元人民币。

目前,一汽大众汽车有限公司员工总人数超过9700人。

在欧美市场,汽车成品运输量是每年1300万辆,这是目前的汽车运输饱和数量。

不过由于中国和印度的汽车生产的崛起,汽车产品的运输市场在今后6年内可能略有增长[13]。

经过不断发展,一汽大众现已形成日产1000多辆整车的生产能力,同时实现部分整车、总成及零部件的出口。

3.1公司物流体系结构汽车物流是沟通原料供应商、生产厂商、批发商、零件商、物流公司及最终用户满意的一座桥梁,是集现代运输、仓储、保管、搬运、包装、产品流通及物流信息于一体的综合性管理,是实现商品从生产到消费各个流通环节的有机结合。

对汽车企业来说,汽车物流主要包括生产计划的制订、采购订单的下放及跟踪、物料清单的维护、供应商的管理、运输管理、进出口、货物的接收、仓储管理、发料及在制品的管理和生产线的物料管理、整车的发运等[14]。

一汽大众是典型的制造型企业,包含了几乎全部的物流过程,采购,生产,销售。

因此对一汽大众物流体系的研究具有典型性和普遍性,对其他企业有借鉴意义。

【案例】一汽大众运用第三方物流的实践主题词:第三方物流,网络技术,物流配送汽车物流具有一定的复杂性,由于汽车产品的差异化和高质量,要求物流管理必须达到正确的时间、正确的零件、正确的数量、正确的位置和最低的成本,高频度和高精度的物料组织,并要求在千百次重复工作中的每一次必须达到及时、准确。

这也是物流管理的最终目标,物流过程的优劣直接与产品、质量、成本和客户满意度相关,直接影响企业的生存。

中国第一汽车集团公司已挂牌转让成都一汽汽车有限责任公司100%股权。

当成都一汽挂牌转让的消息出来后,立即引起了各方的高度关注。

经记者核实,成都一汽的买家是一汽大众汽车有限公司,收购完成后,一汽大众将成立一汽大众汽车有限公司成都分公司,生产捷达、速腾等大众品牌车型,根据计划,到2014年,一汽大众成都分公司的年产量将达到35万辆。

但由于采用了第三方物流,所以国产化物流组织相对较为顺畅,同时也实现了零库存管理,降低了占用资金。

大众物流公司是在1997年成立的第三方物流公司,主要负责为一汽大众公司提供目前五个车型、近3000种国产化汽车零部件物流服务。

通过近7年不断对物流管理的实践与探索,在信息系统、仓储配送、精确供货方面达到了一定的技术水平,成为一汽大众公司唯一指定的国产化第三方物流服务配套商。

计算机网络技术是保证信息及时、畅通、准确反馈和共享的基础和手段。

目前大众物流公司生产管理系统是以无线网的方式登录一汽大众公司的R3(D2801)系统,共享生产信息,包括物流的入口信息、生产计划信息和供应商供货能力信息。

有安全可靠的信息存档(如条形码扫描)和完善的信息环节,具备用户导向时间短、成本低的接口开发可能性;内部物流作业使用的R3(CY)仓储模块与R3(D2801)属同一软件平台,具有扫描出、入库功能,可与厂家实时共享信息,同时正在完善和所有供应商之间的联网工作,实现科学的要货运营模式。

仓储和库存管理是物流公司管理的核心。

古一汽大众国际物流模式一、一汽大众与一汽轿车公司供应链结构示意简图及其简要说明: 见下页注: 1为专业的运输企业或供应商的自由车队将大批量的零部件送到中间仓库 2为中间仓库调配货车将小批量零部件运送到备件库及生产线3为陆捷公司、长久集团等整车发运企业将备件及成品车送至全国各地的 4S 店国内供应商:分布在全国各地,如长春、哈尔滨、浙江等地国外供应商:分布在世界各地如美国、日本、德国等中间仓库:由大众装配、国际物流等第三方物流企业提供并管理备 件 库:即将发往全国各地4S 店的各种零部件集中存于此处,由陆捷等公 司提供并管理生产 线:为一汽大众或一汽轿车的焊装、涂装、分装及总装线每天一汽大众及一汽轿车的生产能顺利进行,就得益于这条供应链的顺畅流通, 而要保证此供应链的顺利流通,就需要供应链上的伙伴能够共同分享他们所需要 的各种信息,从而使它们能够协调运作。

更重要的是通过业务外包的资源整合, 既节约了运营成本又提高了效率,实现了强强联合达到了共赢的目的。

二、运营模式简介由于本次实习活动只牵涉到大众装配的一汽轿车国产件的仓促与配送业务、 国际 物流的一汽大众的CKD 和国产件的仓促与配送及一汽大众的生产物流,且两家 物流单位在国产件业务上基本相同,因此以下将综合介绍而不再分开说明。

本报 告主要围绕中间仓库进行展开说明。

(一) 订货模式中间仓库的计划员根据生产线的月计划、 周计划与日计划(由于备件量小,此处 忽略不计),再结合仓库的实际情况及供应商的距离远近编制订货计划(举例见 “仓储方式”中例子),然后以电子信息形式发送到各供应商。

其中 CKD 件由生 产线直接向国外供应商订货,经大连港口将装有零部件的集装箱运到国际物流集 装箱仓库中心,然后根据生产需要打开集装箱,将各种零部件送至指定的库房 (DC 或BC )等待配送。

(二) 仓储方式接到订货信息后各供应商将零部件送到指定的仓库, 由负责此件的保管员负责验 收然后入库。

物流一般标准一汽-大众汽车有限公司物流一般标准一汽-大众汽车有限公司生产管理部适用于一汽-大众汽车有限公司供应生产零件和材料的一次配套国内供应商Version:Jan.2006 2006-01-05 1-13 LO-LP FAW-VW 物流一般标准一汽-大众汽车有限公司目录前言 (3)1.原则 (4)2.供货方式 (4)3.结算依据 (4)4.供应商的地理位置 (4)5.供货物流方案 (5)6.运输要求 (5)7.中转仓储要求 (5)8.包装要求 (6)9.零件需求计划 (7)10.要货信息系统 (8)11.处罚原则 (8)12.技术更改 (9)13.工作时间 (9)14.联系人 (9)15.应急预案 (9)16.安全管理 (9)17.物流费用报价 (10)附件1 供货信息系统投资及费用 (11)附件2 一汽-大众生产管理部组织机构及物流联系人员 (12)附件3 零件费用定义 (13)2006-01-05 2-13 LO-LP FAW-VW 物流一般标准一汽-大众汽车有限公司前言此《物流一般标准》是根据一汽-大众生产管理部的要求结合在日常工作中实际发生和存在的情况而制定,其目的是为了能够在新件定点前明确其物流要求,使预选供应商能够更准确的完成物流费用报价,为今后批量供货时实施物流要求提供基础和保证。

在新零件开始实施时,一汽-大众生产管理部将按照零件定点时所确定的物流标准进一步进行明确和调整。

在日常的供货和操作过程中,所有供应商必须遵照此《物流一般标准》和其它一汽-大众书面提出的具体物流要求,履行供应商与一汽-大众合同所规定的各项义务和责任,杜绝所有不符合现象,从而提高整个物流环节的操作效率和控制能力。

一汽-大众生产管理部拥有本《标准》的最终解释权。

随着一汽-大众的发展和有关法规新要求的提出,一汽-大众将予以更新并及时重新发布。

2006-01-05 3-13 LO-LP FAW-VW 物流一般标准1.原则一汽-大众汽车有限公司1.1.预选供应商必须按一汽-大众的物流要求组织、规划自己的物流过程,并按此完成报价,在一汽大众的报价单中明确各项物流费用。

一汽大众国际物流

一汽大众国际物流公司位于苏州,是一家专业制造多样性汽车物流系统的领先企业。

一汽大众国际物流公司专业提供从国际贸易到国内以及国外仓储物流的一站式便捷服务。

公司的使命是努力做到最好的物流服务,专注于客户的服务和分配集中资源,以及满足不断变化的战略需求。

一汽大众国际物流公司拥有雄厚的物流资源,有完善的全球物流网络,能够满足不同国家不同城市的国内外物流需求,实现客户全球最优化物流网络设计。

另外,一汽大众国际物流公司还拥有完善的实时信息化管理系统,以及完备的质量控制和管理机制,使得公司的货物物流服务能够及时准确的到达所要求的地点。

除了为客户提供高效的供应链管理服务外,一汽大众国际物流公司还提供以下服务:集装箱服务、多式联运、冷链物流、保税物流服务、国际海陆联运、高安全性仓储服务以及国际货运代理。

同时,公司还为客户提供全方位的物流咨询服务,以满足客户的不同需求,提高物流运营效率。

一汽大众国际物流公司不仅提供灵活的物流服务,还以优质的服务为依托,努力赢得客户的信赖,让客户的物流费用最小化,将客户的物流成本最大化,为客户提供最好的一站式物流服务。

它一直以创新、诚信、服务至上的态度,为客户提供最高效、最安全、最优质的物流服务。

General Logistic StandardFAW-Volkswagen Co. Ltd.Logistics DepartmentApplies to all domestic first-tier suppliers supplying FAW-Volkswagen Co. Ltd. with manufacturing parts and materialsVersion: Jan. 2006ContentsForeword (3)1. General Principles (4)2. Goods Supply Methods (4)3. Settlements (5)4. Geographical Location of Suppliers (5)5. Logistic Solutions (5)6. Transport Requirements (6)7. Transit Warehouse Requirements (6)8. Packaging Requirements (7)9. Part Requirement Planning (9)10. Goods Demand Information Systems (10)11. Fines (11)12. Changes in Technology (11)13. Working Hours (12)14. Contacts (12)15. Emergency Planning (12)16. Safe Management (12)17. Logistic Cost Quotations (13)Appendix 1 Investment & Running Costs for Goods Supply Information Systems (13)Appendix 2 Organizational Structure & Logistic Contact Persons of FAW-Volkswagen’s Logistics Department (15)Appendix 3 Part Cost Definition (17)ForewordThis “General Logistic Standard” was compiled based on the requirements of FAW-Volkswagen’s Logistics Department and actual and existing circumstances arising from day-to-day work, with the aim of clarifying logistic requirements before a new part is designated, enabling pre-selected suppliers to produce more accurate logistic quotations, and providing a foundation and guarantee for the future implementation of logistic requirements during batch goods supply. When a new part is processed, the FAW-Volkswagen Logistics Department will carry out further confirmation and adjustments according to the logistic standard decided during part designation.During day-to-day goods supply and operations, all suppliers must abide by the specific logistic requirem ents of the “General Logistic Standard” and any other of FAW-Volkswagen's written suggestions, and perform all the duties and obligations stipulated in the contract between the supplier and FAW-Volkswagen, avoiding all non-compliant behavior, and thus improve the operation efficiency and control capabilities of the whole logistic cycle.FAW-Volkswagen reserves the right of final interpretation of the "Standard.” With the development of FAW-Volkswagen and the new requirements of relevant laws and regulations, the Company will update and promptly re-release this document.1. General Principles1.1. Pre-selected suppliers must organize and plan their logistic process based on FAW-Volkswagen's logistic requirements, and in turn complete the quotation according to this process, making sure that each logistic cost is made clear in FAW-Volkswagen’s quotation form. 1.2. During the goods supply process, the supplier must not only abide by the logistic requirements described in the “Standard”, but also abide by other logistic standards and requirements stipulated by FAW-Volkswagen not emphasized or mentioned by the “Standard.”1.3. If, during the goods supply process, there are changes to the quotation and/or mode of operation, the supplier must obtain the approval and agreement of the FAW-Volkswagen Logistics Department before these become effective, otherwise the supplier must take the responsibility for any consequences that arise from these changes.2. Goods Supply MethodsIn principle, parts supplied to FAW-Volkswagen's designated sites can reach their destination via three methods:2.1. Kanban Goods Supply: The supplier delivers goods to FAW-Volkswagen's logistic entranceaccording to the goods demand sent by FAW-Volkswagen via electronic Kanban (or telephone).2.2. Just In Time (JIT) Goods Supply: The supplier delivers goods to FAW-Volkswagen’s logistic entranceaccording to the car manufacturing sequence. Whenever necessary, internal JIT production must be carried out according to FAW-Volkswagen's requirements.2.3. Requirement Planning Goods Supply: The supplier (outside Changchun) supplies goods to a specified transit warehouse (the parts remain the property of the supplier) according to the goods arrival time and quantities required in the Part Requirement Plan, and are then sent from the transit warehouse to FAW-Volkswagen’s logistic entrancevia Kanban or JIT methods.Pre-selected suppliers can obtain relevant information from FAW-Volkswagen’s Contracting-Out New Parts document.3. Settlements3.1. Parts Supplied Via Kanban: FAW-Volkswagen will make settlements according to the number of parts registered in its logistic entry system as having entered the warehouse.3.2. Parts Supplied Via JIT: FAW-Volkswagen will make settlements according to the number of parts at point CP7 , after cars have come off the assembly line.4. Geographical Location of SuppliersIn order to ensure that a supplier can dispatch goods to FAW-Volkswagen upon receipt of its goods demand within the controlled time, suppliers should be located near the Company (suppliers located near the transit warehouse would also fulfill this requirement).4.1. Kanban Parts: After receiving FAW-Volkswagen’s goods demand notice, goods must be delivered to the Company’s logistic entrance within 2 hours.4.2. JIT Parts: Ideally, the supplier will be located within a 5 km radius of FAW-Volkswagen. The limit is 25 km.5. Logistic Solutions5.1. After pre-selected suppliers sign a Test Manufacture Agreement (TMA) with FAW-Volkswagen, they should immediately get in contact with the Logistic Planning Section of the Logistics Department and decide upon a “Part Supply Logistic Solution,” seeking final confirmation with the Logistic Planning Section.The “Part Supply Logistic Solution” includes transport, tra nsit warehouse, packaging, etc solutions required for parts to deliver from the supplier to FAW-Volkswagen’s entrance.5.2. Before the batch goods supply, the supplier must make preparations according to the “Part Supply Logistic Solution.” If for any reas on something cannot be completed according to plan, the supplier must contact the Logistic Planning Section in advance.5.3. The supplier must rigorously execute the logistic solution; if any changes are required, the supplier must contact the Logistic Planning Section in advance and, having obtained its approval, carry out the changes.6. Transport RequirementsWhen transporting parts, in addition to abiding by Chinese laws, regulations and industry standards, the supplier must also pay attention to the following:6.1. The vehicle used to transport the parts must be of a van-type with a sealed hold and convenient for loading and unloading. The vehicle must also be in good condition and all equipment (fastenings, fire prevention equipment, etc) must be in full working order. During transport, containers and racks should be appropriately fixed down.6.2. Vehicles that enter FAW-Volkswagen must fulfill the Company’s requirements.6.3. Drivers and delivery men must be well-trained, ensuring that suppliers are contacted swiftly during transportation.6.4. Chemicals, oils & lubricants and dangerous articles must be transported in special vehicles, while the transport of easily flammable and explosive chemicals must be approved by the Public Security Department, and transported according to the requirements of Chinese regulations, also taking the necessary safety measures (i.e. warning signs in clear view).6.5. In order to enhance core competitiveness by lowering part transport costs, FAW-Volkswagen may entrust the one carrier to transport the goods of more than one supplier:6.5.1. If the part transport cost of a supplier can be optimized, FAW-Volkswagen will organize joint transportation, pay the carrier, and deduct the relevant amount from the part cost it owes the suppliers. Moreover, in any subsequent quotations, the supplier will not have to include transport costs. FAW-Volkswagen will notify the implementation of this measure at a later date;6.5.2. If the part transport cost cannot be optimized, the supplier must make its own transport arrangements.7. Transit Warehouse Requirements7.1. Currently, FAW-Volkswagen has designated two localized transit warehouses in Changchun; for FAW-Volkswagen’s Car Plant 1 and Car Plant 2 respectively:A. Transit Warehouse of Factory 1: Volkswagen Logistics Changchun Co. Ltd., abbreviatedto LILA1B. Transit Warehouse of Factory 2: FAW International Logistics Center, abbreviated to LILA27.2. In principle, FAW-Volkswagen requires suppliers outside Changchun to store their parts at LILA1 or LILA2; depending on the supplier’s region, the following time appl ies for transit warehouse storage:7.3. The exact storage time for each part must be confirmed with the Material Disposition Section of the Logistics Department.7.4. If the usage time of the smallest capacity package of a part exceeds the above stipulated time, it should be used as the standard time for that particular part.7.5. Parts must be sent and stored in the corresponding transit warehouse depending on the car and machinery types produced respectively at the two factories. Parts required by both factories should be dealt with according to the Logistic Solution determined with the Logistic Planning Section.7.6. In order to facilitate unified management, FAW-Volkswagen does not encourage suppliers to set up their own transit warehouse in Changchun; moreover the supplier is fully responsible for any inconveniences or increased expense that such a move might entail.7.7. For parts stored at LILA1:7.7.1. Currently, it is the supplier that pays for storage costs at LILA1;7.7.2. In order to enhance core competitiveness by lowering part storage costs, FAW-Volkswagen plans to directly pay for LILA1 storage costs and then deduct the relevant amount from the part costs it owes the suppliers. Moreover, in any subsequent quotations, the supplier will not have to include part storage costs. FAW-Volkswagen will notify the implementation of this measure at a later date;7.8. For parts stored at LILA2: FAW-Volkswagen directly pays for LILA2 storage costs; quotations should not include part storage costs.8. Packaging Requirements8.1. In principle, when parts that are due to be sent directly from supplier to FAW-Volkswagen leave the factory, they are packaged in re-usable logistic equipment (plastic containers, metal containersand racks); when parts that are due to go through the transit warehouse leave the factory, they are packaged in disposable packaging (paper packaging). These parts are then re-packaged into re-usable logistic equipment at the transit warehouse, before being sent to FAW-Volkswagen's logistic entrance. All packaging must conform to quality, safety and environmental-friendly requirements, and the exact packaging solution of each part must be determined with the Logistic Planning Section, ensuring that all preparations are completed within its time requirements.8.2. Manufacture and maintenance:8.2.1. Re-usable logistic boxManufacturing standards and quantities are determined by the Logistic Planning Section, meaning that the supplier should only manufacture or purchase this equipment from the box-manufacturers designated by FAW-Volkswagen; however the price of this equipment should be negotiated independently. At the same time, the supplier must carry out maintenance, updating, cleaning and the processing of signs according to FAW-Volkswagen's requirements;8.2.1.1. Logistic equipment in common-use(1.1) From supplier directly to FAW-Volkswagen’s entrance: All equipment is to beprovided by the supplier;(1.2) From supplier to transit warehouse: All equipment is to be provided by the supplier;(1.3) From LILA1 to FAW-Volkswagen’s entrance: Equipment used during transport is tobe provided by the supplier;From LILA2 to FAW-Volkswagen’s entrance: E quipment used during transport is to be provided by FAW-Volkswagen;8.2.1.2. Special Logistic Equipment(2.1) From supplier directly to FAW-Volkswagen’s entrance: All equipment is to beprovided by the supplier;(2.2) From supplier to transit warehouse: All equipment is to be provided by the supplier;(2.3) From LILA1 to FAW-Volkswagen’s entrance: All equipment is to be provided by thesupplier;From LILA2 to FAW-Volkswagen’s entrance: Equipment used during transport is to be provided by FAW-Volkswagen;8.2.2. Disposable packaging: The supplier must manufacture or purchase this according to therequirements of FAW-Volkswagen's Logistic Planning Section.8.3. Equipment depreciation: Metal equipment depreciation is calculated on a 6 year basis, while plastic equipment depreciation is calculated on a 3 year basis.8.4. Equipment maintenance: In principle, equipment maintenance should be carried out at FAW-Volkswagen-designated logistic equipment suppliers; if the supplier carries out maintenance independently, this must still be done in accordance with FAW-Volkswagen’s equipment standards.8.4.1. From supplier directly to FAW-Volkswagen’s entrance: All equipment is to be maintained by the supplier;8.4.2. From supplier to transit warehouse: All equipment is to be maintained by the supplier;8.4.3. From LILA1 to FAW-Volkswagen’s entrance: Equipment used during transport is to be maintained by the supplier;8.4.4. From LILA2 to FAW-Volkswagen’s entrance: Equipment used during transport is to be maintained by FAW-Volkswagen;8.4.5. When responsibility for damaged equipment is indisputable, whoever is responsible will carry out the repair.8.5. Package signs: the supplier must place signs on packages according to the requirements of FAW-Volkswagen’s Logistic Pl anning Section, and ensure that signs are correct, in good condition, and in clear view; after empty equipment is returned, suppliers must promptly process old signs to ensure the traceability of parts.8.6. Return of empty equipment: the supplier and transit warehouse should promptly return empty equipment according to the requirements of FAW-Volkswagen’s Logistic Planning Section.9. Part Requirement Planning9.1. The supplier should organize and arrange its own production and material preparation work according to FAW-Volkswagen’s Part Requirement Plan.9.2. Outside suppliers must supply goods to a designated transit warehouse according to the goods arrival time and quantity stipulated in the Part Requirement Plan.9.3. The supplier must apply for a free email address from FAW-Volkswagen’s Supply Department; when batch goods supply status has been achieved, FAW-Volkswagen will send the PartRequirement Plan to this address.9.4. The supplier should ensure that the email account is checked regularly every FAW-Volkswagen working day and that messages and notices from the Company are acted upon; if a problem with the email account arises, the supplier should immediately contact FAW-Volkswagen; if the Company does not receive any feedback from the supplier, it will assume that everything is proceeding according to plan.9.5. FAW-Volkswagen’s Part Requirement Planning:9.5.1. Net Requirement Planning: the SAP System provides Rolling Requirement Plans for parts. The goods demand plan, sent weekly, includes 26 weeks of weekly part requirements. Whenever necessary, the detailed goods demand, sent daily, includes 4 weeks of daily requirements.9.5.2. Supplementary Planning: In the event of part shortage, wrong-delivery, damage, etc, additional plans (as agreed earlier) must be carried out via telephone, fax or email.9.6. The supplier must possess efficient planning capabilities, and have sufficient stock to satisfy requirements besides those of FAW-Volkswagen.10. Goods Demand Information Systems10.1. Kanban parts10.1.1. The supplier must establish an R/3 System connection with FAW-Volkswagen, which the Company’s logistic entry will use to send an Electronic Kanban containing goods demand information. The supplier will carry out the goods supply by connecting to the R/3 System and printing a bar-coded Goods Supply Form;10.1.2. Each year the supplier must pay an information service charge to FAW-Volkswagen, see appendix 1.10.2. JIT parts10.2.1. The supplier must purchase the FIS System provided by FAW-Volkswagen. JIT goods supply will be carried out according to the part requirement messages sent by the FIS System based on the CP5A manufacturing sequence;10.2.2. Via a computer system, the supplier receives, respectively, the assembly sequence plan guidelines sent by body shop point R100 (car bodies are online) or a later-stage information pointand the assembly sequence plan guidelines sent by point M100 (CP5A). JIT production or back-up preparations are carried out according to the assembly sequence plan guidelines;10.2.3. The supplier must pay FAW-Volkswagen for the equipment essential for JIT, and also pay an information service charge, see appendix 1.10.3. FAW-Volkswagen’s Company Management Services and Logistics Departments will be jointly responsible for the management of the Logistics Information System (hardware and software). Should a problem with the goods supply system arise, the supplier should promptly report to FAW-Volkswagen.11. Fines11.1. If, because of a problem with the supplier (late goods supply, batch production quality falls short of the mark, etc), FAW-Volkswagen has to halt production, the Production Control Section of the Logistics Department will notify the supplier of the need for improvement and give out a fine according to the standards stipulated by the relevant department. Currently the fine is set at: 150 RMB/min.11.2. If the supplier violates any of FAW-Volkswagen’s relevant regulations and causes the Company’s logistic operations to incur additional costs, the Company’s relevant de partment will calculate these and ask the supplier to provide compensation.12. Changes in Technology12.1. If the technology of a part changes, the supplier should determine the time for production preparations according to accurate drawings, and notify FAW-Volkswagen’s Procurement Department the production time of the new part, as well as completing production preparations within the stipulated time.12.2. Via the Procurement Department, the Pre-series Management Section of the Logistics Department will i ssue the supplier with a “Technology Change Timetable", the supplier must then provide the goods according to the technology change implementation time.13. Working HoursThe supplier must arrange its working hours (shift changes, rest days, holidays, meetings, production capacity fluctuations, etc) according to FAW-Volkswagen’s production calendar and specific circumstances, and complete goods delivery within the requirements of FAW-Volkswagen's goods delivery windows.14. Contacts14.1. In order to efficiently carry out goods delivery and other relevant business, the supplier must designate a contact person for each section of the Logistics Department, and ensure that these can be contacted at all time during FAW-Volkswagen's working hours.14.2. As soon as there is a contact person or contact details change, the relevant section of FAW-Volkswagen should be immediately notified and the relevant information passed on.14.3. For the contact person and contact details of each section of FAW-Volkswagen’s Logist ics Department, see appendix 2; after a part TMA has been signed between the supplier and FAW-Volkswagen, the relevant person in charge of the Logistic Planning Section must be immediately contacted in order to decide upon the logistic solutions and other relevant logistic matters.15. Emergency PlanningThe supplier must carefully consider all the factors that may affect the normal operation of all the cycles of the logistic process, and on the basis of this stipulate an effective emergency plan to safeguard FAW-Volkswagen’s production. Whenever necessary, the emergency plan must be approved by FAW-Volkswagen.16. Safe ManagementThe supplier must ensure its compliance with Chinese and local laws and regulations, safety regulations, Identificatio n Technology regulations, FAW-Volkswagen safety regulations, etc, and ensure that day-to-day operations conform to these.17. Logistic Cost QuotationsFAW-Volkswagen employs an A-B split-cost method to carry out new part cost enquiries; for the definition of part costs see appendix 3. Before making a logistic cost quotation, the supplier must first carefully read the present standard and all of its appendices; otherwise it will be responsible for any consequences arising from mismanagement.Appendix 1 Investment & Running Costs for Goods Supply Information SystemsI. Hardware for Electronic Kanban Goods Demand System1) One network password card (6 month waiting period, FAW-Volkswagen to order on behalfof supplier)2) One personal computer (20,000 RMB, to be paid by supplier to FAW-Volkswagen)3) One printer (Model no. HP2000 or above, to be purchased independently by supplier)4) Kanban printing paper (4 sheets per document, to be purchased independently bysupplier)5) Annual service charge (3,000 RMB, to be paid by supplier to FAW-Volkswagen)II. One-off investment & annual costs for JIT goods supply factoriesAppendix 2 Organizational Structure & Logistic Contact Persons of FAW-Volkswagen’s Logistics DepartmentI. Organizational structure of FAW-Volkswagen's Logistics DepartmentII. FAW-Volkswagen's logistic contact personsAppendix 3 Part Cost DefinitionI. A-B cost definitionTransport Costs - A, Direct delivery to FAW-Volkswagen’s entrance: Transport from supplier to FAW-Volkswagen’s entranceB, Via transit warehouse: Transport from supplier to transit warehouse(Including the return of empty equipment)Storage Costs - A, Direct delivery to FAW-Volkswagen's entrance: No storage costsB, Via transit warehouse: Storage in transit warehouse and delivery of parts toproduction line (transport, hand-over and return of empty containers) Equipment Costs - Including re-usable equipment depreciation and maintenanceSorting Costs: Costs specially incurred during part sorting. Including sorting equipment, information equipment, workers, dimensions, etcPlease Note:1. The logistic cost of JIT parts includes points 1-4, while the logistic cost of non-JITparts includes points 1-3;2. If a supplier builds or rents its own warehouse in Changchun, it must still pay forstorage costs.。