YSF6型系列压力释放阀说明书

- 格式:pdf

- 大小:231.49 KB

- 文档页数:4

箱式变压器运行规程1 适用范围本规程适用于中国水电顾问集团风电××有限公司××风电场风力发电机组专用组合箱式变压器正常运行维护和事故处理。

2 引用标准国家电网公司电力安全工作规程(变电部分)国家电网公司电力安全工作规程(线路部分) 1995 电力变压器运行规程DLT572——电力设备预防性试验规程DLT596——1996相关设备技术参数说明及使用手册相关参数33.2 负荷开关技术参数4 运行前检查和试验4.1核对变压器铭牌数据、开关分接位置和变压器接线是否和电网匹配。

4.2检查箱变外观是否良好,是否有渗漏油现象,高、低压开关室门锁是否完好,有无锈蚀、磕碰和破损现象;检查低压开关室内的元件二次接线是否松动。

4.3上述检查完毕后,箱变须按GB50150-1990《电气装置安装工程电气设备交接试验标准》进行安装前试验。

通过上述交接试验即可投入运行。

5 运行规定5.1投入运行5.1.1箱变应可靠接地。

高低压开关室内均有接地螺栓。

5.1.2箱变投入运行前,必须先操作压力释放阀将油箱内部可能存在的压力释放掉。

5.1.3压力释放阀的操作应在压力表处于正压的情况下进行,否则会使油箱呈负压而吸入潮气。

5.1.4在运行过程中,切换负荷开关必须由持有高压操作证书的电工使用专用操作杆按《高压操作规定》进行操作。

5.1.5当有异常情况发生时,可通过检查油位、温度、取油样等进行判断。

5.2箱变允许运行方式额定运行5.2.15.2.1.1 在规定的冷却条件下,可按铭牌规范运行。

5.2.1.2箱变运行中的允许温度应按油面温度来检查,油面温升值应不超过标准中规定的数值。

5.2.1.3箱变的输入电压可以比额定值较高,但一般不超过额定值的5‰。

5.2.2 过负荷运行5.2.2.1箱变可以在正常过负荷和事故过负荷的情况下运行,正常过负荷可以经常使用,其允许值根据变压器的负荷曲线,冷却介质的温度以及过负荷前变压器所带的负荷来确定,事故过负荷只允许在事故情况下(例如:运行中的若干台变压器中有一台损坏,又无备用变压器可以按事故过负荷运行)使用。

一、油浸纸电容式套管;1.适用范围;油纸电容式变压器套管(以下简称套管)用于变压器出线导体穿过外壳起绝缘和支持导体之用,套管在变压器安装时,其轴线与垂线间的角度最大不超过300。

2.套管的主要结构;套管是由油枕、瓷套、法兰及电容芯子连接组成。

主绝缘电容芯子是由绝缘纸和铝箔电极在导电管上卷绕而成的同心圆柱形串联电容器用以均匀电场,经真空干燥、浸油处理后成为电气性能极高的油纸绝缘体。

瓷套为外绝缘同时还作为保护主绝缘的容器。

套管的头部油枕上设有油位表可以指示油位变化。

套管的中间设有供安装连接用的法兰,法兰上设有供变压器注油时放出变压器上部空气的放气阀及测量套管tgδ的测量引线装置。

套管采用全密封金属结构,其内部充以经特殊处理的优质的10GBX尼纳斯变压器油,套管的电容芯子完全不与大气相通。

可以避免阳光的照射和大气中的有害物浸入套管内部,而使绝缘老化。

所有连接件不受气候影响。

3.安装程序;①安装前应查清套管型号、代号、规格是否符合订货单的使用要求,按装箱单查看零附件及文件是否齐全,检查套管在运输过程中有无损伤及渗漏现象。

②以正确方式把包装箱水平放在地面上,打开箱盖,把挂钩挂在法兰凸缘的吊环孔中固定绳吊具,当吊具附有撑板时应有足够的长度,当套管在垂直位置时,撑板至少应高出套管顶部600mm把提绳滑轮安装在撑板中心或吊钩上,并在套管由枕与第一个瓷扇之间加上一条绳,(套管的重量、吊车的选用上)固定好滑轮、套管提出包装箱。

彻底地清洁套管安装法兰的底面,接地部分及下瓷套。

③按正确位置将均压球安装到位。

④变压器引线装置;把接线板(引线接头)应固定在变压器输出端,注意密封圈不要遗忘。

在安装引线接头时,用细绳足够力的拉线穿入套管中心管并用这根线把引线接头的M12螺栓连接。

⑤把引线接头安装到变压器输出端的未端上,并彻底清洁引线接头表面和变压器引线清洁变压器升高座顶部表面的密封垫、并固定其位置,检查套管的法兰及下瓷套是否完全清洁和擦干。

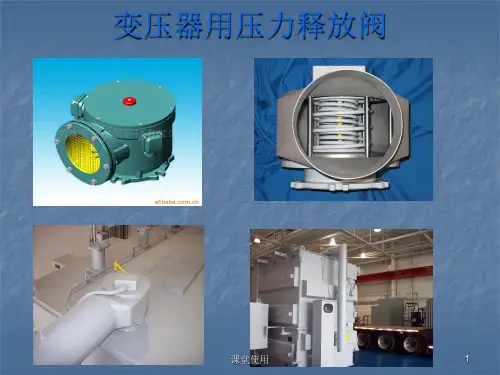

YSF压力释放阀YSF Pressure release valve使用说明书Instructions沈阳市金钟电器厂Shenyang Jinzhong electrical appliance factoryYSF Pressure release valve带防护罩的YSF4,5型压力释放阀定向喷油螺纹安装的YSF6型压力释放阀With a protective hood Specify the direction of Spray oil , Thread Installed定向喷油法兰安装的YSF7型压力释放阀定向导油法兰安装的YSF8,9型压力释放阀Specify the direction of Spray oil , Flange Installation Specify the direction of Oil Guide,Flange Installation YSF7 Pressure release valve YSF8,9 Pressure release valve- 1 -二, 型号、规格与基本技术参数Models, specifications and basic technical parameters:1, 型号Model :Y S F / D(S)KJTHB压力释放阀Pressure release valve 型号举例Model example: YSF 5 –55 / 130 D(S)KJTHBYSF 代表压力释放阀, 5 代表设计序号, 55 代表开启压力, 130 代表有效口径,YSF On behalf of pressure release valve,5 Serial number of Design,55 Opening pressure,130 Effective aperture D ( S ) 代表开关数量单( 双 ), K 代表电信号, J 代表机械信号, TH 代表湿热带地区,B 代表闭锁装置 D(S) -Switch amount one(two), K -Electric Signal, J - Mechanical signal, TH -Humid Tropics, B-Locking Device 2, 使用条件:-30℃至+100℃ 如遇寒带地区,采用特殊密封圈可满足-45℃Exploitation conditions -30℃ to +100℃ In case the frigid zone area, uses the special seal packing collar to be possible to satisfy -45℃3, 基本技术参数Basic technical parameters :有效口径Effective aperture (mm) 开启压力Opening pressure(KPa)关闭压力(不小于)Close Pressure (Not less than)(KPa)∮25∮5015±58 25 13.5 35 19 55 29.5 ∮80 ∮1303519 55 29.5 70 37.5 85 45.5 13874.5三, 带有电信号的输出接线线路图With electrical signal output wiring circuit diagram:a, 单开关接线线路图 b, 双开关接线线路图 C,双开关接线线路图Single-switch Two-switch Two-switch wiring circuit diagram wiring circuit diagram wiring circuit diagram信号开关接点容量Signal switch contact capacity :AC 220V 5A DC 220V 0.3A(电阻负载Resistive load )- 2 -。

YSH55-8580-130型压力释放阀使用说明书西安西变组件有限公司1.适用范围压力释放阀使用与油浸式变压器等电气设备,用于释放变压器油内部过压力的一种保护装置,当油箱内部压力升高至压力方法的开启压力值时,在2ms内迅速开启,使得油箱内压力很快降低,当降低至阀的关闭压力值时,阀门又可靠关闭,油箱内保持正常压力。

2产品型号编制办法2.1型号组成:Y(压力)S(释放)F(阀门)□(设计序列号)-□(开启压力kPa)/□(配有口径mm)KJ(带信号开关和机械信号)□(特殊环境代号)(注意:特殊环境代号:干热带地区“TA”;湿热地区“TH”;干、湿热带地区2.2型号举例:YSF1-55/130KJTH适用于湿热带地区的配有口径为130mm,开启压力为55kPa,带信号开关和机械信号装置、第一次设计的压力释放阀。

3.基本参数(见表1):表1开启压力35 55 70 85开启压力偏差±5关闭压力不小于19 29.5 37.5 45.5密封压力不小于21 33 42 514、结构和工作原理:4.1 压力释放阀的主要结构型式是外弹簧式,并可带或不带定向导流装置,它的主要部件由弹簧、阀座、弹簧座、阀壳体(罩)、标志杆、信号开关(出现盒)、密封圈等零部件组成。

4.2工作原理压力释放阀是用来保护油浸式变压器等电气设备过压力保护的安全装置,可以避免变压器油箱变形或爆裂。

当油浸式变压器内部发生事故时,油箱内的油被气化,产生大量气体,使得油箱内部压力急剧升高。

此压力如果不及时释放,将造成油箱变形或爆裂。

安装压力释放阀就是当油箱内压力升高到压力释放阀的开启压力时,压力释放阀在2ms内迅速开启,使得油箱内的压力很快降低。

当压力降到压力释放阀的关闭压力值时,压力释放阀又可靠关闭,使得油箱内永远保持正压,有效地防止外部空气、水气及其他杂质进入油箱;在压力释放阀开启同时,标志杆向上动作且明显伸出顶盖,表示压力释放阀已动作过,在压力释放阀关闭时,标志杆仍滞留在开启后的位置上,然后必须由手动才能复位。

防城港电厂#1主变压力释放阀动作机组跳闸事件报告批准:审核:编写:8月21日#1主变压力释放阀动作引起机组跳闸事件报告一、事件经过:8月21日中午12:00,#1机组有功负荷降至505MW,,机组运行正常,12:05分,#1机组跳闸,出口跳5012、5021开关,跳#1机厂用分支并切换厂用电,跳#1发电机灭磁开关,关闭#1机主汽门,光子牌“#1主变压力释放”发出。

检查发现#1主变本体压力释放#1,#3阀喷油,主变压器油枕油位处于约9.3位置,主变压器油温68℃。

总共7组冷却器中有4组冷却器运行。

#1机组非电量保护非电量13(油位异常)报警,非电量8(主变压力释放)动作。

对#1主变瓦斯继电器油样取样盒进行放油排气,未发现瓦斯继电器内有气体产生,对#1主变压器取油样化验,油击穿电压试验和色谱分析试验数据均在标准范围之内,与8月19日投运之前比较,油各项指标未出现增长。

机组跳闸后,立即成立了调查小组对原因进行调查分析,通过油枕油位、变压器油温、冷却器运行情况、油色谱分析结果,排除了变压器存在内部故障,于8月21日21时30分,#1机组并网成功,并网后油化验各项指标正常。

二、原因分析:按照电力事故四不放过原则,进行认真分析,总结工作中的不足,现汇报如下:1、主变冷却器运行方式投入不正确。

主变压器冷却器控制开关投入到“远方”位置,未投入到“自动”位置,此种控制方式下变压器冷却器不能随着油温升高自动投入运行,造成高负荷情况下,主变压器只有4组风扇运行。

按照当时变压器油温情况,应至少有6组冷却器运行,变压器冷却器投入不够,变压器温度不断上升,上层油温最高68℃,较正常情况升高约13℃,油温升高引起变压器油体积膨胀,外加油位偏高因素,造成主变压器油枕油位过高,压力释放阀动作。

2、主变压器油位偏高,较正常油温油位曲线高出约0.9个刻度(刻度指示值1—10)。

留给变压器油发热膨胀后的空间变小,本次变压器油温较平时升高10℃以上,造成变压器油枕油位过高。

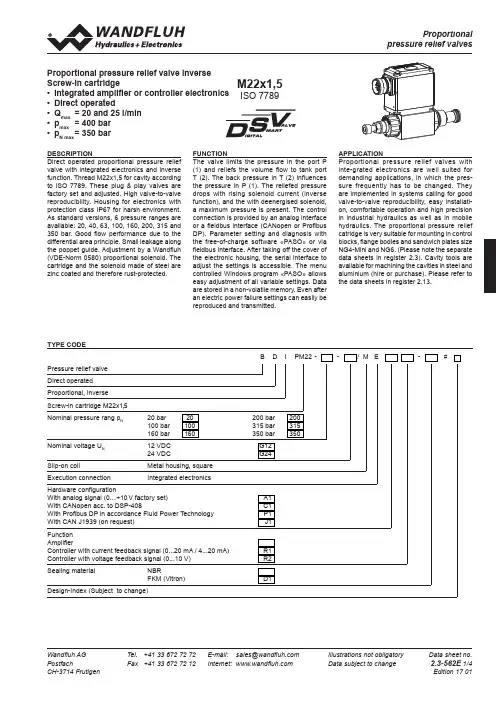

Wandfluh AG Tel. +41 33 672 72 72 E-mail: ******************Illustrations not obligatoryData sheet no.PostfachFax +41 33 672 72 12 Internet: Data subject to change 2.3-562E 1/4 CH-3714 Frutigen Edition 17 01TYPE CODEB D IPM22 --/ M E-#Pressure relief valve Direct operated Proportional, inverse Screw-in cartridge M22x1,5Nominal pressure rang p N 20 bar 20 200 bar 200 100 bar 100 315 bar 315160 bar 160 350 bar 350Nominal voltage U N 12 VDC G1224 VDCG24Slip-on coilMetal housing, square Execution connectionIntegrated electronicsHardware configurationWith analog signal (0…+10 V factory set)A1With CANopen acc. to DSP-408C1With Profibus DP in accordance Fluid Power Technology P1With CAN J1939 (on request) J1Function AmplifierController with current feedback signal (0...20 mA / 4...20 mA) R1Controller with voltage feedback signal (0...10 V) R2Sealing material NBRFKM (Vitron)D1Design-Index (Subject to change)Proportional pressure relief valve inverse Screw-in cartridge• Integrated amplifier or controller electronics • Direct operated• Q max = 20 and 25 l/min • p max = 400 bar • p N max = 350 barDESCRIPTIONDirect operated proportional pressure relief valve with integrated electronics and inverse function. Thread M22x1,5 for cavity according to ISO 7789. These plug & play valves are factory set and adjusted. High valve-to-valve reproducibility. Housing for electronics with protection class IP67 for harsh environment. As standard versions, 6 pressure ranges are available: 20, 40, 63, 100, 160, 200, 315 and 350 bar. Good flow performance due to the differential area principle. Small leakage along the poppet guide. Adjustment by a Wandfluh (VDE-Norm 0580) proportional solenoid. The cartridge and the solenoid made of steel are zinc coated and therefore rust-protected.FUNCTIONThe valve limits the pressure in the port P (1) and reliefs the volume flow to tank port T (2). The back pressure in T (2) influences the pressure in P (1). The reliefed pressure drops with rising solenoid current (inverse function), and the with deenergised solenoid, a maximum pressure is present. The control connection is provided by an analog interface or a fieldbus interface (CANopen or Profibus DP). Parameter setting and diagnosis with the free-of-charge software «PASO» or via fieldbus interface. After taking off the cover of the electronic housing, the serial interface to adjust the settings is accessible. The menu controlled Windows program «PASO» allows easy adjustment of all variable settings. Data are stored in a non-volatile memory. Even after an electric power failure settings can easily be reproduced and transmitted.APPLICATIONProportional pressure relief valves with inte-grated electronics are well suited for demanding applications, in which the pres-sure frequently has to be changed. They are implemented in systems calling for good valve-to-valve reproducibility, easy installati-on, comfortable operation and high precision in industrial hydraulics as well as in mobile hydraulics. The proportional pressure relief catridge is very suitable for mounting in control blocks, flange bodies and sandwich plates size NG4-Mini and NG6. (Please note the separate data sheets in register 2.3). Cavity tools are available for machining the cavities in steel and aluminium (hire or purchase). Please refer to the data sheets in register 2.13.M22x1,5ISO 7789Wandfluh AG Tel. +41 33 672 72 72 E-mail: ******************Illustrations not obligatory Data sheet no.Postfach Fax +41 33 672 72 12 Internet: Data subject to change 2.3-562E 2/4CH-3714 FrutigenEdition 17 01SYMBOL37s3M22x1.5T(2)X1X2X4 (nur Regler)(controller only)35.583X1X3X225,30501821, 2240706s613M DELECTRICAL SPECIFICATIONSProtection class IP 67 acc. to EN 60 529with suitable connector and closedelectronics housingSupply voltageRampsParameterisationInterfaceAnalog interface:Mating connectorPreset value signalFieldbus interface:Device receptaclesupply (male)Mating connectorDevice receptacleCANopen (male)Mating connectorDevice receptacleProfibus (female)Mating connectorPreset value signalFeedback signal interface (Sensor):(controller only)Device receptacle (female) M12, 5-polesMating connector Plug (male), M12, 5-poles(not incl. in delivery)Feedback signal:: Voltage / current state when orderingCONNECTOR WIRING DIAGRAMAnalog interface:Supply voltage +Supply voltage 0 VDCStabilised output voltagePreset value voltage +Preset value voltage -Preset value current +Preset value current -Reserved for extensionsReserved for extensionsEnable control (Digital input)Preset value voltage (PIN 4/5) resp. current (PIN 6/7) are selected withV), (PIN 4/5)Parameterisation interface (USB, Mini B) X2Under the closing screw of the housing coverFeedback signal interface (Sensor)Device receptacle (female) X4 (only controller)1 = Supply voltage (output) +2 = Feedback signal +3 = Supply voltage 0 VDC4 = not connected5 = stab. output voltage2 = Reserved for extensionsDevice receptacle Device receptacleCANopen (male) X3 Profibus (female) X3CAN PROFIBUS1 = not connected 1 = VP2 = not connected 2 = RxD / TxD - N3 = CAN Gnd 3 = DGND4 = CAN High 4 = RxD / TxD - P5 = CAN Low 5 = Shield31452123543145212354123451234123431452HYDRAULIC SPECIFICATIONSFluid Mineral oil, other fluids on requestContamination ISO 4406:1999, class 18/16/13efficiency (Required filtration grade ß 6…10≥75)see data sheet 1.0-50/2Viscosity range 12 mm2/s…320 mm2/sFluid temperature -20…+70°CPeak pressure pmax= 400 barNominal pres. ranges pN= 20 bar, 100 bar, 160 bar, 200 bar,315 bar, 350 barMin. volume flow Qmin= 0,1 l/minMax. volume flow Qmax= 25 l/min for pN=20 bar / 100 bar /160 bar / 200 barQmax= 20 l/min for pN= 315 barQmax= 5 l/min for pN= 350 barLeakage volume flow see characteristicsRepeatability ≤ 3 %Hysteresis ≤ 5 %GENERAL SPECIFICATIONSDescription Direct operated proportional pressure reliefvalve with integrated electronics inverse functionConstruction Screw-in cartridge for cavity acc. to ISO 7789Operations Proportional solenoid wet pin push type,pressure tightMounting Screw-in thread M22x1,5Ambient temperature -20…+65°C (typical)(The upper temperature limit is a guideline value for typicalapplications, in individual cases it may also be higher or lower.The electronics of the valve limit the power in case of a toohigh electronics temperature. More detailed information can beobtained from the operating instructions «DSV».)Mounting position any, preferably horizontalFastening torque MD= 50 Nm for screw-in cartridgeMD= 5 Nm for knurled nutWeight m = 1,0 kgWandfluh AG Tel. +41 33 672 72 72E-mail: ******************Illustrations not obligatoryData sheet no.PostfachFax +41 33 672 72 12 Internet: Data subject to change 2.3-562E 3/4 CH-3714 FrutigenEdition 17 01CHARACTERISTICS Oil viscosity υ = 30 mm 2/s p = f (Q) Pressure volume flow characteristics (Maximum adjustable pressure)p= f (Q) Pressure volume flow characteristics (Minimum adjustable pressure)Q L = f (p)Leakage volume flow characteristicsp red = f (l) Pressure adjustment characteristics[at Q = 10 l/min] / (s corresponds to preset value signal)p = f (l) Pressure adjustment characteristics [at Q = 5 l/min] /(s corresponds to preset value signal)NOTE!Detailed electrical characteristics and description of «DSV » electronics are shown on data sheet 1.13-76.START-UPFor DSV amplifiers as a rule no parameter settings by the customer are required. The plugs have to be connected in accordance with the chapter «Pin assignment».Controllers are supplied configured as amplifiers. The setting of the mode of control and the setting of the controller are done by the customer by software setting (USB interface, Mini B).Additional information can be found on our website:«»Free-of-charge download of the «PASO»-software and the instruction manual for the «DSV » hydraulic valves as well as the operation instruc-tion CANopen eg.Profibus DP protocol with device profile DSP-408 for «DSV ».NOTE!The mating connectors and the cable to adjust are settings is not part of the delivery. Refer to chapter «Accessories».Factory settings:Dither set for optimal hysteresis= Deadband: Solenoid switched offwith command preset value signal <5 % p Nmechanicallly pre-set at Q = 5 l/min= Limited pressure in port P (1) at 70 % of preset value signal: 95 bar with pressure range 350 bar 65 bar with pressure range 315 bar 56 bar with pressure range 200 bar 32 bar with pressure range 160 bar 25 bar with pressure range 100 bar 4 bar with pressure range 20 bar0 10 20 30 40 50 60 70 80 90 100s [%]p [bar]4003002001000 10 20 30 40 50 60 70 80 90 100s [%]p [bar]1209060300p = f (l) Pressure adjustment characteristics [at Q = 5 l/min] / (s corresponds to preset value signal)40030020010000 5 10 15 20 25Q [l/min]p [bar]N = 200 bar N = 160 bar N = 100 bar N= 20 bar504030201000 5 10 15 20 25Q [l/min]403020100 50 100 150 200 250 300 350 p [bar]Q [cm 3/min]0 10 20 30 40 50 60 70 80 90 1001251007550250I [%]p [%]Wandfluh AG Tel. +41 33 672 72 72 E-mail: ******************Illustrations not obligatoryData sheet no.PostfachFax +41 33 672 72 12 Internet: Data subject to change 2.3-562E 4/4 CH-3714 Frutigen Edition 17 01Cavity drawing according to ISO 7789–22–02–0–98For detailed cavity drawing and cavity toolssee data sheet 2.13-1003With fieldbus interface Amplifier With fieldbus interface ControllerDIMENSIONS / SECTIONAL DRAWINGS*Adjusting screw for setting the nominal pressure (-20 % / +30 %)With analog interface Amplifier and ControllerACCESSORIES • Cartridge built in:flange and sandwich bodies see register 2.3• Set-up softwaresee start-up• Cable to adjust the settings through interface USB (from plug type A to Mini B, 3 m) article no. 219.2896• Cable connector for analog interface: – straight, soldering contact article no. 219.2330 – 90°, soldering contact article no. 219.2331Recommended cable size: – Outer diameter 9…10,5 mm – Single wire max. 1 mm 2 – Recommended wire size: 0…25 m = 0,75 mm 2 (AWG18) 25…50 m = 1 mm 2 (AWG17)Technical explanation see data sheet 1.0-100PARTS LIST Position Article Description17160.2187O-ring ID 18,72 x 2,62 (NBR)18160.2170O-ring ID 17,17 x 1,78 (NBR)20154.2700Knurled nut21223.1317Dummy plug M16 x1,522160.6131O-ring ID 13,00 x1,525062.0102Cover square 30072.0021Gasket 33,2 x 59,9 x 240208.0100Socket head cap screw M4 x1050160.2188160.6188O-ring ID 18,77 x 1,78 (NBR)O-ring ID 18,77 x 1,78 (FKM)60160.2140160.6141O-ring ID 14,00 x 1,78 (NBR)O-ring ID 14,00 x 1,78 (FKM)70049.3177Back-up ring RD 14,6 x 17,5 x 1,4353790.2s 30M 22x 1.5T(2)X2X1X3X4172.4P(1).5(1)E: Venting。

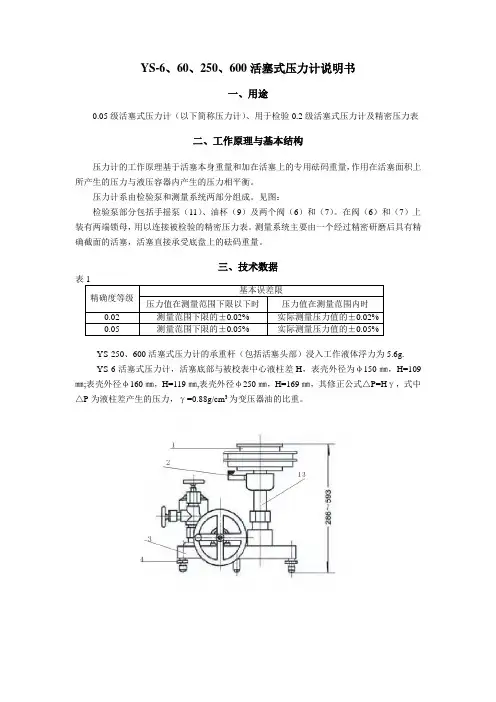

YS-6、60、250、600活塞式压力计说明书一、用途0.05级活塞式压力计(以下简称压力计)、用于检验0.2级活塞式压力计及精密压力表二、工作原理与基本结构压力计的工作原理基于活塞本身重量和加在活塞上的专用砝码重量,作用在活塞面积上所产生的压力与液压容器内产生的压力相平衡。

压力计系由检验泵和测量系统两部分组成。

见图:检验泵部分包括手摇泵(11)、油杯(9)及两个阀(6)和(7)。

在阀(6)和(7)上装有两端锁母,用以连接被检验的精密压力表。

测量系统主要由一个经过精密研磨后具有精确截面的活塞,活塞直接承受底盘上的砝码重量。

三、技术数据表1精确度等级基本误差限压力值在测量范围下限以下时压力值在测量范围内时0.02 测量范围下限的±0.02% 实际测量压力值的±0.02%0.05 测量范围下限的±0.05% 实际测量压力值的±0.05%YS-250、600活塞式压力计的承重杆(包括活塞头部)浸入工作液体浮力为5.6g.YS-6活塞式压力计,活塞底部与被校表中心液柱差H,表壳外径为φ150㎜,H=109㎜;表壳外径φ160㎜,H=119㎜,表壳外径φ250㎜,H=169㎜,其修正公式△P=Hγ,式中△P为液柱差产生的压力,γ=0.88g/cm3为变压器油的比重。

1、砝码2、指标板3、底座4、调整螺钉5、连接管部件6、7、8阀9、油杯10、水平仪11、手摇泵12、手轮13、测量系统参数单位值力值0.6MPa 6 MPa25MPa60 MPa测量上限MPa0.66256060测量下限MPa0.040.10.511活塞公称面积cm210.50.20.10.05底盘及活塞公称质量㎏0.40.5110.5产生产压力MPa0.040.10.511专用砝码公称质量㎏0.1;0.5 0.5;2.5 1;51;50.5;2.5产生的压力MPa0.010.050.010.50.5;2.51;51;5数量个6;104;114;94;111;11两端锁母M20×1.5M20×1.5M20×1.5M20×1.5M20×1.5重量㎏3565859575工作液体变压器油20℃时运动粘度9~12厘沲酸值不大于0.5毫克KOH/克癸二酸酯20℃时运动20~25mm2/s,酸值不大于0.05毫克KOH/克四、验收与保管1、用户收到装箱压力计,应先检查压力计包装是否完整;如有损伤,应即查明原因。

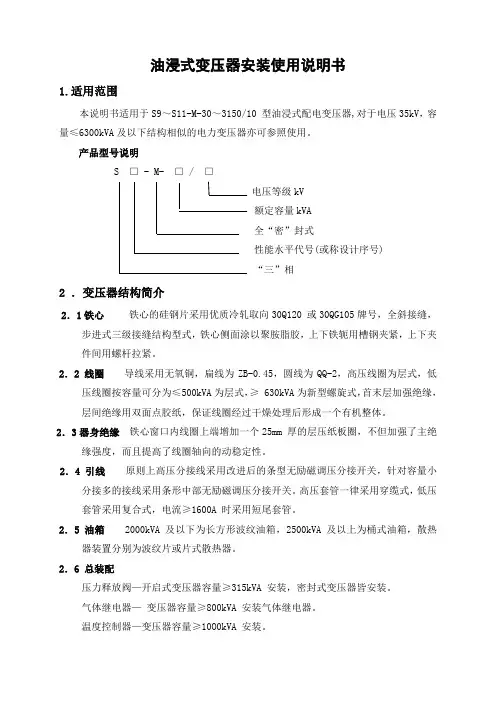

油浸式变压器安装使用说明书1.适用范围本说明书适用于S9~S11-M-30~3150/10 型油浸式配电变压器,对于电压35kV,容量≤6300kVA及以下结构相似的电力变压器亦可参照使用。

产品型号说明S □ - M- □ / □电压等级kV额定容量kVA全“密”封式性能水平代号(或称设计序号)“三”相2 .变压器结构简介2.1铁心铁心的硅钢片采用优质冷轧取向30Q120 或30QG105牌号,全斜接缝,步进式三级接缝结构型式,铁心侧面涂以聚胺脂胶,上下铁轭用槽钢夹紧,上下夹件间用螺杆拉紧。

2.2 线圈导线采用无氧铜,扁线为ZB-0.45,圆线为QQ-2,高压线圈为层式,低压线圈按容量可分为≤500kVA为层式,≥ 630kVA为新型螺旋式,首末层加强绝缘,层间绝缘用双面点胶纸,保证线圈经过干燥处理后形成一个有机整体。

2.3器身绝缘铁心窗口内线圈上端增加一个25mm 厚的层压纸板圈,不但加强了主绝缘强度,而且提高了线圈轴向的动稳定性。

2.4 引线原则上高压分接线采用改进后的条型无励磁调压分接开关,针对容量小分接多的接线采用条形中部无励磁调压分接开关。

高压套管一律采用穿缆式,低压套管采用复合式,电流≥1600A 时采用短尾套管。

2.5 油箱 2000kVA 及以下为长方形波纹油箱,2500kVA 及以上为桶式油箱,散热器装置分别为波纹片或片式散热器。

2.6 总装配压力释放阀—开启式变压器容量≥315kVA 安装,密封式变压器皆安装。

气体继电器—变压器容量≥800kVA 安装气体继电器。

温度控制器—变压器容量≥10O0kVA 安装。

储油柜—开启式变压器均装,密封式变压器不安装,在油箱盖上增加一个油位指示表。

管式油位计—无储油柜全密封变压器均装,安装在变压器油箱箱盖上部,显示油箱内的油位。

3.运输3.1变压器至安装地点主要运输方式为汽运,运输时变压器中装满变压器油,影响运输尺寸界限的较大组件单独运输到现场安装,对于易损件如吸湿器等及出厂的随机文件单独包装随变压器主体发运,较大件如散热器,简易包装随变压器主体发运。

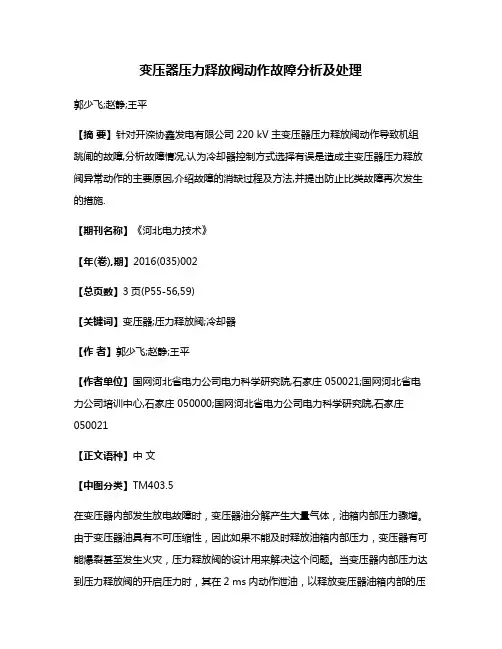

变压器压力释放阀动作故障分析及处理郭少飞;赵静;王平【摘要】针对开滦协鑫发电有限公司220 kV主变压器压力释放阀动作导致机组跳闸的故障,分析故障情况,认为冷却器控制方式选择有误是造成主变压器压力释放阀异常动作的主要原因,介绍故障的消缺过程及方法,并提出防止比类故障再次发生的措施.【期刊名称】《河北电力技术》【年(卷),期】2016(035)002【总页数】3页(P55-56,59)【关键词】变压器;压力释放阀;冷却器【作者】郭少飞;赵静;王平【作者单位】国网河北省电力公司电力科学研究院,石家庄 050021;国网河北省电力公司培训中心,石家庄 050000;国网河北省电力公司电力科学研究院,石家庄050021【正文语种】中文【中图分类】TM403.5在变压器内部发生放电故障时,变压器油分解产生大量气体,油箱内部压力骤增。

由于变压器油具有不可压缩性,因此如果不能及时释放油箱内部压力,变压器有可能爆裂甚至发生火灾,压力释放阀的设计用来解决这个问题。

当变压器内部压力达到压力释放阀的开启压力时,其在2 ms内动作泄油,以释放变压器油箱内部的压力[1]。

以下对开滦协鑫发电有限公司4号主变压器非电量保护“主变压器本体压力释放跳闸”动作,导致4号机组跳闸的故障进行分析。

开滦协鑫发电有限公司3号、4号机组属于二期扩建工程,发电机组经1台370 MVA双绕组三相主变压器接入开滦唐家庄坑口热电厂220 k V升压站。

4号主变压器型号SFP-370000/220,容量为370 MVA,接线方式YNd11,额定电流882.7 A/10 681 A,空载损耗138.18 kW,空载电流0.05%,负载损耗721.02 k W,总损耗859.20 k W。

压力释放阀型号为YSF6-55/130 KJ。

在AGC试验过程中,4号主变压器重载运行,油位、油温均较高。

2015年5月15日15:25,4号主变压器非电量保护“主变本体压力释放跳闸”动作,压力释放阀动作喷油,喷油量约15 kg。

1/10Proportional pressure relief valve, pilot operated, with on-board elec-tronics (OBE) and position feedbackType DBEBE6XNominal size 6Unit series 1XMaximum working pressure P 315 bar, T 250 bar Maximum flow rate 40 l/minRE 29159/07.05List of ContentsContents Pageeatures 1Ordering data2Preferred types, symbol 2Function, sectional diagram 3T echnical data4 to 6On-board trigger electronics 7 and 8Characteristic curves 9Unit dimensions10Features– Pilot operated valves with position feedback and on-board electronics for limiting system pressure (pilot oil internal only)– A djustable through the position of the armature against the compression spring– Position-controlled, minimal hysteresis <1%, rapid response times, see T echnical Data– P ressure limitation to a safe level even with faulty electronics (solenoid current I > I max )– F or subplate attachment, mounting hole configuration to ISO 4401-03-02-0-94. Subplates as per catalog sheet RE 45053 (order separately)– P lug-in connector to DIN 43563-AM6, see catalog sheet RE 08008 (order separately)– D ata for the on-board trigger electronics• Complies with CE, EMC directives EN 61000-6-2: 2002-08 and EN 61000-6-3: 2002-08• U B = 24 V nom DC• Electrical connection 6P+PE • Signal actuation– Standard 0...+10 V (A1) – Version 4...20 mA (F1)• Valve curve calibrated at the factoryOrdering dataProportional pressure reliefvalve with inductive positiontransducer on the coneWith on-board electronics = ENominal size = 6Mounting hole configuration toISO 4401-03-02-0-94 = XUnit series 10 to 19 = 1X(10 to 19: installation and connection dimensionsunchanged)Max. pressure stageup to 80 bar = 800up to 180 bar = 180up to 315 bar = 315 Voltage supply of trigger electronics = G24 24 V DCFurther informationin plain text M = NBR seals, suitable formineral oils (HL, HLP)to DIN 51524Interface for trigger electronics A1 = Setpoint input 0...+10 VF1 = Setpoint input 4...20 mA K31 =Electrical connectionwithout plug-in connector,with unit plug to DIN 43563-AM6Order plug-in connector separatelyDBEB E6X1X G24 K31M*Preferred typesType .......A1 (0...+10 V) Material Number Type .......F1 (4...20 mA)Material Number DBEBE6X–1X/80G24K31A1M0 811 402 078DBEBE6X–1X/80G24K31F1M0 811 402 084 DBEBE6X–1X/180G24K31A1M0 811 402 077DBEBE6X–1X/180G24K31F1M0 811 402 079 DBEBE6X–1X/315G24K31A1M0 811 402 076SymbolFor on-board electronicsFunction, sectional diagramGeneralType DBEBE6X proportional pressure relief valves are pilot valves that are used to limit system pressure. The valves are actuated by means of a position-controlled proportional solenoid with on-board electronics.With these valves, rapid response times with low hysteresis can be achieved.Basic principleT o adjust the system pressure, a setpoint is set in the trigger electronics. Based on this setpoint, the electronics control the position-controlled solenoid.The proportional solenoid maintains its position against a spring force, which is proportionate to the system pressure. The pilot stage is supplied with pilot oil through a bore holeat < 0.6 l/min. The “pmax” pressure stage is determined by the cone and seating bore configuration.Pressure limitation for maximum safetyIf a fault occurs in the electronics, so that the solenoid current (Imax) would exceed its specified level in an uncontrolledmanner, the pressure cannot rise above the level determined bythe maximum spring force.Testing and service equipmentT est box type VT-PE-TB3, see RE 30065Measuring adapter 6P+PE type VT-PA-2, see RE 30068Proportional solenoid with position transducer Valve bodyAccessoriesType Material Number(4 x) f ISO 4762-M5x30-10.9Cheese-head bolts 2 910 151 166*Plug-in connectors 6P+PE,see also RE 08008KS 1 834 482 022KS 1 834 482 026MS 1 834 482 023MS 1 834 482 024KS 90° 1 834 484 252 EN 61000-6-2: 2002-08EN 61000-6-3: 2002-08Technical data1)T he purity classes stated for the components must be complied with in hydraulic systems.Effective filtration prevents problems and also extends the service life of components.For a selection of filters, see catalog sheets RE 50070, RE 50076 and RE 50081.Technical dataElectrical, trigger electronics integrated in valveCyclic duration factor %100Degree of protection IP 65 to DIN 40050 and IEC 14434/5Connection Plug-in connector 6P+PE, DIN 43563Supply voltage T erminal A:T erminal B: 0 V 24 V DC nomMin. 21 V DC/max. 40 V DC Ripple max. 2 V DCPower consumption Solenoid 45 mm = 40 VA max.External fuse2.5 A FInput, “standard” version A1T erminal D: U E T erminal E:Differential amplifier, R i = 100 k Ω0...+10 V 0 V Input, “mA signal” version F1T erminal D: I D–E T erminal E: I D–EBurden, R sh = 200 Ω4...20 mACurrent loop I D–E feedbackMax. voltage to differential inputs over 0 V D Ǟ BE Ǟ B }max. 18 V DCT est signal, “standard” version A1T erminal F: U T est T erminal C:L VDT0...+10 VReference 0 VT est signal, “mA signal” version F1T erminal F: I F–C T erminal C: I F–CL VDT signal 4...20 mA at external load 200...500 Ω max.4...20 mA outputCurrent loop I F–C feedbackSafety earth conductor and shield See pin assignment (installation in conformity with CE)Recommended cableSee pin assignmentup to 20 m 7 x 0.75 mm 2up to 40 m 7 x 1 mm 2CalibrationCalibrated at the factory, see valve curveVersion A1:StandardVersion F1:mA signalConnectionFor electrical data, see page 5 and Operating Instructions1 819 929 083Technical notes for the cableVersion: – Multi-wire cable – Extra-finely stranded wire to VDE 0295, Class 6 – Safety earth conductor, green/yellow – Cu braided shield Type: – e.g. Ölflex-FD 855 CP (from Lappkabel company)No. of wires: – Determined by type of valve, plug type and signal assignment Cable Ø: – 0.75 mm 2 up to 20 m long – 1.0 mm 2 up to 40 m long Outside Ø: – 9.4...11.8 mm – Pg11– 12.7...13.5 mm – Pg16ImportantPower supply 24 V DC nom,if voltage drops below 18 V DC, rapid shutdown resembling “Enable OFF” takes place internally.In addition, with the “mA signal” version:I D–E м 3 mA – valve is activeI D–E Ϲ 2 mA – valve is deactivated.Electrical signals emitted via the trigger electronics (e.g. actual values) must not be used to shut down safety-relevant machine functions!(See also European Standard, “T echnical Safety Requirements for Fluid-Powered Systems and Components – Hydraulics”, EN 982).On-board trigger electronics Circuit diagram/pin assignment Version A1: UD–E0...+10 VPin assignmentVersion A1: UD–E 0...+10 V(Ri = 100 k Ω)Supply UBSupply zeroRef. zero *Setpoint 0...+10 VActual value 0...+10 VSafety earth conductor ƄShield* D o not connect to supply zero!On-board trigger electronics Circuit diagram/pin assignment Version F1: ID–E4...20 mAPin assignment 6P+PEVersion F1: ID–E 4...20 mA(Rsh = 200 kΩ)Characteristic curves (measured with HLP 46,oil = 40 °C ±5 °C)Pressure in port P as a function of the setpoint* Factory setting at Q = 1 l/min ±5 % manufacturing tolerance1) Version: U D–E = 0...+10 V 2) Version: ID–E = 4...20 mAU D-E 1)[V]I D-E 2)[mA]4,07,210,413,616,820Pressure in port P proportionate to the maximum flow rate of the main stageSet pressure p Ј = f (Q P–T )Bosch Rexroth AGHydraulicsZum Eisengießer 197816 Lohr am Main, GermanyT elefon +49 (0) 93 52 / 18-0T elefax +49 (0) 93 52 / 18-23 58 ***************************** www.boschrexroth.de © This document, as well as the data, specifications and other information set forth in it, are the exclusive property of Bosch Rexroth AG. It may not be reproduced or given to third parties without its consent.The data specified above only serve to describe the product. No state-ments concerning a certain condition or suitability for a certain application can be derived from our information. The information given does not release the user from the obligation of own judgement and verification. It must be remembered that our products are subject to a natural process of wear and aging.Unit dimensions (nominal dimensions in mm)Required surface qualityof mating component Mounting hole configuration: NG6 (ISO 4401-03-02-0-94)For subplates see catalog sheet RE 450531) Deviates from standard2)T hread depth:Ferrous metal 1.5 x ØNon-ferrous 2 x ØNot included in scope of deliveryBosch Rexroth AGHydraulicsZum Eisengießer 197816 Lohr am Main, GermanyT elefon +49 (0) 93 52 / 18-0T elefax +49 (0) 93 52 / 18-23 58 ***************************** www.boschrexroth.de © This document, as well as the data, specifications and other information set forth in it, are the exclusive property of Bosch Rexroth AG. It may not be reproduced or given to third parties without its consent.The data specified above only serve to describe the product. No state-ments concerning a certain condition or suitability for a certain application can be derived from our information. The information given does not release the user from the obligation of own judgement and verification. It must be remembered that our products are subject to a natural process of wear and aging.NotesBosch Rexroth AGHydraulicsZum Eisengießer 197816 Lohr am Main, GermanyT elefon +49 (0) 93 52 / 18-0T elefax +49 (0) 93 52 / 18-23 58 ***************************** www.boschrexroth.de © This document, as well as the data, specifications and other information set forth in it, are the exclusive property of Bosch Rexroth AG. It may not be reproduced or given to third parties without its consent.The data specified above only serve to describe the product. No state-ments concerning a certain condition or suitability for a certain application can be derived from our information. The information given does not release the user from the obligation of own judgement and verification. It must be remembered that our products are subject to a natural process of wear and aging.Notes。

YSF系列Ф50mm 以下口径的压力释放阀一.产品简介YSF系列Ф50mm 以下口径的压力释放阀是一种新型压力释放阀,并已申请专利。

本产品用于保护油浸电气设备的油室,例如变压器、高压开关、电力电容器、电抗器、有载分接开关等。

二.型号说明2.1 YSF环境条件、特殊说明* 喷油有效口径 (mm) 开启压力 (kPa) 设计序号 压力释放阀代号标注实例:YSF 9—35/50DSKJTHB 表示第9次设计的喷油口径为Ф50mm ,开启压力35kPa ,(D )带定向导油功能,(K)带电气报警信号(S )双电气报警信号,(J) 带机械报警信号,(TH )湿热带地区用,(B )带闭锁装置的压力释放阀。

2.2使用范围:1.安装位置:油箱盖上、升高座上或油箱上部侧壁上;2.环境要求:-30℃~+50℃; 工作环境要求:-50℃~+100℃ 3.相对湿度:+20℃时,不大于95%。

2.3信号开关接点容量(带电气接点的压力释放阀):图1 二(或四)芯出线释放阀开关连线原理图 图2 三(或六)芯出线释放阀开关连线原理图 三、外形及安装尺寸图(未表明设计序号的压力释放阀均为九型阀)3.1 Φ8mm、Φ18mm、Φ25mm、Φ25 mm 六型、Φ50mm 压力释放阀见图3-1、表2-1图3-1电流A电源种类 电压(V )电阻负载 感性负载 AC 220~400 5 3(cos φ=0.4)DC 110 0.3 0.05(T=7ms )1(4)3(6)2(4)单位mm 表2-1型号 D0 D1 D2 H0 H1 H2 B MФ8 16 22 46 14 18 M14×1Ф18 49 54 59 85 16 19 62 M42×3 Ф2555 62 68 95 18 22 70 M48×3 Ф25(六型)40 54 54 87 18 21 62 M38×2Ф5093 100 105 100 22 28 112 M80×33.2 Ф25K、Ф50K 压力释放阀见图3-2、表2-2图3-2单位mm 表2-2 型号D0 D1 D2 H0 H1 H2 A M Ф25KJB 55 80 68 103 18 22 55 M48×3Ф50KJB 93 115 105 120 22 28 75 M80×33.3 Ф50DK 压力释放阀见图3-3;图3-33.4 Ф25K四型阀见图3-4,Ф50K四型阀见图3-5,Ф25DK四型阀见图3-6,Ф50DK四型阀见图3-7;图 3-4图 3-5。

真空压力释放阀参数真空压力释放阀是一种常用于真空系统中的阀门,用于控制系统内的真空压力。

它的参数包括阀门类型、材料、尺寸、连接方式、压力范围等。

1. 阀门类型真空压力释放阀的类型有很多种,常见的有直通式、角式、扇形式、膜片式等。

不同类型的阀门适用于不同的工作条件和压力范围。

2. 材料真空压力释放阀的主要材料通常是不锈钢、铜、铝等耐腐蚀材料。

材料的选择取决于阀门的工作环境和介质,以确保阀门的稳定性和耐用性。

3. 尺寸真空压力释放阀的尺寸通常根据系统的流量和连接管道的直径来确定。

尺寸的选择要考虑到系统的工作压力和流量要求,以保证阀门的正常运行。

4. 连接方式真空压力释放阀通常有螺纹连接、法兰连接和焊接连接等不同的方式。

连接方式的选择要根据系统的要求和管道的类型来确定,以确保阀门与管道的连接紧密可靠。

5. 压力范围真空压力释放阀的压力范围通常根据系统的工作压力来确定。

阀门的选择要考虑到系统的最高和最低压力要求,以确保阀门能够有效地控制系统的压力。

6. 其他参数除了上述基本参数外,真空压力释放阀还可能具有其他特殊的参数,如温度范围、流量系数、密封性能等。

这些参数的选择要根据系统的具体要求和工作条件来确定,以保证阀门的正常运行和系统的安全性。

总结:真空压力释放阀是真空系统中常用的阀门,通过控制系统内的真空压力来保证系统的稳定运行。

选择合适的真空压力释放阀参数是确保系统正常工作的关键。

通过了解阀门的类型、材料、尺寸、连接方式和压力范围等参数,可以选择适合系统要求的阀门,提高系统的效率和安全性。

在选择阀门参数时,还需要根据系统的具体要求和工作环境来考虑其他特殊的参数,以确保阀门能够满足系统的需求。

10kV级液浸式配电变压器安装使用说明书电气设备有限公司目录1.适用范围 (3)2.变压器结构简介 (4)3.运输 (4)4.验收 (4)5.储存 (5)6.安装变压器 (5)7.变压器投入运行 (6)8.变压器投入运行后的注意事项 (6)附录组件使用说明A.压力释放阀 (7)B.无励磁分接开关 (8)C.套管 (10)D.吸湿器 (13)E.温度控制器 (13)F.气体继电器型 (15)1 范围本说明书适用于10kV三相液浸式配电变压器安装、试验、调试、试运行、投入运行。

2 引用文件下列文件对于本文件的应用是必不可少的。

凡是注日期的引用文件,仅注日期的版本适用于本文件。

凡是不注日期的引用文件,其最新版本适用于本文件。

GB 1094.1 电力变压器第1部分:总则GB 1094.2 电力变压器第2部分:液浸式变压器的温升GB 1094.3 电力变压器第3部分:绝缘水平、绝缘试验和外绝缘空气间隙GB/T 1094.4 电力变压器第4部分:电力变压器和电抗器的雷电冲击和操作冲击试验导则GB 1094.5 电力变压器第5部分:承受短路的能力GB/T 1094.7 电力变压器第7部分:油浸式电力变压器负载导则GB/T 1094.10 电力变压器第10部分:声级测定GB 2536 电工流体变压器和开关用的未使用过的矿物绝缘油GB 311.1 绝缘配合第1部分:定义、原则和规则GB/T 2900.15 电工术语变压器、互感器、调压器和电抗器GB/T 4109 交流电压高于1000V的绝缘套管GB 4208 外壳防护等级(IP代码)GB/T 5273 变压器、高压电器和套管的接线端子GB/T 6451 油浸式电力变压器技术参数和要求GB/T 7252 变压器油中溶解气体分析和判断导则GB/T 7354 局部放电测量GB/T 7595 运行中变压器油质量GB/T 8287.1 标称电压高于1000V系统用户内和户外支柱绝缘子第1部分:瓷或玻璃绝缘子的试验GB/T 8287.2 标称电压高于1000V系统用户内和户外支柱绝缘子第2部分:尺寸与特性GB/T 11022 高压开关设备和控制设备标准的共用技术要求GB 11604 高压电器设备无线电干扰测试方法GB/T 13499 电力变压器应用导则GB/T 16927.1 高电压试验技术第1部分:一般定义及试验要求GB/T 16927.2 高电压试验技术第2部分:测量系统GB/T 17468 电力变压器选用导则GB 20052 三相配电变压器能效限定值及能效值GB/T 25446 油浸式非晶合金铁芯配电变压器技术参数和要求GB/T 26218.1 污秽条件下使用的高压绝缘子的选择和尺寸确定第1部分:定义、信息和一般原则GB/T 26218.2 污秽条件下使用的高压绝缘子的选择和尺寸确定第2部分:交流系统用瓷和玻璃绝缘子GB 50150 电气装置安装工程电气设备交接试验标准DL/T 572 电力变压器运行规程DL/T 593 高压开关设备和控制设备标准的共用技术要求DL/T 596 电力设备预防性试验规程DL/T 984 油浸式变压器绝缘老化判断导则DL 5027 电力设备典型消防规程JB/T 3837 变压器类产品型号编制方法JB/T 10088 6kV~500kV电力变压器声级JB/T 10428 变压器用多功能保护装置3.S11液浸式变压器结构简介3.1铁心铁心的硅钢片采用优质冷轧取向27QG100、30Q110或30Q120牌号,全斜三级接缝结构型式,铁心外面涂以聚胺脂胶,上下铁轭用槽钢夹紧,上下夹件间用螺杆拉紧。