压力释放阀说明书中英

- 格式:doc

- 大小:416.00 KB

- 文档页数:16

![压力释放阀说明书[中英]](https://uimg.taocdn.com/2e96aecc76c66137ef06192d.webp)

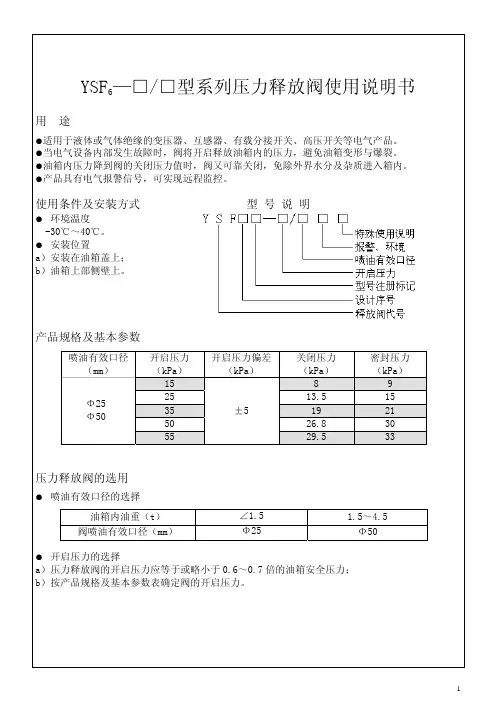

压力释放阀PRESSURE RELEASE VALVE使用说明书OPERATION INSTRUCTION明远电器设备SHENYANG MINGYUAN ELECTRIC EQUIPMENT CO., Ltd.本说明书适用于我公司生产的系列变压器用压力释放阀,阐述其用途、性能、规格、技术参数、使用及安装,供用户参考。

The Operation Instruction is applicable to pressure release valve of a series of transformers manufactured by our company, indicating its application, performances, specifications, technical parameters, usage and installation for uses’ reference.1. 压力释放阀用途和性能压力释放阀适用于油浸式电力变压器、电力电容器及有载分接开关等,用来保护油箱。

当油浸式变压器在运行中出现故障时,由于线圈过热,使一部分变压器油汽化,变压器油箱中压力迅速增加,这时压力释放阀在2ms迅速动作,释放压力,保护油箱不致变形或爆裂。

油箱的压力再升高而达到开启压力时,压力释放阀应再次动作,直到油箱的压力降到正常值。

由于压力释放阀动作后能可靠关闭,油箱外的水和空气不能进入油箱,变压器部不会受大气污染。

1.Application and performancePressure release valves play a vital role in the protection of oil-immersed electrical equipments, such as transformers, high voltage switch gears, capacitor and on load tap-changers, etc. This device can prevent the oil-immersed electrical equipment from deformation or rupture. Should a fault occur in such electrical equipment, from deformation of rupture? Should a fault occurring in such electrical equipment, they are instantaneously vaporize the oil causing extremely rapid build-up of gaseous pressure? If mounting this type pressure release device on the oil-tank, when the pressure reaches to its opening pressure, it opens automatically within 2ms and relieves the pressure.2.型号、规格及基本参数Type, specification and technical parameters2.1 型号的含义 Meaning of typeY S F□—□ / □□□特殊环境代号(Special environment)带机械信号标“J”(“J”:mechanical signal)带信号开关标“K”(“K”:electrical signal)两者都带标“KJ”(“KJ”:Both with signal)喷油有效口径(Caliber of oil-gushing tube)mm开启压力(Opening pressure)kPa设计序号(Design serial number)阀(valve)释放(release)压力(pressure)注:特殊环境代号 note: special environment:TA: 干热带地区 dry tropicTH: 湿热带地区 humid tropicT: 干、湿热带地区 dry、humid tropic例:YSF16-55/130KKJT开启压力为55kPa,喷油口径为φ130mm,带电信号、机械信号。

v e n t i n g| g a u g e h atc h e sS E R I E S4000 M A R S H H AW K T RVFeatures• Premium deep-set gauge hatch with integral pressure & vacuum relief offers superior performance in normal and cold conditions.• reliable, bubble-tight sealing with standard Fkm ( viton) seal and stainless steel spring.• Field adjustable pressure settings, from 2 ozsi to 32 ozsi.• manual relief, inconel trim, alternative seals and various coatings optionally available.F E AT U RE SDeep-set venting gauge hatch• the series 4000 marsh hawk trv offers tank access combined with pressure and vacuum reliefin a deep-set design.• situating valve seats below the tank roof permits latent heat from the product to keep the seals ice-free.Reliable, bubble-tight sealing• the series 4000 has class-leading sealperformance as compared to any other premium or economy venting gauge hatch currently available.• improved sealing performance eliminates flutter and periodic small-scale venting which can cause frost closure in competitor top-mount hatches.Variety of pressure settings• the series 4000 marsh hawk pressure relief is adjustable between 2 ozsi and 16 ozsi in 2 ozsi increments.• the optional double-weight spring allows relief pressure between 18 and 32 ozsi, in 2 ozsiincrements.• 1 ozsi increments optionally available.• vacuum relief is fixed at 0.4 ozsi.Suitable for Sour Service• the series 4000 is ready for sour service out of the box with Fkm ( viton) seals and stainlesssprings.• For more adverse applications, alternative seal and spring materials are available, along withhard anodization or fusion-bond epoxy coatings.S P E C I F I C AT I O NS¹temperatures provided are continuous service temperatures for the indicated seal materials. see the short term extended service temperatures below in “seal materials and configuration” section.D I M E N S I O NSFalse-colour cutaway of a series 4000 marsh hawk trv showing the deep-set seal (orange), pressure spacers(blue) and springs (red).F LOW C H A R AC T E R I S T I C-3.2-3-2.8-2.6-2.4-2.2-2-1.8-1.6-1.4-1.2-1-0.8-0.6-0.4-0.20T A N K V A C U U M , V (O Z S I )024681012141618202224262830323436384042444648505254565860626401234567891011121314151617181920212223242526272829303132333435T A N K P R E S S U R E , P (O Z S I )FL OW RA T E T H R O UG H M A R S H H AW K, Q , X 1000 SCF H (AIR)O P T I O N S A N D AC C E S S O R I E SManual Reliefthe manual relief option allows an operator to manu-ally activate the vent.Pressing the hatch cover’s large red button on the actu-ates the vacuum pallet, relieving pressure in the tank to allow safe removal of the spider cage assembly for tank gauging or hatch maintenance. the button and actuating poppet are supported independently of the vacuum disc, and do not interfere with normal relieving operation.Hard Anodized (Type III)For situations requiring improved corrosion resistance over the standard marsh hawk, a hard anodization option is available. this electrochemical process in-creases the thickness and durability of the ceramic-like natural aluminum oxide layer.all aluminum components are anodized to meet miL-a-862F type iii engineering hardcoat. the anodization slightly darkens the cast components and imparts a slight bronze tinge to the machined components.anodization improved performance in moderate brines, as well as acetic, boric and nitric acid. For prolonged exposure to concentrated brines, or strong mineral acids, consider the severe service coating.Severe Service CoatingFor situations demanding the highest corrosion resis-tance, consider the severe service coating.the body of the marsh hawk is coated with a red Fusion Bond epoxy (FBe) for resistance to mineral acids,(including sulphuric and hydrochloric acids up to 15%) high-chloride ion solutions (including alumi-num chloride, potassium chloride and brine) as well as many other petrochemicals.the marsh hawk internals are coated in a proprietary black PFa (teFLOn) providing the same excellent fluo-ropolymer chemical resistance as the FBe above.series 4000 marsh hawk trv with manual relief Optionseries 4000 marsh hawk trv with hard anodizationseries 4000 marsh hawk trv with severe service coatingO P T I O N S A N D AC C E S S O R I E S (C O N T I N U E D )S E A L C O N F I G U R AT I O N A N D M AT E R I A L S the series 4000 marsh hawk combines the pressure and vacuum valve in an innovative design that requires only one shared gasket.to improve valve sealing performance, gaskets are factory coated with a pliable silane-based sealant. an optional oil-based sealant for use in sour gas applica-tions is also available. Both sealants are available in small packages for maintenance and reapplication.hawkeye offers three material options for the pressure / vacuum seal, beyond the standard Fkm (viton®) seal.• For applications where sealing is the first priority and the vent is not expected to operate often and has low set pressures (under 4 ozsi), eFkm (sponge viton®) can be supplied.• For higher temperature, minimally freezing conditions and acid service FePm (aflas®) is available.• For extreme applications FFkm (kalrez®) is also available.the use of ePDm seals in any hawkeye vent is contra-indicated due to its unsuitability in common petrochem-ical applications.hawkeye does not offer or recommend using solid fluoropolymer (PtFe, PFa, FeP, etc.), nor expanded flu-ropolymer (gOre-tex®) as a gasket material and any venting device. although the material may be chemi-cally suitable, the harder crystalline polymer structure of these materials impedes sealing at the typically low interfacial pressures found in the marsh hawk, as well as other low-pressure (i.e. <15 psi) vents.GENE R A L FLU OROEL A STOM E R CHEM ICA L C OM PATI BI LI T Y¹FKM / VI TON N.B.¹ THIS CHART I S F OR R EFE REN CE ONLY. ALT HOUG H HAWKEYE STRI VES TO E NSU RE P RE SE NTE D I NF OR MATI ON I S ACCURATE, A QUALIF I ED PE RSON SHO ULD EN SURE TH E SUI TABILI T YO F A S E LECTED MATER IA L I N T HE SPECIF IC CHEMI CAL, TEMP ERATURE A ND PRE SSU RE C O NTE XT O F TH EI R APPLI CATIO N.² SH OWN F OR COMPA RI SON PURPOSE S ON LY, NOT AVA ILABLE AS A SEAL M ATE RIAL O N H AW KE YE VE N TS60330OPE R AT I NG TE M PE R ATU R E , °CNOR MA L RAN G EVITON IDHOLE AFLAS IDHOLES KALREZ ID HOLESID E N T IF Y IN G M AR S H H AWK GAS K E T M AT E R I A LMesh Hata formed 10 mesh 304 stainless steel cover to keep insects and debris from interfering with the marsh hawk internals.De-icing Systemallows direct injection of a seal-appropriate de-icing solution onto the marsh hawk internals from ground level. includes spray nozzle and hose assembly.PA RTS L I S T&M AT E R I A L S O F C O N S T R U C T I ONPAC K AG I N Gseries 4000 marsh hawks are shipped complete and boxed. in addition to the marsh hawk itself,the car-ton contains bolt kit(s), tank gasket(s) and installation instructions.weight is approximately 28 lb [12.7 kg].P R E S S U R E T E S T I N G series 4000 marsh hawks are tested prior to packaging to ensure pressure-tightness and relief setting accuracy. items passing the quality control measures are marked with the label at right.•P A S S•P R E SS UR E T ES T E DV E N T M A R K I N Gthe spider cage assembly of the series 4000 marsh hawk is tagged with the initial factory confi guration of the valve. as the relief pressure is fi eld-adjustable, space is left on the tag to record future set pressures,should they change.C E RT I F I C AT I O Nthe pressure and vacuum relief settings of the series 4000 marsh hawk can be factory certifi ed at an addi-tional expense. certifi ed hatches are accompanied by a certifi cate stating the relief pressure of the hatches.R I S E RS & S P O O L SBolt-on risers account for the slope of the tank roof ensuring the series 4000 marsh hawk sits level for trouble-free operation. adapter spools allow installa-tion of a marsh hawk or other 8” aPi 12B/F device onto an ansi B16.5 fl at-face fl ange or other aPi man-way or tank opening. see the “risers, spools & rings” brochure for more information. 12:1 Bolt-on Hatch Riserthe most popular riser used with the series 4000 marsh hawk, the HRSP-0800, ensures a vertical gauge hatch orientation on a 12:1 sloped tank roof with an existing 8” aPi 12B/F fl at-face connection.[in.][mm.]rh riser height (max) 4.2107rcmin minimum fl ange gap2.563.5P Pitch12:1 4.8°rd Outisde Diameter 12.0305riinside Diameter8.0203the series 4000 marsh hawk is just one part of tank-age product lines from hawkeye industries, that also includes:Vapor Controlseries 5000 ePrv series 6000 Pvrv Mechanical Level Indicationmodel 1000 Redtail & model 1500 Roadside Dry seal Zero emission Level gauging systems model 2000 Goshawk Level transmitter for Dry seal Zero emission Level gauging systemsR E L AT E D P R O D U C TScontents © 2006 - 2021 hawkeye industries inc. this document is uncontrolled, and is subject to change without notice. Please refer to for the most up-to-date product information. 2110 70 ave nwedmonton, aB, canada t6P 1n6toll Free: (800) 910-4295Phone: (780) 490-4295Fax: (780) venting - series 4000 marsh hawk trv 01Jun2021Printed in canada.O R D E R I N G I N F O R M AT I O Nstandard series 4000 marsh hawk configurations are stocked ready to ship. Other configurations are typically assemble-to-order and available in under two weeks. configure your desired series 4000 marsh hawk trv us-ing the part number legend below. items in bold are standard items and have fastest lead times. all series 4000 marsh hawks ship complete with a gr. 5 Bolt kit and cr (neoprene) Base gasket, both upgradable (see below). For project quantities, contact your hawkeye sales rep for delivery schedules.Relief & MaterialOptionsMHMSMesh ScreenMHKD De-icing System0000Accessories Base GasketBolting KitSeries 6000 PVRV。

YSF压力释放阀YSF Pressure release valve使用说明书Instructions沈阳市金钟电器厂Shenyang Jinzhong electrical appliance factoryYSF Pressure release valve带防护罩的YSF4,5型压力释放阀定向喷油螺纹安装的YSF6型压力释放阀With a protective hood Specify the direction of Spray oil , Thread Installed定向喷油法兰安装的YSF7型压力释放阀定向导油法兰安装的YSF8,9型压力释放阀Specify the direction of Spray oil , Flange Installation Specify the direction of Oil Guide,Flange Installation YSF7 Pressure release valve YSF8,9 Pressure release valve- 1 -二, 型号、规格与基本技术参数Models, specifications and basic technical parameters:1, 型号Model :Y S F / D(S)KJTHB压力释放阀Pressure release valve 型号举例Model example: YSF 5 –55 / 130 D(S)KJTHBYSF 代表压力释放阀, 5 代表设计序号, 55 代表开启压力, 130 代表有效口径,YSF On behalf of pressure release valve,5 Serial number of Design,55 Opening pressure,130 Effective aperture D ( S ) 代表开关数量单( 双 ), K 代表电信号, J 代表机械信号, TH 代表湿热带地区,B 代表闭锁装置 D(S) -Switch amount one(two), K -Electric Signal, J - Mechanical signal, TH -Humid Tropics, B-Locking Device 2, 使用条件:-30℃至+100℃ 如遇寒带地区,采用特殊密封圈可满足-45℃Exploitation conditions -30℃ to +100℃ In case the frigid zone area, uses the special seal packing collar to be possible to satisfy -45℃3, 基本技术参数Basic technical parameters :有效口径Effective aperture (mm) 开启压力Opening pressure(KPa)关闭压力(不小于)Close Pressure (Not less than)(KPa)∮25∮5015±58 25 13.5 35 19 55 29.5 ∮80 ∮1303519 55 29.5 70 37.5 85 45.5 13874.5三, 带有电信号的输出接线线路图With electrical signal output wiring circuit diagram:a, 单开关接线线路图 b, 双开关接线线路图 C,双开关接线线路图Single-switch Two-switch Two-switch wiring circuit diagram wiring circuit diagram wiring circuit diagram信号开关接点容量Signal switch contact capacity :AC 220V 5A DC 220V 0.3A(电阻负载Resistive load )- 2 -。

Doc. No. VH*-OMX0068-APressure Relief 3 Port Valve with Locking HolesVHS20-(F,N)01~(F,N)02(-R,Z)-DVHS30-(F,N)02~(F,N)03(-R,Z)-DVHS40-(F,N)02~(F,N)04(-R,Z)-DPage 1. Safety Instructions 1~52. Application 63. Specifications 64. How to Order 7~85. Construction / Parts List 96. Dimensions10with Locking Holes Safety InstructionsThese safety instructions are intended to prevent hazardous situations and/or equipment damage.These instructions indicate the level of potential hazard with the labels of “Caution,” “Warning” or “Danger.”They are all important notes for safety and must be followed in addition to International Standards (ISO/IEC)*1) , and other safety regulations.*1) ISO 4414: Pneumatic fluid power -- General rules relating to systems. ISO 4413: Hydraulic fluid power -- General rules relating to systems.IEC 60204-1: Safety of machinery -- Electrical equipment of machines .(Part 1: General requirements)ISO 10218: Manipulating industrial robots -Safety. etc.Caution Caution indicates a hazard with a low level of risk which, if not avoided, could resultin minor or moderate injury.Warning Warning indicates a hazard with a medium level of risk which, if not avoided, could result in death or serious injury.DangerDanger indicates a hazard with a high level of risk which, if not avoided, will resultin death or serious injury.Warning 1. The compatibility of the product is the responsibility of the person who designs theequipment or decides its specifications.Since the product specified here is used under various operating conditions, its compatibility with specific equipment must be decided by the person who designs the equipment or decides its specifications based on necessary analysis and test results.The expected performance and safety assurance of the equipment will be the responsibility of the person who has determined its compatibility with the product.This person should also continuously review all specifications of the product referring to its latest catalog information, with a view to giving due consideration to any possibility of equipment failure when configuring the equipment.2. Only personnel with appropriate training should operate machinery and equipment.The product specified here may become unsafe if handled incorrectly.The assembly, operation and maintenance of machines or equipment including our products must be performed by an operator who is appropriately trained and experienced.3. Do not service or attempt to remove product and machinery/equipment until safety is confirmed.1.The inspection and maintenance of machinery/equipment should only be performed after measures to prevent falling or runaway of the driven objects have been confirmed.2.When the product is to be removed, confirm that the safety measures as mentioned above are implemented and the power from any appropriate source is cut, and read and understand the specific product precautions of all relevant products carefully.3. Before machinery/equipment is restarted, take measures to prevent unexpected operation and malfunction.4. Contact SMC beforehand and take special consideration of safety measures if the product is to be used in any of the following conditions.1. Conditions and environments outside of the given specifications, or use outdoors or in a place exposed to direct sunlight.2. Installation on equipment in conjunction with atomic energy, railways, air navigation, space, shipping, vehicles, military, medical treatment, combustion and recreation, or equipment in contact with food and beverages, emergency stop circuits, clutch and brake circuits in press applications, safety equipment or other applications unsuitable for the standard specifications described in the product catalog.3. An application which could have negative effects on people, property, or animals requiring special safety analysis.e in an interlock circuit, which requires the provision of double interlock for possible failure by using a mechanical protective function, and periodical checks to confirm proper operation.with Locking HolesSafety InstructionsCautionThe product is provided for use in manufacturing industries.The product herein described is basically provided for peaceful use in manufacturing industries.If considering using the product in other industries, consult SMC beforehand and exchange specifications ora contract if necessary.If anything is unclear, contact your nearest sales branch.Limited warranty and Disclaimer/Compliance RequirementsThe product used is subject to the following “Limited warranty and Disclaimer” and “Compliance Requirements”. Read and accept them before using the product.Limited warranty and Disclaimer1.The warranty period of the product is 1 year in service or 1.5 years after the product is delivered,whichever is first.∗2)Also, the product may have specified durability, running distance or replacement parts. Please consult your nearest sales branch.2. For any failure or damage reported within the warranty period which is clearly our responsibility,a replacement product or necessary parts will be provided.This limited warranty applies only to our product independently, and not to any other damage incurred due to the failure of the product.3. Prior to using SMC products, please read and understand the warranty terms and disclaimersnoted in the specified catalog for the particular products.∗2) Vacuum pads are excluded from this 1 year warranty.A vacuum pad is a consumable part, so it is warranted for a year after it is delivered.Also, even within the warranty period, the wear of a product due to the use of the vacuumpad or failure due to the deterioration of rubber material are not covered by the limitedwarranty.Compliance Requirements1. The use of SMC products with production equipment for the manufacture of weapons of massdestruction(WMD) or any other weapon is strictly prohibited.2. The exports of SMC products or technology from one country to another are governed by therelevant security laws and regulation of the countries involved in the transaction. Prior to the shipment of a SMC product to another country, assure that all local rules governing that export are known and followed.CautionSMC products are not intended for use as instruments for legal metrology.Measurement instruments that SMC manufactures or sells have not been qualified by type approval tests relevant to the metrology (measurement) laws of each country.Therefore, SMC products cannot be used for business or certification ordained by the metrology (measurement) laws of each country.Warning1. Please consult with SMC if the intended application calls for absolutely zero leakage due tospecial atmospheric requirement, or if the use of a fluid other than air is required.2. Do not apply negative pressure, as may cause malfunction.3. Do not supply air pressure from ports other than the 1(P) port, as may cause malfunction.4. When lockout is to be used, recommend using a lock with a shackle diameter of φ5 or more.Less than φ5 is to be used, please test it on the actual machine.Warning1. In some cases, mineral oil grease used for internal parts and sealant may be carried todownstream side. Please consult with SMC if this causes any inconvenience in use.Warning1. Do not drop or apply impact during transportation or installation, as may cause breakageor malfunction.2. Do not install in locations of high humidity or high temperature. Operation outside of theproduct specification range may cause breakage, malfunction, or shorten life performance.3. Connect the product ensuring the direction of "1"(IN) and "2"(OUT) for air direction andindicated arrow. Reverse connection may cause malfunction.Caution4. The valve must be switched to each position instantly and securely. Stopping the handlebetween the extreme positions may cause malfunction.Warning1. Before piping is connected, it should be thoroughly blown out with air (flushing) or washed to remove chips, cutting oil and other debris from inside. Should they remain, they could cause malfunction.2. When screwing piping or fittings into ports, ensure that chips from the pipe threads or sealing material do not enter the piping. Also, if sealant tape is used, leave 1.5 to 2 thread ridges exposed at the end of threads.3. When screwing piping into a component, hold female threaded side and apply the recommended tightening torque. Insufficient tightening torque may cause loosening or sealing failure and excess tightening torque may cause damage to threads. Tightening without holding female threaded side, excess force is applied to the bracket directly, and may cause breakage.4. Do not apply torsion or bending moment other than the product's own weight. Support external piping separately as it may cause breakage. Non-flexible piping, such as steel tube piping, are prone to be affected by excess moment load or vibration. Use flexible piping in between to avoid such affects.5. For piping into the exhaust port, it is recommended to use a resin silencers (AN series). After tightening the silencer by hand, use a suitable wrench on the hexagonal flats to tighten an additional 1/4 turn. When installing one-touch fittings (KQ2 series) or the piping, add 1/2 turn after tightening by hand. Excess tightening torque may cause damage to threads.Warning1. Use clean air. Do not use compressed air which contains chemicals, organic solvent, synthetic oil or corrosive gas, etc., as it may cause breakage or malfunction.2. Install an air dryer or after cooler on upstream side. Air containing excess drainage may cause malfunction.Caution3. Install an air filter of 5 µm filtration on upstream side.4. Install a mist separator on upstream side to remove carbon powder from the compressor or other equipment. Excess carbon dust may cause malfunction.Refer to SMC’s “Air Cleaning Equipment” catalog for further details on compressed air quality.Recommended tightening torque Unit: N-m Thread size 1/8 1/4 3/8 1/2Torque 7 to 912 to 1422 to 2428 to 30Warning1. Do not use in atmospheres contacting corrosive gases, chemicals, sea water, water,water steam, or where there is direct contact with any of these.2. Do not use in explosive atmosphere.3. Do not use in locations subject to vibration or impact.4. Do not expose to direct sunlight for an extended period of time. Protective cover should beused to shield.5. Do not mound in locations where is nearby heat source. Radiated heat should be alsoprevented.6. Implement suitable protective measures in locations where there is contact withwater droplets, oil, or welding spatter.7. Install a silencer into exhaust port to prevent the dust ingress if there is a lot of dust inatmosphere, as dust may cause air leakage.Warning1. When equipment is to be removed, first confirm that measures are in place to preventworkpieces from dropping, run-away of equipment, etc.. Then cut off the supply air pressure and electric power, and exhaust all compressed air from the system using its residual pressure release function.When the equipment is to be restarted after remounting or replacement, first confirm that measures are in place to prevent lurching of actuators and then confirm that equipment operates normally.2. Do not disassemble. Improper handling may cause malfunction or breakage of themachinery or equipment.2. ApplicationsThis product is a residual pressure release valve which is switched by hand.3. Specifications(1) Standard specifications (2) Flow characteristics-6- Model VHS20VHS30 VHS40FluidAirAmbient and fluid temperature -5 to 60o C (No freezing)Proof pressure1.5MPa Maximum operating pressure 1.0MPa Handle operation Switching angle 90o Rotating torque Note1)0.8N-m or less 1.0N-m or less 3.0N-m or less Weight95g 181g400gNote 1) Supply pressure: 1.0 MPaModelPort size Supply (IN →OUT) Exhaust (OUT →EXH) IN, OUT EXH C(dm 3/s-bar)b Cv C(dm 3/s-bar)b Cv VHS201/8 1/84.0 0.41 1.1 3.7 0.42 1.1 1/45.8 0.31 1.4 3.8 0.42 1.1 VHS30 1/4 1/48.8 0.44 2.4 8.0 0.46 2.3 3/8 14.1 0.28 3.5 7.8 0.46 2.2 VHS401/43/8 9.5 0.49 2.8 13.3 0.47 3.6 3/8 17.2 0.47 4.8 13.6 0.47 3.7 1/226.70.296.313.40.433.74. How to Order- - - VHS 30 03 D❶❷❸❹# A spacer or spacer with bracket is required if the valve is combined with modular F.R.L. Please order it separately.VHS type can be ordered from How to Order of modular F.R.L. combination.Spacer (Y □-D)Spacer with bracket(Y □T-D)Pressure relief 3 port valve Spacer part no. Spacer with bracketpart no. Applicable F.R.L. combinationVHS20 Y200-D Y200T-D AC20-D VHS30 Y300-D Y300T-D AC30-D VHS40Y400-DY400T-DAC40-D* New VHS series compatible with previous model spacer Y200(T)-A to Y400(T)-A.Pressure relief 3 port valve5. Construction/ Parts list-9-No.DescriptionStandard specificationsMaterial Note 1 Body ADC12 White 2 Body cover POM White 3 Handle POM Red 4 Bonnet PBT- 5Valve guideFlame resistant PBT (UL94 standard V-0 equivalent )White 6 Cam ring POM - 7 Sleeve POM - 8 Spool PBT - 9 O-ring H-NBR - 10Spring Stainless steel-# The VHS series cannot be disassembled. Parts cannot be shipped separately.6. Dimensions-10-Model Standard specifications P1 P2 A B C D E F G H VHS20 1/8, 1/4 1/8 71.5 23 40 37 28 42 17.5 40 VHS30 1/4, 3/8 1/4 873253 49 38 53 20 53 VHS401/4, 3/8, 1/23/8111 42.3706352712970Padlock mounting position(Port size)(Port size)Rev. A - Safety Instructions (Piping) corrected.- How to Order added *2 and *3.4-14-1, Sotokanda, Chiyoda-ku, Tokyo 101-0021 JAPANTel: + 81 3 5207 8249 Fax: +81 3 5298 5362© 2019 SMC Corporation All Rights Reserved。

Wandfluh AG Tel. +41 33 672 72 72 E-mail: ******************Illustrations not obligatoryData sheet no.PostfachFax +41 33 672 72 12 Internet: Data subject to change 2.3-562E 1/4 CH-3714 Frutigen Edition 17 01TYPE CODEB D IPM22 --/ M E-#Pressure relief valve Direct operated Proportional, inverse Screw-in cartridge M22x1,5Nominal pressure rang p N 20 bar 20 200 bar 200 100 bar 100 315 bar 315160 bar 160 350 bar 350Nominal voltage U N 12 VDC G1224 VDCG24Slip-on coilMetal housing, square Execution connectionIntegrated electronicsHardware configurationWith analog signal (0…+10 V factory set)A1With CANopen acc. to DSP-408C1With Profibus DP in accordance Fluid Power Technology P1With CAN J1939 (on request) J1Function AmplifierController with current feedback signal (0...20 mA / 4...20 mA) R1Controller with voltage feedback signal (0...10 V) R2Sealing material NBRFKM (Vitron)D1Design-Index (Subject to change)Proportional pressure relief valve inverse Screw-in cartridge• Integrated amplifier or controller electronics • Direct operated• Q max = 20 and 25 l/min • p max = 400 bar • p N max = 350 barDESCRIPTIONDirect operated proportional pressure relief valve with integrated electronics and inverse function. Thread M22x1,5 for cavity according to ISO 7789. These plug & play valves are factory set and adjusted. High valve-to-valve reproducibility. Housing for electronics with protection class IP67 for harsh environment. As standard versions, 6 pressure ranges are available: 20, 40, 63, 100, 160, 200, 315 and 350 bar. Good flow performance due to the differential area principle. Small leakage along the poppet guide. Adjustment by a Wandfluh (VDE-Norm 0580) proportional solenoid. The cartridge and the solenoid made of steel are zinc coated and therefore rust-protected.FUNCTIONThe valve limits the pressure in the port P (1) and reliefs the volume flow to tank port T (2). The back pressure in T (2) influences the pressure in P (1). The reliefed pressure drops with rising solenoid current (inverse function), and the with deenergised solenoid, a maximum pressure is present. The control connection is provided by an analog interface or a fieldbus interface (CANopen or Profibus DP). Parameter setting and diagnosis with the free-of-charge software «PASO» or via fieldbus interface. After taking off the cover of the electronic housing, the serial interface to adjust the settings is accessible. The menu controlled Windows program «PASO» allows easy adjustment of all variable settings. Data are stored in a non-volatile memory. Even after an electric power failure settings can easily be reproduced and transmitted.APPLICATIONProportional pressure relief valves with inte-grated electronics are well suited for demanding applications, in which the pres-sure frequently has to be changed. They are implemented in systems calling for good valve-to-valve reproducibility, easy installati-on, comfortable operation and high precision in industrial hydraulics as well as in mobile hydraulics. The proportional pressure relief catridge is very suitable for mounting in control blocks, flange bodies and sandwich plates size NG4-Mini and NG6. (Please note the separate data sheets in register 2.3). Cavity tools are available for machining the cavities in steel and aluminium (hire or purchase). Please refer to the data sheets in register 2.13.M22x1,5ISO 7789Wandfluh AG Tel. +41 33 672 72 72 E-mail: ******************Illustrations not obligatory Data sheet no.Postfach Fax +41 33 672 72 12 Internet: Data subject to change 2.3-562E 2/4CH-3714 FrutigenEdition 17 01SYMBOL37s3M22x1.5T(2)X1X2X4 (nur Regler)(controller only)35.583X1X3X225,30501821, 2240706s613M DELECTRICAL SPECIFICATIONSProtection class IP 67 acc. to EN 60 529with suitable connector and closedelectronics housingSupply voltageRampsParameterisationInterfaceAnalog interface:Mating connectorPreset value signalFieldbus interface:Device receptaclesupply (male)Mating connectorDevice receptacleCANopen (male)Mating connectorDevice receptacleProfibus (female)Mating connectorPreset value signalFeedback signal interface (Sensor):(controller only)Device receptacle (female) M12, 5-polesMating connector Plug (male), M12, 5-poles(not incl. in delivery)Feedback signal:: Voltage / current state when orderingCONNECTOR WIRING DIAGRAMAnalog interface:Supply voltage +Supply voltage 0 VDCStabilised output voltagePreset value voltage +Preset value voltage -Preset value current +Preset value current -Reserved for extensionsReserved for extensionsEnable control (Digital input)Preset value voltage (PIN 4/5) resp. current (PIN 6/7) are selected withV), (PIN 4/5)Parameterisation interface (USB, Mini B) X2Under the closing screw of the housing coverFeedback signal interface (Sensor)Device receptacle (female) X4 (only controller)1 = Supply voltage (output) +2 = Feedback signal +3 = Supply voltage 0 VDC4 = not connected5 = stab. output voltage2 = Reserved for extensionsDevice receptacle Device receptacleCANopen (male) X3 Profibus (female) X3CAN PROFIBUS1 = not connected 1 = VP2 = not connected 2 = RxD / TxD - N3 = CAN Gnd 3 = DGND4 = CAN High 4 = RxD / TxD - P5 = CAN Low 5 = Shield31452123543145212354123451234123431452HYDRAULIC SPECIFICATIONSFluid Mineral oil, other fluids on requestContamination ISO 4406:1999, class 18/16/13efficiency (Required filtration grade ß 6…10≥75)see data sheet 1.0-50/2Viscosity range 12 mm2/s…320 mm2/sFluid temperature -20…+70°CPeak pressure pmax= 400 barNominal pres. ranges pN= 20 bar, 100 bar, 160 bar, 200 bar,315 bar, 350 barMin. volume flow Qmin= 0,1 l/minMax. volume flow Qmax= 25 l/min for pN=20 bar / 100 bar /160 bar / 200 barQmax= 20 l/min for pN= 315 barQmax= 5 l/min for pN= 350 barLeakage volume flow see characteristicsRepeatability ≤ 3 %Hysteresis ≤ 5 %GENERAL SPECIFICATIONSDescription Direct operated proportional pressure reliefvalve with integrated electronics inverse functionConstruction Screw-in cartridge for cavity acc. to ISO 7789Operations Proportional solenoid wet pin push type,pressure tightMounting Screw-in thread M22x1,5Ambient temperature -20…+65°C (typical)(The upper temperature limit is a guideline value for typicalapplications, in individual cases it may also be higher or lower.The electronics of the valve limit the power in case of a toohigh electronics temperature. More detailed information can beobtained from the operating instructions «DSV».)Mounting position any, preferably horizontalFastening torque MD= 50 Nm for screw-in cartridgeMD= 5 Nm for knurled nutWeight m = 1,0 kgWandfluh AG Tel. +41 33 672 72 72E-mail: ******************Illustrations not obligatoryData sheet no.PostfachFax +41 33 672 72 12 Internet: Data subject to change 2.3-562E 3/4 CH-3714 FrutigenEdition 17 01CHARACTERISTICS Oil viscosity υ = 30 mm 2/s p = f (Q) Pressure volume flow characteristics (Maximum adjustable pressure)p= f (Q) Pressure volume flow characteristics (Minimum adjustable pressure)Q L = f (p)Leakage volume flow characteristicsp red = f (l) Pressure adjustment characteristics[at Q = 10 l/min] / (s corresponds to preset value signal)p = f (l) Pressure adjustment characteristics [at Q = 5 l/min] /(s corresponds to preset value signal)NOTE!Detailed electrical characteristics and description of «DSV » electronics are shown on data sheet 1.13-76.START-UPFor DSV amplifiers as a rule no parameter settings by the customer are required. The plugs have to be connected in accordance with the chapter «Pin assignment».Controllers are supplied configured as amplifiers. The setting of the mode of control and the setting of the controller are done by the customer by software setting (USB interface, Mini B).Additional information can be found on our website:«»Free-of-charge download of the «PASO»-software and the instruction manual for the «DSV » hydraulic valves as well as the operation instruc-tion CANopen eg.Profibus DP protocol with device profile DSP-408 for «DSV ».NOTE!The mating connectors and the cable to adjust are settings is not part of the delivery. Refer to chapter «Accessories».Factory settings:Dither set for optimal hysteresis= Deadband: Solenoid switched offwith command preset value signal <5 % p Nmechanicallly pre-set at Q = 5 l/min= Limited pressure in port P (1) at 70 % of preset value signal: 95 bar with pressure range 350 bar 65 bar with pressure range 315 bar 56 bar with pressure range 200 bar 32 bar with pressure range 160 bar 25 bar with pressure range 100 bar 4 bar with pressure range 20 bar0 10 20 30 40 50 60 70 80 90 100s [%]p [bar]4003002001000 10 20 30 40 50 60 70 80 90 100s [%]p [bar]1209060300p = f (l) Pressure adjustment characteristics [at Q = 5 l/min] / (s corresponds to preset value signal)40030020010000 5 10 15 20 25Q [l/min]p [bar]N = 200 bar N = 160 bar N = 100 bar N= 20 bar504030201000 5 10 15 20 25Q [l/min]403020100 50 100 150 200 250 300 350 p [bar]Q [cm 3/min]0 10 20 30 40 50 60 70 80 90 1001251007550250I [%]p [%]Wandfluh AG Tel. +41 33 672 72 72 E-mail: ******************Illustrations not obligatoryData sheet no.PostfachFax +41 33 672 72 12 Internet: Data subject to change 2.3-562E 4/4 CH-3714 Frutigen Edition 17 01Cavity drawing according to ISO 7789–22–02–0–98For detailed cavity drawing and cavity toolssee data sheet 2.13-1003With fieldbus interface Amplifier With fieldbus interface ControllerDIMENSIONS / SECTIONAL DRAWINGS*Adjusting screw for setting the nominal pressure (-20 % / +30 %)With analog interface Amplifier and ControllerACCESSORIES • Cartridge built in:flange and sandwich bodies see register 2.3• Set-up softwaresee start-up• Cable to adjust the settings through interface USB (from plug type A to Mini B, 3 m) article no. 219.2896• Cable connector for analog interface: – straight, soldering contact article no. 219.2330 – 90°, soldering contact article no. 219.2331Recommended cable size: – Outer diameter 9…10,5 mm – Single wire max. 1 mm 2 – Recommended wire size: 0…25 m = 0,75 mm 2 (AWG18) 25…50 m = 1 mm 2 (AWG17)Technical explanation see data sheet 1.0-100PARTS LIST Position Article Description17160.2187O-ring ID 18,72 x 2,62 (NBR)18160.2170O-ring ID 17,17 x 1,78 (NBR)20154.2700Knurled nut21223.1317Dummy plug M16 x1,522160.6131O-ring ID 13,00 x1,525062.0102Cover square 30072.0021Gasket 33,2 x 59,9 x 240208.0100Socket head cap screw M4 x1050160.2188160.6188O-ring ID 18,77 x 1,78 (NBR)O-ring ID 18,77 x 1,78 (FKM)60160.2140160.6141O-ring ID 14,00 x 1,78 (NBR)O-ring ID 14,00 x 1,78 (FKM)70049.3177Back-up ring RD 14,6 x 17,5 x 1,4353790.2s 30M 22x 1.5T(2)X2X1X3X4172.4P(1).5(1)E: Venting。

DRP SELF REGULA TING SERIESDRP Series - Control ValvesProduct FeaturesArmstrong Delta2 - DRP SERIES is a globe self actuated pressure reducing/relief Control Valve for a wide range of process applications.• available size from DN15 to DN100 and from 1/2" to 4".• available pressure rating DIN from PN10 to PN40.• available pressure rating ANSI from 150lbs to 300lbs.MaterialsFull range of materials and special alloys are available for valve body and trim including hardening treatment. Special NACE design andmaterial construction for Sour Service with a Compliance Declaration in accordance to NACE regulations. GuidingValve guiding is top for standard disk plug and is made directly on plug shaft to guarantee a larger guiding and plug stability for accurate control application.TrimStandard construction includes disk plug and threaded replaceable seat.Stem SealStandard stem seal for DRP - Pressure Reducing valves up to 50 barg is full Stainless Steel Bellow seal for zero leakage in case of Higher class or Pressure Relief applications a Standard Low Emission packing and the integral diaphragm is used.SPECIAL DESIGNDRP Series - Control Valves Standard Part List1918DRP Series - Control ValvesFunctioning of pressure reducing valves on steamSteam enters through port 1 (valve is normally open but flow direction close the plug), flowing through seat 2 and plug 3 and reduces its pressure moving out through port 4.The piping 5 connect the condensation pot 6 with the control area 7 andtransmits the variation of reduced pressure at the bottom of Diaphragm 8.Example given is supposing that the reduced pressure exceeds thevalue of valve spring range setted up.Then the control spring 9 will be compressed by the higher force present in the control area 7 and therefore the plug will close slicely to valveseat causing an higher pressure drop that in a short time will results in a downstream pressure balanced according to the spring set range.In fact an opposite action happens when the downstreampressuretend to decrease: the pressure of controlarea 7 decreases, allowing to control spring 9 tomove the plug in opening direction and therefore the downstream pressure will be re-established.The value of reduced pressure can be change by operating on thespring range setting with the apposite key.(1)ANSI / ISA 75.08.01 or ISA S75.03 on request(2) Special high capacity trim are available on request.(3) Standard rangeability 30:1. Optional higher rangeabilities can be provided.Valve SpecificationValve ConnectionsStandard Facing according to EN 1092-1 Form B1 up to PN40 and Form B2 above.Standard Facing according to ASME B16.5 Form RF (Ra 125-250 AARH Smooth Finish).Materials of Construction(1)= Special materials available on request.Materials of ConstructionPressure and Temperature Ratings(*)= Maximum allowable temperature of Gases without Condensation Pot is 120°C.Pressure and Temperature CurvesFlow Coefficient TableOptions:- Full Hard Facing through Overlaying or Treatments available for all Port Size. Actuators Down Pressure Range Table113/8"Designs, materials, weights and performance ratings are approximate and subject to change without notice.Visit armstrong for up-to-date information.North America • Latin America • India • Europe / Middle East / Africa • China • Pacific Rimarmstrong international.euValve Dimensions1) DIN PN10 to PN40 Face to Face lenght according to EN 558-1 serie 1, DIN 3202 F1 (ANSI/ISA 75.08.01 on request)Actuators Dimensions 1) ED = Envelope Diameter is the minimum horizontal space necessary for valve maintenence.2) EH = Envelope Height is the minimum vertical space necessary for valve maintenence.Condensate Pot DimensionsValve Condensate PotActuatorINTELLIGENT SOLUTIONS IN STEAM, AIR, AND HOT WATERarmstrong international.eu。

CROSBY 800 和 900 OMNI-TRIM ® 系列压力释放阀安装及维修说明书1概述Crosby 阀门已在出厂前进行了测试和调整。

当使用条件有变化时可能还需要作少量的调整。

只要遵循本文的指示,进行调整是很容易的。

警示为达到无故障运行,应确保在安装阀门前彻底清洁阀门的进口和出口。

2存放和搬运阀门在安装之前通常会在工作现场保存几个月。

如果存放和防护不当,阀门性能可能造成不利影响。

粗鲁的搬运和污物可能损伤阀门或造成阀门零件的对正性。

建议将阀门留在原包装箱内,并存放在仓库里,或者至少要放置在干燥的表面并加防护罩,直到阀门使用。

压力释放阀必须小心搬运,不得遭受剧烈冲击载荷。

它们不应遭受冲击、颠簸和坠落。

粗鲁的搬运可能改变阀门的整定压力,使阀门零件变形,从而对阀门密封和性能造成不利的影响。

注对于配有D 型和E 型保护罩的带扳手阀门,不可利用扳手来提升或搬运阀门。

在阀门准备好进行系统安装之前,不应去掉阀门进口和出口的防护罩盖。

警示确保材料及产品对买方预期用途的适应性是买方的责任。

储藏、安装和适当的使用也是买方自己的责任。

Emerson 不承担由此产生的任何和所有责任。

注意生命和财产安全常常有赖于压力释放阀的正常工作。

因此,阀门应保持清洁并应定期进行测试和检修,以确保压力释放阀正常的工作。

工程文档编号IS-V3117对压力释放阀的任何安装、维护、调整、修理和测试按相关规范和标准的要求进行。

按照这些要求执行此类工作的人员应从相应的管理机构得到适当的授权。

任何由本公司之外人员进行的修理、装配和测试工作均不在本公司对用户担保的范围内。

你对你的工作承担全部责任。

在维修本公司产品时,应当只使用本公司制造的零件。

如果需要现场协助,请联系离您最近的Emerson 区域销售办公室或代表。

目录1. 概述 ...............................................................12. 存放和搬运 ...................................................13. 安装 ...............................................................24. 试验 ...............................................................35. 整定压力 .......................................................36. 维修-解体......................................................37. 清洁 ...............................................................48. 密封面研磨-仅对金属密封阀门...................49. 维修-装配......................................................410. 保护罩和提升扳手的装配 ............................511. 更换用备件 (6)800系列螺纹连接铅封O 型圈O 型圈软密封金属对金属密封阀座固定螺钉阀杆保护罩调整螺杆调节螺栓螺母上弹簧座弹簧下弹簧座阀瓣座导向套固定螺钉垫片阀瓣调节圈阀体罩盖弹簧垫片(顶部)调节螺栓主轴900系列螺纹连接调节螺栓螺母阀芯基座气缸阀板固定器密封件和线材O 形圈引导O 形环柔性阀座金属对金属阀座弹簧弹簧垫片(底部)3安装• 进口管道压力释放阀应以垂直向上的位置直接安装于压力容器的接管嘴上,或安装于容器的短的连接附件上。

![压力释放阀说明书[中英]](https://uimg.taocdn.com/2e96aecc76c66137ef06192d.webp)

压力释放阀PRESSURE RELEASE VALVE使用说明书OPERATION INSTRUCTION明远电器设备SHENYANG MINGYUAN ELECTRIC EQUIPMENT CO., Ltd.本说明书适用于我公司生产的系列变压器用压力释放阀,阐述其用途、性能、规格、技术参数、使用及安装,供用户参考。

The Operation Instruction is applicable to pressure release valve of a series of transformers manufactured by our company, indicating its application, performances, specifications, technical parameters, usage and installation for uses’ reference.1. 压力释放阀用途和性能压力释放阀适用于油浸式电力变压器、电力电容器及有载分接开关等,用来保护油箱。

当油浸式变压器在运行中出现故障时,由于线圈过热,使一部分变压器油汽化,变压器油箱中压力迅速增加,这时压力释放阀在2ms迅速动作,释放压力,保护油箱不致变形或爆裂。

油箱的压力再升高而达到开启压力时,压力释放阀应再次动作,直到油箱的压力降到正常值。

由于压力释放阀动作后能可靠关闭,油箱外的水和空气不能进入油箱,变压器部不会受大气污染。

1.Application and performancePressure release valves play a vital role in the protection of oil-immersed electrical equipments, such as transformers, high voltage switch gears, capacitor and on load tap-changers, etc. This device can prevent the oil-immersed electrical equipment from deformation or rupture. Should a fault occur in such electrical equipment, from deformation of rupture? Should a fault occurring in such electrical equipment, they are instantaneously vaporize the oil causing extremely rapid build-up of gaseous pressure? If mounting this type pressure release device on the oil-tank, when the pressure reaches to its opening pressure, it opens automatically within 2ms and relieves the pressure.2.型号、规格及基本参数Type, specification and technical parameters2.1 型号的含义 Meaning of typeY S F□—□ / □□□特殊环境代号(Special environment)带机械信号标“J”(“J”:mechanical signal)带信号开关标“K”(“K”:electrical signal)两者都带标“KJ”(“KJ”:Both with signal)喷油有效口径(Caliber of oil-gushing tube)mm开启压力(Opening pressure)kPa设计序号(Design serial number)阀(valve)释放(release)压力(pressure)注:特殊环境代号 note: special environment:TA: 干热带地区 dry tropicTH: 湿热带地区 humid tropicT: 干、湿热带地区 dry、humid tropic例:YSF16-55/130KKJT开启压力为55kPa,喷油口径为φ130mm,带电信号、机械信号。

ContentsGENERAL DESCRIPTION 3 TYPICAL SECTION 3 FUNCTIONAL SYMBOLS 4 MODEL CODES 5 OPERATING DATA 6 PERFORMANCE DATAPressure override, Off-Load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8 Pressure override when relieving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 Pressure gain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 Step response . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9INSTALLATION DIMENSIONSKBCG-6/8 Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10 Mounting surfaces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11 CGVM-6-10-R Subplate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11ELECTRICAL INFORMATIONBlock diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12 Wiring connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13FURTHER INFORMATION 152EATON Proportional pressure relief valves V-VLPO-MC003-E1 September 20203EATON Proportional pressure relief valves V-VLPO-MC003-E1 September 2020These two-stage pressure relief valves offer extensive application possibilities through their ability to control the pressure setting in proportion to an applied electrical input (up to a pressure limit which is manually adjustable and lockable) .The integral amplifier allows the pressure to be controlled from a low power command signal: either a voltage or current command . The amplifier is mounted in a robust metal housing and electrical connections are via an industry standard 7-pin plug . Factory-set adjustments ensure high reproducibility valve-to-valve .Basic characteristicsMax . pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .350 bar (5000 psi) Max . flow rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .400 L/min (106 USgpm)Mounting face to ISO 6264:For KBCG-6 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . AR-06-2-A For KBCG-8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . AS-08-2-AFeatures and benefits • Remote electrical proportional control of pressure from a choice of five pressure ranges per valve size .• Excellent repeatability and stable performance results from cartridge design of mainstage elements .• Low installed cost and space requirement from high power/size ratios (more than double that of many conventional designs) .• On-board ramp adjustment .General descriptionT ypical sectionManual and electricalpilots internallydrained to port T.Model code 7= Blank7-pin plugManual pilot internallydrained to port T;electrical pilot drainedto side drain port u.Model code 7= 37-pin plugu Tapped port on side of pilot head . Manual and electrical pilots drained to side drain port u.Model code 7= 17-pin plug¨¨¨Functional symbolsu Tapped port on side of pilot head .4EATON Proportional pressure relief valves V-VLPO-MC003-E1 September 20205EATON Proportional pressure relief valves V-VLPO-MC003-E1 September 20201KB 8Z 2*9*3G 1034*11A 5*12P*76***13*7*14111Valve typeKB Proportional valve with integral amplifier, B series 2TypeC Pressure relief 3MountingG Subplate mounted 4Interface - ISO 6264With B port high pressure inlet, A port reduced pressure outlet 6 AR-06-2-A 8 AS-08-2-A 5Manual adjustment W Screw/locknut 6Controlled pressure rangeBased on inlet pressure of 350 bar (5000 psi) . Note, with 100 bar (1450 psi) inlet the lower limits will be 2-3 bar (30-43 psi) lower40 100 160 250 3506-40 bar (87-580 psi) 7,75-100 bar (112-1450 psi) 8,5-160 bar (125-2300 psi) 8,5-250 bar (125-3625 psi) 9-350 bar (139-5000 psi)7DrainBlankManual and electrical pilots drain internally to T port 1Manual and electrical pilots drained to side port drain 3Manual pilot internally drained to T port, electrical pilot drained to side port drain 8Manual overridesZ No overrides 9Electrical command options M1+/- 10 volts control signal M24-20 mA control signal 10Ramps3Standard ramp for KBCG- 6/8 valve types 11Command/pressure characteristicA Standard 12Electrical connection PC77 pin connector, without plug supplied PE77 pin connector, with plug supplied PH7As PE7 but with pin ‘C’ used for enable signal PR7as PC7 but with pin ‘C’ used for enable signal 13Coil rating H124V DC amplifier supply 14Design number, 1* series 11Subject to change . Installation dimensions unaltered for design numbers 10 to 19 respectivelyModel codesT o conform to the EC Electromagnetic Compatibility directive (EMC) this KBCG valve must be fitted with a metal 7-pin plug. The screen of the cable must be securely connected to the shell of the metal connector. A suitable IP67 rated connector is available from Eaton, part no. 934939. Alternatively a non IP67 rated connector is available from ITT -Cannon, part no. CA 02 COM-E 14S A7 P .6EATON Proportional pressure relief valves V-VLPO-MC003-E1 September 2020Operating dataStandard test conditions are with antiwear hydraulic oil at 36 cSt (168 SUS) and 50°C (122°F)Maximum pressures:Ports P and X ▲350 bar (5000 psi)Port T ▲ in KBCG-*-****-Z valves2 bar (30 psi)Port T ▲ in KBCG-*-****-1/3-Z valves350 bar (5000 psi)Side drain port ▲2 bar (30 psi)▲ Back pressure at these ports additive to the pressuresetting of the valve.Rated flow at Δp = 6 bar (87 psi):KBCG-6200 L/min (52.8 USgpm)KBCG-8400 L/min (105.7 USgpm)Vent u flow with valve at rated flow1 L/min (0.26 USgpm)u See “Venting”, page 8.Pilot control drain flow, when valve is limiting systempressure, i.e. flow P to T occurring:KBCG-61,3 L/min (0.34 USgpm)KBCG-82,0 L/min (0.53 USgpm)Coil or amplifier rating24V x 40W max. (22 to 36V including 10% pk.-to-pk.max. ripple)Command signal:Volts (see model code 9 - 1)0 to +10V or 0 to -10VInput impedance 47 kΩCommon mode voltage to pin B 4VCurrent (see model code 9 - 2) 4 to 20 mAInput impedance 100ΩValve enable signal:Enable >9.0V (36V max)Disable <2.0VInput impedance 36 kΩ7-pin plug connector Pin DescriptionA Power supply positive (+)B Power supply 0V and current command returnC Valve enable (PH7 & PR7)D Command signal (+V or current in)E Command signal (-V or current GND)F Output monitorView of pins of fixed half G Protective groundElectromagnetic compatibility (EMC)IEC 61326-2-1 (Electrical equipment for measurement, control and laboratory use)Conducted Emissions CISPR11 -2015-06 Ed 6.0/EN55011 - Class A, 150kHz to 30MHzRadiated Emissions CISPR11 -2015-06 Ed 6.0 /EN55011 - Class A, 30MHz – 1GHzRF Continuous Conducted disturbances IEC 61000-4-6, 3Vrms Class A 150 KHz to 80 MHzRF Electromagnetic Field, 80MHz to 1GHZ, 10V/m; 1.4GHz to 2.7GHz, 3V/m; Meets Criterion ASurge: IEC 61000-4-5• DC Power Port : ±1kV• Signal/Control Port : ±1kVElectrical Fast Transients IEC 61000-4-4, Class B• DC Power Port : ±1kV• Signal/Control Port : ±0.5kVElectrostatic discharges (ESD) IEC 61000-4-2, Class B• Air ±8kV• Contact ±4kVROHS Compliance:Complies with: Restriction of Hazardous Substances (RoHS) Directive 2011/65/EUMonitor signal (pin F) 1.7 V/amp solenoid currentOutput impedance10 kΩOperating dataPressure gain See graphFactory setting - Maximum with 100% command signal.Pressure override when relieving and when off-load See graphsLinearity, between 10% and 100% of rated pressure:KBCG-6 models at 100 L/min (26 USgpm)<6%KBCG-8 models at 200 L/min (52 USgpm)<6%Hysteresis<6% (with factory-set dither)Repeatability<1.3% of rated pressureReproducibility, valve-to-valve (at factory settings):Pressure at 100% command signal≤5%Protection:Electrical Reverse polarity protectedEnvironmental IEC 529, Class IP67Mass (weight):KBCG-65,36 kg (11.8 lb)KBCG-86,26 kg (13.8 lb)Supporting products:Auxiliary electronic modules (DIN-rail mounting):EHA-CON-201-A-2* Signal converter See catalog 2410BEHD-DSG-201-A-1* Command signal generator See catalog 2470EHA-RMP-201-A-2* Ramp generator See catalog 2410BEHA-PID-201-A-2* PID controller See catalog 2427EHA-PSU-201-A-10 Power supply See catalog 2410BSubplates, size 03See catalog 2425Mounting bolts n See catalog 2314An Note: If not using Vickers™ recommended bolt kits, boltsmust be to ISO 898 grade 12.9 or stronger.Mounting attitude No restriction, provided that the valve is kept full of fluid through port T.7EATON Proportional pressure relief valves V-VLPO-MC003-E1 September 20208EATON Proportional pressure relief valves V-VLPO-MC003-E1 September 2020Pressure override, off-load Graphs show the minimum pressures obtainable:a) With 0 mA current to the solenoid coil b) When the valve is vented (see following explanation) .Venting When the vent port X (or alternative vent port in the valve body) is connected to the reservoir via a suitable 2-way pilot valve, the mainstage of the relief valve opens to allow full flow from P to T at low pressure drop . The minimum pressure drop is obtained when the pilot valve is also de-energized . The total pressure drop through the venting 2-way valve and pipework is additive to the pressure at P . While the valve is vented the system pressure cannot be controlled via the proportional solenoid . This control feature is frequently used during off-load periods in machine cycle times . If lower off-load system pressures are required then additional full flow unloading valves are recommended, e .g . Vickers™ CV series cartridge valves . Note: All valves are with pilot valve de-energized .Data is typical with oil at 36 cSt (168 SUS) and at 50°C (122°F)024810bar 60255075100125psiKBCG-815097531V al vepre ssur ed rop400 L/min400608010020030020Flow rate 100USgpm 024810bar 60255075100125150psi13579KBCG-6V al vepre ssur ed ro pKBCG-6*-160/250/350KBCG-6*-100KBCG-6*-40 (also KBCG-6*-350 vented)KBCG-6*-40 vented 0501001502001020304050USgpm Flow rate L/min Performance data9EATON Proportional pressure relief valves V-VLPO-MC003-E1 September 2020Performance data050100150200250300350bar 010002000300040005000psiKBCG-8KBCG-6020406080100200400L/min USgpm Flow rate40801200203040L/minUSgpm16030010020050P r e s s u r e1002030405060708090100%50100150200250300bar 01000200030004000psi % max. solenoid current P r e s s u r e 10Pressure override when relievingPressure gain Typical pressure versus command signal response of KBCG-6-250 model .Step response KBCG models with factory-set gain .Test method 1 . T rapped volume between pump and test valve, as in table .2 . Flow rate set at pump, as in table .3 . Response = time from step input signal until pressure reaches 90% of step change, as measured by transducer .ModelCurve number 123456789KBCG-**-40•KBCG-**-100••KBCG-**-160•••KBCG-**-250••••••KBCG-**-350••••••Valve sizeTest conditions:Trapped volume Flow rate Step size:Pressure demand Response Time (ms)62,0 liters (0.53 USg)100 L/min (26 USgpm)0 to 100%100% to 025 to 100%100 to 25%10070405084,0 liters (1.06 USg)200 L/min (52 USgpm)0 to 100%100% to 025 to 100%100 to 25%11070506510EATON Proportional pressure relief valves V-VLPO-MC003-E1 September 2020KBCG-6/8 modelsDimensions are shown in mm (inches)To bleed air,end of coretoafter bleedingis complete.connectorremoval directive (EMC) this KBCG valve must be fitted with a metal 7-pin plug. The screen of the cable must be securely connected to the shell of the metal con-nector. A suitable IP67 rated connector is available from Eaton, part no. 934939. Alternatively a non IP67 rated connector is available from ITT -Cannon, part no. CA 02 COM-E 14S A7 P .Model A B C D E RAD ØF (DIA)KBCG-658,035,068,035,012,020,0(2 .3)(1 .4)(2 .7)(1 .4)(0 .5)(0 .78)KBCG-842,039,083,030,016,026,0(1 .7)(1 .54)(3 .3)(1 .2)(0 .63)(1 .02)Model G H ØJ (DIA)K L KBCG-679,082,013,5176,020,0(3 .1)(3 .23)(0 .53)(7 .0)(0 .78)KBCG-8103,0106,017,0183,025,0(4 .1)(4 .2)(0 .7)(7 .2)(1 .0)Installation dimensions11EATON Proportional pressure relief valves V-VLPO-MC003-E1 September 2020Mounting surfaces,ISO 6264AR-06-2-A AS-08-2-AWhen a subplate is not used, a raised pad must be provided for mounting . The pad must be flat within 0,001 mm/100 mm (0 .0001”/10”) and smooth within 0,8 μm (32 μin) . Dimensional tolerances are ±0,2 mm (±0 .008”) except where indicated .Port functions:P = Pressure inlet T = Outlet to reservoirX = Vent, or remote control portCGVM-6-10-R Subplate▲ Tolerance on bolt and pin locations ±0,1 mm (±0 .004”) .u T hese ISO standard dimensions can be used, but improved flow paths to and from valve are obtained by using 48,0 (1 .89) instead of 47,5 (1 .87), and 22,6 (0 .89) instead of 22,1 (0 .87) .● I SO standard does not give UNC bolt sizes . These are recommended equivalents to metric sizes specified in the standard .(0.24) deep min.remote port is not to be usedG 1/4 (1/4" BSPF) x 12,0 (0.47)Installation dimensionsSize A B C D EFH JK LAR-0680 (3 .2)13,1 (0 .5)53,8 (2 .12)13,1 (0 .5)47,5u (1 .87)22,1(0 .87)22,1u (0 .87)13,1 (0 .5)53,8 (2 .12)AS-08118 (4 .7)35,0 (1 .4)66,7 (2 .63)16,3 (0 .7)55,6 (2 .19)33,4 (1 .35)11,1 (0 .44)23,8 (0 .94)16,0 (0 .63)70,0 (2 .76)Size M N ØP (DIA)Q ØT (DIA)ØX (DIA)Y Thread x Min. Full thread DepthAR-0613,1 (0 .5)26,9 (1 .06)14,7 (0 .58)80 (3 .2)14,7 (0 .58)4,8 (0.19)M12 x 21 (7/16” UNF x 0.83) ●AS-0816,0 (0 .63)35,0 (1 .38)23,4 (0 .92)102 (4 .0)23,4 (0 .92)6,3 (0.25)M16 x 30 (5/8” UNF x 1.2) ●12EATON Proportional pressure relief valves V-VLPO-MC003-E1 September 20207-pin plug connectionsA +24V BPower 0VC EnableD Non-inverting EInvertingCommand signalFCurrent monitor GProtective ground Block diagramWiringConnections must be made via the 7-pin plug mounted on the amplifier . Recommended cable sizes are:Power cablesFor 24V supply:0,75 mm 2 (18 AWG) up to 20m (65 ft)1,00 mm 2 (16 AWG) up to 40m (130 ft)Signal cables0,50 mm 2 (20 AWG)Screen (Shield)A suitable cable should have at least 6 cores with pairs of conductors individually screened and an overall screen . Cable outside diameter 8,0-10,5 mm (0 .31- 0 .41 inches) . See connection diagrams on next page .▲ In valves with PH7 or PR7 type electrical connection .Electrical informationAll power must be switched off before connecting or disconnecting any plugs.13EATON Proportional pressure relief valves V-VLPO-MC003-E1 September 2020Wiring connections for M1 valves with enable featureotee:N In applications where the valve must conform toEuropean RFI/EMC regulations, the outer screen (shield) must be connected to the outer shell of the 7 pin connector, and the valve body must befastened to the earth ground . Proper earth grounding practices must be observed in this case, as any differences in command source and valve ground potentials will result in a screen (shield) ground loop .User PanelshellKB.. PR7/PH7 valveconnected to groundVoltage input (M1) wiringSpool position monitor voltage (pin F) will be referenced to the KB valve local ground .Electrical information14EATON Proportional pressure relief valves V-VLPO-MC003-E1 September 2020Wiring connections for M2 valves with enable featureotee:N In applications where the valve must conform toEuropean RFI/EMC regulations, the outer screen (shield) must be connected to the outer shell of the 7 pin connector, and the valve body must befastened to the earth ground . Proper earth grounding practices must be observed in this case, as any differences in command source and valve ground potentials will result in a screen (shield) ground loop .Electromagnetic Compatibility (EMC) It is necessary to ensure that the valve is wired up as above. For effective protection the user electrical cabinet, the valve subplate or manifold and the cable screens should be connected to efficient ground points. The metal 7 pin connector part no. 934939 should be used for the integral amplifier. In all cases both valve and cable should be kept as far away as possible from any sources of electromagnetic radiation such as cables carrying heavy current, relays and certain kinds of portable radio transmitters, etc. Difficult environ-ments could mean that extra screening may be necessary to avoid the interfer-ence. It is important to connect the 0V lines as shown above. The multi-core cable should have at least two screens to separate the demand signal and monitor output from the power lines. The enable line to pin C should be outside the screen which contains the demand signal cables.User Panel shellKB.. PR7/PH7connected to groundCurrent input (M2) wiringSpool position monitor voltage (pin F) will be referenced to the KB valvelocal ground .Electrical informationFurther informationHydraulic fluidsMaterials and seals used in these valves are compatible with:Anti-wear petroleum oils . . .L-HM Non-alkyl basedphosphate esters . . . . . . . . . . . . .L-HFD The extreme operating range is 500 to 13 cSt (270 to 70 SUS) but the recommended running range is 54 to 13 cSt (245 to 70 SUS) . For further technical information about fluids see 694 .Contamination control requirements Recommendations on contamination control methods and the selection of products to control fluid condition are included in publication 9132or 561, “Guide to Systemic Contamination Control” . The book also includes information on the concept of “ProActive Maintenance” . The following recommendations are based on ISO cleanliness levels at 2 μm, 5 μm and 15 μm .For products in this catalog the recommended levels are:Up to 210 bar(3000 psi) . . . . . . . . . . . . . . . . . . . . .18/16/13 Above 210 bar(3000 psi) . . . . . . . . . . . . . . . . . . . . .17/15/12Installation and start-upguidelinesThe proportional valves inthis catalog can be mountedin any attitude but it may benecessary, in certain demandingapplications, to ensure thatthe solenoids are kept full ofhydraulic fluid .If this proves to be the caseany accumulated air can bebled from the solenoid bleedscrew . This task is easier if thevalve has been mounted basedownwards . Good installationpractice dictates that the tankport, and any drain port, arepiped so as to keep the valve fullof fluid once the system start-uphas been completed .TemperaturesFor petroleum oil:Min . . . . . . . . . . . . . . . . . . . . . . . . .-20°C (-45°F)Max . . . . . . . . . . . . . . . . . . . . .+70°C (158°F)For fluids where limits areoutside those of petroleum oil,consult fluid manufacturer orEaton representative . Whateverthe actual temperature range,ensure that viscosities staywithin those specified under“Hydraulic Fluids” .Ambient for:Valves at full performancespecification: -20 to +70°C(-4 to +158°F) .Valves, as above, will operateat temperatures of 0 to -20°C(32 to -4°F) but with a reduceddynamic response .Storage:-25 to +85°C (-13 to +185°F)Seal kitsPilot valve:KBCG-3 . . . . . . . . . . . . . . . . . . . . .02-145869Mainstage valves:KBCG-6 . . . . . . . . . . . . . . . . . . . . . . . . . .614824KBCG-8 . . . . . . . . . . . . . . . . . . . . . . . . . .61493115 EATON Proportional pressure relief valves V-VLPO-MC003-E1 September 2020Eaton1000 Eaton Boulevard Cleveland, OH 44122 United States © 2020 EatonAll Rights ReservedPrinted in USADocument No. V-VLPO-MC003-E1 September 2020Eaton is a registered trademark.All trademarks are propertyof their respective owners.EatonHydraulics Operations Asia Pacific11th Floor Hong Kong New World Tower300 Huaihai Zhong RoadShanghai 200021ChinaTel: 86-21-6387-9988Fax: 86-21-6335-3912EatonHydraulics Operations EuropeRoute de la Longeraie 71110 MorgesSwitzerlandTel: +41 (0) 21 811 4600Fax: +41 (0) 21 811 4601EatonHydraulics Operations USA14615 Lone Oak RoadEden Prairie, MN 55344USATel: 952-937-9800Fax: 952-294-7722www .hydraulics .eaton .comChanges to the products, to the information contained in thisdocument, and to prices are reserved; so are errors and omissions.Only order confirmations and technical documentation by Eaton isbinding. Photos and pictures also do not warrant a specific layout orfunctionality. Their use in whatever form is subject to prior approvalby Eaton. The same applies to Trademarks (especially Eaton, Moeller,and Cutler-Hammer). The Terms and Conditions of Eaton apply, asreferenced on Eaton Internet pages and Eaton order confirmations.。

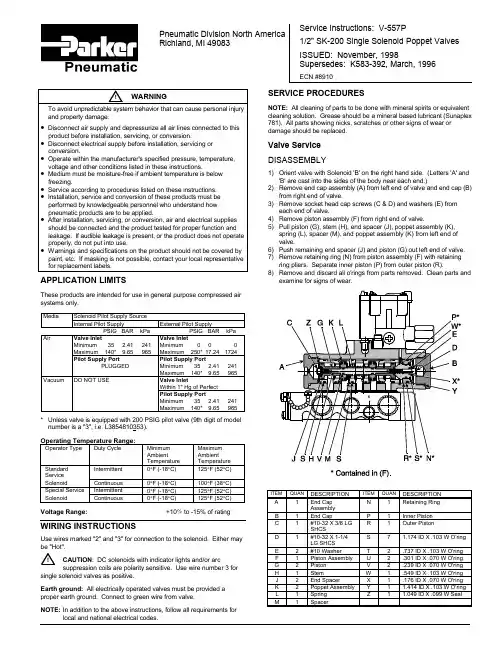

APPLICATION LIMITSThese products are intended for use in general purpose compressed air systems only.MediaSolenoid Pilot Supply Source Internal Pilot SupplyExternal Pilot SupplyPSIG BAR kPaPSIG BAR kPaAirValve Inlet Minimum 35 2.41241Maximum 140*9.65965Valve Inlet Minimum 000Maximum 250*17.241724Pilot Supply PortPLUGGED Pilot Supply Port Minimum 35 2.41241Maximum 140*9.65965VacuumDO NOT USEValve InletWithin 1" Hg of Perfect Pilot Supply Port Minimum 35 2.41241Maximum 140*9.65965*Unless valve is equipped with 200 PSIG pilot valve (9th digit of model number is a "3", i.e. L3854810353).Operating Temperature Range:Operator TypeDuty CycleMinimum AmbientTemperature Maximum AmbientTemperature Standard Service Intermittent 0°F (-18°C)125°F (52°C)SolenoidContinuous 0°F (-18°C)100°F (38°C)Special Service Intermittent 0°F (-18°C)125°F (52°C)SolenoidContinuous0°F (-18°C)125°F (52°C)Voltage Range:+10% to -15% of ratingWIRING INSTRUCTIONSUse wires marked "2" and "3" for connection to the solenoid. Either may be "Hot".CAUTION : DC solenoids with indicator lights and/or arcsuppression coils are polarity sensitive. Use wire number 3 forsingle solenoid valves as positive.Earth ground: All electrically operated valves must be provided a proper earth ground. Connect to green wire from valve.NOTE:In addition to the above instructions, follow all requirements forlocal and national electrical codes.SERVICE PROCEDURESNOTE: All cleaning of parts to be done with mineral spirits or equivalent cleaning solution. Grease should be a mineral based lubricant (Sunaplex 781). All parts showing nicks, scratches or other signs of wear or damage should be replaced.Valve Service DISASSEMBLY1)Orient valve with Solenoid 'B' on the right hand side. (Letters 'A' and'B' are cast into the sides of the body near each end.)2)Remove end cap assembly (A) from left end of valve and end cap (B)from right end of valve.3)Remove socket head cap screws (C & D) and washers (E) fromeach end of valve.4)Remove piston assembly (F) from right end of valve.5)Pull piston (G), stem (H), end spacer (J), poppet assembly (K),spring (L), spacer (M), and poppet assembly (K) from left end of valve.6)Push remaining end spacer (J) and piston (G) out left end of valve.7)Remove retaining ring (N) from piston assembly (F) with retainingring pliers. Separate inner piston (P) from outer piston (R).8)Remove and discard all o'rings from parts removed. Clean parts andexamine for signs of wear.ITEM QUANDESCRIPTION ITEM QUANDESCRIPTION A 1End Cap Assembly N 1Retaining Ring B 1End CapP 1Inner Piston C 1#10-32 X 3/8 LG SHCSR 1Outer PistonD 1#10-32 X 1-1/4LG SHCS S 71.174 ID X .103 W O’ring E 2#10 Washer T2.737 ID X .103 W O'ring F 1Piston Assembly U 2.301 ID X .070 W O'ring G 2Piston V 2.239 ID X .070 W O'ring H 1StemW 1.549 ID X .103 W O'ring J 2End SpacerX 1.176 ID X .070 W O'ring K 2Poppet Assembly Y 1 1.414 ID X .103 W O'ring L 1Spring Z11.049 ID X .099 W SealM1SpacerService Instructions: V-557P1/2" SK-200 Single Solenoid Poppet Valves ISSUED: November, 1998Supersedes: K583-392, March, 1996ECN #8910Pneumatic Division North America Richland, MI 49083!SERVICE PROCEDURES (CONTINUED)REASSEMBLY1)Apply lubricant to all o'rings from kit, the main valve bore and stem(H).2)Assemble o'rings (S) to spacer (M), end spacers (J) and outer piston(R). Assemble o'rings (T & U) to pistons (G). Assemble o'rings (V)to stem (H). Assemble o'rings (W & X) to inner piston (P).3)Push inner piston (P) into outer piston (R). Reinstall retaining ring(N).4)Slide one piston (G) onto stem (H).5)Take the sub assemblies created in steps 3) and 4) and assembleusing cap screw (D) and washer (E).6)Slide one end spacer (J) into left end of valve until it stops on theretaining ring.7)Slide the sub assembly created in step 5) into the right end of thevalve.8)From the left end of the valve - Slide one poppet assembly (K) andspring (L) onto stem (H). Next push spacer (M) into main valve bore.Slide other poppet assembly (K) onto stem (H). Push end spacer (J)into main valve bore. Slide piston (G) onto stem (H) and secure with cap screw (C) and washer (E).9)Assemble o'ring (Y) to end cap (B). Screw end cap (B) into right endof valve and tighten to 30-40 ft.-lb.10)Assemble seal (Z) to end cap (A). Screw end cap (A) into left end ofvalve and tighten to 30-40 ft.-lb.Pilot Valve ServiceSee Service Instructions V-644P L-Pilot Valves and Operators packed with Pilot Valve Service Kit K352166 included in this kit.Coil / Indicator Light ReplacementSee Service Instructions V-644P L-Pilot Valves and Operators packed with replacement coils and lights.MANUAL OVERRIDE REPLACEMENT OR CONVERSIONThe following override assemblies are interchangeable and can be replaced or field converted:Non-locking override . . . . . . . . . . . . . . . .K162001Locking override . . . . . . . . . . . . . . . . . . .K152003Extended locking override . . . . . . . . . . . .K152006Remove override and clean internal threads in housing. Apply pipesealant sparingly to threads of override housing and assemble override to pilot valve housing.NOTE: Overrides are held out by air pressure and may not extend until pressure is reapplied to the valve.CONVERSION PROCEDURE FOR EXTERNAL PILOTFor field conversion to external pilot supply, remove (2) 1/8" pipe plugs from top of valve body and movebottom plug from "Y" to "Z". Replace 1/8" pipe plugs and connect pilot pressure to the 1/4" pipe external pilot supply port "X" in subbase or manifold.SERVICE KITS / PARTSService Kit (Single Solenoid - Standard Service). . . . . . . . .K352088Service Kit (Single Solenoid - Special Service). . . . . . . . . .K352089Poppet Assembly (2 required). . . . . . . . . . . . . . . . . . . . . . .K242002Pilot Valve / Remote Pilot Gasket. . . . . . . . . . . . . . . . . . . . .K183001Body to Base Gasket. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .K183030Indicator Light (24VDC - Base Mounting). . . . . . . . . . . . . . .H19112Indicator Light (120V / 60 HZ - Base Mounting). . . . . . . . . . .H19105Replacement CoilsVoltageCoil 60 Hz 50 Hz D. C.No Light With Light12----K593052--24--6K593048----24--K593061----36--K593062------12K593055------24(Standard)K593060K593274----24(Arc Suppressed)K593305K593275----48K593074--120110--K593071K593125240220--K593081----240--K593079--V-557PINSTRUCTION MANUALS THAT UTILIZE THESE PRODUCTS. CONTACT YOUR LOCAL REPRESENTATIVE.。

(如有重复,纯属我懒)平时在使用呼吸机的时候,存在很多英语单词、缩写和短语,如果不了解它的意义,容易给操作和治疗带来困扰,而且由于呼吸机品牌繁多,命名又不统一,更是容易造成混淆和误解。

在这里,把常见的机械通气相关的英语专用名词做一个汇总,并进行简单的注释,希望能够给大家日常的应用带来一些方便。

一、模式篇Volume Control --- 容量控制,简称VC基础通气模式之一,预设潮气量,呼吸频率,通气效率保证,气道压力可变IPPV --- Intermittent Positive Pressure Ventilation 间歇气道正压通气Drager产的呼吸机上的叫法,其实就是容量控制通气Pressure Control ---- 压力控制,简称PC基础通气模式之一,预设吸气压力,呼吸频率,气道压力固定,潮气量可变A/C --- Assist/ Control 辅助/控制通气基础通气模式之一,允许患者自主触发辅助通气,目前的呼吸机上的容量控制和压力控制通气都有A/C的含义SIMV --- Synchronized Intermittent Mandatory Ventilation 同步间歇指令通气混合模式,同步给予强制或辅助通气,间歇期允许患者自主呼吸或触发支持通气PSV --- Pressure Support Ventilation 压力支持通气支持模式,所有呼吸均由患者触发,呼吸机给予正压支持ASB --- Assisted Spontaneous Breathing 辅助自主呼吸Drager呼吸机上的叫法,其实就是PSVBIPAP --- Biphasic Positive Airway Pressure 双水平气道正压Drager呼吸机首创模式,两个气道正压周期性转换,产生潮气量,同时允许患者在两个压力水平上自主呼吸BiPAP --- Bilevel Positive Airway Pressure 双相气道正压伟康无创呼吸机专有模式,吸气相和呼气相交替切换两个压力水平,无创通气模式注:目前对于BIPAP和BiPAP的中文译名存在一定混乱,这里采用Drager呼吸机说明书上的说法,可能有的文献命名方法完全相反,个人感觉搞清楚两者的区别比纠缠名字更有意义APRV --- Airway Pressure Release Ventilation 气道压力释放通气BIPAP的一种形式,低压相时间特别短,欧洲也把APRV与BIPAP通用CPAP --- Continuous Positive Airway Pressure 持续气道正压自主呼吸模式,呼吸机只给予一个持续的正压,患者自主完成呼吸过程PRVC --- Pressure Regulated Volume Control 压力调节容量控制双重控制模式,MAQUET Servo呼吸机首创,预设潮气量,呼吸机自动调节吸气压力,保证以最低的压力输送预设潮气量APV --- Adaptive Pressure Ventilation 适应性压力通气Hamilton呼吸机上的叫法,与PRVC相似VTPC --- Volume Target Pressure Control 容量目标压力通气Newport呼吸机上的叫法,与PRVC相似VAPS --- Volume Assured Pressure Support 容量保障压力支持鸟牌呼吸机上的双控模式,在一次呼吸内,如果指定时间内未输送完预设潮气量,即转为压力支持直至潮气量完成Paug --- 压力扩增熊牌呼吸机上的双控模式,与VAPS相似VSV --- Volume Support Ventilation 容量支持通气双重控制模式,与PRVC不同处在于所有的呼吸必须由患者自己触发MMV --- Minute Mandatory Ventilation 分钟指令通气预设目标分钟通气量,当实际通气量不足时呼吸机给予指令通气,保证达到预设通气量目标ASV --- Adaptive Support Ventilation 适应性支持通气闭合环通气模式,呼吸机自动调节支持水平,使得患者处在预设的“理想通气范围”内PAV --- Proportional Assist Ventilation 成比例辅助通气PB以及Stephanie呼吸机上的一种模式,呼吸机监测气道阻力和顺应性变化,间接判断患者吸气努力大小,并成比例的给予通气辅助PPS --- Proportional Pressure Support 成比例压力支持Drager呼吸机上的特有模式,与PAV相似accumulator贮气箱(装置)adap ter接合器,接口adjusting tap 调节柄air inlet filter空气输入滤过器airway p ressure呼吸道压alarm indicator报警显示alveolar p ressure肺泡内压amp lifier增幅唇apnea呼吸暂停apnea indicator呼吸暂停显示装置assembly装置、组合assist/controlmode,A /C辅助/控制通气back - up ventilation备用通气bacterial filter细菌滤过器bag囊ballon valve球囊式活瓣bellows风箱bleed regulator排气调节器blower鼓风机calibration校准、定标chamber腔check valve单向阀compensator代偿装置comp ressor压缩器、压缩装置continuous positive airway pressure (CPAP)持续呼吸道正压continuous flow持续气流control knob调节炳cooling fan冷却扇corrugated hose螺纹管、呼吸管道crossover soleniod交通电磁阀delay dial廷迟设定demand flow按需气流demand valve按需供气阀diaphragm 隔膜digital amp lifer数字型增幅器drive system驱动系统electrical switch电子开关electrodynamic valve电动阀exhaled gas呼出气exhalation time呼出时间exhalation valve呼出阀exhaust valve气体排出活瓣(阀)exp ired minute volume呼气分钟通气量feed back servocontrol反馈伺服控制filling solenoid充气电磁阀(气流开关)filter滤过器flap valve平行阀flow control valve流量控制(调节)阀flowrate流速flow transducer流量传感器flow trigger流量触发(器)flush knob冲洗按键gas outlet气体出口gas samp ing pump 气体采样泵gas supp ly气体供应generated p ressure驱动压SPONT = CPAPPSV = CPAP + 吸气压力支持举例来说,CPAP=125px H2O,那么患者在吸气和呼气的时候,气道内的压力都是125px H2O;PSV模式下,如果PS=5,PEEP=125px H2O,那么在呼气相的时候气道内的压力为125px H2O,吸气相的时候气道内的压力为250px H2O,也就是患者在吸气的时候得到了125px H2O的压力支持。

SFF508型压力真空释放阀SFF508 Press/Vacuum Release Valve使用说明书Operation Instruction江苏国能环保设备有限公司Jiangsu Guoneng Environment Protection Equipment Co,. Ltd.目录Contents产品型号、名称 (2)Product model, name外形图 (2)Outside drawing用途和适用范围 (2)Function and applicable range主要技术参数 (2)Main technical parameter结构与工作原理 (3)Structure and working principle一、产品型号、名称1. Product model, name1.型号:SFF5081.1 Model: SFF5082.名称:压力真空释放阀1.2 Name: pressure/vacuum release valve二、外形图2. Outside drawing三、用途和适用范围3. Function and applicable range1.用途:3.1 Function:在充气、排气和不正常的温度变化时,保护容器不受过量的正压和负压。

In the case of gas filling, exhausting and abnormal temperature variation,it can protect the vessel from excessive positive pressure and negative pressure.2.适用范围:3.2 Applicable range:1)在容器正常通气时,延迟气化物的逃逸以降低有价值的蒸发气的损失;3.2.1 In the case of normal ventilation of vessel, delay the escape of gasifying agent so as to reduce the loss of valuable vapour.2)在贮存产品时,保持惰性气体密封层;3.2.2 When storing products, it maintains the seal course of inert gas.3)在处理因外部热源引起内部压力过量时,作为优良的二次或备用保险。

GRUNDFOS说明书PRVPressure relief valves安装和使用说明书Other languages/qr/i/96681525中文 (CN)2中文 (CN) 安装和使用说明书翻译原来的英文版这些安装与操作指导对格兰富PRV(泄压阀)进行了说明。

章节1-4介绍了以安全的方式安装和启动本产品所需的信息。

章节5-10介绍了有关产品的重要信息,以及有关服务、故障查找和产品处置的信息。

目录页1. 概述1.1 目标人群本文档适用于运营公司和用户。

在产品安装前以及产品操作和检修过程中必须遵守本手册中规定的一般安全说明。

负责人员在对产品进行任何操作之前必须阅读这些说明。

1.1.1 资格和培训负责本文档所述任务的人员必须具有相关资质。

1.1.2 运营公司的义务•遵守地方安全规章。

•请始终在安装地点放置安装与操作指导,以供随时查阅。

•按照章节9.技术参数的说明协调安装位置的准备。

•确保用户经过针对相关任务的培训。

•提供规定的安全设备和个人防护设备。

•安排定期维护。

1.1.3 用户责任•遵守公认的健康和安全规定以及本地事故预防规定。

•在操作产品和处理化学品时,按照当地健康和安全规定穿戴防护装备。

•阅读并理解本文档。

1.2 安全运行如果阀门已经无法保证安全运行,必须将产品从系统中解除并保证不会被意外地再次用于运行。

以下情况属于上述说明:•产品出现明显可见的损坏。

•如果产品看起来无法操作。

•在恶劣的条件下存放了较长的时间。

1.概述21.1目标人群21.1.1资格和培训21.1.2运营公司的义务21.1.3用户责任21.2安全运行21.3本文献中所用符号32.安装产品32.1位置32.2机械安装32.2.1安装要求32.2.2安装示范32.2.3泄压阀高达460 l/h 42.2.4泄压阀DN 6543.调试产品43.1设置泄压压力43.1.1最佳安装53.1.2其他安装54.搬运和储存产品54.1搬运产品54.2储存产品55.产品介绍55.1设计用途55.1.1不恰当的操作方法55.2型号55.2.1铭牌(泄压阀从60到460 l/h)55.2.2型号66.维护产品76.1维护日程76.2清洁处理76.3更换隔膜77.配件77.1联接螺母适配器(高达460 l/h)77.2用于泄压阀DN 65的一组对接法兰78.故障查找89.技术参数89.1允许介质温度89.2存放温度与环境温度89.3泄压阀高达60 l/h 89.3.1技术参数89.3.2材料89.3.3尺寸图89.4泄压阀从60到460 l/h 99.4.1技术参数99.4.2材料99.4.3尺寸图99.5泄压阀DN 65109.5.1技术参数109.5.2尺寸图1010.产品废弃10开始安装前,请先阅读本文件。