弗兰德Flender Couplings 高速联轴器样本

- 格式:pdf

- 大小:4.62 MB

- 文档页数:19

更多图片请点击进入相册网页位置:首页 >>联轴器>>kc型滚子链联轴器>>联轴器配件Roller Chain Coupling - Products for Roller Chain Coupling - Manufacturers,Exporters,Suppliers,Companies,Fact KC Chain Coupling ,Roller Chain Couplings kc3012 kc-4012 kc-4014 kc-4016 kc-5014 kc-5016 kc-5018 kc-6018 kc-6联轴器联轴器联轴器弹性联轴器联轴器联轴器链轮联轴器联轴器点击放大Roller Chain Coupling - Products for Roller Chain Coupling - Manufacturers,Exporters,Suppliers,Companies,Factories KC Chain Coupling ,Roller Chain Couplings kc3012 kc-4012 kc-4014 kc-4016 kc-5014 kc-5016 kc-5018 kc-6018 kc-6最小最大L I S D O KC-301206B-2121664.829.8 5.23545KC-401214642122279.4367.43562链条尺寸型号链条孔径,Factorieskc-6022 kc-8018 kc-8020 kc-8022 kc-10020 kc-12018 cr 4012 cr 4014 cr 4016 cr 5014 cr 5016 cr 5018 cr 6018 cr 6,Companies,Factorieskc-6022 kc-8018 kc-8020 kc-8022 kc-10020 kc-12018 cr 4012 cr 4014 cr 4016 cr 5014 cr 5016 cr 5018 cr 6018 cr 6外壳尺寸扭距重量重量C kgf.m2kg A B kg10.20.2330.469630.314.4 1.020.877720.314.4 1.924 1.184750.4 14.4 3.285 1.492720.4 18.1 6.01 2.2101850.5 18.19.72 2.7110870.6 18.115.42 3.8122850.8 22.840.21 6.2147105 1.2 22.862.877.8158105 1.6 22.893.4510.4168117 1.8 29.3142.0312.7190129 2.5 29.3204.916210137 2.9 29.3341.1720.2226137 3.6 35.8646.2933281153 4.6 45.41075.7147307181 6.2 45.42454.5723571818cr 6022 cr 8018 cr 8020 cr 8022 cr 10020 cr 12018cr 6022 cr 8018 cr 8020 cr 8022 cr 10020 cr 12018。

弗兰德减速机制造标准Flender gearbox is a well-known brand for manufacturing high-quality gears and gearboxes. 弗兰德减速机是一家以制造高品质齿轮和齿轮箱而闻名的品牌。

With a history dating back over a century, Flender has built a reputation for delivering reliable and efficient products. 具有100年历史的弗兰德已经建立起了可靠和高效产品的声誉。

Flender gearboxes are used in a wide range of industries, including mining, cement, and power generation. 弗兰德减速机在矿业、水泥和发电等各行各业都有广泛的应用。

Their gearboxes are known for their durability, performance, and precision engineering. 他们的减速机以耐用、高性能和精密工程而著称。

One of the key factors that make Flender gearboxes stand out is their adherence to strict manufacturing standards. 使弗兰德减速机脱颖而出的一个关键因素是他们严格遵守制造标准。

From design to production, Flender gears are manufactured with precision and attention to detail. 从设计到生产,弗兰德齿轮都精确制造,注重细节。

This ensures that each gearbox meets the highest quality standards and performs reliably in demanding industrial environments. 这确保每台减速机符合最高的质量标准,在苛刻的工业环境中可靠运行。

偶合器(Coupling)偶合器(Coupling)是利用某种介质,将原动机的动力传给从动机的机械装置。

以液体为工作介质的一种非刚性联轴器,又称联轴器。

性能1、具有减缓冲击和隔离扭振的性能;可以使电机起动有一个延迟时间,缓慢加速,减少骤然起动而引起的零件间的相互冲击。

2、具有使电机轻载起动性能:由于偶合器的泵轮力矩与其转速的平方成正比,故当起动瞬间泵轮因转速低而力矩甚微,电机近似于带泵轮空载起动,所以起动时间短,起动电流小,起动平稳,尤其适合起动大惯量沉重负载。

3、具有过载保护性能:由于偶合器无机械直接连接,当外负荷超过一定限度后,泵轮力矩便不再上升,此时电机照常转动,输出减速直至停止,从电源吸取的功率转化为热能使偶合器升温,直至易熔塞喷液,从而输入与输出被切断,保护了电机,工作机不受损坏,从而降低了机器故障率,维护费用和停工时间,延长了电机荷工作机使用寿命。

4、具有节电的性能:由于偶合器有效地解决了电机起动和“大马拉小车”的现象,与刚性传动相比至少可降低一个电机机座号,加上可以降低起动电流和持续时间,降低对电网的冲击节能率达10—20%,尤其在起动大惯量沉重负载时更为显著。

限矩型液力偶合器的特点:除轴承和油封外,无任何机械磨檫,使用寿命长,故障率低,不需特殊维护保养。

常见类型编辑液力偶合器的实质是离心泵与涡轮机的组合。

主要由输入轴、输出轴、泵轮、涡轮、外亮、辅室及安全保护装置等构成。

输入轴一端与动力机相连,另一端与泵鸵相连:输出轴一端与涡轮相连,另一端与工作机相连。

泵轮与涡轮对称布置,轮内布置一定数量的叶片。

外亮与泵轮固联成密封腔,腔内充填工作液体以传递动力;当原动机通过输入轴带动泵轮旋转时,充填在工作腔内的工作液体受离心力和工作轮叶片的作用由半径较小的泵轮入口被加速加压抛向半径较大的泵轮出口,同时液体的动量矩产生增量,即偶合器泵轮将输入的机械能转化成了液体动能:当携带液体动能的工作液体由泵轮出口冲向对面的涡轮时,液流便沿涡鸵叶片所形成的流道做向心流动,同时释放液体动能转化成机械能驱动涡轮旋转并带动负载做功。

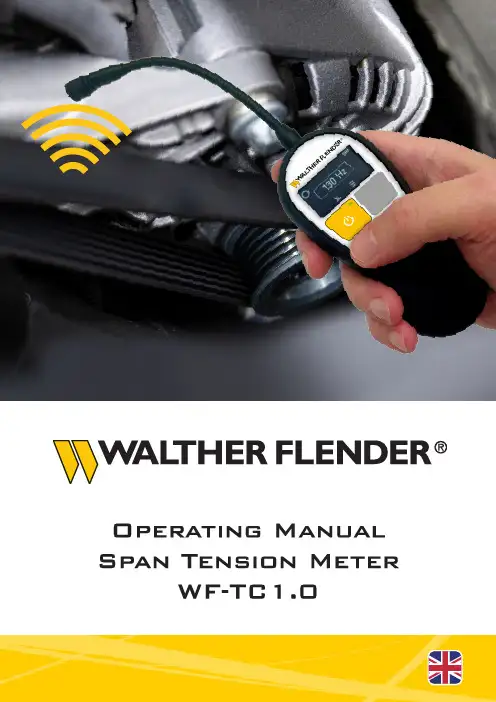

OUR KNOW-HOW –YOUR ADVANTAGESNo presettings required, the device is immediatelyNon-contact, acoustic measurement technologyFor all toothed belt, V-belt and V-ribbedsuitable for belt typesDelivery with previous factory calibration,recalibration possible if required (e.g. due tointernal guidelines)LONG LIFE SPAN THROUGHAN OPTIMUM BELT TENSIONO ptimum belt tension is necessary to to ensure a longlife span of the belt and the trouble-free functioningof the entire drive.Walther Flender is your expert for the perfect drive and will be happy to support you in calculating the exactlife span or with solutions from the field of predictive main-tenance. Feel free to contact us!LATEST GENERATION USER-FRIENDLINESS CUSTOMIZED SOLUTIONSDo you need additional features such as data transfer via Bluetooth to your system? Just talk to us! We would be happy to coordinate a possible individual version of the WF-TC measuring device with you.***********************Ergonomic shape for optimal one-hand use Small sensor head on the flexible gooseneck for measurements, even in placesthat are difficult to access Integrated, rechargeable and sustainable lithium polymer Battery incl. USB-C cableModern, particularly high- contrast OLED display for good legibility, even from different viewing anglesCompact, stable hard case OLED-displayFlexible gooseneckSmall sensor headConnection for On/Off button3 function keys for menu controlUSB-C charging cableEuroplugSCOPE OF DELIVERY IN A COMPACT SETMENU CONTROLF1 for right center functions F1F1F2F2F3F3On/Off button Battery charge statusMeasurement result displayBattery charge statusDisplay BluetoothPower Delete MenuLockScrollSound off Sound on STANDARD DISPLAY MAIN MENU MENU CONTROL VIA THE FUNCTION KEYS F1, F2 AND F3incl. alternative key assignmentReturn Measurement process displayTable of contents1. Specifications82. Safety notes 103. The measurement process12 3.1. The measuring principle13 3.2. Calculation formulas15 3.3. Operation of the meter16 3.4. Possible problem sources194. Maintenance & calibration215. Disposal instructions226. Certificates 23SPAN TENSION METERWF-TC 1.01. SPECIFICATIONS2. SAFETY NOTESCaution! The measurement must never be carried out while the drive is running! Before starting the measure-ment, ensure that the drive unit is switched off and secured against being switched on unintentionally.The safety recommendations of the machine manufacturer must be observed.• Never use the device in hazardous areas.• Protect the device from shock, impact andstrong vibrations.• Do not bring the device into contact with water,solvents or other liquids.• Clean the device with a dry cloth.• Never use cleaning agents containing solvents.• Protect the device from dust and dirt.• Please note that the OLED display only works in thetemperature range between + 4°C and + 60°C.Measurement readings outside of this temperaturerange cannot be guaranteed.• The device contains a lithium polymer battery. Therefore, do not expose it to high temperatures and/or directsunlight, e. g. when storing in the car. If handledimproperly, lithium polymer batteries can explode, burn and release toxic gases as well as cause chemical burns or poisoning.• When shipping devices with a lithium polymer battery,it is essential to observe the relevant shipping regulations and warnings.• No technical changes may be made to the device.If the safety instructions are not observed, the operator may be injured and the device may be damaged, for which we assume no liability.113. THE MEASUREMENT PROCESSGeneral informationCaution! The measurement must never be carried out whi-le the drive is running! Please note the safety instructions. Make sure that there is as little interference and back-ground noise as possible during the measurement. More on this under 3.3. “Possible problem sources”.When not in use, the device switches to an energy save mode, i.e. the display goes dark. This idle state is auto-matically terminated by pressing any function key or by transmitting acoustic signals. In order to optimizebattery performance, the device switches off automatically after about 2 minutes of idle status.Note on remounting belts: After remounting a belt, the drive should be rotated a few times by hand to allow the belt to fully seat, as well as enabling any tension differences in the belt spans to be equalized prior to measurement.123.1. The measuring principleThis acoustic tension meter is used for quick and easy measurement of the belt tension, also called span tension, belt strand force or belt tension force.Optimal belt tension is necessary to ensure a long service life of the belt and a trouble-free operation of your drive. The device is fully electronic and equipped with the latest microprocessor technology for simple, high-precision measurements. It is suitable for all belt types, e. g. V-belts, toothed and power belts or ribbed belts, which are in the measuring frequency range between 10 and 600 Hz. The type, color and quality of the belt have no influence on the measurement result.An impact impulse on the belt, e. g. by hand or a suitable tool, creates a fundamental frequency, which is measured in Hertz (Hz) and is shown on the display of the device.13This fundamental oscillation is in a fixed relationship with the belt tension. This means the higher the frequency of a belt, the higher its tension.14153.2. Calculation formulasThe span force target value can be calculated using the fol-lowing formulas:Formula A)f = — · —or Formula B) F V = 4 · m · L 2· f 2F V = initial tension force (N)m = belt weight per meter (kg/m)L = oscillating belt length (m)f = belt oscillation frequency (Hz)F V1m 2 · L3.3. Operation of the meterThe device is switched on with the on/off button.The start screen …Welcome“ now appears briefly on the display. The display then changes to the standard screen with the main menu.A short signal confirms readiness for measurement.All acoustic impulses are immediately recorded bythe sensor.The measuring process on the belt can now begin.The measurement should be taken in the middle of the free span length. Hold the sensor head at least 0.4 inches to max. 1.2 inches (1 cm to max. 3 cm) away from the straps. A greater distance can falsify the measurement result.16Strike the belt with your hand or a suitable tool, e. g. a wrench or hammer handle, in the middle of the span length. The sensor now measures the fundamental oscillation frequency of the belt.The ring symbol on the upper left side of the display is shown as a filled circle to indicate the measurement process. —›The measurement result is now shown in the field inthe middle of the display in Hertz (Hz).In order to secure the measurement result, e. g. if accessto the machine is difficult, the measurement should be saved by pressing …Lock“ (F1).We recommend using the …Lock“ function for all measurements, since the measured value cannot be overwritten, e. g. by loud machine and backgroundnoise or an accidental hitting of the sensor.17By pressing …Delete“ (F3) you delete the saved measure-ment result in order to carry out a new measurement.If you have not secured the measurement result via …Lock“ , you can take a new measurement immediately without any further key operations.The keys are coupled with a sound signal as standard.…Menu“ (F2) takes you to the submenu of the device. By pressing …Sound on/off“ you can switch off the sound signals (F3). By pressing (F3) once more, you switch them on again.…Return“ (F2) takes you back to the standard screen with the main menu.…Scroll“ (F1) takes you one level down in the submenu. There you can see the serial number of your device and the version of the firmware.18Use …Return“ (F2) to go back to the standard screen with the main menu.3.4. Possible problem sourcesInterfering background noise can falsify the measure-ment result. Therefore, ensure that background noiseis kept to a minimum during the measurement. When measuring in a windy environment, the sensor shouldbe shielded, as it also reacts to drafts.T oothed belts have a certain transverse rigidity depending on the belt width. In the case of very short strand lengths in particular, this can lead to measurement results that are higher than the actual belt tension. The measurement should therefore be made on span lengths that are more than twenty times the length of the belt pitch.19If no measurement result appears despite repeated impact impulses on the belt, this can have several causes:• The belt oscillates outside the measurable frequencyrange of 10 - 600 Hz.• There is a noise source within the measurementenvironment that is in the same frequency range.• The belt oscillates only slightly or not at all.• The initial tension on the belt is too low.• The distance between the belt and the sensor istoo great.204. MAINTENANCE & CALIBRATION Before delivery, the device is subjected to a factory calibration, during which the device is checked at defined measuring points within the measuring range and the results are confirmed in a calibration protocol.If recalibration is required by internal guidelines, youcan request a new factory calibration from us.215. DISPOSAL INSTRUCTIONS Lithium polymer batteries contain toxic substances and do not belong in the household waste!The customer is legally obliged to dispose of the batteries professionally and responsibly.226. CERTIFICATES23Our detailed operating manual can be found in the download area of our website www.walther-flender.deWALTHER FLENDER GMBH Schwarzer Weg 100-10740593 Düsseldorf Germany***********************+49 (0)211 – 7007 00www.walther-flender.deW F T C 1.0_d e _N o v 22。

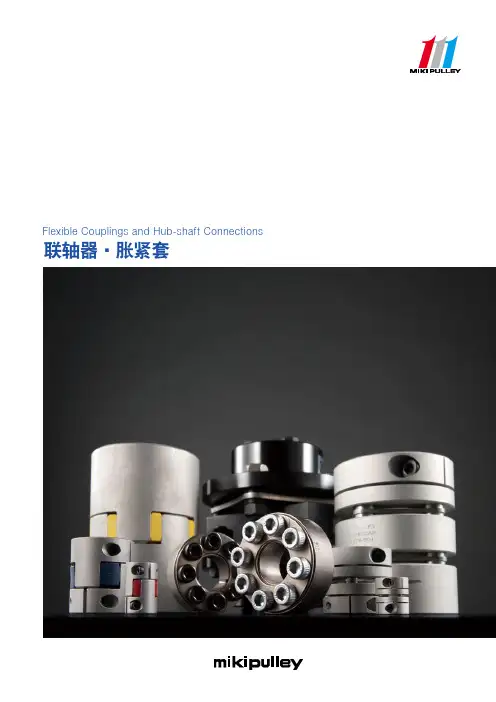

联轴器的名词解释联轴器(Coupling)是一种在机械设备中广泛使用的装置,用于连接两个轴或传动装置,使其能够相互传递动力和转矩。

在工业生产中,联轴器作为一个重要的机械元件,起着承担转动和传递力矩的关键作用。

一、联轴器的基本结构和功能联轴器通常由两个连接部分组成,分别连接在两个相邻轴上。

其基本结构包括两个相互扣合的轴套和一个传递力矩的元件,如弹性轴套、铰链轴套或齿轮等。

联轴器的作用是实现两个轴之间的动力传递,并能够在一定程度上吸收或减轻因转动不平衡和轴向位移引起的振动和冲击。

不同类型的联轴器具有不同的功能和适用范围。

弹性联轴器主要用于传递较小的转矩和扭矩,具有良好的减震和消除轴间误差的功能;齿轮联轴器适用于要求传递大转矩和扭矩的场合,具有较高的传动效率和承载能力;铰链联轴器则适用于需要轴向位移的场合,如柔性机械装配线等。

联轴器的选择要根据具体的应用需求来确定。

在选择时,需要考虑传递的转矩、转速、工作环境以及运行条件等因素。

此外,还要注意联轴器的安装和维护,以确保其正常运行并延长使用寿命。

二、联轴器的应用领域联轴器广泛应用于各个领域的机械设备中。

在工业生产中,联轴器被广泛应用于传动装置、发动机、风电设备、机床、泵、压缩机、冶金设备、船舶等。

以机械设备为例,联轴器在其中起到了连接和传递动力的重要作用。

在传动装置中,联轴器可用于连接电机和传动装置,实现传递动力;在发动机系统中,联轴器用于连接发动机和传动系统,实现发动机的启动和驱动;在船舶中,联轴器用于连接主机和螺旋桨,实现船舶的前进。

不仅如此,联轴器还广泛应用于医疗设备、食品包装机械、石油和化工设备等行业。

在医疗设备中,联轴器可用于连接医用电机和传动装置,实现医用设备的运行;在食品包装机械中,联轴器用于传动机械臂、传动模块等,实现食品包装过程中的传动和控制。

三、联轴器的发展趋势随着科技的不断进步,联轴器的设计和制造技术也在不断发展。

现代联轴器的研发趋势主要体现在以下几个方面:1.智能化:现代联轴器趋向于智能化发展,可以通过传感器实时监测联轴器的运行状态和工况参数,从而实现故障诊断和远程监控。

Xik齿轮油Flender认证规格第16版浅析周康中国石油兰州润滑油研究开发中心微点蚀又称“灰斑”、“微剥落”等,是齿轮工作过程中齿面出现微小疲劳裂纹并伴随少量材料转移的综合过程。

它宏观上相对点蚀较为密集,肉眼可见片区灰斑;微 观上表现为浅表凹坑(裂纹深度约为10〜20pm,长度约25〜100pm,宽度约10〜20nm)l1]o近年来,微点蚀作为一种新型的齿面疲劳磨损而受到关注,它通常发生在凸轮、齿轮和滚动轴承等受交变负荷的机械零件中,容易引起轮齿精度降低、动载荷和噪音增大,从而减少齿轮的使用寿命,导致许多大型工业传动机械和一些汽车传动机械失效,在兆瓦级风电齿轮等工业应用中显得尤为突出。

成立于1899年的德国西门子弗兰德FLENDER集团是世界领先的顶级专业动力传动设备制造商,凭借齿轮制造的悠久历史,FLENDER已成为高速齿轮领域的领导者。

满足西门子弗兰德减速机润滑需求的Flender工业齿轮油认证规格(以下简称Flender认证规格)是风力发电、冶金、矿山、水泥、造纸等行业工业齿轮和减速机等传动部件最重要的OEM(原始设备制造商)认证标准,代表着工业齿轮油的发展趋势。

2011年以来,Flender认证规格多次更新,于2011年2月28曰、2013年12月17曰、2015年8月7曰先后颁布了Rev.13、Rev.14、Rev.15要求(第13版〜第15版)。

笔者在2017年的研究中对这3个版本的规格进行了比较⑵。

最新的版本是2018年5月颁布的Rev.16(第16版,2017年10月1日首次颁布,2017年12月6曰和2018年5月风电、造船及航空等行业所用齿轮箱111于载荷大、工况复杂多变容易出现微点蚀现象,山此引发了近年來对低速重载齿轮传动中微点蚀现象的重视和深入系统的研究。

山于齿轮微点蚀已成为影响其传动精度、使用寿命及运行可靠件的一个重要影响因素,越來越多的齿轮制造商要求在其设备上使用抗微点蚀工业齿轮油。

Hydraulic Fit Coupling Assemblies液压配合联轴器Dresser-Rand Product Training德莱赛兰产品培训[Revision: March, 2009]Asia Pacific© Copyright 2009Summary 概述Flexible Couplings (hydraulic fit hub) 弹性联轴器(液压安装轮毂) Coupling Design 联轴器的设计(3~25页) Disassembly Procedure 拆卸程序(26~36页) Assembly Procedure 装配程序(37~51页)2© Copyright 2009Flexible Coupling 弹性联轴器Couplings shall perform these main tasks: 联轴器将履行这些主要的任务:1) Transmit torque from driving to driven shaft 将扭距从驱动端 传送到被驱动轴3© Copyright 20092) Accommodate shaft misalignments 容许轴的不 对中3) Compensate for end movement 轴端位移补偿Flexible Disc Coupling 弹性膜片式联轴器….. consists of one or more flexible elements that are alternately attached circumferentially to the two parts of the coupling …... 由一个或更多的弹性元件组成,弹性元件沿周向交错地与两半联轴器联接 Transmit torque through flexible, Stainless Steal disc packs instead of gear teeth. 由弹性的不锈钢膜片组件代替齿轮轮齿传送扭距 Compensate for misalignment by deflection of disc packs instead of gear teeth. 通过膜片组件的偏转代替齿轮轮齿来补偿两轴线偏移 No wearing parts - flexing instead of sliding 无易损件 – 弹性,而不是滑动 No lubrication required 不需要润滑油 High torque ratings 高扭距级别4© Copyright 2009Flexible Coupling 弹性联轴器Disc element is made from a corrosion resistant high strength 301 Stainless Steel > (.012” to .015” thick) 膜片元件由高强度、抗腐蚀的301不锈钢制造,厚度> (.012” 到.015” ) (0.30~0.38mm) Each disc element is coated with KOPLON to prevent fretting corrosion 每一个膜片元件都有防腐蚀 的高湿模量粘胶纤维 涂层KOPLON = Teflon based material (PTFE) KOPLON =基础材料是聚四氟乙烯( PTFE) Hubs , sleeves and spacers are heattreated alloy steel 轮毂、衬套和定距套是经热处理的不锈钢 Fasteners – high quality alloy steel 紧固件 – 优质不锈钢5© Copyright 2009Flexible Coupling弹性联轴器Shipping screws 运输用螺钉: Lock and stabilize the flexing subassembly during machining, balancing and shipping 用于加工、平衡及运输过程中锁紧 和固定联轴器的弹性组件 Provide built in tooling to collapse the disc packs during the installation procedure 提供安装过程中膜片组件叠加 所用的调整固定工具 Yellow collapsing screws (socket head cap screws) are used to collapse the disc pack 黄色的调整螺钉(内六角螺钉)用于膜片组件的叠 加© Copyright 2009The red locking screws (setscrews) holds the disc pack in the neutral position 红色的锁定螺钉(固定螺钉)使膜片组件保持在中间的位置6Flexible Coupling 弹性联轴器Red locking screws(Yellow collapsing screws红色锁定螺钉黄色调整螺钉(Yellow collapsing screwsRed locking screws黄色调整螺钉红色锁定螺钉Kopflex RMKopflex RZ© Copyright 20097Flexible Coupling Shimming & Prestretch 弹性联轴器垫片及预拉伸8© Copyright 2009…..is the axial stretch of the disc packs establish at coupling installation to accommodate changes in the shaft separation, such as thermal growth 联轴器安装时建立的膜片组件的轴向拉伸,可解决诸如热膨胀等而引起的所联两轴的相对 距离的变化 Pre-stretching of the packs ensures the coupling will run with the disc in the neutral position at normal operating conditions 膜片的预拉伸可以确保联轴器在正常操作时膜片在中间位置 Axial misalignment related stresses will be minimized 由于轴线偏移而引起的应力将被最小化Flexible Coupling 弹性联轴器Disc Pack 膜片组件 Coupling 联轴器Shaft 轴Cold alignment (Stretched)冷态对中(拉伸)The coupling accommodates axial misalignment by stretching the disc packs. 联轴器通过膜片的拉伸来调节轴向的不对中度 It must also accommodate changes in the shaft separation, such as thermal growth. 该联轴器还可以补偿由于热膨胀而引起的所联两轴的相对距离的变化 Although the disc pack has a high stretch capacity, the less stretch will reduce the stresses on the coupling. 虽然膜片组件具有较高的拉伸性能,然而较小的拉伸将能够减少膜片对联轴器的应力9© Copyright 2009Flexible Coupling弹性联轴器Shaft 轴Disc Pack 膜片组件 Coupling 联轴器Operating Alignment (Neutral) 运行对中(中间位置) Achieving the correct cold axial alignment, will ensure that when the equipment reaches running temperature, the disc pack will be running as close to neutral as possible. 达到正确的冷态对中,将能够确保设备在运行温度下,膜片将尽可能地接近中 间位置 This will reduce the stresses acting on the disc pack and ensure long term operation. 这样将能够减少作用在膜片上的应力,以确保长期运行10© Copyright 2009Flexible Coupling 弹性联轴器Disc Pack 膜片组件Calculated Cold separation 计算出的冷态距离Disc Pack 膜片组件11© Copyright 2009In cold condition after installation of the spacer the disc packs will be stretched. This is known as pre-stretch. 定距段安装后,膜片在冷态下将被拉伸。

弗兰德联轴器德国Flender弗兰德集团是世界上最大的专业动力传动设备制造商之一,成立于1899年,总部在德国的Bocholt市,至今已有百年的制造经验。

在世界范围内有14个制造厂,营销网络遍布世界各地,共有员工7000余人,年产值18亿马克。

一百年来,以其雄厚的技术资源、领先的制造技术、优秀的产品质量、高踞世界驱动行业的领先地位。

深圳市惠佳捷科技有限公司长期经销FLENDER公司生产的各类联轴器,包括:Flender弗兰德N-EUPEX-DS柱销式联轴器Flender弗兰德BIPEX爪型弹性联轴器Flender弗兰德ELPEX环式高弹性联轴器Flender弗兰德ELPEX-S盘式高弹性联轴器Flender弗兰德ELPEX-B轮胎式高弹性联轴器Flender弗兰德ARPEX膜片式联轴器Flender弗兰德ZAPEX-ZIN齿形联轴器Flender弗兰德ZAPEX-ZW齿形联轴器产品介绍:1.产品名称:Flender N-EUPEX-DS柱销式联轴器产品简述:N-EUPEX-DS柱销式联轴器(未配置失效保护功能) Flender N-EUPEX 联轴器的金属部件由优质灰口铸铁GG-25制成. 其弹性元件由合成橡胶制成,在出现轴对中偏差时传递转距不会发生磨损.特点:在弹性元件失效后电机与从驱动机自动脱离 (无失效保护功能); 可以与N-EUPEX 联轴器的所有附件组合; 具有17种规格,其转距传递范围为60 Nm至 21,200 Nm, 适用环境温度范围-20°C 至 +80°C; 弹性元件具有良好的线性变形特性;应用范围:Flender N-EUPEX 联轴器作为高速联轴器广泛应用在机械设备,例如泵驱动系统或发动机驱动系统, 或者作为低速大转距联轴器用于联接齿轮箱和驱动设备.2.产品名称:Flender BIPEX爪型弹性联轴器产品简述:FlenderBIPEX爪型弹性联轴器标准结构型式BWN系列由两个外形相同的轮毂(材质为灰口铸铁GG-25)和中间填充一个塑料凸轮构成.在出现轴对中偏差时无磨损,BIPEX联轴器具有很小的扭转侧隙,可以装配不同弹性的弹性环.凸轮铸件传递转矩的各个面均由相互呈一定角度的而且大小不同的两个面构成,未作表面加工,这样就可以使塑料环内部的径向反作用力相互抵消,既不会产生反作用力,并且在铸件和塑料凸轮之间不会形成相对运动,从而无磨损.此外,由于凸轮铸件传递转矩的各个面摩擦系数很大,可以有效的避免塑料凸轮环的滑动,因此在允许的轴对中偏差内无磨损.特点:具有失效保护功能的通用弹性联轴器; 结构紧凑,重量轻; 采用插式安装; 具有3种结构式和13种规格,其转矩传递范围 13.5 Nm 至3,700 Nm , 适用环境温度范围 -20°C至少+80°C. 结构型式BWT 配装锥形紧固套筒,易于安装和拆卸.应用范围:BIPEX联轴器广泛应用在通用机械设备中,特别是作为高速联轴器可以在电机侧,并可以采用法兰盘安装方式,例如应用在液压设备,齿轮电机,泵设备以及轴承设备上.3.产品名称:Flender ELPEX-B轮胎式高弹性联轴器产品简述:Flender ELPEX-B轮胎式高弹性联轴器的金属部件由优质球墨铸铁GGG-40构成, 转矩的传递主要由具有丝线嵌入层的轮胎式弹性元件承担.特点:无扭转侧隙的轮胎式高弹性联轴器; 可以补偿很大的轴对中偏差;更换弹性元件无需移动所连接的机器设备; 根据用户要求可以用锥形紧固套筒装配方案; 具有3种结构型式和15种规格, 其转矩传递范围24 Nm 至14,500 Nm , 适用环境温度范围-30°C至+60°C.应用范围:ELPEX联轴器广泛应用在冶金工业,建材工业,泵转动系统,压缩机,挖掘机以及备用供电设备中4.产品名称:Flender ELPEX-S盘式高弹性联轴器产品简述:ELPEX-S盘式高弹性联轴器,橡胶盘弹性元件的内径硫化到轮毂上, 轮毂可以采用锥形紧固套筒连接.特点:盘式高弹性联轴器,特别适用于连接具有不均匀转矩特性的机械设备;弹性元件具有良好的线性变形特性,扭转振动缓冲性能好;法兰连接尺寸采用SAE J620d 标准;可以采用简单的插入式安装;更换橡胶盘无需移动所连接的机器设备;转矩传递范围为此330 Nm 至40,000 Nm ,适用环境温度范围-30°C至少+60°C.应用范围: Flender ELPEX-S联轴器可以广泛应用在通用机械设备上,特别适用于包括内燃机的机械设备,往复式压缩机,或者水泥磨等设备.5.产品名称:Flender ELPEX环式高弹性联轴器产品简述: Flender ELPEX环式高弹性联轴器的金属部件由灰口铸铁GG-25或钢制成,其弹性环由优质天然橡胶制成,硫化到弹性环中的双尼龙线嵌入层主要承担传递转矩的功能.特点:无扭转侧隙的高弹性联轴器;可以用在轴对中偏差很大的场合;可以承受较大的动载,具有良好的缓冲特性;有8种结构型式和12种规格, 其转矩传递范围100 Nm 至90,000 Nm , 适用环境温度范围-30°C至少+80°C.不同弹性的弹性环可用作联轴器动态调节以适配不同转动系统的最佳运行;一部分结构型式配置了失效保护功能.一、N-EUPEX 柱销式弹性联轴器产品介绍N-EUPEX 联轴器的金属部件由优质灰口铸铁GG-25制成. 其弹性元件由合成橡胶制成,具有稳定的转距传递性,脆化效应小. 由于柱销和弹性元件的优化设计,即使出现轴对中偏差也无磨损.特点:配置失效保护功能以保证运行安全至铸件断裂为止;插入式安装,特别有利于三件式部件的安装;有8种结构型式和23种规格可供选择,转距传递范围为19 Nm至62,000 Nm,适用环境温度范围-20°C 至+80°C;可以通过选择不同硬度的弹性元件对联轴器功能进行动态调节.应用范围:N-EUPEX 联轴器作为高速联轴器广泛应用在机械设备,例如泵驱动系统或发动机驱动系统, 或者作为低速大转距联轴器用于联接齿轮箱和驱动设备.二、N-EUPEX-DS柱销式弹性联轴器产品介绍:N-EUPEX 联轴器的金属部件由优质灰口铸铁GG-25制成. 其弹性元件由合成橡胶制成,在出现轴对中偏差时传递转距不会发生磨损.特点:在弹性元件失效后电机与从驱动机自动脱离(无失效保护功能);可以与N-EUPEX 联轴器的所有附件组合;具有17种规格,其转距传递范围为60 Nm至21,200 Nm, 适用环境温度范围-20°C 至+80°C;弹性元件具有良好的线性变形特性;应用范围:N-EUPEX 联轴器作为高速联轴器广泛应用在机械设备,例如泵驱动系统或发动机驱动系统, 或者作为低速大转距联轴器用于联接齿轮箱和驱动设备.三、BIPEX 爪形弹性联轴器产品介绍:标准结构型式BWN系列由两个外形相同的轮毂(材质为灰口铸铁GG-25)和中间填充一个塑料凸轮构成.在出现轴对中偏差时无磨损,BIPEX联轴器具有很小的扭转侧隙,可以装配不同弹性的弹性环.凸轮铸件传递转矩的各个面均由相互呈一定角度的而且大小不同的两个面构成,未作表面加工,这样就可以使塑料环内部的径向反作用力相互抵消,既不会产生反作用力,并且在铸件和塑料凸轮之间不会形成相对运动,从而无磨损.此外,由于凸轮铸件传递转矩的各个面摩擦系数很大,可以有效的避免塑料凸轮环的滑动,因此在允许的轴对中偏差内无磨损.特点:具有失效保护功能的通用弹性联轴器;结构紧凑,重量轻;采用插式安装;具有3种结构式和13种规格,其转矩传递范围13.5 Nm 至3,700 Nm,适用环境温度范围-20°C至少+80°C.结构型式BWT配装锥形紧固套筒,易于安装和拆卸.应用范围:BIPEX联轴器广泛应用在通用机械设备中,特别是作为高速联轴器可以在电机侧,并可以采用法兰盘安装方式,例如应用在液压设备,齿轮电机,泵设备以及轴承设备上.四、RUPEX刚性柱销式弹性联轴器产品介绍:基本结构型式RWN的金属部件由灰口铸铁GG-25制成,而结构型式RWS的金属部件则由高温淬火的C 45 N钢材制成,联轴器各面均进行了表面加工,并且达到了较高的精度,因此特别适合高转速作业场合.弹性元件由优质合成橡胶制成,在孔壁上采用了两层纤维进行加强以避免橡胶的流动并提高了单位负荷能力.标准的弹性元件是导电的以防止静电产生,也可以提供绝缘弹性元件,主要是应用在电机转子不接地的情况下.可以采用软的或硬的弹性材料制成弹性元件,原则上可以适配所有转动环境的要求.特点:配置失效保护功能的通用弹性联轴器,主要应用在传递大转矩以及吸收轴对中偏差很大的场合;紧凑型设计,重量轻,惯性转矩小;适用于插入式安装;具有5种结构型式,26种规格,转矩传递范围为210 至 1,400,000 Nm,此适用环境温度范围-20°C至80°C.应用范围:N-EUPEX 联轴器作为高速联轴器广泛应用在机械设备,例如泵驱动系统或发动机驱动系统, 或者作为低速大转距联轴器用于联接齿轮箱和驱动设备.五、ELPEX环式高弹性联轴器产品介绍:ELPEX联轴器的金属部件由灰口铸铁GG-25或钢制成,其弹性环由优质天然橡胶制成,硫化到弹性环中的双尼龙线嵌入层主要承担传递转矩的功能.特点:无扭转侧隙的高弹性联轴器;可以用在轴对中偏差很大的场合;可以承受较大的动载,具有良好的缓冲特性;有8种结构型式和12种规格, 其转矩传递范围100 Nm 至90,000 Nm,适用环境温度范围-30°C至少+80℃.不同弹性的弹性环可用作联轴器动态调节以适配不同转动系统的最佳运行;一部分结构型式配置了失效保护功能.应用范围:ELPEX联轴器特别适用在具有周期性激励系统的转动设备中,例如内燃机,往复式压缩机或往复式泵,并且适用于具有高冲击负荷或轴对中偏差很大的场合,例如水泥工业等.六、ZAPEX-ZW齿形联轴器产品介绍:ZAPEX齿形联轴器ZW系列是由优质高温淬火钢材按模块化原理制造,外齿轮具有鼓形齿,这种齿轮顶短,齿根有力,弯曲应力小,断裂危险小,而且易于润滑.此系列有31种规格,其中常用的14种规格可用于传递转矩至250,000 Nm, 孔径可达275 mm, 有现货供应.根据要求还可提供转矩可达10,000,000 Nm 的齿形联轴器.适用环境温度-20°C至+80°C.特点:齿形联轴器ZW系列,可以用于补偿轴向,经向和角对中偏;在出现轴对中偏差时回复力小;通过设计和采用特殊材料可以保持长期润滑;体积小,可以用于大的冲击负荷,具有较大的安全余量;可用于两个扭转方向和可逆运行方式.应用范围:通用机械设备冶金工业重型机械材料加工泵转动设备水泥工业港口起重机械等七、ARPEX膜片式联轴器产品介绍:ARPEX膜片式联轴器具有7种结构型式,最小的联轴器传递转矩范围从10 Nm 起始,而最大的联轴器传递转矩范围可达8,100,000 Nm, 由于膜片具有6角,8角或多或10角的造型,所以转矩传递十分均匀,其适用环境温度可从-20°C至少+280°C, 采用特殊材质适用环境温度可从-196°C至少+350°C,可以用在有爆炸危险的区域.这些结构型式各具有一些不同的结构特点和性能以适应广泛应用的需要.特点:无扭转侧隙的钢性联轴器;通过应用两组膜片补偿轴的径向,轴向和角对中偏差;由具有弹力的优质CrNi-不锈钢制成,耐磨损,无需维护;膜片安装,更换方便;部件按模块化原理制造,应用十分广泛.应用范围:作为高速联轴器和低速大转矩联轴器可以广泛应用在通用机械设备上,例如造纸机械设备,泵转动系统,通风设备,材料加工等.最小的联轴器可用于控制系统.八、FLUDEX液力偶合器产品介绍:FLUDEX偶合器是一种无机械磨擦的液力偶合器,是由一个离心泵和一个涡轮机组成的.转矩是由叶片加速的,在偶合器中旋转流动的稀油传递的.FLUDEX偶合器具有16种结构型式和16种规格,按模块化原理制造,其最大功率可达1900 kW,适用环境温度-20°C至+45°C.FLUDEX偶合器本身并不具备弹性,既它们不能补偿轴对中偏差,因此通常与N-EUPEX联轴器,BLAURIV型皮带或制动盘组合应用.特点:软启动,无冲击,使电机无负载启动从而保护电机;在电机起动过程或在过载时具有转矩限制功能;优异的振动隔离和冲击缓冲特性;转矩传递无磨损;允许内燃发动机带载起动。

LS高弹性联轴器安装使用维护说明书Technical Manual forThe Highly Flexible LS Coupling上海大华联轴器厂SHANGHAI DAHUA COUPLINGS PLANTLS型高弹性联轴器是一种扭转弹性橡胶联轴器,可以补偿相连机器轴线的径向位移、轴向位移和角向位移。

用弹性元件来保证联轴器的扭转传递,并且具有各种不同的扭转刚度和阻尼系数可供选择,因而能充分地调节传动系统的扭转振动性能。

LS型高弹性联轴器主要由扭转弹性部件、膜片部件、联接件及扭转限位装置组成。

扭转弹性部件由多个元件组合而成,它根据结构尺寸和刚度级别的要求布置成单排和多排型。

每排弹性元件又由多个扇形块组成。

膜片部件是由多个呈正切方向布置的挠性杆组成。

它们都是布置在弹性部件的后端,并允许承受轴向位移。

扭转限位装置是当弹性部件破坏的瞬间,防止联接机器的断开,这时就变成扭转刚度联接。

The highly flexible LS coupling is a torsionally flexible rubber coupling that compensates redical, axial and angular shaft displacements of the connected machinery.The torque is transmitted by flexible elements. And the different torsional stiffness and damping factors available provided the possibility to satisfactorily tune the torsional vibration behaviour of the drive system.The main parts of the LS coupling are: the torsionally flexible part, the membrane part the connecting parts and the torsional limit device. The torsionally flexible part consists of elements, which can be arranged in one row or more rows respectively, dependent on the coupling size and the stiffness level. The flexible elements are divided into several segments. The membrane part consists of a number of flexible links whgich are arranged tangential. They are arranged behiand the flexible part and permit axial displacement. The torsional limit device will at the moment of failure of the flexible elements, prevent separation of the connected macinery. The connectionwill then be torsionally rigid.1 连接盘、扭转限位装置2 挠性杆座3 轴套4 挠性杆5 LS弹性元件disassemby ring flanged casing hub flexible link LS element弹性元件是用耐热橡胶制造的,允许使用环境温度-45℃~+70℃,同时要防止联轴器橡胶部分永不受油和热辐射的影响,为使使用寿命长,应注意足够的通风口孔。

操作说明书BA 5010 ZH 06.03减速机型号规格3至26A.Friedr. 弗兰德有限公司·波绰尔特46393·电话02871/92-0·传真02871/92-2596·目录1. 技术数据 4 1.1 通用技术数据 4 1.1.1 重量 5 1.1.2 测量减速机表面的噪声水平 6 1.1.2.1 配备了风扇的伞齿轮-斜齿轮减速机(B…)的测量表面噪声水平 6 1.1.2.2 无风扇的伞齿轮-斜齿轮减速机(B…)的测量表面噪声水平7 1.1.2.3 配备了风扇的斜齿轮减速机(H…)的测量表面噪声水平81.1.2.4 无风扇的斜齿轮减速机(H…)的测量表面噪声水平92. 通用说明10 2.1 前言102.2 版权103. 安全说明` 10 3.1 合理使用10 3.2 用户的责任11 3.3环境保护11 3.4 特殊危险123.5 在本说明书中所使用的警告标识和符号124. 搬运和储存12 4.1 供货范围12 4.2 搬运12 4.3减速机的储存144.4 标准防锈措施145. 技术说明15 5.1 综合说明15 5.2 输出轴的设计方案16 5.3 箱体16 5.4 有齿零件18 5.5 润滑18 5.4.1 浸油润滑18 5.5.2 通过附加供油装置实现的压力润滑19 5.6 轴承19 5.7 轴封20 5.7.1 径向轴封环20 5.7.2 迷宫密封20 5.7.3 塔康耐特密封20 5.8 止回机构22 5.9 冷却23 5.9.1 风扇23 5.9.2 冷却螺旋管24 5.9.3 安装在减速机上的空气冷却润滑油装置25 5.9.4 安装在减速机上的水冷却润滑油装置26 5.10 加热元件27 5.11 测量润滑油的温度28 5.12 油面监测系统28 5.13 轴承监测系统29 5.14 速度发送器296.1 关于安装的综合信息30 6.2 在基座上安装减速机30 6.2.1 基础30 6.2.2 有关安装工作的说明31 6.2.2.1 对中表面和对中螺纹32 6.2.2 在基础支架上的安装32 6.2.2.3在混凝土地基上用地脚螺栓或者地基块安装减速机33 6.2.2.4用锚定螺栓在混凝土地基上安装减速机34 6.3 联轴器36 6.4 配备了空心轴和平键的用轴安装的减速机的组装38 6.4.1 准备工作38 6.4.2 组装38 6.4.2.1 安装39 6.4.2.2 轴向固定装置39 6.4.3. 拆卸40 6.5 配备了空心轴和符合DIN 5480标准的内花键的用轴安装的减速机42 6.5.1 准备工作42 6.5.2 组装42 6.5.2.1 安装43 6.5.2.2 轴向定位装置43 6.5.3 拆卸44 6.6 配备了空心轴和收缩盘的用轴安装的减速机46 6.6.1 组装46 6.6.1.1 安装46 6.6.1.2 轴向定位装置47 6.6.2 型号HSD的收缩盘47 6.6.2.1 收缩盘的组装47 6.5.2.2 拆卸收缩盘48 6.6.2.3 清理收缩盘并涂抹润滑脂49 6.6.3 拆卸49 6.7 配备了法兰轴的用轴安装的减速机51 6.8 配备了实体法兰盘的用轴安装的减速机52 6.9 安装减速机箱体的扭力臂53 6.9.1 安装扭力臂53 6.10 减速机摆动座的安装支撑54 6.10.1 安装支撑54 6.11 配备了冷却螺旋管的减速机55 6.12 安装了附件的减速机55 6.13 配备了润滑油空气冷却装置的减速机55 6.14 配备了水冷却润滑油的减速机55 6.15 配备了加热装置的减速机55 6.16 配备了油温测量装置的减速机55 6.17 配备了油面高度监测装置的减速机55 6.18 配备了转速发送器的减速机55 6.19 最后的工作557.1 起动之前的准备工作56 7.1.1 排放保护剂56 7.1.2 添加润滑油57 7.1.2.1 润滑油的数量58 7.2 起动59 7.2.1 油面59 7.2.2 配备了冷却螺旋管或者外部润滑油冷却系统或者供油系统的减速机59 7.2.3 配备了止回装置的减速机59 7.2.4 检查步骤59 7.3 退出工作59 7.3.1 在长期保存中内部保护剂60 7.3.1.1 用齿轮油进行内部保护60 7.3.1.2 用特种保护剂进行内部保护60 7.3.1.3 内部保护的步骤60 7.3.2 外部保护617.3.2.1 外部保护步骤618.操作619.故障、原因和措施61 9.1 有关故障的通用信息619.2 可能发生的故障6210.维修64 10.1 有关维修的通用说明64 10.2 关于维修工作的说明65 10.2.1 检验润滑油中的水分65 10.2.2 更换润滑油65 10.2.3 清理通气阀65 10.2.4 塔康耐特密封要添加润滑脂65 10.2.5 清理风扇和减速机66 10.2.6 检查冷却螺旋管66 10.2.7 检查润滑油空气冷却器66 10.2.8 检查润滑油水冷装置67 10.2.9 加油67 10.2.10 检查紧固螺栓的紧密程度67 10.3 最后的工作68 10.3.1 对于减速机的总体检查6810.4 润滑油6811.备件和服务设施的地址68 11.1 储存备件6811.2 备件和服务设施地址6912. 制造厂商申明701. 技术数据1.1 通用技术数据在铭牌上示出了最重要的技术数据。

安装/操作和维护手册(用户说明)联轴器图纸号:07598-00用户:MAN TURBO AG用户订单参考号:706/4132248 日期2007年12月18日联轴器型号:8GH-330-S联轴器号:71850项目:HAMIAIR内容:1.联轴器说明2.操作条件和限值3.一般说明(允许及禁止)4.安装说明5.安装找正说明6. 如果发生预期和不常有的故障时,应采取的预防步骤7. 维护说明8. 安装说明简图9. 联系详情(C)MAN TURBO AG1.联轴器说明Euroflex联轴器是干式叠层盘类型,挠性是通过圆盘(叶片)在圆盘组(部件总成)中变形获得。

由一个或多个部分组成的中心件来隔离圆盘组件。

圆盘组在轴向和角角向所能承受的变形和偏心量是具有限度的。

这些限制是针对联轴器规定的,并且要注意以确保不能超过这些值。

单独的圆盘外形为规则的多边形,并安装进规定的圆盘组,并在正常情况下由套筒保护。

转矩传递及挠性是通过套筒,孔连接圆盘组实现的,套筒孔具有相同的螺栓圆周直径,且连接螺栓交替固定在传动及从动机械部件上。

将螺栓,套筒和有关联的孔都生产成为拥有很精密的公差。

然而,由于实际安装的需要,安装套筒和螺栓时,其与孔之间可能会有微小的间隙。

为弥补这些间隙以及确保临近圆盘组的部件保持同一轴心,法兰上的螺栓圆周直径比圆盘组件的螺栓圆周直径稍微大一些。

因此,圆盘组相对于组件有微小凸出。

螺栓在组装时要紧固到相当高的程度,提供大的预负荷。

预加负荷很重要,在操作期间用来预防任何界面的划移,并且当传输转矩时,消除由于外伸扭矩导致的任何螺栓弯曲。

因此,螺栓的紧固应重视。

总的来说,设计原理与很多已运行的单元是相同的。

2.操作条件和限值在操作期间,圆盘组需承受高强度的拉伸应力和弯曲应力,这是由于施加的转矩,速度及偏心度而造成的。

这些应力之间是相互联系的,某一个应力的改变,将直接影响另一应力的允许限值。

在正常的稳定转矩和速度的情况下,这种关系集中在偏差度上。