沧州天硕精密联轴器电子样本

- 格式:pdf

- 大小:9.80 MB

- 文档页数:77

机械手-木琴演奏机械手的设计-说明书摘要音乐机器人属于表演类特种机器人,其研究主要集中于国外,国内迄今未见有相关文献。

木琴演奏机械手是键盘型音乐机器人的一种,具有典型的运动机构、可选用可编程序控制器、PLC、微机等多种控制方式。

本文就木琴演奏机械手为研究对象,对于其机械部分和控制部分进行设计。

机械部分主要包括移槌装置、击槌装置和握槌机构。

其中移槌装置主要由直流伺服电动机、滚珠丝杠和滚动直线导轨副组成;击槌装置由步进电动机、减速器、机械手臂组成;握槌机构由夹具和护板组成。

控制部分由可编程控制器(PLC)控制直流伺服电动机和步进电动机来完成移槌定位和木槌击键动作。

关键词:木琴演奏机械手,移槌装置,击槌装置,可编程控制器(PLC)ABSTRACTMusic robots are special types of robots, their research focused on foreign and domestic so far there is no literature. Xylophone playing robots are one type of music keyboard robots, have typical of the sport organizations ,can use programmable logic controller, PLC, computer and other control methods In this paper, Xylophone playing robots to object of study, for the mechanical part and control part of the design. Mechanical parts mainly include the shifting hammer device, the hitting hammer device and the holding hammer device. The shifting hammer devicemainly consists of DC servo motor, Ball screw and rolling linear guides; the hitting hammer device consists of stepper motor, reducer, mechanical arm; the holding hammer device consists of clamp and retaining plateControl part by the programmable logic controller PLC control of DC servo motors and stepper motors to complete the shift position and mallet hammer keystroke action.Key words: Xylophone playing robots, shifting hammer device, hitting hammer device, programmable logic controller PLC 目录1 绪论1.1机器人的发展历史1.2音乐机器人的发展状况2 木琴演奏机械手的设计方案2.1机械部分和控制部分总体设计方案2.2拟采用的设计方案3 移槌装置的设计3.1滚珠丝杠的选型3.2移槌装置电机的确定3.3导轨的选型3.4联轴器的选用4 击槌装置的设计4.1一级减速齿轮的计算4.2轴的计算4.3轴的结构设计4.4估算击槌过程中机械手的运动范围及距离5 支架的设计5.1支架结构的设计5.2支架尺寸确定6 控制系统的设计6.1总体设计思路6.2系统中的检测元件6.3数字伺服系统的分类6.4可编程控制器PLC的选用6.5驱动器的选择6.6限位开关的选择6.7系统工作原理和I/O端口分配6.8软件设计7 结论参考文献致谢1绪论1.1机器人的发展历史机器人的历史并不算长,1959年美国英格伯格和德沃尔制造出世界上第一台工业机器人,机器人的历史才真正开始。

定位平行夹紧平行定位螺纹夹紧螺纹定位梅花夹紧梅花胀套梅花ML梅花单节膜片双节膜片法兰式单节法兰式双节单节DJM 单节夹紧DJM 双节DJM 单节JM 单节胀套双节胀套定位波纹管夹紧波纹管定位滑块夹紧滑块定位刚性夹紧刚性Z1胀套Z2胀套Z3胀套Z4胀套Z5胀套Z6胀套Z7胀套Z8胀套Z9胀套同步轮NL联轴器NM联轴器XL联轴器万向节L联轴器KC联轴器HRC联轴器公司简介:昆山市曙达锐传动机械有限公司是一家集生产、销售一体的企业。

公司专业生产各类弹性联轴器、胀紧套、同步轮等传动产品。

本司产品种类、规格齐全,价格优惠,现备有大量库存,欢迎全国各地工厂,代理商,行家来洽谈、批发、零售。

WB1A定位平行联轴器特点﹡一体成型的金属弹性联轴器﹡零回转间隙﹡弹性作用补偿径向、角向、轴向偏差﹡顺时针与逆时针回转特性完全相同﹡定位螺丝或加键槽固定﹡铝合金材质﹡适用于编码器、激光机选型举例例:WB1A-25-0810WB1A:定位平行型25:外径尺寸08:d1轴径尺寸10:d2轴径尺寸注:加键槽需另外注明型号Ød1 Ød2ØD L L1 M拧紧力矩轴径(N.m)WB1A-15□□□□ 3 4 5 6 6.35 8 15.5 23 3 M3 0.7 WB1A-17□□□□ 3 4 5 6 6.35 8 17.5 23 3 M3 0.7 WB1A-19□□□□ 3 4 5 6 6.35 8 19.1 19.1 2.55 M3 0.7 WB1A-25□□□□ 5 6 6.35 8 10 25.4 25.4 3.80 M4 1.7 WB1A-28□□□□ 6 6.35 8 10 12.7 28.6 28.6 4.00 M4 1.7 WB1A-38□□□□8 10 12 12.7 14 15 38.1 38.1 5.00 M5 3.8 WB1A-42□□□□10 12 14 15 16 18 20 42.0 50.0 7.80 M6 4.5 WB1A-50□□□□12 14 15 16 18 19 20 21 24 50.0 50.0 7.80 M6 7.0型号额定扭矩(N.m)最大扭矩(N.m)最高转速(rpm)径向偏差(m m)角向偏差(。

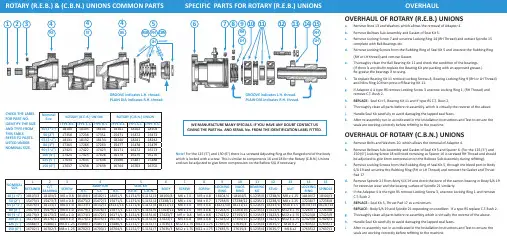

CHECK THE LABEL FOR PART NO. IDENTIFY THE SIZE AND TYPE FROM THIS TABLE. REFER TO PARTS LISTED UNDER NOMINAL SIZE.GROOVE indicates L.H. thread.PLAIN DIA indicates R.H. thread.Nominal Size ROTARY (R.E.B.) UNION ROTARY (C.B.N.) UNIONTYPE B.E.TYPE S.T.TYPE R.S.TYPE B.E.TYPE S.T.TYPE R.S.40 (1 ½")18104181051810618101181021810350 (2")17350172381735115471154721547365 (2 ½")18131181321813318240182411824280 (3") 17265172661726315477154781547990 (3 ½")174211742217423161711617216173100 (4")174241742517426161741617516176125 (5")176341763517636154861548715488150 (6")176371763817639167041670316702GROOVE indicates L.H. thread. PLAIN DIA indicates R.H. thread.Note! For the 125 (5") and 150 (6") there is a screwed Adjusting Ring at the flanged end of the body which is locked with a screw. This is similar to components 16 and 18 for the Rotary (C.B.N.) Unions and can be adjusted to give 6mm compression on the Bellow S/A if necessary.OVERHAUL OF ROTARY (R.E.B.) UNIONSa. Remove Nuts 13 and Washers which allows the removal of Adaptor 4.b. Remove Bellows Sub-Assembly and Gasket of Seal Kit 5.c. Remove Locking Screw 7 and unscrew Locking Ring 14 (RH Thread) and extract Spindle 15 complete with Ball Bearings etc.d. Remove Locking Screws from the Rubbing Ring of Seal Kit 5 and unscrew the Rubbing Ring (RH or LH thread) and remove Gasket.e. Thoroughly clean the Ball Bearing Kit 11 and check the condition of the bearings. (If there is any doubt replace the Bearing Kit pre-packing with an approved grease.) Re-grease the bearings if re-using.f. To replace Bearing Kit 11 remove Locking Screws 8, Bearing Locking Ring 9 (RH or LH Thread)and Nilos Ring 10 then press off Bearing Kit 11.g. If Adaptor 4 is type RS remove Locking Screw 3 unscrew Locking Ring 1, (RH Thread) and remove C.T. Bush 2.h. REPLACE :- Seal Ki t 5, Bearing Kit 11 and if type RS C.T. Bush 2.i. Thoroughly clean all parts before re-assembly, which is virtually the reverse of the above.j.Handle Seal Kit carefully to avoid damaging the lapped seal faces.k. After re-assembly run-in as indicated in the Installation Instructions and Test to ensure theseals are working correctly before refitting to the machine.OVERHAUL OF ROTARY (C.B.N.) UNIONSa.Remove Bolts and Washers 20, which allows the removal of Adaptor 4.b. Remove Bellows Sub-Assembly and Gasket of Seal Kit 5 and Spacer 6. (For the 125 (5") and 150 (6") Locking Screw 18 will need removing as Spacer 16 is screwed RH Thread and should be adjusted to give 6mm compression on the Bellows Sub-Assembly during refitting).c. Remove Locking Screws from the Rubbing Ring of Seal Kit 5, through the bleed port in Body S/A 19 and unscrew the Rubbing Ring (RH or LH Thread) and remove the Gasket and Thrust Pad 17.d. Remove Spindle 21 from Body S/A 19 and check the bore of the carbon bearing in Body S/A 19 for excessive wear and the bearing surface of Spindle 21 similarly.e. If the Adaptor 4 is the type RS remove Locking Screw 3, unscrew Locking Ring 1 and remove C.T. Bush 2f. REPLACE:- Seal Kit 5, Thrust Pad 17 as a minimum.REPLACE :- Body S/A 19 and Spindle 21 depending on condition. If a type RS replace C.T. Bush 2.g. Thoroughly clean all parts before re-assembly which is virtually the reverse of the above.h. Handle Seal Kit carefully to avoid damaging the lapped seal faces.i. After re-assembly run-in as indicated in the Installation Instructions and Test to ensure theseals are working correctly before refitting to the machine.NOMINAL SIZE 123456789101112131415RETAINER C/T BEARING SCREW ADAPTOR SEAL KIT BODY SCREW SCREW LOCKING RING NILOS RING BEARING KIT STUD NUT LOCKING RING SPINDLE R.S.S.T. B.E.R.E.B. C.B.N.40 (1 ½")18103/318103/2M5 x 0.818103/118102/118101/1S.1151/3S.1151/318104/8M6 x 1.0M5 x 0.818104/418104/5S.1235/017238/4M8 x 1.25 18104/218104/350 (2")15473/115473/3M5 x 0.815473/215472/115471/1S.1171/4S.1151/417238/11M6 x 1.0M4 x 0.717238/517238/12S.1235/117238/4M8 x 1.2517238/717238/865 (2 ½")15476/318133/2M6 x 1.018133/118132/118131/16S.1171/8S.1151/818131/15M6 x 1.0M5 x 0.818131/1018131/11S.1235/518131/6M10 x 1.518131/1318131/1480 (3")15479/315479/2M6 x 1.015479/115478/115477/1S.1171/5S.1151/517263/11M6 x 1.0M5 x 0.817263/517263/16S.1235/217423/1M12 x 1.7517263/717263/890 (3 ½")16173/316173/2M6 x 1.016173/116172/116171/1S.1151/6S.1151/617423/7M5 x 0.8M5 x 0.817423/217155/15S.1235/317423/1M12 x 1.7517423/817423/9100 (4")16176/316176/2M6 x 1.016176/116175/116174/1S.1151/6S.1151/617423/7M5 x 0.8M5 x 0.817423/217155/15S.1235/317423/1M12 x 1.7517423/817426/1125 (5")15488/315488/2M8 x 1.2515488/115487/115486/1S.1151/7S.1151/717635/3M12 x 1.75M12 x 1.7517635/517635/4S.1235/417635/7M16 x 217635/217635/1150 (6")16702/116702/3M8 x 1.2516702/216703/116704/1S.1151/7S.1151/717635/3M12 x 1.75M12 x 1.7517635/517635/4S.1235/417635/7M16 x217635/217637/1445RH LHREB CBNG AS K E T B E L L O W S S /A R U BB I N G RI N G GASKET15WE MANUFACTURE MANY SPECIALS. IF YOU HAVE ANY DOUBT CONTACT USGIVING THE PART No. AND SERIAL No. FROM THE IDENTIFICATION LABEL FITTED.WE MANUFACTURE MANY SPECIALS. IF YOU HAVE ANY DOUBT CONTACT US GIVING THE PART No. AND SERIAL No. FROM THE IDENTIFICATION LABEL FITTED.PLAIN DIA indicates R.H. thread.Note! For the 125 (5") and 150 (6") spacer 16 is screwed into Bearing S/A 19 and locked with screw 18. Compression on the Bellows S/A can be adjusted using these to obtain the correct compression of 6mm.161718192021NOMINAL SIZE SPACER THRUST PAD SCREW BEARING S/A BOLT SPINDLE 18101/1018101/5N/A 18101/12M8 x 1.2518101/840 (1 ½")15325/715325/11N/A 15325/15M8 x 1.2515472/350 (2")18240/618240/2N/A 18240/7M10 x 1.518240/565 (2 ½")15478/715478/10N/A 15478/14M12 x 1.7515478/1380 (3")16172/1216172/7N/A 16172/16M12 x 1.7516172/1090 (3 ½")16172/1216172/7N/A 16172/16M12 x 1.7516175/2100 (4")16702/1316702/9M12 x 1.7516702/16M16 x 2.015487/2125 (5")16702/1316702/9M12 x 1.7516702/16M16 x 2.016702/12150 (6")ROTARY (C.B.N.) UNIONSThe Filton Bellows Seal fitted to the Rotary (C.B.N.) Union is self-adjusting within its working life.The Rotary (C.B.N.) Union has dry carbon journal and thrust bearings operating on hardened surfaces. DO NOT GREASE. We advise periodic inspection for bearing wear.HEALTH & SAFETYThe Rotary Unions shown in this leaflet should not present any hazard when correctly fitted and used. To ensure satisfactory performance, every Rotary Union is run-in and leakage tested before despatch.De-pressurise and drain the system before removing Rotary Unions for repair.It is essential to use the correct hand of rotary connection thread to ensure the Rotary Union will not unscrew (see the Installation Instructions). If a shaft reverses rotation the connection thread should be locked or preferably a flanged connection should be use.At some time the seals in the Rotary Union will leak, so inspect daily. Also, ensure that leakages are not hazardous to personnel and that the Rotary Union is removed for repair immediately. If leakages are not attended to promptly, bearing seizure may occur causing flexible hose failure and massive leakage.Fit protective guards if leakages or the rotating spindle are likely to be hazardous to personnel.For hazardous application fit an excess torque detector to stop the machine before major damage occurs to flexible hoses causing massive leakage.With oil systems minor leakages occur due to the natural characteristics of oil preventing seal faces from contacting fully. Gaskets are now non-asbestos but existing units may have gaskets manufactured from compressed asbestos fibre fitted.These should be handled and disposed of according to the Asbestos Products (Safety) Regulations 1985.HAVE BEEN LEAKAGE TESTED – DISMANTLING INVALIDATES THE WARRANTY.INSTALLATIONRun in before fitting – rotate R.E.B. at 100 r.p.m. for 30 minutes for sizes 40 (1 ½") to 80 (3") and at 50 r.p.m. for 1 hour for other sizes and C.B.N. at half the speed for twice the time. Add system liquid if the seals squeak.(A TORQUE ARRESTOR SHOULD BE FITTED BUT THIS MUST NOT RESTRICT THE NATURAL MOVEMENT OF THE ROTARY UNION)MINIMUM LENGTHS FOR FLEXIBLE HOSENom size 20 ( ¾")25 (1")32/40 (1 ¼ "/1 ½ ")50/65 (2"/2 ½ ")80 (3")100/125/150 (4"/5"/6")Length mm 305380460610760915FILTON HOSE M240/4M240/5M240/ 6 & 7M240/ 8 & 9M240/10M240/ 11,12 & 13ALUMINIUM WASHER S593(PROVIDED WITH CLOCKWISE ROTATIONFITTED WITH A CURVE TO SUIT THE DIRECTION OF ROTATION AS SHOWN (Obtainable from Filton Limited)ELBOW S.1286 Filton Limited)GROOVE INDICATESL.H. THREAD ABUTMENT FACE MUST BE SQUARETYPE ST OR RSANTI CLOCKWISEROTATION DIAMETER INDICATES R.H. THREADCENTRE TUBE FOR TYPE STFIXED TO ROTARY UNIONFOR TYPE RS FIXED TO MACHINE (not supplied by Filton Limited unlessspecified)DO NOT:-1. FIX VALVES etc., directly onto the Rotary Union.2. Connect with Rigid Pipe.3. CLAMP THE ROTARY UNION.L.H.R.H.Caswell RoadSydenham Industrial EstateRoyal Leamington Spa Warwickshire United Kingdom CV31 1QF TEL: +44 1926 423191FAX: +44 1926 450610Email:******************.uk Web: ALL TYPES ARESUPPLIED WITH R.H. OR L.H. SPINDLE THREADS。

联轴器、离合器与制动器名词术语联轴器coupling刚性联轴器rigid couping套筒联轴器sleeve couping凸缘联轴器flange couping夹壳联轴器split couping齿式联轴器gear couping十字滑块联轴器Oldham couping滑块联轴器NZ claw type couping链条联轴器chain couping万向联轴器universal joint双万向联轴器double universal joint十字轴式万向联轴器universal coupling with spider 弹性联轴器resilient shaft couping金属弹性元件联轴器couping with metallic elastic element 簧片联轴器flat spring couping蛇行弹簧联轴器serpentine steel flex couping波纹管联轴器couping with corrugated pipe 牙签式联轴器jaw and toothed couping膜片联轴器diaphragm couping非金属弹性元件联轴器couping with non-metallic elastic element 轮胎式联轴器couping with rubber type element橡胶金属环联轴器couping with rubber-metal ring 橡胶套筒联轴器couping with rubber sleeve橡胶块联轴器couping with rubber pads橡胶板联轴器couping with rubber plates多角形橡胶联轴器couping with polygonal rubber element 弹性套柱销联轴器pin coupling with elastic sleeve 梅花形弹性联轴器coupling with elastic spider弹性柱销联轴器elastic pin coupling弹性柱销齿式联轴器gear coupling with elastic pins离合器clutch超越离合器overrunning clutch离心离合器centrifugal clutch安全离合器safety clutch嵌合式离合器positive clutch摩擦式离合器friction clutch干式离合器dry clutch湿式离合器wet clutch弹性离合器flexible clutch刚性离合器rigid clutch单向离合器one-way clutch双向离合器two-directional clutch常开离合器normally disengaged clutch 常合离合器normally engaged clutch 片式离合器disc clutch牙嵌离合器jaw clutch齿形离合器toothed clutch圆锥离合器cone clutch摩擦块离合器friction block clutch销式离合器pin-type clutch键式离合器key-type clutch涨圈离合器expansion ring clutch扭簧离合器torsional spring clutch闸块离合器brake-shoe clutch闸带离合器brake-band clutch鼓式离合器drum clutch隔膜离合器diaphragm clutch气胎离合器pneumatic tyre clutch滚轴离合器roller clutch楔块离合器sprag clutch棘轮离合器ratchet clutch同步离合器synchro clutch钢球离合器steel ball clutch磁粉离合器magnetic-particle clutch双作用离合器dual clutch调速离合器adjustable-speed clutch制动器brake直接接触式制动器direct contact brake非直接接触式制动器non-friction brake常开制动器normally disengaged brake常闭制动器normally engaged brake单向制动器uni-directional brake双向制动器bi-directional brake干式制动器dry brake湿式制动器wet brake液压制动器hybraulically controlled brake 气压制动器pneumatically controlled brake 电磁制动器electromagnetic brake惯性制动器inertia brake重力制动器gravity brake离心制动器centrifugal brake机械制动器mechanically controlled brake 人力制动器manual brake自锁制动器self-locking brake牙嵌式制动器drum brake带式制动器band brake盘式制动器disk brake圆锥制动器cone brake块式制动器block brake外抱式制动器external-contacting brake内账式制动器internal-expanding brake楔快制动器wedge brake凸轮制动器cam brake推杆制动器pusher brake单蹄制动器one shoe brake双蹄制动器two-shoe brake领蹄制动器leading shoe brake从蹄制动器training shoe brake气胎制动器pneumatic tube brake磁粉制动器magnetic powder brake电磁涡制动器electromagnetic whirlpool brake 水涡制动器water whirlpool brake安全制动器safety沧州天硕联轴器,专业生产各种型号联轴器===The Cangzhou Tianshuo couplings,professional production of various types of couplings。

Enterprise Development专业品质权威Analysis Report企业发展分析报告沧州迈拓斯机床附件制造有限公司免责声明:本报告通过对该企业公开数据进行分析生成,并不完全代表我方对该企业的意见,如有错误请及时联系;本报告出于对企业发展研究目的产生,仅供参考,在任何情况下,使用本报告所引起的一切后果,我方不承担任何责任:本报告不得用于一切商业用途,如需引用或合作,请与我方联系:沧州迈拓斯机床附件制造有限公司1企业发展分析结果1.1 企业发展指数得分企业发展指数得分沧州迈拓斯机床附件制造有限公司综合得分说明:企业发展指数根据企业规模、企业创新、企业风险、企业活力四个维度对企业发展情况进行评价。

该企业的综合评价得分需要您得到该公司授权后,我们将协助您分析给出。

1.2 企业画像类别内容行业空资质增值税一般纳税人产品服务附件、机床防护罩、排屑机、拖链、工作灯、操1.3 发展历程2工商2.1工商信息2.2工商变更2.3股东结构2.4主要人员2.5分支机构2.6对外投资2.7企业年报2.8股权出质2.9动产抵押2.10司法协助2.11清算2.12注销3投融资3.1融资历史3.2投资事件3.3核心团队3.4企业业务4企业信用4.1企业信用4.2行政许可-工商局4.3行政处罚-信用中国4.4行政处罚-工商局4.5税务评级4.6税务处罚4.7经营异常4.8经营异常-工商局4.9采购不良行为4.10产品抽查4.11产品抽查-工商局4.12欠税公告4.13环保处罚4.14被执行人5司法文书5.1法律诉讼(当事人)5.2法律诉讼(相关人)5.3开庭公告5.4被执行人5.5法院公告5.6破产暂无破产数据6企业资质6.1资质许可6.2人员资质6.3产品许可6.4特殊许可7知识产权7.1商标7.2专利7.3软件著作权7.4作品著作权7.5网站备案7.6应用APP7.7微信公众号8招标中标8.1政府招标8.2政府中标8.3央企招标8.4央企中标9标准9.1国家标准9.2行业标准9.3团体标准9.4地方标准10成果奖励10.1国家奖励10.2省部奖励10.3社会奖励10.4科技成果11土地11.1大块土地出让11.2出让公告11.3土地抵押11.4地块公示11.5大企业购地11.6土地出租11.7土地结果11.8土地转让12基金12.1国家自然基金12.2国家自然基金成果12.3国家社科基金13招聘13.1招聘信息感谢阅读:感谢您耐心地阅读这份企业调查分析报告。