高精度 精密数字压力表使用说明

- 格式:pdf

- 大小:314.48 KB

- 文档页数:2

CWY系列精密数字压力表使用说明书CWY系列周密数字压力表使用讲明书陕西创威科技有限公司目录产品概述1技术参数1外表操作面板与按键介绍2软件2校准方法4安装要求5使用与爱护5保管与运输5订货须知与技术服务6一、产品概述CWY周密数字压力表是我公司按照国家最新标准研制生产的高精度智能压力测量外表。

CWY系列数字压力表要紧由压力传感器和信号处理电路组成。

采纳进口的压力传感器,性能优越,具有精度高、抗腐蚀性、抗冲击、抗震动、低温漂、高稳固性等优点;信号处理电路采纳最新的超低功耗处理器、信号处理芯片及电源治理芯片组成。

采纳大容量高性能锂电池供电,无需外部电源供电。

该外表外观精巧、小巧、美观,使用操作简单。

CWY系列周密数字压力表按压力特性可分为:表压、差压和绝压三种。

按压力量程可分为:微压、中低压、高压。

要紧应用于各级计量部门对各种压力(差压)变送器、一般压力表、血压计等其它压力仪器外表进行校验。

二、技术参数1.测量范畴:(-0.1~250)MPa2.输出信号:4~20mA、RS485、0~5V(可选)3.准确度等级:0.05级、0.1级、0.2级、0.4级4.显示方式:5位数字动态显示+模拟光柱指示5.过载压力:1.5~2倍的量程6.关闭电流:<20μA7.供电电源:3.6V高能双节锂电池,寿命2到3年8. 介质温度:(-45~120 )℃9.工作环境:温度:(-20~60)℃;湿度:≤85%RH;校正参比环境:(20±2)℃10.温度补偿范畴:(0~50)℃11.防爆级不:ExiaIICT412. 防护等级:IP6513. 过程接口:M20×1.5(外螺纹),专门的螺纹接口需要定制-1-三、外表操作面板与按键介绍采样状态下的功能:“开关”键:开关机功能键。

当外表不使用时能够关闭,以降低功耗。

用磁笔刷一下此键,2秒内显示该外表量程的起始点和满量程点,外表进入测量状态;再刷一下此键,2秒后外表进入关机状态。

智能数字压力表使用说明书杭州美仪自动化有限公司U-SUP-Y810-MYCN 6第6版杭州美仪自动化有限公司前言●感谢您购买本公司产品。

●本手册是关于产品的各项功能、接线方法、设置方法、操作方法、故障处理方法等的说明书。

●在操作之前请仔细阅读本手册,正确使用本产品,避免由于错误操作造成不必要的损失。

●在您阅读完后,请妥善保管在便于随时取阅的地方,以便操作时参照。

注意●本手册内容如因功能升级等有修改时,恕不通知。

●本手册内容我们力求正确无误,如果您发现有误,请与我们联系。

●本手册内容严禁转载、复制。

●本产品禁止使用在防爆场合。

版本U-SUP-Y810-MYCN6第六版2020年12月确认包装内容打开包装箱后,开始操作之前请先确认包装内容。

如发现型号和数量有误或者外观上有物理损坏时,请与本公司联系。

产品清单使用注意事项●在不需要使用背光的情况下,请关闭背光,以延长电池使用时间。

●长期不使用产品的情况下,请取出电池。

目录第一章产品概述 (1)第二章主要特点 (2)第三章技术参数 (3)第四章显示与按键功能概述 (5)4.1显示界面 (5)4.2压力表校准 (8)4.3按键功能说明 (8)第五章尺寸结构与安装 (10)第六章代码说明 (11)第七章注意事项 (12)第八章质保及售后服务 (13)第一章产品概述第一章产品概述高精度数字压力表,内置高精度压力传感器,能够准确的实时显示压力,并且具有精度高,长期稳定性好的特点。

本产品配备段式液晶显示屏,具有清零、背光、开关机、单位切换多项功能,操作简单,安装方便。

本产品采用优质304不锈钢壳体和接头,抗震性好,能够测量气体、水、油等对不锈钢无腐蚀的介质。

本产品适合于便携式压力测量、设备配套、校验设备等压力测量应用。

第二章主要特点第二章主要特点●一键清零,使用方便。

●优质304不锈钢壳体和接头,抗震耐用。

●多种测量单位,一键切换,使用更省心。

●具有温度补偿,温漂系数小,测量更精准。

N70/N80/N90智能数字压力表使用说明书一、概述(一)功能介绍:N70/N80/N90型智能数字压力表是我公司最新开发的新产品,融汇了多项国际上先进的电子技术、单片计算机技术、电擦除技术、抗干扰技术等,从而保证了仪表具有测控精度高,抗干扰性能强等优点。

整机选用96×96×100(N70)/48×96×100(N80)/ 96×48×100(N90)外壳,具有整机体积小、重量轻、耗电省、功能齐全、工作可靠、使用方便灵活,配用我公司PT100-系列高温熔体压力传感器或PT200-系列常温压力传感器,作为高精度压力测量与控制,可广泛地使用于液压、石油、塑料、橡胶、印染、纺织等行业的压力显示和自动化控制场合,还可与其他厂家的电阻应变式压力传感器配套使用;可以设定上下限值报警,具有发光管报警指示、继电器触点输出控制外部执行机构;具有高精度的电压输出模块、电流输出模块、继电器输出控制模块以及通讯模块供用户选择;本机采用人性化的操作方法,操作简单易学。

(二)主要技术指标及性能:⑴.显示器双层四位高亮度绿色和红色发光数码管⑵.显示分辨率0001⑶.显示数值范围0001-9999 Mpa(小数点可变)⑷.仪表精度0.2%FS ±1位⑸.指示灯显示效准指示灯、FUNC输出指示灯、AL1,AL2报警指示灯⑹.输入信号2/3.3 mV/V 0-20mA/4-20mA/0-5V/0-10V(定货时说明)⑺.采样速度 4 次/ 秒⑻.供电+9V 高精度直流电源(配压力传感器)/24V电源(配变送器)⑼.输出控制与满量程信号成线性的电压或电流输出⑽.主报警输出上限报警具有继电器输出(220V 1A)上限报警指示灯(OUT)亮⑾.辅助输出辅助输出可通过配以不同的功能模块并通过仪表设定来达到不同的输出要求。

⑿.报警范围0001-9999 MPa (小数点可变)⒀.效准指示显示传感器满量程80%值(传感器应空载),效准指示灯(CAE)亮⒁.使用温度及湿度 0-55 ℃ ,≤ 80% RH ⒂.电源要求 85-265 V AC 50Hz - 60Hz⒃.外型尺寸 96×96×100mm/96×48×100 mm 48×96×100mm ⒄.开孔尺寸 92×92mm /92×46mm /46×92mm ⒅.自身重量约 400克/200克//200克(三)模块功能说明N70N80/N90智能数字压力表有2个功能模块插座,通过安装不同的模块可以实现不同的功能及类型输出。

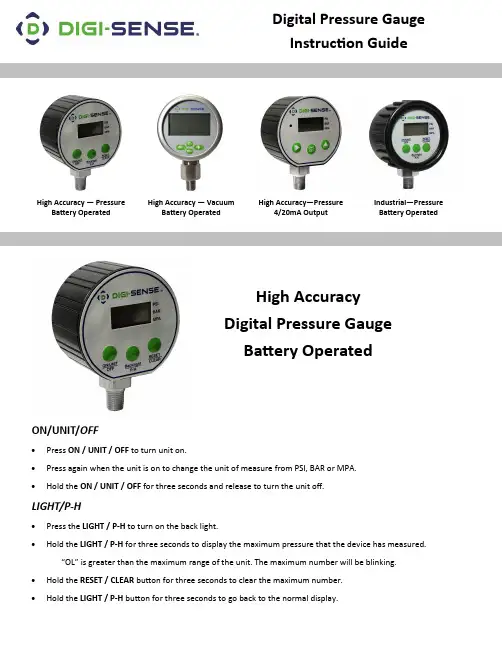

Digital Pressure GaugeInstruction GuideHigh Accuracy — PressureBattery OperatedHigh Accuracy — VacuumBattery OperatedHigh Accuracy—Pressure4/20mA OutputIndustrial—PressureBattery OperatedON/UNIT/OFF∙ Press ON / UNIT / OFF to turn unit on.∙ Press again when the unit is on to change the unit of measure from PSI, BAR or MPA.∙ Hold the ON / UNIT / OFF for three seconds and release to turn the unit off.LIGHT/P-H∙ Press the LIGHT / P-H to turn on the back light.∙ Hold the LIGHT / P-H for three seconds to display the maximum pressure that the device has measured.“OL” is greater than the maximum range of the unit. The maximum number will be blinking.∙ Hold the RESET / CLEAR button for three seconds to clear the maximum number.∙ Hold the LIGHT / P-H button for three seconds to go back to the normal display.High AccuracyDigital Pressure GaugeBattery OperatedRESET/CLEAR∙ In a normal function if you press the RESET/CLEAR the display will not change.∙If you hold the RESET/CLEAR for three seconds it will reference the gauge to whatever pressure is currently ap-plied to the unit.For example; if you have 20psi on the display and you hold down RESET/CLEAR then the display will show0.0 and a measurement of 30psi would then read as 10psi on the display.∙Hold RESET/CLEAR for three seconds to reset unit to original setting. Unit must be disconnected or have an input of 0psi.ON/OFF∙Short press to power on, long press to power off.UNIT CHANGE∙Short press to switch units.(Different pressure ranges have different units available )ZERO CLEARING∙Without pressure, long press ‘ZERO’ button for 4 seconds to zero clearing.BACK -LIGHT∙Short press back -light button, back -light on for 20 seconds. Long press back -light button for 3 seconds, the back -light will keep on.ADJUST OF FILTER CONSTANT∙Short press ‘back -light’and ‘ZERO’ buttons together, it shows ‘r -03', and means the filter constant is 03. Then change the value through pressing ‘ZERO’ button, the value is between 01~10. After setting, press back -light button to save and quit.High Accuracy Digital Vacuum Gauge Battery OperatedBUTTON GUIDE:∙ Change pressure reading units by pressing the UNIT/SET button until the arrow point to the units of preference. ∙ Check low pressure setting by pressing and releasing the → button (Displayed for 30 seconds) ∙ Check high pressure setting by pressing and releasing the ↑ button. (Displayed for 30 seconds) ∙ See maximum peak pressure by pressing and holding the → button for 3 seconds (Display will blink) ∙ Reset maximum peak pressure by pressing and holding the ↑ button for 3 seconds.∙ Return to pressure measurement mode by holding the → button for 3 seconds (Display will not blink)∙Reference the MG -MD to the input port by pressing and holding both the → button and the ↑ button simultane-ously for 3 seconds∙Reset the MG -MD reference by either disconnecting the input port or attaching a 0 psi input then press and hold down the → button and the ↑ button simultaneously for 3 SecondsPROGRAMMING THE HIGH AND LOW PRESSURE SET POINTS:1. Enter Programmable Set Point Mode by pressing and holding the UNIT/SET button for 3 seconds. The screenshows ↑ on the top, left hand side indicating high pressure setting, and the first digit will be flashing. 2. Set the first digit value by pressing the ↑ Button (select from 0 to 9). Then press the → Button, which shifts to thesecond digit. Again use the ↑ Button to select 0 thru 9 followed by the → Button to complete the third and forth digits. 3. After all 4 digits of the high pressure settings are done press the → Button one more time, the screen will show ↓on the top, left hand side indicating low pressure setting. Repeat step 2 above to set the 4 digits of the low pres-sure settings. 4. After all 4 digits of the low pressure settings are done press the → Button one more time, the screen will show“Load”, indicating your pressure settings have been saved into memory. 5. To make sure that the settings are correct, you can press the → Button to check the value of the low pressuresetting and press the ↑ Button to check the value of the high pressure setting.High Accuracy Digital Pressure Gauge 4/20mA OutputON/UNIT/OFF∙ Press ON / UNIT / OFF to turn unit on.∙ Press again when the unit is on to change the unit of measure from PSI, BAR or MPA. ∙Hold the ON / UNIT / OFF for three seconds and release to turn the unit off.LIGHT/P -H∙ Press the LIGHT / P -H to turn on the back light.∙Hold the LIGHT / P -H for three seconds to display the maximum pressure that the device has measured.“OL” is greater than the maximum range of the unit. The maximum number will be blinking. ∙ Hold the RESET / CLEAR button for three seconds to clear the maximum number. ∙Hold the LIGHT / P -H button for three seconds to go back to the normal display.Wiring Instructions:∙Power to the unit: There is no ON/OFF button on the MediaGauge™ MG -MD model. The MG -MD unit is powered on and off via the external 12V supply voltage source. ∙ Electrical Interface: (MG -MD harness connections) ∙ White wire: Power Lead for supply input (12 Vdc) ∙ Black wire: Return Lead∙ Brown wire: Limit Switch output (NPN Transistor output)∙ Blue Wire: 4-20 mA output for meter. (Must be loop grounded with black wire)∙Note: The 4-20mA (Blue Wire) must be connected directly to ground when not being used for monitoring pur-poses.IndustrialDigital Pressure Gauge Battery OperatedRESET/CLEAR∙ In a normal function if you press the RESET/CLEAR the display will not change.∙If you hold the RESET/CLEAR for three seconds it will reference the gauge to whatever pressure is currently ap-plied to the unit.For example; if you have 20psi on the display and you hold down RESET/CLEAR then the display willshow 0.0 and a measurement of 30psi would then read as 10psi on the display.∙Hold RESET/CLEAR for three seconds to reset unit to original setting. Unit must be disconnected or have an input of 0psi.Part Number Guide。

精密数显数字压力表安全操作及保养规程1. 引言精密数显数字压力表是一种常见的用于测量液体或气体压力的仪器。

为了确保其正常工作并延长使用寿命,正确的操作和定期的保养是至关重要的。

本文将介绍精密数显数字压力表的安全操作及保养规程。

2. 安全操作规程在操作精密数显数字压力表时,必须遵循以下安全操作规程:2.1. 操作前准备在进行任何压力测量之前,请确保以下操作准备工作已完成: -检查压力表的电源线是否连接稳固; - 检查压力表的显示屏是否正常;- 清理工作区域,确保没有干扰或阻碍操作的物体。

2.2. 压力测量遵循以下步骤进行压力测量: 1. 打开压力表的电源开关; 2. 使用正确的接头将压力表与被测压力介质连接; 3. 轻轻打开被测介质流动的阀门,使压力逐渐升高; 4. 等待压力稳定并读取压力值; 5. 关闭阀门,将压力缓慢释放,确保压力降至零; 6. 关闭压力表的电源开关。

2.3. 注意事项在操作精密数显数字压力表时,请注意以下事项: - 不要超过压力表的额定压力范围; - 不要在压力表上施加冲击或振动; - 避免接触液体或腐蚀性气体; - 不要将压力表暴露在高温、高湿度或腐蚀性环境中;3. 保养规程定期的保养可以保证精密数显数字压力表的准确性和可靠性。

以下是保养规程的建议:3.1. 清洁定期清洁压力表的外壳和显示屏,可使用柔软的布料轻轻擦拭。

避免使用化学溶剂或腐蚀性清洁剂。

3.2. 校准根据需要,对精密数显数字压力表进行校准。

校准可以保证压力表的精确度。

建议每年至少进行一次校准。

校准过程应当由经验丰富的技术人员完成。

3.3. 存储在长时间不使用压力表时,应妥善存放。

建议将压力表放置在干燥、通风良好且温度适宜的地方。

避免暴露在阳光下或高温环境中。

3.4. 保护保护精密数显数字压力表免受外部冲击或振动。

使用压力表时,请确保工作环境安全,并避免碰撞或摔落。

3.5. 定期检查定期检查精密数显数字压力表的电源线、连接管路和阀门等部件。

KTE-100型精密数字压力表操作说明无锡康特尔仪表科技有限公司一、产品概述KTE-100型精密数字压力表主要由外壳、压力传感器和信号处理电路及显示系统组成,采用高品质压力传感器芯,具有精度高、抗腐蚀性、抗冲击、抗震动、温漂小、稳定性好等优点;使用低功耗微处理器,无需外部供电。

数字压力表按压力特性可分为:表压、差压和绝压三种。

按压力量程可分为:微压、低压、中压、高压。

按温度可分为:常温、中温、高温。

该产品融汇了目前多项国际流行的先进电子技术、传感技术、单片计算机技术、抗干扰技术等,从而保证了产品具有测控精度高、抗干扰性能强、防护性能优越、操作简洁、适用范围宽、在线单位转换等优点。

二、应用范围产品整机选用不锈钢外壳,整机体积小、重量轻、功能齐全、超低功耗,且工作可靠、使用方便灵活。

十分适合用作高精度压力测量,通过专用接口也作为工业控制前端。

因此,该产品可广泛地使用于液压、石油、塑料、橡胶、印染、纺织等工业行业的压力调节和自动化控制场合是指针式精密压力表的更新换代产品。

三、技术参数1.测量范围:(-0.1~7~60)MPa【单位:Pa Kpa Mpa bar psi可选】2.仪表精度:0.2%/FS、0.4%/FS、0.5%/FS3.显示方式:6位数字动态显示4.过载压力:1.5倍5.供电电源:2节5号电池(0.2级3.6V锂电池)6.介质温度:(-20~80)℃7.工作环境温度:(-10~60)℃;8.工作环境湿度:≤80%RH;9.接口:G1/41/4NTP M20*1.5G1/2螺纹接口可选四、仪表操作功能1.开关机:长按“开/关”键(见图:左边按键)≥2秒,开机或关机。

2.清零:当仪表没有压力的情况下,出现零漂,可短按“清零”键(见图:右边按键),即可清零。

3.满量程查询与单位切换:长按“清零”键(见图:右边按键)≥2秒,可看到最大满量程;此页短按“开关”键,切换压力单位,长按“设置”键(见图:中间按键)≥2秒,保存选择好的压力单位。

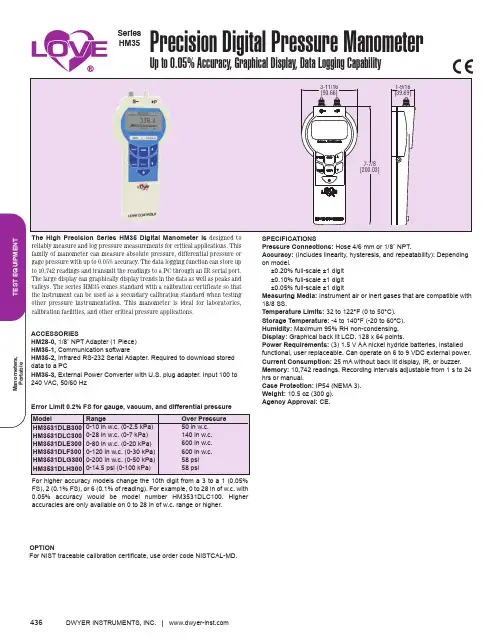

DWYER INSTRUMENTS, INC.| 436The High Precision Series HM35 Digital Manometer is designed to reliably measure and log pressure measurements for critical applications. This family of manometer can measure absolute pressure, differential pressure or gage pressure with up to 0.05% accuracy. The data logging function can store up to 10,742 readings and transmit the readings to a PC through an IR serial port.The large display can graphically display trends in the data as well as peaks and valleys. The series HM35 comes standard with a calibration certificate so that the instrument can be used as a secondary calibration standard when testing other pressure instrumentation. This manometer is ideal for laboratories,calibration facilities, and other critical pressure applications.Series HM35Precision Digital Pressure ManometerUp to 0.05% Accuracy, Graphical Display, Data Logging CapabilitySPECIFICATIONSPressure Connections: Hose 4/6 mm or 1/8˝ NPT.Accuracy: (Includes linearity, hysteresis, and repeatability):Depending on model.±0.20% full-scale ±1 digit ±0.10% full-scale ±1 digit ±0.05% full-scale ±1 digitMeasuring Media: Instrument air or inert gases that are compatible with 18/8 SS.Temperature Limits: 32 to 122°F (0 to 50°C).Storage Temperature: -4 to 140°F (-20 to 60°C).Humidity: Maximum 95% RH non-condensing.Display: Graphical back lit LCD. 128 x 64 points.Power Requirements: (3) 1.5 V AA nickel hydride batteries, installed functional, user replaceable. Can operate on 6 to 9 VDC external power.Current Consumption: 25 mA without back lit display, IR, or buzzer.Memory: 10,742 readings. Recording intervals adjustable from 1 s to 24hrs or manual.Case Protection:IP54 (NEMA 3).Weight:10.5 oz (300 g).Agency Approval:CE.Error Limit 0.2% FS for gauge, vacuum, and differential pressure OPTIONFor NIST traceable calibration certificate, use order code NISTCAL-MD.ACCESSORIESHM28-0,1/8˝ NPT Adapter (1 Piece)HM35-1,Communication softwareHM35-2,Infrared RS-232 Serial Adapter. Required to download stored data to a PCHM35-3,External Power Converter with U.S. plug adapter. Input 100 to 240 VAC, 50/60 HzFor higher accuracy models change the 10th digit from a 3 to a 1 (0.05%FS), 2 (0.1% FS), or 6 (0.1% of reading). For example, 0 to 28 in of w.c. with 0.05% accuracy would be model number HM3531DLC100.Higher accuracies are only available on 0 to 28 in of w.c. range or higher.。

智能数字压力显示仪表上海朝辉压力仪器有限公司N70 / N80 / N90 使用 说 明书N70/N80/N90智能数字压力表使用说明书一、概述(一) 功能介绍:N70/N80/N90型智能数字压力表是我公司最新开发的新产品,融汇了多项国际上先进的电子技术、单片计算机技术、电擦除技术、抗干扰技术等,从而保证了仪表具有测控精度高,抗干扰性能强等优点。

整机选用96×96×100(N70)/48×96×100(N80)/ 96×48×100(N90)外壳,具有整机体积小、重量轻、耗电省、功能齐全、工作可靠、使用方便灵活,配用我公司PT100-系列高温熔体压力传感器或PT200-系列常温压力传感器,作为高精度压力测量与控制,可广泛地使用于液压、石油、塑料、橡胶、印染、纺织等行业的压力显示和自动化控制场合,还可与其他厂家的电阻应变式压力传感器配套使用;可以设定上下限值报警,具有发光管报警指示、继电器触点输出控制外部执行机构;具有高精度的电压输出模块、电流输出模块、继电器输出控制模块以及通讯模块供用户选择;本机采用人性化的操作方法,操作简单易学。

(二)主要技术指标及性能:⑴.显示器 双层四位高亮度绿色和红色发光数码管 ⑵.显示分辨率 0001⑶.显示数值范围 0001-9999 Mpa (小数点可变) ⑷.仪表精度 0.2%FS ± 1位⑸.指示灯显示 效准指示灯、FUNC 输出指示灯、AL1,AL2报警指示灯 ⑹.输入信号 2/3.3 mV/V 0-20mA/4-20mA/0-5V/0-10V (定货时说明) ⑺.采样速度 4 次/ 秒⑻.供电 +9V 高精度直流电源(配压力传感器)/24V 电源(配变送器) ⑼.输出控制 与满量程信号成线性的电压或电流输出⑽.主报警输出 上限报警具有继电器输出(220V 1A )上限报警指示灯(OUT)亮 ⑾. 辅助输出 辅助输出可通过配以不同的功能模块并通过仪表设定来达到不同的输出要求。

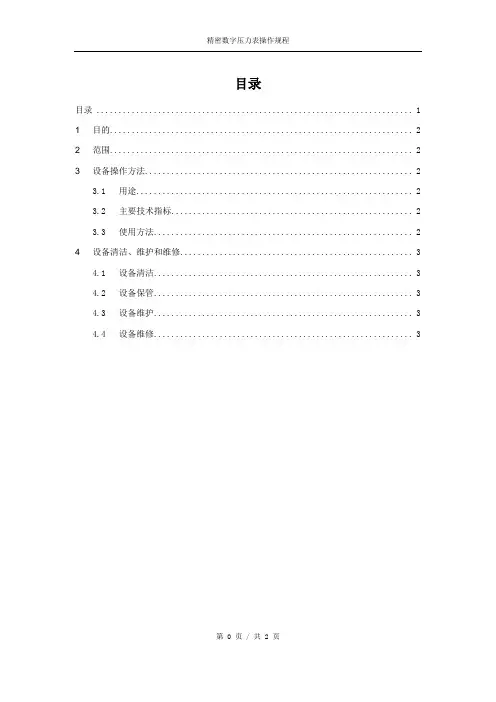

目录目录 (1)1目的 (2)2范围 (2)3设备操作方法 (2)3.1用途 (2)3.2主要技术指标 (2)3.3使用方法 (2)4设备清洁、维护和维修 (3)4.1设备清洁 (3)4.2设备保管 (3)4.3设备维护 (3)4.4设备维修 (3)第 0 页 / 共 2 页1 目的规定了2000A4型精密数字压力表的操作和保养。

2 范围各相关使用部门负责仪器的保养、点检、使用和保管。

3 设备操作方法3.1用途用于普通压力表、压力变送器的校验和检定,也可作为压力基准在实验室及压力仪器生产过程中使用。

3.2主要技术指标1)压力测量范围有:-100~0kPa;0~160kPa;0~600kPa;0~1Mpa;0~1.6Mpa;0~6Mpa;0~10Mpa;0~16Mpa;0~40Mpa;0~60Mpa等。

2)压力测量准确度等级有:0.05%F*S±3个字;0.1%F*S±3个字;0.2%F*S±3个字。

3)正常工作条件A.温度:5~40℃B.湿度:<80%RHC.电源电压:直流4.8~5.6VD.通电预热时间:30minE.参比工作条件。

温度:20±2℃;湿度:<70%RH3.3使用方法1)开机:按下“开关”按钮直至电源通,LCD闪烁显示仪表量程。

2)关机:按“开关”按钮,直至LCD显示“OFF”后熄灭。

3)清零:在压力为零时按“清零”按钮,显示熄灭时松开,显示“00000”;再次按下清零键,则显示非零状态。

4)按下“单位”按钮,显示熄灭时松开,显示单位可自动变换,变换次序为MPa,Psi或Bar。

5)为确保计量准确性,请开机预热10分钟后使用6)使用附带充电器(7.1V充电器)充电,充电灯有红变绿后说明充电完成。

7)电池指示:电源指示符号说明电池的电量状态,当符号显示为空符号时应进行充电。

否则测量将产生误差。

4 设备清洁、维护和维修4.1设备清洁使用干毛巾擦拭设备表面浮尘。

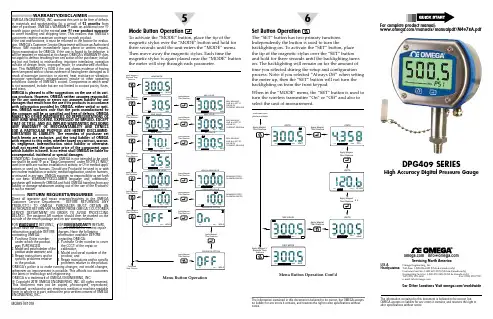

Mode Button OperationTo activate the “MODE” button, place the tip of the magnetic stylus over the “MODE” button and hold for three seconds until the unit enters the “MODE” menu. Then move away the magnetic stylus. Each time themagnetic stylus is again placed near the “MODE” button the meter will step through each parameter.Menu Button OperationWGS/START HERE ARRO 5WGS/START HERE ARRO6DPG409 SERIESHigh Accuracy Digital Pressure Gauge/manuals/manualpdf/M4978A.pdfApply Magnet 3 MIN, MAX AND AVG ALL SET TO VALUE OFCURRENT READINGMIN, MAX AND AVG ALL SET TO VALUE OFCURRENT READINGMIN, MAX AND AVG ALL SET TO VALUE OFCURRENT READINGBLINKING STOPS ALARM SILENCEDBLINKING STOPS ALARM SILENCEDSet Button OperationThe “SET” button has two primary functions. Independently the button is used to turn thebacklighting on. To activate the “SET” button, place the tip of the magnetic stylus over the “SET” button and hold for three seconds until the backlighting turns on. The backlighting will remain on for the amount of time you selected during the setup and configuration process. Note: if you selected “Always Off” when setting the meter up, then the “SET” button will not turn the backlighting on from the front keypad.When in the “MODE” menu, the “SET” button is used to turn the wireless transmitter “On” or “Off” and also to select the unit of measurement.Menu Button Operation Cont'dContinued from previous columnWARRANTY/DISCLAIMEROMEGA ENGINEERING, INC. warrants this unit to be free of defects in materials and workmanship for a period of 13 months from date of purchase. OMEGA’s WARRANTY adds an additional one (1) month grace period to the normal one (1) year product warranty to cover handling and shipping time. T his ensures that OMEGA’s customers receive maximum coverage on each product.If the unit malfunctions, it must be returned to the factory for evalua-tion. OMEGA’s Customer Service Department will issue an Authorized Return (AR) number immediately upon phone or written request. Upon examination by OMEGA, if the unit is found to be defective, it will be repaired or replaced at no charge. OMEGA’s WARRANTY does not apply to defects resulting from any action of the purchaser, includ-ing but not limited to mishandling, improper interfacing, operation outside of design limits, improper repair, or unauthorized modifica-tion. This WARRANTY is VOID if the unit shows evidence of having been tampered with or shows evidence of having been damaged as a result of excessive corrosion; or current, heat, moisture or vibration; improper specification; misapplication; misuse or other operating conditions outside of OMEGA’s control. Components in which wear is not warranted, include but are not limited to contact points, fuses, and triacs.OMEGA is pleased to offer suggestions on the use of its vari-ous products. However, OMEGA neither assumes responsibil-ity for any omissions or errors nor assumes liability for any damages that result from the use if its products in accordance with information provided by OMEGA, either verbal or writ-ten. OMEGA warrants only that the parts manufactured by the company will be as specified and free of defects. OMEGA MAKES NO OTHER WARRANTIES OR REPRESENTATIONS OF ANY KIND WHATSOEVER, EXPRESSED OR IMPLIED, EXCEPT THAT OF TITLE, AND ALL IMPLIED WARRANTIES INCLUDING ANY W ARRANTY OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE HEREBY DISCLAIMED. LIMITATION OF LIABILITY: The remedies of purchaser set forth herein are exclusive, and the total liability of OMEGA with respect to this order, whether based on contract, warran-ty, negligence, indemnification, strict liability or otherwise, shall not exceed the purchase price of the component upon which liability is based. In no event shall OMEGA be liable for consequential, incidental or special damages.CONDITIONS: Equipment sold by OMEGA is not intended to be used, nor shall it be used: (1) as a “Basic Component” under 10 CFR 21 (NRC), used in or with any nuclear installation or activity; or (2) in medical appli-cations or used on humans. Should any Product(s) be used in or with any nuclear installation or activity, medical application, used on humans, or misused in any way, OMEGA assumes no responsibility as set forth in our basic WARRANT Y/DISCLAIMER language, and, additionally, purchaser will indemnify OMEGA and hold OMEGA harmless from any liability or damage whatsoever arising out of the use of the Product(s) in such a manner.RETURN REQUESTS/INQUIRIESDirect all warranty and repair requests/inquiries to the OMEGA Customer Service Department. BEFORE RE URNING ANY PRODUC (S) O OMEGA, PURCHASER MUS OB AIN AN AUTHORIZED RETURN (AR) NUMBER FROM OMEGA’S CUSTOMER SERVICE DEPART MENT (IN ORDER T O AVOID PROCESSING DELAYS). T he assigned AR number should then be marked on the outside of the return package and on any correspondence.FOR WARRANTY RETURNS, please have the followinginformation available BEFORE contacting OMEGA:1. Purchase Order number under which the product was PURCHASED,2. Model and serial number of the product under warranty, and3. Repair instructions and/or specific problems relative to the product.FOR NON-WARRANTY REPAIRS, consult OMEGA for current repair charges. Have the following information available BEFORE contacting OMEGA:1. P urchase Order number to cover the COST of the repair or calibration,2. Model and serial number of the product, and3. R epair instructions and/or specific problems relative to the product.OMEGA’s policy is to make running changes, not model changes, whenever an improvement is possible. This affords our customers the latest in technology and engineering.OMEGA is a trademark of OMEGA ENGINEERING, INC.© Copyright 2018 OMEGA ENGINEERING, INC. All rights reserved. T his document may not be copied, photocopied, reproduced, translated, or reduced to any electronic medium or machine-readable form, in whole or in part, without the prior written consent of OMEGA ENGINEERING, INC.MQS4978/1018***********************The information contained in this document is believed to be correct, but OMEGA accepts no liability for any errors it contains, and reserves the right to alter specifications without notice.Servicing North America:U.S.A. Omega Engineering, Inc.Headquarters: Toll-Free: 1-800-826-6342 (USA & Canada only)Customer Service: 1-800-622-2378 (USA & Canada only) Engineering Service: 1-800-872-9436 (USA & Canada only) Tel: (203) 359-1660 Fax: (203) 359-7700 e-mail:**************For Other Locations Visit /worldwidedamage to your unit when the meter is exposed to wet conditions. When reinstalling enclosure screws they must be tightened to 9 in-lb +/- 10%.Switching On Your DPG409 MeterBefore you connect your USB cable to the USBprogramming connector on the DPG409, you will need to switch on the unit.Setting Up Your MeterConnect the USB Programming cable included with your unit to your PC and your meter.USB Connector LocationNow that you have connected your USB cable to your PC and to your meter, you can now configure yourmeter before placing the unit into operation. You will be using the configuration software utility that you installed onto your PC. If you have not installed the configuration software utility you should do so now.Configuring your MeterThe Omega Digital Gauge Configuration Wizard will open once you have launched the DG Configuration Wizard software. Follow the step-by-step instructions given to you by the Configuration Wizard. Step 5 - Choose Options: Select the type of analog output your application requires. You can leave the default setting if of your meter to match the analog output type you selected here in the setup process.WGS/START HERE ARROWGS/START HERE ARRO 2WGS/START HERE ARRO34Using This Quick Start ManualUse this Quick Start Manual with your DPG409 Series high accuracy digital pressure gauge for quick installation and basic operation. For detailed information, refer to the User’s Guide available at https:///manuals/manualpdf/M4978A.pdf.General DescriptionOmega’s DPG409 Series Digital Pressure Gaugesincorporate rugged, 316 Stainless Steel enclosures that are designed specifically for wash-down,sanitary and marine applications. The large backlit LCD display features 1" high digits that make reading at distances up to 35 feet easy. Models are available with integral standard or sanitary pressure sensors that incorporate highly stable silicon wafer technology which is micro-machined to precision tolerances and then has strain gauges molecularly embedded.The DPG409 is NEMA 4X rate (water tight, dust tight, corrosion – resistance - indoor & outdoor use). The pressure gauge can be installed inlocations where it will be intermittently exposed to spraying water, rain or high humidity. The meter should never be used under water.Software InstallationDownload the Configuration Wizard software from ftp:///public/DASGroup/products/dpg409/. To install run the setup.exe application. The installer will guide you through the steps required to install the DG Configuration Wizard on your computer.Lid/Cover RemovalTo switch on your unit and access the USB programming connector on your meter, theenclosure lid/cover must be removed. Four screws must be removed. Be careful to not lose or discard these screws. These screws play a vital part inproviding the water tight seal on your unit.Lid/Cover RemovalWiring (Power, Analog Output)Wiring - Power SupplyWiring - Analog OutputFor alarm wiring information refer to the User's Guide, Page 4-4, Figure 4-5.Keypad Operation Magnetic StylusA magnetic stylus is attached to your meter. This stylus is used to activate the front buttons on the display. If you do not need to view the “MIN”, “MAX” or “AVERAGE” readings during normal operation, or have a need to turn the backlight on during normal operation you can remove and store this stylus. You will need to select “Disable Keypad” during the setup and configuration process.The “MODE” and “SET” buttons located on the front of the display of your meter areactivated by waving or tapping the magnetic stylus included with your unit above or onto the keypad button symbol on the front meter label.REMOVE THESE FOUR SCREWSIN ORDER TO REMOVE THE METER FRONT COVERAnalog Output OptionsInstallationMountingFor mounting dimensions refer to the User’s Guide, Page 4-1, Figure 4-1.Ambient TemperatureYour meter should only be installed in locations that maintain an ambient temperature between -18 to 66°C (0 to 150°F).Battery Installation/ReplacementTo install or replace the battery in your DPG409pressure gauge you must first remove the four screws located on the Lid of the enclosure. This will allow you to remove the meter assembly and access the battery operation (Battery 1). A second battery (Battery 2) can be added to extend operation when on battery power. It is also recommended that the additional battery (Battery 2) be installed for models that include the optional wireless transmitter.Battery PlacementTB1CHART RECORDER+–45PIN 1。

背光超高精度数字压力表不锈钢接液部件和壳体快速交付一般只需2周!标配模拟输出,可选配无线变送器标准一体式压力传感器。

磁针(随附)。

NEMA 4X 等级外壳。

DPG409-500G , 图片小于实际尺寸。

规格CE 合规性: 当使用3 m (98')的模拟输出电缆和随附的铁氧体磁心时,符合EN1326-1:2006关于工业场所的规定精度(综合线性度、滞后性和重复性) : ±0.08% BSL (复合压仅可正向校准)温度:储存温度: -40 ~ 82°C (-40 ~180°F) 工作温度: -18 ~ 66°C (0 ~ 150°F)热效应(在工作范围内) : 零点平衡: 范围 >5 psi: 量程的±0.3% 范围 ≤5 psi: 量程的±0.5% 量程设置: 范围 >5 psi: 量程的±0.3% 范围 ≤5 psi: 量程的±0.5%传感器壳体与任何电缆之间的最小电阻: 100M Ω @ 50 Vdc 压力循环: 至少100万次长期稳定性(1 年): 通常为满量程的±0.1% 模拟输出: 用户可选0 ~ 5 Vdc 、 0 ~ 10 Vdc 或4 ~ 20 mA (需要外部24 Vdc 电源)注: 复合压力范围具有等于其满量程的单向模拟输出,即-15 ~ +15 psi = 0 ~ 10 Vdc 。

设置跳线可选择电流或电压 软件选择 0 ~ 5 Vdc 、0 ~ 10 Vdc 或4 ~ 20 mA模拟输出 电缆: 2.7 m (8.9'),带铁氧体磁心精度: 通常为0.08%(10V/m 射频场中最大0.15%)过压力: 表压和密封压10 inH 2O: 10倍量程1 psi: 6倍量程2.5 ~ 3500 psi:4倍量程 5000 psi:最大15,000 psi绝对压力/大气压范围 5 psia: 6倍量程,范围 >5 psia , 4倍量程 5000 psi 范围: 达15,000 psia 围阻压力: 表压 10 inH 2O ~ 5 psi: 达1000 psi 15 ~ 1000 psi: 达3000 psi 1500 ~ 5000 psi: 达15,000 psi绝对压力/大气压:5 ~ 1000 psi :达6000 psia显示屏: 4位数字LCD ,用户可选背光, (9999计数)25 mm (1")字符高度计算机接口: 用于设置的USB 连接, 含电缆采样/显示范围: 用户可选0.38 ~ 30 sec (预设为1/sec )电源: 含一节3.6V 8.4 Ah 锂电池 (C 电池)(对于无线选件, 则提供两枚)(备用电池零件号 BA TT -C-3.6V ) 电池寿命(常规): 可达4年 外壳: 材质: 316不锈钢和ABS 中心垫圈 表面处理: 电镀 环境等级:防水,NEMA 4X (IP65)传感器接液部件: 316L 不锈钢压力连接口: 1⁄4-18 NPT 外螺纹连接位置: 下部外形尺寸: 显示屏: 115(高) x 89(宽) x 74 mm (厚)(4.5 x 3.5 x 2.9") 传感器: 显示屏下方 72 ~ 89 mm 长 (2.8 x 3.5")重量: 900 g (2 lb)典型,取决于配置前面板功能背光: 手动开/关背光最小/最大值: 调用最小/最大值归零/清除: 归零显示或清除最小/ 最大值软件设置(通过USB )更新速率: 4个选项:每秒10、 5、 2或1次单位: psi 、inHg 、inH 2O 、bar 、mbar 、hPa 锁定: 允许锁定前面板功能报警: 用户可选“上限”和“下限”报警限值 (开路集电极)背光: 开/关、10 sec 、30 sec 、 1 min 、5 min无线变送器(可选): 通道编号、 传输速度、报警、传感器偏移、 图表记录、数据记录校准: 归零和量程 超出范围指示: “_ _ _ _”无线选件规格传输采样率: 用户可编程:从1个采样/2分到1个采样/2 秒 射频(RF)收发器 载波: ISM 2.4 GHz射频输出: 10 dBm (10 mW)射频链路范围: 室外(视线内): 最远120 m (400')室内/市区: 最远40 m (130') 随附的软件: 需要Windows ® 7(32位);XP 或Vista传输到主机的数据: 压力读数、环境温度读数、射频传输强度及电池电量水平新的安全功能使用磁针(内含) 激活键盘。

CWY122 Precision Pressure Gauge Instruction Manual陕西创威科技有限公司Shaanxi Creat Wit Technology Co., LtdInstruction manual-CWY122 Content1Product Selection (1)2Specification (7)3Notes (9)4Button Description (9)5Basic Functions (10)5.1 S TARTUP/S HUTDOWN (10)5.2 P RESSURE M EASUREMENT (10)5.3 P RESSURE C LEARANCE (11)5.4 UNIT CONVERSION (11)5.5 D OUBLE-R ANGE S WITCH (12)5.6 B ACKLIGHT (12)5.7 B ASIC P ARAMETER D ISPLAY (12)6Usage as External Module of CWY Series Automatic Pressure Calibrator (13)7Use Softare TMMS-2000 to do calibration (13)8Pressure Sensor Calibration (14)8.1 CALIBRATION CONDITIONS (14)8.2 S TART C ALIBRATION (14)8.3 C ALIBRATION P ROCESS (15)8.4 C HANGE S ETTINGS (17)8.5 E XIT C ALIBRATION (17)8.6 N OTICE (18)9Battery Charging And Repalacement (18)10Fault Analysis And Solution (18)11Order List (19)Instruction manual-CWY122 OverviewCWY122 digital pressure gauge is an intelligent micro-power consumption product, which adopts international leading measurement circuit, realizing precise and reliable temperature compensation function. It can truly and continuously measure the pressure values, very suitable for field and laboratory uses to complete precision pressure measurement and calibration of general pressure gauges, precision pressure gauges and other pressure gauges. It can also be widely used in occasions requiring precision pressure measurement.Product selection1.Gauge pressure rangesPressure range Accuracy Medium Bursting pressure (-2.5~0)kPa 0.05 gas 3x(0~2.5)kPa 0.05 gas 3x(-3.5~0)kPa 0.05 gas 3x(0~3.5)kPa 0.05 gas 3x(-4~0)kPa 0.05 gas 3x(0~4)kPa 0.05 gas 3x(-6~0)kPa 0.05 gas 3x(0~6)kPa 0.05 gas 3x(-7~0)kPa 0.05 gas 3x(0~7)kPa 0.05 gas 3x(-10~0)kPa 0.05 gas 3x(0~10)kPa 0.05 gas 3x(-16~0)kPa 0.05 gas 3x(0~16)kPa 0.05 gas 3xInstruction Manual-CWY122 Pressure range Accuracy Medium Bursting pressure (-25~0)kPa 0.05 gas 3x(0~25)kPa 0.05 gas 3x(-35~0)kPa 0.05 gas 3x(0~35)kPa 0.05 gas 3x(-40~0)kPa 0.05 gas 3x(0~40)kPa 0.05 gas 3x(-50~0)kPa 0.02(0.05)gas 3x(0~50)kPa 0.02(0.05)gas 3x(-60~0)kPa 0.02(0.05)gas 3x(0~60)kPa 0.02(0.05)gas 3x(-70~0)kPa 0.02(0.05)gas 3x(0~70)kPa 0.02(0.05)gas 3x(-100~0)kPa 0.02(0.05)gas 3x(0~100)kPa 0.02(0.05)gas 3x(0~160)kPa 0.02(0.05)gas 3x(0~200)kPa 0.02(0.05)gas 3x(0~250)kPa 0.02(0.05)gas 3x(0~350)kPa 0.02(0.05)gas 3x(0~400)kPa 0.02(0.05)gas 3x(0~600)kPa 0.02(0.05)gas 3x(0~700)kPa 0.02(0.05)gas 3x(0~1000)kPa 0.02(0.05)gas 3x(0~1600)kPa 0.02(0.05)gas 3x(0~2000)kPa 0.02(0.05)gas 3x(0~2500)kPa 0.02(0.05)gas 3x(0~3.5)MPa 0.02(0.05)gas /liquid 3xInstruction Manual-CWY122 Pressure range Accuracy Medium Bursting pressure (0~4)MPa 0.02(0.05)gas /liquid 2x(0~6)MPa 0.02(0.05)gas /liquid 2x(0~7)MPa 0.02(0.05)gas /liquid 2x(0~10)MPa 0.02(0.05)gas /liquid 2x(0~16)MPa 0.02(0.05)gas /liquid 2x(0~20)MPa 0.02(0.05)gas /liquid 2x(0~25)MPa 0.02(0.05)gas /liquid 2x(0~35)MPa 0.02(0.05)gas /liquid 2x(0~40)MPa 0.02(0.05)gas /liquid 1.5x(0~60)MPa 0.02(0.05)gas /liquid 1.5x(0~70)MPa 0.02(0.05)gas /liquid 1.1x Compound pressure rangePressure range Accuracy Medium Bursting pressure ±1kPa 0.05 gas 10x±2kPa 0.05 gas 10x±2.5kPa 0.05 gas 10x±3.5kPa 0.05 gas 10x±4kPa 0.05 gas 5x±6kPa 0.05 gas 5x±7kPa 0.05 gas 5x±10kPa 0.05 gas 3x±16kPa 0.05 gas 3x±20kPa 0.05 gas 3x±25kPa 0.05 gas 3x±35kPa 0.02(0.05)gas 3xInstruction Manual-CWY122 Pressure range Accuracy Medium Bursting pressure ±40kPa 0.02(0.05)gas 3x±50kPa 0.02(0.05)gas 3x±60kPa 0.02(0.05)gas 3x±70kPa 0.02(0.05)gas 3x±100kPa 0.02(0.05)gas 3x (-100~160)kPa 0.02(0.05)gas 3x(-100~200)kPa 0.02(0.05)gas 3x(-100~250)kPa 0.02(0.05)gas 3x(-100~350)kPa 0.02(0.05)gas 3x(-100~400)kPa 0.02(0.05)gas 3x(-100~600)kPa 0.02(0.05)gas 3x(-100~700)kPa 0.02(0.05)gas 3x(-100~900)kPa 0.02(0.05)gas 3x(-100~1000)kPa 0.02(0.05)gas 2x(-100~1600)kPa 0.02(0.05)gas 2x(-100~2000)kPa 0.02(0.05)gas 2x(-100~2500)kPa 0.02(0.05)gas 2x Double-rangePressure range Accuracy Medium Bursting pressure ±100kPa/±50kPa 0.02(0.05)gas 3x-100kPa/-50kPa 0.02(0.05)gas 3x100kPa/50kPa 0.02(0.05)gas 3x160kPa/80kPa 0.02(0.05)gas 3x200kPa/100kPa 0.02(0.05)gas 3x250kPa/120kPa 0.02(0.05)gas 3xInstruction Manual-CWY122 Pressure range Accuracy Medium Bursting pressure 350kPa/160kPa 0.02(0.05)gas 3x400kPa/200kPa 0.02(0.05)gas 3x600kPa/300kPa 0.02(0.05)gas 3x700kPa/350kPa 0.02(0.05)gas 3x1000kPa/500kPa 0.02(0.05)gas 3x1600kPa/800kPa 0.02(0.05)gas 3x2000kPa/1000kPa 0.02(0.05)gas 3x2500kPa/1200kPa 0.02(0.05)gas 3x3.5MPa/1.6MPa 0.02(0.05)gas/liquid 3x4MPa/2MPa 0.02(0.05)gas/liquid 2x6MPa/3MPa 0.02(0.05)gas/liquid 2x7MPa/3.5MPa 0.02(0.05) gas/liquid 2x10MPa/4MPa 0.02(0.05) gas/liquid 2x16MPa/8MPa 0.02(0.05) gas/liquid 2x20MPa/10MPa 0.02(0.05) gas/liquid 2x25MPa/12MPa 0.02(0.05) gas/liquid 2x35MPa/16MPa 0.02(0.05) gas/liquid 2x40MPa/20MPa 0.02(0.05) gas/liquid 1.5x60MPa/30MPa 0.02(0.05) gas/liquid 1.5x70MPa/35MPa 0.02(0.05) gas/liquid 1.1xInstruction Manual-CWY122 Differential pressure rangePressure range Accuracy Medium Bursting pressure ±100Pa 0.5 gas 5x±160Pa 0.5 gas 5x±250Pa 0.2 gas 5x±600Pa 0.1 gas 5x±1kPa 0.05 gas 5x±2kPa 0.05 gas 5x±2.5kPa 0.05 gas 5x±3.5kPa 0.05 gas 5x±4kPa 0.05 gas 5x±6kPa 0.05 gas 5x±7kPa 0.05 gas 5x±10kPa 0.05 gas 5x±16kPa 0.05 gas 3x±20kPa 0.05 gas 3x±25kPa 0.05 gas 3x±35kPa 0.02(0.05)gas 3x±40kPa 0.02(0.05)gas 3x±50kPa 0.02(0.05)gas 3x±60kPa 0.02(0.05)gas 2x±70kPa 0.02(0.05)gas 2xInstruction Manual-CWY122 Absolute pressure rangePressure range Accuracy Medium Bursting pressure (0~110)kPa.a 0.1 gas 3x(0~160)kPa.a 0.05(0.1) gas 3x(0~200)kPa.a 0.05(0.1) gas 3x(0~250)kPa.a 0.05(0.1) gas 3x(0~350)kPa.a 0.05(0.1) gas 3x(0~400)kPa.a 0.05(0.1) gas 3x(0~600)kPa.a 0.05(0.1) gas 3x(0~700)kPa.a 0.05(0.1) gas 3x(0~1000)kPa.a 0.05(0.1) gas 3x(0~1600)kPa.a 0.05(0.1) gas 3x(0~2000)kPa.a 0.05(0.1) gas 3x(0~2500)kPa.a 0.05(0.1) gas 3x(0~3.5)MPa.a 0.02(0.05) gas/liquid 3x(0~4)MPa.a 0.02(0.05) gas/liquid 3x(0~6)MPa.a 0.02(0.05) gas/liquid 3x(0~7)MPa.a 0.02(0.05) gas/liquid 3x(0~10)MPa.a 0.02(0.05) gas/liquid 2x(0~16)MPa.a 0.02(0.05) gas/liquid 2x(0~20)MPa.a 0.02(0.05) gas/liquid 2x(0~25)MPa.a 0.02(0.05) gas/liquid 2x(0~35)MPa.a 0.02(0.05) gas/liquid 2x(0~40)MPa.a 0.02(0.05) gas/liquid 1.5x(0~60)MPa.a 0.02(0.05) gas/liquid 1.5x(0~70)MPa.a 0.02(0.05) gas/liquid 1.5xInstruction Manual-CWY122 Caution: It is forbidden to enter liquid, especially the high viscosity oil for gas medium calibrator, or it will affect return difference and accuracy.2 SpecificationPressure range:-100kPa~70MPa,Accuracy: 0.02, 0.05, 0.1, 0.2O, mmHg, mmH2O, MPa, Pressure units (12 units): kPa, psi, inHg, inH2bar, mbar, atm, kg/cm2, Pa. (According to the full range to judge which unitcan be converted to display, because the display is not more than 5 digits).Pressure overload: When the pressure measurement value exceeds 105%FS, overpressure and alarm are displayed.Ambient conditions:a. Ambient temperature: (-5~50)℃;b. Relative humidity: ﹤95%;c. Atmospheric pressure: (86~106)kPa.Compensated temperature:(-5~50)℃(accuracy guarantee).Storage temperature:(-30~80)℃.Display: LCD screen, backlight, 5 digits.Power supply:1x3.7V replaceable Lithium ion battery or 1x9V batteryAuto power-off: Automatic shutdown occurs when no keyboard is pressed and pressure changes are less than 1% of the range within 1minute.Communication series port configuration: Baud rate: 57600; Calibration bits: no, data bits: 8 bits, stop bits: 1 bit; it can be used for CWY automaticpressure calibrator as its external pressure module and be connected withTMMS2000 to print verification report automatically.Dimension: Φ107mm×37mm, total length:165mmWeight: approx. 0.48kg;Instruction Manual-CWY122 Connection: M20×1.5(or user defined e.g.NPT).Additional function: temperature measurement resolution is ±0.1℃3 NotesInstallation should comply with the relevant provisions of electrical installations (except coal mines) in hazardous sites.Low power warning: if there is an automatic shutdown, please replace new battery; battery replacement should be carried out in well ventilated and nogas leak condition, and use the same model battery.It is prohibited to connect RS232 communication in the explosive gas environment.Forbidden to change or remove any components and structures which may affect the safe explosion-proof, such as the electronic batteries and therelated components.It should not be used for long period if overload to avoid pressure sensor damage.In order not to damage CWY series mechanical part, don't apply torque between the shell and pressure connection.4 Button description“”power on/off:Power on/off the pressure gauge;“”mode/calibration key: short press the key to switch display module, pressure display mode and basic parameter, ambient temperature display mode;Long press “”to enter “calibration”, then correct accuracy; under this status, short press the key to calibrate pressure.“”confirm button: In the "calibration status" short press the key toInstruction Manual-CWY122 calibrate the pressure;“” Plus and minus button: In "verification state", the pressure unit can be switched; In the "calibration status" short press the key to change the calibration set value;“”: “Zero” key: clear pressure data;“”: “Backlight” key: Turn on/off backlight.5 Basic functions5.1 Power on/offMake a long press “”for 3 seconds to power on; in the state of power-on, long press it for 3 seconds to power off. The gauge will buzz when it powers on or off.5.2 Pressure measurementAfter startup, the instrument will display pressure measurement as following picture:pressure gaugebattery power iconpressure measuring valuePressure unit5.3 Pressure clearancePlace the pressure connection toward air. If the current pressureInstruction Manual-CWY122 measured value is within (-10% ~ 10%) of the full range, press "ZERO" button to clear the measured value.5.4 Pressure unit conversionPress “” button to convert pressure units.①Precision digital pressure gauges(<2.5MPa)units are converted in thefollowing order: kPa, psi、inHg, inH2O, mmHg, mmH2O, MPa, bar, mbar, atm, kg/cm2,Pa.②Precision digital pressure gauges(>4MPa)units are converted in thefollowing order: MPa, psi, inHg, inH2O, mmHg, mmH2O, kPa, bar, mbar, atm, kg/cm2, Pa.Notice:In order to ensure that under each optional unit, pressure measurement is not shortage or overflow of digits in length, so different range gauges have different pressure unit configuration, not all pressure units.The conversion between units is as following table:1 kPa 1 7 MPa 0.0012 psi 0.1450377 8 bar 0.013 inHg 0.2953 9 mbar 104 inH2O 4.01463 10 atm 0.00986925 mmHg 7.50061 11 kg/cm20.0101976 mmH2O 102.047 12 Pa 10005.5 Double range switchFor double range digital pressure gauge, press "ZERO" button to switch two ranges. The current range is displayed in the top left corner of the screen.Instruction Manual-CWY122 If the pressure range is switched to a lower range status, the input pressure exceeds the low range, and then the high range is automatically switched to protect the sensor.5.6 BacklightPress button to turn on backlight, and then press to adjustbrightness, press again to turn it off. The backlight will turn on automatically when it is external module connected to CWY automatic pressure calibrator.5.7 Basic parameter displayPress “” button to display basic parameter: Model, serial no., production date, battery voltage.Press "" button again to switch to temperature and version as following photo at right.6 Usage as external module of CWY series automatic pressure calibratorThe precision digital pressure gauge is installed on the left side of the pressure connection on the calibrator, using specialized communicationInstruction Manual-CWY122 lines to connect to the left side of the external standard communication port of the calibrator; the gauge will automatically power on and turn on the backlight and automatic shutdown when the calibrator is powered off.7 Use software TMMS-2000 to do calibrationCWY model precision pressure gauge can be connected with TMMS-2000 (automatic calibration software) to do real-time calibration, and then the data will be uploaded to computer and print calibration report automatically.Automatic pressure calibrator can be used as pressure generation, and other hand pump or equipment will also be workable.About calibration data uploading, please check data memory function.8 Pressure sensor calibration8.1 Calibration permissible condition1)Ambient condition:Ambient temperature: 20℃±2℃Relative humidity: (45~75)%Atmospheric pressure: (86~106)kPa2)Standard pressure generationIt should meet requirement of verification regulation of digital pressure gauge JJG875.8.2 Start calibrationLong press "" button to enter the calibration status, as shown below, the top row is set value, positive-negative pressure range using three pointInstruction Manual-CWY122 to calibrate., use""button to change Settings: the lower limit, 0,upper limit; Other ranges are calibrated at 2 points, and use""button to change Settings : 0%, 100%. The bottom line displays reading value of actual pressure.8.3 Calibration process8.3.1 Positive and negative pressure range calibration process.The following working steps are assumed: the range of calibration is (-60 ~ 60) kPa, and the pressure calibration points are -60kpa, 0kPa and60kPa. The calibration can only be completed when the actual pressure value and the pressure setting value are 10 percent difference.1)Preparation: turn on the power to warm up for 10 minutes.Zero calibration:Set the pressure setting value to "0.000kPa"and confirm the system pressure as "0", after the ""calibration key and""confirm key, the" pressure set value "is 60.000kPa and" actual pressure value "is 0.000kPa (It indicates that the system has saved zero information. After calibration, the pressure value is still 0.000kpa, indicating thatInstruction Manual-CWY122 the system does not accept calibration data. The error of actual pressure value and pressure setting value may exceed 10% of the range, and the other points are the same condition.).2)Upper limit of calibration:Adjust the pressure setting to the upper limit (60 kPa), add pressure accurately to the maximum pressure value (60 kPa), press "" "" button, then the “pressure setting” displays 0.00 kPa, "actual pressure value" displays 60.00 kPa. Now, calibration is done.3)Lower limit of calibration:Adjust the pressure setting to the lower limit value (-60 kPa), add the accurate pressure to the minimum pressure value (-60 kPa), press "" "" button, then the pressure setting displays 0.00 kPa, "actual pressure value" displays -60.00 kPa, the calibration is done.8.3.2 Calibration instructions for other rangesThe following working steps are assumed: the range of calibration is (0~400) kPa, and the pressure calibration points are 0kpa, 400kPa. The calibration can only be completed when the actual pressure value and the pressure setting value are 10 percent difference.1)Preparation: turn on the power to warm up for 10 minutes.Zero calibration:Set the pressure setting value to "0.000kPa"and confirm the system pressure as "0", after pressing the ""calibration key and""confirm key, the" pressure set value "is 400.000kPa and" actual pressure value "is 0.000kPa (ItInstruction Manual-CWY122 indicates that the system has saved zero information.After calibration, the pressure value is still 0.000kpa,indicating that the system does not accept calibration data.The error of actual pressure value and pressure setting value may exceed 10% of the range, and the other points are thesame condition.).2)Calibration range: Adjust the pressure setting to scale value (400 kPa), add pressure accurately to pressure value (400 kPa), press "" "" button, then the “pressure setting” displays 0.00 kPa, "actual pressure value" displays 400.00 kPa. Now, calibration is done.8.3.3 Double range switchFor double-range digital pressure gauges, in the calibration mode, short press "ZERO" key can switch two ranges. The current range is displayed in top right corner of the screen.8.4 Change settingsWhen calibrating the pressure, sometimes it is necessary to modify the set value. For example, when the vacuum cannot be drawn to -100kPa inInstruction Manual-CWY122 a place, it is impossible to calibrate the -100kPa, and the setting value must be set artificially. If you want to modify settings, long press "" button to enter modify Settings status, as the picture below (left), whereabove the set value, there is " "indicating the digit can be modified, press""button, the corresponding figures will add 1, if you want to minus 1, then press "" button to change the direction of valuechanges, as the picture on the right,"",and"", The calibration data of the set value is saved.8.5 Exit calibrationLong press "" to exit the calibration status, and then enter the measurement condition.Instruction Manual-CWY122 8.6 NoticeThis function is used to modify the accuracy of pressure measurement, and the arbitrary operation of calibration function will affect the measurement accuracy, which can lead to the failure of normal work, possibly. If the measurement accuracy is deviated during the periodic verification, the calibration can be carried out. The calibration personnel must be the professional metrological verification personnel. In calibrating pressure measurement, the pressure should be pressurized to full range, then directly reduced to zero, and repeat the operation three times to make the pressure measurements to the optimum and then calibrate them.Caution: Calibration must be operated in calibration condition!9 Battery charging and replacementWhen the instrument appears automatic shutdown, please charge in time, if it is rechargeable battery,The instrument can use 9V battery or rechargeable battery with 9V charger. Replace the battery if the battery failed. When replacing the battery, remove the battery cover and place the new battery.When replacing the battery, please note that if the positive and negative electrode of the battery is in accordance with the installation direction;If the battery fails, it can be powered directly with a 4.2v-9v power adapter.Instruction Manual-CWY122 10 Fault analysis and solution1)If the external pressure exceeds 5% of the full range, the overpressure alarms, and the pressure should be reduced immediately to avoid damaging the pressure sensor.2)Replace the battery in time if the battery is abnormal.11 Order listNo. Description Quantity1 Precision digital pressure gauge 1pc2 9V battery 1pc3 Certification of approval 1pc4 Delivery inspection report 1pc5 Operating manual 1pc6 Warranty card 1pc陕西创威科技有限公司Shaanxi Creat Wit Technology Co., LtdAddress: No. 80, Gaoxin Road, Hi-Techzone, Xi’an, ChinaTel: +86 029********Fax: +86 89250364Mobile:+86182****6927Email:******************19Tel:+8602986690023Email:******************。

精密数字压力计使用注意事项压力计如何操作精密数字压力计的内部结构是特别精密的,我们在使用的过程中有很多需要注意的地方,往往一个错误的使用方法会导致产品损坏大量的机能,甚至导致产品报废。

今日我们精密数字压力计的内部结构是特别精密的,我们在使用的过程中有很多需要注意的地方,往往一个错误的使用方法会导致产品损坏大量的机能,甚至导致产品报废。

今日我们就来实在介绍一下精密数字压力计的使用注意事项,希望可以帮忙用户更好的应用产品。

(1)精密数字压力计装在锅炉、压力容器上的数字压力表,其最大量程(表盘上刻度极限值)应与设备的工作压力相适应。

精密数字压力计的量程一般为设备工作压力的1.5~3倍,可以取2倍。

若选用的数字压力表量程过大,由于同样精度的精密数字压力计,量程越大,允许误差的确定值和肉眼察看的偏差就越大,则会影响压力读数的精准性;反之,若选用的数字压力表量程过小,设备的工作压力等于或接近精密数字压力计的刻度极限,则会使数字压力表中的弹性元件长期处于最大的变形状态,易产生永久变形,引起精密数字压力计的误差增大和使用寿命降低。

另外,精密数字压力计的量程过小,万一超压运行,指针越过最大量程接近零位,而使操作人员产生错觉,造成更大的事故。

因此,精密数字压力计的使用压力范围,应不超过刻度极限的60~70%.(2)工作用数字压力表的精度是以允许误差占表盘刻度极限值的百分数来表示的。

精度等级一般都标在表盘上,选用精密数字压力计时,应依据设备的压力等级和实际工作需要来确定精度。

(3)表盘直径为了使操作人员能精准地看清压力值,数字压力表的表盘直径不应过小,假如数字压力表装得较高或离岗位较远,表盘直径应增大。

(4)精密数字压力计用于测量的介质假如有腐蚀性,那么确定要依据腐蚀性介质的实在温度、浓度等参数来选用不同的弹性元件材料,否则达不到预期的目的。

(5)日常重视使用维护,定期进行检查、清洗并做好使用情况记录。

(6)精密数字压力计一般检定周期为半年。

YSB-120数字精密压力表使用说明书YSB-120型数字精密压力表是我公司最新开发的新产品,融汇了多项国际上先进的电子技术、单片计算机技术、电源技术、抗干扰技术等,从而保证了仪表具有测控精度高、抗干扰性能强等优点。

整机采用圆形结构,选用直径120mm ×35mm 外壳,具有整机体积小、重量轻、耗电省、功能齐全、工作可靠、使用方便灵活等特点。

YSB-120型数字精密压力表配用我公司定制筛选的进口精密压力传感器,以及内部精密温度补偿传感器,作为高精度压力测量的温度、线性补偿措施,使得整体测量达到了并远高于0.05%的精度。

此外,为了取得更好的长期稳定性,本产品出厂前均已经过两万次满量程压力交变实验、,高低温环境补偿与实验、三个月通电老化实验。

因此,是我国进行的实际疲劳、老化实验的产品和专业厂家。

由于每台产品均经过上述工艺、检验,因此,一年内在(0---50)℃范围内,其准确度完全满足技术指标要求。

YSB-120型数字精密压力表可广泛地应用于计量行业,可作为一等压力标准或二等压力标准校验传递使用。

该产品也可作为化工、液压、石油、塑料、橡胶、印染、纺织等行业的压力显示和自动化控制场合,当使用数字接口时,还可与其他仪表、系统配套使用。

本产品采用人性化的操作方法,面板设计清晰明了,操作简单易学。

一、概述1、数字显示单层五位高清晰液晶显示2、显示分辨率±000013、显示数值范围00001~实际量程值(小数点可变)4、仪表精度0.05%FS 0.1%FS5、背光显示淡蓝色、单次显示为5秒,自动关闭6、采样速度4 次/ 秒7、供电三节五号干电池 ,连续使用1000小时8、使用环境温度:(0~50)℃相对湿度:<95%气压:(86 ~ 106)K Pa10、压力范围:0~10 K Pa ~0~60 MPa11、压力介质:压力介质为与316不锈钢相兼容的液体或气体12 外型尺寸:直径120mm ×35mm13、重量:0.8Kg13、输出接口:RS48514、连接:M20X1.5(可根据用户要求加工)数字精密压力表面板设有6个功能键,使用该键可以给用户带来很大的便利,其主要功能如下* 电源键该健是本产品的电源开关,当使用时,按动此键即打开电源,再次按动关闭电源。

目次前言1. 概述2. 用途3. 工作原理4. 技术指标5. 使用操作6. 注意事项7. 附件前言衷心感谢贵单位使用我公司生产的Y-100S 系列精密数字压力表。

使用前敬请仔细阅读使用说明书,以期您在使用时得心应手。

Y-100S系列精密数字压力表是我厂根据多年生产经验及市场需求,经科研技术人员精心设表,软应件齐全,性能稳定可靠,使用广泛的又一系列产品。

为使您快速正确掌握该系列产品的使用方法,本使用说明书较详细地介绍了该系列产品的技术指标、用途、仪器的组成、使用操作、注意事项等。

使用前务请仔细阅读使用说明书,以期永久地保证该系列仪表的可靠性和稳定性。

1.1、Y-100S系列精密数字压力表为交直流两用的便携式仪表。

1.2、高性能的微处理器对仪表的各项性能及技术指标作连续修正,保证仪表长时间内宽温度范围内使用而不影响仪表的精度。

1.3、功耗低。

电池采用进口镍氢高能电池,保证仪表在长时间内工作。

1.4、恒流充电,具有电池电压的过充电、欠压自动关机及自动保护功能,保证电池不因过充电或欠压而损坏,电池使用寿命长。

1.5、微功耗的欠电压自动保护功能,保证仪表即使操作者因故而连续开机过长也不会因欠电压而损坏电池。

1.6、仪表量程功能丰富,一表多用。

1.7、软件内容丰富,操作简单、明了。

1.8、采用薄膜面板轻触开关,款式新颖,按键寿命长。

1.9、可直接在面板上操作调校满量程。

1.10、便携式金属外壳,抗干扰强,牢固耐冲击。

2、用途Y-100S精密数字压力表除可作较高准确度校正标准器(表)外,也可作为仪表使用,广泛用于冶金、石油、化工、电力、天然气、表量及科研等部门。

3、工作原理3.1、原理框图:压力信号运放 A/D CPU 显示稳压电压鉴别及保护稳压充电 220V AC 50Hz3.2、工作原理:Y-100S系列精密数字压力表是采用进口高精度压力传感器和24位高分辩率Y-100S精密数字压力陕西西仪测控技术有限责任公司充电单位开压力关校零前面板图示型号:量程:精度:编号:出厂日期:12V DC充电后面板图示A/D转换器,以单片机为核心的高精度压力测量和校验仪器,大大提高压力表精度。

ZHT-2000精密数字压力表使用说明书西安智拓仪器仪表有限公司产品研发部修订前言◎感谢您购买我公司生产ZHT-2000系列精密数字压力表。

◎本使用手册是以初次购买者或考虑选用者为对象,对ZHT-2000系列精密数字压力表的功能及其使用进行说明。

◎在您读完后,请妥善保管在便于翻阅的地方,以便操作时参照。

注意◎本手册版权属有,未经许可不得复制、传递、使用和修改本手册或其中的内容。

◎我公司保留在预先不通知的情况下,对此手册中描述的任何产品进行修改和改进的权利;保留在预先不通知的情况下,修订或废止本文档的权利。

对改进后的产品有相应的使用手册或改进说明。

◎关于本手册内容我们力保正确无误,但是一旦您发现有不妥或错误请与我们联系。

目录一、概述 (2)1.1注意事项 (2)1.2产品特点 (2)二、技术指标 (2)2.1使用环境 (2)2.2显示 (2)2.3供电方式 (2)2.4压力指标 (3)2.5产品尺寸 (3)2.6可选功能 (3)三、仪表显示面板及功能键 (3)3.1按键功能说明 (3)3.2显示内容说明 (4)四、压力表校准 (4)五、基本功能使用 (4)5.1开关机 (4)5.2背光的打开/关闭 (4)5.3压力清零 (5)5.4单位切换 (5)5.5压力峰值记录 (5)六、设置菜单功能使用说明 (5)6.1菜单的进入 (5)6.2设置菜单的选项 (6)6.3设置测量速度 (6)6.4背光点亮时间设定设置 (6)6.5设置显示位数 (6)七、安装与维护 (6)7.1安装 (6)7.2维护 (7)八、保管与运输 (7)一、概述我公司沿用实验室用高精度数字压力计技术,将该技术运用于工业级压力表,确保了压力表的精度,非常适合于现场及实验室使用,完成精密压力测量和一般压力表、精密压力表等压力仪表的校验工作,它完全可以代替指针式精密压力表,性能更优越。

1.1注意事项⏹在不使用背光的情况下,请关闭背光,以延迟电池寿命。

精密智能数字压力表安全操作及保养规程1. 引言精密智能数字压力表是一种广泛应用于工业领域的仪器设备,用于测量和监控液体或气体的压力值。

为了确保其正常运行和延长使用寿命,本文档将提供一份详细的安全操作及保养规程。

2. 安全操作2.1 事前准备在操作精密智能数字压力表之前,应该确保符合以下条件:•工作环境清洁、干燥,并且没有暴露于高温或腐蚀性气体中。

•工作场所电源稳定,电压符合设备要求。

•确保操作人员已经接受了相关的压力表操作培训。

2.2 操作步骤1.首先,检查压力表的外观是否完好无损,确保没有明显的机械损坏或破损。

2.将压力表连接到被测压力系统,并确保连接口处没有泄漏。

3.打开电源,并检查仪表的显示屏是否正常工作。

4.根据被测介质的特性,选择相应的压力单位和测量范围。

5.缓慢打开被测介质的阀门,使其进入压力表,并观察压力表的读数。

6.完成测量后,关闭被测介质的阀门,并关闭电源。

7.拆下压力表,并将其清洁干净。

2.3 注意事项在操作精密智能数字压力表时,需要注意以下事项:•避免使用压力超过压力表测量范围的被测介质,否则可能损坏压力表。

•禁止在高温或腐蚀性气体环境下使用压力表。

•避免将压力表接触到磨损、腐蚀或有其他潜在损坏的表面。

•不要在清洗或维修压力表时使用有机溶剂或腐蚀性液体。

3. 保养规程3.1 清洁保养定期清洁精密智能数字压力表是保证其正常运行的重要措施。

按照以下步骤进行清洁保养:1.关闭压力表的电源,并将其拆下。

2.使用干净的软布蘸水或者中性清洁剂擦拭压力表的表面。

3.避免使用有机溶剂或腐蚀性液体进行清洁。

4.将清洗干净的压力表放置在通风的地方晾干。

3.2 定期校准定期校准精密智能数字压力表是确保其准确度的重要措施。

根据厂商提供的校准方法和周期,定期使用专业校准设备对压力表进行校准。

3.3 存储保养正确的存储精密智能数字压力表可以延长其使用寿命。

按照以下建议进行存储保养:•将压力表存放在干燥、清洁、无腐蚀性气体和恶劣环境的地方。