5S

工作场地的有序安排

=5S Workplace Organization

5 Self Discipline自律

4 Sustain保持 3 Sweep清扫 2 Sort整理 1 Sift筛选

10

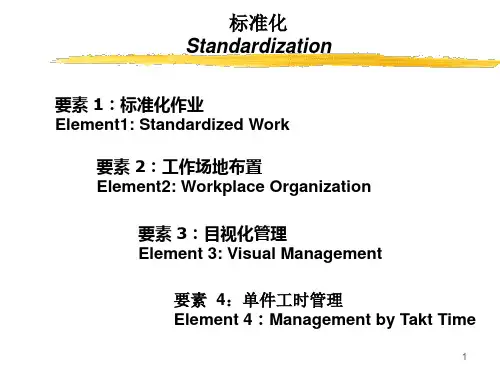

标准化 Standardization

5S-筛选

5S-Sift

1,制定必需和非必需品的评判标准,消除不必要的工具,设备,材料和次品; Make judgement criteria for necessary and unnecessary, Eliminate non-essential tools, equipment , material and salvage.

不可在线上修复的缺陷

For defects that can nFilled in defect record and keep it 反馈给操作工 feedback to T/M

通知返修工段 Advise repair group

8

标准化 Standardization

: 可 疑 零 件

: 报 废 零 件

零

件

scrap dubious

repaired

线旁已不再使用的工具应去除 Tools (not used any more) attached with red label

可疑、报废零件分区域放置 Scrap/dubious part put in different colored area

Andon

操作工拉动暗灯T/M pull Andon 暗灯(Andon)=求助(HELP)

在什么时候拉动暗灯

WHEN PULL?

FPS

70% FPS

5

标准化 Standardization