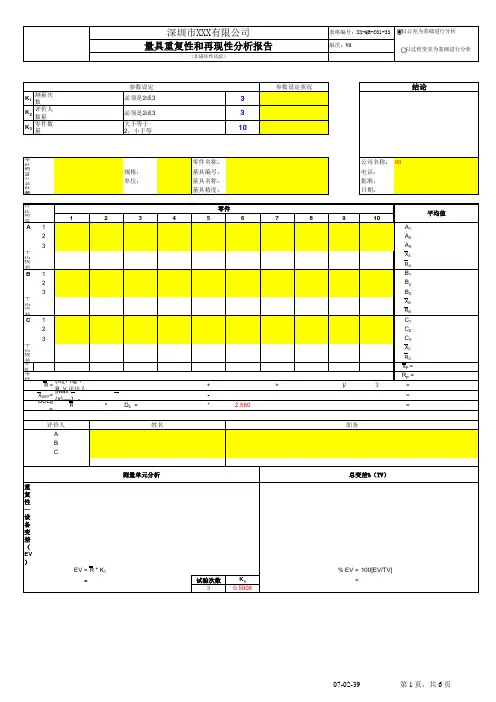

量具的重复性和再现性报告模板

- 格式:xls

- 大小:99.00 KB

- 文档页数:3

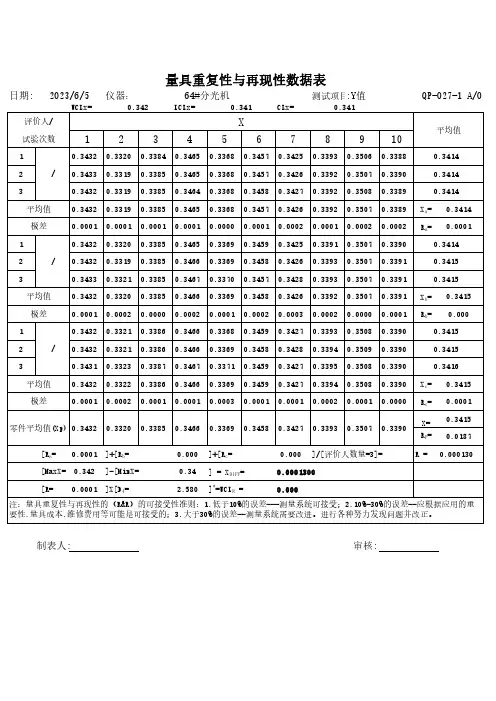

量具重复性与再现性数据表

日期: 2023/6/5仪器:64#分光机测试项目:Y值QP-027-1 A/0

制表人:审核:

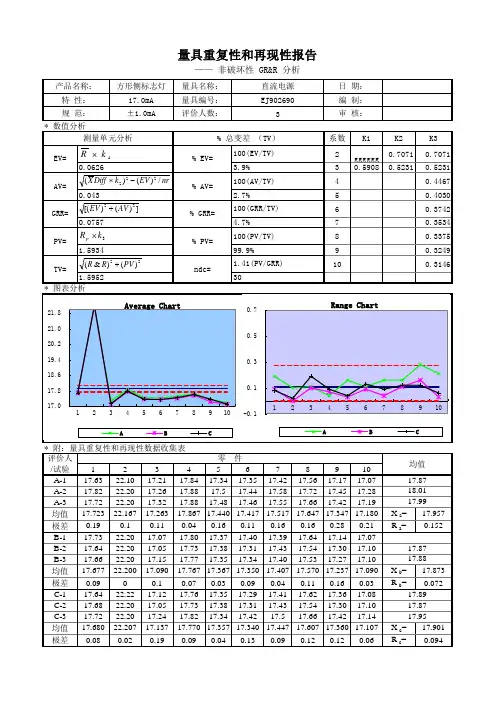

量具重复性和再现性報告

制表人:审核:

量具重复性与再现性数据表

日期: 2023/6/5仪器:64#分光机测试项目:X值QP-027-1 A/0

制表人:审核:

量具重复性和再现性報告

制表人:审核:

量具重复性与再现性数据表

日期: 2023/6/5仪器:64#分光机测试项目:VF QP-027-1 A/0

制表人:审核:

量具重复性和再现性報告

制表人:审核:

量具重复性与再现性数据表

日期: 2023/6/5仪器:64#分光机测试项目:Flux QP-027-1 A/0

制表人:审核:

量具重复性和再现性報告

制表人:审核:。

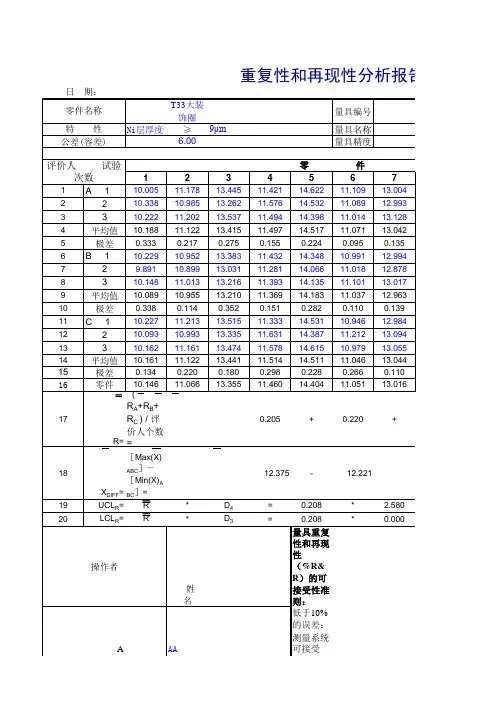

文件号:零件名称芯片推力量具编号量具名称>100g 量具精度评价人试验次数123456781 A 1180.500110.000260.000130.500100.200100.200110.200120.60022180.200120.200260.200130.800100.300100.300110.200120.50033180.300120.300260.500130.900100.800100.200110.500120.200180.333116.833260.233130.733100.433100.233110.300120.4330.30010.3000.5000.4000.6000.1000.3000.4006 B 1180.500120.400250.900130.700100.900100.500110.800120.40072170.500110.500250.800130.600100.200100.600110.500120.40083150.600110.600300.000130.800100.200100.800110.300120.500167.200113.833267.233130.700100.433100.633110.533120.43329.9009.90049.2000.2000.7000.3000.5000.10011C 1180.900130.000280.000130.800100.500100.500110.600120.300122190.200130.500280.500120.900100.600100.600110.200120.800133180.500140.000280.800130.900100.800100.700110.600120.700183.867133.500280.433127.533100.633100.600110.467120.6009.70010.0000.80010.0000.3000.2000.4000.500177.1333#######269.3000129.6556100.5000100.4889110.4333120.488917R= ( R A +R B +R C ) / 评价人个数 =3.3600+10.1000+ 3.240018X DIFF =[Max(X)ABC ]-[Min(X)ABC ]=139.900-135.55019UCL R =R *D 4= 5.567*2.58020LCL R =R *D 3= 5.567*0.000 姓 名量具重复性和再现性(%R&R )的可接受性准则:A低于10%的误差: 测量系统可接受B10%至30%的误差: 根据应用的重要性。

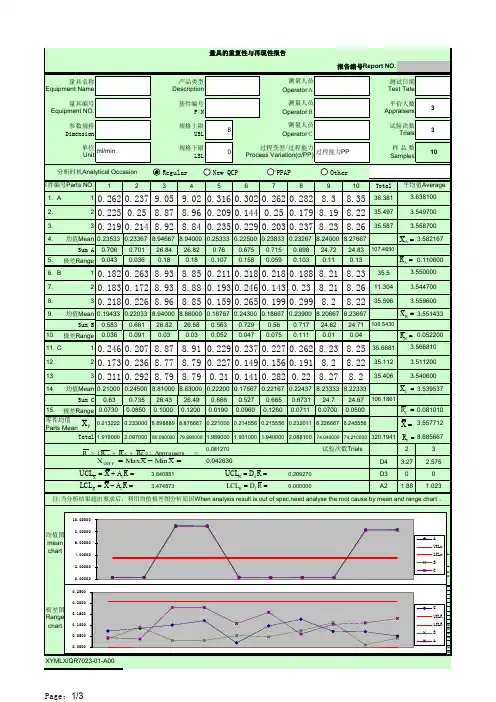

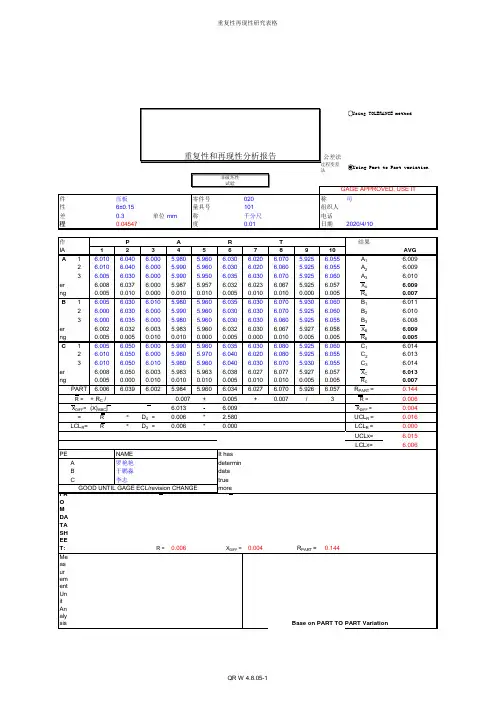

重复性和再现性分析报告公差法过程变差法非破坏性试验'[1204442'[1204442528.xls]01'[1204442528.xls]01'[1204442528.xls]01'[1204442528.xls]01GAGE APPROVED, USE IT 零件压板零件号CL3202020单位名称*****有限公司特性6±0.15量具号LQT-101组织人公差0.3单位mm量具名称千分尺电话过程0.04547量具精度0.01日期2020/4/10操作P A R T 结果TR IA 12345678910AVG A 1 6.010 6.040 6.000 5.980 5.960 6.030 6.020 6.070 5.925 6.055A 1 6.0092 6.010 6.040 6.000 5.990 5.960 6.030 6.020 6.060 5.925 6.055A 2 6.00936.005 6.030 6.000 5.990 5.950 6.035 6.030 6.070 5.925 6.060A 36.010Av er 6.008 6.037 6.000 5.987 5.957 6.032 6.023 6.067 5.925 6.057X A 6.009Ra ng 0.0050.0100.0000.0100.0100.0050.0100.0100.0000.005R A0.007B 1 6.005 6.030 6.010 5.980 5.960 6.035 6.030 6.070 5.930 6.060B 1 6.0112 6.000 6.030 6.000 5.990 5.960 6.030 6.030 6.070 5.925 6.060B 2 6.0103 6.000 6.035 6.000 5.980 5.960 6.030 6.030 6.060 5.925 6.055B 36.008Av er 6.002 6.032 6.003 5.983 5.960 6.032 6.030 6.067 5.927 6.058X B 6.009Ra ng 0.0050.0050.0100.0100.0000.0050.0000.0100.0050.005R B0.005C 1 6.005 6.050 6.000 5.990 5.960 6.035 6.030 6.080 5.925 6.060C 1 6.0142 6.010 6.050 6.000 5.980 5.970 6.040 6.020 6.080 5.925 6.055C 2 6.0133 6.0106.050 6.010 5.980 5.960 6.040 6.030 6.070 5.930 6.055C 36.014Av er 6.008 6.050 6.003 5.983 5.963 6.038 6.027 6.077 5.927 6.057X C 6.013Ra ng0.0050.0000.0100.0100.0100.0050.0100.0100.0050.005R C0.007PART 6.006 6.0396.0025.984 5.9606.034 6.027 6.070 5.926 6.057R PART =0.144R =R A + R B + R C /0.007+0.005+0.007/3R =0.006X DIFF =[Max (X )ABC ] 6.013- 6.009X DIFF =0.004UCL R =R*D 4 =0.006* 2.580UCL R =0.016LCL R =R*D 3 =0.006*0.000LCL R =0.000UCL X =6.015LCL X =6.006O PENAMENOTE :It has A 罗艳艳todetermin B 于鹏淼Kurtosis data C 李志from the true GOOD UNTIL GAGE ECL/revision CHANGEneed moreFR O M DA TA SH EE T:R =0.006X DIFF =0.004R PART =0.144Me as ur em ent Un it An aly sisBase on PART TO PART VariationUsing TOLERANCE methodUsing Part to Part variation重复性和再现性分析报告公差法过程变差法非破坏性试验'[1204442'[1204442528.xls]01'[1204442528.xls]01'[1204442528.xls]01'[1204442528.xls]01GAGE APPROVED, USE IT 零件压板零件号CL3202020单位名称*****有限公司特性6±0.15量具号LQT-101组织人公差0.3单位mm量具名称千分尺电话过程0.04547量具精度0.01日期2020/4/10Using TOLERANCE methodUsing Part to Part variation重复性和再现性分析报告公差法过程变差法非破坏性试验'[1204442'[1204442528.xls]01'[1204442528.xls]01'[1204442528.xls]01'[1204442528.xls]01GAGE APPROVED, USE IT 零件压板零件号CL3202020单位名称*****有限公司特性6±0.15量具号LQT-101组织人公差0.3单位mm量具名称千分尺电话过程0.04547量具精度0.01日期2020/4/10Using TOLERANCE methodUsing Part to Part variation重复性和再现性分析报告公差法过程变差法非破坏性试验'[1204442'[1204442528.xls]01'[1204442528.xls]01'[1204442528.xls]01'[1204442528.xls]01GAGE APPROVED, USE IT 零件压板零件号CL3202020单位名称*****有限公司特性6±0.15量具号LQT-101组织人公差0.3单位mm 量具名称千分尺电话过程0.04547量具精度0.01日期2020/4/10Using TOLERANCE methodUsing Part to Part variation量具重复性和再现性的()的可接受性准则:低于的误差测量系统可接受;的误差应根据应用的重要重复性和再现性分析报告公差法过程变差法非破坏性试验'[1204442'[1204442528.xls]01'[1204442528.xls]01'[1204442528.xls]01'[1204442528.xls]01GAGE APPROVED, USE IT 零件压板零件号CL3202020单位名称*****有限公司特性6±0.15量具号LQT-101组织人公差0.3单位mm量具名称千分尺电话过程0.04547量具精度0.01日期2020/4/10Using TOLERANCE methodUsing Part to Part variationRange Chart by appraiser重复性和再现性分析报告公差法过程变差法非破坏性试验'[1204442'[1204442528.xls]01'[1204442528.xls]01'[1204442528.xls]01'[1204442528.xls]01GAGE APPROVED, USE IT 零件压板零件号CL3202020单位名称*****有限公司特性6±0.15量具号LQT-101组织人公差0.3单位mm量具名称千分尺电话过程0.04547量具精度0.01日期2020/4/10Using TOLERANCE methodUsing Part to Part variation重复性和再现性分析报告公差法过程变差法非破坏性试验'[1204442'[1204442528.xls]01'[1204442528.xls]01'[1204442528.xls]01'[1204442528.xls]01GAGE APPROVED, USE IT 零件压板零件号CL3202020单位名称*****有限公司特性6±0.15量具号LQT-101组织人公差0.3单位mm量具名称千分尺电话过程0.04547量具精度0.01日期2020/4/10Using TOLERANCE methodUsing Part to Part variation。

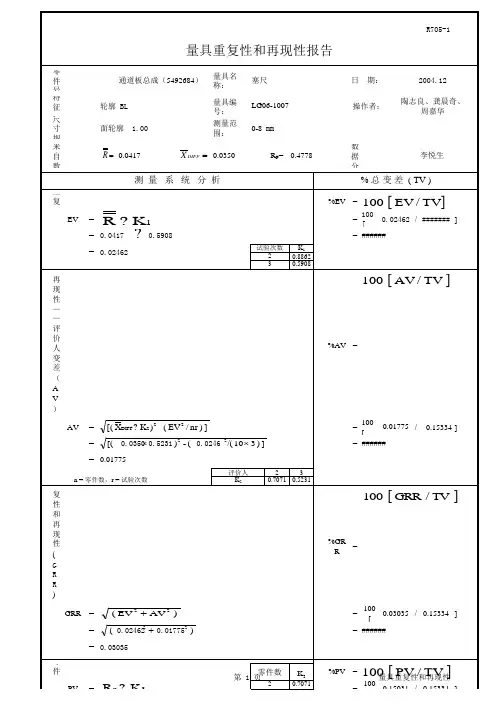

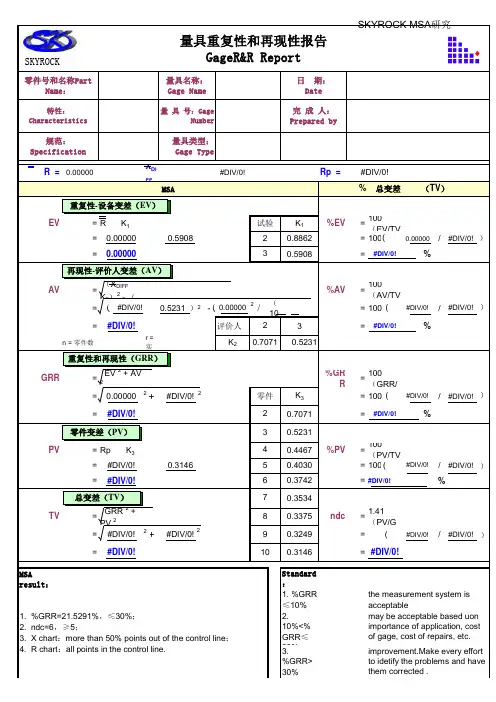

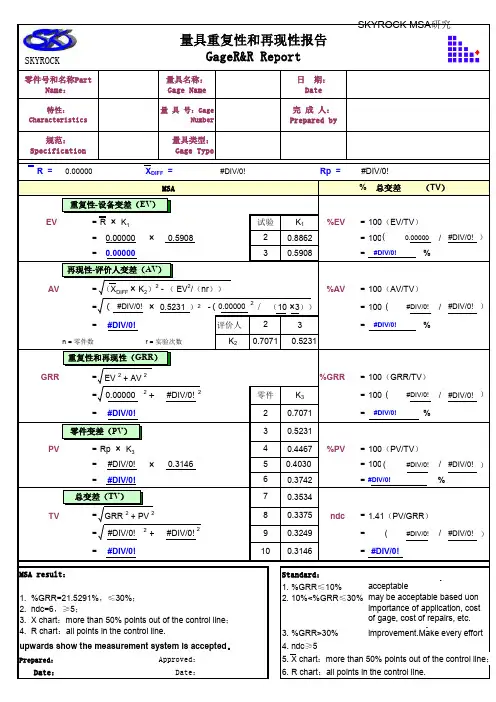

R = 0.00000X DIFF =#DIV/0!Rp =EV=R × K 1K 1%EV=100(EV/TV )=0.00000×0.59080.8862=1000.00000/#DIV/0!=0.000000.5908=#DIV/0!%AV= (X DIFF × K 2)2 - ( EV 2/(nr ))%AV=100(AV/TV )=#DIV/0!×0.5231-0.00000/(10 ×3))=100#DIV/0!/#DIV/0!=#DIV/0!评价人3=#DIV/0!%n = 零件数r = 实验次数K 20.5231GRR= EV 2 + AV 2%GRR =100(GRR/TV )=0.00000+#DIV/0!K 3=100#DIV/0!/#DIV/0!=#DIV/0!0.7071=#DIV/0!%0.5231PV=Rp × K 30.4467%PV=100(PV/TV )=#DIV/0!×0.31460.4030=100#DIV/0!/#DIV/0!=#DIV/0!0.3742=%0.3534TV= GRR 2 + PV 20.3375ndc =1.41(PV/GRR )=#DIV/0!+#DIV/0!0.3249=1.41#DIV/0!/#DIV/0!=#DIV/0!0.3146=#DIV/0!MSA result:Standard:1. %GRR ≤10%2. 10%<%GRR ≤30%3. %GRR>30%upwards show the measurement system is accepted 。

4. ndc ≥5Prepared:Approved:5. X chart :more than 50% points out of the control line ;Date:Date:6. R chart :all points in the control line.#DIV/0!% 总变差 (TV )#DIV/0!1. %GRR=21.5291%,≤30%;2. ndc=6,≥5;3. X chart :more than 50% points out of the control line ;4. R chart :all points in the control line.may be acceptable based uonimportance of application, cost of gage, cost of repairs, etc.MSA7103量具名称:Gage Name量具类型:Gage Type完 成 人:Prepared by日 期:Date2试验230.7071量具重复性和再现性报告GageR&R Report零件号和名称PartName:特性:Characteristics规范:Specification 量 具 号:GageNumberthe measurement system isacceptable measurement system needs improvement.Make every effort 98零件2456( )2 ( 22222( )( )( )( ) ( )重复性-设备变差(EV ) 再现性-评价人变差(AV ) 重复性和再现性(GRR )零件变差(PV ) 总变差(TV )SKYROCK))))):more than 50% points out of the control line;。

顾 客:量具名称:规范结论:零件号:量具编号:上限:11日期:特 性:量具类型:下限:9编制:评价人12345678910均值10.29(0.56) 1.340.47(0.80)0.020.59(0.31) 2.26(1.36)0.19420.41(0.68) 1.170.50(0.92)(0.11)0.75(0.20) 1.99(1.25)0.16630.64(0.58)1.270.64(0.84)(0.21)0.66(0.17)2.01(1.31)0.211测量系统分析均值0.447-0.607 1.2600.537-0.853-0.1000.667-0.227 2.087-1.307XBARA 0.190极差0.3500.1200.1700.1700.1200.2300.1600.1400.2700.110RBARA0.1840.199评价人 B姓名:0.23012345678910均值10.08(0.47) 1.190.01(0.56)(0.20)0.47(0.63) 1.80(1.68)0.0010.30420.25(1.22)0.94 1.03(1.20)0.220.55(0.08) 2.12(1.62)0.09930.07(0.68)1.340.20(1.28)0.060.83(0.34)2.19(1.50)0.089零件变差(PV ): 1.104均值0.133-0.790 1.1570.413-1.0130.0270.617-0.350 2.037-1.600XBARB 0.063总变差 (TV):1.145极差0.1800.7500.4001.0200.7200.4200.3600.5500.3900.180RBARB0.497ndc:% TOLERANCE 评价人 C姓名:5VARIATION (TOL)12345678910均值10.04(1.38)0.880.14(1.46)(0.29)0.02(0.46) 1.77(1.49)-0.223% EV:17.35 5.962(0.11)(1.13) 1.090.20(1.07)(0.67)0.01(0.56) 1.45(1.77)-0.256% AV:20.08 6.903(0.15)(0.96)0.670.11(1.45)(0.49)0.21(0.49)1.87(2.16)-0.284% R & R:26.549.12均值-0.073-1.1570.8800.150-1.327-0.4830.080-0.503 1.697-1.807XBARC -0.254% PV:96.4133.12极差0.1900.4200.4200.0900.3900.3800.2000.1000.4200.670RBARC0.328极差控制图XBARp0.169-0.851 1.0990.367-1.064-0.1860.454-0.3601.940-1.571# PARTS 10M (FOR EV(K1) = # OF TRIALS)(FOR AV(K2) = # APPR AND G=1)(FOR PV(K3) = # OF PARTS AND G=1)UCL-R 0.8660.8660.8660.8660.8660.8660.8660.8660.8660.866OP1?1d22345678910LCL-R0.0000.0000.0000.0000.0000.0000.0000.0000.0000.000OP2?11 1.410 1.910 2.240 2.480 2.670 2.830 2.960 3.080 3.180RBARBAR 0.3360.3360.3360.3360.3360.3360.3360.3360.3360.336OP3?12 1.280 1.810 2.150 2.400 2.600 2.770 2.910 3.020 3.130XBARBAR 0.0000.0000.0000.0000.0000.0000.0000.0000.0000.000# OPER 33 1.230 1.770 2.120 2.380 2.580 2.750 2.890 3.010 3.110UCL-XBAR 0.34373570.34373570.34373570.34373570.34373570.34373570.34373570.34373570.34373570.3437357# TRIALS (M)34 1.210 1.750 2.110 2.370 2.570 2.740 2.880 3.000 3.100LCL-XBAR -0.344402-0.344402-0.344402-0.344402-0.344402-0.344402-0.344402-0.344402-0.344402-0.344402(G)30.000G5 1.190 1.740 2.100 2.360 2.560 2.730 2.870 2.990 3.100d2A(EV)= 1.128d2(EV)= 1.6936 1.1801.7302.090 2.350 2.560 2.730 2.870 2.9903.100d2(PV)= 3.180d2(AV)= 1.910均值控制图7 1.170 1.730 2.090 2.3502.550 2.7202.870 2.9903.100COUNTD4D3A23/d2SIZEA2D3D43/d2TOLERANCE XDiff (Ro):0.4458 1.170 1.720 2.080 2.350 2.550 2.720 2.870 2.980 3.0903 2.5740 1.023 1.7722 1.880 3.2682.65920Rp:3.5119 1.160 1.720 2.080 2.340 2.550 2.720 2.860 2.980 3.0903 1.0230 2.574 1.7720.1917AV1:0.05410 1.160 1.720 2.080 2.340 2.550 2.720 2.860 2.980 3.09040.7290 2.282 1.457AV2:0.00111 1.160 1.710 2.080 2.340 2.550 2.720 2.860 2.980 3.09050.5770 2.1141.2912 1.150 1.7102.070 2.340 2.550 2.720 2.850 2.9803.090G13 1.150 1.710 2.070 2.340 2.550 2.710 2.850 2.980 3.09014 1.150 1.710 2.070 2.340 2.540 2.710 2.850 2.980 3.08015 1.150 1.710 2.070 2.340 2.540 2.710 2.850 2.980 3.080>15 1.1281.6932.059 2.3262.534 2.7042.847 2.9703.078% 过程变差 (TV)所有计算的理论和常数信息见MSA 参考手册,第三版。