SMA量具重复性和再现性分析报告

- 格式:xls

- 大小:295.00 KB

- 文档页数:1

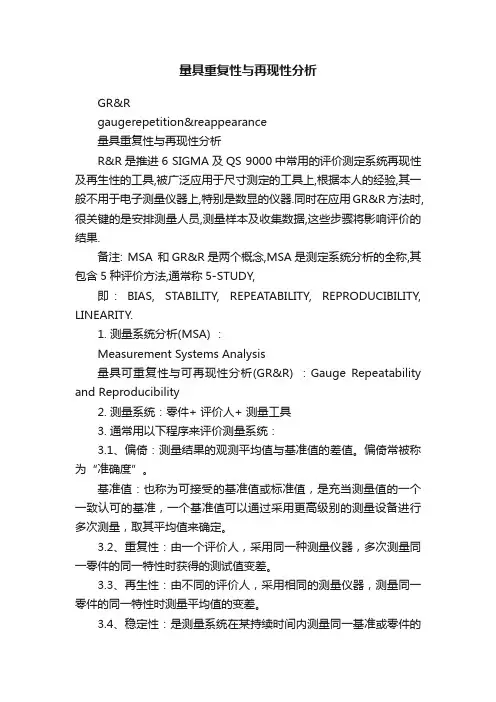

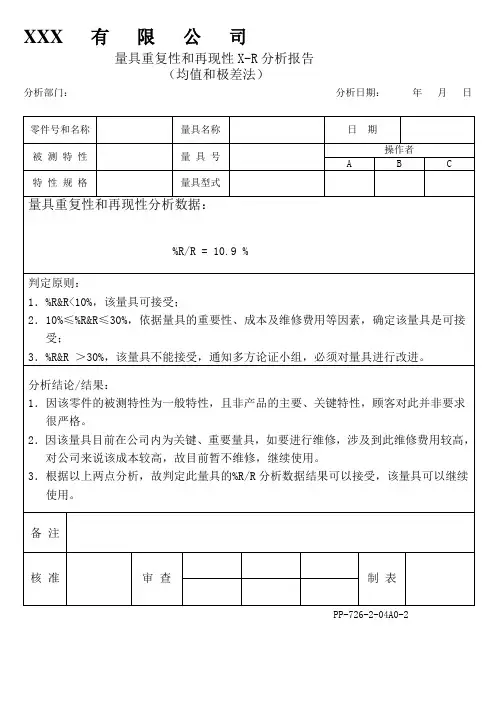

量具重复性与再现性分析GR&Rgaugerepetition&reappearance量具重复性与再现性分析R&R是推进6 SIGMA及QS 9000中常用的评价测定系统再现性及再生性的工具,被广泛应用于尺寸测定的工具上,根据本人的经验,其一般不用于电子测量仪器上,特别是数显的仪器.同时在应用GR&R方法时,很关键的是安排测量人员,测量样本及收集数据,这些步骤将影响评价的结果.备注: MSA 和GR&R是两个概念,MSA是测定系统分析的全称,其包含5种评价方法,通常称5-STUDY,即: BIAS, STABILITY, REPEATABILITY, REPRODUCIBILITY, LINEARITY.1. 测量系统分析(MSA) :Measurement Systems Analysis量具可重复性与可再现性分析(GR&R) :Gauge Repeatability and Reproducibility2. 测量系统:零件+ 评价人+ 测量工具3. 通常用以下程序来评价测量系统:3.1、偏倚:测量结果的观测平均值与基准值的差值。

偏倚常被称为“准确度”。

基准值:也称为可接受的基准值或标准值,是充当测量值的一个一致认可的基准,一个基准值可以通过采用更高级别的测量设备进行多次测量,取其平均值来确定。

3.2、重复性:由一个评价人,采用同一种测量仪器,多次测量同一零件的同一特性时获得的测试值变差。

3.3、再生性:由不同的评价人,采用相同的测量仪器,测量同一零件的同一特性时测量平均值的变差。

3.4、稳定性:是测量系统在某持续时间内测量同一基准或零件的单一特性时获得的测量值总变差。

3.5、线性:在量具预期的工作量程内,偏倚值的差值。

4. 总体说来,以上这些程序有时被称为“量具R&R ”程序,这是因为它们常常只是用来评价再现性和重复性这两项统计特性。

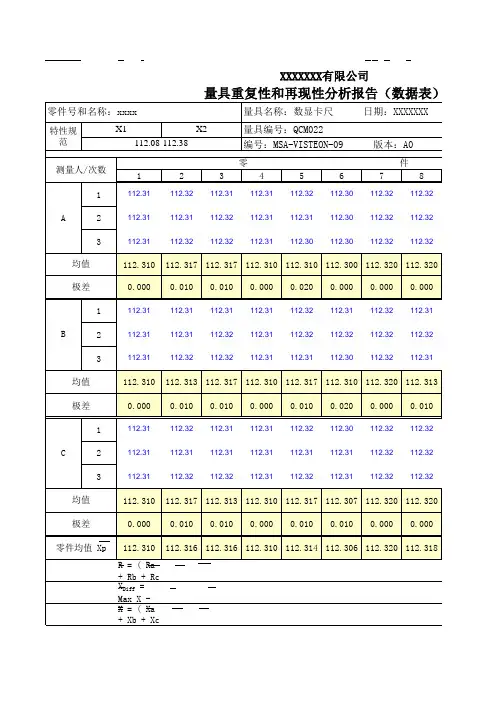

PLEASE SPECIFY THE FOLLOWING PARAMETERS AND COMPLETE THE FORM ACCORDINGLY PARAMETERS AREK1Number of Trials Must be either 2 or 33OKK2Number of Operators Must be either 2 or 33OKK3Number of Parts Can be any value between 2 and 10 10OK'01 PSW'01 PSW'!A6'01 PSW'!A21'01 PSW'!A54'01 PSW'!H54GAGE APPROVED, USE IT Part number Part name缸体Plant一发Characteristic Gage number Coord by张伟17.25-17.75Tolerance0.5Units mm Gage name游标卡尺Phone #Total Variation (TV)0.164754Gage ECL/revision DateOPERATOR P A R T RESULTSTRIAL #12345678910AVG A117.5817.5617.5417.5617.5417.4817.5617.5417.5417.54A117.54400 217.617.5417.5417.5617.5617.517.5417.5417.5617.54A217.54800 317.617.5617.5417.5617.5417.517.5417.5417.5417.54A317.54600 Average17.5933317.5533317.5417.5617.5466717.4933317.5466717.5417.5466717.54X A17.54600 Range0.020.020.00.00.020.020.020.00.020.0R A0.01200 B117.617.5617.5617.5617.5617.517.5417.5417.5417.56B117.55200 217.617.5817.5417.5617.5617.517.5417.5417.5417.54B217.55000 317.617.5617.5617.5417.5617.517.5417.5417.5417.54B317.54800 Average17.617.5666717.5533317.5533317.5617.517.5417.5417.5417.54667X B17.55000 Range0.00.020.020.020.00.00.00.00.00.02R B0.00800 C117.5817.5617.5617.5617.5417.517.5617.5417.5417.54C117.54800 217.5817.5817.5617.5617.5417.4817.5417.5417.5417.54C217.54600 317.617.5617.5617.5617.5417.4817.5617.5417.5417.54C317.54800 Average17.5866717.5666717.5617.5617.5417.4866717.5533317.5417.5417.54X C17.54733 Range0.020.020.00.00.00.020.020.00.00.0R C0.00800 Part Avg17.5933317.5622217.5511117.5577817.5488917.4933317.5466717.5417.5422217.54222x PART =17.54778 Part Range R PART =0.10000 R =R A+ R B + R C / No of operators =0.01200+0.00800+0.00800/3R =0.00933 X DIFF=[Max (X)ABC] - [Min (X)ABC] =17.55000-17.54600X DIFF =0.00400 UCL R=R*D4 =0.00933* 2.580UCL R =0.02408 LCL R=R*D3 =0.00933*0.000LCL R =0.00000 UCLx=X+A2*R=17.54778+0.010UCLx=17.55733 LCLx=X-A2*R=17.54778-0.010LCL x=17.53823 OPERATOR NAME NOTE: It has been statistically proven that the Tolerance Method is betterA wangshouxin to determine measurement equipment reliability. Even with negativeB许多Kurtosis data sets, the recorded measurements will be less than 1% away C张伟from the true value if GR&R is below 30%. Contact Quality Group if you GOOD UNTIL GAGE ECL/revision CHANGE need more information.FROM DATA SHEET:R =0.00933X DIFF =0.00400R PART =0.10000Measurement Unit Analysis Base on PART TO PART Variation Repeatibility - Equipment Variation (EV)EV =R * K1% EV = 100[EV/TV]EV =0.02847Trials K1% EV =17.283 3.05Reproducibility - Appraiser Variation (AV)AV= [ ( X DIFF * K2)2 - (EV2 / nr)](n parts, r trials)% AV = 100[AV/TV]AV=0.00947Oper K2% AV = 5.753 2.70Repeatibility & Reproducibility (R & R)% R&R = 100[R&R/TV]R&R= (EV2 + AV2)% R&R =18.21R&R=0.03000Part Variation (PV)PV=R PART * K3Parts K3% PV = 100[PV/TV]PV=0.1620010 1.62% PV =98.33Total Variation (TV) 1.62PLEASE SPECIFY THE FOLLOWING PARAMETERS AND COMPLETE THE FORM ACCORDINGLY PARAMETERS AREK 1Number of Trials Must be either 2 or 33OK K 2Number of OperatorsMust be either 2 or 33OK K 3Number of PartsCan be any value between 2 and 1010OK'01 PSW '01 PSW'!A6'01 PSW'!A21'01 PSW'!A54'01 PSW'!H54GAGE APPROVED, USE ITPart number Part name缸体Plant 一发Characteristic Gage number Coord by 张伟Tolerance0.5Units mm Gage name游标卡尺Phone #Total Variation (TV)0.164754Gage ECL/revisionDate17.25-17.75。

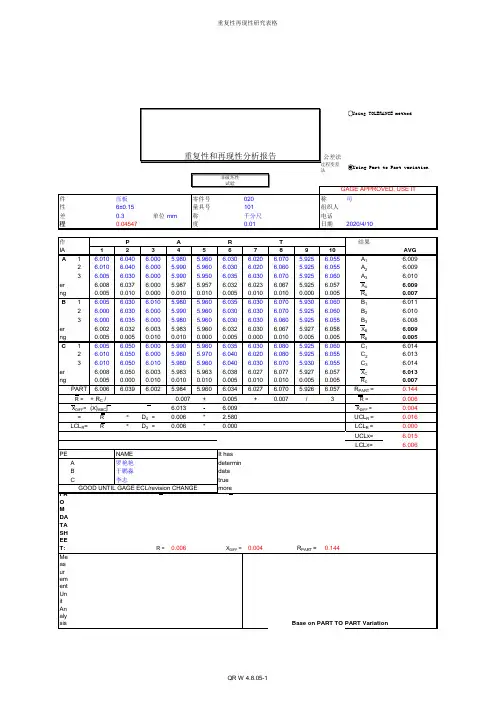

重复性和再现性分析报告公差法过程变差法非破坏性试验'[1204442'[1204442528.xls]01'[1204442528.xls]01'[1204442528.xls]01'[1204442528.xls]01GAGE APPROVED, USE IT 零件压板零件号CL3202020单位名称*****有限公司特性6±0.15量具号LQT-101组织人公差0.3单位mm量具名称千分尺电话过程0.04547量具精度0.01日期2020/4/10操作P A R T 结果TR IA 12345678910AVG A 1 6.010 6.040 6.000 5.980 5.960 6.030 6.020 6.070 5.925 6.055A 1 6.0092 6.010 6.040 6.000 5.990 5.960 6.030 6.020 6.060 5.925 6.055A 2 6.00936.005 6.030 6.000 5.990 5.950 6.035 6.030 6.070 5.925 6.060A 36.010Av er 6.008 6.037 6.000 5.987 5.957 6.032 6.023 6.067 5.925 6.057X A 6.009Ra ng 0.0050.0100.0000.0100.0100.0050.0100.0100.0000.005R A0.007B 1 6.005 6.030 6.010 5.980 5.960 6.035 6.030 6.070 5.930 6.060B 1 6.0112 6.000 6.030 6.000 5.990 5.960 6.030 6.030 6.070 5.925 6.060B 2 6.0103 6.000 6.035 6.000 5.980 5.960 6.030 6.030 6.060 5.925 6.055B 36.008Av er 6.002 6.032 6.003 5.983 5.960 6.032 6.030 6.067 5.927 6.058X B 6.009Ra ng 0.0050.0050.0100.0100.0000.0050.0000.0100.0050.005R B0.005C 1 6.005 6.050 6.000 5.990 5.960 6.035 6.030 6.080 5.925 6.060C 1 6.0142 6.010 6.050 6.000 5.980 5.970 6.040 6.020 6.080 5.925 6.055C 2 6.0133 6.0106.050 6.010 5.980 5.960 6.040 6.030 6.070 5.930 6.055C 36.014Av er 6.008 6.050 6.003 5.983 5.963 6.038 6.027 6.077 5.927 6.057X C 6.013Ra ng0.0050.0000.0100.0100.0100.0050.0100.0100.0050.005R C0.007PART 6.006 6.0396.0025.984 5.9606.034 6.027 6.070 5.926 6.057R PART =0.144R =R A + R B + R C /0.007+0.005+0.007/3R =0.006X DIFF =[Max (X )ABC ] 6.013- 6.009X DIFF =0.004UCL R =R*D 4 =0.006* 2.580UCL R =0.016LCL R =R*D 3 =0.006*0.000LCL R =0.000UCL X =6.015LCL X =6.006O PENAMENOTE :It has A 罗艳艳todetermin B 于鹏淼Kurtosis data C 李志from the true GOOD UNTIL GAGE ECL/revision CHANGEneed moreFR O M DA TA SH EE T:R =0.006X DIFF =0.004R PART =0.144Me as ur em ent Un it An aly sisBase on PART TO PART VariationUsing TOLERANCE methodUsing Part to Part variation重复性和再现性分析报告公差法过程变差法非破坏性试验'[1204442'[1204442528.xls]01'[1204442528.xls]01'[1204442528.xls]01'[1204442528.xls]01GAGE APPROVED, USE IT 零件压板零件号CL3202020单位名称*****有限公司特性6±0.15量具号LQT-101组织人公差0.3单位mm量具名称千分尺电话过程0.04547量具精度0.01日期2020/4/10Using TOLERANCE methodUsing Part to Part variation重复性和再现性分析报告公差法过程变差法非破坏性试验'[1204442'[1204442528.xls]01'[1204442528.xls]01'[1204442528.xls]01'[1204442528.xls]01GAGE APPROVED, USE IT 零件压板零件号CL3202020单位名称*****有限公司特性6±0.15量具号LQT-101组织人公差0.3单位mm量具名称千分尺电话过程0.04547量具精度0.01日期2020/4/10Using TOLERANCE methodUsing Part to Part variation重复性和再现性分析报告公差法过程变差法非破坏性试验'[1204442'[1204442528.xls]01'[1204442528.xls]01'[1204442528.xls]01'[1204442528.xls]01GAGE APPROVED, USE IT 零件压板零件号CL3202020单位名称*****有限公司特性6±0.15量具号LQT-101组织人公差0.3单位mm 量具名称千分尺电话过程0.04547量具精度0.01日期2020/4/10Using TOLERANCE methodUsing Part to Part variation量具重复性和再现性的()的可接受性准则:低于的误差测量系统可接受;的误差应根据应用的重要重复性和再现性分析报告公差法过程变差法非破坏性试验'[1204442'[1204442528.xls]01'[1204442528.xls]01'[1204442528.xls]01'[1204442528.xls]01GAGE APPROVED, USE IT 零件压板零件号CL3202020单位名称*****有限公司特性6±0.15量具号LQT-101组织人公差0.3单位mm量具名称千分尺电话过程0.04547量具精度0.01日期2020/4/10Using TOLERANCE methodUsing Part to Part variationRange Chart by appraiser重复性和再现性分析报告公差法过程变差法非破坏性试验'[1204442'[1204442528.xls]01'[1204442528.xls]01'[1204442528.xls]01'[1204442528.xls]01GAGE APPROVED, USE IT 零件压板零件号CL3202020单位名称*****有限公司特性6±0.15量具号LQT-101组织人公差0.3单位mm量具名称千分尺电话过程0.04547量具精度0.01日期2020/4/10Using TOLERANCE methodUsing Part to Part variation重复性和再现性分析报告公差法过程变差法非破坏性试验'[1204442'[1204442528.xls]01'[1204442528.xls]01'[1204442528.xls]01'[1204442528.xls]01GAGE APPROVED, USE IT 零件压板零件号CL3202020单位名称*****有限公司特性6±0.15量具号LQT-101组织人公差0.3单位mm量具名称千分尺电话过程0.04547量具精度0.01日期2020/4/10Using TOLERANCE methodUsing Part to Part variation。

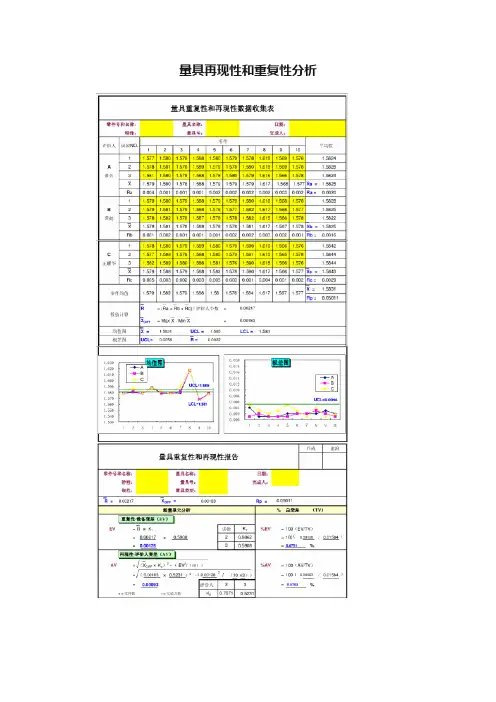

量具再现性和重复性分析如何正确理解量具可重复性&再现性(GR&R)如何正确理解量具可重复性&再现性(GR&R)如何正确理解量具可重复性&再现性(GR&R)对于过程控制系统来说,量具的可重复性及再现性(以下称量具R&R)研究十分重要。

下面就学习下如何正确的实施研究并解释结果。

任何一个真正称得上专业人士的质量人都深知:R&R研究报告是成功实施过程控制系统的关键部分。

但是令人吃惊的是,很多人却不知道如何正确地进行可重复性及可重现性研究,也不知该如何解释研究结果。

质量专业人士知道,测量产品对满足客户公差要求至关重要。

此外,测量产品对于统计过程控制系统的必要性——统计过程控制系统的价值在于改进制造过程本身。

但他们容易忽视:只有测量系统本身完善且准确,数据才有价值。

量具R&R研究目的不仅在于告诉评价人测量系统是否能实现其应实现的用途,还揭示测量系统的哪一部分引起的测量波动最大,从而帮助评价人有计划地改进系统。

测量系统中的波动主要来自于三个方面:产品本身、实施测量的人员,以及用于测量的设备。

量具研究的意义之一就是揭示这三个因素分别对波动所产生的影响。

如果测量系统够完善,那么大部分波动应该来自产品本身。

而如果波动绝大部分是由评价人或测量设备造成的,那么这个系统可能就不合适了。

量具研究包括数个零件,多个评价人重复测量这些零件。

虽然零件和评价人的数量可变,但是大多数研究需使用10个零件,3个评价人来对每个零件至少测三次。

重复的测量叫作试验。

测量完成后的计算结果将决定评价人之间,零件之间和跨试验的波动水平。

这里没有必要讲解实际计算方法,因为有很多软件和模板可以帮助评价人计算。

因此我们应更关注于如何开展合理的研究及如何解释结果。

选择零件样本也许是实施一次成功研究的最重要的步骤——同时也是最易误解的地方。

用于量具研究的零件样本应该能反映生产过程的真实波动。

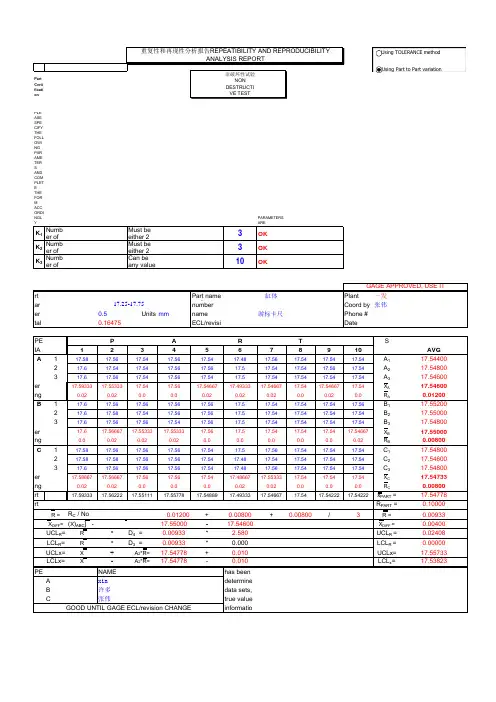

PLEASE SPECIFY THE FOLLOWING PARAMETERS AND COMPLETE THE FORM ACCORDINGLY PARAMETERS AREK1Number of Trials试验次数Must be either 2 or 3必须为2或32OKK2Number of Operators操作人数Must be either 2 or 3必须为2或33OKK3Number of Parts零件数Must be either 10必须为1010OK'01 PSW'!H6'01 PSW'!A21'01 PSW'!A54'01 PSW'!H54GAGE APPROVED, USE IT Part number零件号4975198Part name零件名称信号盘Plant厂家#REF!Characteristic特性位置度Gage number量具编号Coord by#REF!Tolerance0.25Units Gage name量具名称三坐标Phone ##REF!Tolerance (Tol)公差/60.0416667Gage ECL/revision Date日期OPERATOR P A R T RESULTSTRIAL #12345678910AVG A10.050.020.130.050.040.060.130.110.120.05A10.0750020.050.010.130.050.040.070.130.110.120.04A20.074203A3Average均值0.05350.01550.12950.0480.04250.06050.12850.10650.1180.0435X A0.07460 Range极差0.0010.0050.0030.0020.0010.0090.0070.0010.0020.003R A0.00340 B10.050.020.130.050.040.060.130.120.120.05B10.0771020.050.020.130.040.040.060.140.120.120.04B20.076803B3Average均值0.05250.01550.1320.0450.03950.05950.1340.12050.12350.0475X B0.07695 Range极差0.0010.0010.00.0040.0030.0050.0020.0030.0010.009R B0.00290 C10.050.010.130.050.050.060.130.110.130.05C10.0780020.050.020.130.050.050.070.140.120.130.05C20.080303C3Average均值0.050.01450.130.0470.0510.0650.1350.11550.1330.0505X C0.07915 Range极差0.0040.0030.0080.0020.0040.0060.0020.0070.0020.003R C0.00410 Part Avg0.0520.015170.13050.046670.044330.061670.13250.114170.124830.04717x PART =0.07690 Part Range R PART =0.11733R =R A+ R B + R C / No. of operators =0.00340+0.00290+0.00410/3R =0.00347 X DIFF=[Max (X)ABC] - [Min (X)ABC] =0.07915-0.07460X DIFF =0.00455 UCL R=R*D4 =0.00347* 3.270UCL R =0.01134 LCL R=R*D3 =0.00347*0.000LCL R =0.00000 OPERATOR NAME NOTE: It has been statistically proven that the Tolerance Method is betterA chan to determine measurement equipment reliability. Even with negativeB lee Kurtosis data sets, the recorded measurements will be less than 1% awayC zhang from the true value if GR&R is below 30%. Contact Quality Group if youGOOD UNTIL GAGE ECL/revision CHANGE need more information.FROM DATA SHEET:R =0.00347X DIFF =0.00455R PART =0.11733Measurement Unit Analysis测量数据分析Based on the TOLERANCE Method采用公差法Repeatibility - Equipment Variation (EV)重复性-设备变差EV =R * K1% EV = 100[EV/Tol]EV =0.00307Trials K1% EV =7.3720.8862Reproducibility - Appraiser Variation (AV)再现性-评价人变差AV= [ ( X DIFF * K2)2 - (EV2 / nr)](n parts, r trials)% AV = 100[AV/Tol]AV=0.00228Oper K2% AV = 5.4730.5231Repeatibility & Reproducibility (R & R)重复性和再现性% R&R = 100[R&R/Tol]R&R= (EV2 + AV2)% R&R =9.18R&R=0.00383Part Variation (PV)零件变差% PV = 100[PV/Tol]PV=R PART * K3Parts K3% PV =88.59PV=0.03691100.3146ndc=(1.41PV/R&R)Total Variation (TV)总变差0.3146ndc=13.606922TV= (R&R2 + PV2)#REF!GAGE IS ACCEPTEDTV=0.03711Part CertificationNON DESTRUCTIVE TEST 非破坏性试验PLEASE SPECIFY THE FOLLOWING PARAMETERS AND COMPLETE THE FORM ACCORDINGLY PARAMETERS AREK 1Number of Trials 试验次数Must be either 2 or 3必须为2或32OKK 2Number of Operators 操作人数Must be either 2 or 3必须为2或33OK K 3Number of Parts 零件数Must be either 10必须为1010OK'01 PSW'!H6'01 PSW'!A21'01 PSW'!A54'01 PSW'!H54GAGE APPROVED, USE ITPart number 零件号4975198Part name 零件名称信号盘Plant 厂家#REF!Characteristic 特性位置度Gage number 量具编号Coord by #REF!Tolerance0.25UnitsGage name 量具名称三坐标Phone ##REF!Tolerance (Tol)公差/60.0416667Gage ECL/revisionDate 日期。

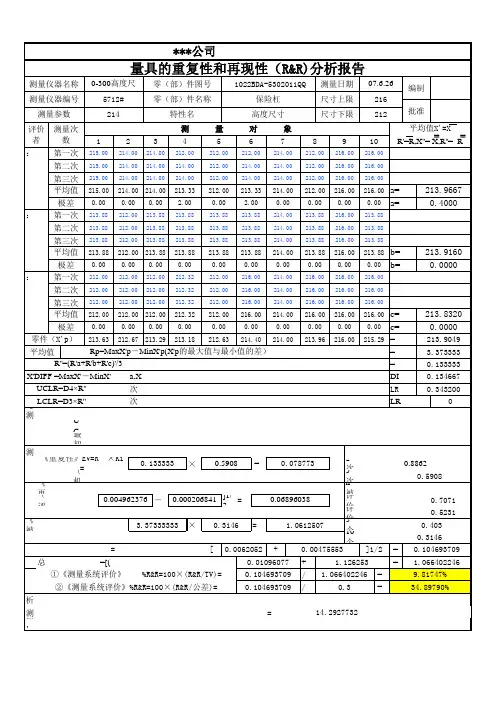

温量具重复性和再现性数据表12345678910A 160.0260.0459.9560.0560.0360.0759.9660.0560.0159.94A 1260.0260.0459.9460.0560.0360.0859.9660.0560.0059.94A 2360.0160.0459.9560.0660.0360.0859.9660.0560.0159.94A 3平均60.0260.0459.9560.0560.0360.0859.9660.0560.0159.94X A 圾差0.010.000.010.010.010.010.010.000.020.01R AB 160.0360.0559.9560.0660.0260.0759.9760.0660.0059.94B 1260.0260.0559.9560.0660.0360.0859.9760.0560.0059.94B 2360.0260.0459.9460.0560.0360.0859.9860.0660.0059.95B3平均60.0260.0559.9560.0660.0360.0859.9760.0660.0059.94X B 圾差0.010.010.010.010.010.010.010.010.010.01R BC 160.0260.0459.9560.0560.0360.0859.9660.0660.0059.94C 1260.0260.0459.9560.0660.0360.0859.9760.0560.0159.94C 2360.0360.0559.9560.0660.0260.0759.9760.0560.0159.95C 3平均60.0260.0459.9560.0660.0360.0859.9760.0560.0159.94X C 圾差0.010.010.000.010.000.010.010.010.000.01R C X=R PART =R =R A +R B +R C /No ofoperators =0.01+0.01+0.01/3.00R =X DIFF =[Max (X)ABC ] -[Min (X)ABC ] =60.02-60.01X DIFF =UCL R =R *D 4 =0.01* 2.58UCL R =LCL R R *D 3 =0.01*0.00LCL R =UCL X X +A 2*R =60.01+0.01UCL X =LCL X =X -A 2*R =60.01-0.01LCL X =评价姓名备注: 1.这是一种统计A B C测量前量具是好的,未经过修理。

量具台帐与检校记录引言:在生产和制造行业中,量具(也称为测量仪器或测量工具)是非常重要的工作设备。

它们用于检测和测量零件的尺寸、形状和其他关键参数,以确保产品质量符合要求。

为保证量具的精度和准确性,企业通常会建立量具台账并进行定期的检校记录。

本文将详细介绍量具台账的编制和检校记录的目的、内容及步骤。

一、量具台账的编制量具台账是用于记录企业所拥有的各种量具的一份清单。

编制量具台账的目的是为了管理和跟踪量具的数量、位置和状态,以及及时进行维护和校准。

以下是编制量具台账的几个重要步骤:1. 确定台账格式:根据企业的具体需求,确定量具台账的格式。

可以使用电子表格软件如Excel或专用的资产管理软件进行记录。

2.注册量具:将所有的量具按照一定的分类方法进行登记。

可以根据量具的类型(例如卡尺、游标卡尺、千分尺等)或使用场所(例如生产车间、质检部门)进行分类。

3.记录基本信息:对每一个登记的量具记录其基本信息,如量具编号、名称、型号、生产商、购买日期、购买价格等。

此外,还可以记录量具的使用者和存放位置等信息。

4.进行定期检查和清点:通过定期检查和清点已登记的量具,确保量具台账中的记录与实际情况一致。

记录量具的使用情况、损坏情况以及是否需要维护或校准等。

5.维护台账的完整性:跟踪量具的位置和使用情况,及时更新量具台账,确保台账的完整性和准确性。

二、检校记录的目的及内容检校记录是对量具进行校准的过程和结果进行详细记录的文件。

量具的校准是一种通过比较和调整量具与标准量具之间误差的过程,以确保量具的精度和准确性。

检校记录的目的是跟踪和控制量具的测量性能,并提供校准结果的证明。

以下是检校记录中应包括的内容:1.量具信息:记录被校准的量具的基本信息,如量具编号、名称、型号、生产商等。

确保记录准确无误。

2.校准日期和周期:记录量具的校准日期以及校准的周期。

根据量具的使用频率和重要性,制定合理的校准计划。

3.校准方法:记录所采用的校准方法和标准,以及校准的详细过程。

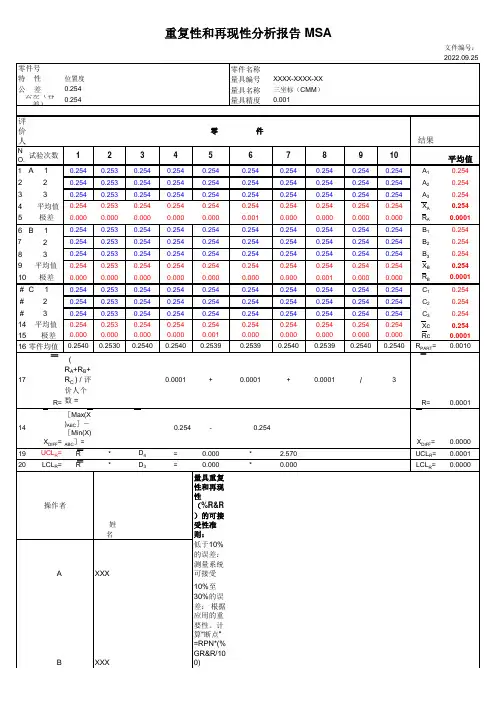

31.35831.3421012345678910Total 1.A 1 1.352 1.35 1.35 1.349 1.351 1.35 1.352 1.35 1.35 1.35213.5062.21.3511.3491.3511.351.351.3511.3521.3491.3511.35213.5063.3 1.352 1.35 1.35 1.349 1.351 1.35 1.352 1.35 1.35 1.35213.5064.均值Mean 1.35167 1.34967 1.35033 1.34933 1.35067 1.35033 1.35200 1.34967 1.35033 1.35200 1.350600SumA 4.055 4.049 4.051 4.048 4.052 4.051 4.056 4.049 4.051 4.05640.51805. 极差Rang0.0010.0010.0010.0010.0010.00100.0010.00100.0008006.B 1 1.352 1.35 1.35 1.352 1.351 1.35 1.35 1.352 1.35 1.34913.5067.21.3511.3491.3511.3521.351.3491.3511.3521.3511.3511.3048.3 1.352 1.35 1.35 1.352 1.351 1.35 1.35 1.352 1.35 1.34913.5069.均值Mean 1.35167 1.34967 1.35033 1.35200 1.35067 1.34967 1.35033 1.35200 1.35033 1.34933 1.350600SumB 4.055 4.049 4.051 4.056 4.052 4.049 4.051 4.056 4.051 4.04840.518010. 极差Rang0.0010.0010.00100.0010.0010.00100.0010.0010.00080011.C 1 1.35 1.352 1.35 1.349 1.351 1.352 1.35 1.35 1.35 1.3513.50412.21.3511.3521.3511.351.351.3521.3511.3491.3511.34913.50613.3 1.35 1.352 1.35 1.349 1.351 1.352 1.35 1.35 1.35 1.3513.50414.均值Mean 1.35033 1.35200 1.35033 1.34933 1.35067 1.35200 1.35033 1.34967 1.35033 1.349671.350467SumC 4.051 4.056 4.051 4.048 4.052 4.056 4.051 4.049 4.051 4.04940.51415. 极差Rang0.00100.00000.00100.00100.00100.00000.00100.00100.00100.00100.0008001.351222 1.350444 1.350333 1.350222 1.350667 1.350667 1.350889 1.350444 1.350333 1.3503331.35055612.16100012.15400012.15300012.15200012.15600012.15600012.15800012.15400012.15300012.153000121.550.0010000.0008023D4 3.27 2.5751.3513740.002060D3001.3497370.00000A2 1.88 1.02312345678910UCLx1.3514 1.3514 1.3514 1.3514 1.3514 1.3514 1.3514 1.3514 1.3514 1.3514LCLx 1.3497 1.3497 1.3497 1.3497 1.3497 1.3497 1.3497 1.3497 1.3497 1.3497UCLR 0.00210.00210.00210.00210.00210.00210.00210.00210.00210.0021LCLR0.00000.00000.00000.00000.00000.00000.00000.00000.00000.0000公差:6σpp 变差PV PV 0.000315PV TV TV#DIV/0!TV 基于公差base%#DIV/0!基于零件变差%#DIV/0!基于过程变差%#DIV/0!基于过程能力%#DIV/0!公式A Formulandc 0.9385282%R&R 大于公式B FormulaX^2/nkr 164.16002164.16002164.160035164.16010164.16011Source DF SS MS F P Source DF SS MS F P Parts 90.000010.000000.235370.9841490.000010.000000.82110.5984720.000000.000000.048420.9528620.000000.000000.16890.84484180.000070.0000013.768520.00000600.000020.00000780.000080.00000Total 890.00009890.00009极差图Range Repeatability Repeatability Total Gauge R&R With Operator*Part Interaction Gauge R&R Without Operator*Part InteractionSUMSQ(sum(men-part))/r sumSQ(all)n=part k=men ANOVA Table With Operator*Part Interaction ANOVA Table Without Operator*Part InteractionParts Operators Operators Operators*Part 注:当分析结果超出要求后,利用均值极差图分析原因When analysis result is out of spec,need analyse the root cause by mean and range chart 。

重复性和再现性分析报告公差法Using TOLERANCE method过程变差法非破坏性试验.xls]01 PSW'!H54GAGE SYSTEM NEEDS IMPROVEMENT '[757137'[757137103.x'[757137103.xls]0'[757137103.xls]0零件名称 从动件分总成零件号 3081411A单位名称特性 41.35±0.13量具号组织人 朱跃全公差0.26单位mm量具名称游标卡尺电话65501544过程变差 (TV)25.9812量具精度0.02日期2006/8/25操作员P A R T结果TRIAL #12345678910AVGA141.38041.26041.42041.32041.46041.28041.40041.38041.40041.350A141.365 241.37041.26041.40041.32041.46041.28041.41041.38041.40041.360A241.364 341.38041.26041.42041.32041.45041.28041.40041.37041.38041.360A341.362 Average41.37741.26041.41341.32041.45741.28041.40341.37741.39341.357X A41.364 Range0.0100.0000.0200.0000.0100.0000.0100.0100.0200.010R A0.009B141.35041.28041.40041.34041.44041.30041.38041.38041.40041.380B141.365 241.34041.26041.40041.34041.44041.30041.38041.38041.40041.390B241.363 341.34041.28041.41041.35041.44041.30041.37041.40041.40041.380B341.367 Average41.34341.27341.40341.34341.44041.30041.37741.38741.40041.383X B41.365 Range0.0100.0200.0100.0100.0000.0000.0100.02041.4000.010R B 4.149C141.36041.26041.41041.34041.44041.32041.38041.36041.40041.390C141.366 241.37041.26041.41041.34041.43041.30041.38041.36041.40041.380C241.363 341.36041.26041.40041.34041.43041.30041.39041.36041.40041.390C341.363 Average41.36341.26041.40741.34041.43341.30741.38341.36041.40041.387X C41.364 Range0.0100.0000.0100.0000.0100.0200.0100.00041.4000.010R C 4.147 PART41.36141.26441.40841.33441.44341.29641.38841.37441.40041.376R PART =41.364 R =R A+ R B + R C / No of operators =0.009+ 4.149+ 4.14741.4003R =10.541 X DIFF=[Max (X)ABC] - [Min (X)ABC] =41.365-41.364X DIFF =41.364 UCL R=R*D4 =10.541* 2.580UCL R = 6.561 LCL R=R*D3 =10.541*0.000LCL R = 5.271UCL X=#DIV/0!LCL X=#DIV/0! OPERATOR NAME NOTE: It has been statistically proven that the Tolerance Method is better A李宽芳to determine measurement equipment reliability. Even with negativeB颜利君Kurtosis data sets, the recorded measurements will be less than 1% away重复性和再现性分析报告公差法Using TOLERANCE method过程变差法非破坏性试验'[757137'[757137103.x'[757137103.xls]0'[757137103.xls]0.xls]01 PSW'!H54GAGE SYSTEM NEEDS IMPROVEMENT 零件名称 从动件分总成零件号 3081411A单位名称特性 41.35±0.13量具号组织人 朱跃全公差0.26单位mm量具名称游标卡尺电话65501544过程变差 (TV)25.9812量具精度0.02日期2006/8/25重复性和再现性分析报告公差法过程变差法非破坏性试验'[757137'[757137103.x '[757137103.xls]0'[757137103.xls]0.xls]01 PSW'!H54GAGE SYSTEM NEEDS IMPROVEMENT零件名称 从动件分总成零件号 3081411A单位名称特性 41.35±0.13量具号组织人 朱跃全公差0.26单位mm 量具名称 游标卡尺电话65501544过程变差 (TV)25.9812量具精度0.02日期2006/8/25Using TOLERANCE method重复性和再现性分析报告公差法过程变差法非破坏性试验'[757137'[757137103.x '[757137103.xls]0'[757137103.xls]0.xls]01 PSW'!H54GAGE SYSTEM NEEDS IMPROVEMENT零件名称 从动件分总成零件号 3081411A单位名称特性 41.35±0.13量具号组织人 朱跃全公差0.26单位mm 量具名称 游标卡尺电话65501544过程变差 (TV)25.9812量具精度0.02日期2006/8/25Using TOLERANCE method。