(完整版)IPC标准清单-中文英文对照版

- 格式:pdf

- 大小:181.85 KB

- 文档页数:12

IPC标准中英名称对照IPC-M-105 Rigid Printed Board Manual刚性印制板设计手册IPC-D-325A Documentation Requirements for Printed Boards印制板设计文件图册要求IPC-PE-740A Troubleshooting for Printed Board Manufacture and Assembly印制板制造和组装的故障排除IPC-6010 Series IPC-6010 Qualification and Performance SeriesIPC-6010印制电路板质量标准和性能规范系列手册IPC-6011 Generic Performance Specification for Printed Boards印制板通用性能规范IPC-6013A Qualification & Performance Specification for Flexible Printed Boards (Includes Amendment 1)挠性印制板的鉴定与性能规范(包括修改单1)IPC-6016 Qualification & Performance Specification for High Density Interconnect (HDI) Layers or Boards高密度互连(HDI)层或印制板的鉴定与性能规范IPC-6012A-AM Qualification and Performance Specification for Rigid Printed Boards, Includes Amendment 1刚性印制板的鉴定与性能规范(包括修改单1)IPC-6018A Microwave End Product Board Inspection and Tech微波成品印制板的检验和测试IPC-6015 Qualification & Performance Specification for Organic Multichip Module (MCM-L) Mounting and Interconnections有机多芯片模块(MCM-L)安装及互连结构的鉴定与性能规范IPC-A-600F Acceptability of Printed Boards印制板验收条件IPC-QE-605A Printed Board Quality Evaluation Handbook印制板质量评价IPC-QE-605A-KIT Hard Copy and CD印制板质量评价书和光盘(CD)IPC-HM-860 Specification for Multilayer Hybrid Circuits多层混合电路规范IPC-TF-870 Qualification and Performance of Polymer Thick Film Printed Boards聚合物厚膜印制板的鉴定与性能IPC-ML-960 Qualification and Performance Specification for Mass Lamination Panels for Multilayer printed Boards多层印制板的鉴定与性能规范用预制内层在制板的鉴定与性能规范IPC-TR-481 Results of Multilayer Tests Program Round Robin多层印制板联合试验计划结果IPC-TR-551 Quality Assessment of Printed Boards Used for Mounting and Interconnecting Electronic Components用于电子元件安装与互连的印制板质量评价IPC-TR-579 Round Robin Reliability Evaluation of Small Diameter Plated Through Holes in PCBs印制板中小直径镀覆孔可靠性评价联合试验IPC-4552 Specification for Electroless Nickel/Immersion Gold(ENIG) Plating for Printed Circuit Boards印制电路板表面非电镀镍/沉金规范IPC-DR-572 Drilling Guidelines for Printed Boards印制板钻孔导则IT-95080 Improvements/Alternatives to Mechanical Drilling of PCB Vias印制板通孔机加工方案的改进和优选手册IPC-NC-349 Computer Numerical Control Formatting for Drillers and Routers钻床和铣床用计算机数字控制格式IPC-SM-839 Pre & Post Solder Mask Application Cleaning Guidelines施加阻焊前及施加后清洗导则IPC-HDI-1 High Density Interconnect Microvia Technology Compendium高密度(HDI)互连微通孔技术纲要IPC/JPCA-4104 Specification for High Density Interconnect (HDI) and Microvia Materials高密度互连(HDI)及微导通孔材料规范IPC-6016 Qualification & Performance Specification for High Density Interconnect (HDI) Layers or Boards高密度互连(HDI)层或印制板的鉴定与性能规范IPC/JPCA-6801 IPC/JPCA Terms & Definitions, Test Methods, and Design Examples for Build-Up/High Density Interconnection积层/高密度互连的术语和定义、试验方法与设计例IPC-DD-135 Qualification Testing for Deposited Organic Interlayer Dielectric Materials for Multichip Modules多芯片组件内层有机绝缘材料的鉴定试验IT-96060 High Density PCB Microvia Evaluation (October Project), Phase I, Round 1高密度印制板微通孔评价指标手册, 第一期第一版IT-97071 High Density PCB Microvia Evaluation, Phase I, Round 2高密度印制板微通孔评价指标手册, 第一期第二版IT-30101 High Density PCB Microvia Evaluation, Phase I, Round 3高密度印制板微通孔评价指标手册, 第一期第三版IT-98123 Microvia Manufacturing Technology Cost Analysis Report微通孔制作技术成本核算报告IPC-2141 Controlled Impedance Circuit Boards & High Speed Logic Design控制阻抗电路板与高速逻辑设计IPC-2252 Design Guide for RF/Microwave Circuit Boards射频/微波电路板设计指南IPC-4103 Specification for Base Materials for High Speed/High Frequency Applications高速高频用基材规范IPC-6018A Microwave End Product Board Inspection and Test微波成品印制板的检验和测试IPC-D-317A Design Guidelines for Electronic Packaging Utilizing High Speed Techniques采用高速技术电子封装设计导则IPC-M-102 Flexible Circuits Compendium挠性电路纲要IPC-4202 Flexible Base Dielectrics for Use in Flexible Printed Circuitry挠性印制线路用挠性绝缘基底材料IPC-4203 Adhesive Coated Dielectric Films for Use as Cover Sheets for Flexible Printed Circuitry and Flexible Adhesive Bonding Films挠性印制线路覆盖层用涂粘接剂绝缘薄膜IPC-4204 Flexible Metal-Clad Dielectrics for Use in Fabrication of Flexible Printed Circuitry挠性金属箔去电应用于柔性电路组装IPC-6013-K Qualification & Performance Specification for Flexible Printed Boards & Amendment 1挠性印制板的鉴定与性能规范(包括修改单1)IPC/JPCA-6202 IPC/JPCA Performance Guide Manual for Single- and Double-Sided Flexible Printed Wiring BoardsIPC/JPCA单双面挠性印制板性能手册IPC-FA-251 Guidelines for Assembly of Single- and Double-Sided Flex Circuits单面和双面挠性电路组装导则IPC-FC-234 Composite Metallic Materials Specification for Printed Wiring Boards印制线路板复合金属材料规范IPC-MB-380 Guidelines for Molded Interconnection Devices模压互连器件导则IPC-M-107 Standards for Printed Board Materials Manual印制板材料标准手册IPC-MI-660 Incoming Inspection of Raw Materials Manual原材料接收检验手册IPC-4101A Specifications for Base Materials for Rigid and Multilayer Printed Boards刚性及多层印制板用基材规范IPC-4121 Guidelines for Selecting Core Construction for Multilayer Printed Wiring Board Applications多层印制板用芯板结构选择导则IPC-4562 Metal Foil for Printed Wiring Applications印制线路用金属箔IPC-CF-148A Resin Coated Metal for Printed Boards印制板用涂树脂金属箔IPC-CF-152B Composite Metallic Materials Specification for Printed Wiring Boards印制线路板复合金属材料规范IPC-TR-482 New Developments in Thin Copper Foils薄铜箔的新发展IPC-TR-484 Results of IPC Copper Foil Ductility Round Robin StudyIPC铜箔延展性联合研究结果IPC-TR-485 Results of Copper Foil Rupture Strength Test Round Robin Study铜箔断裂强度试验联合研究结果IPC-4412 Specification for Finished Fabric Woven from ”E” Glass for Printed Boards“E”类精纺玻璃纤维层印制板技术规范IPC-4130 Specification & Characterization Methods for Nonwoven "E" Glass MaterialsE 玻璃纤维非织布材料规范及性能确定方法IPC-4110 Specification and Characterization Methods for Nonwoven Cellulose Based Paper for Printed Boards印制板用纤维纸规范及性能确定方法IPC-4411-K Specification and Characterization Methods for Non-Woven Para-Aramid Reinforcement, with Amendment 1聚芳基酰胺非织布规范及性能确定方法, 包括修改单1IPC-4411-AM1 Specification and Characterization Methods for Non-Woven Para-Aramid Reinforcement, Amendment 1关于聚芳基酰胺非织布规范及性能确定方法的修改单 1IPC-SG-141 Specification for Finished Fabric Woven from "S" Glass for Printed Boards印制板用经处理S玻璃纤维织物规范IPC-A-142 Specification for Finished Fabric Woven from Aramid for Printed Boards印制板用经处理聚芳酰胺纤维编织物规范IPC-QF-143 Specification for Finished Fabric Woven from Quartz (Pure Fused Silica) for Printed Boards印制板用经处理石英(熔融纯氧化硅)纤维编织物规范IPC-2524 PWB Fabrication Data Quality Rating System印制板制造数据质量定级体系IPC-9151A Printed Board Process, Capability, Quality and Relative Reliability Benchmark Test Standard and Database印制板工艺, 容量, 质量,可靠性试验标准和数据库IPC-9191 General Guidelines for Implementation of Statistical Process Control (SPC)实施统计过程控制(SPC)的通用导则IPC-9199 Statistical Process Control (SPC) Quality Rating统计分析控制IPC-9252 Guidelines and Requirements for Electrical Testing of Unpopulated Printed Boards未组装印制板电测试要求和指南IT-97061 PWB Hole to Land Misregistration: Causes and Reliability印制线路板通孔与焊盘的错位: 原因和可靠性IT-98103 Reliability of Misregistered and Landless Innerlayer Interconnects in Thick Panels多层板内部无焊盘层互连错位的可靠性IPC-MS-810 Guidelines for High V olume Microsection大批量显微剖切导则IPC-QL-653A Certification of Facilities that Inspect/Test Printed Boards, Components & Materials印制板、元器件及材料检验试验设备的认证IPC-TR-483 Dimensional Stability Testing of Thin Laminates-Report on Phase 1 & 2 International Round Robin Test薄层压板尺寸稳走性试----国际联合试验计划I阶段及II阶段报告IPC-TR-486 Round Robin Study to Correlate IST & Microsectioning Evaluations for Inner-Layer Separation内层分离的互连应力测试(IST)与显微剖切相关性联合研究。

IPC-A-600E 中英文对照一.外观特性(Externally Observable Characteristics)1.板边(Board edges)1.1毛刺 (Burrs)1.2缺口 (Nicks)1.3晕圈(Haloing)2.基材的表面与次表面(Base Material Surface and Subsurface) 2.1露织物/显布纹(Weave Exposure/Texture Conditions)2.2麻点和微空洞 (Pits and Micro voids)3.基材的次表面 (Base Material Subsurface)3.1白斑/龟裂 (Measling/Crazing)3.2分层/起泡 (Delamination/Blister)3.3外来夹杂物 (Foreign Inclusions)4.焊料涂覆层和熔融锡铅层 (Solder Coatings and Fused Tin Lead) 4.1不润湿 (No wetting)4.2半润湿 (De wetting)5.镀通孔 (Holes-Plated Through)5.1结瘤/毛刺 (Nodules/Burrs)5.2粉红圈 (Pink Ring)5.3铜镀层空洞 (Plating Voids- Copper Plating)5.4成品镀覆层的镀层空洞 (Plating Voids – Finished Coating)6.非支撑孔 (Holes Unsupported)6.1晕圈(Haloing)7.印制插头 (Printed Contacts)7.1表面镀层概况 (Surface Plating – General)7.2板边插头的毛刺 (Burrs on Edge-Board Contacts)7.3表面镀层的附着力 (Adhesion of Over plate)8.标记 (Marking)9.阻焊剂(阻焊) (Solder Resist or Solder Mask)9.1导线表面的涂覆层 (Coverage Over Conductors)9.2对焊盘的重合度 (Registration to Lands)9.3镀通孔焊盘以外其它图形的重合度(Registration to Features other than PTH Lands)9.4起泡/分层 (Blisters/Delamination)9.5附着力(剥落或起皮) Adhesion (Flaking or Peeling)9.6涂层漏印 (Skip Coverage)9.7波纹/皱褶/皱纹 (Waves/Wrinkles/Ripples)9.8掩孔(导通孔) Tenting (Via Holes)9.9吸管式空隙 (Soda Strawing)9.10厚度 (Thickness)10.尺寸特性 (Dimensional Characteristics)10.1导线宽度和间距 (Conductor Width and Spacing)10.2孔环的测量 (Annular Ring – Measurement)10.3支撑孔的孔环 (Annular Ring – Supported Holes)10.4非支撑孔的孔环 (Annular Ring – Unsupported Holes)10.5不规则形状焊盘的孔环(Annular Ring –Irregular Shaped Lands)10.6平整度 (Flatness)二.可观测的内在特性(Internally Observable Voids (outside thermal zone)1.介质材料 (Dielectric Materials)1.1层压空洞(受热区之外) Laminate Voids (outside thermal zone 1.2重合度/连接通孔的导体 (Registration/Conductors to Holes)1.3非支撑隔离孔对电源层/接地层的关系(Clearance Hole, Unsupported, to Power/Ground Planes1.4分层/起泡 (Delamination/Blister1.5凹蚀 (Etch back)1.5.1正凹蚀 (Positive Etch back)1.5.2负凹蚀 (Negative Etch back)1.6金属层间的介质间隙 (Dielectric Material, Clearance, MetalPlanes)1.7层间的间距 (Layer-to-layer Spacing)1.8树脂凹缩 (Resin Recession)2.导电图形概述 (Conductive Patterns – General)2.1 蚀刻特性 (Etching Characteristics)2.2标准的印制与蚀刻 (Standard Print & Etch)2.3内层铜箔导体的列缝 (Conductor Crack – Internal Foil)2.4外层铜箔导体的列缝 (Conductor Crack – External Foil)2.5表面导体厚度(铜箔加镀层)Surface Conductor Thickness (foil plus plating)2.6内层铜箔厚度 (Foil Thickness – Internal Layers)3.镀通孔概述 (Plated – Through – Holes – General)3.1内层孔环 (Annular Ring – Internal Layers)3.2焊盘起翘(显微切片)Lifted Lands – (Cross – sections)3.3孔壁镀层裂缝 (Plating Crack – <Barrel>)3.4拐角镀层裂缝 (Plating Crack – <Corner>)3.5镀层结瘤 (Plating Nodules)3.6孔壁铜镀层厚度 (Copper Plating Thickness – Hole Wall)3.7镀层空间(Plating Voids)3.8焊料涂覆层厚度 (Solder Coating Thickness)3.9芯吸作用 (Wicking)3.9.1 有空隙的通孔的芯吸作用 (Wicking, Clearance Holes)3.10 内层间分离-垂直的(纵向)显微切片Inter-Plane Separation-Vertical (axial) Microsection3.11 内层间分离-水平的(横向)显微切片Inter-Plane Separation-Horizontal (transverse) Microsection 4.钻孔的镀通孔 (Plated – Through – Holes – Drilled4.1毛刺 (Burrs)4.2钉头 (Nailheading)5.冲孔的镀通孔 (Plated – Through – Holes – Punched)5.1粗糙与结瘤 (Roughness and Nodules)5.2嗽叭口 (Flare)三.其它类型板 (Miscellaneous)1.挠性印制电路 (Flexible Printed Circuits)1.1.覆盖层分层 (Coverlay Delamination)1.2.边缘修整 (Trimmed Edges)1.3.余隙孔的重合度 (Access Hole Registration)1.4.镀孔规范 (Plated Holes Criteria)1.5.焊盘覆盖层(Land Coverage)1.6.增强板的粘结 (Stiffener Bonding)2. 刚-挠印制板 (Rigid – Flex Printed Boards)2.1 层压缺陷 (Laminate Defects)2.2挠性区的板边分层 (Edge Delamination – Flex Areas)2.3刚性部分的板边缺陷 (Edge Imperfections – Rigid Section)3. 金属芯印制板 (Metal Core Printed Boards)3.1 分类 (Type Classifications)3.2层压型的间距 (Spacing Laminated Type)3.3绝缘厚度,绝缘的金属基材(Insulation Thickness, Insulated Metal Substrate) 3.4层压型金属芯板的填充绝缘材料(Isulation Material Fill, Laminated Type Metal Core) 3.5层压型的绝缘填料中的裂缝(Cracks in Insulation Material Fill, Laminated Type) 3.6与镀通孔壁连接的金属芯(Core Bond to Plated- Through –hole Wall)4. 齐平印制板 (Flush Printed Boards)4.1 表面导体的齐平度 (Flushness of Surface Conductor)5. 清洁度测试 (Cleanliness Testing)5.1 可焊性试验 (Solder ability Testing)5.3电气完整性 (Electrical Integrity)。

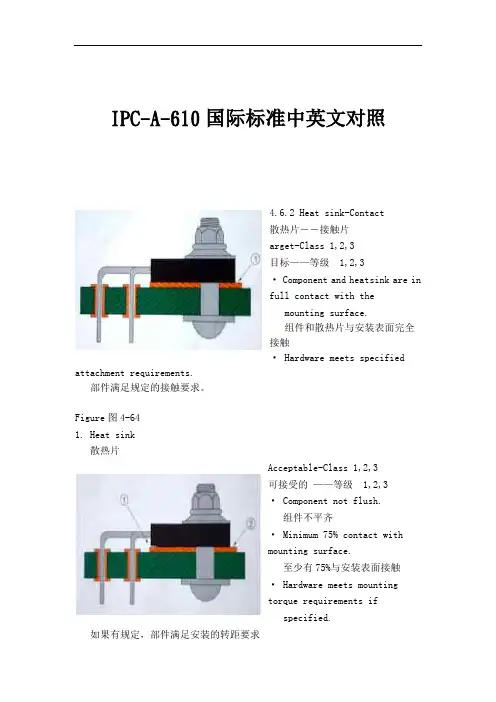

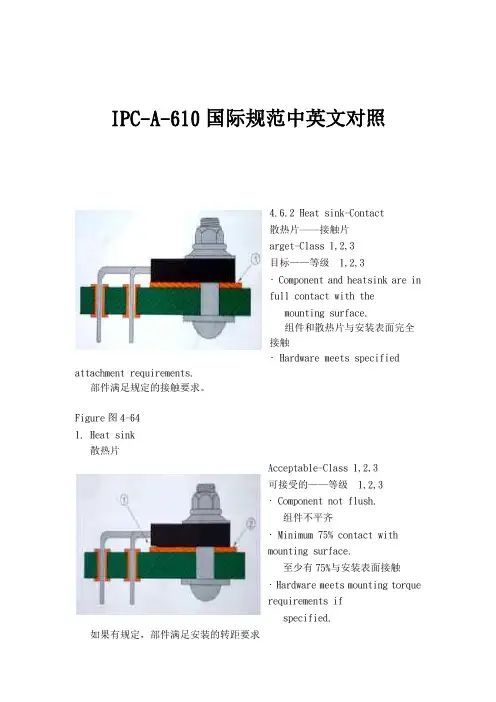

IPC-A-610国际标准中英文对照4.6.2 Heat sink-Contact散热片――接触片arget-Class 1,2,3目标——等级1,2,3· Component and heatsink are infull contact with themounting surface.组件和散热片与安装表面完全接触· Hardware meets specified attachment requirements.部件满足规定的接触要求。

Figure图4-641. Heat sink散热片Acceptable-Class 1,2,3可接受的——等级1,2,3· Component not flush.组件不平齐· Minimum 75% contact withmounting surface.至少有75%与安装表面接触· Hardware meets mountingtorque requirements ifspecified.如果有规定,部件满足安装的转距要求Figure图4-651. Gap2. Heat sink间隙散热片Defect-Class 1,2,3缺点——等级1,2,3· Component is not in contactwith mounting surface.组件没有接触到安装表面· Hardware is loose and can bemoved.部件松弛可以移动。

Figure图4-661. Heat sink2. Gap散热片间隙5.1 Orientation方向5.1.1 Orientation-Horizontal方向——水平Target-Class 1,2,3目标——等级1,2,3•Components are centered betweentheir lands.组件位于焊盘中央•Component markings arediscernible.组件标识清晰可见•Nonpolarized components are oriented so thatmarkings all read the same way (left-to-rightor top-to-bottom).Figure图5-1 无极性组件的方向应使其标识都能按同样方式进行辨识(从左到右或从上到下)Acceptable-Class 1,2,3可接受的——等级1,2,3•Polarized and multileadcomponents are orientedcorrectly.有极性和多引脚的组件应按正确方向安装。

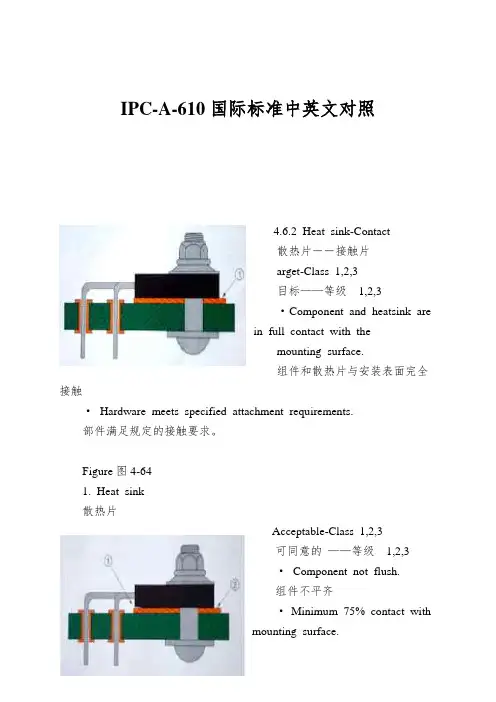

IPC-A-610国际标准中英文对照4.6.2 Heat sink-Contact散热片――接触片arget-Class 1,2,3目标——等级1,2,3·Component and heatsink arein full contact with themounting surface.组件和散热片与安装表面完全接触·Hardware meets specified attachment requirements.部件满足规定的接触要求。

Figure图4-641. Heat sink散热片Acceptable-Class 1,2,3可同意的——等级1,2,3·Component not flush.组件不平齐·Minimum 75% contact withmounting surface.至少有75%与安装表面接触·Hardware meets mounting torque requirements ifspecified.如果有规定,部件满足安装的转距要求Figure图4-651. Gap2. Heat sink间隙散热片Defect-Class 1,2,3缺点——等级1,2,3·Component is not in contactwith mounting surface.组件没有接触到安装表面·Hardware is loose and can be moved.部件放松能够移动。

Figure图4-661. Heat sink2. Gap散热片间隙5.1 Orientation方向5.1.1 Orientation-Horizontal方向——水平Target-Class 1,2,3目标——等级1,2,3•Components are centered between their lands.组件位于焊盘中央•Component markings are discernible.组件标识清晰可见•Nonpolarized components are oriented so thatmarkings all read the same way (left-to-rightor top-to-bottom).Figure图5-1 无极性组件的方向应使其标识都能按同样方式进行辨识(从左到右或从上到下)Acceptable-Class 1,2,3可同意的——等级1,2,3•Polarized and multilead components are orientedcorrectly.有极性和多引脚的组件应按正确方向安装。

IPC-A-610国际规范中英文对照4.6.2 Heat sink-Contact散热片――接触片arget-Class 1,2,3目标——等级1,2,3· Component and heatsink are infull contact with themounting surface.组件和散热片与安装表面完全接触· Hardware meets specified attachment requirements.部件满足规定的接触要求。

Figure图4-641. Heat sink散热片Acceptable-Class 1,2,3可接受的——等级1,2,3· Component not flush.组件不平齐· Minimum 75% contact withmounting surface.至少有75%与安装表面接触· Hardware meets mounting torquerequirements ifspecified.如果有规定,部件满足安装的转距要求Figure图4-651. Gap2. Heat sink间隙散热片Defect-Class 1,2,3缺点——等级1,2,3· Component is not in contactwith mounting surface.组件没有接触到安装表面· Hardware is loose and can bemoved.部件松弛可以移动。

Figure图4-661. Heat sink2. Gap散热片间隙5.1 Orientation方向5.1.1 Orientation-Horizontal方向——水平Target-Class 1,2,3目标——等级1,2,3•Components are centeredbetween their lands.组件位于焊盘中央•Component markings arediscernible.组件标识清晰可见•Nonpolarized components are oriented so thatmarkings all read the same way (left-to-rightor top-to-bottom).Figure图5-1 无极性组件的方向应使其标识都能按同样方式进行辨识(从左到右或从上到下)Acceptable-Class 1,2,3可接受的——等级1,2,3•Polarized and multileadcomponents are orientedcorrectly.有极性和多引脚的组件应按正确方向安装。

IPC相關標準目錄(部分)目錄題目IPC-SC-60A 錫焊後溶劑清洗手冊IPC-SA-61 錫焊後半水溶劑清洗手冊IPC-AC-62A 錫焊後水溶液清洗手冊IPC-CH-65A 印製板及組裝件清洗導則IPC-FC-234 單面和雙面印製電路壓敏膠粘劑組裝導則IPC-D-279 高可靠表面安裝印製板組裝件技術設計導則IPC-A-311 照相版製作和使用的程序控制IPC-D-316 高頻設計導則IPC-D-317A 採用高速技術電子封裝設計導則IPC-C-406 表面安裝連接器設計及應用導則IPC-CI-408 使用無焊接表面安裝連接器設計及應用導則IPC-TR-579 印製板中小直徑鍍覆孔可靠性評價聯合試驗IPC-A-600F中文版印製板驗收條件IPC-QE-605A 印製板品質評價IPC-A-610C中文版印製板組裝件驗收條件IPC-ET-652 未組裝印製板電測試要求和指南IPC-PE-740A 印製板製造和組裝的故障排除IPC-CM-770D 印製板元件安裝導則IPC-SM-780 以表面安裝為主的元件封裝及互連導則IPC-SM-782A 表面安裝設計及連接盤圖形標準(包括修訂1和2)IPC-SM-784 晶片直裝技術實施導則IPC-SM-785 表面安裝焊接件加速可靠性試驗導則IPC-SM-786A 濕度/再流焊敏感積體電路的特性分級與處置程式IPC-CA-821 導熱膠粘劑通用要求IPC-SM-839 施加阻焊前及施加後清洗導則IPC-1131 印製板印製造商用資訊技術導則IPC/JPCA-2315 高密度互連與微導通孔設計導則IPC-4121 多層印製板用芯板結構選擇導則(代替IPC-CC-110A)IPC/JPCA-6801 積層/高密度互連的術語和定義、試驗方法與設計例IPC-7095 球柵陣列的設計與組裝過程的實施IPC-7525 網版設計導則IPC-7711 電子組裝件的返工IPC-7721 印製板和電子組裝的修復與修正IPC-7912 印製板和電子組裝件的DPMO(每百萬件缺陷數)和製造指數的計算IPC-9191 實施統計程序控制(SPC)的通用導則IPC-9201 表面絕緣電阻手冊IPC-9501 電子元件的印製板組裝過程模擬評價(積體電路預處理)IPC-9502 電子元件的印製板組裝焊接過程導則IPC-9503 非積體電路元件的濕度敏感度分級IPC-9504 非積體電路元件的組裝過程模擬評價(非積體電路元件預處理)J-STD-012 倒裝晶片及晶片級封裝技術的應用J-STD-013 球柵陣列及其它高密度封裝技術的應用IPC/EIA J-STD-026 倒裝晶片用半導體設計標準IPC/EIA J-STD-028 倒裝芯版面及晶片凸塊結構的性能標準IPC/JEDEC J-STD-035 非氣密封裝電子元件用聲波顯微鏡IPC-HDBK-001 已焊接電子組裝件的要求手冊與導則IPC-T-50F 電子電路互連與封裝術語和定義IPC-L-125A 高速高頻互連用覆箔或未覆箔塑膠基材規範IPC-DD-135 多晶片組件內層有機絕緣材料的鑒定試驗IPC-EG-140 印製板用經處理E玻璃纖維編織物規範(包括修改1及修改2)IPC-SG-141 印製板用經處理S玻璃纖維織物規範IPC-A-142 印製板用經處理聚芳醯胺纖維編織物規範IPC-QF-143 印製板用經處理石英(熔融純氧化矽)纖維編織物規範IPC-CF-148A 印製板用塗樹脂金屬箔IPC-CF-152B 印製線路板複合金屬材料規範IPC-FC-231C 撓性印製線路用撓性絕緣基底材料(包括規格單修改)IPC-FC-232C 撓性印製線路和撓性粘結片用塗粘接劑絕緣薄膜(包括規格單修改)IPC-FC-241C 製造撓性印製線路板用撓性覆箔絕緣材料(包括規格單修改)IPC-D-322 使用標準在制板尺寸的印製板尺寸選擇指南IPC-MC-324 金屬芯印製板性能規範IPC-D-325A 印製板、印製板組裝件及其附圖的檔要求IPC-D-326 製造印製板組裝件的資料要求IPC-NC-349 鑽床和銑床用電腦數位控制格式IPC-D-356A 裸基板電檢測的資料格式IPC-DW-424 封入式分立佈線互連板通用規範IPC-DW-425A 印製板分立線路的設計及成品要求(包括修改1)IPC-DW-426 分立線路組裝規範IPC-OI-645 目視光學檢查工具標準IPC-QL-653A 印製板、元器件及材料檢驗試驗設備的認證IPC-CA-821 導熱粘接劑通用要求IPC-CC-830A 印製板組裝件用電絕緣複合材料的鑒定與性能(包括修改1)IPC-SM-840C 永久性阻焊劑的鑒定及性能(包括修改1)IPC-D-859 厚膜多層混合電路設計標準IPC-HM-860 多層混合電路規範IPC-TF-870 聚合物厚膜印製板的鑒定與性能IPC-ML-960 多層印製板用預製內層在制板的鑒定與性能規範IPC-1902/IEC 60097 印製電路網格體系IPC-2221 印製板設計通用標準(代替IPC-D-275)(包括修改1)IPC-2222 剛性有機印製板設計分標準(代替IPC-D-275)IPC-2223 撓性印製板設計分標準(代替IPC-D-249)IPC-2224 PC卡用印製電路板分設計分標準IPC-2225 有機多晶片模組(MCM-L)及其組裝件設計分標準IPC-2511A 產品製造資料及其傳輸方法學的通用要求IPC-2524 印製板製造資料品質定級體系IPC-2615 印製板尺寸和公差IPC-3406 表面貼裝導電膠使用指南IPC-3408 各向異性導電膠膜的一般要求IPC-4101 剛性及多層印製板用基材規範IPC/JPCA-4104 高密度互連(HDI)及微導通孔材料規範IPC-4110 印製板用纖維紙規範及性能確定方法IPC-4130E 玻璃非織布規範及性能確定方法IPC-4411 聚芳基醯胺非織布規範及性能確定方法IPC-DR-570A,IPC-4562,IPC6016 印製線路用金屬箔(代替IPC-MF-150F)IPC-6011中文版印製板通用性能規範(代替IPC-RB-276)IPC-6012A中文版剛性印製板的鑒定與性能規範(包括修改1)IPC-6013 撓性印製板的鑒定與性能規範(包括修改1)IPC-6015 有機多晶片模組(MCM-L)安裝及互連結構的鑒定與性能規範IPC-6016 高密度互連(HDI)層或印製板的鑒定與性能規範IPC-6018 微波成品印製板的核對總和測試(代替IPC-HF-318A)IPC/JPCA-6202 單雙面撓性印製板性能手冊J-STD-001C 電氣與電子組裝件錫焊要求IPC/EIA J-STD-002A 元件引線、端子、焊片、接線柱及導線可焊性試驗J-STD-003 印製板可焊性試驗(代替IPC-S-804A)J-STD-004 錫焊焊劑要求(包括修改1)J-STD-005 焊膏技術要求(包括修改1)J-STD-006 電子設備用電子級錫焊合金、帶焊劑及不帶焊劑整體焊料技術要求(包括修改1)IPC/JEDEC J-STD-020A 非密封固態表面貼裝器件濕度/再流焊敏感度分類IPC/JEDEC J-STD-033 對濕度、再流焊敏感表貼裝器件的處置、包裝、發運和使用。

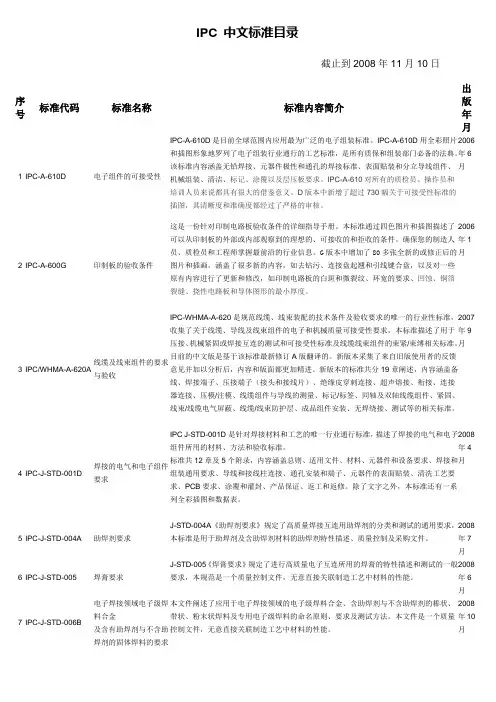

IPC 中文标准目录截止到2008年11月10日序号标准代码标准名称标准内容简介出版年月1IPC-A-610D电子组件的可接受性IPC-A-610D是目前全球范围内应用最为广泛的电子组装标准。

IPC-A-610D用全彩照片和插图形象地罗列了电子组装行业通行的工艺标准,是所有质保和组装部门必备的法典。

该标准内容涵盖无铅焊接、元器件极性和通孔的焊接标准、表面贴装和分立导线组件、机械组装、清洁、标记、涂覆以及层压板要求。

IPC-A-610对所有的质检员、操作员和培训人员来说都具有很大的借鉴意义。

D版本中新增了超过730幅关于可接受性标准的插图,其清晰度和准确度都经过了严格的审核。

2006年6月2IPC-A-600G印制板的验收条件这是一份针对印制电路板验收条件的详细指导手册。

本标准通过四色图片和插图描述了可以从印制板的外部或内部观察到的理想的、可接收的和拒收的条件。

确保您的制造人员、质检员和工程师掌握最前沿的行业信息。

G版本中增加了80多张全新的或修正后的图片和插画,涵盖了很多新的内容,如去钻污、连接盘起翘和引线键合盘,以及对一些原有内容进行了更新和修改,如印制电路板的白斑和微裂纹、环宽的要求、凹蚀、铜箔裂缝、挠性电路板和导体图形的最小厚度。

2006年1月3IPC/WHMA-A-620A 线缆及线束组件的要求与验收IPC-WHMA-A-620是规范线缆、线束装配的技术条件及验收要求的唯一的行业性标准,收集了关于线缆、导线及线束组件的电子和机械质量可接受性要求,本标准描述了用于压接、机械紧固或焊接互连的测试和可接受性标准及线缆线束组件的束紧/束缚相关标准。

目前的中文版是基于该标准最新修订A版翻译的。

新版本采集了来自旧版使用者的反馈意见并加以分析后,内容和版面都更加精进。

新版本的标准共分19章阐述,内容涵盖备线、焊接端子、压接端子(接头和接线片)、绝缘皮穿刺连接、超声熔接、衔接、连接器连接、压模/注模、线缆组件与导线的测量、标记/标签、同轴及双轴线缆组件、紧固、线束/线缆电气屏蔽、线缆/线束防护层、成品组件安装、无焊绕接、测试等的相关标准。

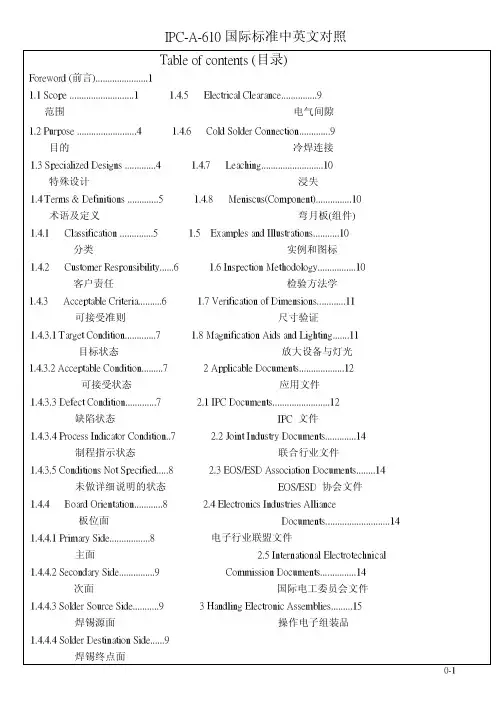

IPC中⽂版⽬录1.范围1.1范围声明1.2⽬的1.3性能分级,印制板分类及安装⽤途1.3.1性能分级1.3.2印制板类型1.3.3安装使⽤类别1.3.4采购的选择1.3.5材料、电镀⼯艺和表⾯涂覆层1.4术语及定义1.4.1由供需双⽅协商确定1.4.2覆盖层1.4.3覆盖膜1.4.4覆盖涂覆层1.4.5覆盖材料1.5对“应当”的说明1.6单位说明1.7版本修订2.适⽤⽂件2.1IPC2.2联合⼯业标准2.3其他出版物2.3.1美国材料及测试协会2.3.2国家电⼦制造商协会2.3.3 美国质量协会2.3.4 美国宇航材料规范2.3.5 美国机械⼯程师协会2.3.6 联邦标准3. 要求3.1 总则3.2 本技术规范中所使⽤的材料3.2.1 层压板和粘接材料3.2.2 外部粘接材料3.2.3 其他介电材料3.2.4 ⾦属箔3.2.5 ⾦属层/⾦属芯3.2.6 ⾦属镀层和涂覆层3.2.7 有机可焊性保护剂(OSP)3.2.8 阻焊层3.2.9 热熔液和助焊剂3.2.10 标记油墨3.2.11 填孔绝缘材料3.2.12 外部散热板3.2.13 导通孔保护3.2.14 埋⼊式⽆源材料3.3 ⽬检3.3.1 外观3.3.2 结构缺陷3.3.3 孔内的电镀层和涂覆层空洞3.3.4 连接盘起翘3.3.5 标记3.3.6 可焊性3.3.7 镀层附着⼒3.3.8板边接触⽚镀⾦层与焊料涂覆的结合3.3.9 加⼯质量3.4 尺⼨要求3.4.1 孔径,孔形精度和孔位精度3.4.2 孔环及孔破环(外层)3.4.3 ⼸曲和扭曲(仅指单独刚性或增强层部分)3.5 导体精度3.5.1 导体的宽度和厚度3.5.2 导体间距3.5.3 导体缺陷3.5.4 导电表⾯3.6 结构完整性3.6.1 热应⼒测试3.6.2附连测试板或⽣产板的显微切⽚要求3.7 阻焊要求3.7.1 阻焊覆盖层3.7.2 阻焊层固化及附着⼒3.7.3 阻焊层厚度3.8 电⽓要求3.8.1 耐电压3.8.2 电路连通性和介电性3.8.3 电路/镀通孔与⾦属基板之间的短路3.8.4 耐湿及绝缘电阻(MIR)3.9 清洁度3.9.1 施加阻焊层前的清洁度3.9.2 施加阻焊层,焊料或其他可代⽤表⾯涂覆后的清洁度3.9.3 压合前内层氧化处理后的清洁度3.10 特殊要求3.10.1 挥发物3.10.2 有机物污染3.10.3 抗霉性3.10.4 振动测试3.10.5 机械冲击3.10.6 阻抗测试3.10.7 热膨胀系数(CTE)3.10.8 热冲击3.10.9 表⾯绝缘电阻(验收时)3.10.10 ⾦属芯(⽔平显微切⽚)3.10.11 离⼦污染(溶剂萃取法测电阻率)3.10.12 模拟返⼯3.10.13 弯折测试3.10.14 耐弯曲性3.10.15 粘结强度(⾮⽀撑连接盘)3.10.16 粘结强度(增强层)3.11 维修3.11.1 电路维修3.12 返⼯4. 质量保证条款4.1 总则4.1.1 资格认证4.1.2 抽样检验4.2 验收检验和频度4.2.1 C=0零缺陷抽样计划4.2.2 仲裁测试4.3 质量⼀致性试验4.3.1 附连测试板的选⽤5. 注意5.1 订单信息5.2 所取代的技术规范附录A图图3-1 过渡区域图3-2不可接受的涂覆覆盖层图3-3 焊料芯吸和电镀渗透图3-4 孔环测量(外层)图3-5 90o和180o孔破环图3-6 导体宽度减少图3-7挠性板较⼤和较⼩余隙孔允许的相切图3-8 覆盖层黏结剂挤出和涂覆层渗出图3-9 覆盖层边缘材料脱落或碎屑粘附在挤出的黏结剂⾥图3-10导体之间不必要的铜和导体瘤图3-11 矩形表明贴装焊盘图3-12 圆形表明贴装焊盘图3-13 外层铜箔分离图3-14 裂缝定义图3-15 典型的显微切⽚评价试样图3-16 凹蚀深度允许量图3-17 去钻污允许量图3-18 负凹蚀图3-19 电镀褶皱/闭合褶皱图3-20 孔环测量(内层)图3-21旋转显微切⽚检测孔破环图3-22 显微切⽚的旋转对⽐图3-23 表⾯包裹铜测量(适⽤于所有填塞镀覆孔)图3-24 4型印制板上的包裹铜图3-25过度的研刷/平整处理去除了包裹铜(不接收)图3-26⾦属芯到镀覆孔的间距图3-27最⼩介质间距测量图3-28 弯折测试表表1-1 默认要求表3-1内层或外层⾦属层表3-2表⾯涂覆层和镀铜层的要求表3-3 涂覆层附着⼒表3-4 焊料芯吸/电镀渗透限值表3-5 增强板空洞占增强板表⾯积百分⽐限定值表3-6 镀层与涂覆层空洞的⽬视检查表3-7 板边接触⽚间隙表3-8 最⼩蚀刻孔环表3-9 覆盖层粘合剂挤出和涂覆层渗出允许值表3-10 连接盘区域的最⼩可焊接环宽表3-11 导体间距要求表3-12 热应⼒测试后镀覆孔的完整性表3-13加⼯后的内层铜箔厚度表3-14 电镀后外层导体厚度表3-15 阻焊层附着⼒表3-16 耐电压测试电压表3-17 绝缘电阻表4-1 资格认证测试表4-2 C=0各级批量板抽样计划表4-3 验收测试和频度表4-4 质量⼀致性测试IPC-6013B 挠性印制板的质量要求与性能规范1.范围1.1范围声明本技术规范涵盖了挠性印制板(印制板)的质量要求与性能规范。

IPC相關標準目錄(部分)目錄題目IPC-SC-60A 錫焊後溶劑清洗手冊IPC-SA-61 錫焊後半水溶劑清洗手冊IPC-AC-62A 錫焊後水溶液清洗手冊IPC-CH-65A 印製板及組裝件清洗導則IPC-FC-234 單面和雙面印製電路壓敏膠粘劑組裝導則IPC-D-279 高可靠表面安裝印製板組裝件技術設計導則IPC-A-311 照相版製作和使用的程序控制IPC-D-316 高頻設計導則IPC-D-317A 採用高速技術電子封裝設計導則IPC-C-406 表面安裝連接器設計及應用導則IPC-CI-408 使用無焊接表面安裝連接器設計及應用導則IPC-TR-579 印製板中小直徑鍍覆孔可靠性評價聯合試驗IPC-A-600F中文版印製板驗收條件IPC-QE-605A 印製板品質評價IPC-A-610C中文版印製板組裝件驗收條件IPC-ET-652 未組裝印製板電測試要求和指南IPC-PE-740A 印製板製造和組裝的故障排除IPC-CM-770D 印製板元件安裝導則IPC-SM-780 以表面安裝為主的元件封裝及互連導則IPC-SM-782A 表面安裝設計及連接盤圖形標準(包括修訂1和2)IPC-SM-784 晶片直裝技術實施導則IPC-SM-785 表面安裝焊接件加速可靠性試驗導則IPC-SM-786A 濕度/再流焊敏感積體電路的特性分級與處置程式IPC-CA-821 導熱膠粘劑通用要求IPC-SM-839 施加阻焊前及施加後清洗導則IPC-1131 印製板印製造商用資訊技術導則IPC/JPCA-2315 高密度互連與微導通孔設計導則IPC-4121 多層印製板用芯板結構選擇導則(代替IPC-CC-110A)IPC/JPCA-6801 積層/高密度互連的術語和定義、試驗方法與設計例IPC-7095 球柵陣列的設計與組裝過程的實施IPC-7525 網版設計導則IPC-7711 電子組裝件的返工IPC-7721 印製板和電子組裝的修復與修正IPC-7912 印製板和電子組裝件的DPMO(每百萬件缺陷數)和製造指數的計算IPC-9191 實施統計程序控制(SPC)的通用導則IPC-9201 表面絕緣電阻手冊IPC-9501 電子元件的印製板組裝過程模擬評價(積體電路預處理)IPC-9502 電子元件的印製板組裝焊接過程導則IPC-9503 非積體電路元件的濕度敏感度分級IPC-9504 非積體電路元件的組裝過程模擬評價(非積體電路元件預處理)J-STD-012 倒裝晶片及晶片級封裝技術的應用J-STD-013 球柵陣列及其它高密度封裝技術的應用IPC/EIA J-STD-026 倒裝晶片用半導體設計標準IPC/EIA J-STD-028 倒裝芯版面及晶片凸塊結構的性能標準IPC/JEDEC J-STD-035 非氣密封裝電子元件用聲波顯微鏡IPC-HDBK-001 已焊接電子組裝件的要求手冊與導則IPC-T-50F 電子電路互連與封裝術語和定義IPC-L-125A 高速高頻互連用覆箔或未覆箔塑膠基材規範IPC-DD-135 多晶片組件內層有機絕緣材料的鑒定試驗IPC-EG-140 印製板用經處理E玻璃纖維編織物規範(包括修改1及修改2)IPC-SG-141 印製板用經處理S玻璃纖維織物規範IPC-A-142 印製板用經處理聚芳醯胺纖維編織物規範IPC-QF-143 印製板用經處理石英(熔融純氧化矽)纖維編織物規範IPC-CF-148A 印製板用塗樹脂金屬箔IPC-CF-152B 印製線路板複合金屬材料規範IPC-FC-231C 撓性印製線路用撓性絕緣基底材料(包括規格單修改)IPC-FC-232C 撓性印製線路和撓性粘結片用塗粘接劑絕緣薄膜(包括規格單修改)IPC-FC-241C 製造撓性印製線路板用撓性覆箔絕緣材料(包括規格單修改)IPC-D-322 使用標準在制板尺寸的印製板尺寸選擇指南IPC-MC-324 金屬芯印製板性能規範IPC-D-325A 印製板、印製板組裝件及其附圖的檔要求IPC-D-326 製造印製板組裝件的資料要求IPC-NC-349 鑽床和銑床用電腦數位控制格式IPC-D-356A 裸基板電檢測的資料格式IPC-DW-424 封入式分立佈線互連板通用規範IPC-DW-425A 印製板分立線路的設計及成品要求(包括修改1)IPC-DW-426 分立線路組裝規範IPC-OI-645 目視光學檢查工具標準IPC-QL-653A 印製板、元器件及材料檢驗試驗設備的認證IPC-CA-821 導熱粘接劑通用要求IPC-CC-830A 印製板組裝件用電絕緣複合材料的鑒定與性能(包括修改1)IPC-SM-840C 永久性阻焊劑的鑒定及性能(包括修改1)IPC-D-859 厚膜多層混合電路設計標準IPC-HM-860 多層混合電路規範IPC-TF-870 聚合物厚膜印製板的鑒定與性能IPC-ML-960 多層印製板用預製內層在制板的鑒定與性能規範IPC-1902/IEC 60097 印製電路網格體系IPC-2221 印製板設計通用標準(代替IPC-D-275)(包括修改1)IPC-2222 剛性有機印製板設計分標準(代替IPC-D-275)IPC-2223 撓性印製板設計分標準(代替IPC-D-249)IPC-2224 PC卡用印製電路板分設計分標準IPC-2225 有機多晶片模組(MCM-L)及其組裝件設計分標準IPC-2511A 產品製造資料及其傳輸方法學的通用要求IPC-2524 印製板製造資料品質定級體系IPC-2615 印製板尺寸和公差IPC-3406 表面貼裝導電膠使用指南IPC-3408 各向異性導電膠膜的一般要求IPC-4101 剛性及多層印製板用基材規範IPC/JPCA-4104 高密度互連(HDI)及微導通孔材料規範IPC-4110 印製板用纖維紙規範及性能確定方法IPC-4130E 玻璃非織布規範及性能確定方法IPC-4411 聚芳基醯胺非織布規範及性能確定方法IPC-DR-570A,IPC-4562,IPC6016 印製線路用金屬箔(代替IPC-MF-150F)IPC-6011中文版印製板通用性能規範(代替IPC-RB-276)IPC-6012A中文版剛性印製板的鑒定與性能規範(包括修改1)IPC-6013 撓性印製板的鑒定與性能規範(包括修改1)IPC-6015 有機多晶片模組(MCM-L)安裝及互連結構的鑒定與性能規範IPC-6016 高密度互連(HDI)層或印製板的鑒定與性能規範IPC-6018 微波成品印製板的核對總和測試(代替IPC-HF-318A)IPC/JPCA-6202 單雙面撓性印製板性能手冊J-STD-001C 電氣與電子組裝件錫焊要求IPC/EIA J-STD-002A 元件引線、端子、焊片、接線柱及導線可焊性試驗J-STD-003 印製板可焊性試驗(代替IPC-S-804A)J-STD-004 錫焊焊劑要求(包括修改1)J-STD-005 焊膏技術要求(包括修改1)J-STD-006 電子設備用電子級錫焊合金、帶焊劑及不帶焊劑整體焊料技術要求(包括修改1)IPC/JEDEC J-STD-020A 非密封固態表面貼裝器件濕度/再流焊敏感度分類IPC/JEDEC J-STD-033 對濕度、再流焊敏感表貼裝器件的處置、包裝、發運和使用。

35IPC-QL 365A Certification of Facilities That Inspect/Test Printed Boards, Components and Materials36IPC-MI-660 Incoming Inspection of Raw Materials Manual 37IPC-HDBK-005 Guide to Solder Paste Assessment38IPC-HDBK-830 Guideline for Design, Selection and Application of Conformal Coatings39IPC-7530 Guidelines for Temperature Profiling for Mass Soldering (Reflow & Wave) Processes40IPC-TP-1115 Selection and Implementation Strategy for a Low-Residue No-Clean Process41IPC-S-816 SMT Process Guideline & Checklist42IPC-CM-770E Component Mounting Guidelines for Printed Boards43IPC-9850-K Surface Mount Placement Equipment Characterization-KIT44IPC-9850-TM-KW, IPC-9850-TM-K Test Materials Kit for Surface Mount Placement Equipment Standardization45• 4 IPC-9850 Placement Accuracy Verification Panels46• 1 IPC-9850 CMM Measurement Verification Panels47• 150 IPC-9850 QFP-100 Glass Components48• 130 IPC-9850 QFP-208 Glass Components49• 150 IPC-9850 BGA-228 Glass Components50• NIST Traceable Measurement Certificate51• Custom Storage Case52IPC-TR-464 Accelerated Aging for Solderability Evaluations53SMC-WP-001 Soldering Capability White Paper Report54SMC-WP-005 PCB Surface FinishesIPC:Association Connecting Electronics Industries(电子制造协会),从The Institute of Printed Cir Institute of the Interconnecting and Packing Electronic Circuit”(电子电路互连与封装协会)逐步发展衍印制板, 元件和材料检验/试验企业的授证原材料接收检验手册焊膏性能评价手册敷形涂层的设计,选择和应用手册大规模焊接(回流焊与波峰焊)过程温度曲线指南低残留不清洗工艺的选择和实施表面安装技术过程导则及检核表印制板元件安装导则表面贴装设备性能检测方法的描述(附Gerber格式CD盘)表面贴装设备性能测试用的标准工具包可焊性加速老化评价(附修订)可焊性工艺导论印制电路板表面清洗电子组装的IPC标准列表子制造协会),从The Institute of Printed Circiut(印制电路板协会),The rcuit”(电子电路互连与封装协会)逐步发展衍变而来.IPC标准清单No.英文名称1IPC-T-50G Terms and Definition for Interconnecting and Packaging Electronic Circuits2IPC-TM-650 Test Methods Manual3IPC/EIA J-STD-001C Requirements for Soldered Electrical & Electronic Assemblies4IPC-HDBK-001 Handbook and Guide to Supplement J-STD-001—Includes Amendment 15IPC-A-610D Acceptability of Electronic Assemblies6IPC-HDBK-610 Handbook and Guide to IPC-A-610 (Includes IPC-A-610B to C Comparison7IPC-EA-100-K Electronic Assembly Reference Set8IPC/WHMA-A-620 Requirements and Acceptance for Cable and Wire Harness Assemblies9IPC/EIA J-STD-012 Implementation of Flip Chip and Chip Scale Technology 10IPC-SM-784 Guidelines for Chip-on-Board Technology Implementation 11IPC/EIA J-STD-026 Semiconductor Design Standard for Flip Chip Applications 12J-STD-027 Mechanical Outline Standard for Flip Chip and Chip Size Configurations13IPC/EIA J-STD-028 Performance Standard for Construction of Flip Chip and Chip Scale Bumps14J-STD-013 Implementation of Ball Grid Array and Other High Density Technology15IPC-7095 Design and Assembly Process Implementation for BGAs 16IPC/EIA J-STD-032 Performance Standard for Ball Grid Array Balls 17IPC-MC-790 Guidelines for Multichip Module Technology Utilization 18IPC-M-108 Cleaning Guides and Handbook Manual19IPC-5701 Users Guide for Cleanliness of Unpopulated Printed Boards 20IPC-TP-1113 Circuit Board Ionic Cleanliness Measurement: What Does It Tell Us?21IPC-CH-65A Guidelines for Cleaning of Printed Boards & Assemblies 22IPC-SC-60A Post Solder Solvent Cleaning Handbook23IPC-SA-61A Post Solder Semi-aqueous Cleaning Handbook 24IPC-AC-62A Aqueous Post Solder Cleaning Handbook25IPC-TR-476A Electrochemical Migration: Electrically Induced Failures in Printed Circuit Assemblies26IPC-TR-582 Cleaning and Cleanliness Test Program for: Phase 3 --Low Solids, Fluxes and Pastes Processed in Ambient Air 27IPC-TR-583 An In-Depth Look At Ionic Cleanliness Testing 28IPC-9201 Surface Insulation Resistance Handbook29IPC-TP-104-K Cleaning & Cleanliness Test Program, Phase 3 Water Soluble Fluxes,30IPC-M-109 Component Handling Manual31IPC/JEDEC J-STD-020C Moisture/Reflow Sensitivity Classification for Nonhermetic Solid State Surface Mount Devices32IPC/JEDEC J-STD-033A Handling, Packing, Shipping and Use of Moisture/Reflow Sensitive Surface Mount Devices33IPC/JEDEC J-STD-035 Acoustic Microscopy for Non-Hermetic Encapsulated Electronic Components34IPC-DRM-18G Component Identification Desk Reference Manual 35IPC-DRM-SMT-C Surface Mount Solder Joint Evaluation Desk Reference Manual36IPC-DRM-40E Through-Hole Solder Joint Evaluation Desk Reference Manual 37IPC-DRM-56 Wire Preparation & Crimping Desk Reference Manual 38IPC-DRM-53 Introduction to Electronics Assembly Desk Reference Manual 39IPC-M-103 Standards for Surface Mount Assemblies Manual 40IPC-M-104 Standards for Printed Board Assembly Manual 41IPC-TA-722 Technology Assessment of Soldering42IPC-TA-723 Technology Assessment Handbook on Surface Mounting 43IPC-TA-724 Technology Assessment Series on Clean Rooms 44IPC-SM-780 Component Packaging and Interconnecting with Emphasis on Surface Mounting45IPC-SM-785 Guidelines for Accelerated Reliability Testing of Surface Mount Attachments46IPC-9701 Performance Test Methods and Qualification Requirements for Surface Mount Solder Attachments47IPC/JEDEC-9702 Monotonic Bend Characterization of Board-Level Interconnects48IPC-PD-335 Electronic Packaging Handbook 49IPC-7525 Stencil Design Guidelines50IPC-QL 365A Certification of Facilities That Inspect/Test Printed Boards, Components and Materials51IPC-9191 General Guidelines for Implementation of Statistical Process Control 52IPC-TR-581 IPC Phase III Controlled Atmosphere Soldering Study 53IPC-MI-660 Incoming Inspection of Raw Materials Manual54IPC/EIA J-STD-004A Requirements for Soldering Fluxes-Includes Amendment 155IPC/EIA J-STD-005 Requirements for Soldering Pastes-Includes Amendment 156IPC-HDBK-005 Guide to Solder Paste Assessment57IPC/EIA J-STD-006A Requirements for Electronic Grade SolderAlloys and Fluxed and Non-Fluxed Solid Solders 电子设备用电子级锡焊合金、带焊剂及不带剂整体焊料技术要求58IPC-SM-817 General Requirements for Dielectric Surface Mounting Adhesives 59ELEC-SOLDER Modern Solder Technology for Competitive Electronics Manufacturing60IPC-WP-006 Round Robin Testing & Analysis: Lead-Free Alloys-Tin,Silver, & Copper61IPC-CA-821 General Requirements for Thermally Conductive Adhesives 62IPC-3406 Guidelines for Electrically Conductive Surface Mount Adhesives63IPC-3408 General Requirements for Anisotropically Conductive Adhesives Films64IPC-CC-830B Qualification and Performance of Electrical Insulating Compound for Printed Wiring Assemblies65IPC-HDBK-830 Guideline for Design, Selection and Application of Conformal Coatings66IPC-SM-840C Qualification and Performance of Permanent Solder67IPC-HDBK-840 Guide to Solder Paste Assessment68ELEC-MICRO Handbook of Lead Free Solder Technology for Microelectronic Assemblies69IPC-TP-1114 The Layman’s Guide to Qualifying a Process to J-STD-00170IPC-AJ-820 Assembly & Joining Handbook71IPC-7530 Guidelines for Temperature Profiling for Mass Soldering (Reflow & Wave) Processes72IPC-TP-1090 The Layman’s Guide to Qualifying New Fluxes73IPC-TP-1115 Selection and Implementation Strategy for a Low-Residue No-Clean Process74IPC-S-816 SMT Process Guideline & Checklist75IPC-TR-460A Trouble-Shooting Checklist for Wave Soldering Printed Wiring Boards76IPC-CM-770E Component Mounting Guidelines for Printed Boards77IPC-7912A Calculation of DPMO & Manufacturing Indices for Printed Board Assemblies78IPC-9261 In-Process DPMO and Estimated Yield for PWAs79IPC-DPMO-202 IPC-7912/9261 End Item and In Process DPMO Set80IPC-9500-K Assembly Process Component Simulations, Guidelines & Classifications Package81IPC-9501 PWB Assembly Process Simulation for Evaluation of Electronic Components82IPC-9502 PWB Assembly Soldering Process Guideline for Electronic Components83IPC-9503 Moisture Sensitivity Classification for Non-IC Components84IPC-9504 Assembly Process Simulation for Evaluation of Non-IC Components (Preconditioning Non-IC Components)85IPC-9850-K Surface Mount Placement Equipment Characterization-KIT86IPC-9850-TM-KW, IPC-9850-TM-K Test Materials Kit for Surface Mount Placement Equipment Standardization87• 4 IPC-9850 Placement Accuracy Verification Panels 88• 1 IPC-9850 CMM Measurement Verification Panels 89• 150 IPC-9850 QFP-100 Glass Components90• 130 IPC-9850 QFP-208 Glass Components91• 150 IPC-9850 BGA-228 Glass Components92• NIST Traceable Measurement Certificate93• Custom Storage Case94IPC-7711/21A95IPC/EIA J-STD-002B Solderability Tests for Component Leads, Terminations, Lugs, Terminals and Wires96IPC/EIA J-STD-003A Solderability Tests for Printed Boards97IPC-TR-461 Trouble-Shooting Checklist for Wave Soldering Printed Wiring Boards98IPC-TR-462 Solderability Evaluation of Printed Boards with Protective Coatings Over Long-term Storage99IPC-TR-464 Accelerated Aging for Solderability Evaluations100IPC-TR-465-1 Round Robin Test on Steam Ager Temperature Control Stability101IPC-TR-465-2 The Effect of Steam Aging Time and Temperature on Solderability Test Results103IPC-TR-466 Technical Report: Wetting Balance Standard Weight Comparison Test104SMC-WP-001 Soldering Capability White Paper Report105SMC-WP-005 PCB Surface FinishesIPC:Association Connecting Electronics Industries(电子制造协会),从The Institute of Printed Cir Institute of the Interconnecting and Packing Electronic Circuit”(电子电路互连与封装协会)逐步发展衍标准清单中文名称电子电路互连与封装的定义和术语试验方法手册电气与电子组装件锡焊要求J-STD-001辅助手册及指南及修改说明1印制板组装件验收条件IPC-610手册和指南(包括IPC-A-610B和C的对比)电子组装成套手册,包括:IPC/EIA J-STD-001C,IPC-HDBK-001,IPC-A-610C。