ipc标准中英名称对照

- 格式:doc

- 大小:30.50 KB

- 文档页数:10

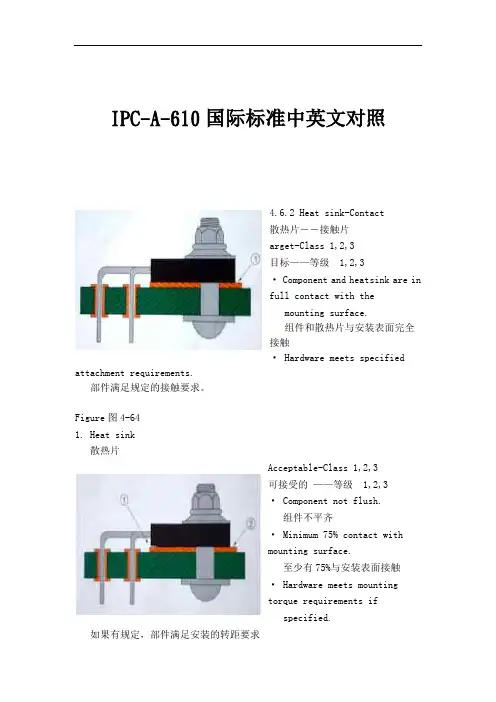

IPC-A-610国际标准中英文对照4.6.2 Heat sink-Contact散热片――接触片arget-Class 1,2,3目标——等级1,2,3· Component and heatsink are infull contact with themounting surface.组件和散热片与安装表面完全接触· Hardware meets specified attachment requirements.部件满足规定的接触要求。

Figure图4-641. Heat sink散热片Acceptable-Class 1,2,3可接受的——等级1,2,3· Component not flush.组件不平齐· Minimum 75% contact withmounting surface.至少有75%与安装表面接触· Hardware meets mountingtorque requirements ifspecified.如果有规定,部件满足安装的转距要求Figure图4-651. Gap2. Heat sink间隙散热片Defect-Class 1,2,3缺点——等级1,2,3· Component is not in contactwith mounting surface.组件没有接触到安装表面· Hardware is loose and can bemoved.部件松弛可以移动。

Figure图4-661. Heat sink2. Gap散热片间隙5.1 Orientation方向5.1.1 Orientation-Horizontal方向——水平Target-Class 1,2,3目标——等级1,2,3•Components are centered betweentheir lands.组件位于焊盘中央•Component markings arediscernible.组件标识清晰可见•Nonpolarized components are oriented so thatmarkings all read the same way (left-to-rightor top-to-bottom).Figure图5-1 无极性组件的方向应使其标识都能按同样方式进行辨识(从左到右或从上到下)Acceptable-Class 1,2,3可接受的——等级1,2,3•Polarized and multileadcomponents are orientedcorrectly.有极性和多引脚的组件应按正确方向安装。

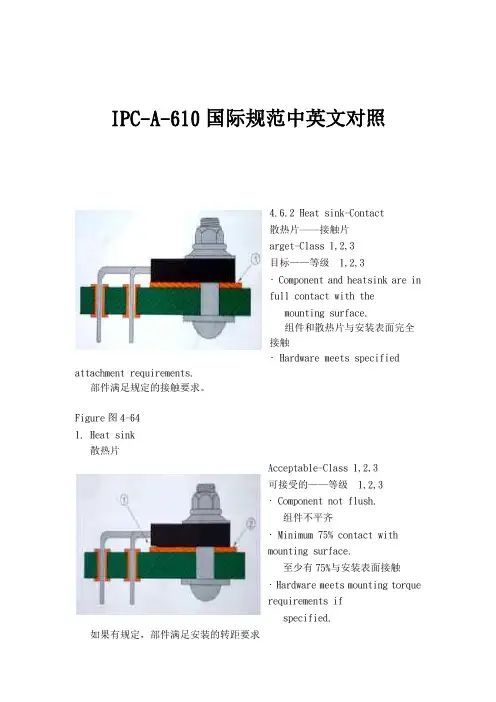

IPC-A-610国际规范中英文对照4.6.2 Heat sink-Contact散热片――接触片arget-Class 1,2,3目标——等级1,2,3· Component and heatsink are infull contact with themounting surface.组件和散热片与安装表面完全接触· Hardware meets specified attachment requirements.部件满足规定的接触要求。

Figure图4-641. Heat sink散热片Acceptable-Class 1,2,3可接受的——等级1,2,3· Component not flush.组件不平齐· Minimum 75% contact withmounting surface.至少有75%与安装表面接触· Hardware meets mounting torquerequirements ifspecified.如果有规定,部件满足安装的转距要求Figure图4-651. Gap2. Heat sink间隙散热片Defect-Class 1,2,3缺点——等级1,2,3· Component is not in contactwith mounting surface.组件没有接触到安装表面· Hardware is loose and can bemoved.部件松弛可以移动。

Figure图4-661. Heat sink2. Gap散热片间隙5.1 Orientation方向5.1.1 Orientation-Horizontal方向——水平Target-Class 1,2,3目标——等级1,2,3•Components are centeredbetween their lands.组件位于焊盘中央•Component markings arediscernible.组件标识清晰可见•Nonpolarized components are oriented so thatmarkings all read the same way (left-to-rightor top-to-bottom).Figure图5-1 无极性组件的方向应使其标识都能按同样方式进行辨识(从左到右或从上到下)Acceptable-Class 1,2,3可接受的——等级1,2,3•Polarized and multileadcomponents are orientedcorrectly.有极性和多引脚的组件应按正确方向安装。

IPC-A-610国际标准中英文对IPC-A-610 XXX-Chinese Comparison4.6.2 Heat Sink-Contact散热片――接触片Target - Class 1.2.3目标——等级1,2,3The component and heat sink are in full contact with the mounting surface.组件和散热片与安装表面完全接触。

XXX.部件满足规定的接触要求。

Figure 4-641.Heat Sink散热片Acceptable - Class 1.2.3可接受的——等级1,2,3The component is not flush.组件不平齐。

There is a minimum of 75% contact with the mounting surface.至少有75%与安装表面接触。

XXX specified.如果有规定,部件满足安装的转距要求。

Figure 4-651.Gap。

2.Heat Sink间隙散热片Defect - Class 1.2.3缺点——等级1,2,3The component is not in contact with the mounting surface.组件没有接触到安装表面。

XXX XXX.部件松弛可以移动。

Figure 4-661.Heat Sink。

2.Gap散热片间隙5.1 XXX方向5.1.1 XXX - Horizontal方向——水平Target - Class 1.2.3目标——等级1,2,3The components are XXX.组件位于焊盘中央。

The component markings are discernible. 组件标识清晰可见。

Non-polarized components are oriented so that markings all read the same way (left-to-right or top-to-bottom).非极性元件的标识朝向应相同(从左到右或从上到下)。

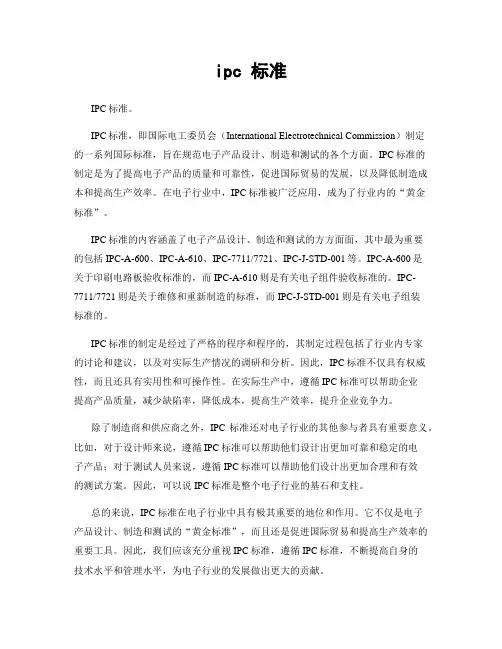

ipc 标准IPC标准。

IPC标准,即国际电工委员会(International Electrotechnical Commission)制定的一系列国际标准,旨在规范电子产品设计、制造和测试的各个方面。

IPC标准的制定是为了提高电子产品的质量和可靠性,促进国际贸易的发展,以及降低制造成本和提高生产效率。

在电子行业中,IPC标准被广泛应用,成为了行业内的“黄金标准”。

IPC标准的内容涵盖了电子产品设计、制造和测试的方方面面,其中最为重要的包括IPC-A-600、IPC-A-610、IPC-7711/7721、IPC-J-STD-001等。

IPC-A-600是关于印刷电路板验收标准的,而IPC-A-610则是有关电子组件验收标准的。

IPC-7711/7721则是关于维修和重新制造的标准,而IPC-J-STD-001则是有关电子组装标准的。

IPC标准的制定是经过了严格的程序和程序的,其制定过程包括了行业内专家的讨论和建议,以及对实际生产情况的调研和分析。

因此,IPC标准不仅具有权威性,而且还具有实用性和可操作性。

在实际生产中,遵循IPC标准可以帮助企业提高产品质量,减少缺陷率,降低成本,提高生产效率,提升企业竞争力。

除了制造商和供应商之外,IPC标准还对电子行业的其他参与者具有重要意义。

比如,对于设计师来说,遵循IPC标准可以帮助他们设计出更加可靠和稳定的电子产品;对于测试人员来说,遵循IPC标准可以帮助他们设计出更加合理和有效的测试方案。

因此,可以说IPC标准是整个电子行业的基石和支柱。

总的来说,IPC标准在电子行业中具有极其重要的地位和作用。

它不仅是电子产品设计、制造和测试的“黄金标准”,而且还是促进国际贸易和提高生产效率的重要工具。

因此,我们应该充分重视IPC标准,遵循IPC标准,不断提高自身的技术水平和管理水平,为电子行业的发展做出更大的贡献。

综上所述,IPC标准是电子行业的重要组成部分,它的制定和遵循对于提高产品质量、降低成本、提高生产效率具有重要意义。

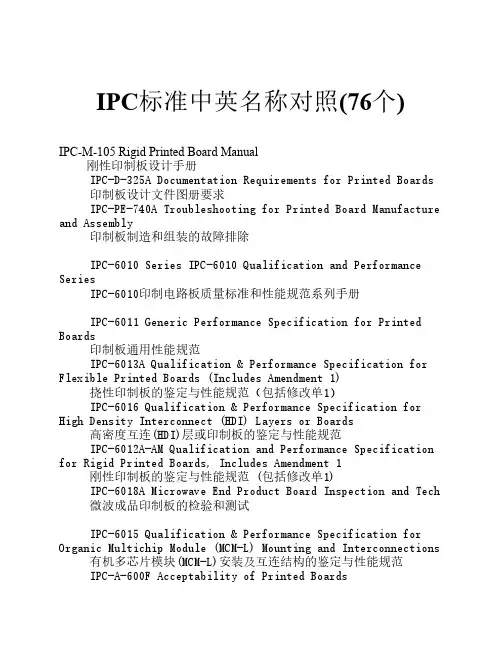

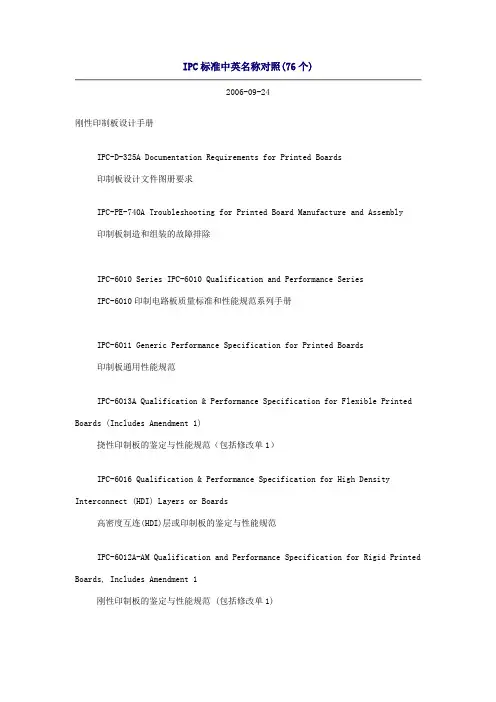

IPC标准中英名称对照(76个)2006-09-24刚性印制板设计手册IPC-D-325A Documentation Requirements for Printed Boards印制板设计文件图册要求IPC-PE-740A Troubleshooting for Printed Board Manufacture and Assembly印制板制造和组装的故障排除IPC-6010 Series IPC-6010 Qualification and Performance SeriesIPC-6010印制电路板质量标准和性能规范系列手册IPC-6011 Generic Performance Specification for Printed Boards印制板通用性能规范IPC-6013A Qualification & Performance Specification for Flexible Printed Boards (Includes Amendment 1)挠性印制板的鉴定与性能规范(包括修改单1)IPC-6016 Qualification & Performance Specification for High Density Interconnect (HDI) Layers or Boards高密度互连(HDI)层或印制板的鉴定与性能规范IPC-6012A-AM Qualification and Performance Specification for Rigid Printed Boards, Includes Amendment 1刚性印制板的鉴定与性能规范 (包括修改单1)IPC-6018A Microwave End Product Board Inspection and Tech微波成品印制板的检验和测试IPC-6015 Qualification & Performance Specification for Organic Multichip Module (MCM-L) Mounting and Interconnections有机多芯片模块(MCM-L)安装及互连结构的鉴定与性能规范IPC-A-600F Acceptability of Printed Boards印制板验收条件IPC-QE-605A Printed Board Quality Evaluation Handbook印制板质量评价IPC-QE-605A-KIT Hard Copy and CD印制板质量评价书和光盘(CD)IPC-HM-860 Specification for Multilayer Hybrid Circuits多层混合电路规范IPC-TF-870 Qualification and Performance of Polymer Thick Film Printed Boards 聚合物厚膜印制板的鉴定与性能IPC-ML-960 Qualification and Performance Specification for Mass Lamination Panels for Multilayer printed Boards多层印制板的鉴定与性能规范用预制内层在制板的鉴定与性能规范IPC-TR-481 Results of Multilayer Tests Program Round Robin多层印制板联合试验计划结果IPC-TR-551 Quality Assessment of Printed Boards Used for Mounting and Interconnecting Electronic Components用于电子元件安装与互连的印制板质量评价IPC-TR-579 Round Robin Reliability Evaluation of Small Diameter Plated Through Holes in PCBs印制板中小直径镀覆孔可靠性评价联合试验IPC-4552 Specification for Electroless Nickel/Immersion Gold(ENIG) Plating for Printed Circuit Boards印制电路板表面非电镀镍/沉金规范IPC-DR-572 Drilling Guidelines for Printed Boards印制板钻孔导则IT-95080 Improvements/Alternatives to Mechanical Drilling of PCB Vias印制板通孔机加工方案的改进和优选手册IPC-NC-349 Computer Numerical Control Formatting for Drillers and Routers 钻床和铣床用计算机数字控制格式IPC-SM-839 Pre & Post Solder Mask Application Cleaning Guidelines施加阻焊前及施加后清洗导则IPC-HDI-1 High Density Interconnect Microvia Technology Compendium高密度(HDI)互连微通孔技术纲要IPC/JPCA-4104 Specification for High Density Interconnect (HDI) and MicroviaMaterials高密度互连(HDI)及微导通孔材料规范IPC-6016 Qualification & Performance Specification for High Density Interconnect (HDI) Layers or Boards高密度互连(HDI)层或印制板的鉴定与性能规范IPC/JPCA-6801 IPC/JPCA Terms & Definitions, Test Methods, and Design Examples for Build-Up/High Density Interconnection积层/高密度互连的术语和定义、试验方法与设计例IPC-DD-135 Qualification Testing for Deposited Organic Interlayer Dielectric Materials for Multichip Modules多芯片组件内层有机绝缘材料的鉴定试验IT-96060 High Density PCB Microvia Evaluation (October Project), Phase I, Round 1高密度印制板微通孔评价指标手册, 第一期第一版IT-97071 High Density PCB Microvia Evaluation, Phase I, Round 2高密度印制板微通孔评价指标手册, 第一期第二版IT-30101 High Density PCB Microvia Evaluation, Phase I, Round 3高密度印制板微通孔评价指标手册, 第一期第三版IT-98123 Microvia Manufacturing Technology Cost Analysis Report微通孔制作技术成本核算报告IPC-2141 Controlled Impedance Circuit Boards & High Speed Logic Design控制阻抗电路板与高速逻辑设计IPC-2252 Design Guide for RF/Microwave Circuit Boards射频/微波电路板设计指南IPC-4103 Specification for Base Materials for High Speed/High Frequency Applications高速高频用基材规范IPC-6018A Microwave End Product Board Inspection and Test微波成品印制板的检验和测试IPC-D-317A Design Guidelines for Electronic Packaging Utilizing High Speed Techniques采用高速技术电子封装设计导则IPC-M-102 Flexible Circuits Compendium挠性电路纲要IPC-4202 Flexible Base Dielectrics for Use in Flexible Printed Circuitry 挠性印制线路用挠性绝缘基底材料IPC-4203 Adhesive Coated Dielectric Films for Use as Cover Sheets for Flexible Printed Circuitry and Flexible Adhesive Bonding Films挠性印制线路覆盖层用涂粘接剂绝缘薄膜IPC-4204 Flexible Metal-Clad Dielectrics for Use in Fabrication of Flexible Printed Circuitry挠性金属箔去电应用于柔性电路组装IPC-6013-K Qualification & Performance Specification for Flexible Printed Boards & Amendment 1挠性印制板的鉴定与性能规范(包括修改单1)IPC/JPCA-6202 IPC/JPCA Performance Guide Manual for Single- and Double-Sided Flexible Printed Wiring BoardsIPC/JPCA单双面挠性印制板性能手册IPC-FA-251 Guidelines for Assembly of Single- and Double-Sided Flex Circuits 单面和双面挠性电路组装导则IPC-FC-234 Composite Metallic Materials Specification for Printed Wiring Boards印制线路板复合金属材料规范IPC-MB-380 Guidelines for Molded Interconnection Devices模压互连器件导则IPC-M-107 Standards for Printed Board Materials Manual印制板材料标准手册IPC-MI-660 Incoming Inspection of Raw Materials Manual原材料接收检验手册IPC-4101A Specifications for Base Materials for Rigid and Multilayer Printed Boards刚性及多层印制板用基材规范IPC-4121 Guidelines for Selecting Core Construction for Multilayer Printed Wiring Board Applications多层印制板用芯板结构选择导则IPC-4562 Metal Foil for Printed Wiring Applications印制线路用金属箔IPC-CF-148A Resin Coated Metal for Printed Boards印制板用涂树脂金属箔IPC-CF-152B Composite Metallic Materials Specification for Printed Wiring Boards印制线路板复合金属材料规范IPC-TR-482 New Developments in Thin Copper Foils薄铜箔的新发展IPC-TR-484 Results of IPC Copper Foil Ductility Round Robin StudyIPC铜箔延展性联合研究结果IPC-TR-485 Results of Copper Foil Rupture Strength Test Round Robin Study 铜箔断裂强度试验联合研究结果IPC-4412 Specification for Finished Fabric Woven from ”E” Glass for PrintedBoards“E”类精纺玻璃纤维层印制板技术规范IPC-4130 Specification & Characterization Methods for Nonwoven "E" Glass MaterialsE 玻璃纤维非织布材料规范及性能确定方法IPC-4110 Specification and Characterization Methods for Nonwoven Cellulose Based Paper for Printed Boards印制板用纤维纸规范及性能确定方法IPC-4411-K Specification and Characterization Methods for Non-WovenPara-Aramid Reinforcement, with Amendment 1聚芳基酰胺非织布规范及性能确定方法, 包括修改单 1IPC-4411-AM1 Specification and Characterization Methods for Non-WovenPara-Aramid Reinforcement, Amendment 1关于聚芳基酰胺非织布规范及性能确定方法的修改单 1IPC-SG-141 Specification for Finished Fabric Woven from "S" Glass for Printed Boards印制板用经处理S玻璃纤维织物规范IPC-A-142 Specification for Finished Fabric Woven from Aramid for Printed Boards印制板用经处理聚芳酰胺纤维编织物规范IPC-QF-143 Specification for Finished Fabric Woven from Quartz (Pure Fused Silica) for Printed Boards印制板用经处理石英(熔融纯氧化硅)纤维编织物规范IPC-2524 PWB Fabrication Data Quality Rating System印制板制造数据质量定级体系IPC-9151A Printed Board Process, Capability, Quality and Relative Reliability Benchmark Test Standard and Database印制板工艺, 容量, 质量,可靠性试验标准和数据库IPC-9191 General Guidelines for Implementation of Statistical Process Control (SPC)实施统计过程控制(SPC)的通用导则IPC-9199 Statistical Process Control (SPC) Quality Rating统计分析控制IPC-9252 Guidelines and Requirements for Electrical Testing of Unpopulated Printed Boards未组装印制板电测试要求和指南IT-97061 PWB Hole to Land Misregistration: Causes and Reliability印制线路板通孔与焊盘的错位: 原因和可靠性IT-98103 Reliability of Misregistered and Landless Innerlayer Interconnects in Thick Panels多层板内部无焊盘层互连错位的可靠性IPC-MS-810 Guidelines for High Volume Microsection大批量显微剖切导则IPC-QL-653A Certification of Facilities that Inspect/Test Printed Boards, Components & Materials印制板、元器件及材料检验试验设备的认证IPC-TR-483 Dimensional Stability Testing of Thin Laminates-Report on Phase 1 & 2 International Round Robin Test薄层压板尺寸稳走性试----国际联合试验计划I阶段及II阶段报告IPC-TR-486 Round Robin Study to Correlate IST & Microsectioning Evaluations for Inner-Layer Separation内层分离的互连应力测试(IST)与显微剖切相关性联合研究。

ipc标准是什么IPC标准是什么。

IPC标准,全称为国际电子零件组装协会(The Institute for Interconnecting and Packaging Electronic Circuits),是一家致力于电子零件组装和连接技术的国际性组织,其总部位于美国。

IPC标准作为电子行业的技术标准之一,对于电子零件的设计、制造、组装和连接工艺等方面有着重要的指导意义。

那么,IPC标准究竟是什么呢?下面将从IPC标准的内容、应用和意义等方面进行介绍。

首先,IPC标准的内容主要包括了电子零件的设计、制造、组装和连接等方面的技术要求和规范。

在电子零件的设计方面,IPC标准规定了元件的尺寸、布局、引脚设计、焊盘设计等方面的要求,旨在确保电子零件的设计符合工艺要求,能够满足电子产品的功能和可靠性需求。

在电子零件的制造方面,IPC标准规定了元件的工艺要求、质量控制要求等,以确保元件的生产过程符合标准,产出的元件质量可靠。

在电子零件的组装和连接方面,IPC标准规定了焊接工艺、组装工艺、连接可靠性测试等方面的要求,以确保元件在组装和连接过程中能够保持良好的连接可靠性,确保整个电子产品的可靠性和稳定性。

其次,IPC标准在电子行业中有着广泛的应用。

无论是电子零件的设计、制造、组装还是连接工艺,IPC标准都提供了相应的技术规范和指导,为电子行业的从业人员提供了重要的参考依据。

在电子零件的设计阶段,工程师可以根据IPC标准对元件的设计进行评估和优化,确保元件的设计符合标准要求;在电子零件的制造和组装阶段,生产人员可以根据IPC标准进行工艺控制和质量检验,确保元件的生产和组装过程符合标准要求;在电子零件的连接工艺中,焊接人员可以根据IPC标准进行焊接工艺的控制和连接可靠性测试,确保连接的可靠性和稳定性。

可以说,IPC标准已经成为了电子行业的重要参考标准,对于提高电子产品的质量和可靠性有着重要的作用。

最后,IPC标准的意义不言而喻。

IPC-A-610国际标准中英文对照4.6.2 Heat sink-Contact散热片――接触片arget-Class 1,2,3目标——等级1,2,3· Component and heatsink are infull contact with themounting surface.组件和散热片与安装表面完全接触· Hardware meets specified attachment requirements.部件满足规定的接触要求。

Figure图4-641. Heat sink散热片Acceptable-Class 1,2,3可接受的——等级1,2,3· Component not flush.组件不平齐· Minimum 75% contact withmounting surface.至少有75%与安装表面接触· Hardware meets mounting torquerequirements ifspecified.如果有规定,部件满足安装的转距要求Figure图4-651. Gap2. Heat sink间隙散热片Defect-Class 1,2,3缺点——等级1,2,3· Component is not in contactwith mounting surface.组件没有接触到安装表面· Hardware is loose and can bemoved.部件松弛可以移动。

Figure图4-661. Heat sink2. Gap散热片间隙5.1 Orientation方向5.1.1 Orientation-Horizontal方向——水平Target-Class 1,2,3目标——等级1,2,3?Components are centeredbetween their lands.组件位于焊盘中央?Component markings arediscernible.组件标识清晰可见?Nonpolarized components are oriented so thatmarkings all read the same way (left-to-rightor top-to-bottom).Figure图5-1 无极性组件的方向应使其标识都能按同样方式进行辨识(从左到右或从上到下)Acceptable-Class 1,2,3可接受的——等级1,2,3?Polarized and multileadcomponents are orientedcorrectly.有极性和多引脚的组件应按正确方向安装。

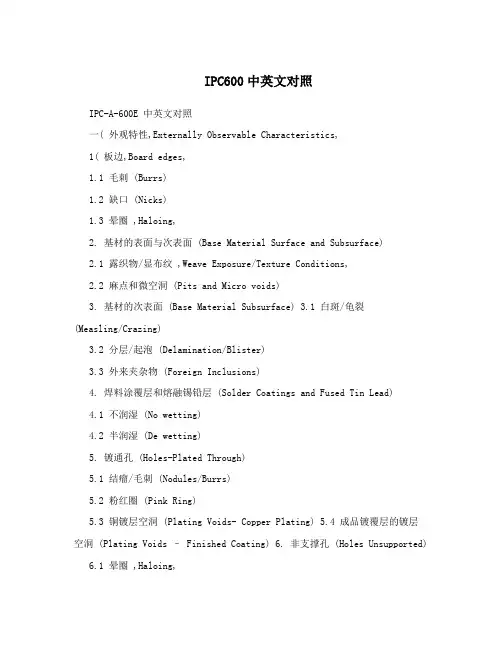

IPC600中英文对照IPC-A-600E 中英文对照一( 外观特性,Externally Observable Characteristics,1( 板边,Board edges,1.1 毛刺 (Burrs)1.2 缺口 (Nicks)1.3 晕圈 ,Haloing,2. 基材的表面与次表面 (Base Material Surface and Subsurface)2.1 露织物/显布纹 ,Weave Exposure/Texture Conditions,2.2 麻点和微空洞 (Pits and Micro voids)3. 基材的次表面 (Base Material Subsurface) 3.1 白斑/龟裂(Measling/Crazing)3.2 分层/起泡 (Delamination/Blister)3.3 外来夹杂物 (Foreign Inclusions)4. 焊料涂覆层和熔融锡铅层 (Solder Coatings and Fused Tin Lead)4.1 不润湿 (No wetting)4.2 半润湿 (De wetting)5. 镀通孔 (Holes-Plated Through)5.1 结瘤/毛刺 (Nodules/Burrs)5.2 粉红圈 (Pink Ring)5.3 铜镀层空洞 (Plating Voids- Copper Plating) 5.4 成品镀覆层的镀层空洞 (Plating Voids – Finished Coating) 6. 非支撑孔 (Holes Unsupported)6.1 晕圈 ,Haloing,7( 印制插头 (Printed Contacts)7.1 表面镀层概况 (Surface Plating – General)7.2 板边插头的毛刺 (Burrs on Edge-Board Contacts)7.3 表面镀层的附着力 (Adhesion of Over plate)8. 标记 (Marking)9. 阻焊剂,阻焊, (Solder Resist or Solder Mask) 9.1 导线表面的涂覆层(Coverage Over Conductors)9.2 对焊盘的重合度 (Registration to Lands)9.3 镀通孔焊盘以外其它图形的重合度(Registration to Features other than PTH Lands)9.4 起泡/分层(Blisters/Delamination)9.5 附着力,剥落或起皮, Adhesion (Flaking or Peeling) 9.6 涂层漏印(Skip Coverage)9.7 波纹/皱褶/皱纹 (Waves/Wrinkles/Ripples) 9.8 掩孔,导通孔, Tenting (Via Holes)9.9 吸管式空隙 (Soda Strawing)9.10 厚度 (Thickness)10. 尺寸特性 (Dimensional Characteristics) 10.1 导线宽度和间距(Conductor Width and Spacing) 10.2 孔环的测量 (Annular Ring –Measurement)10.3 支撑孔的孔环 (Annular Ring – Supported Holes) 10.4 非支撑孔的孔环 (Annular Ring – Unsupported Holes) 10.5 不规则形状焊盘的孔环 ,Annular Ring – Irregular Shaped Lands,10.6 平整度 (Flatness)二( 可观测的内在特性(Internally Observable Voids (outside thermal zone)1. 介质材料 (Dielectric Materials)1.1 层压空洞,受热区之外, Laminate Voids (outside thermal zone1.2 重合度/连接通孔的导体 (Registration/Conductors to Holes)1.3 非支撑隔离孔对电源层/接地层的关系(Clearance Hole, Unsupported, to Power/Ground Planes1.4 分层/起泡 (Delamination/Blister 1.5 凹蚀 (Etch back)1.5.1 正凹蚀 (Positive Etch back) 1.5.2 负凹蚀 (Negative Etch back)1.6 金属层间的介质间隙 (Dielectric Material, Clearance, MetalPlanes)1.7 层间的间距 (Layer-to-layer Spacing)1.8 树脂凹缩 (Resin Recession)2.导电图形概述 (Conductive Patterns – General) 2.1 蚀刻特性(Etching Characteristics) 2.2 标准的印制与蚀刻 (Standard Print & Etch)2.3 内层铜箔导体的列缝 (Conductor Crack – Internal Foil) 2.4 外层铜箔导体的列缝 (Conductor Crack – External Foil) 2.5 表面导体厚度 ,铜箔加镀层, Surface Conductor Thickness (foil plus plating)2.6 内层铜箔厚度 (Foil Thickness – Internal Layers)3. 镀通孔概述(Plated – Through – Holes – General)3.1 内层孔环 (Annular Ring – Internal Layers) 3.2 焊盘起翘,显微切片,Lifted Lands – (Cross – sections) 3.3 孔壁镀层裂缝 (PlatingCrack – <Barrel>)3.4 拐角镀层裂缝 (Plating Crack – <Corner>)3.5 镀层结瘤 (Plating Nodules)3.6 孔壁铜镀层厚度 (Copper Plating Thickness – Hole Wall) 3.7 镀层空间(Plating Voids)3.8 焊料涂覆层厚度 (Solder Coating Thickness) 3.9 芯吸作用 (Wicking)3.9.1 有空隙的通孔的芯吸作用 (Wicking, Clearance Holes) 3.10 内层间分离-垂直的,纵向,显微切片Inter-Plane Separation-Vertical (axial) Microsection3.11 内层间分离-水平的,横向,显微切片Inter-Plane Separation-Horizontal (transverse) Microsection4. 钻孔的镀通孔 (Plated – Through – Holes – Drilled 4.1 毛刺(Burrs)4.2 钉头 (Nailheading)5. 冲孔的镀通孔 (Plated – Through – Holes – Punched) 5.1 粗糙与结瘤 (Roughness and Nodules)5.2 嗽叭口 (Flare)三( 其它类型板 (Miscellaneous)1. 挠性印制电路 (Flexible Printed Circuits) 1.1. 覆盖层分层(Coverlay Delamination) 1.2. 边缘修整 (Trimmed Edges)1.3. 余隙孔的重合度 (Access Hole Registration)1.4. 镀孔规范 (Plated Holes Criteria) 1.5. 焊盘覆盖层(Land Coverage)1.6. 增强板的粘结 (Stiffener Bonding)2. 刚-挠印制板 (Rigid – Flex Printed Boards) 2.1 层压缺陷 (Laminate Defects)2.2 挠性区的板边分层 (Edge Delamination – Flex Areas) 2.3 刚性部分的板边缺陷 (Edge Imperfections – Rigid Section)3. 金属芯印制板 (Metal Core Printed Boards)3.1 分类 (Type Classifications)3.2 层压型的间距 (Spacing Laminated Type)3.3 绝缘厚度~绝缘的金属基材(Insulation Thickness, Insulated Metal Substrate) 3.4 层压型金属芯板的填充绝缘材料(Isulation Material Fill, Laminated Type Metal Core)3.5 层压型的绝缘填料中的裂缝(Cracks in Insulation Material Fill, Laminated Type)3.6 与镀通孔壁连接的金属芯(Core Bond to Plated- Through –hole Wall)4. 齐平印制板 (Flush Printed Boards)4.1 表面导体的齐平度 (Flushness of Surface Conductor)5. 清洁度测试(Cleanliness Testing)5.1 可焊性试验 (Solder ability Testing)5.3 电气完整性 (Electrical Integrity)。

ipc一二三级标准IPC(International Electronics Packaging and Assembly Association)是电子组装和封装协会的缩写,IPC一二三级标准是该协会为了保证电子装配品质而制定的一种国际标准。

在电子行业中,IPC标准在电路板设计、制造、装配、检测、维修等方面被广泛应用。

IPC一级标准IPC一级标准是针对电子元器件插入质量而制定的。

插入元器件是指像电阻、电容、二极管这样的元器件,它们需要通过插入来实现在电路板上的连接。

IPC一级标准主要包括插入方向、插入深度、插入力等要求。

IPC一级标准的实现,可以使插入元器件的质量得到保证,能够避免插入不良、脱落、松动等问题的发生。

IPC二级标准IPC二级标准是针对电路板质量而制定的。

电路板是逐步发展起来的一种基础元器件,它是支撑整个电子系统的重要组成部分。

IPC二级标准主要包括线路细节、板面状况、表面处理、光学检测、性能测试等要求。

IPC二级标准的实现,可以使电路板质量的稳定性得到保证,减少线路接触不良、短路等问题的出现,提高电路板的可靠性和使用寿命。

IPC三级标准IPC三级标准是针对电子装配质量而制定的。

电子装配是将各种元器件按照设计要求一步一步组装在一起,形成电子产品的过程。

IPC三级标准主要包括元器件塑封、表面粘接剂、后续加工、防尘、耐热等要求。

IPC三级标准的实现,可以使电子产品质量得到保证,减少元器件相互干扰、脱落、磨损等问题的出现,确保电子系统的稳定运作。

总结IPC一二三级标准是在电子组装和封装协会制定的国际标准,针对电子插件、电路板和电子装配的三个方面来保证电子产品的质量。

IPC标准的实现可以保证电子产品的质量,减少故障率,提高稳定性和可靠性。

在电子制造发展的今天,IPC标准已成为行业内规范化生产和管理的重要保证。

IPC标准中英名称对照IPC-M-105 Rigid Printed Board Manual刚性印制板设计手册IPC-D-325A Documentation Requirements for Printed Boards印制板设计文件图册要求IPC-PE-740A Troubleshooting for Printed Board Manufacture and Assembly印制板制造和组装的故障排除IPC-6010 Series IPC-6010 Qualification and Performance SeriesIPC-6010印制电路板质量标准和性能规范系列手册IPC-6011 Generic Performance Specification for Printed Boards印制板通用性能规范IPC-6013A Qualification & Performance Specification for Flexible Printed Boards (Includes Amendment 1)挠性印制板的鉴定与性能规范(包括修改单1)IPC-6016 Qualification & Performance Specification for High Density Interconnect (HDI) Layers or Boards高密度互连(HDI)层或印制板的鉴定与性能规范IPC-6012A-AM Qualification and Performance Specification for Rigid Printed Boards, Includes Amendment 1刚性印制板的鉴定与性能规范 (包括修改单1)IPC-6018A Microwave End Product Board Inspection and Tech微波成品印制板的检验和测试IPC-6015 Qualification & Performance Specification for Organic Multichip Module (MCM-L) Mounting and Interconnections有机多芯片模块(MCM-L)安装及互连结构的鉴定与性能规范IPC-A-600F Acceptability of Printed Boards印制板验收条件IPC-QE-605A Printed Board Quality Evaluation Handbook印制板质量评价IPC-QE-605A-KIT Hard Copy and CD印制板质量评价书和光盘(CD)IPC-HM-860 Specification for Multilayer Hybrid Circuits多层混合电路规范IPC-TF-870 Qualification and Performance of Polymer Thick Film Printed Boards聚合物厚膜印制板的鉴定与性能IPC-ML-960 Qualification and Performance Specification for Mass Lamination Panels for Multilayer printed Boards多层印制板的鉴定与性能规范用预制内层在制板的鉴定与性能规范IPC-TR-481 Results of Multilayer Tests Program Round Robin多层印制板联合试验计划结果IPC-TR-551 Quality Assessment of Printed Boards Used for Mounting and Interconnecting Electronic Components用于电子元件安装与互连的印制板质量评价IPC-TR-579 Round Robin Reliability Evaluation of Small Diameter Plated Through Holes in PCBs印制板中小直径镀覆孔可靠性评价联合试验IPC-4552 Specification for Electroless Nickel/Immersion Gold(ENIG) Plating for Printed Circuit Boards印制电路板表面非电镀镍/沉金规范IPC-DR-572 Drilling Guidelines for Printed Boards印制板钻孔导则IT-95080 Improvements/Alternatives to Mechanical Drilling of PCB Vias印制板通孔机加工方案的改进和优选手册IPC-NC-349 Computer Numerical Control Formatting for Drillers and Routers钻床和铣床用计算机数字控制格式IPC-SM-839 Pre & Post Solder Mask Application Cleaning Guidelines 施加阻焊前及施加后清洗导则IPC-HDI-1 High Density Interconnect Microvia Technology Compendium高密度(HDI)互连微通孔技术纲要IPC/JPCA-4104 Specification for High Density Interconnect (HDI) and Microvia Materials高密度互连(HDI)及微导通孔材料规范IPC-6016 Qualification & Performance Specification for High Density Interconnect (HDI) Layers or Boards高密度互连(HDI)层或印制板的鉴定与性能规范IPC/JPCA-6801 IPC/JPCA Terms & Definitions, Test Methods, and Design Examples for Build-Up/High Density Interconnection 积层/高密度互连的术语和定义、试验方法与设计例IPC-DD-135 Qualification Testing for Deposited Organic Interlayer Dielectric Materials for Multichip Modules多芯片组件内层有机绝缘材料的鉴定试验IT-96060 High Density PCB Microvia Evaluation (October Project), Phase I, Round 1高密度印制板微通孔评价指标手册, 第一期第一版IT-97071 High Density PCB Microvia Evaluation, Phase I, Round 2 高密度印制板微通孔评价指标手册, 第一期第二版IT-30101 High Density PCB Microvia Evaluation, Phase I, Round 3 高密度印制板微通孔评价指标手册, 第一期第三版IT-98123 Microvia Manufacturing Technology Cost Analysis Report 微通孔制作技术成本核算报告IPC-2141 Controlled Impedance Circuit Boards & High Speed Logic Design控制阻抗电路板与高速逻辑设计IPC-2252 Design Guide for RF/Microwave Circuit Boards射频/微波电路板设计指南IPC-4103 Specification for Base Materials for High Speed/High Frequency Applications高速高频用基材规范IPC-6018A Microwave End Product Board Inspection and Test微波成品印制板的检验和测试IPC-D-317A Design Guidelines for Electronic Packaging Utilizing High Speed Techniques采用高速技术电子封装设计导则IPC-M-102 Flexible Circuits Compendium挠性电路纲要IPC-4202 Flexible Base Dielectrics for Use in Flexible Printed Circuitry挠性印制线路用挠性绝缘基底材料IPC-4203 Adhesive Coated Dielectric Films for Use as Cover Sheets for Flexible Printed Circuitry and Flexible Adhesive Bonding Films 挠性印制线路覆盖层用涂粘接剂绝缘薄膜IPC-4204 Flexible Metal-Clad Dielectrics for Use in Fabrication of Flexible Printed Circuitry挠性金属箔去电应用于柔性电路组装IPC-6013-K Qualification & Performance Specification for Flexible Printed Boards & Amendment 1挠性印制板的鉴定与性能规范(包括修改单1)IPC/JPCA-6202 IPC/JPCA Performance Guide Manual for Single- and Double-Sided Flexible Printed Wiring BoardsIPC/JPCA单双面挠性印制板性能手册IPC-FA-251 Guidelines for Assembly of Single- and Double-Sided Flex Circuits单面和双面挠性电路组装导则IPC-FC-234 Composite Metallic Materials Specification for Printed Wiring Boards印制线路板复合金属材料规范IPC-MB-380 Guidelines for Molded Interconnection Devices模压互连器件导则IPC-M-107 Standards for Printed Board Materials Manual印制板材料标准手册IPC-MI-660 Incoming Inspection of Raw Materials Manual原材料接收检验手册IPC-4101A Specifications for Base Materials for Rigid and Multilayer Printed Boards刚性及多层印制板用基材规范IPC-4121 Guidelines for Selecting Core Construction forMultilayer Printed Wiring Board Applications多层印制板用芯板结构选择导则IPC-4562 Metal Foil for Printed Wiring Applications印制线路用金属箔IPC-CF-148A Resin Coated Metal for Printed Boards印制板用涂树脂金属箔IPC-CF-152B Composite Metallic Materials Specification for Printed Wiring Boards印制线路板复合金属材料规范IPC-TR-482 New Developments in Thin Copper Foils薄铜箔的新发展IPC-TR-484 Results of IPC Copper Foil Ductility Round Robin Study IPC铜箔延展性联合研究结果IPC-TR-485 Results of Copper Foil Rupture Strength Test Round Robin Study铜箔断裂强度试验联合研究结果IPC-4412 Specification for Finished Fabric Woven from ”E” Glass for Printed Boards“E”类精纺玻璃纤维层印制板技术规范IPC-4130 Specification & Characterization Methods for Nonwoven "E" Glass MaterialsE 玻璃纤维非织布材料规范及性能确定方法IPC-4110 Specification and Characterization Methods for Nonwoven Cellulose Based Paper for Printed Boards印制板用纤维纸规范及性能确定方法IPC-4411-K Specification and Characterization Methods for Non-Woven Para-Aramid Reinforcement, with Amendment 1聚芳基酰胺非织布规范及性能确定方法, 包括修改单 1IPC-4411-AM1 Specification and Characterization Methods for Non-Woven Para-Aramid Reinforcement, Amendment 1关于聚芳基酰胺非织布规范及性能确定方法的修改单 1IPC-SG-141 Specification for Finished Fabric Woven from "S" Glass for Printed Boards印制板用经处理S玻璃纤维织物规范IPC-A-142 Specification for Finished Fabric Woven from Aramid for Printed Boards印制板用经处理聚芳酰胺纤维编织物规范IPC-QF-143 Specification for Finished Fabric Woven from Quartz (Pure Fused Silica) for Printed Boards印制板用经处理石英(熔融纯氧化硅)纤维编织物规范IPC-2524 PWB Fabrication Data Quality Rating System印制板制造数据质量定级体系IPC-9151A Printed Board Process, Capability, Quality and Relative Reliability Benchmark Test Standard and Database印制板工艺, 容量, 质量,可靠性试验标准和数据库IPC-9191 General Guidelines for Implementation of Statistical Process Control (SPC)实施统计过程控制(SPC)的通用导则IPC-9199 Statistical Process Control (SPC) Quality Rating统计分析控制IPC-9252 Guidelines and Requirements for Electrical Testing of Unpopulated Printed Boards未组装印制板电测试要求和指南IT-97061 PWB Hole to Land Misregistration: Causes and Reliability 印制线路板通孔与焊盘的错位: 原因和可靠性IT-98103 Reliability of Misregistered and Landless Innerlayer Interconnects in Thick Panels多层板内部无焊盘层互连错位的可靠性IPC-MS-810 Guidelines for High Volume Microsection大批量显微剖切导则IPC-QL-653A Certification of Facilities that Inspect/Test Printed Boards, Components & Materials印制板、元器件及材料检验试验设备的认证IPC-TR-483 Dimensional Stability Testing of Thin Laminates-Report on Phase 1 & 2 International Round Robin Test薄层压板尺寸稳走性试----国际联合试验计划I阶段及II阶段报告IPC-TR-486 Round Robin Study to Correlate IST & Microsectioning Evaluations for Inner-Layer Separation内层分离的互连应力测试(IST)与显微剖切相关性联合研究。

IPC标准中英名称对照IPC-M-105 Rigid Printed Board Manual刚性印制板设计手册IPC-D-325A Documentation Requirements for Printed Boards印制板设计文件图册要求IPC-PE-740A Troubleshooting for Printed Board Manufacture and Assembly印制板制造和组装的故障排除IPC-6010 Series IPC-6010 Qualification and Performance SeriesIPC-6010印制电路板质量标准和性能规范系列手册IPC-6011 Generic Performance Specification for Printed Boards印制板通用性能规范IPC-6013A Qualification & Performance Specification for Flexible Printed Boards (Includes Amendment 1)挠性印制板的鉴定与性能规范(包括修改单1)IPC-6016 Qualification & Performance Specification for High Density Interconnect (HDI) Layers or Boards高密度互连(HDI)层或印制板的鉴定与性能规范IPC-6012A-AM Qualification and Performance Specification for Rigid Printed Boards, Includes Amendment 1刚性印制板的鉴定与性能规范(包括修改单1)IPC-6018A Microwave End Product Board Inspection and Tech微波成品印制板的检验和测试IPC-6015 Qualification & Performance Specification for Organic Multichip Module (MCM-L) Mounting and Interconnections有机多芯片模块(MCM-L)安装及互连结构的鉴定与性能规范IPC-A-600F Acceptability of Printed Boards印制板验收条件IPC-QE-605A Printed Board Quality Evaluation Handbook印制板质量评价IPC-QE-605A-KIT Hard Copy and CD印制板质量评价书和光盘(CD)IPC-HM-860 Specification for Multilayer Hybrid Circuits多层混合电路规范IPC-TF-870 Qualification and Performance of Polymer Thick Film Printed Boards聚合物厚膜印制板的鉴定与性能IPC-ML-960 Qualification and Performance Specification for Mass Lamination Panels for Multilayer printed Boards多层印制板的鉴定与性能规范用预制内层在制板的鉴定与性能规范IPC-TR-481 Results of Multilayer Tests Program Round Robin多层印制板联合试验计划结果IPC-TR-551 Quality Assessment of Printed Boards Used for Mounting and Interconnecting Electronic Components用于电子元件安装与互连的印制板质量评价IPC-TR-579 Round Robin Reliability Evaluation of Small Diameter Plated Through Holes in PCBs印制板中小直径镀覆孔可靠性评价联合试验IPC-4552 Specification for Electroless Nickel/Immersion Gold(ENIG) Plating for Printed Circuit Boards印制电路板表面非电镀镍/沉金规范IPC-DR-572 Drilling Guidelines for Printed Boards印制板钻孔导则IT-95080 Improvements/Alternatives to Mechanical Drilling of PCB Vias印制板通孔机加工方案的改进和优选手册IPC-NC-349 Computer Numerical Control Formatting for Drillers and Routers钻床和铣床用计算机数字控制格式IPC-SM-839 Pre & Post Solder Mask Application Cleaning Guidelines施加阻焊前及施加后清洗导则IPC-HDI-1 High Density Interconnect Microvia Technology Compendium高密度(HDI)互连微通孔技术纲要IPC/JPCA-4104 Specification for High Density Interconnect (HDI) and Microvia Materials高密度互连(HDI)及微导通孔材料规范IPC-6016 Qualification & Performance Specification for High Density Interconnect (HDI) Layers or Boards高密度互连(HDI)层或印制板的鉴定与性能规范IPC/JPCA-6801 IPC/JPCA Terms & Definitions, Test Methods, and Design Examples for Build-Up/High Density Interconnection积层/高密度互连的术语和定义、试验方法与设计例IPC-DD-135 Qualification Testing for Deposited Organic Interlayer Dielectric Materials for Multichip Modules多芯片组件内层有机绝缘材料的鉴定试验IT-96060 High Density PCB Microvia Evaluation (October Project), Phase I, Round 1高密度印制板微通孔评价指标手册, 第一期第一版IT-97071 High Density PCB Microvia Evaluation, Phase I, Round 2高密度印制板微通孔评价指标手册, 第一期第二版IT-30101 High Density PCB Microvia Evaluation, Phase I, Round 3高密度印制板微通孔评价指标手册, 第一期第三版IT-98123 Microvia Manufacturing Technology Cost Analysis Report微通孔制作技术成本核算报告IPC-2141 Controlled Impedance Circuit Boards & High Speed Logic Design控制阻抗电路板与高速逻辑设计IPC-2252 Design Guide for RF/Microwave Circuit Boards射频/微波电路板设计指南IPC-4103 Specification for Base Materials for High Speed/High Frequency Applications高速高频用基材规范IPC-6018A Microwave End Product Board Inspection and Test微波成品印制板的检验和测试IPC-D-317A Design Guidelines for Electronic Packaging Utilizing High Speed Techniques采用高速技术电子封装设计导则IPC-M-102 Flexible Circuits Compendium挠性电路纲要IPC-4202 Flexible Base Dielectrics for Use in Flexible Printed Circuitry挠性印制线路用挠性绝缘基底材料IPC-4203 Adhesive Coated Dielectric Films for Use as Cover Sheets for Flexible Printed Circuitry and Flexible Adhesive Bonding Films挠性印制线路覆盖层用涂粘接剂绝缘薄膜IPC-4204 Flexible Metal-Clad Dielectrics for Use in Fabrication of Flexible Printed Circuitry挠性金属箔去电应用于柔性电路组装IPC-6013-K Qualification & Performance Specification for Flexible Printed Boards & Amendment 1挠性印制板的鉴定与性能规范(包括修改单1)IPC/JPCA-6202 IPC/JPCA Performance Guide Manual for Single- and Double-Sided Flexible Printed Wiring BoardsIPC/JPCA单双面挠性印制板性能手册IPC-FA-251 Guidelines for Assembly of Single- and Double-Sided Flex Circuits单面和双面挠性电路组装导则IPC-FC-234 Composite Metallic Materials Specification for Printed Wiring Boards印制线路板复合金属材料规范IPC-MB-380 Guidelines for Molded Interconnection Devices模压互连器件导则IPC-M-107 Standards for Printed Board Materials Manual印制板材料标准手册IPC-MI-660 Incoming Inspection of Raw Materials Manual原材料接收检验手册IPC-4101A Specifications for Base Materials for Rigid and Multilayer Printed Boards刚性及多层印制板用基材规范IPC-4121 Guidelines for Selecting Core Construction for Multilayer Printed Wiring Board Applications多层印制板用芯板结构选择导则IPC-4562 Metal Foil for Printed Wiring Applications印制线路用金属箔IPC-CF-148A Resin Coated Metal for Printed Boards印制板用涂树脂金属箔IPC-CF-152B Composite Metallic Materials Specification for Printed Wiring Boards印制线路板复合金属材料规范IPC-TR-482 New Developments in Thin Copper Foils薄铜箔的新发展IPC-TR-484 Results of IPC Copper Foil Ductility Round Robin StudyIPC铜箔延展性联合研究结果IPC-TR-485 Results of Copper Foil Rupture Strength Test Round Robin Study铜箔断裂强度试验联合研究结果IPC-4412 Specification for Finished Fabric Woven from ”E” Glass for Printed Boards“E”类精纺玻璃纤维层印制板技术规范IPC-4130 Specification & Characterization Methods for Nonwoven "E" Glass MaterialsE 玻璃纤维非织布材料规范及性能确定方法IPC-4110 Specification and Characterization Methods for Nonwoven Cellulose Based Paper for Printed Boards印制板用纤维纸规范及性能确定方法IPC-4411-K Specification and Characterization Methods for Non-Woven Para-Aramid Reinforcement, with Amendment 1聚芳基酰胺非织布规范及性能确定方法, 包括修改单1IPC-4411-AM1 Specification and Characterization Methods for Non-Woven Para-Aramid Reinforcement, Amendment 1关于聚芳基酰胺非织布规范及性能确定方法的修改单 1IPC-SG-141 Specification for Finished Fabric Woven from "S" Glass for Printed Boards印制板用经处理S玻璃纤维织物规范IPC-A-142 Specification for Finished Fabric Woven from Aramid for Printed Boards印制板用经处理聚芳酰胺纤维编织物规范IPC-QF-143 Specification for Finished Fabric Woven from Quartz (Pure Fused Silica) for Printed Boards印制板用经处理石英(熔融纯氧化硅)纤维编织物规范IPC-2524 PWB Fabrication Data Quality Rating System印制板制造数据质量定级体系IPC-9151A Printed Board Process, Capability, Quality and Relative Reliability Benchmark Test Standard and Database印制板工艺, 容量, 质量,可靠性试验标准和数据库IPC-9191 General Guidelines for Implementation of Statistical Process Control (SPC)实施统计过程控制(SPC)的通用导则IPC-9199 Statistical Process Control (SPC) Quality Rating统计分析控制IPC-9252 Guidelines and Requirements for Electrical Testing of Unpopulated Printed Boards未组装印制板电测试要求和指南IT-97061 PWB Hole to Land Misregistration: Causes and Reliability印制线路板通孔与焊盘的错位: 原因和可靠性IT-98103 Reliability of Misregistered and Landless Innerlayer Interconnects in Thick Panels多层板内部无焊盘层互连错位的可靠性IPC-MS-810 Guidelines for High V olume Microsection大批量显微剖切导则IPC-QL-653A Certification of Facilities that Inspect/Test Printed Boards, Components & Materials印制板、元器件及材料检验试验设备的认证IPC-TR-483 Dimensional Stability Testing of Thin Laminates-Report on Phase 1 & 2 International Round Robin Test薄层压板尺寸稳走性试----国际联合试验计划I阶段及II阶段报告IPC-TR-486 Round Robin Study to Correlate IST & Microsectioning Evaluations for Inner-Layer Separation内层分离的互连应力测试(IST)与显微剖切相关性联合研究。