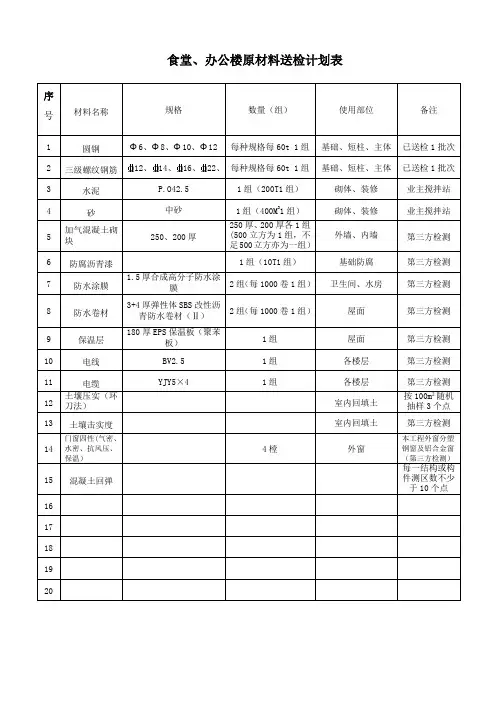

材料送检计划表

- 格式:doc

- 大小:171.50 KB

- 文档页数:5

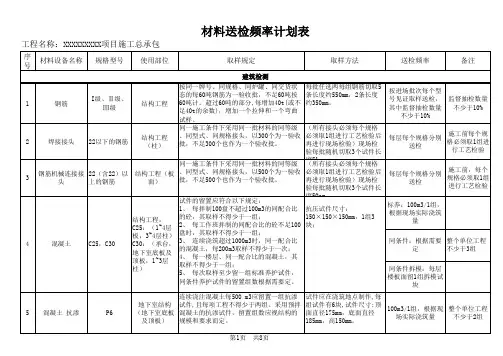

材料定样、进场及送检计划英文回答:Material Sampling, Site Entry, and Inspection Plan.Material Sampling:In order to ensure the quality and reliability of the materials used in our project, it is crucial to have a proper material sampling plan. This involves selecting representative samples from different batches or lots of materials and sending them for testing to a certified laboratory. The sampling plan should be designed in accordance with relevant standards and specifications.Firstly, I will review the project requirements and specifications to determine the types of materials that need to be sampled. For example, if we are working on a construction project, we may need to sample materials such as concrete, steel, or asphalt.Next, I will identify the appropriate sampling methods for each material. For instance, for concrete, I may use a drill to extract core samples from the structure, while for steel, I may take samples from the delivered batches.Once the sampling methods are determined, I will create a sampling schedule, taking into consideration factors such as the availability of materials, project timeline, and laboratory testing capacity. It is important to ensure that the samples are collected at the right time and in theright quantity.After the samples are collected, they need to be properly labeled and documented. This includes recording information such as the date, time, location, and batch number. Clear and accurate documentation is essential for traceability and quality control purposes.Finally, the samples will be securely packaged and transported to the laboratory for testing. It is crucial to ensure that the samples are not contaminated or compromisedduring transportation.Site Entry:Before any materials can be delivered to the site, proper site entry procedures need to be followed. This is to ensure the safety of personnel and to prevent unauthorized access to the site.Firstly, I will establish a site entry plan that includes the necessary safety measures and access control procedures. This may involve setting up a designated entry point where all personnel and vehicles entering the site must check in.At the entry point, personnel will be required to provide identification and undergo any necessary safety inductions or training. This could include wearing personal protective equipment (PPE) such as hard hats, safety vests, and steel-toed boots.In addition, all vehicles entering the site will needto be registered and inspected for compliance with safety standards. This may include checking for valid licenses, proper vehicle maintenance, and adherence to weight restrictions.Inspection Plan:Once the materials have been delivered to the site, it is important to have an inspection plan in place to ensure that they meet the required quality standards.I will develop an inspection checklist that includes the specific criteria and parameters for each type of material. For example, for concrete, the checklist may include factors such as slump test, compressive strength, and air content.The inspection plan will outline the frequency and method of inspection for each material. This could involve conducting spot checks on a random sample basis or inspecting every batch of materials.During the inspection process, any deviations or non-conformities will be documented and reported. This could include issues such as incorrect material specifications, damaged packaging, or signs of contamination.In conclusion, a well-planned material sampling, site entry, and inspection plan are crucial for ensuring the quality and reliability of materials used in a project. By following proper procedures and adhering to standards, we can mitigate risks and ensure the successful completion of our project.中文回答:材料定样、进场及送检计划。

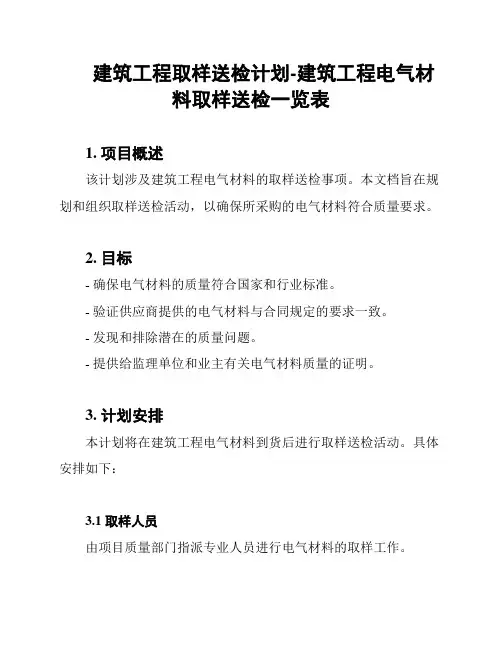

建筑工程取样送检计划-建筑工程电气材料取样送检一览表1. 项目概述该计划涉及建筑工程电气材料的取样送检事项。

本文档旨在规划和组织取样送检活动,以确保所采购的电气材料符合质量要求。

2. 目标- 确保电气材料的质量符合国家和行业标准。

- 验证供应商提供的电气材料与合同规定的要求一致。

- 发现和排除潜在的质量问题。

- 提供给监理单位和业主有关电气材料质量的证明。

3. 计划安排本计划将在建筑工程电气材料到货后进行取样送检活动。

具体安排如下:3.1 取样人员由项目质量部门指派专业人员进行电气材料的取样工作。

3.2 取样时间与地点根据具体工程进度,确定合适的取样时间与地点。

3.3 取样方法根据国家和行业标准,采用适当的取样方法进行取样,确保取样的代表性和准确性。

3.4 送检机构选择符合相关认证要求的第三方检测机构进行电气材料的送检工作。

3.5 样品管理由专人负责电气材料样品的管理,包括标识、保管和保存等。

4. 送检内容本计划涵盖以下电气材料的取样送检:- 灯具及配件- 开关插座及电器附件- 电线电缆- 开关柜及电气元件5. 样品送检流程本计划执行的样品送检流程如下:5.1 样品接收取样人员收到电气材料后,按照取样方法进行取样,并进行标识。

5.2 样品送检将取样好的电气材料样品送交给选择的第三方检测机构进行检测。

5.3 检测报告第三方检测机构完成检测后,提供检测报告,并将报告送交项目质量部门。

5.4 报告评审项目质量部门对检测报告进行评审,确保电气材料符合质量要求,并记录评审结果。

5.5 审核与验证监理单位和业主根据评审结果对电气材料进行审核与验证,确认质量合格。

6. 取样送检记录将每次取样送检的相关记录进行归档和保存,以备后续查阅和追溯。

以上即为本文档对建筑工程电气材料取样送检计划的内容安排和流程规划。

通过执行该计划,我们将保证所采购的电气材料质量符合要求,并为监理单位和业主提供相关的质量保证证明。

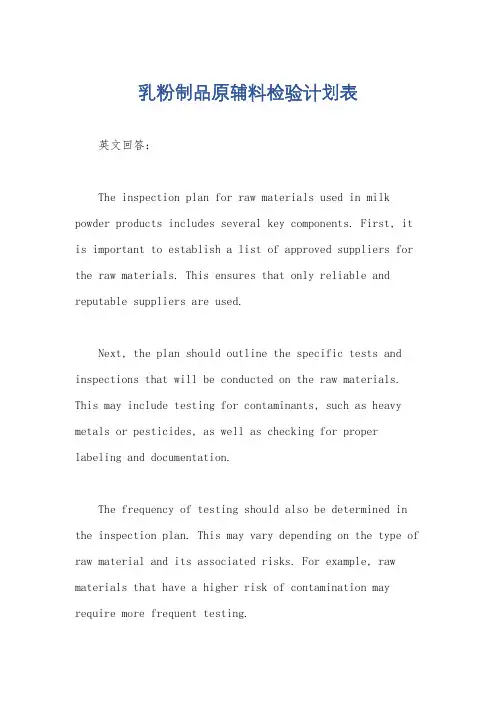

乳粉制品原辅料检验计划表英文回答:The inspection plan for raw materials used in milk powder products includes several key components. First, it is important to establish a list of approved suppliers for the raw materials. This ensures that only reliable and reputable suppliers are used.Next, the plan should outline the specific tests and inspections that will be conducted on the raw materials. This may include testing for contaminants, such as heavy metals or pesticides, as well as checking for proper labeling and documentation.The frequency of testing should also be determined in the inspection plan. This may vary depending on the type of raw material and its associated risks. For example, raw materials that have a higher risk of contamination may require more frequent testing.In addition to testing the raw materials, theinspection plan should also include procedures forinspecting the production facilities. This may involve on-site visits to ensure that proper hygiene and safety practices are being followed.Finally, the inspection plan should outline the actions that will be taken if any non-compliance or issues are identified. This may include rejecting or quarantining the raw materials, as well as conducting further investigations or audits.中文回答:乳粉制品原辅料检验计划包括几个关键组成部分。

节能材料试验送检计划

工程名称:宣城市文鼎中学体艺综合办公楼

建设单位:宣城市私立文鼎中学

设计单位:安徽省建材工业设计院

监理单位:广德县建达监理有限公司

施工单位:安徽龙升建筑工程有限公司

质量监督单位:宣城市建设监督管理局

安徽龙升建筑工程有限公司

节能材料试验、送检检测计划表

根据GB50411-2007标准要求,经建设、监理、施工单位共同确定文鼎中学体艺综合办公楼工程的节能材料试验、送检检测计划如下:

施工单位:监理单位: 建设单位:。

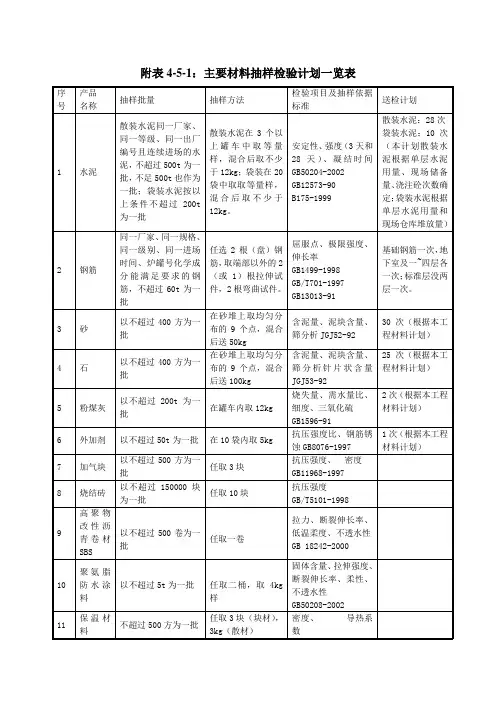

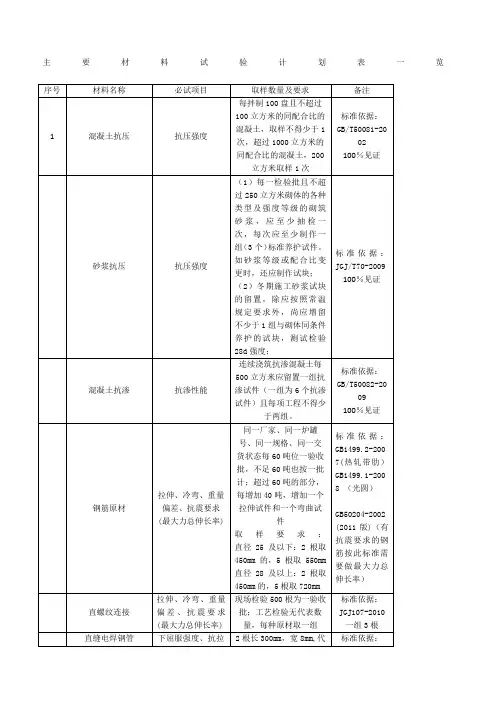

主要材料试验计划表一览序号材料名称必试项目取样数量及要求备注1 混凝土抗压抗压强度每拌制100盘且不超过100立方米的同配合比的混凝土,取样不得少于1次,超过1000立方米的同配合比的混凝土,200立方米取样1次标准依据:GB/T50081-2002100%见证砂浆抗压抗压强度(1)每一检验批且不超过250立方米砌体的各种类型及强度等级的砌筑砂浆,应至少抽检一次,每次应至少制作一组(3个)标准养护试件。

如砂浆等级或配合比变更时,还应制作试块;(2)冬期施工砂浆试块的留置,除应按照常温规定要求外,尚应增留不少于1组与砌体同条件养护的试块,测试检验28d强度;标准依据:JGJ/T70-2009100%见证混凝土抗渗抗渗性能连续浇筑抗渗混凝土每500立方米应留置一组抗渗试件(一组为6个抗渗试件)且每项工程不得少于两组。

标准依据:GB/T50082-2009100%见证钢筋原材拉伸、冷弯、重量偏差、抗震要求(最大力总伸长率)同一厂家、同一炉罐号、同一规格、同一交货状态每60吨位一验收批,不足60吨也按一批计;超过60吨的部分,每增加40吨,增加一个拉伸试件和一个弯曲试件取样要求:直径25及以下:2根取450mm的,5根取550mm直径28及以上:2根取450mm的,5根取720mm标准依据:GB1499.2-2007(热轧带肋)GB1499.1-2008 (光圆)GB50204-2002(2011版)(有抗震要求的钢筋按此标准需要做最大力总伸长率)直螺纹连接拉伸、冷弯、重量偏差、抗震要求(最大力总伸长率)现场检验500根为一验收批;工艺检验无代表数量,每种原材取一组标准依据:JGJ107-2010一组3根直缝电焊钢管下屈服强度、抗拉2根长300mm,宽8mm,代标准依据:强度、断后伸长率表批量400根GB/T13793-2008脚手架旋转扣件抗滑、抗破坏取样要求:代表批量281-500个,取8个/组;代表批量501-1200个,取13个/组;代表批量1201-10000个,取20个/组。

2024年送检计划表范本计划名称: 2024年送检计划表计划起止日期: 2024年1月1日 - 2024年12月31日责任部门: 质量控制部门制定日期: [制定日期]序号送检内容负责人计划日期实际日期备注1 原材料检测 [负责人姓名] [计划日期] [实际日期] [备注]2 产品配件检测 [负责人姓名] [计划日期] [实际日期] [备注]3 产品生产线检测 [负责人姓名] [计划日期] [实际日期] [备注]4 成品检测 [负责人姓名] [计划日期] [实际日期] [备注]5 包装材料检测 [负责人姓名] [计划日期] [实际日期] [备注]6 储存条件检测 [负责人姓名] [计划日期] [实际日期] [备注]7 运输检测 [负责人姓名] [计划日期] [实际日期] [备注]8 质量管理体系检测 [负责人姓名] [计划日期] [实际日期] [备注]9 客户投诉检测 [负责人姓名] [计划日期] [实际日期] [备注]10 监督抽检 [负责人姓名] [计划日期] [实际日期] [备注]11 认证审核 [负责人姓名] [计划日期] [实际日期] [备注]12 售后服务检测 [负责人姓名] [计划日期] [实际日期] [备注]备注:- 请在实际日期栏填写每项检测的实际完成日期。

- 若计划日期需要调整,请及时通知负责人并在备注栏注明调整原因。

- 若发生了意外情况导致计划日期不能按时完成,请及时通知负责人并在备注栏注明原因和预计完成日期。

- 计划表中的每项检测都应进行详细记录,包括相关测试数据、结果和质量评估等。

制定人: [制定人姓名]签字: [签字](此处应留出空白以便于签字确认)。

宁夏城乡工程监理咨询有限公司工程材料见证取样和送检见证计划单位工程名称:施工单位:土建监理:电气监理:水暖监理:编制日期:工程材料见证取样和送检见证计划为规范我公司监理工程见证取样和送检制度,确保工程材料质量和工程实体结构安全,特编制此计划。

一、编制依据1、《建筑工程施工质量验收规范》;2、《建筑工程施工质量验收统一标准》;3、《宁夏回族自治区房屋建筑工程和市政基础设置工程实行见证取样和送检管理办法》;4、施工图纸;5、承包单位报送材料用量计划与见证取样送检计划。

二、见证取样送检范围、数量和程序:㈠见证取样送检范围、数量:1、涉及结构安全的试块、试件和材料见证取样的送检的比例为各相关标准规范中规定应取数量30%,其余70%为常规实验;2、土建工程必须做见证取样的试块、试件和材料的范围:①用于承重结构的砼试块;同一强度等级、同一批次同条件养护试块不少于3组(600℃);②用于承重墙体的砌筑砂浆试块;③用于承重结构的钢筋及连接接头试件;④用于承重墙的砖和砼小型砌块;⑤用于拌制砼和砌筑砂浆的水泥;⑥用于承重结构的砼中使用的掺加剂;⑦地下、屋面、厕浴间使用的防水材料;⑧国家规定必须见证取样和送检的其它试块、试件和材料。

3、建筑节能工程必须做见证取样的范围与数量:①墙体节能工程采用的保温材料和粘结材料;同一厂家同一品种的产品,当单位工程建筑面积在20000㎡以下时各抽查不少于3次;当单位工程建筑面积在20000㎡以上时各抽查不少于6次;②幕墙节能工程使用的材料、构件等;当幕墙面积大于3000㎡或建筑外墙面积50%时,应现场抽取材料和配件,在检测试验室安装制作试件进行性能检测;③门窗节能工程所用建筑外窗;同一厂家同一品种同一类型的产品各抽查不少于3樘(件);④屋面节能工程所使用的保温隔热材料;同一厂家同一品种的产品各抽查不少于3组;⑤地面节能工程采用的保温材料;同一厂家同一品种的产品各抽查不少于3组;⑥采暖节能工程采用的散热器和保温材料等;同一厂家同一规格的散热器按其数量的1%进1行见证取样,但不得少于2组;同一厂家同材质的保温材料见证取样送检的次数不得少于2次;⑦通风与空调节能工程采用的风机盘管机组和绝热材料;同一厂家的风机盘管机组按2%见证,但不得少于2台;同一厂家同材质的绝热材料见证取样送检的次数不得少于2次;⑧空调与采暖系统冷热源及管网节能工程的绝热管道、绝热材料;同一厂家同材质的绝热材料见证取样送检的次数不得少于2次;⑨配电与照明节能工程低压配电系统选择的电缆、电线;同厂家各种规格总数的10%,且不少于2个规格;㈡见证取样送检程序:1、工程开工时,监理单位委派有见证取样合格证书人员签发《见证取样和送检见证人备案表》,并报送该工程的施工单位、质量监督机构和见证检测单位备案,报送施工单位;2、见证人员按批准的见证取样和送检计划表,对施工现场的取样和送检进行见证,见证人员应填写《见证取样记录》;3、见证人员应对试块进行监护并和施工企业取样人员一起将试件和《见证取样记录》送至见证检测机构;4、见证取样和送检的检验报告必须加盖见证取样检测专用章,并注明见证人员姓名和证书号;5、见证取样检测结果不合格,按相应标准规范允许可加倍复试。

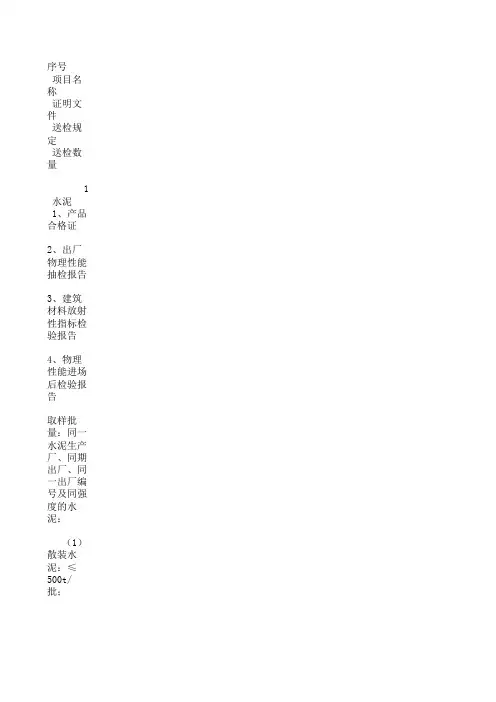

主要原材料:1、水泥—每批代表数量(袋装≤200t;散装≤500t)水泥出厂3个月后应重做试验2、粗集料、细集料—每批代表数量(大型运输工具)不超过400m3或600t。

(在料堆上取样时,取样部位应均匀分布。

取样前先将取样部位表层铲除,然后对于砂子由各部位抽取大致相等的8份,组成一组样品;对于石子由各部位抽取大致相等的15份(在料堆的顶部、中部和底部各由均匀分布的五个不同部位取得)组成一组样品)3、砂、土击实—土样变化时应重新检验4、中海砂(路基回填)—土样变化时应重新检验5、实心砖—每批代表数量3.5~15万块(不足3.5万按一批送检)6、钢材—原材每批代表数量≤60t;单双面焊:每批代表数量不超300个;机械连接:每批代表数量不超500个;钢板每批代表数量≤60t;7、防水材料—每批代表数量5~10t(不足按一批送检)8、水—固定水源抽取送检9、塑料排水板—每批代表数量≤20万米10、土工格栅—每批代表数量≤20000 m211、土工布、经编土工织物—每批代表数量≤20000 m212、钢绞线—每批代表数量≤60t13、塑料波纹管—每批代表数量≤50000m14、锚具—每批代表数量≤1000套;链接器≤500套15、橡胶基座—同生产线(同批)检验一次16、电力、电信排管—每批代表数量≤10t17、雨水UPVC排水管—每批代表数量≤10t18、污水HDPE管—每批代表数量≤10t19、给水PE管—每批代表数量≤10t20、砂浆、混凝土配合比—材料变化配合比重新设计试验21、混合料配合比—材料变化配合比重新设计试验路基工程路基标高3.000m~4.630m回填中砂分层压实,每层压实后厚度≤30cm,每1000 m2取3个点,压实度≥90%;路基标高4.630m以上回填土,压实度距路床0~80cm≥95%,80~150 cm≥93%,大于150cm≥90%,挖方及小于30cm的填方压实度≥95%;超载预压部分压实度应达到重型压实标准的91%,卸除压载土方后,路堤挖至路床后的压实读应≥96%;路床弯沉每车道每20米检测一个点,实测弯沉值应小于设计弯沉值。