OCA规格书

- 格式:pdf

- 大小:426.35 KB

- 文档页数:9

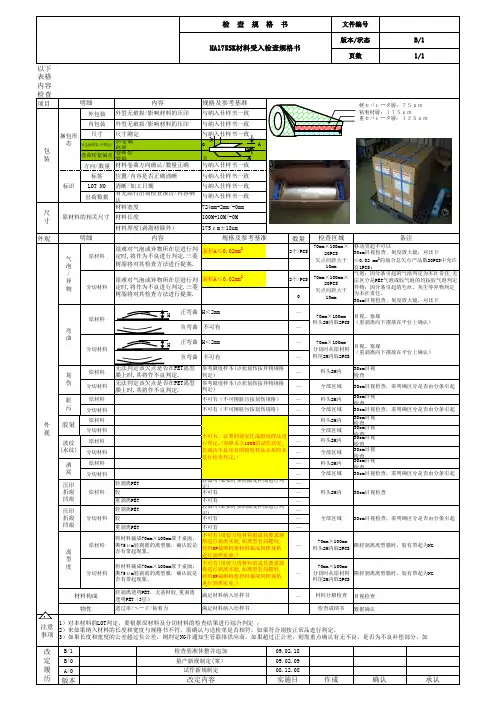

以下表格内容检查项目外包装内包装尺寸回卷偏移量(平整度)回卷偏移量(a)在3mm以下卷曲松紧偏差卷曲松紧量(A-B)在5mm以下方向/数量标签LOT NO 出荷数据外观数量2个/PCS2个/PCS0正弯曲H<2mm —负弯曲不可有—正弯曲H<2mm —负弯曲不可有—原材料—30cm目视检查分切材料—原材料—30cm目视检查分切材料—原材料30cm目视检查分切材料30cm目视检查原材料—30cm目视检查分切材料—30cm目视检查原材料—30cm目视检查分切材料——胶———胶——原材料—分切材料——目视检查数据确认注意事项B/1B/0A/0版本明细内容规格及参考基准检 查 规 格 书文件编号版本/状态B/1外型无破损/影响材料的压印与纳入仕样书一致外型无破损/影响材料的压印与纳入仕样书一致页数1/1材料卷曲方向确认/数量正确与纳入仕样书一致位置/内容是否正确清晰与纳入仕样书一致尺寸测定与纳入仕样书一致a A B材料宽度724mm+2mm/-0mm 材料长度100M+10M/-0M 清晰/加工日期与纳入仕样书一致有无添付出荷检查报告/内容确认与纳入仕样书一致明细内容规格及参考基准检查区域备注面积A≤0.02mm 2面积A≤0.02mm 2材料厚度(剥离材除外)175μm±18um无法判定该欠点是否在PET离型膜上时,其将作不良判定.参考限度样本(点状划伤按异物规格判定)料头2M内无法判定该欠点是否在PET离型膜上时,其将作不良判定.参考限度样本(点状划伤按异物规格判定)全部区域料头2M内30cm目视检查,需明确区分是否由分条引起不可有(不可擦脏污按划伤规格)料头2M内不可有(不可擦脏污按划伤规格)全部区域30cm目视检查,需明确区分是否由分条引起全部区域30cm目视检查,需明确区分是否由分条引起轻剥离PET轻微可(必要时参照限度样品进行判定)不可有、必要的情况作成限度样品进行判定.(参照本次100K的试作状况,作成该不良项目的限度样品并参照其进行检查判定.)全部区域料头2M内不可有重剥离PET不可有将材料裁成70mm×100mm放于桌面,撕75μm轻剥离的离型膜,确认胶是否有带起现象。

OCA操作手册Operating manualDataPhysics OCAVersion 1.4, EnglishFirmware-version from 1.11,Software-version from 1.2Release: November 1999All Rights, also of translation reserved.No part of this document may be reproduced in any form (print, photocopy, microfilm or any other process) or be processed, multiplied or distributed by any electronic means without the prior written approval of DataPhysics. This does not affect the exceptions expressly stated in Ё53, 54 UrhG.DataPhysics Instruments GmbH does not accept any kind of liability for technical or printing mistakes or defectiveness in this operating manual.We reserve the right to make changes to the content of this operating manual without prior announcement.The use of names, trade names, merchandise descriptions and such in this operating manual does not justify the assumption that such names may simply be used by anyone; often we are concerned with legally protected registered trademarks even if they are not marked as such.Text, graphics and layout Gerhard燤aierPrinted in Germany© Copyright 2019 by DataPhysics Instruments GmbH, Filderstadt®is a registered trademark of DataPhysics Instruments GmbH, Filderstadt® IBM and IBM-PC are registered trademarks of International Business Machine Corporation® Microsoft and Windows are registered trademarks of Microsoft CorporationDataPhysics Instrument GmbHRaiffeisenstra遝34D-70794 Filderstadtphone ++49 (0)711-770556-0fax ++49 (0)711-770556-99email info@dataphysics.de目录1.前言1.1遵守条约1.2安全警告1.3详细安全提示2.概要描述2.1关于本手册2.2应用2.3OCA系列的装置2.4测试方法和结果3.安装及设置3.1概述3.2检查清单和发货单3.3OCA的安装3.3.1 水平调节3.3.2计量针、计量单元的安装3.3.3标准样品台的安装3.3.4注射单元的安装3.3.5目镜测角仪的安装(OCA5/10)3.3.6电路连接3.4计算机的设置3.5软件的安装4.操作说明4.1操作概述4.2OCA的使用4.2.1样品台的固定4.2.2计量针的安装4.2.3灯的调整4.2.4图像镜头的调整5.测量5.1测试程序和方法5.2测量手册(OCA5/10)5.2.1Tan 方法5.2.2SCA10,表面自由能的计算5.3软件的使用5.3.1参数的选取5.3.2取线框的设置5.3.3动态跟踪功能5.3.4电影播放功能5.3.5坐滴法5.3.6悬滴法5.3.7薄片法5.3.8液体的分配5.3.9计算结果窗口5.3.10表面自由能的计算5.3.11液体基础数据库6.维护6.1概述6.2仪器的清洗6.3更换卤灯光源7.技术数据8.保证协议9.附件部分9.1所需的主要电线9.2其余部分9.3高速系统OCAH 200的设置9.4可选附件部分9.4.1SD-D9.4.2TFC 100.WORD完美格式.9.4.3TEC 3509.4.4TPC 1509.4.5玻璃样品池9.4.6TBA 60M9.4.7TBA 60E9.4.8WT 200M/300M9.4.9WT 200E/300E9.5 声明序言本操作手册适用于OCA系列所有型号的光学接触角测量仪。

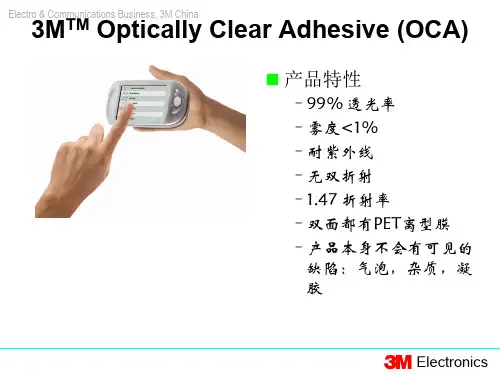

oca配制操作流程OCA(Optically Clear Adhesive)是一种透明胶粘剂,广泛应用于电子产品的显示屏保护和封装中。

在生产过程中,正确的OCA 配制操作流程对产品的质量和性能起着至关重要的作用。

下面将介绍一下OCA配制操作流程。

首先,准备工作。

在进行OCA配制之前,需要准备好所需的材料和设备,包括OCA胶片、清洁布、刮刀、真空除气机等。

确保工作环境干净整洁,避免灰尘和杂质污染OCA胶片。

其次,准备OCA胶片。

将OCA胶片取出并放置在干净的工作台上,用清洁布轻轻擦拭表面,确保没有灰尘和污垢。

然后使用刮刀将OCA胶片切割成所需的尺寸和形状,以适应产品的封装需求。

接着,除气处理。

将切割好的OCA胶片放置在真空除气机中,启动机器进行除气处理。

通过减压和振动的方式,将OCA胶片中的气泡和杂质排除,确保OCA胶片的质量和透明度。

然后,封装操作。

将除气处理好的OCA胶片粘贴在产品的显示屏上,确保贴合完整和平整。

使用专业的工具和技术,将OCA胶片与显示屏粘合在一起,形成保护层。

同时,通过加热和压力处理,确保OCA胶片与显示屏之间的结合牢固和稳定。

最后,质量检验。

完成OCA配制操作后,需要进行质量检验,确保产品符合要求。

检查OCA胶片的透明度、粘合度和平整度,排除可能存在的质量问题。

只有通过严格的质量检验,才能保证产品的质量和性能。

总的来说,OCA配制操作流程包括准备工作、OCA胶片处理、除气处理、封装操作和质量检验等环节。

正确的操作流程和技术,能够保证OCA胶片的质量和性能,提高产品的竞争力和市场占有率。

希望以上介绍能够帮助您更好地了解OCA配制操作流程。

- 4 -- 1 -IMPORTANT: It is of vital importance, before attempting to operate your OCA-150 to read through this instruction manual.BRUSHLESS MOTOR ESCFOR HELICOPTERS/AIRPLANESINSTRUCTION MANUALThe OCA-150 is ECS installed with the latest FET for brushless motors. By using an optional extra ESC Programmer OCP-1, settings of ESC can be programmed quickly and securely to meet model’s specific requirements. Before operating OCA-150M i s u s e o r a b u s e o f L i P o b a t t e r i e s i s v e r y dangerous. Be sure to follow the instruction manual supplied with the batteries.Be sure to install the connectors which match the batteries, securely soldering to the battery connecting wires of the ESC. Never use the ESC with the connectors temporarily connected.B a t t e r i e s c a n b e u s e d : L i P o 2~6 c e l l s (7.4~22.2V), NiCd/NiMH 6~18 cells (7.2~21.6V)OCA-150 is equipped with BEC output as power output for receiver. Do not connect the battery for receiver when connecting the OCA-150. If both the ESC and the receiver battery are connected to a receiver, receiver, ESC and batterieswill be failed.Solder the corresponding battery connector to the battery connection wires of the ESC. Also, use a heat-shrink tube to isolate the connection. Solder the corresponding connectors (female) to the motor connection wires of the ESC. Also, use a heat-shrink tube to isolate the connection.PREPARATION Connect to the OCP-1 when the settings are made with the OCP-1.Connect to the brushless motor.The average RPM during the last flight is indicated.RPM to indicate is calculated by motor pole number and gear ratio. Default is testvalue when the ESC leaves the factory. It changes when the motor is run.Beep once every second continues until the process is completed. If you want to quit in the middle, press DEC(-).This is to store the set date in the programmer’s memory. Press INC(+) to start the process.Cool Power FET: Latest generation power FETESC Programmer OPC-1: By connecting to OCA-150, detailed setting can be done easily.Start protection: Stops involuntary starting of the motor.Low voltage cut-off: Stops the motor before the voltage reaches the level where control is lost and potential over-discharge damage to the cells occurs.No signal cut-off: Switches the ESC OFF when signal from the transmitter is not received.Overheat protection: When the temperature rises extraordinary due to overload, restrict output to protect the ESC.Battery cell number auto recognition: Function to recognize automatically cell number of the battery to connect.BEC output: Power to receiver is supplied from the ESC.SPECIFICATIONS- 2 -- 3 -Set the high point and the slowest point as follows. (In case of model type AIR/HELI)As explained before, connect the ESC, receiver and motor. Do not connect power battery atthis time.PreparationPreparationSet the throw angle of the throttle channel on the transmitter 100%. In case of Futaba, set the reverse function of the throttle channel to the reverse.When the LED on the ESC flashes, reverse the throttle channel using the servo reverse function on the transmitter. Disconnect the power battery and repeat the procedure from the beginning.In case of model type CAR or BOAT and reverse function ON, step should be replaced with the following.Set the throttle stick neutral (a short beep)→reverse(a short beep)→(a double beep)→disconnect power battery to set high point, neutral point and reverse point.Five parameters can be set without using the programmer in the following manner.How to select parameter type (number).Select the parameter type (number) with the following procedure.As explained before, connect the ESC, receiver and motor. Do not connect power battery at this time.PreparationHow to change parameter.After selecting the parameter No. as explained above, change the parameter with the following procedure.The following example explains how to set initial setting to use governor (in case of HELI) or air brake (in case of AIR).WARNINGSBe sure to set the parameters according to the throttle positions and using conditions before using the OCA-150.When normal operation is ready, check the direction of motor rotation. If the rotation is reverse, correct it by re-setting of the parameter or changing connection of the motor.Wrong setting may cause sudden rotation of the motor or out of model control which is very dangerous.If the power battery is connected with the throttle stick not at the slowest position, LED flashes. In this case, move the throttle stick to the slowest position and a set of very short and short beep is emitted to confirm ready to operate.If the power battery is connected with the throttle stick at high and entered into the setting mode, disconnect the power battery and repeat from the beginning.By using an optional extra ESC Programmer OCP-1, settings of ESC can be programmed quickly and securely to meet model’s specific requirements.LCDEditing ButtonsConnection of the programmerConnect the OCP-1, power battery and motor to OCA-150 as explained before.Operation of editing buttonsSetting itemsItems can be programmed with the OCP-1 are listed below.How to setWhen the OCP-1 and power battery are connected to the ESC, current settings of the ESC are automatically stored in the OCP-1.Select the item to change with the arrow buttons (↓ or ↑) and change the setting with INC(+) and DEC(-) buttons.When the parameter setting of the ESC with the OCP-1 is completed,write the set data to the ESC with “ Down load the set data to the ESC” function. Set data cannot be written to the ESC with only parameter setting.Selection of battery typeSetting range: LiPo, NiCd Default: LiPoSelect power battery type to use with INC(+) and DEC(-) buttons.When the battery type is changed, “CUT OFF VOLTAGE” and “CUT OFF TYPE”parameters are changed.Setting range: Slow/Normal/Fast or Value 5~100%Default: NormalSlow FastWith model type AIR, adjust the air brake effect. Select to stop the motor gradually or suddenly with INC(+) and DEC(-) buttons.With 100% motor stops suddenly.。

O C A简要操作说明开关机注意事项:测试接触角时,如果不需要控制温度,则不需要打开水浴箱和温度控制器。

开机时,先打开仪器,而后打开软件运行。

关机时,先关闭软件,后关闭仪器。

静态接触角测试:夹持试样——sessile drop ——File ——new——结果窗口——M-Info——ref-size——针外径尺寸(根据选用的针设定)——————ESE6 ——5.000——速度中等——调节试样台和针头使在屏幕上出现清晰的象(现在针头上)————注射——调节试样台,将水滴接于试样上————选基线——————在此窗口下File——export(保存图像)——关闭测试窗口——File ——new——新的测试窗口——下一次测试动态接触角的测试夹持试样——sessile drop [need in]——File ——new——结果窗口——M-Info——ref-size——针外径尺寸(根据选用的针设定)——————ESE6 ——5.000——速度中等——ARCA——编辑ARCA——调节试样台和针头使在屏幕上出现清晰的象(现在针头上)————注射——调节试样台,将水滴接于试样上——调节试样台和针头使针头伸进试样上的水滴中——绿色胶片——run ARCA——选基线——————选定Caplelation——黑三角(边播放边计算)——结果窗口——Arca ranges average ——left 【液体体积从开始增加到体积最大】——right[液体体积从最大到最低]表面张力的测试:夹持试样——更换snp针——File ——new——结果窗口——system——system phases——water(或其他)——M-Info——ref-size——针外径尺寸(根据选用的针设定)——————ESE6——Live video——Pendantdrop——dispense(液滴越大越好,但不能滴落,针头下出现白点即可)————第三根线放在针头下的白点一下——————。

Documnet No.To : CustomerSPECIFICATION FOR"HANWHA Optically Clear Adhesive (HOCA)"• General Name : HANWHA Optically Clear Adhesive (HOCA) • Your Part Numbers : • Our Part Numbers : HO-1-050, HO-1-100 • Purchaser We received this document on Dept. Name Responsible Person Person in charge , ,Business Part• ManufacturerThis specification covers HOCA intended for using in display module between Hanwha L&C Corporation and Shanghai-leadtech CO.,LTD onDept. name Quality Assurance Business Part Manufacturing Section Marketing Department Manager Manager ManagerElectronic Material DivisionDocumnet No.Specification For "HANWHA Opically Clear Adhesive"1. Material Light release PET film, Acid-free acryl adhesive and heavy release PET in the form of film 2. Product constitution Product NameHO-1-050 HO-1-100 Light release PET film(㎛) P50H(1SM)L2A : 50±2㎛Adhesive(㎛)Acid Free Thickness 50±2㎛ Acid Free Thickness 100±3㎛Heavy release Product Total PET film(㎛) thickness constitutionP100(1SM)4H : 100±2㎛ 200±4㎛ 250±5㎛Light release PET Adhesive Heavy release PET3. Appearance and Uniformity Material shall be uniform in composition and free from defects which impair functionality and/or appearance of the consumer products as process capability permit 1) Defects - The broken and groove of surface - The bow and air bladder of adhesive layer ※ The position of Defect is flagged by polyester tape at the roll edge The position of the flag is subject to mutual discussion 4. Width, Length and Splices Item Width Standard Length / Roll Maximun number of splices Minimum splice-free length Unit ㎜ m m HO-1-050 HO-1-100250/500±2.0 100±2.0 3 30*Required further consultation between Hanwha L&C Corp. and customer.Electronic Material DivisionDocumnet No.5. Typical Properties and Performance Characteristics ItemLight release PETUnitSpecificationHO-1-050 HO-1-100Test Method/ Condition50±1 ㎛ 50±2 100±1 >1.70Kgf/25㎜50±1 100±3 100±1 >1.70 1.50 >1.70+100℃/2HR +85℃/85%RH /48HR -40℃/1HR↔ +85℃/1HR, 200 CycleThicknessAdhesive Heavy release PETMicro meterPET(Peel angle : 180° Peeling speed : 305㎜/min.)Peel StrengthGlass PC>1.50 >1.70ASTM D3330Heat ResistanceHaze Resistance Under Heat and HumidNo change in appearance-No change in appearance No change in appearanceThermal Shock Cycling Test Transmittance Optical Properties Haze Refractive Index UV-light Resistance ITO Deterioration % % %>98.0 <1.00>98.0 <1.00≥300nm ASTM D1003-92Measured for Sodium D line UVA-340 lamp, 068w/㎡, 500HR>1.460 No discoloration <20+85℃/90%RH /960HR*Required further consultation between Hanwha L&C Corp. and customer.6. Test Procedures Test procedures are shown in Appendix 1.Electronic Material DivisionDocumnet No.7. Index of codeHO - 1 - ***① ② ③ ① Product type : HANWAH optically clear adhesive ② Film type : 1- Non carrier film 3- Carrier film ③ Adhesive thickness : 050 - 50㎛ 100 - 100㎛ 125 - 125㎛ 8. Test Report The test report shall be submitted for each delivered lot ( Appendix 2 ) Test test report of each lot shall include the following : 1) Product Code 2) Lot No. 3) The date of production 4) The date of test 5) Width 6) Length 7) Materials 8) Thickness 9) Peel strength 10) Heat Resistance 11) Haze Resistance Under Heat and Humid 12) Thermal Shock Cycling Test 13) Transmittance 14) Haze 15) Refractive Index 16) UV-light Resistance 17) ITO DeteriorationElectronic Material DivisionDocumnet No.8. Packing 1) Packing unit The roll shall be rolled up to 3 inches paper core. The width of paper core is 252mm or 502 mm. 2) The method for packing Each roll shall be packed into one carton so as not to be damaged during transportation and storage. 9. Marking The following items shall be marked on the surface of each carton. ( Appendix 3 ) 1) Product name 2) Product Code 3) Width 4) Description 5) Length 6) Weight 7) Splice number 8) Lot number 9) Manufacturer 10. Storage condition Store our product below 5℃ 11. Addition This specification will come into effect on , ,Electronic Material DivisionDocumnet No.< Appendix 1 > HANWHA Optically Clear Adhesive (HOCA) TEST PROCEDURE 1. Appearance : See with the naked eye. 2. Width : Measure with the JIS stainless scale (capable of reading to 0.5mm) 3. Length : Measure with the tachometer (capable of reading to 0.1m ) 4. Thickness : We measure the thickness 5 points on the crossway with the micrometer (unit 1㎛) and then calculate the average value 5. Wet processing : According to HFTM 2.2- the method for making the specimen. 6. Peel Strength : According to ASTM D3330 (using 180˚ grip) Specimen size : 25mm×100mm Peel speed : 305mm/min Temp. & Humidity : +25℃/65% Calculate the average of 7 specimens 7. Heat Resistance : Specimen size : 50mm×100mm Adherend : Bare PET Test condition : +100℃/2HR Calculate the average of 7 specimens 8. Haze Resistance Under Heat and Humid : Specimen size : 50mm×100mm Adherend : Bare PET Test condition : +85℃/85%RH, 48HR Calculate the average of 5 specimensElectronic Material DivisionDocumnet No.9. Thermal Shock Cycling Test : Specimen size : 50mm×100mm Adherend : Bare glass Test condition : -40℃/1HR ↔ +85℃/1HR, 200 Cycle Calculate the average of 5 specimens 10. Transmittance : According to ASTM D1003 Specimen size : 20mm×20mm Test range : >300nm Calculate the average of 5 specimens 11. Haze : According to ASTM D1003-92 Specimen size : 20mm×20mm Calculate the average of 5 specimens 12. Refractive Index : Measured for sodium D line Calculate the average of 3 specimens 13. UV-light Resistance : According to ASTM G155 Specimen size : 100mm×100mm Test condition : UVA-340 lamp, 068w/㎡, 500HR Calculate the average of 3 specimens 14. ITO Deterioration : Specimen size : 40mm×160mm Test condition : +25℃/50%RH Adherend : ITO film Applied voltage : 10V Time : 30sec Calculate the average of 3 specimensElectronic Material DivisionDocumnet No.< Appendix 2 > Test Report HANWHA L&C CORPORATION1 Janggyo-dong, Jung-gu, Seoul, Korea TEL : 02-729-1330, FAX : 02-729-1321Test Report on HANWHA OCAHANWHA HOCA Code : HO-1-050, HO-1-100 Lot Number : C********* Date of Fabrication : 2012/05/14 Date of Examination : ****/**/** Dimension Width[㎜] Heavy release film Adhesive Light release film Properties Test Item Thickness Peel Strength(180°, Glass) Heat ResistanceHaze Resistance Under Heat and Humid250 / 500 Thickness[㎛] Thickness[㎛] Thickness[㎛]Length[m] *** *** *** MeasurementHO-1-050 HO-1-100*** *** ***Test Method/ Condition Micro meter ASTM D3330+100℃/2HR +85℃/85%RH /48HR -40℃/1HR↔ +85℃/1HR, 200 CycleUnit ㎛Kgf/25㎜200(ave.) 1.86250(ave.) 1.91% % ratioPass Pass Pass 99.2 0.4 1.476 No discoloration +1.19 99.3 0.5Thermal Shock Cycling Test Transmittance Optical Properties Haze Refractive Index UV-light Resistance ITO Deterioration≥300nm ASTM D1003-92Measured for Sodium D line UVA-340 lamp, 068w/㎡, 500HR+85℃/90%RH /960HRElectronic Material DivisionDocumnet No.< Appendix 3 > LabelH A N W H A F L E X HANWHA OCA(HOCA)Model Type Width Description Length Net Weight Splice Lot Number***HO-1) Product Name 2) Product Code 3) Width 250/500㎜OCA**㎛ PET1**㎛ P 4) Description 100 5) Lengthkg Gloss Weight 6)WeightEA7) Splice Number Defect 8) Lot NumberC*********HANWHA L&C CORPORATION9) Manufacturer229, Kumho-Ri, Buyoung-Myun, Cheongwon-Kun, Chungbuk, KOREA Manufactory : 82-43-279-8531 Fax : 82-43-279-8540 Head Office : 82-2-729-1330 Fax : 82-2-729-1321NotificationThe General description, application data and statements in the product literature and label are guidelines only. Users should test this product in advance to verify suitability for particular uses.Electronic Material Division。