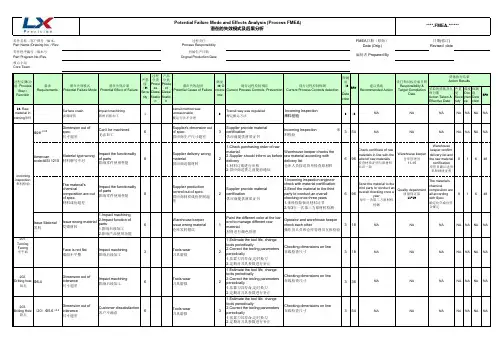

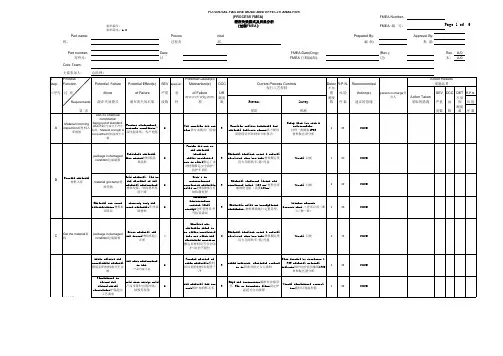

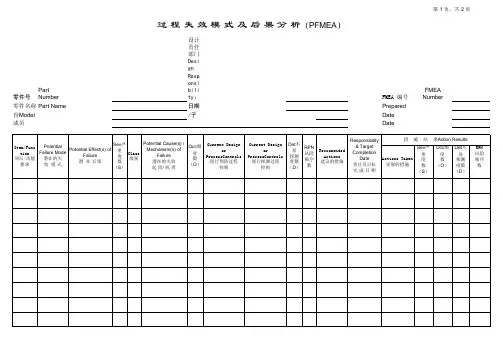

零件机械加工 PFMEA潜在失效模式及分析标准表格模版

- 格式:xls

- 大小:190.00 KB

- 文档页数:10

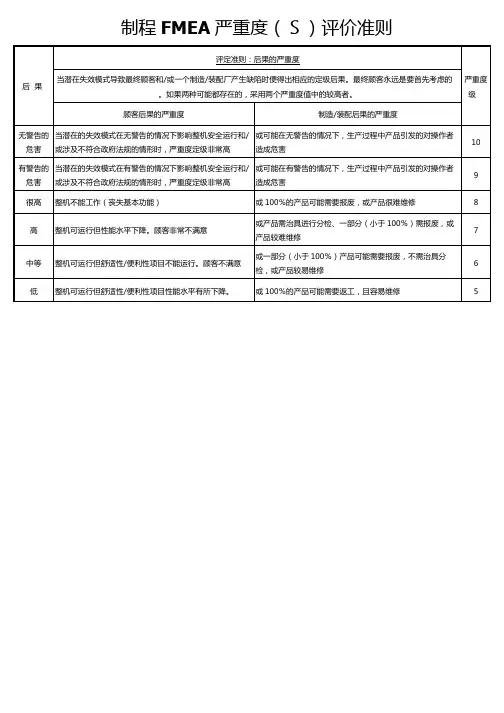

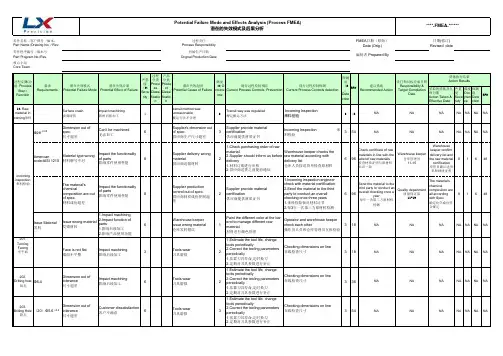

日期(修订)Revised date采取的措施及生效日期Action Taken &Effective Date 严重度Seve ruty 频度Occ yran ce探测度Dete ctionRPN10.Raw material in coming 来料4transit method was unreasonable 搬运方法不合理2648NA NA NA NA NA NA NAФ28-0.036Supplier's dimension out of spec供应商生产尺寸超差3354NA NA NA NA NA NA NAAmericancode:AISI 12158Supplier delivery wrong material供应商送错材料2696Check certificate of raw materials in line with the label of raw materials检查材质证明与原材料标识一致Warehouse keeper仓库管理员11-15Warehouse keeper confirm delivery list and the raw material certification 库管员确认送货单和材质证明816488Supplier production control out of spec.供应商材质成份控制超差2696Send the material to thethird party to conduct anoverall checking once ayear每年一次第三方原材料检测Quality department 质量保证部11-19The material'schemicalcomposition areall according with Spec.确定化学成份符合规定81648Issue Material 发料6Warehouse keeper issue wrong material 仓库发料错误1318NA NA NA NA NA NA NA201.Turning Facing 光平面3Tools wear 刀具磨损2318NA NA NA NA NA NA NA202.Drilling hole 钻孔Φ5.46Tools wear 刀具磨损2336NA NA NA NA NA NA NA203.Brilling Hole 镗孔(20)Φ5.6 +0.26Tools wear 刀具磨损3354NA NA NA NA NA NA NATransit way was regulated 规定搬运方法Incoming Inspection 来料检验Surface crash 表面碰伤****-FMEA-******Potential Failure Mode and Effects Analysis (Process FMEA)潜在的失效模式及后果分析FMEA 日期(原始)Date (Orig.)Dimension out of tolerance 尺寸超差Dimension out of tolerance 尺寸超差Dimension out of spec 尺寸超差The material's chemicalcomposition are out of spec.材料成份超差Issue wrong material发错材料Face is not flat 端面不平整严重度(S)Seve rity过程分类Proce ss Classi ficatio nincoming inspection 来料检验Material type wrong 材料牌号不对Impact machining 影响后续加工过程步骤/功能 Process Step /Function要求Requirements 潜在失效模式Potential Failure Mode 潜在失效后果Potential Effect of Failure零件程序编号 /版本号Part Program No./Rev.核心小组Core Team零件名称 /客户图号 /版本:Part Name /Drawing No. / Rev.初始生产日期Orignal Production Date编制者 Prepared By过程责任Process Responsibility 潜在失效起因Potential Cause of Failure 频度(O)O ccurre nce产品分类ProductClassificatio n现行过程控制预防Current Process Controls Prevention现行过程控制探测Current Process Controls delection 探测度(D)Dete ctionRPN 建议措施Recommended Action责任和目标完成日期Responsibility &Target Completion Date措施执行结果Action Results Incoming Inspection 来料检验Warehouse keeper checks the raw material according with delivery list仓库人员按送货单检查原材料1.Incoming inspection engineer check with material certification2.Send the material to the third party to conduct an overall checking once three years 1.来料检验核对材料证书2.每3年一次第三方原材料检测Operator and warehouse keepercheck each other操作员人员和仓库管理员互相检验Checking dimensions on line 在线检查尺寸Checking dimensions on line 在线检查尺寸Checking dimensions on line 在线检查尺寸Supplier provide material certification供应商提供材质证书1.Check purchasing order of raw material2.Supplier should inform us before delivery1.材料订购进行审核2.供应商送货之前提前通知Supplier provide material certification供应商提供材质证书Paint the different color at the barend to manage different rawmaterial材料进行颜色管理1.Estimate the tool life, change tools periodically2.Correct the tooling parameters periodically1.估算刀具寿命,定时换刀2.定期对刀具参数进行补正1.Estimate the tool life, change tools periodically2.Correct the tooling parameters periodically1.估算刀具寿命,定时换刀2.定期对刀具参数进行补正1.Estimate the tool life, change tools periodically2.Correct the tooling parameters periodically1.估算刀具寿命,定时换刀2.定期对刀具参数进行补正Customer dissatisfaction客户不满意Can't be machined 无法加工Impact the functionality of parts影响零件使用性能Impact the functionality of parts影响零件使用性能1.Impact machining2.Impact function ofparts1.影响后续加工2.影响产品使用功能Impact machining 影响后续加工Impact machining 影响后续加工Effective Date ruty ce ctionn n203.Brilling Hole镗孔(32,42)20°5Tools wear刀具磨损3345NA NA NA NA NA NA NA (19)Φ5.9±0.15Tools wear刀具磨损3345NA NA NA NA NA NA NA (15)14.5+0.26Tools wear刀具磨损3354NA NA NA NA NA NA NA204 Reameringhole铰孔(21)Φ5.5 +0.02/-0.0058Tools wear刀具磨损441281.Determine the toolmaterial and enactmenttool life2.Determine theprocess parameters onthe machine3.SPC control1.确定刀具材质和设定刀具使用寿命2.确定过程参数3.SPC控制TechnologyDepartment技术部ProductionDepartment生产部11-171.Tool materialand tool lifeweredetermined.2.PPK≥1.67.1.刀具材质和刀具寿命已经确定2.PPK≥1.6782464205. Dilling hole钻孔Φ104Tools wear刀具磨损2324NA NA NA NA NA NA NA206. Boring hole镗孔(18)Φ12.2+0.04/08Tools wear刀具磨损441281.Determine the toolmaterial and enactmenttool life2.Determine theprocess parameters onthe machine3.SPC control1.确定刀具材质和设定刀具使用寿命2.确定过程参数3.SPC控制TechnologyDepartment技术部ProductionDepartment生产部11-171.Tool materialand tool lifeweredetermined.2.PPK≥1.67.1.刀具材质和刀具寿命已经确定2.PPK≥1.6782464(16)17.5 +0.02/-0.036Tools wear刀具磨损3354NA NA NA NA NA NA NAChecking dimensions on line在线检查尺寸Dimension out oftolerance尺寸超差Customer dissatisfaction客户不满意1.Estimate the tool life, changetools periodically2.Correct the tooling parametersperiodically1.估算刀具寿命,定时换刀2.定期对刀具参数进行补正Dimension out oftolerance尺寸超差Dimension out oftolerance尺寸超差Dimension out oftolerance尺寸超差Dimension out oftolerance尺寸超差Dimension out oftolerance尺寸超差Dimension out oftolerance尺寸超差Customer dissatisfaction客户不满意Customer dissatisfaction客户不满意Checking dimensions on line在线检查尺寸Checking dimensions on line在线检查尺寸Checking dimensions on line在线检查尺寸Checking dimensions on line在线检查尺寸Checking dimensions on line在线检查尺寸Checking dimensions on line在线检查尺寸1.Estimate the tool life, changetools periodically2.Correct the tooling parametersperiodically1.估算刀具寿命,定时换刀2.定期对刀具参数进行补正1.Estimate the tool life, changetools periodically2.Correct the tooling parametersperiodically1.估算刀具寿命,定时换刀2.定期对刀具参数进行补正1.Estimate the tool life, changetools periodically2.Correct the tooling parametersperiodically1.估算刀具寿命,定时换刀2.定期对刀具参数进行补正1.Estimate the tool life, changetools periodically2.Correct the tooling parametersperiodically1.估算刀具寿命,定时换刀2.定期对刀具参数进行补正1.Estimate the tool life, changetools periodically2.Correct the tooling parametersperiodically1.估算刀具寿命,定时换刀2.定期对刀具参数进行补正1.Estimate the tool life, changetools periodically2.Correct the tooling parametersperiodically1.估算刀具寿命,定时换刀2.定期对刀具参数进行补正Customer dissatisfaction客户不满意Impact assembly影响客户装配Impact machining影响后续加工Impact assembly影响客户装配Effective Date ruty ce ctionn n206.Boring hole镗孔(37)61,Tools wear刀具磨损2,The machine centerline offset机床中心线偏移3354NA NA NA NA NA NA NA207. Turning OutsideDiameter车外圆(4)Φ14.035Tools wear刀具磨损3345NA NA NA NA NA NA NA(5)Φ12.6±0.035Tools wear刀具磨损3345NA NA NA NA NA NA NA(1)Φ16.18 0/-0.046Tools wear刀具磨损3354NA NA NA NA NA NA NA(25)45.6°±5°4Tools wear刀具磨损3336NA NA NA NA NA NA NA208.Groovin g 割槽(2)Ф 14+0.057Tools wear刀具磨损441121.Determine the toolmaterial and enactmenttool life2.Determine theprocess parameters onthe machine3.SPC control1.确定刀具材质和设定刀具使用寿命2.确定过程参数3.SPC控制TechnologyDepartment技术部ProductionDepartment生产部11-171.Tool materialand tool lifeweredetermined.2.PPK≥1.67.1.刀具材质和刀具寿命已经确定2.PPK≥1.6772456(11)2.2 +0.2/06Tools wear刀具磨损3354NA NA NA NA NA NA NA(26)R0.1 +0.1(2X)5Tools wear刀具磨损3345NA NA NA NA NA NA NA 1.Dimension out oftolerance2.Surface is rough1.尺寸超差2.表面粗糙Dimension out oftolerance尺寸超差Dimension out oftolerance尺寸超差1.Dimension out oftolerance2.Surface is rough1.尺寸超差2.表面粗糙Dimension out oftolerance尺寸超差Dimension out oftolerance尺寸超差Dimension out oftolerance尺寸超差Dimension out oftolerance尺寸超差Checking dimensions on line在线检查尺寸Checking dimensions on line在线检查尺寸Checking dimensions on line在线检查尺寸Checking dimensions on line在线检查尺寸Checking dimensions on line在线检查尺寸Checking dimensions on line在线检查尺寸Checking dimensions on line在线检查尺寸Checking dimensions on line在线检查尺寸1.Estimate the tool life, changetools periodically2.Correct the tooling parametersperiodically3,Setup the machine center lineperiodically1.估算刀具寿命,定时换刀2.定期对刀具参数进行补正3.定期调整机床中心1.Estimate the tool life, changetools periodically2.Correct the tooling parametersperiodically1.估算刀具寿命,定时换刀2.定期对刀具参数进行补正1.Estimate the tool life, changetools periodically2.Correct the tooling parametersperiodically1.估算刀具寿命,定时换刀2.定期对刀具参数进行补正1.Estimate the tool life, changetools periodically2.Correct the tooling parametersperiodically1.估算刀具寿命,定时换刀2.定期对刀具参数进行补正1.Estimate the tool life, changetools periodically2.Correct the tooling parametersperiodically1.估算刀具寿命,定时换刀2.定期对刀具参数进行补正1.Estimate the tool life, changetools periodically2.Correct the tooling parametersperiodically1.估算刀具寿命,定时换刀2.定期对刀具参数进行补正1.Estimate the tool life, changetools periodically2.Correct the tooling parametersperiodically1.估算刀具寿命,定时换刀2.定期对刀具参数进行补正1.Estimate the tool life, changetools periodically2.Correct the tooling parametersperiodically1.估算刀具寿命,定时换刀2.定期对刀具参数进行补正Impact functionality影响使用性能Customer dissatisfaction客户不满意Customer dissatisfaction客户不满意Customer dissatisfaction客户不满意Customer dissatisfaction客户不满意Impact assembly影响客户装配Customer dissatisfaction客户不满意Customer dissatisfaction客户不满意(36)tolerance尺寸超差Effective Date ruty cectionn n212Boring Hole 镗孔(30)0.1*45°5Tools wear 刀具磨损3345NA NA NA NA NA NA NA(13)2.5+0.26Tools wear 刀具磨损3354NA NA NA NA NA NA NA(12)1.2±0.0256Tools wear 刀具磨损3354NA NA NA NA NA NA NA(35)6The machine center offset机床中心线偏移3354NA NA NA NA NA NA NA(24)Φ13 +0.048Tools wear 刀具磨损3496 1.Determine the tool material and enactment tool life2.Determine theprocess parameters on the machine3.SPC control1.确定刀具材质和设定刀具使用寿命2.确定过程参数3.SPC 控制Technology Department 技术部Production Department 生产部11-171.Tool material and tool life weredetermined.2.PPK ≥1.67.1.刀具材质和刀具寿命已经确定2.PPK ≥1.6782464213.Turning Outside Diameter 车外圆(6)Φ14.6+0.16Tools wear 刀具磨损3354NA NA NA NA NA NA NA(29)0.2±0.1*45°4Tools wear 刀具磨损2324NA NA NA NA NA NA NA(9)3.8+0.16Tools wear 刀具磨损3354NA NA NA NA NA NA NA0.2±0.01*45°5Tools wear 刀具磨损3345NA NA NA NA NA NA NAChecking dimensions on line 在线检查尺寸Checking dimensions on line 在线检查尺寸1.Dimension out oftolerance2.Surface is rough 1.尺寸超差2.表面粗糙Dimension out of tolerance 尺寸超差Dimension out of tolerance 尺寸超差Dimension out of tolerance 尺寸超差Dimension out of tolerance 尺寸超差Dimension out of tolerance 尺寸超差Dimension out of tolerance 尺寸超差Dimension out of tolerance 尺寸超差Dimension out of tolerance 尺寸超差Checking dimensions on line 在线检查尺寸Checking dimensions on line 在线检查尺寸Checking dimensions on line 在线检查尺寸Checking dimensions on line 在线检查尺寸Checking dimensions on line 在线检查尺寸Checking dimensions on line 在线检查尺寸Checking dimensions on line 在线检查尺寸1.Estimate the tool life, change tools periodically2.Correct the tooling parameters periodically1.估算刀具寿命,定时换刀2.定期对刀具参数进行补正1.Estimate the tool life, change tools periodically2.Correct the tooling parameters periodically1.估算刀具寿命,定时换刀2.定期对刀具参数进行补正1.Estimate the tool life, change tools periodically1.估算刀具寿命,定时换刀2.Correct the tooling parameters periodically2.定期对刀具参数进行补正Setup the machine center periodically定期调整机床中心1.Estimate the tool life, change tools periodically2.Correct the tooling parameters periodically1.估算刀具寿命,定时换刀2.定期对刀具参数进行补正1.Estimate the tool life, change tools periodically2.Correct the tooling parameters periodically1.估算刀具寿命,定时换刀2.定期对刀具参数进行补正1.Estimate the tool life, change tools periodically2.Correct the tooling parameters periodically1.估算刀具寿命,定时换刀2.定期对刀具参数进行补正1.Estimate the tool life, change tools periodically2.Correct the tooling parameters periodically1.估算刀具寿命,定时换刀2.定期对刀具参数进行补正1.Estimate the tool life, change tools periodically2.Correct the tooling parameters periodically1.估算刀具寿命,定时换刀2.定期对刀具参数进行补正Customer dissatisfaction 客户不满意Customer dissatisfaction 客户不满意Customer dissatisfaction 客户不满意Impact functionality 影响使用性能Impact assembly 影响客户装配Customer dissatisfaction 客户不满意Customer dissatisfaction 客户不满意Customer dissatisfaction 客户不满意Customer dissatisfaction 客户不满意Effective Date ruty ce ctionn n213.TurningOutsideDiameter车外圆(27)0.3±0.05*20°5Tools wear刀具磨损3345NA NA NA NA NA NA NA (7)19.6+0.05/06Tools wear刀具磨损3354NA NA NA NA NA NA NA(28)0.2±0.05*45°5Tools wear刀具磨损3345NA NA NA NA NA NA NA(3)Φ27.3+0.06/+0.027Tools wear刀具磨损441121.Determine the toolmaterial and enactmenttool life2.Determine theprocess parameters onthe machine3.SPC control1.确定刀具材质和设定刀具使用寿命2.确定过程参数3.SPC控制TechnologyDepartment技术部ProductionDepartment生产部11-171.Tool materialand tool lifeweredetermined.2.PPK≥1.67.1.刀具材质和刀具寿命已经确定2.PPK≥1.6772456 (10)3.6+0.056Tools wear刀具磨损3354NA NA NA NA NA NA NA30Washing清洗6The operater mixdifferent parts操作员将不同零件混合清洗2336NA NA NA NA NA NA NA 6The operater mix thedifferent batch parts操作员将不同批次混合清洗2224NA NA NA NA NA NA NA 6Washing too manypieces one time resultsin parts colliding eachother清洗数量太多导致零件堆积相互碰撞2336NA NA NA NA NA NA NAWashing solution isdurty, parts are notcleaned up completely清洗液脏,零件清洗不干净2336NA NA NA NA NA NA NAWashing time short清洗时间短2116NA NA NA NA NA NA NAThe concentration andtemperature don't meetthe requirements清洗液浓度,温度未达指定要求2336NA NA NA NA NA NA NA Dimension out oftolerance尺寸超差Dimension out oftolerance尺寸超差Customer dissatisfaction客户不满意1.Estimate the tool life, changetools periodically2.Correct the tooling parametersperiodically1.估算刀具寿命,定时换刀2.定期对刀具参数进行补正Dimension out oftolerance尺寸超差Dimension out oftolerance尺寸超差6Different parts mixed不同的零件混合在一起Part Surface crash零件表面碰伤Cuting oil not cleanup油污没有清洗干净Dimension out oftolerance尺寸超差Different batches aremix不同批次混在一起Checking dimensions on line在线检查尺寸1.Estimate the tool life, changetools periodically2.Correct the tooling parametersperiodically1.估算刀具寿命,定时换刀2.定期对刀具参数进行补正Checking dimensions on line在线检查尺寸Checking dimensions on line在线检查尺寸Checking dimensions on line在线检查尺寸Checking dimensions on line在线检查尺寸Visual checking目视检查Check the quantity after washing清洗完后核对数量Visual checking目视检查Visual checking目视检查Visual checking目视检查Visual checking目视检查Set up the washing time设定清洗时间1.Estimate the tool life, changetools periodically2.Correct the tooling parametersperiodically1.估算刀具寿命,定时换刀2.定期对刀具参数进行补正1.Estimate the tool life, changetools periodically2.Correct the tooling parametersperiodically1.估算刀具寿命,定时换刀2.定期对刀具参数进行补正Use the dempty washing basket使用空的清洗篮1.Estimate the tool life, changetools periodically2.Correct the tooling parametersperiodically1.估算刀具寿命,定时换刀2.定期对刀具参数进行补正ing different color of flowsheet to distinguish shifts of everyday2.Put the machine no. card on thePut only one layer of parts on thewashing basket清洗篮内只能放一层零件Periodically change washingsolution定期更换清洗液Check washing solution'sconcentration and temperatureperiodically定期检查清洗液浓度与温度Customer dissatisfaction客户不满意Customer dissatisfaction客户不满意Parts can not betraceable零件无法追溯Impact functionality影响功能Customer dissatisfaction客户不满意Customer dissatisfaction客户不满意Customer dissatisfaction客户不满意Customer dissatisfaction客户不满意Effective Date ruty ce ctionn n40Surface of partplate Zn 5~10µm 表面镀Zn5~10µm 61.The concentration ofliquor is low溶液浓度低2.Voltage instability电压不稳定4372NA NA NA NA NA NA NASalt Spray Test198H盐雾试验198小时61.The concentration ofliquor is low溶液浓度低2.Voltage instability电压不稳定4372NA NA NA NA NA NA NA50Final Inspection成品检查6Measure tools notprecise测量工具不精确4248NA NA NA NA NA NA NA 6Parts accumulate collideone another零件堆积相互碰撞4248NA NA NA NA NA NA NA 6Working environmentnot clean工作环净不干净4248NA NA NA NA NA NA NA60Packaging包装72.The intensity ofpacking material is notstrong enough包装材料强度不够3484Inspection packagingmaterial包装材料进货检验Quality department质量保证部11-17Packagingmaterial wereinspected 包装材料进货检验714286Package people iscareless包装人员疏忽3590NA NA NA NA NA NA NA6Package people iscareless包装人员疏忽3590NA NA NA NA NA NA NA61.Have chips adhere onthe packing material2.Packagingenvironment not clean1.包装材料上粘有碎屑2.包装环境不干净3236NA NA NA NA NA NA NA70检验/入库Inspection / Storing 6Package people iscareless包装人员疏忽3236NA NA NA NA NA NA NA80检验/出货Dock audit /Shipment4Shipping people arecareless出货人员疏忽3672NA NA NA NA NA NA NA 4Wrong handling methodduring transportation运输中不正确的搬运方法3672NA NA NA NA NA NA NA ApprovalThe test was unfail试验不合格Impact the functionalityof parts影响零件使用性能1.Check the supplier's test report检查供应商的测试报告2.Send the parts to third party tochecking the thicknessperiodically.定期第三方检测。

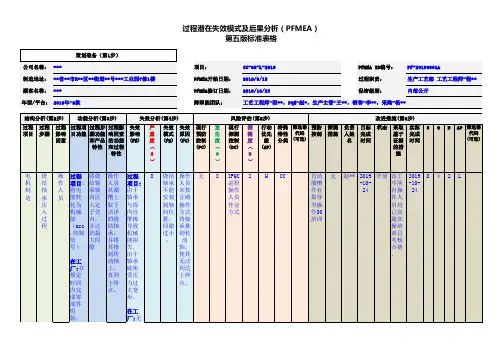

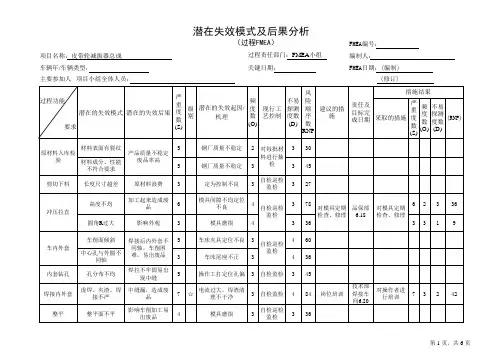

编制人:FMEA日期:(编制)

(修订)

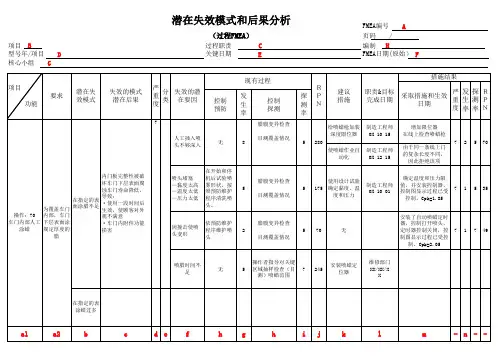

FMEA编号:项目名称:皮带轮减振器总成车辆年/车辆类型:

过程责任部门:FMEA 小组关键日期:

主要参加人 项目小组全体人员:

(过程FMEA)

编制人:FMEA日期:(编制)

(修订)

FMEA编号:项目名称:皮带轮减振器总成车辆年/车辆类型:

过程责任部门:FMEA 小组关键日期:

主要参加人 项目小组全体人员:

(过程FMEA)

编制人:FMEA日期:(编制)

(修订)

FMEA编号:项目名称:皮带轮减振器总成车辆年/车辆类型:

过程责任部门:FMEA 小组关键日期:

主要参加人 项目小组全体人员:

(过程FMEA)

编制人:FMEA日期:(编制)

(修订)

FMEA编号:项目名称:皮带轮减振器总成车辆年/车辆类型:

过程责任部门:FMEA 小组关键日期:

主要参加人 项目小组全体人员:

(过程FMEA)

编制人:FMEA日期:(编制)

(修订)

FMEA编号:项目名称:皮带轮减振器总成车辆年/车辆类型:

过程责任部门:FMEA 小组关键日期:

主要参加人 项目小组全体人员:

(过程FMEA)

编制人:FMEA日期:(编制)

(修订)

FMEA编号:项目名称:皮带轮减振器总成车辆年/车辆类型:

过程责任部门:FMEA 小组关键日期:

主要参加人 项目小组全体人员:

(过程FMEA)

△----产品特性☆----过程特性。

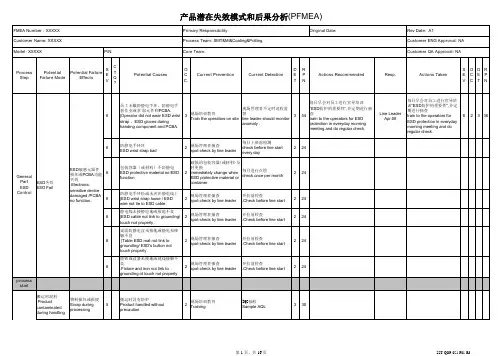

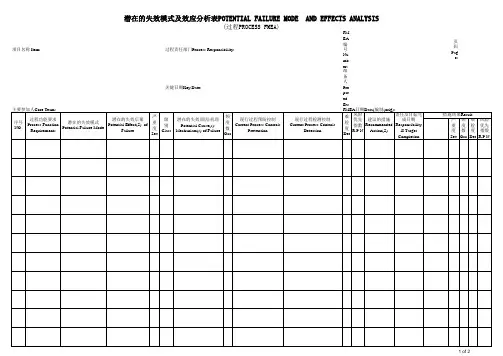

零件名称:过程责技术部编制:批准:Part number:KeyDate FMEA Date(Orig):FMEA Date(Rev.):Rev.A/0零件号:关键日FMEA 日期(编制):FMEA 日期(修订):版本:A/0Core Team:preservation溶解,保温零件名称:过程责技术部编制:批准:Part number:KeyDate FMEA Date(Orig):FMEA Date(Rev.):Rev.A/0零件号:关键日FMEA 日期(编制):FMEA 日期(修订):版本:A/0Core Team:零件名称:过程责技术部编制:批准:Part number:KeyDate FMEA Date(Orig):FMEA Date(Rev.):Rev.A/0零件号:关键日FMEA 日期(编制):FMEA 日期(修订):版本:A/0Core Team:零件名称:过程责技术部编制:批准:Part number:KeyDate FMEA Date(Orig):FMEA Date(Rev.):Rev.A/0零件号:关键日FMEA 日期(编制):FMEA 日期(修订):版本:A/0Core Team:零件名称:过程责技术部编制:批准:Part number:KeyDate FMEA Date(Orig):FMEA Date(Rev.):Rev.A/0零件号:关键日FMEA 日期(编制):FMEA 日期(修订):版本:A/0Core Team:零件名称:过程责技术部编制:批准:Part number:KeyDate FMEA Date(Orig):FMEA Date(Rev.):Rev.A/0零件号:关键日FMEA 日期(编制):FMEA 日期(修订):版本:A/0Core Team:。

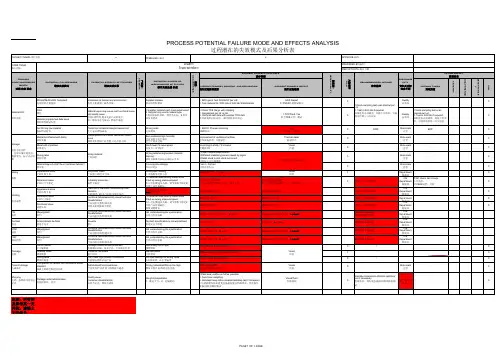

FMEA 编号Number:页码Page:准备人Prepared By:

关键日期Key Date: 2009.09.07车型年/车辆类潜在的失效模式及效应分析表POTENTIAL FAILURE MODE AND EFFECTS ANALYSIS

(Process- FMEA)

过程责任部门Process Responsibility: 质量部 QA Dept.项目名称 Item:工

FMEA 编号Number:页码Page:准备人Prepared By:

关键日期Key Date: 2009.09.07车型年/车辆类潜在的失效模式及效应分析表POTENTIAL FAILURE MODE AND EFFECTS ANALYSIS

(Process- FMEA)

过程责任部门Process Responsibility: 质量部 QA Dept.项目名称 Item:工

FMEA 编号Number:页码Page:准备人Prepared By:

关键日期Key Date: 2009.09.07车型年/车辆类潜在的失效模式及效应分析表POTENTIAL FAILURE MODE AND EFFECTS ANALYSIS

(Process- FMEA)

过程责任部门Process Responsibility: 质量部 QA Dept.项目名称 Item:工

FMEA 编号Number:页码Page:准备人Prepared By:

关键日期Key Date: 2009.09.07车型年/车辆类潜在的失效模式及效应分析表POTENTIAL FAILURE MODE AND EFFECTS ANALYSIS

(Process- FMEA)

过程责任部门Process Responsibility: 质量部 QA Dept.项目名称 Item:工

FMEA 编号Number:页码Page:准备人Prepared By:

关键日期Key Date: 2009.09.07

车型年/车辆类潜在的失效模式及效应分析表POTENTIAL FAILURE MODE AND EFFECTS ANALYSIS

(Process- FMEA)

过程责任部门Process Responsibility: 质量部 QA Dept.项目名称 Item:工

FMEA 编号Number:页码Page:准备人Prepared By:

关键日期Key Date: 2009.09.07车型年/车辆类潜在的失效模式及效应分析表POTENTIAL FAILURE MODE AND EFFECTS ANALYSIS

(Process- FMEA)

过程责任部门Process Responsibility: 质量部 QA Dept.项目名称 Item:工

FMEA 编号Number:页码Page:准备人Prepared By:

关键日期Key Date: 2009.09.07车型年/车辆类潜在的失效模式及效应分析表POTENTIAL FAILURE MODE AND EFFECTS ANALYSIS

(Process- FMEA)

过程责任部门Process Responsibility: 质量部 QA Dept.项目名称 Item:工

FMEA 编号Number:页码Page:准备人Prepared By:

关键日期Key Date: 2009.09.07车型年/车辆类潜在的失效模式及效应分析表POTENTIAL FAILURE MODE AND EFFECTS ANALYSIS

(Process- FMEA)

过程责任部门Process Responsibility: 质量部 QA Dept.项目名称 Item:工

FMEA 编号Number:页码Page:准备人Prepared By:

关键日期Key Date: 2009.09.07车型年/车辆类潜在的失效模式及效应分析表POTENTIAL FAILURE MODE AND EFFECTS ANALYSIS

(Process- FMEA)

过程责任部门Process Responsibility: 质量部 QA Dept.项目名称 Item:工

FMEA 编号Number:页码Page:准备人Prepared By:

关键日期Key Date: 2009.09.07车型年/车辆类潜在的失效模式及效应分析表POTENTIAL FAILURE MODE AND EFFECTS ANALYSIS

(Process- FMEA)

过程责任部门Process Responsibility: 质量部 QA Dept.项目名称 Item:工。