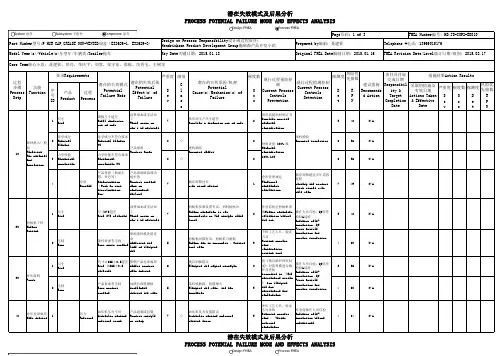

汉语英语版制程失效模式及效应分析(PFMEA)表

- 格式:xls

- 大小:95.00 KB

- 文档页数:5

pfmea(制程失效模式与效应分析)PFMEAmedical aircraftPFMEA PFMEA analysis principle is the process failure mode and effects analysis (Process Failure Mode and Effects Analysis) the English referred to, is responsible for manufacturing / Assembly Engineer / team mainly uses an analytical technique to maximize the potential failure modes and their associated causes / mechanisms have been considered and discussion.Catalogbrief introductionPrinciple analysis"Process / consequence analysis" process function / requirement""Potential failure mode""Consequences of failure""Seriousness""Cause / mechanism of failure"Current control method""Risk level" (RPN)""Recommended measures""Results of measures"Case study of PFMEA in SMT assembly applicationRisk analysis of manufacturing process using PFMEAbrief introductionPrinciple analysis"Process / consequence analysis" process function / requirement""Potential failure mode""Consequences of failure""Seriousness""Cause / mechanism of failure"Current control method""Risk level" (RPN)""Recommended measures""Results of measures"Case study of PFMEA in SMT assembly applicationRisk analysis of manufacturing process using PFMEAExpand the edition of this sectionPFMEA[1]: failure under specified conditions (environment, operation, time), cannot complete its function or product parameter values and cannot be maintained within the prescribed limits, and the cause of rupture of components damage to the phenomenon of the dead in the scope of work. PFMEASeverity (S): the level of the most serious impact consequence of a given failure mode, which is the relative grading result within a single FMEA range. Numerical reduction of severity can only be achieved by design change or redesign. Frequency (O): the occurrence of a particular cause / mechanism. The number of grades describing the possibility of occurrence is relative, but not absolute. Detection (D): refers to the manufacturing process or assembly parts before leaving, using second kinds of current process control methods to find the failure cause / mechanism evaluation index sequence occurs after the process defects or the possibility of failure mode; evaluation index or by third kinds of process control method to find out the order after the possibility of failure mode. Risk priority number (RPN): the product of the three numbers of strict numbers (S) and frequency (O) and D. Customer: generally referred to as "enduser", but it can also be a subsequent or downstream manufacturing or assembly process, maintenance procedure or government regulation.Principle analysis of editing paragraphThe analysis principle of PFMEA, PFMEA's analysis principle is as follows: it includes the following key steps: PFMEA(1) identify potential failure modes and causes associated with the production process or product manufacturing process; (2) evaluate the failure potential impact on product quality and customer; (3) find out how to reduce failure or failure conditions of the control variables, and formulate corrective and preventive measures; (4) preparing a ranked list of potential failure modes sure, the failure mode serious priority control; (5) tracking the implementation of control measures, update failure mode classification table. The potential failure modes and causes of failure; (2) evaluate the potential impact on the quality of products and customers; (3) find out how to reduce failure or failure conditions of the control variables, and formulate corrective and preventive measures;(4) preparing a ranked list of potential failure modes, failure mode to ensure serious priority control; (5) tracking the implementation of control measures, update failure mode classification table.Edit paragraph model and consequence analysis"Process function / requirement""The process or process of being analyzed. The process or process can be a technical process, such as welding, product design, software code preparation, etc., can also be the management process, such as planning, design review. Explain the purpose of the process or process as simply as possible,If the process involves many processes with different failure modes, these procedures or requirements can be listed as independent processes;"Potential failure mode""Refers to the process may not meet the process requirements or design intent form or problem point, is a specific process does not meet the requirements of the description. It may be the potential failure mode causing the next process, or the consequence of the failure mode of the previous process. Typical failure modes include fracture, deformation, improper installation and debugging, etc.;Consequences of failure"Refers to the adverse effects of the failure mode may lead to the quality of products and customers, according to customer might notice or experience to describe the consequences of failure, for the end user, the consequences of failure should be used to explain the product or system performance, such as noise, smell, no effect etc.;"Seriousness""The severity of the consequences is the potential failure mode to the customer, in order to accurately define the adverse effects of the failure mode, usually need to evaluate the potential impact of each failure mode and give a score, represented by 1-10, the higher the score of more serious effects. "Possibility" refers to the probability of occurrence of specific causes, classification number possibility focuses on its meaning rather than value, usually 1 - 10 points to evaluate the possibility of the size, the higher the score appeared more chances. "Detection": refers to the manufacturing process or equipment parts before leave the station, found the degree of difficulty of failure cause defects in the process, the evaluation index is also divided into 1 - level 10, the higher the score of Zeyu is difficult to find and check out;Cause / mechanism of failure"Refers to the failure happened, and on the basis of the principle of control can be corrected or to describe, for each potential failure mode in the range as wide as possible, a list of every failure cause assignable causes, if only for the failure mode, then consider the process is complete. No PFMEAIn addition, the root causes should be analyzed in order to take corrective actions against the relevant factors. The typical causes of failure include incorrect welding, improper lubrication, wrong assembly of parts, etc.;Current control method"It is a description of the current control method that can prevent the failure mode from occurring or detect the failure mode that will occur. These control methods can be physical process control methods, such as the use of error proofing system, management or process control methods, such as the use of statistical process control (SPC) technology;"Risk level" (RPN)"It is the product of the three things: severity, possibility, and detectability. The greater the value is, the more serious the potential problem is, and the more timely corrective actions should be taken in order to reduce the value. In general, no matter how much the risk level is, when the severity is high, special attention should be paid to it;"Recommended measures""In order to reduce the seriousness, possibility, or non detectable value of the risk, it includes the action plan or measure, the responsible person, the possible resources and the completion date, etc.. When the failure mode of discharge order should first of the row in front of the risk event or high severity events to take corrective measures, any suggestions and measures for the purpose of preventing the occurrence, or reduce the impact after the occurrence and loss;Results of measures"Follow up and confirm the implementation of the "proposed measures" plan scheme. The corrective measures, re estimate andrecord the corrective measures the severity, possibility and detection of numerical calculation, and record the resulting new risk level, the level of risk should be numerical measures than the results of previous value is much lower, so that to take measures to reduce the risk to the failure of the.Edit this paragraph case analysisExamples of PFMEA assembly application in SMTIn practical application, SMT is equipped with single and double such as Mount mount and double mixed operation, the production process of various modes of operation are different.R explains how to apply PFMEA to the SMT assembly process. Now, the object of this paper is to describe the application of PFMEA with the relatively simple single-sided smt. One side mount process function is described as follows: the main part of single mount printing paste, mount components and welding parts, the technological process is: 11 printing paste mount components - AOT test 11 11 solder reflow soldering test, the assembly process involves the main equipment, screen printing machine, SMT machine, reflow oven and testing equipment. Based on the long-term SMT production process are summarized, the single solder joints exposed to mount in the working way of the common failure modes are: solder ball, cold welding, welding bridge, vertical plate, the causal analysis diagram as shown in figure. Figure 2 according to the failure mode on the causal analysis and test and practical experience of the designers, the analysis of these failure modes are as follows: solder ball, solder balls is a problem often encountered in the reflowsoldering. Solder balls often appear between side or fine pitch pins. The consequences of failure: solder ball will cause short circuit, and the circuit board pollution. May cause a small number of products scrapped or all products rework, severity will be assessed as 5. Existing fault detection methods: artificial vision and X ray detector. The reason for failure is: solder paste defect - low viscosity, oxidation, etc., the frequency is 5, detection difficulty is 5, risk index PRN is 125. The current control measures can be used to restrain solder ball solder paste, and solder paste quality is tested before assembly. Flux defect - activity decreased, frequency was 3, detection difficulty was 6, risk index PRN was 90. The defect of the template is that the size of the hole is not enough, the pad is too large, the frequency is 5, the detection difficulty is 4, and the risk index PRN is 100. The reflux temperature curve was set improperly, the frequency was 7, the detection difficulty was 5, and the risk index PRN was 175. Current control measures: adjust reflow temperature curve to adapt to the characteristics of solder paste. Cold cold solder joint appearance is black, not completely melted solder paste. The consequences of failure: open and weld, may lead to a small number of products or all products scrap rework, severity assessment for the 50 existing fault detection methods: artificial visual and X ray detector. Reasons of failure: reflow soldering parameter is set properly, the temperature is too low, the transmission speed is too fast, the frequency is 3, the detection difficulty is 5, the risk index for the 750 current control measures: according to the data or practical experience of setting up solder reflow profile. Welding bridge welding bridge often appears in the pin closer to the pin C or the smaller spacing between the pieces, this defect is a majorflaw in the inspection standards. Welding bridge will seriously affect the electrical performance of the product, so it must be eradicated. Failure consequence; welding bridge will cause short circuit and other consequences; serious will make the system or mainframe lose the main function, cause the product all scrapped, the user dissatisfaction is high, the severity is assessed as 8. Existing fault detection methods: artificial vision and X ray detector. The failure reasons are as follows: the template defect size is too large, the frequency is 7, the detection difficulty is 6, and the risk index PRN is 336. Solder paste defects such as improper viscosity, frequency is 5, detection difficulty is 5, risk index PRN is 200. The solder paste printing process parameters are unsuitable, the frequency is 8, the detection difficulty is 6, and the risk index PRN is 384. Current control measures: keep the scraper pressure constant, slow down the printing speed, and achieve good solder paste molding. In addition, the minimum clearance between the mold release rate and the template and the PCB is controlled. The preheating temperature and preheating time of reflow soldering were not set properly, the frequency was 5, the detection difficulty was 4, and the risk index PRN was 160. Current control measures: reduce preheating temperature, shorten preheating time. The vertical chip mainly occurs in the small rectangular chip elements (such as chip resistors, capacitors) reflow process. The main reason for this phenomenon is uneven heating at both ends of the element, and the melting of solder paste is caused successively. Failure consequence: lead to open circuit,The failure of the circuit leads to the loss of the main function of the system or the whole machine, and the severity isevaluated as 7. Existing fault detection methods: manual visual inspection. Causes of failure are: patch accuracy frequency was 3, detection was 5, the risk index PRN 105. reflow welding preheating temperature is low, the preheating time is short, the frequency is 5, the detection difficulty is 4, the risk index PRN was 140. Current control measures: appropriately increase preheating temperature and prolong preheating time. The thickness of solder paste is 175, the frequency is 5, the detection difficulty is 5, and the risk index PRN is 0. Current control measures: choose appropriate thickness of silk screen template for different devices. After each potential failure mode to calculate the RPN value of the corresponding process test is to carry out follow-up work, seek for high RPN value and the severity of the potential failure modes of corrective measures, and after correcting, re evaluate the risk, verify the feasibility and correctness of the corrective measures.Risk analysis of manufacturing process using PFMEATaking the manufacturing process of automobile interior decoration Automobile Interior decoration as an example, this paper briefly introduces how to analyze and improve the risk of manufacturing process with PFMEA. In order to make PFMEA clear, need to use a table, (see Table 1), was introduced according to the numbering in the table corresponding to the content. 1. the basic data in the upper part of the table to fill in the analysis of components and PFMEA group members of the relevant information. The 2. process function / requirement describes briefly the process or operation that will be analyzed and numbered. According to the process flow chart, the planning process is described accurately, and the descriptionmust be complete. If there are many jobs with different potential failure modes, these items can be listed as independent items. Potential failure mode, the so-called potential failure mode, means that the process may not meet the requirements of the process, and it is a description of the specific work that does not meet the requirements. To collect possible defects in the process, and even possible defects under specific conditions should also be listed. It also includes the experience of past history. Potential failure consequence is the effect of failure mode on the customer. The customer can describe the failure consequence from the customer's point of view. The customer can be the next process or the final user. For example, the car door trim plate for the end user, the consequences can be leakage, noise, appearance and so on, the failure of the next operation, the consequences can be unable to install, can not drill holes. 5. severity is the most serious impact rating of a presumed failure mode. To reduce the severity level of identification, only by changing the design of the parts or redesigning the process, otherwise the severity will not change. Severity was 1 (without influence) -10 (severe consequence) grade. The 6. classification is to classify some special process characteristics of process control, the symbol is the internal provisions of the company, or the provisions of the customer. 7. the cause / mechanism of failure is simply the possible cause of each defect, which can be determined by production or assembly. It is necessary to give a brief description of each reason. 8. frequency (incidence) refers to the possibility of the occurrence of specific causes of failure, the possibility of classification only represents its meaning, does not mean the specific figures. Frequency levels can be changed only through design changes or processchanges. The frequency is divided into 1 (very low frequency) -10 (very high frequency) levels. 9. the existing process control can prevent the existing process failure mode as far as possible, and the method of error proofing or post processing evaluation can be adopted. For example, F increases the error proofing device or increases the inspection frequency. 10. detection rate (discovery rate) is the probability of discovery when defects occur. It's also divided into 1 (probably) (impossible) 5 levels. 11. the order of risk (RPN) is the product of product severity, frequency and measure. If the severity is S, the frequency is O, the detection degree is D, then RPN= (S) x (O) x (D). The value is from 1 (no wind) -1000 (high risk). For high, severe, high RPN defects, priority should be taken to remove measures. TwelveThe proposed measures usually take the components of the order of risk as a basis for finding the measures. But for the serious impact on the user, it should be improved through the product or process, rather than through a large number of tests. If the frequency is very high, the product or process should be improved. If a defect is difficult to find, that is to say, the measure is low, then the inspection measures should be improved and the frequency of defects will be reduced. 13. the responsibility of the proposed measures records the relevant personnel responsible for the implementation of the proposed measures and the completion date of the plan, so as to track and evaluate the measures. 14. the measures taken to record the measures that have been implemented. 15. after the implementation of the measures RPN, after the implementation of the measures, re evaluate the risk of defects (RPN). The new risk order is obtained and compared with the situation beforethe improvement so as to estimate whether the measures taken are effective and whether further measures are necessary. It can be seen from the example: after taking measures, RPN is obviously reduced, the measures are effective. The above is the use of PFMEA process risk analysis, quality improvement of a simple description, we can summarize. One, PFMEA is constantly updated, is dynamic. Requirements in product development and process development of the manufacturing process or PFMEA to update and processing continuously, regardless of history or possible defects should be embodied in two, at the time of the PFMEA must be on the defect and risk objectively and assess the actual, not without inference, resulting in PFMEA the lack of accuracy. Three, PFMEA is not the surface of things, is the collective efforts of the group members, should include, but not limited to the design, manufacture, quality, service and other departments. Four, PFMEA is a purposeful method, which can be used to detect defects as early as possible, assess the risk of defects, and then formulate countermeasures to avoid these defects.。

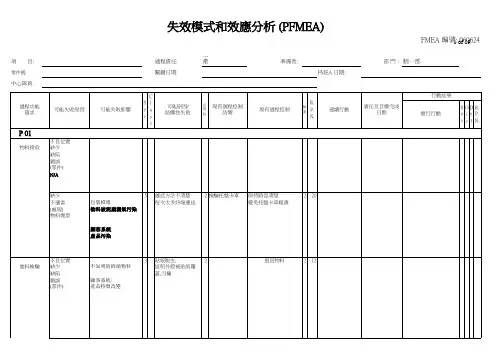

1 of 19項 目:過程責任:生產準備者:部 門:制一部零件號:關鍵日期:FMEA 日期:中心隊員:FMEA 編號: 0606242 of 19項 目:過程責任:生產準備者:部 門:制一部零件號:關鍵日期:FMEA 日期:中心隊員:FMEA 編號: 0606243 of 19項 目:過程責任:生產準備者:部 門:制一部零件號:關鍵日期:FMEA 日期:中心隊員:FMEA 編號: 0606244 of 19項 目:過程責任:生產準備者:部 門:制一部零件號:關鍵日期:FMEA 日期:中心隊員:FMEA 編號: 0606245 of 19項 目:過程責任:生產準備者:部 門:制一部零件號:關鍵日期:FMEA 日期:中心隊員:FMEA 編號: 0606246 of 19項 目:過程責任:生產準備者:部 門:制一部零件號:關鍵日期:FMEA 日期:中心隊員:FMEA 編號: 0606247 of 19項 目:過程責任:生產準備者:部 門:制一部零件號:關鍵日期:FMEA 日期:中心隊員:FMEA 編號: 0606248 of 19項 目:過程責任:生產準備者:部 門:制一部零件號:關鍵日期:FMEA 日期:中心隊員:FMEA 編號: 0606249 of 19項 目:過程責任:生產準備者:部 門:制一部零件號:關鍵日期:FMEA 日期:中心隊員:FMEA 編號: 06062410 of 19項 目:過程責任:生產準備者:部 門:制一部零件號:關鍵日期:FMEA 日期:中心隊員:FMEA 編號: 06062411 of 19項 目:過程責任:生產準備者:部 門:制一部零件號:關鍵日期:FMEA 日期:中心隊員:FMEA 編號: 06062412 of 19項 目:過程責任:生產準備者:部 門:制一部零件號:關鍵日期:FMEA 日期:中心隊員:FMEA 編號: 06062413 of 19項 目:過程責任:生產準備者:部 門:制一部零件號:關鍵日期:FMEA 日期:中心隊員:FMEA 編號: 06062414 of 19項 目:過程責任:生產準備者:部 門:制一部零件號:關鍵日期:FMEA 日期:中心隊員:FMEA 編號: 06062415 of 19項 目:過程責任:生產準備者:部 門:制一部零件號:關鍵日期:FMEA 日期:中心隊員:FMEA 編號: 06062416 of 19項 目:過程責任:生產準備者:部 門:制一部零件號:關鍵日期:FMEA 日期:中心隊員:FMEA 編號: 06062417 of 19項 目:過程責任:生產準備者:部 門:制一部零件號:關鍵日期:FMEA 日期:中心隊員:FMEA 編號: 06062418 of 19項 目:過程責任:生產準備者:部 門:制一部零件號:關鍵日期:FMEA 日期:中心隊員:FMEA 編號: 06062419 of 19項 目:過程責任:生產準備者:部 門:制一部零件號:關鍵日期:FMEA 日期:中心隊員:FMEA 編號: 060624。

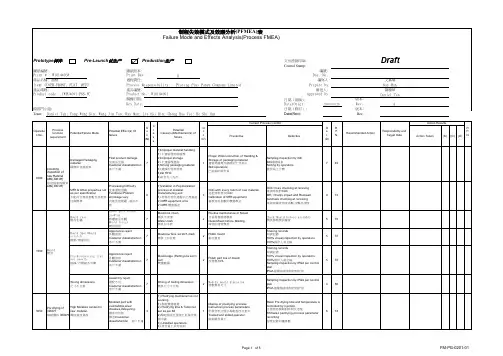

FAILURE MODE & EFFECT ANALYSIS FORM (失效模式及后果分析)FMEA Type (FMEA类型) :Report No. & Date (报告编号&日期):LOGO Product Family/Process (产品家族/过程):Revision (版本号) :Prepared By (制作人):Sheet No. (页面) :ITEM NEWN0.编号Prevention预防行动RPN新RPN Description ofproductcharacteristic orprocess stepProduct deviationsfrom requirements orway process failsSxOxDDescription of recommendedactions with quantifiableresults (insert NR if notrequired)Name of personresponsible forcorrective actionsDescription of actual actiontaken after implementationS O D SxOxD产品特性或工艺描述产品与要求或工艺不相符建议行动及合格结果(如不需要写入NR)负责纠正措施的人姓名完善后实际行动的描述S O DAction Date行动日期Change No.更改编号目前预防失效措施及失效的预见性级数估计All potential failure causes per failuremode including occurrence of failureranking estimateCURRENT CONTROLSRPNFAILURE CAUSE失效原因ACTION DATE ANDCHANGE NUMBER行动时间及更改号RANKINGDetection侦测行动RECOMMENDED ACTIONS建议行动RESPONSIBILITY责任FAILURE MODE失效模式FAILURE EFFECT失效结果FUNCTION功能Classification失效影响包括严重性的描述Description of how customermight see the effects of thefailure including Severityranking estimate每一失效模式的全部失效原因ESTIMATES预计级数Effective finalization dateof agreed corrective action采取纠正行动的最终生效日期Current controls to prevent failures occurring or detection of failure includingDetectability ranking estimateACTION TAKEN采取的行动。

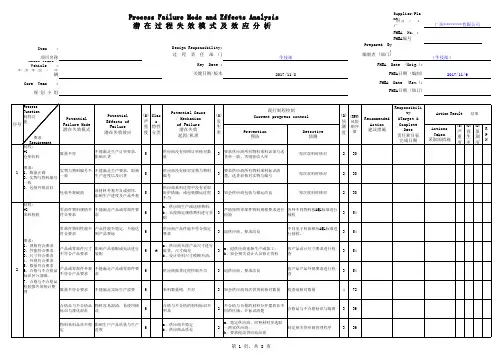

过程失效模式及后果分析(Process FlureMode and Effects Analysis,PFMEA)1. 概述过程失效模式及后果分析,英文缩写为PFMEA,是一种常用的质量管理工具,被广泛应用于各行业中,特别是制造业和服务业。

通过对过程失效模式及后果进行细致的分析,可以帮助组织发现潜在的问题,制定相应的预防措施,从而降低质量风险,提高产品或服务的质量。

2. 过程失效模式及后果分析的流程过程失效模式及后果分析通常包括以下几个步骤:2.1 确定分析范围在进行过程失效模式及后果分析之前,首先需要明确分析范围。

确定要分析的具体过程或工作流程,并明确分析的目的和依据。

2.2 制定团队选择一支多学科的团队,包括工程师、技术专家、质量专员等相关人员。

团队成员的经验和专业知识对于分析的质量起到关键作用。

2.3 识别失效模式团队成员集体讨论,识别出可能会发生的过程失效模式。

失效模式可以是过程中的错误、故障、缺陷等。

根据每个失效模式,评估其可能导致的后果。

后果可以是质量问题、安全问题、环境问题等。

2.5 评估失效严重性根据失效后果的严重程度,对每个失效模式进行评估。

一般采用定性或定量的方法来评估失效严重性,如风险矩阵法、风险优先数法等。

对每个失效模式,识别出其可能的原因。

原因可以是人、机、料、法、环的问题。

2.7 评估失效频率根据失效原因的发生频率,对每个失效模式进行评估。

评估失效频率有助于确定应对措施的优先级。

2.8 制定预防措施通过分析失效模式、后果、严重性、原因和频率,制定相应的预防措施。

预防措施可以是人员培训、工艺改进、设备维护等。

2.9 实施和跟踪将预防措施落实到实际操作中,并对其进行跟踪和监控,确保其有效性。

3. 过程失效模式及后果分析的优点过程失效模式及后果分析具有以下几个优点:3.1 早期发现问题通过对过程失效模式及后果进行分析,可以在产品或服务开发的早期阶段发现潜在的问题,从而避免问题进一步扩大和影响产品或服务质量。

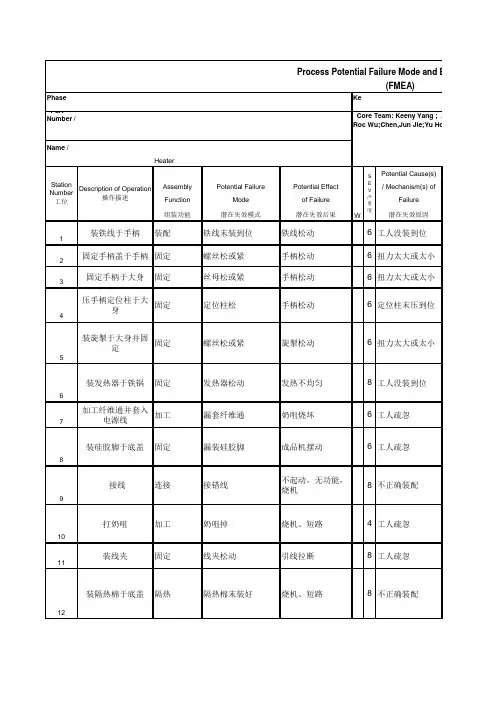

PFMEA作业指导书1 PURPOSE(目的)The purpose of this work instruction is to provide a method for continuous improvement through the use of PFMEAs.此作业指导书的目的是为运用制程失效模式及效果分析达到持续改善目的提供方法。

2 SCOUPE(范围)This work instruction applies to any manufacturing process that has a customer requirement for failure mode effect analysis or any process at FLEX (Doumen) where management requires a PFMEA.适用于客户要求或管理要求而需要做失效模式及效果分析的所有制程。

3 DEFINITIONS(定义)3.1 PFMEA: Process Failure Mode and Effect Analysis. It should describe all thepotential failure modes which may occur in process and their corresponding failure effects; evaluate and rank the severity, occurrence and detection of the failures. It should also describe the current control method, recommend corrective action, person responsible responsibility and due date.PFMEA--制程失效模式及效果分析。

Process Responsibility过程责任部门:FMEA Number编号:Page 页码:Key Date关键日期:Prepared by准备人:FMEA Date(Orig.)编制日期:FMEA Date(Rev.)修订日期:PROCESS POTENTIAL FAILURE MODE AND EFFECTS ANALYSIS过程在失效模式及效应分析(PFMEA)ITEM(Part#)项目名称:Modle Years/Programs 模型年/类:Core Team主要参与人员:Process Responsibility过程责任部门:FMEA Number编号:Page 页码:Key Date关键日期:Prepared by准备人:FMEA Date(Orig.)编制日期:FMEA Date(Rev.)修订日期:PROCESS POTENTIAL FAILURE MODE AND EFFECTS ANALYSIS过程在失效模式及效应分析(PFMEA)ITEM(Part#)项目名称:Modle Years/Programs 模型年/类:Core Team主要参与人员:Process Responsibility过程责任部门:FMEA Number编号:Page 页码:Key Date关键日期:Prepared by准备人:FMEA Date(Orig.)编制日期:FMEA Date(Rev.)修订日期:PROCESS POTENTIAL FAILURE MODE AND EFFECTS ANALYSIS过程在失效模式及效应分析(PFMEA)ITEM(Part#)项目名称:Modle Years/Programs 模型年/类:Core Team主要参与人员:。

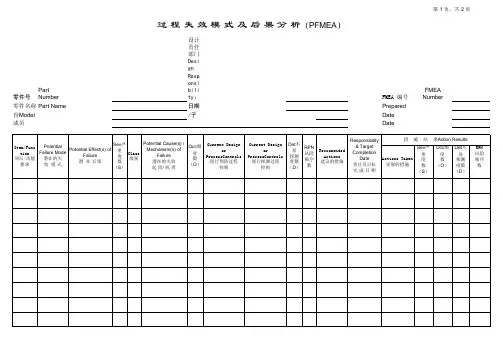

FMEA number:FMEA编号: prepared by:编制人:prepare date:part number/Version 产品编号/图纸版本:responsible dept:制程负责部门:0yearly requirement/vehicle: key date:Ningbo XXX Machinery Co.,Ltd过程潜在失效模式及效果分析(PFMEA)customer/part name:客户名称/产品名称:0 Version 编制 版本:FMEA number:FMEA编号: prepared by:编制人:prepare date:part number/Version 产品编号/图纸版本:responsible dept:制程负责部门:0yearly requirement/vehicle: key date:Ningbo XXX Machinery Co.,Ltd过程潜在失效模式及效果分析(PFMEA)customer/part name:客户名称/产品名称: Version 编制 版本:FMEA number:FMEA编号:prepared by:编制人:prepare date:part number/Version 产品编号/图纸版本:responsible dept:制程负责部门:0 key date:Ningbo XXX Machinery Co.,Ltd过程潜在失效模式及效果分析(PFMEA)customer/part name:客户名称/产品名称: Version 编制 版本:FMEA number:FMEA编号:prepared by:编制人:prepare date:part number/Version 产品编号/图纸版本:responsible dept:制程负责部门:0 key date:Ningbo XXX Machinery Co.,Ltd过程潜在失效模式及效果分析(PFMEA)customer/part name:客户名称/产品名称: Version 编制 版本:FMEA number:FMEA 编号:prepared by:编制人:prepare date:part number/Version 产品编号/图纸版本: responsible dept:制程负责部门:0yearly requirement/vehicle: key date:Ningbo XXX Machinery Co.,Ltd过程潜在失效模式及效果分析(PFMEA)customer/part name:客户名称/产品名称: Version 编制 版本:FMEA number:FMEA编号:prepared by:编制人:prepare date:part number/Version 产品编号/图纸版本:responsible dept:制程负责部门:0 key date:Ningbo XXX Machinery Co.,Ltd过程潜在失效模式及效果分析(PFMEA)customer/part name:客户名称/产品名称: Version 编制 版本:FMEA number:FMEA编号:prepared by:编制人:prepare date:part number/Version 产品编号/图纸版本:responsible dept:制程负责部门:0 key date:Ningbo XXX Machinery Co.,Ltd过程潜在失效模式及效果分析(PFMEA)customer/part name:客户名称/产品名称: Version 编制 版本:FMEA number:FMEA编号:prepared by:编制人:prepare date:part number/Version 产品编号/图纸版本:responsible dept:制程负责部门:0 key date:Ningbo XXX Machinery Co.,Ltd过程潜在失效模式及效果分析(PFMEA)customer/part name:客户名称/产品名称: Version 编制 版本:FMEA number:FMEA编号:prepared by:编制人:prepare date:part number/Version 产品编号/图纸版本:responsible dept:制程负责部门:0 key date:Ningbo XXX Machinery Co.,Ltd过程潜在失效模式及效果分析(PFMEA)customer/part name:客户名称/产品名称: Version 编制 版本:FMEA number:FMEA编号:prepared by:编制人:prepare date:part number/Version 产品编号/图纸版本:responsible dept:制程负责部门:0 key date:Ningbo XXX Machinery Co.,Ltd过程潜在失效模式及效果分析(PFMEA)customer/part name:客户名称/产品名称: Version 编制 版本:FMEA number:FMEA编号:prepared by:编制人:prepare date:part number/Version 产品编号/图纸版本:responsible dept:制程负责部门:0 key date:Ningbo XXX Machinery Co.,Ltd过程潜在失效模式及效果分析(PFMEA)customer/part name:客户名称/产品名称: Version 编制 版本:FMEA number:FMEA编号:prepared by:编制人:prepare date:Ningbo XXX Machinery Co.,Ltd过程潜在失效模式及效果分析(PFMEA)customer/part name:客户名称/产品名称: Version 编制 版本:part number/Version 产品编号/图纸版本:responsible dept:制程负责部门:0 key date:FMEA number:FMEA编号:prepared by:编制人:prepare date:part number/Version 产品编号/图纸版本:responsible dept:制程负责部门:0 key date:Ningbo XXX Machinery Co.,Ltd过程潜在失效模式及效果分析(PFMEA)customer/part name:客户名称/产品名称: Version 编制 版本:FMEA number:FMEA编号:prepared by:编制人:prepare date: responsible dept:制程负责部门:0Ningbo XXX Machinery Co.,Ltd过程潜在失效模式及效果分析(PFMEA)key date:customer/part name:客户名称/产品名称: Version 编制 版本:part number/Version 产品编号/图纸版本:FMEA number:FMEA编号:prepared by:编制人:prepare date:part number/Version 产品编号/图纸版本:responsible dept:制程负责部门:0 key date:Ningbo XXX Machinery Co.,Ltd过程潜在失效模式及效果分析(PFMEA)customer/part name:客户名称/产品名称: Version 编制 版本:FMEA number:FMEA编号:prepared by:编制人:prepare date:part number/Version 产品编号/图纸版本:responsible dept:制程负责部门:0 key date:Ningbo XXX Machinery Co.,Ltd过程潜在失效模式及效果分析(PFMEA)customer/part name:客户名称/产品名称: Version 编制 版本:FMEA number:FMEA编号:prepared by:编制人:prepare date:part number/Version 产品编号/图纸版本:responsible dept:制程负责部门:0 key date:Ningbo XXX Machinery Co.,Ltd过程潜在失效模式及效果分析(PFMEA)customer/part name:客户名称/产品名称: Version 编制 版本:FMEA number:FMEA编号:prepared by:编制人:prepare date:part number/Version 产品编号/图纸版本:responsible dept:制程负责部门:0 key date:Ningbo XXX Machinery Co.,Ltd过程潜在失效模式及效果分析(PFMEA)customer/part name:客户名称/产品名称: Version 编制 版本:FMEA number:FMEA编号:prepared by:编制人:prepare date:part number/Version 产品编号/图纸版本:responsible dept:制程负责部门:0 key date:Ningbo XXX Machinery Co.,Ltd过程潜在失效模式及效果分析(PFMEA)customer/part name:客户名称/产品名称: Version 编制 版本:FMEA number:FMEA编号:prepared by:编制人:prepare date:part number/Version 产品编号/图纸版本:responsible dept:制程负责部门:0 key date:Ningbo XXX Machinery Co.,Ltd过程潜在失效模式及效果分析(PFMEA)customer/part name:客户名称/产品名称: Version 编制 版本:FMEA number:FMEA编号:prepared by:编制人:prepare date:part number/Version 产品编号/图纸版本:responsible dept:制程负责部门:0 key date:Ningbo XXX Machinery Co.,Ltd过程潜在失效模式及效果分析(PFMEA)customer/part name:客户名称/产品名称: Version 编制 版本:FMEA number:FMEA编号:prepared by:编制人:prepare date:part number/Version 产品编号/图纸版本:responsible dept:制程负责部门:0 key date:Ningbo XXX Machinery Co.,Ltd过程潜在失效模式及效果分析(PFMEA)customer/part name:客户名称/产品名称: Version 编制 版本:FMEA number:FMEA编号:prepared by:编制人:prepare date:Ningbo XXX Machinery Co.,Ltd过程潜在失效模式及效果分析(PFMEA)customer/part name:客户名称/产品名称: Version 编制 版本:part number/Version 产品编号/图纸版本:responsible dept:制程负责部门:0 key date:FMEA number:FMEA编号:prepared by:编制人:prepare date:part number/Version 产品编号/图纸版本:responsible dept:制程负责部门:0 key date:Ningbo XXX Machinery Co.,Ltd过程潜在失效模式及效果分析(PFMEA)customer/part name:客户名称/产品名称: Version 编制 版本:FMEA number:FMEA编号:prepared by:编制人:prepare date:part number/Version 产品编号/图纸版本:responsible dept:制程负责部门:0 key date:Ningbo XXX Machinery Co.,Ltd过程潜在失效模式及效果分析(PFMEA)customer/part name:客户名称/产品名称: Version 编制 版本:FMEA number:FMEA编号:prepared by:编制人:prepare date:authorize 批准:date 日期:Prepared by 编制:Auditing 审核:part number/Version 产品编号/图纸版本:responsible dept:制程负责部门:0 key date:Ningbo XXX Machinery Co.,Ltd过程潜在失效模式及效果分析(PFMEA)customer/part name:客户名称/产品名称: Version 编制 版本:。

德信诚培训网

制程潜在失效模式及效应分析表

液晶显示器系统F M E A编号:

车用Monitor 子系统页码:1/6

零组件:1.塑料件(面盖) 2.金属件(支架,螺丝,承座铁片) 3.电子

件(M/B,TV/B,TFT/B, Panel) 4.线材件(Cable, FFC)

设计责任:编制者:李俊煌

机种年型 / 机种类型: HT650 系列关键日期:F M E A日期:核心小组:研发品保生产生技业务

德信诚培训网

制程潜在失效模式及效应分析表

液晶显示器系统F M E A编号:

车用Monitor 子系统页码:2/6 零组件:半成品机台设计责任:编制者:

机种年型 / 机种类型: HT650 系列关键日期:F M E A日期:

核心小组:研发品保生产生技业务。