罗斯蒙特2120音叉液位开关

- 格式:pdf

- 大小:1.32 MB

- 文档页数:16

罗斯蒙特PRO型雷达液位计操作维护规程西部管道新疆输油分公司2010年5月签字职务日期编制人:审核人:批准人:目录1范围错误!未定义书签。

2规范性引用文件错误!未定义书签。

3术语和定义错误!未定义书签。

4操作维护内容错误!未定义书签。

5风险提示错误!未定义书签。

6应急处置错误!未定义书签。

7附件错误!未定义书签。

范围本规程适应于西部管道所有罗斯蒙特PRO型雷达液位计。

规范性引用文件本规程根据技术规格书和设备技术资料,对罗斯蒙特PRO系列雷达液位计的安装环境、设备技术指标、操作和维护进行了说明。

术语和定义操作维护内容概述罗斯蒙特PRO系列雷达液位变送器是一种功能强大的雷达液位变送器,适用于过程中间储罐、物料储罐和其他类型储罐的非接触液位测量。

该变送器的设计可实现轻松安装和免维护运行。

它可以通过特殊设计的Radar Master(雷达主机)软件包进行组态、维护和测量数据显示功能,或采用HART技术,通过手持通讯器或微机对测量数据进行组态和监控。

对于独立系统或作为微机或控制系统的补充部分,可根据特殊的硬件组态采用一个或两个模拟输出对液位数据进行监控。

罗斯蒙特PRO雷达液位变送器可配备易于使用的罗斯蒙特2210显示板。

2210显示板所提供的功能与Radar Master(雷达主机)软件包的功能基本相同。

四个功能强大的软键可向您提供组态程序访问、维护功能和液位监控。

测量原理PRO系列雷达液位计通过从储罐顶部天线发射的雷达信号对储罐内产品的液位进行测量;变送器向产品表面发送频率连续变化的微波信号,在雷达信号被产品表面反射后,回波被天线接收。

由于信号频率不断变化,与此时发射的信号相比,回波的频率稍微有所不同,从而产生与产品表面距离成比例的低频信号。

变送器使用快速傅立叶变换(FFT)技术从而得到储罐内所有回波的频谱,从该频谱可求出表面液位,从而实现对储罐液位的的快速、可靠和精确测量。

基于频率连续变化的雷达扫描调频连续波图该种测量方法被称为FMCW(调频连续波)并应用于所有高性能雷达变送器。

Rosemount™储罐计量系统一切挑战,尽在掌控散装液体存储解决方案目录艾默生帮您应对当下和未来的各种挑战为推动业务绩效,制造商面临规模不断增长的生产力和资源优化的需求。

通过罗斯蒙特储罐计量系统,您可以一直满足效率、安全、精度、可靠性和数据安全性需求。

您将获得精确的净体积库存计算,符合当前和未来最新的防溢罐保护标准。

无论您面临什么样的储罐计量库存测量挑战,我们的解决方案可帮助取得业务优质绩效:• 确保高效运营• 提升安全水平• 确保精确测量系统特性 4–7雷达液位测量 8-10温度测量 11库存管理软件与功能 12-13安全性:防溢罐、证明试验、浮顶监测14-18升级/扩展项目:模拟和无线通讯 19-23液化气全容储罐完整存储解决方案 24-25雷达储罐计量发明者的解决方案26-27运营数据,着手可得。

效率安全精度可扩展性实时访问精确数据促进工厂运营效率防溢罐保护解决方案满足 API 2350 和 IEC 61511 要求可靠的净体积计算,基于 API和 ISO 标准开放通讯标准使设备添加与更换更方便让您的罐区运营尽在掌控之中储罐计量的精度、可靠性和安全性根据 API 行业标准组织所规定,储罐计量系统应能够提供高精度的净体积和质量库存计算。

OIML 标准 R 85:2008 定义了贸易交接应用储罐液位计的最高精度要求。

损耗控制和质量平衡还要求高精度的库存测量。

此外,储罐计量装置为罐区提供基本的过程控制层。

独立的高液位指示器或液位开关则形成另一层保护。

这两个保护层中如果有未检测到的故障,可能会导致灾难性事故发生。

请相信,艾默生提供的可扩展的储罐计量系统解决方案可以满足此需求。

控制库存并准确了解储罐中产品存储量。

库存控制是一种关键的管理工具,涉及大型资产。

精确测量船只、口岸和管道输送系统之间的批次和贸易交接量。

石油动向和运营功能用于日常运作、调度和混合方案。

追踪泄漏并防止溢出,从而降低由于油品损耗造成的环境影响和财务损失。

Reference Manual00809-0100-4029, Rev AA July 2005Rosemount 2110Compact Vibrating Fork Liquid Level SwitchReference Manual00809-0100-4029, Rev AAJuly 2005Rosemount 2110 2110 Compact Vibrating ForkLiquid Level SwitchRead this manual before working with the product. For personal and system safety, and for optimum product performance, make sure you thoroughly understand the contents before installing, using, or maintaining this product.The United States has two toll-free assistance numbers and one International number. Customer Central1-800-999-9307 (7:00 a.m. to 7:00 P.M. CST)International1-(952) 906-8888National Response Center1-800-654-7768 (24 hours a day)Equipment service needsThe products described in this document are NOT designed for nuclear-qualified applications. Using non-nuclear qualified products in applications that require nuclear-qualified hardware or products may cause inaccurate readings.For information on Emerson Process Management nuclear-qualified products, contact your local Emerson Process Management Sales Representative.Rosemount pursues a policy of continuous development and product improvement. The specification in this document may therefore be changed without notice. To the best of our knowledge, the information contained in this document is accurate and Rosemount cannot be held responsible for any errors, omissions or other misinformation contained herein. No part of this document may be photocopied or reproduced without the prior written consent of Rosemount.Reference Manual00809-0100-4029, Rev AA Rosemount 2110July 2005Reference Manual00809-0100-4029, Rev AAJuly 2005Rosemount 2110 Table of ContentsSECTION 1IntroductionSwitch Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2 Short Fork Technology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2 Rosemount 2110 Application and Mounting Examples. . . . . . . . . . . . . . . . . . . . . . . . . . .1-2 Overfill Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3Pump Protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3High and Low Level Alarm. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3Leak Detection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3Pump Control. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3Hygienic Applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3 Application Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4 Handling the 2110. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-4 Rosemount Identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6 Installation Considerations and Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7 Switchpoint. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-8 Service Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9 Warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9 SECTION 2InstallationSafety Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1 Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1 Correct Fork Alignment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2 Pipe Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2 Vessel Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2 Cover Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3 Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4 Mode Selection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-4 LED Indication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-5 Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-7 Reference Manual00809-0100-4029, Rev AA July 2005Rosemount 2110TOC-2SECTION 3Troubleshooting Magnetic Test Point. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2Spare Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-2APPENDIX AReference DataPhysical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1Mechanical . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1Performance Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2Functional Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2Electrical. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3Dimensional Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5Ordering Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7APPENDIX BProduct CertificationsL.V. Directive. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1Electro Magnetic Compatibility (EMC) Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1Overfill Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1Approved Manufacturing Locations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1Reference Manual00809-0100-4029, Rev AAJuly 2005Rosemount 2110S ECTION 1I NTRODUCTIONSwitch Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-2Rosemount 2110 Application and Mounting Examples . . . . . . . . . . . . . page 1-2Application Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-4Handling the 2110 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-4Installation Considerations and Recommendations . . . . . . . . . . . . . . . . page 1-7Rosemount Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-6Service Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 1-9Procedures and instructions in this manual may require special precautions to ensure the issues is indicated by a caution symbol (Reference Manual00809-0100-4029, Rev AAJuly 2005Rosemount 21101-2The Rosemount 2110 is a liquid point level switch based on the vibrating short forktechnology. It is a compact switch with a rugged stainless steel body and forks for use in a wide range of liquid applications. Economical 3/4-in. or 1-in. threaded mounting in pipes or tanks or hygienic mounting for food industry use. Direct load switching suits all supplies or PNP output for direct interface to PLCs. For use in safe area only.Short Fork TechnologyThe natural frequency (~1300Hz) of the fork is chosen to avoid interference from plant vibration which may cause false switching. This also gives short fork length for minimal intrusion into vessel and pipe. Using Short Fork Technology, the Rosemount 2110 isdesigned for use in virtually all liquid applications. Extensive research has maximized the operational effectiveness of the fork design making it suitable for almost all liquids, including coating liquids (avoid bridging of forks), aerated liquids, and slurries.Rosemount 2110 Application and Mounting ExamplesFor most liquids including coating and aerated liquids and slurries, the function is virtually unaffected by flow, turbulence, bubbles, foam, vibration, solid particles, build-up or properties of the liquid.For use in safe area and process temperatures up to 302°F (150°C).Mount in any position in the tank or pipe. Mounting is by 3/4-in. or 1-in. threaded or hygienic fitting.2110c l e a r _r e v .t i fReference Manual00809-0100-4029, Rev AAJuly 2005Rosemount 21101-3Overfill ProtectionSpillage caused by overfilling can be hazardous to people and theenvironment, resulting in lost product, and clean up costs. The 2110 is alimit level switch used to signal overfill at any time.Pump ProtectionShort forks mean minimum intrusion wetside and allow simple low costinstallation at any angle into your pipes or vessels. With the fork projectingonly 2-in. (50 mm) (dependant on connection type), the 2110 can beinstalled in even small diameter pipes. By selecting the option of direct loadswitching electronics, the 2110 is ideal for reliable pump control and can beused to protect against pumps running dry.High and Low Level AlarmMaximum and minimum level detection in tanks containing many differenttypes of liquids are an ideal application for the 2110. The robust 2110operates continuously at temperatures up to 302°F (150°C) and operatingpressure up to 1450 psig (100 barg) making it perfect for use as a high orlow level alarm. It is common practice to fit an independent high level alarmswitch to provide extra back up to the level switch in case of failure.Leak DetectionFlanges, gaskets, seals, corrosive liquids – they all have the potential toleak at the most inconvenient times. Many users site tanks and vesselsabove trays or in containments to prevent any liquids from escaping. Alevel switch can quickly and accurately detect any leakage and therebyeliminating cost.Pump ControlMany processes have batching and header tanks, and there is usually theneed to control a pump to maintain levels between set points. These tanksare often manufactured from thin wall materials and cannot support theweight of heavy instrumentation.Hygienic ApplicationsWith the option of highly polished forks providing a surface finish (Ra)better than 0.8 µm, the 2110 meets the principle design criteria of the moststringent hygienic requirements used in food and beverage, andpharmaceutical applications. Manufactured in stainless steel the 2110 isrobust enough to easily withstand steam cleaning (CIP) routines attemperatures up to 302°F (150°C).Reference Manual00809-0100-4029, Rev AA July 2005Rosemount 21101-4Application Considerations •Ensure liquid is inside the temperature and pressure ranges (see specifications).•Check that the liquid is inside recommended viscosity range 0.2 to 10,000 cP .•Examples of products with too high of viscosity is chocolate syrup, ketchup, peanut butter and bitumen. The switch will still detect these products but the drain time can be very long.•Check that the liquid density is above 37.5 lb/ft 3 (600 kg/m 3).•Examples of products with too low of density is acetone, pentane and hexane. •Check for risk of build-up on the forks.•Avoid situations where drying and coating products may create excessive build-up.•Ensure no risk of bridging the forks.•Examples of products that can create bridging of forks are dense paper slurries and bitumen.•Check if solid content in liquid•Problems may occur if product coats and dries causing caking•As a guideline maximum solid particle diameter in the liquid is 0.2-in. (5 mm)•Extra consideration is needed when dealing with particles bigger than 0.2-in. (5 mm), consult factoryHandling the 2110Figure 1-1. Do not hold the 2110 by forks.2110/2110_19a a , 2110_19a a .e p s1-5Figure 1-2. Do not alter the 2110 in any way.2110/2110_27a a .e p s1-6Rosemount IdentificationFigure 1-3. Load Switching Models: ac/dcFigure 1-4. PNP solid state output Models: dc low voltage: 21...264V AC (50/60Hz) /DC 2110/2110_57a a , 2110_58a a .e p s1-7Installation Considerations and RecommendationsBefore you install the Rosemount 2110 Level Switch, consider specific installation recommendations and mounting requirements.•Install in any orientation in tank containing liquid.•Always install in the normally “on” state•For high level recommendation is Dry = on (see “Function” on page 2-6).•For low level recommendation is Wet = on (see “Function” on page 2-6).•Always ensure the system is tested by using the local magnetic test point during commissioning (see “Magnetic Test Point” on page 3-1).•Ensure sufficient room for mounting and electrical connection (see “Dimensional Drawing” on page A-5).•Ensure that the forks do not come into contact with the tank wall or any internal fittings or obstructions.•Ensure the forks does not come into contact with the tank wall of any internal fitting.•Avoid installing the 2110 where it will be exposed to liquid entering the tank at the fill point.•Avoid heavy splashing on fork •Avoid product buildup•Ensure no risk of bridging the forks.•Ensure there is sufficient distance between build-up on the tank wall and the fork.•Ensure installation does not create tank crevices around the forks where liquid may connect (important in high viscosity and high density liquids).•Extra consideration is needed if the plant vibration is close to the 1300 Hz operating frequency of the 2110.•Ensure sufficient clearance for the fork so highly viscous liquids quickly flow off the forks.•Extra consideration is needed if the plant vibration is close to the 1300 Hz operating frequency of the 2110.Figure 1-5. Example of OK and not OK build-up on tank wall.2110/2110_25a a , 2110_26a a .e p s1-8Switchpoint2120/f i g 12.e p sSwitchpoint (H 20) (SP)Switching hysteresis (HY)In the top diagram a lowerdensity media will give switchpoint closer to the connection. A higher density media will give switchpointcloser to fork tip.Service SupportTo expedite the return process outside of the United States, contact the nearest Rosemount representative.Within the United States, call the Rosemount National Response Center using the1-800-654-RSMT (7768) toll-free number. This center, available 24 hours a day, will assist you with any needed information or materials.The center will ask for product model and serial numbers, and will provide a Return Material Authorization (RMA) number. The center will also ask for the process material to which the product was last exposed.Rosemount National Response Center representatives will explain the additional information and procedures necessary to return goods exposed to hazardous substance can avoid injury if they are informed of and understand the hazard. If the product being returned was exposed to a hazardous substance as defined by OSHA, a copy of the required Material Safety Data Sheet (MSDS) for each hazardous substance identified must be included with the returned goods.WarrantyEmerson Process Management will replace a faulty or failed 2110 with a new unit provided that the fault or failure is reported either directly or via an accredited representative, within 1 year from the date of supply, and the product has been installed and used in accordance with Emerson Process Management instruction manual 00809-0100-4029. Emerson Process Management reserves the right to examine such product and to refuse replacement at its discretion if the above conditions are not met.1-91-10S ECTION 2I NSTALLATIONSafety Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-1Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-1Correct Fork Alignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-2Electrical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 2-4Safety MessagesProcedures and instructions in this manual may require special precautions to ensure the issues is indicated by a caution symbol (). The external hot surface symbol (Mechanical InstallationFigure 2-1. SealingFigure 2-2. Tighten the SwitchGasketBSPP (G1)NPT, BSPT (R)Seal (supplied in 02100-1020-0001)Tri-ClampPTFE (Teflon)2110/2110_28a a , 2110_29a a .e p s2-2Correct Fork AlignmentEnsure correct fork alignment.Pipe InstallationVessel Installation2110/14a a .e p sAlignment groove2110/24a a , 2110_16a a .e p s2110/2110_34a a .t i f2-3Cover Orientation2110/2110_36a a .e p sElectrical Installation Mode SelectionMode Selection by customer wiring.2-4Reference Manual00809-0100-4029, Rev AAJuly 2005Rosemount 2110 LED Indication2-5Reference Manual00809-0100-4029, Rev AAJuly 2005Rosemount 21102-6FunctionPLC (positive output)PNP dcLoad switching ac/dcLEDU <100uAU <100uAReference Manual00809-0100-4029, Rev AA July 2005Rosemount 21102-7WiringThe 2110 is IP66 and IP67 when correctly assembled with the supplied connector and suitable cable.NOTEUse only connector supplied.1.Insert cable into plug housing and connect to terminals.2.Ensure both seals are in place to maintain the weatherproof rating.3.Fit plug to body.Maximum 0.31 (8)Minimum 0.24 (6)5.9 (1.5)2110/2110_15a a .e p s2110/ 2110_15a b .e p s Screw SealPlug Seal2110/ 2110_28a c .e p sReference Manual00809-0100-4029, Rev AAJuly 2005Rosemount 21102-84.Tighten the screw.5.Plug fitted.RELAY CONNECTION WARNING (FOR DIRECT LOAD SWITCHING)The Rosemount 2110 requires a minimum current of 3mA, which continues to flow when the 2110 is ‘off’. If selecting a relay to wire in series with the 2110, the user must ensure that the drop-out voltage of the relay is greater than the voltage which will be generated across the relay coil when 3mA flows through it.NOTE (FOR DIRECT LOAD SWITCHING)DPST = ‘Double Pole, Single Throw’ (on/off) switch - must be fitted for safe disconnection of the power supply. Fit the switch as near to the 2110 as possible. Keep the switch free of obstructions. Label the switch to indicate that it is the supply disconnection device for the 2110.2110/ 2110_28a b .e p sPlug Fitted2110/2110_17a a .e p sReference Manual00809-0100-4029, Rev AA July 2005Rosemount 2110S ECTION 3T ROUBLESHOOTINGMagnetic Test Point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-1Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-1Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-2Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-2Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page 3-2Magnetic Test PointA magnetic test point is marked on the side of the housing allowing a functional test of the 2110. By touching a magnet on the target the 2110 output will change state for as long as the magnet is present.InspectionVisually examine the 2120 for damage. If it is damaged, do not use. Check connector and seals are correctly fitted, also that the connector fixing screw and gland are tight.Ensure the LED flash rate is 1 Hz or continually on. If anything else is demonstrated see “LED Indication” on page 2-5.2110/2110_47a a .e p sNormal Condition Test ConditionNo MagnetMagnetReference Manual00809-0100-4029, Rev AAJuly 2005Rosemount 21103-2MaintenanceNOTEIf using a brush to clean, ensure it is of a soft type.TroubleshootingIf there is a malfunction, see Table 3-1 for information on possible causes.Table 3-1. Troubleshooting chart.Spare PartsSee “Accessories” on page A-7.Symptom/Indication Action/SolutionDoes not switch•No LED; no power•Check the power supply; (checkload on direct load switching electronics model)•LED 3 flashes per second •Internal failure; contact supplier •LED 1 flash every 2 seconds •Uncalibrated; return to supplier •LED 1 flash every 4 seconds•Load fault; load current too high, load short circuit; check installation •Fork damaged•Replace•Thick encrustation on forks•Clean the fork with care • 5 second delay on changing mode/delay•Wait 5 secondsIncorrect switching•Dry = On, Wet = On set correctly•Check wiring in the connector. See “Mode Selection” on page 2-4Faulty switching•Excessive electrical noise•Suppress the cause of the interference2110_07a a , 2110_20a a , 2110_12a aReference Manual00809-0100-4029, Rev AAJuly 2005Rosemount 2110 A PPENDIX A R EFERENCE D ATAPhysical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page A-1 Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page A-2 Functional Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page A-2 Dimensional Drawing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page A-5 Ordering Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page A-6 Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page A-7 Physical SpecificationsProductRosemount 2110 Compact Liquid Level SwitchMeasuring principleVibrating ForkApplicationsMost liquids including coating liquids, aerated liquids, and slurriesMechanicalProcess material316L Stainless Steel (1.4404)For Tri-Clamp connection hand polished to better than 0.8 μm. Gasket material for 1 in. BSPP (G1) is Non-asbestos BS7531 Grade X carbon fiber with rubber binder.Housing materialsBody: 304 SST with polyester labelLED window: Flame retardant Polyamide (Pa12) UL94 V2Plug: Polyamide glass reinforcedPlug seals: Nitrile butadiene rubber 122-in. (50 mm)ConnectionsSee “Process Connection Size / Type” on page A-6.Mounting•3/4-in. BSPT (R) or NPT•1-in. BSPT (R) or BSPP (G) thread, or•Hygienic 2-in. (51 mm) Tri-clamp fittingDimensional DrawingsSee “Dimensional Drawing” on page A-5Ingress of Protection RatingIP66/67 to EN60529Reference Manual00809-0100-4029, Rev AAJuly 2005Rosemount 2110A-2Performance SpecificationsHysteresis (water)±0.039-in. (± 1mm) nom.Switching point (water)0.5-in. (13mm) from tip (vertical) / from edge (horizontal) of fork (this will vary with different liquid densities)Functional SpecificationsMaximum Operating PressureFinal rating depends on tank connectionThreaded Connection See Figure A-1.Hygienic Connection 435 psig (30 barg)Figure A-1. Process PressureTemperature See Figure A-2.Figure A-2. Temperature(-40)(50)(150)Process Temperature °F (°C)P r o c e s s P r e s s u r e p s i g (b a r g )2120/2120_18a b .e p s (0)(60)(-40)(150)Process Temperature °F (°C)A m b i e n t T e m p e r a t u r e °F (°C )2120/2120_18a c .e p s(0)Reference Manual00809-0100-4029, Rev AAJuly 2005Rosemount 2110 Liquid DensityMinimum 37.5 lb/ft3 (600 kg/m3)Liquid Viscosity Range0.2 to 10,000 cP (centiPoise)Solids Content and CoatingMaximum recommended diameter of solid particles in the liquid is 0.2-in. (5 mm).For coating product, avoid bridging of forks.Switching delay1 sec dry to wet/wet to dryCIP (Clean In Place) CleaningWithstands steam cleaning routines up to 302°F (150°C)ElectricalSwitching modeUser selectable (Dry =on or Wet =on) by selecting plug wiringCable connectionVia 4-way plug provided - DIN43650. Max. conductor size - 15AWG. Orientation 4-position(90/180/270/360 deg).Conductor sizeMaximum 0.06 inch2 (1.5 mm2)Cable glandPG9 provided - cable diameter 0.24 to 0.31-in. (6 to 8 mm)ProtectionReverse polarity insensitive. Missing load / short circuit protectionGroundingThe 2110 should always be grounded either through the terminals or using the external ground connection provided.A-3Reference Manual00809-0100-4029, Rev AAJuly 2005Rosemount 2110A-4Operating Voltage21 to 264V ac (50-60Hz)/dc Maximum switched load 500mAMaximum peak load 5A for 40 ms max.Minimum switched load 20mA continuousVoltage drop6.5V @ 24V dc / 5.0V @ 240V ac Current draw (load off)<3.0mA continuousOperating Voltage18-60V dc Maximum switched load 500mAMaximum peak load 5A for 40 ms max.Voltage drop <3VSupply Current3mA nominal Output current (load off)<0.5mALoad0V/N+V/N PEReference Manual00809-0100-4029, Rev AAJuly 2005Rosemount 2110 Dimensional DrawingTable A-1. Dimensions are in inches (millimeters)Connections A B C D3/4-in. BSPT (R) 2.72 (69) 1.97 (50)7.40 (188)N/A 3/4-in. NPT 2.72 (69) 1.97 (50)7.40 (188)N/A1-in. BSPT (R) 2.72 (69) 1.97 (50)7.40 (188)N/A1-in. BSPP (G) 3.07 (78) 2.36 (60)7.91 (201)N/A 2-in. (51 mm) Tri-Clamp 2.72 (69) 1.97 (50)7.40 (188) 2.52 (64)1-in. Semi-extended 4.57 (116) 3.86 (98)9.41 (239)N/AA-5Reference Manual00809-0100-4029, Rev AA July 2005Rosemount 2110A-6Ordering Information2110Compact Vibrating Fork Liquid Level Switch 0Direct load switching with plug connection (2 wire) 21 to 264 V ac 50/60 Hz, 21 to 264 V dc 1PNP/PLC low voltage switching with plug connection 18 to 60 V dc 0A3/4-in. BSPT (R) thread 1A1-in. BSPT (R) thread 0D3/4-in. NPT thread 2R 2-in. (51mm) Tri-clamp 1B1-in. BSPP (G) thread 1L1-in. BSPP (G) Semi-extended 4.6-in. (116 mm)NANo Hazardous Locations Certifications (safe area use only)Overfill U1DIBt/WHG Overfill protection Calibration Data Certificate Q4Certificate of functional test Tag Plates STTag plate SST engraved plate (maximum 16 digits)WT Tag plate laminated paper (maximum 40 digits)。

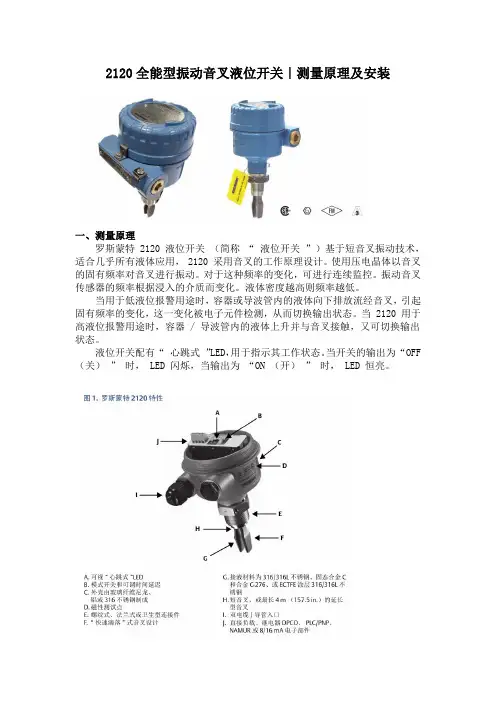

2120全能型振动音叉液位开关|测量原理及安装一、测量原理罗斯蒙特 2120 液位开关(简称“液位开关”)基于短音叉振动技术,适合几乎所有液体应用, 2120 采用音叉的工作原理设计。

使用压电晶体以音叉的固有频率对音叉进行振动。

对于这种频率的变化,可进行连续监控。

振动音叉传感器的频率根据浸入的介质而变化。

液体密度越高则频率越低。

当用于低液位报警用途时,容器或导波管内的液体向下排放流经音叉,引起固有频率的变化,这一变化被电子元件检测,从而切换输出状态。

当 2120 用于高液位报警用途时,容器 / 导波管内的液体上升并与音叉接触,又可切换输出状态。

液位开关配有“心跳式”LED,用于指示其工作状态。

当开关的输出为“OFF (关)”时, LED 闪烁,当输出为“ON (开)”时, LED 恒亮。

二、安装准备工作该液位开关可提供本安或防爆 / 防火型。

还可提供适用于普通场所的液位开关型(针对未分类的安全区域)和卫生型。

带重型法兰和延长型音叉的罗斯蒙特 2120 液位开关(简称“液位开关”)的重量可能超过 18 kg (37 lb)。

搬运、吊装和安装液位开关前需要进行风险评估。

对罗斯蒙特 2120 应轻拿轻放,请采用正确姿势。

如下图:环镜考虑因素:此液位开关设计为在开放式或封闭式储罐以及管道上安装。

它不受天气影响,能够防尘,但必须防止其受到水淹。

确保在储罐或管道外有足够的空间。

需要 30 mm (1.2 in.) 空隙,以便拆卸护盖。

务必安装金属外壳盖,使金属与金属接触,或塑料与塑料接触,从而确保正确密封。

应使用罗斯蒙特 O 形圈。

必须按照国家和当地电气规范将外壳接地。

最有效的接地方法是直接接地来获得最小阻抗。

对于带有 NPT 导管入口的金属外壳,应使用音叉的地线。

三、安装建议*避免安装在储罐进液口附近。

*避免音叉溅上大量液体。

应增加延时以减少意外开关情况。

*避免安装在热源附近。

*确保音叉不与罐壁 / 管壁或配件接触。

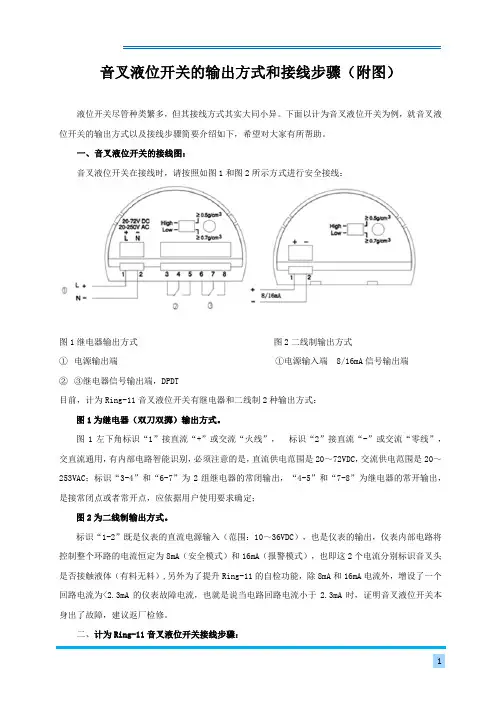

音叉液位开关的输出方式和接线步骤(附图)液位开关尽管种类繁多,但其接线方式其实大同小异。

下面以计为音叉液位开关为例,就音叉液位开关的输出方式以及接线步骤简要介绍如下,希望对大家有所帮助。

一、音叉液位开关的接线图:音叉液位开关在接线时,请按照如图1和图2所示方式进行安全接线:图1继电器输出方式图2二线制输出方式①电源输出端①电源输入端 8/16mA信号输出端②③继电器信号输出端,DPDT目前,计为Ring-11音叉液位开关有继电器和二线制2种输出方式:图1为继电器(双刀双掷)输出方式。

图1左下角标识“1”接直流“+”或交流“火线”,标识“2”接直流“-”或交流“零线”,交直流通用,有内部电路智能识别,必须注意的是,直流供电范围是20~72VDC,交流供电范围是20~253VAC;标识“3-4”和“6-7”为2组继电器的常闭输出,“4-5”和“7-8”为继电器的常开输出,是接常闭点或者常开点,应依据用户使用要求确定;图2为二线制输出方式。

标识“1-2”既是仪表的直流电源输入(范围:10~36VDC),也是仪表的输出,仪表内部电路将控制整个环路的电流恒定为8mA(安全模式)和16mA(报警模式),也即这2个电流分别标识音叉头是否接触液体(有料无料),另外为了提升Ring-11的自检功能,除8mA和16mA电流外,增设了一个回路电流为<2.3mA的仪表故障电流,也就是说当电路回路电流小于2.3mA时,证明音叉液位开关本身出了故障,建议返厂检修。

二、计为Ring-11音叉液位开关接线步骤:对于隔爆型仪表,只有当环境中不存在会引爆的气体或粉尘时才允许打开外盖操作。

请按照如下步骤进行操作:(1)打开外壳盖;(2)松开电缆螺纹接头上的锁紧螺母;(3)去掉连接电缆大约10cm的外皮和芯线末端大约1cm的绝缘层;(4)将电缆穿过电缆螺纹接头插入外壳中;(5)用螺丝刀打开接线端子;(6)按照接线图将芯线末端插入接线端子中;(7)用螺丝刀拧紧接线端子;(8)通过轻拉接入的电缆线来检查接线是否牢靠;(9)拧紧电缆螺纹接头的锁紧螺母,扣紧密封环;(10)拧上外壳盖。

快速安装指南00825-0106-4030, Rev GB2022 年 3 月Rosemount™ 2120 液位开关振动音叉快速安装指南2022 年 3 月内容关于本指南 (3)安装 (5)准备电气连接件 (11)接线和通电 (26)组态 (30)操作 (32)2Rosemount 2120 液位开关2022 年 3 月快速安装指南1关于本指南本快速安装指南提供 Rosemount2120的基本安装指导。

更多说明,请参阅Rosemount 2120参考手册。

手册和本指南的电子版本亦可以从/Rosemount获得。

1.1安全信息警告不遵守安全安装与检修准则,可能导致死亡或严重受伤。

请确保由取得相关资质人员按照相应的操作规程安装物位开关。

只能使用本手册中规定的物位开关。

只能使用本手册中规定的物位开关。

带重型法兰和延长型音叉的物位开关的重量可能超过 37 lb. (18 kg)。

搬运、吊装和安装物位开关前必须执行风险评估。

修理设备(例如更换组件等)可能危害安全性,在任何情况下都是不允许的。

警告爆炸可能会导致死亡或严重受伤。

验证物位开关的工作环境符合相应的危险场所认证。

在易爆气体环境中,连接手持通讯器之前,请确保按照本质安全或非易燃现场接线实践安装仪表。

在隔爆以及非易燃型安装中,不得在液位开关通电的情况下拆卸壳体盖子。

为满足隔爆要求,壳体盖子必须完全盖上。

警告触电可能导致死亡或严重受伤。

不得接触引线或接线端子。

引线上可能存在的高压会导致触电。

在进行物位开关接线时,请确保物位开关的电源处于关闭状态,并且与任何其他外部电源连接的线路均处于断开状态,或者没有通电。

确保接线符合电流要求,且绝缘符合电压、温度和环境要求。

快速安装指南3快速安装指南2022 年 3 月警告过程泄漏可能导致死亡或严重受伤。

请务必轻拿轻放物位开关。

如果过程密封件受损,气体可能会从容器(储罐)或管道中逸出。

警告物理接触未经授权的人员可能会对最终用户的设备造成明显受损和/或误组态。

罗斯蒙特雷达液位计操作说明一、简介罗斯蒙特雷达液位计是一种高精度的测量液位的仪器,具有可靠的测量准确度、超长的距离测量范围、安装快速方便等特点。

它通过发射和接收雷达信号来测量液位,可测量多种液体、干粉、固体等介质,因其使用便捷、精密度高,在工业中得到广泛应用。

二、技术参数1、测量范围:0-60米;2、精度:±2mm;3、响应时间:小于2秒;4、最大功率输出:20dBm;5、电压范围:18-30 VDC;6、电源消费:小于3W;7、工作温度范围:-40~ 60 ℃;8、连接方式:螺纹连接及管径:G2、G3;9、防护等级:IP65。

三、安装1、准备工作:(1)熟悉罗斯蒙特雷达液位计的技术特点及使用范围;(2)准备有关的管路附件,经过简单安装;(3)查看安装现场是否有避雷等安全设施;(4)检查安装地点是否具备一定的防雨和防尘功能。

2、安装步骤:(1)使用密封件密封机体;(2)根据现场实际状况排布软管及连接件,将机体安装在安装现场的任意位置;(3)将先导管装入机体,使其与机体完全密封,然后将其连接到软管;(4)拧紧螺母,使螺母完全紧固在机体上;(5)将电源、信号线等接头线接到控制器上;(6)将控制器安装在材料容器上,检查安装是否正确。

3、检查(1)请确保连接接口、孔板及先导管由专业技术人员操作;(2)检查联接体、接插件和管路紧固是否牢固,电源及信号线的接头是否稳固;(3)仔细检查机体上的各个接口是否完好,接头两端是否有充分的密封;(4)确保机体与上下管路之间没有空气泄漏。

四、操作1、开机操作:(1)查看电源是否符合标准,传感器电源为DC 18-30V,在确认电源正常之后,连接好电源线及控制器,接通电源;(2)将控制器设置为“开机”状态,传感器处于正常工作状态;(3)如果在安装完成后传感器仍然未能正常接收信号,可以手动调整雷达的频率;(4)将传感器的调节组件设置为正常操作状态,检查量程和电平等功能是否正常;2、使用注意事项:(1)安装完毕之后,应进行试验和调整,以保证设备正常运行;(2)罗斯蒙特雷达液位计不宜直接放置于高温、强磁场、易受撞击处;(3)液位仪的使用中应避免粉尘、水及液体等腐蚀性物质进入传感器;(4)在接通电源前要根据实际需要确认电源电压,以免损坏设备;(5)调整时,应避免触摸装置内机械及电子元件;(6)安装之前一定要确认配管断面面积没有大于机体进出口口径。

舟山世纪太平洋化工工程创亚太一流自动化控制基地舟山世纪太平洋化工有限公司舟山世纪太平洋化工工程创亚太一流自动化控制基地舟山世纪太平洋化工库区由南京扬子设计院设计,并对库区所有罐区、码头输配系统的自动控制系统采用以计算机为核心的数据采集和监控系统,油库的计算机控制系统采用分散式的数据采集、控制,集中监视和管理的方式。

控制中心完成对油库的数据采集、数据处理及存储归档、控制、故障处理、安全保护、报警等任务,同时完成罐区管理、罐区液位计量、流量计贸易交接计量、装船油泵运行状态、仪表故障诊断及分析等功能。

控制中心的调度和操作人员通过操作员工作站提供的油库储罐和库内管道的压力、温度、流量、密度、设备运行状态等信息对全库区进行监控及运行管理。

先进、高度集成的储罐自控系统,结合其他安全监控系统和信息管理系统,形成高精度的贸易交接、先进的控制水平、可靠的安全保障、全面、迅速、便捷的信息反应体系。

一:SCADA系统(组态自控系统):我们一期工程选用施耐德电气公司Modicon TSX Quantum大型PLC,分别在中央控制机房、现场机柜间、1#码头机柜间、2#码头机柜间设置1#、2#、3#、4#控制站。

为充分保证设备安全可靠,本系统采用冗余光纤双环网充分保证系统的安全平稳运行,热备系统采用双底板双CPU的热备系统,提供包括CPU、电源和通讯的热备方案,在故障时实现主站到后备站的自动无扰切换,主站和后备站之间采用光纤连接交换数据,保证系统稳定、可靠、高速。

本项目在系统结构设计上,采用符合工业设计规范要求的设备层、控制层和信息层的分层结构模式,在系统设备层中,主要监测和控制的设备参数为:储油罐液位、温度、压力的变化;油泵运行状态;气动蝶阀开关状态、电动消防阀门状态、可燃气体浓度检测和油料计量设备。

与英格索兰空压机采用标准Modbus RS485协议通讯;与氮压机采用PROFIBUS-DP协议通讯。

在软硬件系统的配置和设计上,为将来系统工程扩建以及今后的技术改造预留接口。