G中英文翻译

- 格式:doc

- 大小:46.00 KB

- 文档页数:8

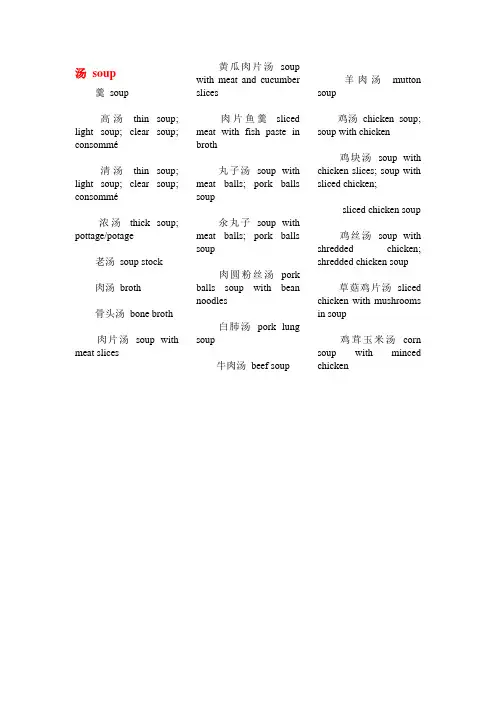

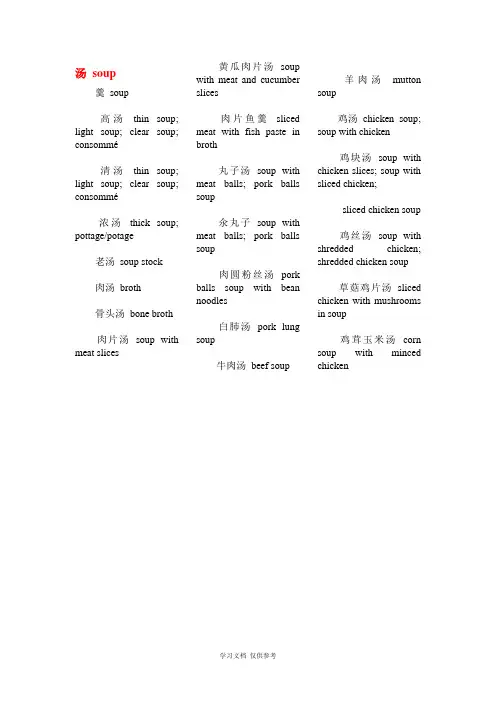

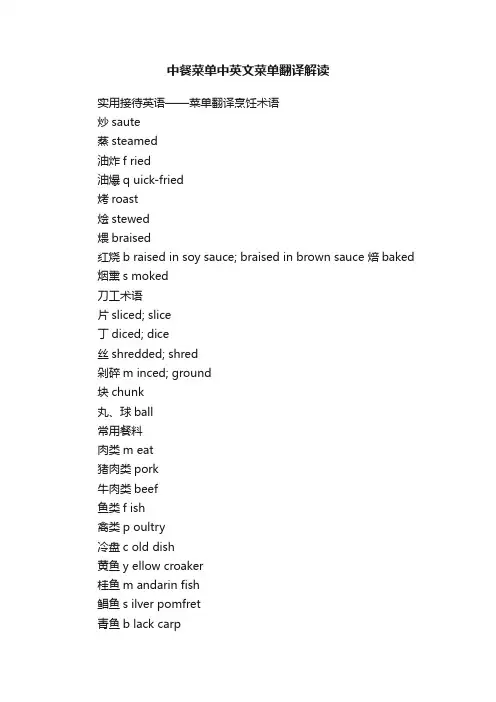

汤soup羹soup高汤thin soup; light soup; clear soup; consommé清汤thin soup; light soup; clear soup; consommé浓汤thick soup; pottage/potage老汤soup stock肉汤broth骨头汤bone broth肉片汤soup with meat slices黄瓜肉片汤soupwith meat and cucumberslices肉片鱼羹slicedmeat with fish paste inbroth丸子汤soup withmeat balls; pork ballssoup氽丸子soup withmeat balls; pork ballssoup肉圆粉丝汤porkballs soup with beannoodles白肺汤pork lungsoup牛肉汤beef soup羊肉汤muttonsoup鸡汤chicken soup;soup with chicken鸡块汤soup withchicken slices; soup withsliced chicken;sliced chicken soup鸡丝汤soup withshredded chicken;shredded chicken soup草菇鸡片汤slicedchicken with mushroomsin soup鸡茸玉米汤cornsoup with mincedchicken鸡茸芦笋汤asparagus soup with mashed chicken鸡茸黄鱼羹yellow croaker potage with minced chicken鸡杂汤chicken giblets soup鸡什汤chicken giblets soup蔬菜鸡什汤chicken giblets soup with vegetables鸭汤duck soup火鸭芥菜汤sliced roasted duck with leaf mustered in soup芥菜鸭汤duck soup with pickled mustard leaves鸭掌汤duck web soup竹笋鸭掌汤du ck’s feet with bamboo shoots in soup鸭肝汤duck liver soup冬菇鸭杂汤duck giblets soup with black mushrooms鸭骨菜汤duck bone soup with vegetables汤泡肫球gizzardballs in soup三鲜汤soup withfish, shrimps and porkballs红鱼汤fish soupwith tomato黄鱼羹yellowcroaker chowder鲫鱼汤soup withgold carp; gold carp soup鱼翅汤soup withshark’s fins鲍鱼汤soup withabalone; abalone soup鲍鱼鸡片汤abalone soup with slicedchicken鲍鱼芦笋汤abalone soup withasparagus干贝汤driedscallop soup; soup withdried scallops燕窝汤bird‘s nestsoup燕窝羹bird‘s nestsoup蛇羹snake soup;soup with snake酸辣汤sour andpepper hot soup豆腐汤bean-cudsoup蔬菜汤vegetablessoup榨菜汤hot pickledtuber mustard soup榨菜肉丝汤hotpickled tuber mustardsoup with shredded pork榨菜粉丝汤hotpickled tuber mustardsoup with bean noodles什锦瓜丁汤assorted meat soup withdiced white gourd鸡蛋羹steamedegg custard鸡蛋汤eggdropsoup; egg soup木须汤eggdropsoup; egg soup蛋花汤eggdropsoup; egg soup蕃茄鸡蛋汤eggsoup with tomatoes锅巴口蘑汤mushroom soup withfried rice crust白豆汤white bean soup玉米羹sweet corn soup面食cooked wheaten food面食cooked wheaten food; food made of flour馒头steamed bread; steamed bun白面馒头steamed bread; steamed bun一屉馒头 a trayful of steamed bread; a trayful of steamed buns馒子steamed bread; steamed bun馍馍steamed bread; steamed bun白面馒steamed bread; steamed bun花卷steamed twisted roll; steamed roll蒸饼steamed cake发面饼leavened pancake烙饼unleavened pancake; flapjack家常饼home-stylepancake薄饼thin pancake荷叶饼lotus-leaf-like pancake; thinpancake锅饼thick pancake饼卷pancake roll葱花饼greenChinese onion pancake;green onion pancake炒饼fried shreddedpancake肉饼fried meat pie;meat pie馅饼fried meat pie;meat pie猪肉馅饼friedpork pie; pork pie三鲜馅饼fried piewith shredded sea foods烧饼baked sesame-seed cake芝麻烧饼bakedsesame-seed cake火烧bakedwheaten cake糖火烧bakedsweeten wheaten cake蜂糕steamedsponge cake米糕steamed ricecake; rice budding年糕New Yearcake made of glutinousrice flour凉糕steamed ricecake served cold insummer丝糕steamed corncake窝头steamed cornbread玉米饼子cornpancake煎饼thin pancakemade of millet flour;millet pancake粽子pyramid-shaped dumpling madeof glutinous rice wrappedinbamboo or reedleaves馕crusty pancake面条noodles切面noodles挂面packaged noodles拉面hand-pulled noodles抻面hand-pulled noodles方便面instant noodles即食面instant noodles通心面macaroni通心粉macaroni细通心粉spaghetti意大利式细面条spaghetti细面条spaghetti米粉条rice -flour noodles面汤water in which noodles have been boiled捞面noodles taken out of the boiling water with a strainer肉丝面noodles with shredded meat肉丝拌面noodles with shredded pork炸酱面noodles withchopped meat infried bean sauce;noodles withsoya bean paste打卤面noodles with meatslices in thickgravy;noodlesserved with thickgravy烩面stewednoodles鸡丝烩面stewed noodleswith chickenshreds凉拌面coldnoodles withsauce凉面coldnoodles withchicken shreds鸡丝凉面cold noodles withchicken shreds芝麻酱面cold noodles withsesame paste麻酱面coldnoodles withsesame paste寿面birthday noodlesa.汤面noodles soup汤面noodles soup;noodles in soup肉丝汤面noodles soup withshredded meat鸡丝汤面noodles soup withshredded chicken三鲜汤面noodles soup withshredded seafoodsb.炒面friednoodles炒面friednoodles; ChowMien肉丝炒面fried noodles withshredded meat牛肉炒面fried noodles withbeef牛肉蔬菜炒面fried noodleswith beef andvegetables鸡丝炒面fried noodles with shredded chicken虾炒面fried noodles with shrimps海鲜炒面fried noodles with sea foods海鲜蔬菜炒面fried noodles with sea foods and vegetables蔬菜炒面fried noodles with vegetables包子steamed bun with stuffing包子steamed stuffed bun; steamed bun with stuffing肉包子steamed bun with meat stuffing; steamed bun with minced pork stuffing肉包steamed bun with meat stuffing; steamed bun with minced pork stuffing猪肉包子steamed bun with pork stuffing三鲜包子steamed bunstuffed withshredded seafoods菜包子steamed bun withvegetable stuffing;steamedvegetable stuffedbun素包子steamed bun withvegetable stuffing;steamedvegetable stuffedbun豆沙包steamed bun withsweetened beanpaste;steamed bunstuffed withmashed red bean蒸包steamed bun withstuffing猪肉蒸包steamed bun withpork stuffing三鲜蒸包steamed bunstuffed withshredded seafoods小笼蒸包steamed stuffedbun by smallbamboo foodsteamer小笼包steamed stuffedbun by smallbamboo foodsteamer蒸饺steameddumpling猪肉蒸饺steamed porkdumpling三鲜蒸饺steameddumpling stuffedshredded seafoods锅贴slightly frieddumpling猪肉锅贴slightly fried porkdumpling三鲜锅贴slightly frieddumpling withshredded seafoods肉卷grilledbun with mincedpork stuffing饺子boileddumpling饺子馅stuffing for dumpling; filling for dumpling饺子皮dumpling wrapper饺子汤water in which dumplings have been boiled速冻饺子instant frozen dumpling猪肉饺子boiled pork dumpling三鲜饺子boiled dumpling with shredded sea foods水饺boiled dumpling手工水饺hand-made boiled dumpling机制水饺machine-made boiled dumpling猪肉水饺boiled pork dumpling韭菜水饺boiled dumpling with Chinese chive三鲜水饺boiled dumpling with shredded sea foods红油水饺boiled dumpling with chili/chili oil馄饨wonton; ravioli soup面球dumpling汤包steamed dumpling filled with minced meat and gravy烧卖steamed dumpling with the dough gathered at the top。

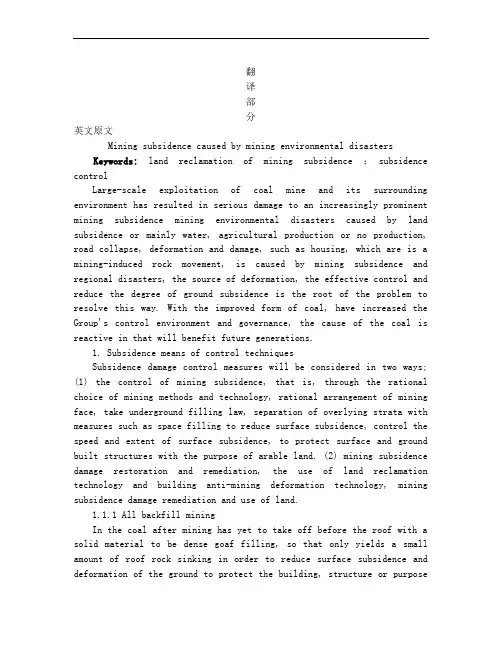

翻译部分英文原文Mining subsidence caused by mining environmental disasters Keywords: land reclamation of mining subsidence ;subsidence controlLarge-scale exploitation of coal mine and its surrounding environment has resulted in serious damage to an increasingly prominent mining subsidence mining environmental disasters caused by land subsidence or mainly water, agricultural production or no production, road collapse, deformation and damage, such as housing, which are is a mining-induced rock movement, is caused by mining subsidence and regional disasters, the source of deformation, the effective control and reduce the degree of ground subsidence is the root of the problem to resolve this way. With the improved form of coal, have increased the Group's control environment and governance, the cause of the coal is reactive in that will benefit future generations.1. Subsidence means of control techniquesSubsidence damage control measures will be considered in two ways;(1) the control of mining subsidence, that is, through the rational choice of mining methods and technology, rational arrangement of mining face, take underground filling law, separation of overlying strata with measures such as space filling to reduce surface subsidence, control the speed and extent of surface subsidence, to protect surface and ground built structures with the purpose of arable land. (2) mining subsidence damage restoration and remediation, the use of land reclamation technology and building anti-mining deformation technology, mining subsidence damage remediation and use of land.1.1.1 All backfill miningIn the coal after mining has yet to take off before the roof with a solid material to be dense goaf filling, so that only yields a small amount of roof rock sinking in order to reduce surface subsidence and deformation of the ground to protect the building, structure or purposeof farmland . Which is the filling of water and sediment filling in the mining method to reduce the effect of surface preparation methods subsidence, followed by the wind and filling away from the filling of waste. However, filling mining method of filling the need for specialized equipment and facilities, but also the need for adequate filling material. Initial investment of mine, and tons of coal a corresponding increase in cost.1.1.2 strip miningBased on coal and overlying strata combination of conditions, according to a certain ratio of mining to remain in the coal seam was mined in a recovery to retain one. As a result of strip mining is only part of the underground mining of coal resources, coal in order to retain a portion of coal overlying strata cylindrical support. Thereby reducing the overburden rock movement, control the movement and deformation of the surface to achieve on the ground to build structures of protection. However, the methods of the low rate of recovery, tunnel boring, and inefficient working.1.1.3 Filling the cover rock band separationMined-out area in accordance with the top of the cover rock band mobile form a three-shift characteristics of the rock, in coal mining after a certain time interval, with drilling to the separation of space with high-pressure grouting, filling, reinforced with separation of space, will be mining the reinforced masonry beam structure for better stability of the continuous beam structures, so that separation of space with the sink is no longer transfer to the surface in order to reduce or mitigate surface subsidence, the protection of ground built structures or farmland. However, the technical difficulty, and then further study.1.1.4 Mining thick limitAccording to the mining area topography, hydro-geological conditions and building the capacity of anti-deformation structures in order to not produce the surface water and to meet the requirements of the protection of buildings based on grades to determine the thickness of coal seam can be mined, mining is only the thickness of the coal mining, none of the remaining coal mining, in order to achieve reduction in the protection of ground subsidence building, structures and land use. However, the lowrate of recovery techniques, only the application of thin coal seam a certain value.1.1.5 Coordination of the exploitation ofSlice mining thick coal seam, the rational design of the exploitation of the working face spacing, location and exploitation of the order of each other, so that a coal mining (face) surface deformation generated by coal and the exploitation of another (face) surface deformation arising from mutual offset or partially offset to reduce the mining of surface deformation caused by the protection of ground built structures. However, the technology's fault in order to maintain a certain distance, it is difficult to organize production. China has yet to carry out such industrial experiment.1.1.6 "Picking - Note - adopted" three-step extractionTake full advantage of the structure of overburden rock strata movement of the control, application of the principle of load replacement for small strip mining - the consolidation grouting filling goaf - strip mining the remaining three-step extraction method, effective mobility and the surface of the rock subsidence control, to solve the large-scale exploitation of ground subsidence control, increased the rate of coal mining, the protection of the ground built structures, but there are complex processes, such as the shortcomings of higher cost.II. Land Reclamation Technology2.2.1 Reclamation of coal gangue and fly ash filling Filling Reclamation(1) generated a large number of underground mining to surface emissions of coal gangue, is there an area of pollution of the environment. The use of coal waste as filling material, so that mining can restore damaged land and reducing the amount of waste to.(2) the use of plant waste - fly ash filled reclaimed land subsidence can be of two evils (subsidence, fly ash) for the three-li (power plants, coal mines, three farmers put a favorable face).2.2.2 Reclamation of the ground and the construction of terracesSubsidence of the water, diving bit lower slope areas, can be taken to the land formation, terraced into the use of the method of reclamation. Terrace level width and height, should be based on easeshaking the ground slope, soil engineering a large quantity of crop filial types of integrated farming mechanization level to consider to determine, the size of the field gradient and slope aspect, slope should be based on the original great filial piety non-irrigated conditions, reclamation of land use to decide.2.2.3 Reclamation Act lost platoonExcavation of drainage channels, will be the introduction of subsidence shallow water of rivers, lakes, reservoirs, etc., as the water used is re-flooded subsidence under cultivation.2.2.4 Reclamation deep shallow padThe use of manual or mechanical methods to the local water or seasonal water subsidence deepened the sinking large area suitable for fish farming, irrigation water, filled with soil dug up small areas of mining subsidence, making it available cultivation of arable land.2.2.5 Utilization of catchment areas for technicalLarge area of ground water and water depth of a lot of subsidence, the utilization of science, the development of Cage Culture, fish fences, storage for irrigation water, construction of water parks.2.2.6 Reclamation of solid microbial technologyAdd the proper amount of gangue microbial activator, after a growing period of plants (about 6 months) can establish a solid layer of plant growth and form of soil aging.Mining subsidence caused by mining environment is the direct cause of geological disasters, effective control and reduce the degree of ground subsidence is to avoid environmental hazards of mining subsidence of the basic approach. Fill mining method is to reduce the effect of surface preparation method of sinking, some mines in recent years in Shandong paste filling are doing the experiment, this method can not face down or reduce the collapse zone, the better to reduce surface subsidence . Technology but its a great line delivery times, and tube obstruction Louis, if successful it would be a coal mining technology revolution.Mining subsidence of the land resources and damage is unavoidable, it should be applied in various coal mines according to their actual situation and conditions of a reasonable application of the prevention and control of mining subsidence land reclamation techniques andtechnology, mining technology, the ecological reclamation of multidisciplinary knowledge to carry out comprehensive management of surface subsidence and the development and utilization in order to better protect the surface, mining environment.中文译文开采沉陷造成的矿区环境灾害关键词开采沉陷;土地复垦;沉陷控制煤炭的大规模开采对矿山及其周围环境造成了严重的破坏日益突出,开采沉陷造成的矿区环境灾害主要有土地塌陷或积水,农田减产或绝产、道路塌陷、房屋变形破坏等,这都是开采引起的岩层移动,是造成矿区塌陷灾害和区域变形的根源,有效控制和减轻地面塌陷程度是解决此问题的根本之路。

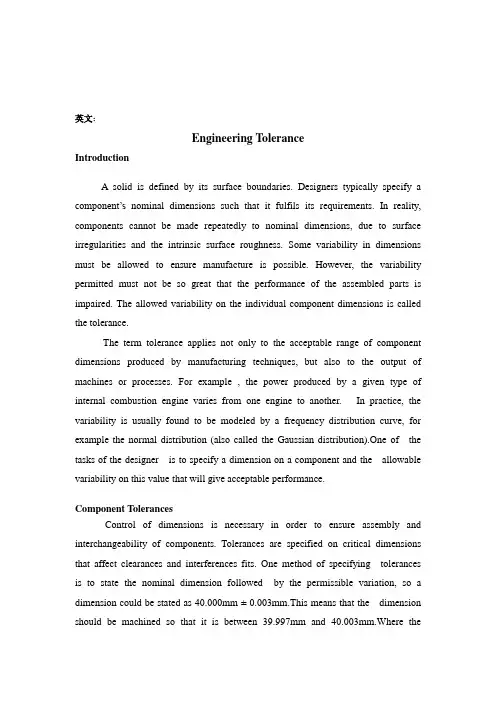

英文:Engineering ToleranceIntroductionA solid is defined by its surface boundaries. Designers typically specify a component’s nominal dimensions such that it fulfils its requirements. In reality, components cannot be made repeatedly to nominal dimensions, due to surface irregularities and the intrinsic surface roughness. Some variability in dimensions must be allowed to ensure manufacture is possible. However, the variability permitted must not be so great that the performance of the assembled parts is impaired. The allowed variability on the individual component dimensions is called the tolerance.The term tolerance applies not only to the acceptable range of component dimensions produced by manufacturing techniques, but also to the output of machines or processes. For example , the power produced by a given type of internal combustion engine varies from one engine to another. In practice, the variability is usually found to be modeled by a frequency distribution curve, for example the normal distribution (also called the Gaussian distribution).One of the tasks of the designer is to specify a dimension on a component and the allowable variability on this value that will give acceptable performance.Component TolerancesControl of dimensions is necessary in order to ensure assembly and interchangeability of components. Tolerances are specified on critical dimensions that affect clearances and interferences fits. One method of specifying tolerances is to state the nominal dimension followed by the permissible variation, so a dimension could be stated as 40.000mm ± 0.003mm.This means that the dimension should be machined so that it is between 39.997mm and 40.003mm.Where thevariation can vary either side of the nominal dimension, the tolerance is called a bilateral tolerance. For a unilateral tolerance, one tolerance is zero, e.g. 40+0.006 .0.000Most organizations have general tolerances that apply to dimensions when an explicit dimension is not specified on a drawing. For machined dimensions a general tolerance may be ±0.5mm. So a dimension specified as 15.0mm may range between 14.5mm and 15.5mm. Other general tolerances can be applied to features such as angles, drilled and punched holes, castings,forgings, weld beads and fillets.When specifying a tolerance for a component, reference can be made to previous drawings or general engineering practice. Tolerances are typically specified in bands as defined in British or ISO standards.Standard Fits for Holes and ShaftsA standard engineering ask is to determine tolerances for a cylindrical component, e.g. a shaft, fitting or rotating inside a corresponding cylindrical component or hole. The tightness of fit will depend on the application. For example, a gear located onto a shaft would require a “tight” interference fit, where the diameter of the shaft is actually slightly greater than the inside diameter of the gear hub in order to be able to transmit the desired torque. Alternatively, the diameter of a journal bearing must be greater than the diameter of the shaft to allow rotation. Given that it is not economically possible to manufacture components to exact dimensions, some variability in sizes of both the shaft and hole dimension must be specified. However, the range of variability should not be so large that the operation of the assembly is impaired. Rather than having an infinite variety of tolerance dimensions that could be specified, national and international standards have been produced defining bands of tolerances. To turn this information into actual dimensions corresponding tables exist,defining the tolerance levels for the size of dimension under consideration.Size:a number expressing in a particular unit the numerical value of a dimension.Actual size:the size of a part as obtained by measurement.Limits of size:the maximum and minimum sizes permitted for a feature.Maximum limit of size the greater of the two limits of size.Minimum limit of size:the smaller of the two limits of size.Basic size:the size by reference to which the limits of size are fixed.Deviation:the algebraic difference between a size and the corresponding basic size.Actual deviation:the algebraic difference between the actual size and the corresponding basic size.Upper deviation:the algebraic difference between the maximum limit of size and the corresponding basic size.Lower deviation:the algebraic difference between the minimum limit of size and the corresponding basic size.Tolerance:the difference between the maximum limit of size and the minimum limit of size.Shaft:the term used by convention to designate all external features of a part.Hole:the term used by convention to designate all internal features of a part.Heat Treatment of MetalThe generally accepted definition for heat treating metals and metal alloys is “heating and cooling a solid metal or alloy in a way so as to obtain specific conditions and I or properties.”Heating for the sole purpose of hot working(as in forging operations) is excluded from this definition.Likewise,the types of heat treatment that are sometimes used for products such as glass or plastics are also excluded from coverage by this definition.Transformation CurvesThe basis for heat treatment is the time-temperature-transformation curves or TTT curves where,in a single diagram all the three parameters are plotted.Becauseof the shape of the curves,they are also sometimes called C-curves or S-curves.To plot TTT curves,the particular steel is held at a given temperature and the structure is examined at predetermined intervals to record the amount of transformation taken place.It is known that the eutectoid steel (T80) under equilibrium conditions contains,all austenite above 723℃,whereas below,it is pearlite.To form pearlite,the carbon atoms should diffuse to form cementite.The diffusion being a rate process,would require sufficient time for complete transformation of austenite to pearlite .From different samples,it is possible to note the amount of the transformation taking place at any temperature.These points are then plotted on a graph with time and temperature as the axes.Classification of Heat Treating ProcessesIn some instances,heat treatment procedures are clear cut in terms of technique and application.whereas in other instances,descriptions or simple explanations are insufficient because the same technique frequently may be used to obtain different objectives .For example, stress relieving and tempering are often accomplished with the same equipment and by use of identical time and temperature cycles.The objectives,however,are different for the two processes .The following descriptions of the principal heat treating processes are generally arranged according to their interrelationships.Normalizing consists of heating a ferrous alloy to a suitable temperature (usually 50°F to 100 °F or 28 ℃to 56℃) above its specific upper transformation temperature. This is followed by cooling in still air to at least some temperature well below its transformation temperature range.For low-carbon steels.the resulting structure and properties are the same as those achieved by full annealing ;for most ferrous alloys, normalizing and annealing are not synonymous.Normalizing usually is used as a conditioning treatment, notably for refining the grain of steels that have been subjected to high temperatures for forging or other hot working operations.The normalizing process usually is succeededby another heat treating operation such as austenitizing for hardening, annealing,or tempering.Annealing is a generic term denoting a heat treatment that consists of heating to and holding at a suitable temperature followed by cooling at a suitable rate.It is used primarily to soften metallic materials,but also to simultaneously produce desired changes in other properties or in microstructure.The purpose of such changes may be,but is not confined to, improvement of machinability, facilitation of cold work ( known as in-process annealing),improvement of mechanical or electrical properties, or to increase dimensional stability.When applied solely to relieve stresses, it commonly is called stress-relief annealing, synonymous with stress relieving.When the term “anneali ng is applied to ferrous alloys without qualification, full annealing is implied.This is achieved by heating above the alloy’s transformation temperature,then applying a cooling cycle which provides maximum softness.This cycle may vary widely, depending on composition and characteristics of the specific alloy.Quenching is the rapid cooling of a steel or alloy from the austenitizing temperature by immersing the workpiece in a liquid or gaseous medium.Quenching media commonly used include water,5% brine,5% caustic in an aqueous solution,oil,polymer solutions,or gas(usually air or nitrogen).Selection of a quenching medium depends largely on the hardenability of the material and the mass of the material being treated(principally section thickness).The cooling capabilities ofthe above-listed quenching media vary greatly.In selecting a quenching medium, it is best to avoid a solution that has more cooling power than is needed to achieve the results,thus minimizing the possibility of cracking and warp of the parts being treated.Modifications of the term quenching include direct quenching,fog quenching,hot quenching,interrupted quenching selective quenching,spray quenching, and time quenching.Tempering .In heat treating of ferrous alloys ,tempering consists of reheating the austenitized and quench-hardened steel or iron to some preselected temperature that is below the lower transformation temperature (generally below 1300°F or 705℃) .Tempering offers a means of obtaining various combinations of mechanical properties.Tempering temperatures used for hardened steels are often no higher than 300°F (150℃).The term “tempering”should not be confused with either process annealing or stress relieving.Even though time and temperature cycles for the three processes may be the same,the conditions of the materials being processed and the objectives may be different.Stress Relieving.Like tempering, stress relieving is always done by heating to some temperature below the lower transformation temperature for steels and irons .For nonferrous metals,the temperature may vary from slightly above room temperature to several hundred degrees,depending on the alloy and the amount of stress relief that is desired.The primary purpose of stress relieving is to relieve stresses that have been imparted to the workpiece from such processes as forming, rolling,machining or welding.The usual procedure is to heat workpieces to the pre-established temperature long enough to reduce the residual stresses (this is a time-and temperature-dependent operation) to an acceptable level;this is followed by cooling at a relatively slow rate to avoid creation of new stresses.Introduction to CAD/CAMThroughout the history of our industrial society, many inventions have been patented and whole new technologies have evolved. Perhaps the single development that has impacted manufacturing more quickly and significantly than any previous technology is the digital computer. Computers are being used increasingly for both design and detailing of engineering components in the drawing office.Computer-aided design (CAD) is defined as the application of computers and graphics software to aid or enhance the product design from conceptualizationto documentation. CAD is most commonly associated with the use of an interactive computer graphics system, referred to as a CAD system. Computer-aided design systems are powerful tools and are used in the mechanical design and geometric modeling of products and components.There are several good reasons for using a CAD system to support the engineering design function:⑴To increase the productivity⑵To improve the quality of the design⑶To uniform design standards⑷To create a manufacturing data base⑸To eliminate inaccuracies caused by hand-copying of drawingsand inconsistency between drawingsComputer-aided manufacturing (CAM) is defined as the effective use of computer technology in manufacturing planning and control. CAM is most closely associated with functions in manufacturing engineering, such as process and production planning, machining, scheduling, management, quality control, and numerical control (NC) part programming. Computer-aided design and computer-aided manufacturing are often combined into CAD/CAM systems.This combination allows the transfer of information from the design stage into the stage of planning for the manufacturing of a product, without the need to reenter the data on part geometry manually. The database developed during CAD is stored; then it is processed further, by CAM, into the necessary data and instructions for operating an controlling production machinery, material-handling equipment, and automated testing and inspection for product quality.Rationale for CAD/CAMThe rationale for CAD/CAM is similar to that used to justify any technology-based improvement in manufacturing. It grows out of a need to continually improve productivity, quality and competitiveness. There are also other reasons why a company might make a conversion from manual processes toCAD/CAM:⑴Increased productivity⑵Better quality⑶Better communication⑷Common database with manufacturing⑸Reduced prototype construction costs⑹Faster response to customersCAD/CAM HardwareThe hardware part of a CAD/CAM system consists of the following components:(1) one or more design workstations,(2) digital computer, (3) plotters, printers and other output devices, and (4) storage devices. In addition, the CAD/CAM system would have a communication interface to permit transmission of data to and from other computer systems, thus enabling some of the benefits of computer integration.The workstation is the interface between computer and user in the CAD system. The design of the CAD workstation and its available features have an important influence on the convenience, productivity, and quality of the user’s output. The workstation must include a graphics display terminal and a set of user input devices. CAD/CAM applications require a digital computer with a high-speed control processing unit (CPU). It contains the main memory and logic/arithmetic section for the system. The most widely used secondary storage medium in CAD/CAM is the hard disk, floppy diskette, or a combination of both.Input devices are generally used to transfer information from a human or storage medium to a computer where “CAD functions” are carried out. There are two basic approaches to input an existing drawing:model the object on a drawing or digitize the drawing. The standard output device for CAD/CAM is a CRT display. There are two major types of CRT displays: random-scan-line-drawing displays and raster-scan displays. In addition to CRT, there are also plasma paneldisplays and liquid-crystal displays.CAD/CAM SoftwareSoftware allows the human user to turn a hardware configuration into a powerful design and manufacturing system. CAD/CAM software falls into two broad categories, 2-D and 3-D, based on the number of dimensions visible in the finished geometry. CAD packages that represent objects in two dimensions are called 2-D software. Early systems were limited to 2-D. This was a serious shortcoming because 2-Drepresentations of 3-Dobjects is inherently confusing. Equally problem has been the inability of manufacturing personnel to properly read and interpret complicated 2-D representations of objects. 3-D software permits the parts to be viewed with the three-dimensional planes-height, width, and depth-visible. The trend in CAD/CAM is toward 3-D representation of graphic images. Such representations approximate the actual shape and appearance of the object to be produced; therefore, they are easier to read and understand.Applications of CAD/CAMThe emergence of CAD/CAM has had a major impact on manufacturing, by standardizing product development and by reducing design effort, tryout, and prototype work; it has made possible significantly reduced costs and improved productivity.Numerical ControlNumerical control (NC) is a form of programmable automation in which the processing equipment is controlled by means of numbers,letters,and other symbols.The numbers,letters,and symbols are coded in an appropriate format to define a program of instructions for a particular workpart or job. Theinstructions are provided by either of the two binary coded decimal systems: the Electronic Industries Association (EIA) code, or the American Standard Code for Information Interchange (ASCII). ASCII-coded machine control units will not accept EIA coded instructions and vice versa. Increasingly, however, control units are being made to accept instructions in either code. Automation operation by NC is readily adaptable to the operation of all metalworking machines. Lathes, milling machines, drill presses, boring machines, grinding machines, turret punches, flame or wire-cutting and welding machines, and even pipe benders are available with numerical controls.Basic Components of NCA numerical control system consists of the following three basic components:(1) Program instructions(2) Machine control unit(3) Processing equipmentThe program instructions are the detailed step by step commands that direct the processing equipment In its most common form,the commands refer to positions of a machine tool spindle with respect to the worktable on which the part is fixed.More advanced instructions include selection of spindle speeds,cutting tools,and other functions.The machine control unit (MCU) consists of the electronics and control hardware that reads and interprets the program of instructions and convert it into mechanical actions of the machine tool or other processing equipment .The processing equipment is the component that performs metal process.In the most common example of numerical control ,it is used to perform machining operations. The processing equipment consists of the worktable and spindle as well as the motors and controls needed to drive them.Types of NCThere are two basic types of numerical control systems:point to point and contouring .Point to point control system, also called positioning, are simpler than contouring control system.Its primary purpose is to move a tool or workpiece from one programmed point to another. Usually the machine function,such as a drilling operation,is also activated at each point by command from the NC Program.Point to point systems are suitable for hole machining operations such as drilling, countersinking,counterboring,reaming,boring and tapping. Hole punching machines,spotwelding machines,and assembly machines also use point to point NC systems.Contouring system,also known as the continuous path system,positioning and cutting operations are both along controlled paths but at different velocities.Because the tool cuts as it travels along a prescribed path ,accurate control and synchronization of velocities and movements are important.The contouring system is used on lathes,milling machines,grinders,welding machinery,and machining centers.Movement along the path,or interpolation, occurs incrementally,by one of several basic methods .There are a number of interpolation schemes that have been developed to deal with the various problems that are encountered in generating a smooth continuous path with a contouring type NC system.They include linear interpolation, circular interpolation, helical interpolation, parabolic interpolation and cubic interpolation. In all interpolations,the path controlled is that of the center of rotation of the tool.Compensation for different tools,different diameter tools,or tools wear during machining,can be made in the NC program.Programming for NCA program for numerical control consists of a sequence of directions that causes an NC machine to carry out a certain operation ,machining being the most commonly used process .Programming for NC may be done by aninternal programming department,on the shop floor,or purchased from an outside source.Also,programming may be done manually or with computer assistance.The program contains instructions and commands.Geometric instructions pertain to relative movements between the tool and the workpiece. Processing instructions pertain to spindle speeds,feeds,tools,and so on.Travel instructions pertain to the type of interpolation and slow or rapid movements of the tool or worktable.Switching commands pertain to on/off position for coolant supplies,spindle rotation,direction of spindle rotation tool changes,workpiece feeding,clamping,and so on. The first NC programming language was developed by MIT developmental work on NC programming systems in the late 1950s and called APT(Automatically Programmed Tools).DNC and CNCThe development of numerical control was a significant achievement in batch and job shop manufacturing,from both a technological and a commercial viewpoint.There have been two enhancements and extensions of NC technology,including:(1) Direct numerical control(2) Computer numerical controlDirect numerical control can be defined as a manufacturing system in which a number of machines are controlled by a computer through direct connection and in real time.The tape reader is omitted in DNC,thus relieving the system of its least reliable component.Instead of using the tape reader,the part program is transmitted to the machine tool directly from the computer memory.In principle,one computer can be used to control more than 100 separate machines.(One commercial DNC system during the l970s boasted a control capability of up to 256 machine tools.) The DNC computer is designed to provide instructions to each machine tool on demand .When the machine needs control commands ,they are communicated to it immediately.Since the introduction of DNC ,there have been dramatic advances in computer technology.The physical size and cost of a digital computer has been significantly reduced at the same time that its computational capabilities have been substantially increased.In numerical control,the result of these advances has been that the large hard-wired MCUs of conventional NC have been replaced by control units based on the digital computer.Initially,minicomputers were utilized in the early 1970s .As further miniaturization occurred in computers ,minicomputers were replaced by today’s microcomputers.Computer numerical control is an NC system using dedicated microcomputer as the machine control unit .Because a digital computer is used in both CNC and DNC,it is appropriate to distinguish between the two types of system.There are three principal differences:(1) DNC computers distribute instructional data to,and collect data from, a large number of machines.CNC computers control only one machine,or a small number of machines.(2) DNC computers occupy a location that is typically remote from the machines under their control. CNC computer are located very near their machine tools.(3) DNC software is developed not only to control individual pieces of production equipment, but also to serve as part of a management information system in the manufacturing sector of the firm. CNC software is developed to augment the capabilities of a particular machine tool.中文翻译:工程公差引言固体由其表面边界确定界限。

汤soup羹soup高汤thin soup; light soup; clear soup; consommé清汤thin soup; light soup; clear soup; consommé浓汤thick soup; pottage/potage老汤soup stock肉汤broth骨头汤bone broth肉片汤soup with meat slices黄瓜肉片汤soupwith meat and cucumberslices肉片鱼羹slicedmeat with fish paste inbroth丸子汤soup withmeat balls; pork ballssoup氽丸子soup withmeat balls; pork ballssoup肉圆粉丝汤porkballs soup with beannoodles白肺汤pork lungsoup牛肉汤beef soup羊肉汤muttonsoup鸡汤chicken soup;soup with chicken鸡块汤soup withchicken slices; soup withsliced chicken;sliced chicken soup鸡丝汤soup withshredded chicken;shredded chicken soup草菇鸡片汤slicedchicken with mushroomsin soup鸡茸玉米汤cornsoup with mincedchicken鸡茸芦笋汤asparagus soup with mashed chicken鸡茸黄鱼羹yellow croaker potage with minced chicken鸡杂汤chicken giblets soup鸡什汤chicken giblets soup蔬菜鸡什汤chicken giblets soup with vegetables鸭汤duck soup火鸭芥菜汤sliced roasted duck with leaf mustered in soup芥菜鸭汤duck soup with pickled mustard leaves鸭掌汤duck web soup竹笋鸭掌汤duck’s feet with bamboo shoots in soup鸭肝汤duck liver soup冬菇鸭杂汤duck giblets soup with black mushrooms鸭骨菜汤duck bone soup with vegetables汤泡肫球gizzardballs in soup三鲜汤soup withfish, shrimps and porkballs红鱼汤fish soupwith tomato黄鱼羹yellowcroaker chowder鲫鱼汤soup withgold carp; gold carp soup鱼翅汤soup withshark’s fins鲍鱼汤soup withabalone; abalone soup鲍鱼鸡片汤abalone soup with slicedchicken鲍鱼芦笋汤abalone soup withasparagus干贝汤driedscallop soup; soup withdried scallops燕窝汤bird‘s nestsoup燕窝羹bird‘s nestsoup蛇羹snake soup;soup with snake酸辣汤sour andpepper hot soup豆腐汤bean-cudsoup蔬菜汤vegetablessoup榨菜汤hot pickledtuber mustard soup榨菜肉丝汤hotpickled tuber mustardsoup with shredded pork榨菜粉丝汤hotpickled tuber mustardsoup with bean noodles什锦瓜丁汤assorted meat soup withdiced white gourd鸡蛋羹steamedegg custard鸡蛋汤eggdropsoup; egg soup木须汤eggdropsoup; egg soup蛋花汤eggdropsoup; egg soup蕃茄鸡蛋汤eggsoup with tomatoes锅巴口蘑汤mushroom soup withfried rice crust白豆汤white bean soup玉米羹sweet corn soup面食cooked wheaten food面食cooked wheaten food; food made of flour馒头steamed bread; steamed bun白面馒头steamed bread; steamed bun一屉馒头 a trayful of steamed bread; a trayful of steamed buns馒子steamed bread; steamed bun馍馍steamed bread; steamed bun白面馒steamed bread; steamed bun花卷steamed twisted roll; steamed roll蒸饼steamed cake发面饼leavened pancake烙饼unleavened pancake; flapjack家常饼home-stylepancake薄饼thin pancake荷叶饼lotus-leaf-like pancake; thinpancake锅饼thick pancake饼卷pancake roll葱花饼greenChinese onion pancake;green onion pancake炒饼fried shreddedpancake肉饼fried meat pie;meat pie馅饼fried meat pie;meat pie猪肉馅饼friedpork pie; pork pie三鲜馅饼fried piewith shredded sea foods烧饼baked sesame-seed cake芝麻烧饼bakedsesame-seed cake火烧bakedwheaten cake糖火烧bakedsweeten wheaten cake蜂糕steamedsponge cake米糕steamed ricecake; rice budding年糕New Yearcake made of glutinousrice flour凉糕steamed ricecake served cold insummer丝糕steamed corncake窝头steamed cornbread玉米饼子cornpancake煎饼thin pancakemade of millet flour;millet pancake粽子pyramid-shaped dumpling madeof glutinous rice wrappedinbamboo or reedleaves馕crusty pancake面条noodles切面noodles挂面packaged noodles拉面hand-pulled noodles抻面hand-pulled noodles方便面instant noodles即食面instant noodles通心面macaroni通心粉macaroni细通心粉spaghetti意大利式细面条spaghetti细面条spaghetti米粉条rice -flour noodles面汤water in which noodles have been boiled捞面noodles taken out of the boiling water with a strainer肉丝面noodles with shredded meat肉丝拌面noodles with shredded pork炸酱面noodles withchopped meat infried bean sauce;noodles withsoya bean paste打卤面noodles with meatslices in thickgravy;noodlesserved with thickgravy烩面stewednoodles鸡丝烩面stewed noodleswith chickenshreds凉拌面coldnoodles withsauce凉面coldnoodles withchicken shreds鸡丝凉面cold noodles withchicken shreds芝麻酱面cold noodles withsesame paste麻酱面coldnoodles withsesame paste寿面birthday noodlesa.汤面noodles soup汤面noodles soup;noodles in soup肉丝汤面noodles soup withshredded meat鸡丝汤面noodles soup withshredded chicken三鲜汤面noodles soup withshredded seafoodsb.炒面friednoodles炒面friednoodles; ChowMien肉丝炒面fried noodles withshredded meat牛肉炒面fried noodles withbeef牛肉蔬菜炒面fried noodleswith beef andvegetables鸡丝炒面fried noodles with shredded chicken虾炒面fried noodles with shrimps海鲜炒面fried noodles with sea foods海鲜蔬菜炒面fried noodles with sea foods and vegetables蔬菜炒面fried noodles with vegetables包子steamed bun with stuffing包子steamed stuffed bun; steamed bun with stuffing肉包子steamed bun with meat stuffing; steamed bun with minced pork stuffing肉包steamed bun with meat stuffing; steamed bun with minced pork stuffing猪肉包子steamed bun with pork stuffing三鲜包子steamed bunstuffed withshredded seafoods菜包子steamed bun withvegetable stuffing;steamedvegetable stuffedbun素包子steamed bun withvegetable stuffing;steamedvegetable stuffedbun豆沙包steamed bun withsweetened beanpaste;steamed bunstuffed withmashed red bean蒸包steamed bun withstuffing猪肉蒸包steamed bun withpork stuffing三鲜蒸包steamed bunstuffed withshredded seafoods小笼蒸包steamed stuffedbun by smallbamboo foodsteamer小笼包steamed stuffedbun by smallbamboo foodsteamer蒸饺steameddumpling猪肉蒸饺steamed porkdumpling三鲜蒸饺steameddumpling stuffedshredded seafoods锅贴slightly frieddumpling猪肉锅贴slightly fried porkdumpling三鲜锅贴slightly frieddumpling withshredded seafoods肉卷grilledbun with mincedpork stuffing饺子boileddumpling饺子馅stuffing for dumpling; filling for dumpling饺子皮dumpling wrapper饺子汤water in which dumplings have been boiled速冻饺子instant frozen dumpling猪肉饺子boiled pork dumpling三鲜饺子boiled dumpling with shredded sea foods水饺boiled dumpling手工水饺hand-made boiled dumpling机制水饺machine-made boiled dumpling猪肉水饺boiled pork dumpling韭菜水饺boiled dumpling with Chinese chive三鲜水饺boiled dumpling with shredded sea foods红油水饺boiled dumpling with chili/chili oil馄饨wonton; ravioli soup面球dumpling汤包steamed dumpling filled with minced meat and gravy烧卖steamed dumpling with the dough gathered at the top。

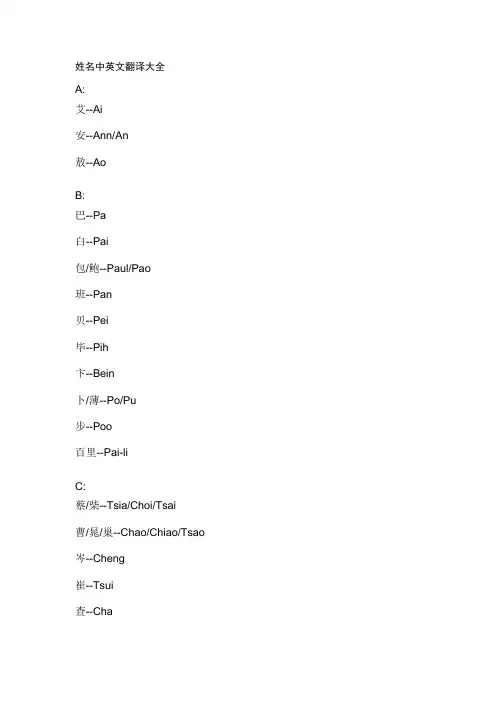

姓名中英文翻译大全A:艾--Ai安--Ann/An敖--AoB:巴--Pa白--Pai包/鲍--Paul/Pao班--Pan贝--Pei毕--Pih卞--Bein卜/薄--Po/Pu步--Poo百里--Pai-liC:蔡/柴--Tsia/Choi/Tsai曹/晁/巢--Chao/Chiao/Tsao 岑--Cheng崔--Tsui查--Cha常--Chiong车--Che陈--Chen/Chan/Tan 成/程--Cheng池--Chi褚/楚--Chu淳于--Chwen-yuD:戴/代--Day/Tai邓--Teng/Tang/Tung狄--Ti刁--Tiao丁--Ting/T董/东--Tung/Tong窦--Tou杜--To/Du/Too段--Tuan端木--Duan-mu东郭--Tung-kuo东方--Tung-fang E:F:范/樊--Fan/Van房/方--Fang费--Fei冯/凤/封--Fung/Fong 符/傅--Fu/FooG:盖--Kai甘--Kan高/郜--Gao/Kao葛--Keh耿--Keng弓/宫/龚/恭--Kung勾--Kou古/谷/顾--Ku/Koo桂--Kwei管/关--Kuan/Kwan 郭/国--Kwok/Kuo公孙--Kung-sun公羊--Kung-yang公冶--Kung-yeh谷梁--Ku-liangH:韩--Hon/Han杭--Hang郝--Hoa/Howe何/贺--Ho桓--Won侯--Hou洪--Hung胡/扈--Hu/Hoo花/华--Hua宦--Huan黄--Wong/Hwang霍--Huo皇甫--Hwang-fu呼延--Hu-yenI:J:纪/翼/季/吉/嵇/汲/籍/姬--Chi 居--Chu贾--Chia翦/简--Jen/Jane/Chieh蒋/姜/江/--Chiang/Kwong金/靳--Jin/King景/荆--King/Ching讦--GanK:阚--Kan康--Kang柯--Kor/Ko孔--Kong/Kung寇--Ker蒯--Kuai匡--KuangL:赖--Lai蓝--Lan郎--Long劳--Lao乐--Loh雷--Rae/Ray/Lei冷--Leng黎/郦/利/李--Lee/Li/Lai/Li 连--Lien梁--Leung/Liang林/蔺--Lim/Lin凌--Lin柳/刘--Liu/Lau龙--Long楼/娄--Lou卢/路/陆鲁--Lu/Loo伦--Lun罗/骆--Loh/Lo/Law/Lam/Rowe 吕--Lui/Lu令狐--Lin-hooM:马/麻--Ma麦--Mai/Mak满--Man/Mai毛--Mao梅--Mei孟/蒙--Mong/Meng米/宓--Mi苗/缪--Miau/Miao闵--Min穆/慕--Moo/Mo 莫--Mok/Mo万俟--Moh-chi慕容--Mo-yungN:倪--Nee甯--Ning聂--Nieh牛--New/Niu农--Long南宫--Nan-kung欧/区--Au/Ou欧阳--Ou-yangP:潘--Pang/Pan庞--Pang裴--Pei/Bae彭--Phang/Pong 皮--Pee平--Ping浦/蒲/卜--Poo/Pu濮阳--Poo-yangQ:祁/戚/齐--Chi/Chyi/Chi/Chih 钱--Chien乔--Chiao/Joe秦--Ching裘/仇/邱--Chiu屈/曲/瞿--Chiu/ChuR:冉--Yien饶--Yau任--Jen/Yum容/荣--Yung阮--Yuen芮--NeiS:司--Sze桑--Sang沙--Sa邵--Shao单/山--San尚/商--Sang/Shang沈/申--Shen盛--Shen史/施/师/石--Shih/Shi苏/宿/舒--Sue/Se/Soo/Hsu 孙--Sun/Suen宋--Song/Soung司空--Sze-kung司马--Sze-ma司徒--Sze-to单于--San-yu上官--Sang-kuan申屠--Shen-tuT:谈--Tan汤/唐--Town/Towne/Tang 邰--Tai谭--Tan/Tam陶--Tao藤--Teng田--Tien童--Tung屠--Tu澹台--Tan-tai拓拔--Toh-bahU:V:W:万--Wan王/汪--Wong魏/卫/韦--Wei温/文/闻--Wen/Chin/Vane/Man 翁--Ong吴/伍/巫/武/邬/乌--Wu/NG/Woo X:奚/席--Hsi/Chi夏--Har/Hsia/(Summer)肖/萧--Shaw/Siu/Hsiao项/向--Hsiang解/谢--Tse/Shieh辛--Hsing刑--Hsing熊--Hsiung/Hsiun许/徐/荀--Shun/Hui/Hsu宣--Hsuan薛--Hsueh西门--See-men夏侯--Hsia-hou轩辕--Hsuan-yuenY:燕/晏/阎/严/颜--Yim/Yen杨/羊/养--Young/Yang姚--Yao/Yau叶--Yip/Yeh/Yih伊/易/羿--Yih/E殷/阴/尹--Yi/Yin/Ying应--Ying尤/游--Yu/You俞/庾/于/余/虞/郁/余/禹--Yue/Yu袁/元--Yuan/Yuen岳--Yue云--Wing尉迟--Yu-chi宇文--Yu-wenZ:藏--Chang曾/郑--Tsang/Cheng/Tseng訾--Zi宗--Chung左/卓--Cho/Tso翟--Chia詹--Chan甄--Chen湛--Tsan张/章--Cheung/Chang赵/肇/招--Chao/Chiu/Chiao/Chioa 周/邹--Chau/Chou/Chow钟--Chung祖/竺/朱/诸/祝--Chu/Chuh庄--Chong钟离--Chung-li诸葛--Chu-keh。

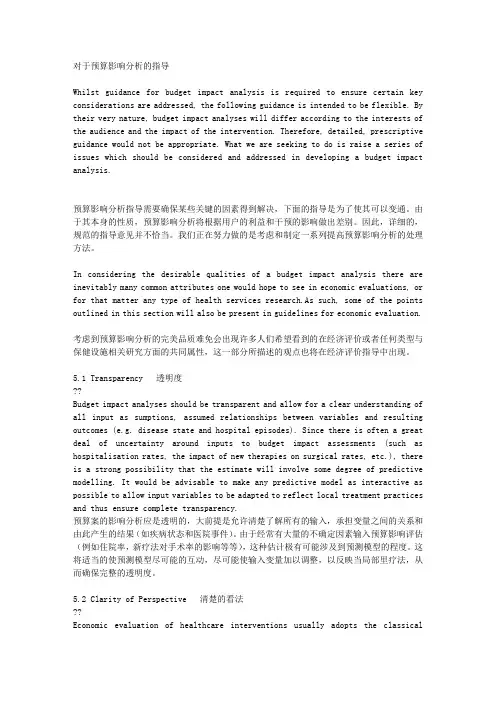

对于预算影响分析的指导Whilst guidance for budget impact analysis is required to ensure certain key considerations are addressed, the following guidance is intended to be flexible. By their very nature, budget impact analyses will differ according to the interests of the audience and the impact of the intervention. Therefore, detailed, prescriptive guidance would not be appropriate. What we are seeking to do is raise a series of issues which should be considered and addressed in developing a budget impact analysis.预算影响分析指导需要确保某些关键的因素得到解决,下面的指导是为了使其可以变通。

由于其本身的性质,预算影响分析将根据用户的利益和干预的影响做出差别。

因此,详细的,规范的指导意见并不恰当。

我们正在努力做的是考虑和制定一系列提高预算影响分析的处理方法。

In considering the desirable qualities of a budget impact analysis there are inevitably many common attributes one would hope to see in economic evaluations, or for that matter any type of health services research.As such, some of the points outlined in this section will also be present in guidelines for economic evaluation.考虑到预算影响分析的完美品质难免会出现许多人们希望看到的在经济评价或者任何类型与保健设施相关研究方面的共同属性,这一部分所描述的观点也将在经济评价指导中出现。

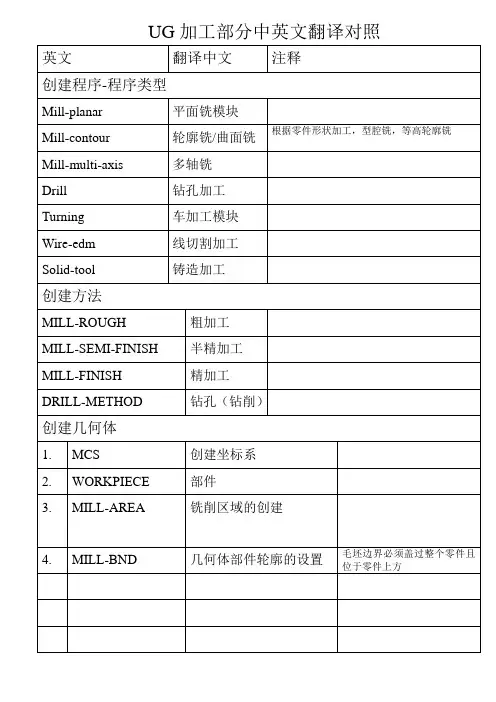

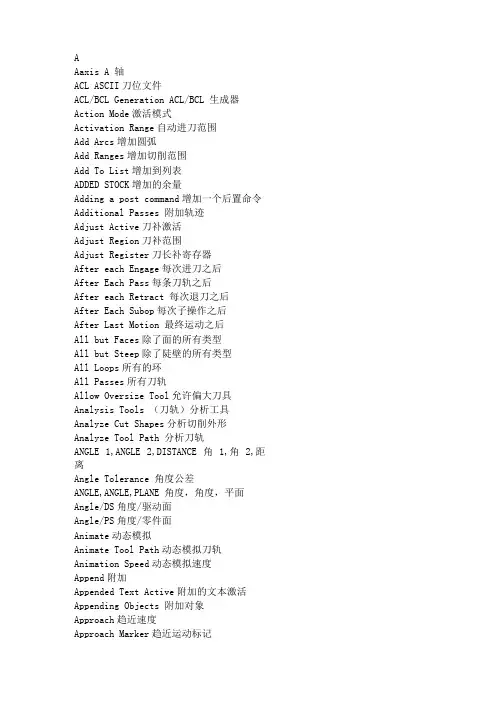

AAaxis A 轴ACL ASCII刀位文件ACL/BCL Generation ACL/BCL 生成器Action Mode激活模式Activation Range自动进刀范围Add Arcs增加圆弧Add Ranges增加切削范围Add To List增加到列表ADDED STOCK增加的余量Adding a post command增加一个后置命令Additional Passes 附加轨迹Adjust Active刀补激活Adjust Region刀补范围Adjust Register刀长补寄存器After each Engage每次进刀之后After Each Pass每条刀轨之后After each Retract 每次退刀之后After Each Subop每次子操作之后After Last Motion 最终运动之后All but Faces除了面的所有类型All but Steep除了陡壁的所有类型All Loops所有的环All Passes所有刀轨Allow Oversize Tool允许偏大刀具Analysis Tools (刀轨)分析工具Analyze Cut Shapes分析切削外形Analyze Tool Path 分析刀轨ANGLE 1,ANGLE 2,DISTANCE 角1,角2,距离Angle Tolerance 角度公差ANGLE,ANGLE,PLANE 角度,角度,平面Angle/DS角度/驱动面Angle/PS角度/零件面Animate动态模拟Animate Tool Path动态模拟刀轨Animation Speed动态模拟速度Append附加Appended Text Active附加的文本激活Appending Objects 附加对象Approach趋近速度Approach Marker趋近运动标记Aquamarine 蓝绿色Arc Center Probe圆心自动定位Arc Output Type圆弧输出类型Arc:Normal Tool axis圆弧:垂直刀具轴 Arc:Parallel to Cut圆弧:平行切削方向 Arc:Parallel Tool axis圆弧:平行刀具轴 Area Centroid 面积质心Area Milling Drive区域铳削驱动Area Milling区域铳削As Final与最终相同As Initial与最初相同At Angle to DS与驱动面成角度At Angle to PS与零件面成角度Automatic自动的Auxfun辅助功能Auxfun Value辅助功能值Available Functions 有效功能Avoid避让AVOID CLEARANCE避让安全平面Avoidance Geometry 避让几何体Away From Line 远离线Away From Point 远离点Axis 轴Axis Off轴关闭Axis On轴开启BBackburn 反切口Bad Chains无效的链接Bad Segments无效的段Bandwidth 带宽Barrel Cutter 鼓形刀Baxis B 轴BCL二进制文件Before 1st Motion第一次运动之前Before each Engage每次进刀之前Before each Retract每次退刀之前Blank Boundary 毛坯边界Blank Distance 毛坯距离Blank Geometry毛坯几何体Blank Shape毛坯外形Blank Stock毛坯余量Blank 毛坯Blind Hole 盲孔Blue蓝色Boring Radius切削刃到车刀轴距离Bottom Regions 底部区域Bottom Surface 底部曲面Boundary Approximation 边界近似Boundary Drive Method 边界驱动方法Boundary Face 边界面Boundary Name 边界名Boundary Type边界类型Boundary 边界Break Chip断削钻Break_corner打断拐角Brown褐色By Name通过名称(过滤)By Tool通过刀具(过滤) CCAM customization CAM 客户化CAM Object CAM 对象CAM Setup CAM 设置CAM Undo Mark CAM 撤消标记Case情形Catalog Number 目录号Cavity Mill 型腔铳Caxis C 轴CCLW逆时针Center中心Chain链接Check检查Check Boundary 检查边界Check Geometry检查几何体Check Shape检查外形Check Stock检查余量Chip Removal切屑去除(方法)Chord tolerance 弦公差Circular Feedrate Compensation 圆弧进给速度补偿Circular-Perp to TA圆弧所在平面垂直于刀具轴(圆弧格式输出)Circular-Perp/par to TA圆弧所在平面垂直或平行于刀具轴(圆弧格式输出)Clamp夹紧Clamp Axis锁紧轴Clamp Status锁紧状态Class Selection 分类选择Cleanup Geometry 清理几何体Cleanup Output清理(几何体)输出Cleanup Output Control清理(几何体)输出控制Clearance安全距离Clearance Geometry 安全几何体Clearance Plane 安全平面CLEARANCE PLANE,DISTANCE 安全平面,距离Climb Cut 顺铳Closed封闭CLSF Actions刀具位置源文件功能CLSF Manager刀具位置源文件管理器CLSF Name刀具位置源文件名CLSF(Cutter Location Source File)刀具位置源文件CLW顺时针CNC (Computerized Numerical Control)计算机数字控制Collect Instances 搜集阵列Collision 碰撞Collision check 碰撞检查Commentary 注释Concave Corner 凹角Concentric Arcs 同心圆弧Configuration File 配置文件Configuration 酉己置Connection Method 连接方法Consistency Check 连续检查Constant 常量Construct Point 构造点Cont. Path连续轨迹Contact (Tool Position)接触(刀具位置)Contact Boundary 接触边界CONTACT DIRECTION 接触方向CONTACT DISTANCE 接触距离Continuous Path Motion 连续刀轨运动Control Points (进刀)控制点Conventional Cut 逆铳Convex Corner 凸角Coolant Off冷却液关Coolant On冷却液开Coordinate 坐标Corner and Feed Rate Control拐角和进给速度控制Corner Angle拐角角度Corner Control 拐角控制Corner Control Angles 拐角控制角Corner Loop Radius 拐弯半径Corner Radius拐角半径Corner Type拐角类型Create Next Boundary 创建下一边界Cs Becomes Ds检查面作为驱动面Cs Becomes Ps检查面作为零件面Current Level当前(切削)层Current Range 当前范围Curve Drive Method曲线驱动方法Curve,Directrix 曲线,准线Curve/Point曲线/点(驱动)Custom Boundary自定义边界参数Custom Member Data自定义(边界)元素数据CUSTOM SURFACE自定义曲面CUSTOM TOOL AXIS自定义刀具轴Customize Dialog客户化对话框Customizing 客户化Cut Angle切削角Cut Area切削区域Cut Depth切削深度Cut Feed Unit切削速度单位Cut Feedrate切削速度Cut Level切削层Cut Method切削方法Cut Order切削顺序Cut Region切削区域Cut Region Display切削区域显示Cut Region Start Point切削区域起始点Cut Step切削步长Cut Type切削类型Cut 切削CUTCOM刀直径补CUTCOM Parameters刀直径补参数Cutcom Register刀直径补寄存器Cutfeed type切削速度类型Cutoff切断Cutoff Status切断状态Cutoff Stock切断余量Cutter Compensation 刀具补偿Cutter Diameter Compensation 刀具直径补偿Cutter Length Compensation 刀具长度补偿Cutting切削(参数)Cutting Move切削运动Cutting Parameters 切削参数Cyan青色Cycle Definition Events固定循环定义事件Cycle Events固定循环事件Cycle Move Events固定循环运动事件Cycle Parameter固定循环参数Cycle Parameter Set固定循环参数组Cycle固定循环DDark Red 暗红Dashed Center刀轨虚线(显示)Data All Chains所有数据链接Data Current Chain当前数据链接Default 缺省Defined Functions 定义的功能Definition File Elements 定义文件要素Definition File 定义文件Delay延迟Departure (刀具)离开Depth First深度优先Depth Offset深度偏置Depth Per Cut每刀切削深度Description 描述Deselect All Members取消选择所有元素Deselect Last Member取消选择最后元素Destination point 目标点Diameter 直径Direction 方向Direction Vector 方向矢量Directional Steep 加工陡峭面Directrix 准线Display 显示DISPLAY ARC AND SHEET HOLE显示圆弧和片体孔Display Cut Direction 显示切削方向Display Drive Path显示驱动轨迹Display Options 显示选项DISPLAY,REVERSE 显示,反向DISPLAY/VERIFY 显示/验证DISTANCE 距离Downward 向下Draft Angle拔模角度DRILL钻肖I」Drilling Geometry 钻削几何体Drilling Tool 钻头Drive Boundary 驱动边界Drive Curve Lathe驱动曲线车削Drive Geometry驱动几何体Drive Method驱动方法DRIVE SURFACE 驱动面DS LOOP PARAMETERS驱动面循环参数Dual 4-Axis on Drive双四轴于驱动面上Dual 4-Axis on Part双四轴于零件面上Dumb Objects非关联对象Dwell暂停Dwell Time暂停时间Dynamic Material Removal 动态材料去除 EEdit Display编辑显示Edit Postprocessing编辑后置处理Edit Status编辑状态Editing a post command 编辑一个后置命令End first %最初结束百分比End last %最后结束百分比End Operation结束操作End Point 端点End-Of-Path刀轨结束End-of-Path Commands 刀轨结束命令END-OF-TOOL-PATH 刀轨结束Engage /Retract进刀/退刀方法ENGAGE ANGLE/ANGLE/DISTANCE 进刀角度/角度/距离ENGAGE ANGLES进刀角度Engage Motion进刀运动ENGAGE POINT 进刀点ENGAGE TOOL AXIS进刀刀具轴ENGAGE VECTOR进刀矢量Engage进刀Entity Subtype实体子类型Entity Type实体类型Entrance Diameter 沉孔直径Environment 环境Event事件Event Generator事件生成器Event Handler事件处理器Excess Material 剩余材料Exclude Face排除的面Expand扩张Ext.Tan相切延伸Extend延伸Extend at Convex Corner 在凸角处延伸Extend open boundary 延伸开口边界Exterior Edges 外部边缘 FFace Geometry面几何体Faces & Curves面和曲线Facing面铳Fan扇形Far Side 远侧Feed per Tooth每齿进给量Feed Rate Output Mode速度输出模式Feed Unit速度单位Feedrate进给速度Feeds and Speeds进给速度和面速度Fillet Radius圆角半径Filter Methods 过滤方法Final最终Final Event最终事件Final Retract最终退刀FINAL STOCK最终余量Finish Cutting 精加工Finish Only只精加工Finish Pass精加工刀轨Finish Stock精加工余量Finished Preview 结束预览First Cut首刀(进给量)First Cut/Last Cut第一刀轨迹/最后一刀轨迹Fixed Contour固定轴曲面轮廓铳Fixed Depth固定深度FIXED POINT 固定点Fixed Tool固定的刀具Fixed Tool Axis固定的刀具轴Fixture 夹具Fixture Offset夹具偏置(号)Fl Stck/Min Clr零件底面余量/最小安全距离Flip Material材料反向Flip Material Side 材料侧反向Flood流水状(冷却液形式)Floor底面Floor & Island Tops切削底平面和各岛屿的顶面Floor Only只切削底平面Floor Plane 底平面Floor Same As Side底面和侧壁(余量)一致Flow Cut - Cut清根切削-切削Flow Cut - Cut Method清根切削-切削方法Flow Cut - Hookup Distance清根切削-连接距离Flow Cut - Manual Assembly清根切削-手工组合Flow Cut - Max concavity清根切削-最大凹度Flow Cut - Min Cut Length清根切削-最小切削长度Flow Cut - Number of offsets清根切削-刀轨偏置条数Flow Cut - Offset Mode清根切削-刀轨偏置模式Flow Cut - Output Type清根切削-输出形式Flow Cut - Overlap清根切削-重叠距离Flow Cut - Reference清根切削―参考刀具(直径) Flow Cut - Sequencing清根切削-刀轨顺序Flow Cut - Stepover清根切削—步距Flow Cut清根切削Flute Length刀刃长度Follow Boundary沿着边界方向Follow Check Geometry沿着检查几何体Follow Part仿形零件Follow Periphery仿形外轮廓Follow Pocket仿形内腔Follow Predrill Points 沿着预钻孔点Follow Start Points 沿着起始点Format 格式FORWARD 向前FPM/FPR每分钟…英尺/每转…英尺Frequency 频率FROM A POINT起始于一点From Marker从点标记From从点Full Cutcom Output完全刀补输出Full Feed Rates完全进给速度 GGenerate 生成Generate ISO CLF生成ISO刀位轨迹文件Generate STD CLF生成标准的刀位轨迹文件Generate Tool Path生成刀位轨迹Generic Plane通用平面Generic Point 通用点Geometry几何体Geometry Groups 几何体组Geometry objects 几何体对象Geometry Type几何体类型Geometry View几何体视图Gohome 回零点GOTO转移到Gouge Check Area过切检查区域Gouge Check过切检查Gouges Detected 过切探测Graphical Editor图形编辑器Graphical Postprocessing Module (GPM)图形后处理模块Gray灰色Green绿色GROOVE 槽Grooving Tool 车槽刀Group 组HHead主轴头Head Designation主轴头选择Heel Angle 后角Helical按螺旋线(斜坡进刀)Helical: Climb螺旋线:顺铳Helical: Conventional 螺旋线:逆铳Highlight 高亮Hin Value锥度刀从刀尖沿着刀轴的垂直距离Holder Length装夹台长度Holder Width装夹台宽度Hookup Distance 连接距离HORIZONTAL CLEARANCE 水平间隙Horizontal Limit 水平限度II direction I 方向Ignore Chamfers 忽略倒角Ignore Holes 忽略孔Ignore Islands 忽略岛屿Ignore Loops 忽略环IN ALL TOOL PATHS在所有刀轨中IN LAST TOOL PATH ONLY只在最后一条刀轨中Inches英寸Increment 增量Incremental Side Stock 侧壁余量增量Incremental Stock 余量增量Info信息Inheritance 继承Initial 初始Initial Engage 初始进刀Initial Event初始事件INITIAL STOCK初始余量Initialize 初始化Input File Name输入文件名Input Units输入单位Insert插入Insert Angle车槽刀角度Insert Width车槽刀宽度Inside内部Inside-Out由内向外Internal Engage 内部进刀Internal Error 内部错误Internal Retract 内部退刀Internal_lift 内部抬刀Interpolate 插补Intol内公差Invalid CLSF specified 无效的 CLSF 指定Invalid configuration 无效的配置INVALID END AXIS结束刀轴无效INVALID END POINT结束点无效Invalid Feed无效的速度Invalid setup template无效的模板设置INVALID START AXIS起始刀轴无效INVALID START POINT 起始点无效Invalid Tool无效刀具Invalid Tool Pattern无效的刀具模式Inward向里Ipm每分钟…英寸Ipr每转…英寸Island Boundary 岛屿边界Island Cleanup 岛屿清理Island岛屿JJ direction J 方向Join Segments 连接段kk direction K 方向LLargest Loop 最大环Laser激光Last Cut最后一刀(轨迹)Lathe Control车削控制Lathe Cross-Section横切面(用于车削)LATHE DRILL车削钻孔LATHE DRIVE CURVE车削驱动曲线Lathe Finish 精车Lathe Groove 车槽Lathe Rough 粗车Lathe Thread 车螺纹Layer/Layout层/视图布局Lead引导Lead Angle 前角Lead In Point 弓|入点Lead in/ Lead Out 引入/引出Lead Out Point 引出点LEAD/LAG(DEGREES)前导角和后导角Left左侧Left Radius 左半径Length长度Level First水平优先Levels At Island Tops切削各岛屿的顶面Libraries 库Lift at Convex Corner 在凸角处抬刀Lifts抬刀Line End Points 直线的端点Line Printer行式打印机Linear线性的Linear Only直线格式(输出)Link MCS/RCS链接加工坐标系/参考坐标系List列表显示List ACL列表显示ACLList All Chains列表显示所有链接List BCL列表显示BCLList Current Chain列表显示当前链接List Tool Path列表显示刀位轨迹Listing Options歹列表选项Listing Output 列表输出Local局部Local Engage/Retract 局部进刀/退刀Local Return局部退刀Longest Line最长直线Loop 环LOOP CONTROL循环控制loop in face在面中的环Loop Type环类型Lower Limit Plane 低限平面Lower Plane最低平面Lower Radius最小半径LPT行式打印机文件MMachine Control 加工控制Machine Control Events 机床控制事件Machine Data File Generator (MDFG)机床数据文件生成器Machine Tool 机床Machine Tool Kinematics 机床运动学Machine Tool Motion Control 机床运动控制Machine Tool Type Options 机床类型选项Machine Tool View 刀具视图Machining Environment 力口工环境Machining Method 力口工方法Machining Method View 力口工方法视图Machining Parameters 加工参数Magenta洋红色Manufacturing 制造(加工)Manufacturing Output Manager (MOM)加工输出管理器Material Retained 材料保留侧Material Side 材料侧Max Concavity最大凹度Max Depth最大深度Max Stepover最大步距Max. Corner Angle最大拐角角度Max. Tool Axis Change最大刀具轴改变Maximum Diameter 最大直径Maximum Height 最大高度Maximum RPM 每分钟最高转速Maximum RPM Active每分钟最高转速激活MCS (Machine Coordinate System)加工坐标系MCS Origin加工坐标系原点MCS Rotate加工坐标系旋转MDF (Machine Data File)机床数据文件MDF Defined机床数据文件定义MDF Name机床数据文件名Member元素,成员Method Groups 方法组Method Objects 方法对象Mid Point 中点Mill铳削Mill Area铳削区域Mill Boundary铳削边界Mill Control铳削控制MILL DRIVE CURVE铳削驱动曲线Mill Geometry铳削几何体Millimeters 毫米Milling Tool 铳刀Min Clearance最小间隙Min Cut Length最小切削长度Min Stepover最小步距Min. Tool Axis Change最小刀具轴改变Minimum Angle 最小角度Minimum Clearance Distance 最小安全距离Minimum Diameter 最小直径Minimum Move最小运动距离Missing END-OF-PATH缺少轨迹结束语句Mist薄雾状(冷却液形式)Mmpm每分钟…毫米Mmpr每转…毫米Modify Boundary End修改边界末端Modify Boundary Start 修改边界始端Modify Ranges修改范围More Drive Parameters 更多驱动参数Motion Output运动输出格式Move Control运动控制Move Down向下运动Move Events运动事件Move Status运动状态Move Up向上运动Movement 运动形式Multi-Depth Cut 多层切削Multiple Offsets 多层偏置NNC (Nunerical Control)数控NC Output NC 输出NC Postprocessing NC 后置处理Near Side 近侧Next Boundary 下一边界Next Chain 下一链接NEXT CUT DIRECTION 下一切削方向Next Member 下一成员Next Segment 下一段No APP_BND无附加的边界No APP_BND_MEMBER无增加的边界成员No Cycle无固定循环No Display无显示No Gouges无过切NO POINTS TO DISPLAY 没有点显示NO POINTS TO OMIT没有点可以省略NO POINTS TO OPTIMIZE没有点可以优化NO POINTS TO REVERSE没有点可以反向NO TOOL PATHS IN CLSF CLSF中没有刀位轨迹Non Cutting Control 非切削控制Non-cutting Move非切削运动Non-Steep (加工)非陡峭面Non-steep Face 非陡峭面Normal to Drive垂直于驱动面Normal to DS垂直于驱动面Normal to Part垂直于零件面Normal to PS垂直于零件面Nose Radius球头半径Not Specified没有指定Number of Flutes切削刃条数(齿数)Number of Offsets 偏置数目Number of Passes 轨迹数目Number of Steps 步长数目Nurbs Motion Nurbs 运动Nurbs (Non Uniform Rational B-spline) Nurbs 格式输出(非均匀有理 B 样条)OOff关闭Offset偏置Offset/Gouge刀具偏置/过切检查Olive橄榄色Omit忽略On (Tool Position)在刀具中心位置上On Lines按直线(斜坡进刀)On Shape按外形(斜坡进刀)On Surface在曲面上On Wall在周壁上ONT (Operation Navigation Tool )操作导航工具Open开口,打开Operation Generation 操作生成器Operation objects 操作对象Operation Transform 操作转换Operation 操作Operator Message操作者提示Optimize 优化Optimize Path优化轨迹Optimize Ponits 优化点Optional Skip Off程序跳段结束Optional Skip On程序跳段开始Orange橙色Orient Angle定向角度Origin原点Output File输出文件Output File Validation 输出文件有效Output Plane输出(插补)平面Output Register Number 输出寄存器号Outside 外部Outside-In由外向内Outtol外公差Outward 向外Overlap 重叠Overlap Distance 重叠距离Oversize Tool偏大刀具PPaint Arrows描绘箭头Paint Display描绘显示Paint Feeds描绘速度Paint Line Numbers 描绘行号Paper Tape 纸带Parallel Lines 平行线Parallel to PS平行于零件面Parallet to DS平行于驱动面Parameter Groups 参数组PARAMETER LINE 参数线PARAMETER SET参数设置Parameters 参数Parent父节点Part零件Part Boundary零件边界Part Containment零件边界控制Part Floor Stock零件底部余量Part Geometry零件几何体Part Intol零件内公差Part Material零件材料Part Outol零件外公差Part Shape零件外形Part Side & Floor零件侧边和底面Part Side Stock零件侧面余量Part Stock零件余量Part Stock Offset零件余量偏置Part Surface 零件面PARTNO零件号Path Display刀轨显示Pattern刀夹,切削模式Pattern Center同心圆模式中心Pattern File Name刀夹文件名Pattern frequency刀夹(显示)频率Pause After Display 显示后暂停Pause After Each每条(刀轨)显示后暂停Peck Drill 啄钻Per Minute每分钟Per Step每步长Percent百分比Percent Tool刀具直径百分比Perform Gouge执行过切检查Permanent Boundary 永久边界Pink粉红色Planar Milling 平面铳Plane Matrix平面矩阵Plane Origin平面原点Plane Type平面类型Plunge插入Pocket Direction 内腔方向Pocket内腔Point Angle 顶尖角Point Boundary 点边界Point Coordinates 点坐标Point to Point Motion 点至“点运动Point to Point点位加工POINTS ONLY, ARCS ONLY, HOLES 仅点,仅圆弧,孔Post Command Dialog后置命令对话框Post Commands后置命令Post Commands At End刀轨结束后的后置处理命令Post Commands At Start刀轨开始前的后置处理命令Postprocess后置处理Postprocess Name后置处理名Postprocessor后置处理器Postprocessor Name后置处理器名Power功率Pre-Drill Engage Points 预钻孔进刀点Predrill Points 预钻孔点Pre-Drill预钻孔Preferences 预设置Prefun准备功能Prefun Value准备功能值preloaded预装载Prepare Geometry准备几何体Preprocess 预处理Preview Region 预览区域Previous 预览Previous Check Surface 先前的检查面Previous Drive Surface 先前的驱动面Previous Part Surface 先前的零件面Previous Tool 前一把刀具Process 过程Process Display 过程显示Profile 轮廓Program Groups 程序组Program objects 程序对象Program Order View程序顺序视图Program 程序Proj DS Normal沿驱动面法向投射Proj PS Normal沿零件面法向投射Projection Vector 投射矢量PS LOOP PARAMETERS零件面循环参数PTP后处理过的文本文件Punch冲床,冲孔Purple紫色RRadial Cut射线状切削Radial Cut Drive射线状切削驱动Radial Lines 射线Ramp Angle斜坡角度Ramp Down Angle向下斜坡角度Ramp Type斜坡进刀类型Ramp Up Angle向上斜坡角度Ramping 斜坡Range切削范围Range Bottom切削范围底部Range Depth切削范围深度Range Selection切削范围选择Range Top切削范围顶部Rapid快速进给速度Rapto Offset快进偏置RCS (Reference Coordinate System)参考坐标系Rebuild Topology重建拓扑关系Red红色Redisplay Tool重新显示刀具Reference 参考Reference Tool Offsets 参考刀具偏置Refresh 刷新Refresh Before Display 显示前刷新Refresh Before Each每条刀轨显示前刷新Regenerate重新生成Region Connection 区域连接Region Sequencing切削区域的顺序Region Type区域类型Register Number (刀具补偿)寄存器号Reinitialize重新初始化Reject拒绝Relative to Drive相对于驱动面Relative to Part相对于零件面Relative to Vector相对于矢量方向Relocate Parameters重新设置参数Remove Boundary 移去边界Remove Current Range移去当前切削范围Remove Edge Trace移去边缘刀轨Remove Last移去最后的Remove Member移去成员Renumber重编号Replace/Add替换/增加Replay重新显示Reposition 重定位Reposition Engage/Retract 重定位进刀/退刀Repost重新后置处理Resequence Regions重新排列区域顺序Reset重新设置,复位Reset All重新设置所有的Reset from Table从表中重新设置Reset to Default重新设置为缺省Reset to Original重新设置为最初的Respecify Tool重指定刀具Restore Original Csys恢复原始坐标系Retract Angles 退刀角度Retract Clearance退刀安全高度Retract Motion 退刀运动Retract plane退刀平面Retract Point 退刀点Retract Vector 退刀矢量Retract 退刀Retrieve 恢复Retrieve Global 恢复全局Retrieve Tools 恢复刀具Return刀具返回Reverse All所有反向Reverse Arc and Sheet Hole圆弧和片体孔反向Reverse Boundary边界方向反向Right右侧Right Radius 右半径Ring Height环状高度Ring Radius环状半径Rotate旋转Rotation Angle Active 旋转角激活Rough & Finish粗加工和精加工Rough Only仅粗加工Rough Operation粗加工操作Rough Pass粗加工刀轨Rough Pass & Backburn粗加工刀轨和反切口Rough - To - Depth粗加工至1」深度RPM每分…转RTRCTO退刀到(距离)SSafe Clearance 安全距离Same As CLS 与CLS 相同Same As Drive Path与驱动刀轨(刀具轴)相同Same Start And End Axis与开始和结束刀轴矢量相同Same Start and End Point与开始和结束点相同Sample样例Save 3D存贮三维模型Save As Global存贮为全局Save Current Csys存贮当前的坐标系Save Failed存贮失败Save/Restore Csys存贮/恢复坐标系Scallop Height 残留高度Seed Face种子面Segment Consistency 段连续SEL END POINT选择终点SEL START POINT 选择起点Select a Group 选择一个组Select Adjacent Faces 选择相邻面Select chain end选择链接末端Select chain start选择链接始端Select Head选择主轴头Select Holes 选择孔Select Next Row 选择下一行Selection Method 选择方法Self Intersection 自相交Separator Item 分隔符Sequence Number 顺序号Sequencing 顺序Sequential Milling 顺序铳Set Modes设置模式SET/ADJUST设置/调整Setup Events设置事件Setup Template 设置模板Setup 设置SFM每分钟…英尺(表面线速度)Shape外形Shop Documentation车间工艺文档Shortest Path, Horizontal 最短刀轨,水平的Show 3D显示三维模型Show Excess显示剩于量Show Gouging显示过切Side Cut侧壁切削Side Trimmed侧壁修剪Silhouette 轮廓Silhouette Display 轮廓显示Simulated 模拟Single 单一Single Pass单条刀轨Skip跳过Slowdowns 降速Smart Object Action相关联对象激活Smart Objects相关联对象SMM每分钟…毫米(表面速度)Solid Center刀轨实线(显示)Specify 指定Specify Boundary 指定边界Specify Boundary Plane 指定边界平面Specify Colors 指定颜色Specify Cut Angle指定切削角度Specify Pattern指定刀夹(切削模式)Specify Point 指定点Specify Setup指定设置Specify Tool Axis指定刀具轴Speed转速Spherical Coords 球坐标Spindle Axis 主轴Spindle Off主轴停止Spindle On主轴启动Spindle Range Active主轴转速范围激活Spindle Speed主轴转速Spindle Speed Active主轴转速激活Spiral螺旋线驱动Spiral Center Point螺旋线中心点Spiral Drive Method螺旋线驱动方法Split Closed Boundary断开封闭的边界Standard Bore 标准镗Standard Bore,Back 标准镗,插孔Standard Bore,Drag 标准镗,快退Standard Bore,Manual标准镗,手工退刀Standard Bore,No Drag标准镗,横向偏置后快退Standard Drill 标准钻削Standard Drill,Break Chip 标准钻削,断屑Standard Drill,Csink 标准钻削,沉孔Standard Drill,Deep 标准钻削,深孔Standard Drive标准驱动铳Standard Tap标准攻螺纹Standard Text标准文本(输出)Start & End Points开始和结束点Start first %最初开始百分比Start last %最后开始百分比Start Marker起始点标记Start of range 起始范围StartPoint 起始点Start step起始步长Startup 启动Startup Commands 启动命令Startup Position 启动位置Static Material Removal 静态材料去除Status状态Steep陡峭壁Steep Angle陡峭壁角度Steep Area陡峭壁区域Steep Faces陡峭壁面Steep Merge陡峭壁合并Steep Option陡峭壁选项Steep Overlap陡峭壁重叠Steep Part陡峭壁零件Step Over步距(进给速度) Step Size步长大小Step Type/Dir步距类型/方向Stepover Method 步距方法Stepover Parameters 步距参数Stepover步星巨Stock余量Stock type余量类型Stock value 余量值Stop Animation停止动态模拟Stopping Position (刀具)停止位置StptChange起始点改变Subop to Execute执行子操作Sub-Operations 子操作Sub-Type子类型Suppress Tool Path 抑制刀轨Surf Cont曲面连续Surf. Contour曲面轮廓Surface Area Drive曲面区域驱动Surface Drive Method曲面驱动方法Surface Inside Tolerance 曲面内公差Surface Outside Tolerance 曲面外公差Surface Percentage Method 曲面百分比方法Surface Region Editing 曲面区域编辑Surface Region曲面区域(特征)Surface Speed表面切削速度Surface Stock曲面余量Swarf Drive直纹面驱动TTable工作台Tangent to Curve相切于曲线Tangent to DS相切于驱动面Tangent to PS相切于零件面Tangential Edge Angle 相切边角度Tanto (Tool Position)相切(刀具位置)Tap攻螺纹Taper Angle 锥度角T-Cutter T 形刀Template Set模板设置Template units 模板单位Templates 模板Temporary Boundary 临时边界Temproary Plane 临时平面The Event Generator 事件生成器The Event Handler事件处理器Thick厚,粗Thin薄,细THREAD螺纹Thread Milling 螺纹铳Threading Tool 螺纹车刀Three Point Probe三点(圆心)探测Thru Fixed Pt通过固定点Thru Hole 通孔Thru point通过点Tilt倾角Tip Angle顶尖角TMARK程序转移标识Tolerances 公差Tolerances -ntol/Outtol 内公差/外公差Tolerant Machining 容错加工Tool Axis Output刀具轴输出Tool Axis刀具轴(刀轴)Tool Axis/Distance 刀具轴/距离Tool Change 换刀Tool Checker刀具检测器Tool Diameter刀具直径Tool Display刀具显示Tool Groups 刀具组Tool Holder 刀柄Tool Material刀具材料Tool Number 刀号Tool Objects刀具对象Tool Path Actions 刀轨功能Tool Path Options 刀轨选项Tool path Reversed 刀轨反向Tool Path刀位轨迹(刀轨)Tool Position刀具位置Tool Preselect 刀具预选Tool Radius刀具半径Tool刀具toolpath_generate 刀轨-生成toolpath_list 刀轨-列表toolpath_reject 刀轨-拒绝toolpath_replay刀轨-重新显示toolpath_verify 刀轨-验证Top Level顶部切削层Topology 拓扑Total Depth 总深度Toward Line 指向线Toward point 指向点Trace (刀轨)迹线TransferMethod 转移方法Traversal 横过Traverse Interior Edge 横过内边缘Traverse Pattern 横过模式Triangle Tolerance 三角形公差Trim修剪Trim Boundary修剪边界Trim Curve修剪曲线Trim Geometry修剪几何体Trim Intol修剪内公差Trim open boundary 修剪开口边界Trim Outtol修剪外公差Trim Shape修剪外形Trim Tool Paths 修剪刀轨Turn车床Turning Tool 车刀Turning 车削Type类型UUGPOST UG后置处理器Uncut Region Display未切削区域显示Uncut Regions未切削区域Undefined未定义Undercut Handing底部切削处理Unidirection 单一方向Unify All统一所有的材料侧Unlink Instances取消所有引用特征的链接Update All Instances更新所有的引用特征Updating Surface 更新曲面Upper Plane 上平面Upward向上Use Check使用检查功能Use Final使用最后退刀Use Initial使用初始进刀Use Local使用局部的进退刀Use Reposition使用重新定位Use Tool Holder 使用刀柄Use Vericut Display使用Vericut模拟切削显示User Abort用户中断User Defined用户定义User Defined Command用户定义命令User Defined Event (UDE)用户定义事件VValley Merge凹处合并Valley Overlap凹处重叠距离Valleys 凹处Variable可变的Variable Contour可变轴曲面轮廓铳Variable Increments 可变增量Vericut Display模拟切削显示Vericut模拟切削Verify验证Verify or modify check surface 验证或修改检查面Verify Points 验证点Verify Predrill Points 验证预钻孔点Vertex Type顶点类型Vertical Clearance 垂直间隙Vertical Limit 垂直限制Visualize可视化切削仿真WWall Cleanup周壁清理Warning 警告WCS Origin WCS 原点WEDM Control线切割控制When Gouging当过切时White白色Wire EDM线切割Wire-EDM Feature线切割特征Workpiece 工件XX Center R1 R1中心至刀轴X向距离X Center R2 R2中心至刀轴X向距离X Delta X向增量X Offset X向偏置Xaxis X 轴YY Center R1 R1中心至刀轴Y向距离Y Center R2 R1中心至刀轴Y向距离Y Delta Y向增量Y/Z Offset Y/Z 向偏置Yaxis Y 轴Yellow黄色ZZ Delta Z向增量Z Offset Z向偏置Zaxis Z 轴Z-Depth Offset Z向深度偏置Zero参考零点Zig with Contour单向带轮廓铳Zig with Stepover单向带步距铳Zig单向切削Zig_Zag Surface往复式曲面铳Zig-Zag with Lifts往复式切削带抬刀Zig-Zag往复式切削Z-Level Milling等高轮廓铳。

BingoThere was a farmer had a dog,and bingo was his name ,OH! 有个农场主有一只狗,它的名字叫宾果B-I-N-G-OB-I-N-G-OB-I-N-G-OAnd bingo was his name,OH! 它的名字叫宾果(Clap)(拍手)There was a farmer had a dog,and bingo was his name,OH!有个农场主有一只狗,它的名字叫宾果啪-I-N-G-O啪-I-N-G-O啪-I-N-G-OAnd bingo was his name, OH! 它的名字叫宾果(Pat your legs!)(拍拍你的腿)There was a farmer had a dog,and bingo was his name,OH!有个农场主有一只狗,它的名字叫宾果啪-啪-N-G-O啪-啪-N-G-O啪-啪-N-G-OAnd bingo was his name, OH! 它的名字叫宾果(Pat your tummy!)(拍拍你的肚子)There was a farmer had a dog,and bingo was his name,OH!有个农场主有一只狗,它的名字叫宾果啪-啪-啪-G-O啪-啪-啪-G-O啪-啪-啪-G-OAnd bingo was his name, OH! 它的名字叫宾果(Pat your head!)(拍拍你的头)There was a farmer had a dog,and bingo was his name,OH!有个农场主有一只狗,它的名字叫宾果啪-啪-啪-啪-O啪-啪-啪-啪-O啪-啪-啪-啪-OAnd bingo was his name, OH! 它的名字叫宾果(Jump!)(跳)There was a farmer had a dog ,and bingo was his name,OH!有个农场主有一只狗,它的名字叫宾果跳-跳-跳-跳跳-跳-跳-跳跳-跳-跳-跳And bingo was his name, OH! 它的名字叫宾果B-I-N-G-OB-I-N-G-OB-I-N-G-OAnd bingo was his name,OH!它的名字叫宾果。