精密注塑机的闭环控制技术

- 格式:pdf

- 大小:291.76 KB

- 文档页数:3

注塑机开环、半闭环、3/4闭环、全闭环控制注塑机的速度及压力的控制方法对注塑成型是非常重要的,我们在制造和使用注塑机时总是要提到一个名词那就是“精度”,注塑机的精度有制品重量重复精度、制品尺寸重复精度等,对于注塑制品精度不只同注塑机有关,还有模具、原料、工艺、环境和人员等几方面。

这六方面对制品的精度都有影响,没有轻重之分,这一点我们一定要知道。

这次我们撇开其它其它方面,我们只是探讨注塑机电器液压控制部分对制品精度的影响。

注塑机是制品生产的关键要项,有一个问题我们要明白,注塑机的精度不等于注塑机的电器液压控制精度,注塑机的机械部分的强度和间隙配合也是影响注塑精度的关键。

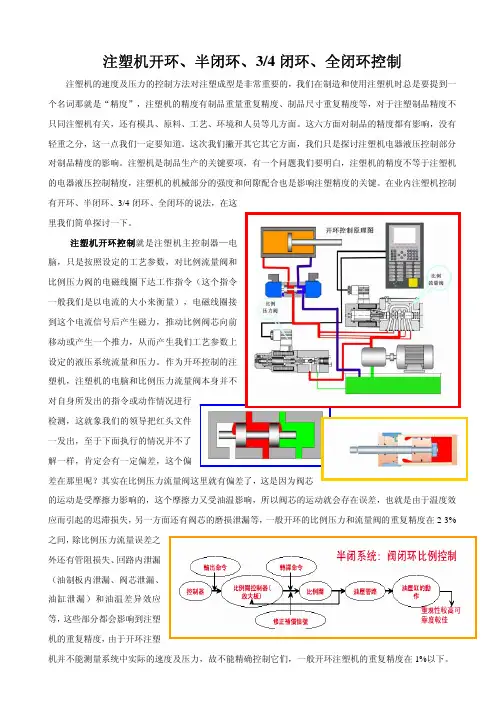

在业内注塑机控制有开环、半闭环、3/4闭环、全闭环的说法,在这里我们简单探讨一下。

注塑机开环控制对自身所发出的指令或动作情况进行检测,这就象我们的领导把红头文件一发出,至于下面执行的情况并不了解一样,肯定会有一定偏差,这个偏的运动是受摩擦力影响的,这个摩擦力又受油温影响,所以阀芯的运动就会存在误差,也就是由于温度效应而引起的迟滞损失,另一方面还有阀芯的磨损泄漏等,一般开环的比例压力和流量阀的重复精度在2-3%之间,除比例压力流量误差之外还有管阻损失、回路内泄漏(油制板内泄漏、阀芯泄漏、油缸泄漏)和油温差异效应等,这些部分都会影响到注塑机的重复精度,由于开环注塑机并不能测量系统中实际的速度及压力,故不能精确控制它们,一般开环注塑机的重复精度在1%以下。

注塑机半闭环控制是注塑机通过自闭环的比例压力和比例流量阀来实现的,自闭环的比例阀有自己的控制器,注塑机电脑把压力流量信号先给自闭环比例阀的控制器,在由其控制器发出指令给比例阀,自闭环比例阀有自己的阀位置检测装置,通过这个检测装置,把阀芯位置信号反馈给阀的控制器,然后阀控制器把注塑机电脑给的压力流量信号和反馈回的信号进行对比,然后给比例阀输出经过修正过的信号,从而使输出的压力和流量无限靠近注塑机电脑的设定值,通过这个方法来提高流量及压力的重复性,一般自闭环的比例压力流量阀的重复精度为0.2%,这个精度是非常高的,普通开环注塑机在用小于10%的流量时就会出现极不稳定的情况,当使用由自闭环比例阀组成的半闭环系统时,这个情况就会消失。

变频注塑机方案(速度+压力闭环)说明:该方案直接面向注塑机生产厂家,目的是将矢量变频技术应用于注塑机电机驱动上,通过速度闭环及压力闭环功能完成对注塑机的精确控制。

油路上取消了传统的流量、压力比例阀,在节约成本的同时可从源头上消除油路中的节流及溢流能量损失,使注塑机获得最佳的节能效果。

以下内容将针对传统定量泵注塑机、变频注塑机及变量泵注塑机的特点做全面分析。

-、流量及压力控制方式分析在塑机的液压系统中,液流的流量、压力和方向是最基本的控制量,其中流量和压力直接决定了系统的输出功率和成型工艺。

按照对工作流量和压力的不同要求,可将塑机的运行状态分为流量控制状态和压力控制状态。

流量控制状态以稳定控制工作回路中的流量并使之达到塑机的设定值为目的,而工作回路中的压力将小于塑机设定压力,塑机的快速锁模、射胶、溶胶等阶段都属于该状态。

压力控制状态以稳定控制工作回路中的压力为目的。

在该状态下,工作压力接近或等于塑机设定压力,而实际工作流量很小,如塑机的高压锁模及保压阶段等,系统过载、油缸推力不足时也属于该状态。

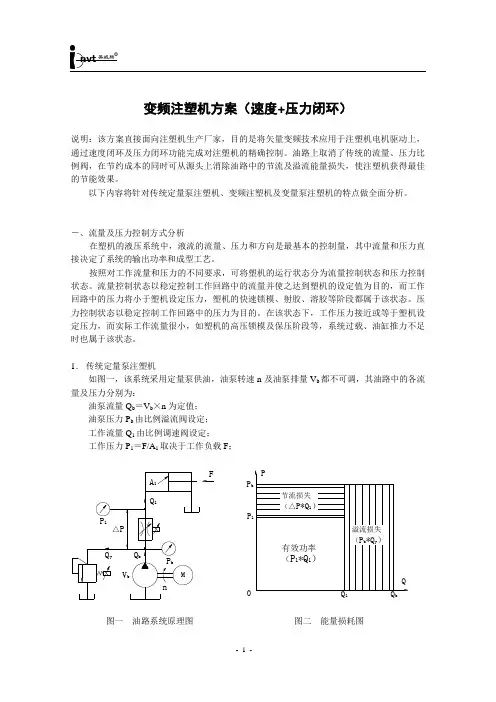

1.传统定量泵注塑机如图一,该系统采用定量泵供油,油泵转速n及油泵排量V b都不可调,其油路中的各流量及压力分别为:油泵流量Q b=V b×n为定值;油泵压力P b由比例溢流阀设定;工作流量Q1由比例调速阀设定;工作压力P1=F/A1取决于工作负载F;1bPP图一油路系统原理图图二能量损耗图A1:油缸无杆腔活塞面积F:工作负载Q1:工作流量P1:工作压力△p:比例调速阀两端的压力差Q y:比例溢流阀流量P b:油泵压力Q b:油泵流量V b:油泵排量n:电动机转速●流量控制状态系统在流量控制状态时,因油泵流量Q b=V b×n为定值,除一部分流量Q1经比例调速阀进入工作回路外,其余流量Q y都经比例溢流阀排回油箱。

●压力控制状态系统处于压力控制状态时,因工作流量Q1极小,油泵流量Q b=V b×n的绝大部分都要经比例溢流阀流回油箱,以此维持油泵压力P b达到设定值,能量浪费巨大。

注塑机的各种控制方式分析传统的注塑机一般采用简单的开环控制,即按照预先设定值进行控制。

在设备制造过程中,预先设定好参数值,例如锁模力、循环时间、温度等,由机器在生产过程中加以保持。

例如模具温度可以通过控制加热流体的温度加以保持,塑化温度可以通过控制外加热装置的功率保持。

这种控制方式结构简单,然而抗干扰能力差,控制温度也比较低。

目前,更多的注塑机采用的是闭环控制,即按照在线测量值与设定值的偏差进行控制。

闭环控制系统采用了负反馈回路,抗干扰能力强,当注射速度、注射压力、模腔温度、模腔压力、熔体温度和油压等在生产过程中因干扰出现偏差,机器则通过自适应控制系统对干扰进行自动修正。

这一控制方法抗干扰能力强,控制精度高。

更先进的控制方法是应用计算机进行控制,即构筑闭环实时计算机控制系统。

它包括直接数字控制系统(DDC)、监督计算机控制系统(SCC)、分散控制系统(DCS)和多级控制等几种类型。

目前,常用的注塑机控制系统有三种,即传统继电器型、可编程控制器型和微机控制型。

近年来,可编程序控制器(简称PLC) 以其高可靠性、高性能的特点,在注塑机控制系统中得到了广泛应用。

为了提高注塑机控制系统的水平和品质,一种较PLC 更高层次的、专为中小型控制系统设计的可编程计算机控制器(PCC)应运而生。

PCC集成了标准的PLC 和工业控制计算机的特点,具有多任务分时操作系统,数据运算和处理能力比PLC 更强大。

用PCC 组成注塑机的控制系统,以实现包括位置控制、速度控制、温度控制、故障控制和实时显示等注塑全过程的多种控制,可大大提高塑料制品的品质,有利于提高经济益。

注塑机控制的内容目前,注塑机的过程控制系统主要包含两大部分:一是温度控制系统,以对料筒、熔体和模具的温度进行控制;二是运动控制系统,以对注塑过程的压力、速度、位移进行多级切换。

在温度控制中,其控制精度已经达到了±1℃。

精确的温度控制在精密注塑上有利于提高产品质量以及原材料的利用率,是一项十分重要的指标。

【工艺进阶】什么是注塑机的闭环系统

注射成型控制系统是一个循环的过程,包含一组预设程序,当(且仅当)上满足一定条件时才会运行下一个循环。

这些条件的检验和监测以及给出每一个循环的开始、结束或者延续命令都是由顺序控制器来完成的。

顺序控制器为注塑机提供了“安全保障”,例如在注塑机前门打开时,控制器就不允许模具移动。

注射成型控制系统有以下三个功能:

▪

设置注塑机动作顺序

▪

▪

调节、控制主要工艺和注塑机参数

▪

▪

检测过程状态与性能

▪

高端的注塑控制系统还发挥着过程变量的管理、工艺监测和统计分析的功能,如何有效避免干扰成为生产高精度、良好表面的复杂制件重要问题。

开环系统(a)与闭环系统(b)如下:

举例:

(a)开环系统包括具有被控变量的设备、驱动设备的执行器和执行器发出指令信号的控制器。

以螺杆速度控制为例,控制对象是注射单元的螺杆,输出为螺杆转速,典型的执行器为液压阀。

控制器按照设定以一定速度向液压阀发出打开指令。

填充阶段:精确合理地控制注射速度可以确保填充动作一致,能够消除成型制件的非均匀性。

短射、缩痕和很多表面问题都可以通过调节注射速度解决,所以在填充阶段注射速度是关键变量。

保压阶段:喷嘴压力是比较接近模腔变量变化过程的,传感器直接装在喷嘴,不需要安装在模具内。

开-合模阶段:必须同步实现快速模具移动和精确模具定位。

闭环控制系统工作原理

闭环控制系统是一种自动控制系统,可以通过对系统输出与期望输入之间差距的反馈进行调整,从而使系统的输出更加接近期望输入。

其工作原理可以归纳为以下几个步骤:

1. 设定期望输入:在闭环控制系统中,首先需要设置一个期望输入信号,即所需的系统输出。

2. 对比期望输入与实际输出:系统会将期望输入信号与系统实际输出信号进行对比,并计算其之间的差距。

3. 生成误差信号:根据期望输入与实际输出之间的差距,系统会生成一个误差信号,该信号用于指示系统是否达到期望输出。

4. 反馈控制调整:误差信号会被送回到系统的控制器中,控制器会根据该信号制定相应的控制策略。

控制策略可以是比例控制、积分控制、微分控制或者它们的组合,以调整系统的输出。

5. 输出调整:经过控制器调整后,系统会根据控制策略对输出信号进行调整,使其更接近期望输入。

6. 循环过程:上述步骤会不断循环进行,系统会不断根据反馈信号进行调整,以使系统输出逐渐接近期望输入。

通过以上循环过程,闭环控制系统可以不断地根据实际输出与期望输入之间的差距进行调整,以使系统的输出更加接近期望

输入。

这种反馈机制可以提高系统的可靠性、稳定性和精度,使系统能够更好地适应不确定性和扰动。

注塑成型机开环闭环控制系统注塑机控制系统的执行元件主要是电机(如交流或直流电机及伺服电机、步进电机等)、液压油缸或液压马达,这两类执行元件的控制并无实质区别,当采用注塑机控制器进行闭环控制时,其控制和校正具有很大的相通性•注塑机闭环控制系统包括通讯、校正、死区补偿、限幅、D/A、A/D、可逆计数模块•系统采用模糊控制器实现模糊控制,采用随机接受信息和主动反馈信息的通讯模式,接受注塑机控制器的各种控制命令和数据,检测反馈信号,自动完成控制任务.注塑机闭环控制系统具有死区补偿、零点漂移自动测定及补偿、注塑机参数可随时修改•所谓闭环控制也称反馈控制,它是指注塑工艺员预先规定注塑参数,通过对注塑机执行机构施加信号,并把注塑机电控系统输出量的一部分或全部,经过一定的转换,反馈到注塑机电控系统的输入端,并与之进行上匕较,将比较得到的差异施加于执行机构,以减少两者之间的偏差而进行的控制。

注塑机闭环控制的突出特点是具有自我调节功能。

控制器在发现某一过程状态记录与实际有偏差时,可以及时采取补救措施,从而保证注塑工艺参数的可靠准确实现。

所谓的闭环,就是将输出量反馈(采集)回来和输入量叠加,与给定量比较,使输出值稳定在给定范围。

所谓的开环,就是无输出量反馈,因而开环不能保证输出量稳定,难以进行精密控制。

什么是注塑机的闭环控制?所谓闭环控制也称反馈控制,它是指注塑工艺员预先规定注塑参数,通过对注塑机执行机构施加信号,并把注塑机电控系统输出量的一部分或全部,经过一定的转换,反馈到注塑机电控系统的输入端,并与之进行t匕较,将比较得到的差异施加于执行机构,以减少两者之间的偏差而进行的控制。

注塑机闭环控制的突出特点是具有自我调节功能。

控制器在发现某一过程状态记录与实际有偏差时,可以及时采取补救措施,从而保证注塑工艺参数的可靠准确实现。

-一闭环控制系统主要适用于高档精密注塑机的控制,它可以实现注塑成型加工过程的全闭环控制,以确保机器运行在最佳状态,制品品质达到最优。

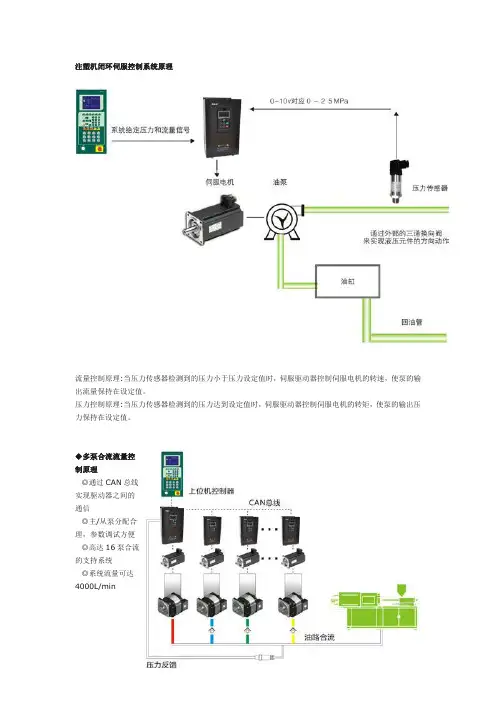

注塑机闭环伺服控制系统原理

流量控制原理:当压力传感器检测到的压力小于压力设定值时,伺服驱动器控制伺服电机的转速,使泵的输出流量保持在设定值。

压力控制原理:当压力传感器检测到的压力达到设定值时,伺服驱动器控制伺服电机的转矩,使泵的输出压力保持在设定值。

◆多泵合流流量控

制原理

◎通过CAN总线

实现驱动器之间的

通信

◎主/从泵分配合

理,参数调试方便

◎高达16泵合流

的支持系统

◎系统流量可达

4000L/min

◆注塑机闭环伺服控制系统解决方案优点

●节能

注塑机闭环伺服控制系统的核心在于:根据制品生产过程中的实际需要,准确、快速提供相应的流量和压力,实现按需供油,完全杜绝溢流损耗。

这就满足了塑料成型快速、精密、节能的要求。

●精密

◎压力控制精度:先进、可靠的PID算法使系统压力波动范围小于±0.5bar,确保制品的高品质。

◎系统精度:射胶终点位置精度可达0.1mm,油泵的重复重量精度可达0.15%,减少次品率。

●响应快

◎“0~最大压力输出量”响应时间:最短20ms;”0~最大流量输出量”响应时间:最短30ms。

◎伺服电机的高转速可以快速增加油泵输出量,提高系统速度,带来极高的生产效率。

●省油

◎液压用的油,温升稳定,既可以节约用油,也可以延长液压部分元件的使用寿命。

●生产性能对比

●实际测试案例。

精密注塑机的闭环控制技术 - 中国注塑论坛(Closed loop control technology of precision injection molding machine - Chinainjection molding Forum)Data worth havingFrom the usual study, accumulation and summaryWhere there is a problem, there must be somePlease also criticize and correct me!Closed loop control technology of precision injection molding machineKeywords: precision injection molding; temperature; injection speed; closed loop controlEngineering plastics because of light weight, high strength, saving resources and energy, industrial products have replaced many components, such as component of electronic and electrical, instrumentation, aerospace, communications, computers, cars, VCRs, watches and other industrial products.Plastic products to replace the metal parts with high precision, the conventional injection molding has been difficult to do, because of the precision plastic parts size precision, stability, residual stress and other aspects have higher requirements, so the concept of precision injection moldingPrecision injection molding is relative to the conventionalinjection molding. It means that the precision of molding products is very high, and it is difficult to achieve an injection molding method by using the general injection molding machine and conventional injection molding processIn precision injection molding technology, it is the main content of precise injection molding to select material, design mould, select or improve precise injection molding machine and operate and manage precisely according to precise injection molding technology1 precision injection molding machine features111 characteristics of technical parametersThe injection pressure is more highGeneral injection molding machine pressure is 147 ~ 177MPa, precision injection molding machine injection pressure is 216~243 MPa, or even up to 243~392 MPaThe injection rate is fasterIncreasing the speed of injection can not only inject complicated shapes, but also play an important role in reducing the dimensional tolerances of productsThe effect of injection pressure and injection speed on the accuracy of the product can be further confirmed by the influence of injection power on the accuracy of the productInjection molding machine with high injection power, the size deviation range of its molding products is reduced, and the dimensional stability is improvedThe injection power increased and the flow length increased (L flow length, H product thickness) than L/ H112 control characteristicsThe injection molding parameters have higher repeatability accuracy requirementsA high precision injection multistage feedback controlIt includes 10 stage injection closed loop injection system with induction displacement control or time control, multilevel dwell time, pressure and speed control, screw temperature, intelligent PID control, etc.Screw and nozzle temperature control is more accurateWhen the temperature rises, the overshoot is small, and the temperature fluctuation is smallFor conventional control, the double position temperature control is over 25~30 degrees centigrade. The temperature fluctuation caused by screw metering is above 4 DEG C, while the precision of the precision injection molding machine is less than 015 DEG CHydraulic oil temperature control accuracy higherChanges in the oil temperature will cause changes in viscosity, so that the flow of the various agencies into the implementation of fluctuations, causing the opening and closing mold speed, injection speed, screw speed instability, but also lead to pressure fluctuationsFor the small injection molding machine, in the absence of oil temperature regulating continuous operation of 5 h, the temperature will rise 28 degrees Celsius, the system pressure will increase 0119 MPa, the conversion of the polymer melt flow into pressure is about 119 ~ 219 MPa, the size of this deviation will affect the products, this is not allowed in precision injection moldingThe precision injection molding machine uses heating and cooling closed loop device, the oil temperature of the work oil is stable at 50~55 degrees centigradeMould temperature control is more strictThe dimensional accuracy of the product is affected by the die temperatureThe thickness of different molding materials is controlled not only by the cooling time, but also by the temperature of the dieIf the cooling time is the same, the mold cavity temperature is low, and its thickness is higher than the temperature of the product thicknessFrom the above analysis, we can see that the control system of the precision injection molding machine has high quality indexes, and complete closed-loop control of parameters such as pressure and speed2 the principle and main mode of closed loop controlThe principle of the closed loop is shown in Figure 1You can see from Figure 1, the starting point of closed-loop control is the measurement of the target variable, and the sensor is composed of a target variable corresponding to the detection of the target variable, a target variable is proportional to the output, usually the voltage and current signal or analog signals; the signal feedback to theclosed-loop controller and compared with the set value, when the target variable deviates from the set value, theclosed-loop controller generates additional control signal by the actuator to adjust the control object, fromThe target variables are consistent with the set requirementsClosed loop control can eliminate the influence of different disturbances on control objects and improve the control accuracyclosed loop control systemClosed loop control system has the following characteristics: 1) the output signal of the system has a direct impact on thecontrol function2) there are feedback links, and the feedback function is used to reduce the system error, so that the output of the system tends to the predetermined value3) when disturbances occur, including internal disturbances and external disturbances, the effects can be weakened4) the system may be unstable, so there is a temperature checking problem (stability criterion)The closed-loop control of injection molding machine usually has two ways: software closed loop control and hardware closed loop controlIn the software closed loop control system, the injection molding machine controller realizes closed-loop control process through software programmingSuch as the control of pressure, the pressure sensor is installed in the injection cylinder to detect pressure and feedback to the controller through the analog input port controller, the controller to complete the comparison and calculation, and generates a correction signal by the hydraulic valve according to the new signal of pressure adjustmentThe closed loop control system of hardware realizes closed-loop control of a certain target variable through a special closed loop controllerGenerally, the corresponding test element and the high response closed loop proportional valve or servo valve should be providedBecause of the infinite sampling period, accurate control of target variables can be achieved3 closed loop control of system temperatureTemperature control is one of the most important parts of the closed-loop control system of injection molding machineIt includes temperature control of cylinder and nozzle, hydraulic oil temperature control and die temperature controlThe PID control of the barrel temperature is the first part of the control system of injection molding machine to realize closed-loop controlIts control accuracy has basically met the needs of the conventional injection moldingA barrel temperature control system based on improved PID algorithm is introduced. The algorithm can achieve higher control accuracyMathematical model of 311 barrel temperature control systemThe temperature of each heating zone is not only related to the heating power in this area, but also has a strong coupling effect with the temperature of the adjacent heating zoneUsing multivariable decoupling method to achieve a simple, intuitive and easy to project, so that only on the basis of the input and output of each control channel values will be able to perform multivariable control according to the single channel control method without coupling, so the system can be simplified as a single input and single output linkThe mathematical model of cylinder heating is established by time domain method, and each heating zone model has first order response characteristics (with time delay). Its transfer function is G (s) = K 1 + Tse - TsControl algorithm of 312 barrel temperature control systemNonlinear digital PID and its improved form have the characteristics of high speed, little memory and easy to implement. It is suitable for real-time controlPosition type PID control algorithm can be expressed as: Ui = Kp EI +TTi =0ej +TdT [sigma (EI - EI - 1 U0)] + (1) = 1 Ui - Kp [EI - 1 +TTi - 1J =0ej +TdT I (EI - 1 - EI - 2 U0)] + (2) - (1) reduce type (2), so the incremental PID control algorithm:Ui = Kp[EI - EI - +TTiei +TdT (1 EI - 2 EI - 1 EI - 2 +)] (3) in the formula, Ui said the position of the actuator; EI temperature deviation sampling time I, I = 0 ~ k; Kp proportional gain; Ti integral time constant. S; Td s; T differential time constant for the sampling period, sIt can be seen that the increment only needs to keep the errorof the previous 3 moments (EI, EI - 1),EI - 2)The role of decision points of static control precision, usually increasing the integration time constant of Ti can improve the static precision, but Ti is too large, the start control or step input values change greatly, the overshoot will be larger, even cause oscillationTherefore, the improved form of PID algorithm is adopted, that is, the integral method with limiting restrictionThe basic idea is: after the integral is started, once the control variable enters the saturation zone, the operation of the integral term is stoppedThat is in the calculation of Ui, to determine whether the system has exceeded the limits; as has been exceeded, according to the deviation of the symbol, to determine whether the system overshoot in the region, which will decide whether the corresponding deviation in the integral term, thus effectively overcoming the integral saturationThe block diagram is shown in Figure 2Fig. 2 flow chart of PID position algorithm of integration method in case of restriction4 injection speed closed loop controlInjection speed refers to the displacement of the injection screw in unit time, and it directly affects the quality and efficiency of the productIn order to melt the material to the die cavity and to obtain the products with uniform density and high accuracy, the molten material must be filled with the mold cavity in a short time for rapid mold fillingSuch as slow injection speed, long filling time, easy to produce cold joints, uneven density, stress and other illsHigh speed injection can reduce the temperature difference of the melt in the cavity, improve the effect of pressure transfer, and obtain the precise products with uniform density and little stressBut the injection speed is too high, the melt flows through the gate and other easy to form irregular flow, and cause material burning and the intake gas and exhaust bad phenomenon, which directly affect the surface quality of the products; at the same time, the injection speed is too high is not easy to achieve switching injection and holding pressure stable, often due to overvoltage and make the products out flashTherefore, it is necessary to control the injection speed effectivelyDuring injection, the velocity at each point on the cross section of the runner and the cavity is uneven. In the injection process, the fluid should be injected slowly into the cavity.At the last stage, the injection speed should be accelerated to ensure substantialTherefore, the speed of injection must be graded closed loop controlFig. 3 is a flow chart of the injection speed classification controlThe injection speed control of injection molding machine can improve the injection precision of injection molding machine, and has certain practical value in production practiceFig. 3 flow chart of injection speed control5 ConclusionPrecision injection molding products have penetrated into every corner of our lives. In twenty-first Century, precision injection molding will continue to develop and improveComputer simulation and simulation design of precision injection molding technology will be more high-speed, ultra precision, micro and intelligent directionPrecision injection molding technology is currently the world's advanced mainly in Germany, Japan, the United States and some other Western European countries, some Southeast Asian countries and regions, such as South Korea, Singapore, and China's Hongkong and Taiwan region is also rapid developmentThe precision injection molding technology in mainland of China has achieved rapid development in recent years, but there is still a gap with some developed countriesThe research of precision injection molding machine and control system in China should develop new products according to their own objective conditions, strengthen the application of high and new technology, raise the level of control technology, and gradually narrow the gap with other developed countriesReference1 minutes Hanru 1 injection molding machine control system of 1 Beijing: Chemical Industry Press industrial equipment and Information Engineering Publishing Center, 2003112 Liu Ting, Chen Jinwei Xiangfang Peng, 1 plastic, 2004, 33 (6): 793 Zhang Tao, 1, Shanghai plastics, 2001, (2): 284 Sun Weiqing, Xu Yuanchang, Huang Min, 1 Journal of Northwest Institute of Light Industry, 2002, 20 (2): 385 Zhangcuihua, Xu Yuanchang, Qi G 1 Journal of Shaanxi University of Science and Technology, 2003, 21(5): 99。

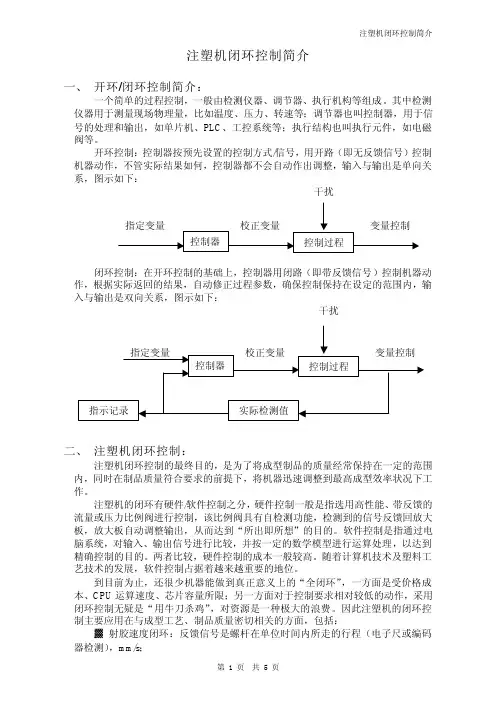

注塑机闭环控制简介注塑机闭环控制简介一、 开环/闭环控制简介:一个简单的过程控制,一般由检测仪器、调节器、执行机构等组成。

其中检测仪器用于测量现场物理量,比如温度、压力、转速等;调节器也叫控制器,用于信号的处理和输出,如单片机、PLC、工控系统等;执行结构也叫执行元件,如电磁阀等。

开环控制:控制器按预先设置的控制方式/信号,用开路(即无反馈信号)控制机器动作,不管实际结果如何,控制器都不会自动作出调整,输入与输出是单向关系,图示如下:干扰闭环控制:在开环控制的基础上,控制器用闭路(即带反馈信号)控制机器动作,根据实际返回的结果,自动修正过程参数,确保控制保持在设定的范围内,输入与输出是双向关系,图示如下:干扰二、 注塑机闭环控制:注塑机闭环控制的最终目的,是为了将成型制品的质量经常保持在一定的范围内,同时在制品质量符合要求的前提下,将机器迅速调整到最高成型效率状况下工作。

注塑机的闭环有硬件/软件控制之分,硬件控制一般是指选用高性能、带反馈的流量或压力比例阀进行控制,该比例阀具有自检测功能,检测到的信号反馈回放大板,放大板自动调整输出,从而达到“所出即所想”的目的。

软件控制是指通过电脑系统,对输入、输出信号进行比较,并按一定的数学模型进行运算处理,以达到精确控制的目的。

两者比较,硬件控制的成本一般较高。

随着计算机技术及塑料工艺技术的发展,软件控制占据着越来越重要的地位。

到目前为止,还很少机器能做到真正意义上的“全闭环”,一方面是受价格成本、CPU运算速度、芯片容量所限;另一方面对于控制要求相对较低的动作,采用闭环控制无疑是“用牛刀杀鸡”,对资源是一种极大的浪费。

因此注塑机的闭环控制主要应用在与成型工艺、制品质量密切相关的方面,包括:▓ 射胶速度闭环:反馈信号是螺杆在单位时间内所走的行程(电子尺或编码器检测),mm/s;▓ 保压压力闭环:反馈信号是螺杆保压压力(压力传感器检测),Bar;▓ 熔胶转速闭环:反馈信号是螺杆转速(光电开关检测),Rpm;▓ 熔胶背压闭环:反馈信号是螺杆背压压力(压力传感器检测),Bar。

一、目的:规范注塑技术员在成型机开关机时的操作方法,保证成型机设备、模具的使用寿命与安全,同时提高开关机的生产效率、保证产品的稳定。

二、定义:对注塑技术员在开、关机的操作手法做出明确规定。

三、适用范围注塑车间全体注塑技术员。

四、作业流程一、停机的操作规范1、在停机前准备好相对应的清洗炮筒用料;2、需清洗螺杆的对象为使用工程塑料(PA66+30%GF、PBT、POM、PPV0、硬质或软质PVC等)生产的机台;3、停机30分钟内的机台可在停机前10分钟将料闸关掉生产至料筒内的余料快完成后,停止生产,将炮台退出,把料管内的余料射完,反复空射几次,再将温度设定为保温状态即可;但如果热敏性材料(如POM、PBT等)必须在余料射完后,将PP料加入炮筒中。

注意:所有的热流道模具要在余料打空后,都必须在模具的流道中再打入PP料。

4、清洗螺杆时应适量增加背压及螺杆转速,以增加塑料与炮筒内壁及槽的摩擦力,以便能更好地清洗螺杆,提高工作效率;5、清洗螺杆时尽量采用手动点射的射胶方式,方便将炮筒壁附着的残料带出来;切记:POM等热敏感性材料,绝对不能使用机器的自动清料,因为设备的自动清料,旋转速度将才高达300,将导致树脂温度迅速升高,而迅速被炭化降解,而出现黑点。

6、在做低温转高温生产转换料的时候,可先用PP料过管,等温度升高后,再换与颜色相近的PC料过管,再换要使用的回料过管,待温度到达需要的温度时再切换为原料;需要注意的是,在转换的过程中要及时对温度进行与使用的料相对应的温度做阶梯性的调整;7、由高温转低温时的操作方法一样按上面的方法操作;8、在完全停机不生产时,在停机前10分钟将料闸关掉,连续生产至料筒内的余料快完成时,停止生产,把料管内的余料射完,反复空射几次(如果使用的是热敏性材料或者热流道,必须再加入PP料清洗)。

然后关掉炮筒与热道流温度,再关闭模温机电源;待模具冷却后(一般30分钟左右),喷上足够的防锈剂,注意在防锈剂前一定要保证模型、模腔的清洁;然后再合模(不可以上高压锁模),关闭成型机电源、机械手电源。

注塑机阀工作原理

注塑机阀的工作原理是通过控制阀门的开关来控制熔融塑料的流动。

下面是注塑机阀的具体工作原理:

1. 开门状态:当阀门完全打开时,熔融塑料可以在注塑机的进料管道中自由流动。

此时电机停止运转。

2. 关门状态:当需要注射塑料时,阀门会关闭,阻止熔融塑料流动。

同时,电机启动并开始运转。

3. 预充状态:在阀门关闭后,电机会以较低的速度将熔融塑料预充入注射缸中。

预充过程可以避免塑料进入模具时产生气泡或过高的压力。

预充时间由操作人员设定。

4. 注射状态:当预充完成后,电机会以较高的速度将熔融塑料注射进模具中。

注射过程中,需要确保注塑机阀门保持关闭状态,以保证注射压力恒定。

5. 压保持状态:当塑料注射完毕后,注塑机阀门会继续保持关闭状态,以保持一定的注射压力,以防止塑料在模具中提前固化。

6. 冷却状态:在一定时间的压保持状态后,注塑机阀门会打开,以允许模具中的塑料冷却和凝固。

此时,模具中的产品已经成型。

综上所述,注塑机阀的工作原理主要是通过阀门的开关控制熔融塑料的流动,并实现塑料的注射、压保持和冷却等工艺过程。

注塑机控制系统技术指标全文共四篇示例,供读者参考第一篇示例:注塑机控制系统是注塑机的重要组成部分,控制系统的性能直接关系到注塑机的生产效率、产品质量和能耗等关键指标。

随着工业自动化的发展,注塑机控制系统的技术指标也在不断提升,以满足市场的需求和用户的要求。

本文将重点介绍注塑机控制系统的技术指标及其作用。

一、闭环控制精度注塑机控制系统的闭环控制精度是评价系统性能的一个重要指标,主要反映了系统对生产过程中各种参数变化的适应能力。

闭环控制精度高,可以保证注塑机在生产过程中精准控制各种运动参数,提高产品的成型精度和一致性。

目前,国内外注塑机控制系统的闭环控制精度一般在0.1%以内,部分高端产品甚至可以达到0.01%。

随着节能环保理念的普及,注塑机能耗控制精度也成为一个重要的关注点。

能耗控制精度高,可以帮助用户减少能源消耗,降低生产成本,提升产品竞争力。

目前,国内外注塑机控制系统的能耗控制精度一般在±3%以内,部分高端产品甚至可以达到±1%。

第二篇示例:注塑机控制系统是注塑成型机器的核心部件之一,对注塑机的运行稳定性、精度和效率起着至关重要的作用。

随着科技的不断发展,注塑机控制系统的技术指标也在不断提升。

下面将对注塑机控制系统的技术指标进行详细介绍。

一、注塑机控制系统的主要技术指标:1. 控制精度:注塑机控制系统的控制精度是指注塑机在运行过程中所能实现的精度。

控制精度越高,注塑机加工出来的产品质量也会越高。

目前,注塑机控制系统的控制精度已经可以达到0.01mm,可以满足各类注塑产品的加工需求。

3. 稳定性:注塑机控制系统的稳定性是指注塑机在长时间运行中,能够保持稳定的控制状态。

稳定性越好,注塑机的故障率也会越低。

目前,注塑机控制系统的稳定性已经得到了很大提升,可以保证长时间连续生产。

5. 人机交互:注塑机控制系统的人机交互功能是指注塑机可以通过人机界面进行操作和监控。

人机交互功能越强,操作注塑机的便利性也会越高。

精密注塑成型PVT控制技术材料的压力(P)、温度(T)和比容(V)是聚合物的本质属性,不随材料加工方式的改变而变化,其控制理论和方法可以用于聚合物的精密注塑成型。

本文基于此提出了一种精密注塑成型控制技术,该技术利用型腔温度作为信号对保压过程进行控制。

研究表明,该控制技术可以显著提高注塑制品的质量重复精度。

1传统精密注塑控制技术的局限随着我国科技的不断发展,各行业对塑料制品的精度和性能提出了更高的要求,如要求制品具有较好的力学性能、重量精度、尺寸精度以及工作稳定性等。

精密制品正在向着高精度化、高功能化、小型化、轻量化、低成本及高附加值的方向发展,精密注塑成型技术则向着精密化、计算机辅助化、无人化及节能化方向发展。

目前,国外的精密注塑成型机已经具有相当高的水平,且欧美和日本的少数几家注塑机生产厂家垄断了我国精密注塑机市场,例如德国的克劳斯玛菲、阿博格和德马格,以及日本的住友重机、东芝等。

为了与精密注塑成型机匹配,这些公司还相应地开发出了高性能、高精度的液压系统和控制系统,以保证塑料制品的质量、减少废品,以及提高注塑成型的生产效率。

综观当今注塑机市场,在保证制品质量的前提下,如何利用成熟的自动化设备,提高产品精度,降低废品、次品率及节约原材料、能源以降低成本,增强市场竞争,己引起国内外注塑机厂商的高度重视,为此采用先进的控制技术和管理手段已成为必然的趋势。

传统注塑机中的过程控制方法大多采用注射压力、保压压力、合模力、注射速度及注射量等参数作为控制量,称为机器变量。

这些变量由操作员根据经验和试模对注塑机预先输入控制参数,通常主要采用时间来控制每个阶段的开始和结束。

这些变量完全由注塑机本身决定,而与材料的特性关系不大。

参数控制作为控制系统的主要功能,需要对连续变化的过程参数,如温度、压力、位置和速度等进行精确的闭环控制。

由于注射过程主要参数都具有相当显著的非线性时变特性,而其动态特性又会随着工艺条件的更改而变化,所以这种对传统的固定参数进行控制的策略很难有效地保证不同操作条件下的控制性能。

在注塑机中,应用最为广泛的控制规律为比例、积分、微分控制,简称PID控制。

当注塑机压力,速度及温度实际参数不能完全可靠掌握,或得不到精确的数学模型,控制理论的其它技术难以采用时,参数必须依靠经验和现场调试来确定,这时应用PID控制技术最为方便。

即当我们不完全了解注塑时实际的压力,速度,温度﹐或不能通过有效的测量手段来获得上述参数时,最适合用PID控制技术。

PID控制,实际中也有PI和PD控制。

PID控制就是根据系统的误差,利用比例、积分、微分计算出控制量进行控制的。

比例(P)控制比例控制是一种最简单的控制方式。

其控制的输出与输入误差信号成比例关系。

当仅有比例控制时系统输出存在稳态误差(Steady-state error)。

积分(I)控制在积分控制中,控制系统的输出与输入误差信号的积分成正比关系。

对一个注塑机控制系统,如果在进入稳态后存在稳态误差,则称这个控制系统是有稳态误差的或简称有差系统(System with Steady-state Error)。

为了消除稳态误差,在注塑机压力,速度,温度控制中必须引入“积分项”。

积分项对误差取决于时间的积分,随着时间的增加,积分项会增大。

这样,即便误差很小,积分项也会随着时间的增加而加大,它推动注塑机电脑的输出增大使稳态误差进一步减小,直到等于零。

因此,比例+积分(PI)控制,可以使注塑机系统在进入稳态后无稳态误差。

微分(D)控制在微分控制中,注塑机电脑中压力,速度,温度的信号输出与输入误差信号的微分(即误差的变化率)成正比关系。

注塑机电脑在克服误差的调节过程中可能会出现振荡甚至失稳。

其原因是由于存在有较大惯性组件(环节)或有滞后(delay)组件,具有抑制误差的作用,其变化总是落后于误差的变化。

解决的办法是使抑制误差的作用的变化“超前”,即在误差接近零时,抑制误差的作用就应该是零。

这就是说,在控制器中仅引入“比例”项往往是不够的,比例项的作用仅是放大误差的幅值,而目前需要增加的是“微分项”,它能预测误差变化的趋势,这样,具有比例+微分的注塑机电脑,就能够提前使抑制误差的控制作用等于零,甚至为负值,从而避免了被控量的严重超调。