霍尼韦尔PKS-C300硬件知识介绍

- 格式:ppt

- 大小:16.69 MB

- 文档页数:85

Process SolutionsHoneywell’s C300 controller provides powerful and robust control for the PlantCruise by Experion® platform. With the C300 and the Control Execution Environment,customers can improve engineering productivity and maintenance, maximize process uptime, and reduce production costs.At the core of the C300 in PlantCruiseis Honeywell’s field-proven deterministic Control Execution Environment (CEE) core software. The CEE provides a superior control execution and scheduling environment. Control strategies are configured and loaded through Control Builder, an easy to use and intuitive engineering tool.The C300 controller hardware offers unique space saving, installation, and maintenance benefits consistent with its innovative Series 8 form factor.The C300 is optionally redundant, requiring no additional hardware other than an identical second hardware module.The ‘designed-vertical’ C300 controller provides a superior control execution and scheduling environment.With the C300 controller, customers can:• Improve engineering productivity with a rich set of function libraries and a seamless and intuitive user environment, • Maximize process uptime and minimize maintenance effort with robust diagnostics and full hardware redundancy, and, • Reduce production costs with flexible and efficient control strategies, on-process migration, and efficient hardware processing power.Easy Control Strategy Creation through Rich Function LibrariesThe Control Execution Environment function blockssupport:• Continuous Control • Logic Based Control • Sequential Control • Model Based ControlEach function block contains a rich set of predefined features, such as alarm limits and priorities, various control algorithms, and maintenance statistics, all of which are configurable parameters. Function blocks are linked together in Control Modules to perform specific control tasks, which provide a foundation for efficient control engineering.Embedded functionality guarantees consistent control strategyexecution and delivers consistent alarming and operations behavior. This consistency reduces operator errors and saves implementation time by eliminating the need to develop low-level basic functions.The CEE fully supports the ISA S88.01 batch standard and integrates sequences with devices. The devices will track the state of the sequences and perform pre-configured actions based on those sequences. This reduces the implementation and complexity of handling abnormal situations. The SCMs support abnormal handling, recipe parameters, and on-line monitoring of the execution through chart visualization.One Seamless Environment through Easy Data CommunicationParameters provide access to every imaginable piece of information in the controller. This data can be used throughout the Experion system, whether for other control strategies or for operator purposes. For example, in custom displays, parameters such as setpoints or outputs can be historized and used in trend views. The engineer does not need to know where the information resides. Instead, he can just reference it, and the system manages the underlying logistics of that information. The system will notify the user based on the status information associated with the value and take appropriate action when required.Each parameter is also protected from accidental changes through a security access level, and certain parameters can only be changed off-line. Communication is based on report- by-exception and publish-subscribe, making efficient use of communication bandwidth by accessing data only when needed and avoiding duplication.Consistent and Predictive Behavior Makes Engineering and Maintenance EasierThe C300 CEE supports an execution period per control strategy, ranging from 50 msec to 2000 msec. The user can make changes to existing or add new control strategies without interrupting other control strategies executed by the controller. The user has full control over the function block execution order within the control strategy and the execution order of multiple control strategies. Control strategies can be easily moved between control environments by using the convenient drag-and-drop feature within Control Builder. Easy and Intuitive Engineering EnvironmentControl Builder is the control engineering and maintenance tool for the Control Execution Environment, and improves the control engineer’s productivity by simplifying configuration with a graphical user interface and predefined function blocks ready for wiring into a specific control strategy. The control engineer can enable and change standard function block features without the need to build these from the ground up. The control strategy can be documented with embedded objects such as text, documents or web-links.Online Monitoring Is Available to the Engineer and OperatorOnce control strategies are created and loaded to the C300 controller, the engineer can monitor the strategy on-line using the same graphical interface. This is helpful for verifying a control strategy or for troubleshooting a process problem. The control or maintenance engineer can directly modify parameters from the engineering environment without needing an operator interface. Controller Based Model Predictive Tuning with ProfitLoopProfit Loop is Honeywell’s patented algorithm that provides a single input / single output model-predictive function block that is included in the standard C300 controller function block library. It has the operating simplicity and computational efficiency of a standard PID function block, yet provides tight, robust control, increasing process stability by up to 30 percent. Profit Loop creates a simple model of the process to predict the effect of control moves on the process (controlled) variable. Because Profit Loop can anticipate future process behavior, the controller knows exactly how much to move the process to meet the desired control objectives. Profit Loop incorporates the best elements of both traditional PID algorithms and the model-based control and optimization technologies of Profit Controller at the regulatory level.For More InformationTo learn more about how Honeywell’sPlantCruise by Experion C300 Controller can improve plant performance, visit our website or contact your Honeywell account manager. Honeywell Process Solutions Honeywell1250 West Sam Houston Parkway South Houston, TX 77042Honeywell House, Arlington Business Park Bracknell, Berkshire, England RG12 1EB Shanghai City Centre, 100 Junyi Road Shanghai, China 20051 Custom Algorithm Blocks Custom Algorithm Blocks (CABs) are similar in purpose and structure to native function blocks included with Control Builder. These blocks have predefined algorithms and data structures. By contrast, Custom Algorithm Blocks have user defined algorithms and data structures. CABs are developed using Visual Basic integrated into Control Builder.The C300 controller supports the execution of CABs in Experion LX. CABs can greatly reduce the effort required to create complex control strategies that require the robust control environment offered by the C300.Investment ProtectionHoneywell is committed to protecting customer investments by supporting and integrating previous control products. Consistent with this philosophy, the Control Execution Environment, which holds the user application, is platform- independent. This allows the user to make use of new, more powerful hardware platforms when they become available, while retaining the specific user application.PN-13-16-ENG February 2014© 2014 Honeywell International Inc.。

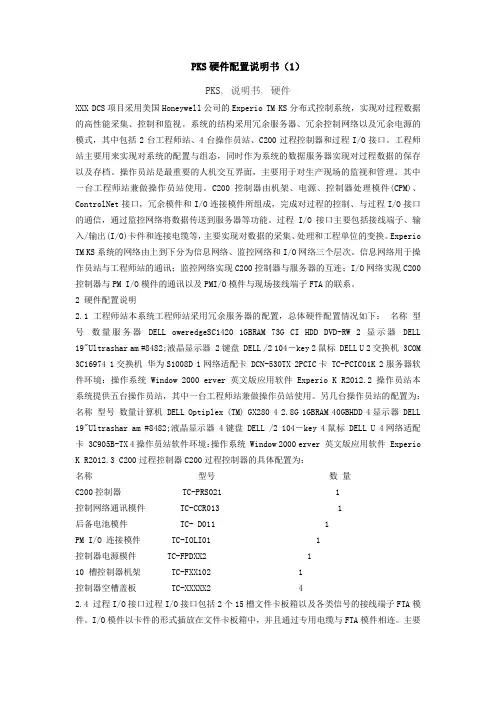

PKS硬件配置说明书(1)PKS, 说明书, 硬件XXX DCS项目采用美国Honeywell公司的Experio TM KS分布式控制系统,实现对过程数据的高性能采集、控制和监视。

系统的结构采用冗余服务器、冗余控制网络以及冗余电源的模式,其中包括2台工程师站、4台操作员站、C200过程控制器和过程I/O接口。

工程师站主要用来实现对系统的配置与组态,同时作为系统的数据服务器实现对过程数据的保存以及存档。

操作员站是最重要的人机交互界面,主要用于对生产现场的监视和管理。

其中一台工程师站兼做操作员站使用。

C200控制器由机架、电源、控制器处理模件(CPM)、ControlNet接口,冗余模件和I/O连接模件所组成,完成对过程的控制、与过程I/O接口的通信,通过监控网络将数据传送到服务器等功能。

过程I/O接口主要包括接线端子、输入/输出(I/O)卡件和连接电缆等,主要实现对数据的采集、处理和工程单位的变换。

Experio TM KS系统的网络由上到下分为信息网络、监控网络和I/O网络三个层次。

信息网络用于操作员站与工程师站的通讯;监控网络实现C200控制器与服务器的互连;I/O网络实现C200控制器与PM I/O模件的通讯以及PMI/O模件与现场接线端子FTA的联系。

2 硬件配置说明2.1 工程师站本系统工程师站采用冗余服务器的配置,总体硬件配置情况如下:名称型号数量服务器DELL oweredgeSC1420 1GBRAM 73G CI HDD DVD-RW 2显示器DELL 19"Ultrashar am #8482;液晶显示器 2键盘 DELL /2 104-key 2鼠标 DELL U 2交换机 3COM 3C16974 1交换机华为S1008D 1网络适配卡 DCN-530TX 2PCIC卡 TC-PCIC01K 2服务器软件环境:操作系统 Window 2000 erver 英文版应用软件 Experio K R2012.2 操作员站本系统提供五台操作员站,其中一台工程师站兼做操作员站使用。

霍尼韦尔PKS常用特性块介绍

霍尼韦尔PKS(Process Knowledge System)是一种用于过程控制的先进解决方案。

下面是一些常用的特性块介绍:

1. 过程控制器(PC)

过程控制器是PKS的核心组件,用于监控和控制工业过程。

它具有高性能、可靠性和可扩展性,并支持广泛的控制策略和算法。

2. 监控界面(HM)

监控界面是PKS的用户界面,用于可视化显示和操作过程控

制系统。

它提供实时数据、趋势图、报警和事件记录等功能,帮助

操作员实时监控和管理工业过程。

3. 逻辑控制器(LC)

逻辑控制器用于执行复杂的逻辑控制算法。

它可以通过配置和

编程实现各种控制策略,如级联控制、比例-积分-微分控制和模糊

控制等。

4. 信号接口模块(SIM)

信号接口模块用于将传感器和执行器与PKS系统连接起来。

它提供多种接口类型,如模拟输入、模拟输出、数字输入和数字输

出等,以便与各种设备进行通信。

5. 数据历史存储(DHS)

数据历史存储用于记录和存储过程控制系统的历史数据。

它可

以存储大量的数据,并提供高速查询和分析功能,帮助用户进行数

据分析和故障诊断。

以上是霍尼韦尔PKS常用特性块的简要介绍。

PKS系统提供

了强大的功能和灵活的配置选项,可满足各种工业过程控制的需求。

1.2 系统硬件介绍1.2.1服务器和工作站Experion PKS的管理基础设施包括一或多个服务器和多个被称作工作站的运行用户界面程序的客户PC。

客户PC通常是指工作站。

功能和特性Experion PKS服务器和客户环境提供:●管理级功能,包括:-已设置过程的监测和管理控制-重大事件的报警-由设备或者操作人员或者根据需要触发的事件的记录和报告-根据预定的时间间隔进行过程历史记录并通过采样、映射、绘图、总计和平均进行显示以帮助你看清趋势。

●管理级特性包括:-时间安排控制-分隔数据库-本地或远程连接-预建的基础设施,包括预定格式的中间过程信息查看的显示和报告-定制的显示界面构建-组合节点结构以减少与现场数据(例如,PID环)有关特征计数和分组-通道、控制器和节点的在线设置以及报告和趋势显示界面的定制-冗余服务器系统选项以得到有效连接以不断进行数据更新的高可用性-分布式系统架构(DSA)将多个服务器集成为一个单一的操作系统。

工作站工作站是Experion PKS的与过程之间的主要人机接口。

工作站为控制和信息提供一个单独的窗口。

总的来说,工作站运行在带有标准键盘、显示器和鼠标的标准计算机上。

然后,工作站支持大多数与Windows兼容的外设,例如轨道球和触摸屏以及两种专业键盘:●操作人员入口面板(OEP)。

这是一种带有专用功能键的膜式键盘。

它适合于在恶劣环境下工作的操作人员使用。

●集成操作人员键盘(IKB)。

这种键盘包括组合有专用功能键和内建轨道球的标准键盘。

它适合于除标准键盘外需要大量功能键的操作人员使用。

对于需求特别的任务,可以Honeywell的Icon Console(图标控制台),它包括多达四个的平板监视器和一个OEP。

Honeywell的图标控制台显示界面工作站显示界面以操作人员易于理解的方式给出了过程信息。

Experion PKS配备有大约300个标准显示界面。

下图显示典型的标准报警总结显示界面。

霍尼韦尔PKS系统及C300控制器在煤间接液化装置上的应用作者:李卓来源:《电子世界》2012年第20期【摘要】鄂尔多斯煤制油分公司煤间接液化生产装置控制系统,采用了霍尼韦尔PKS集散控制系统及C300控制器,进行煤间接液化生产,经过投料试车,系统稳定可靠,操作灵敏方便,提高了分公司的自动化控制水平、创造了显著的经济效益。

【关键词】DCS;霍尼韦尔PKS系统;C300控制器;煤间接液化1.前言由于煤直接液化项目中全部使用的是霍尼韦尔Experion PKS系统,煤间接液化装置建设在煤直接液化项目的厂区内,是以煤直接液化项目中煤气化装置的合成气为原料,利用煤直接液化项目中的公用工程进行煤间接液化生产的。

考虑到相关装置之间的信号传输多、通讯数据量大,以及全厂控制系统一体化等因素。

在煤间接液化项目控制系统的选型上,霍尼韦尔PKS 系统就成了唯一的选择。

2.PKS系统结构霍尼韦尔的Experion PKS过程知识系统,是目前最先进的控制系统之一,包含了霍尼韦尔三十多年来在过程控制、资产管理、行业知识等方面积累的经验,采用最先进的开放平台和网络技术,为工业企业提供一个全厂统一的过程控制、生产管理、设备管理、资产管理、等一体化的知识体系结构和全系列的解决方案。

Experion PKS系统能满足各种自动化应用要求,为过程控制、数据采集和批量控制提供一个开放式控制系统,能满足工业生产领域要求的灵活性、易用性、高性能和高可靠性。

Experion PKS系统的体系结构如图1所示。

Experion PKS系统的控制主干网络是容错以太网——简称FTE,是Honeywell公司开发的FTE驱动程序与Cisco交换机相结合的网络技术。

FTE是在商用以太网技术上结合霍尼韦尔设计的鲁棒控制网络专长,成为霍尼韦尔的专利,作为先进的控制网络解决方案。

通过为任意两个FTE节点提供多达4条通讯路径,FTE既可容错单故障点,还可容错多故障点。