Honeywell最新介绍幻灯EBI

- 格式:ppt

- 大小:886.00 KB

- 文档页数:47

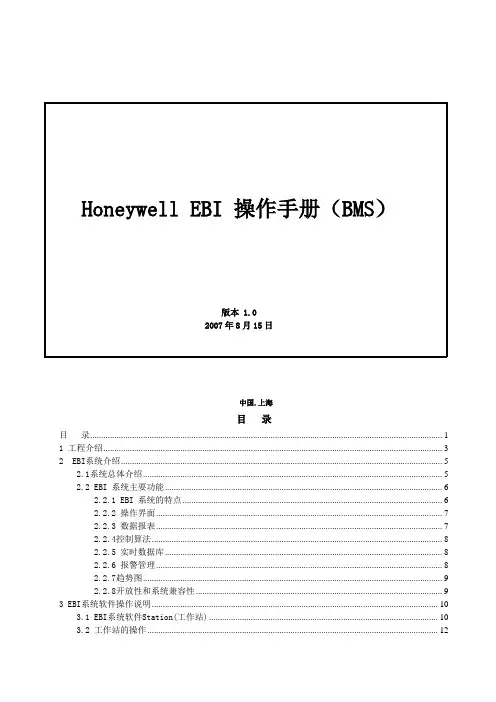

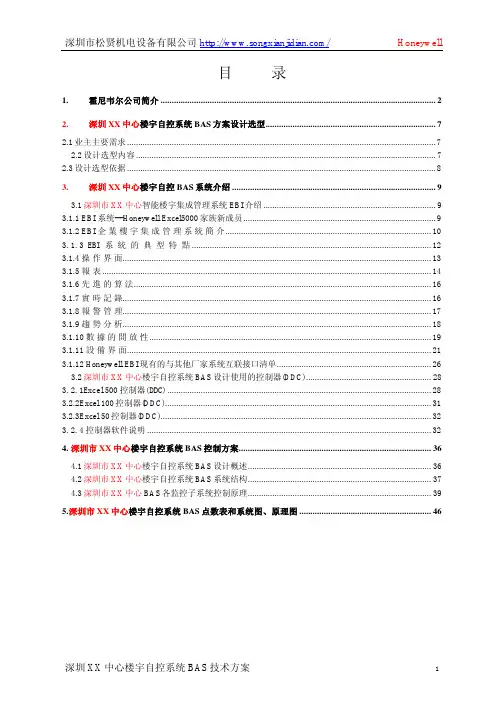

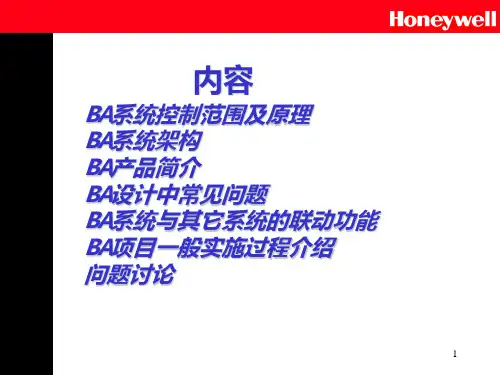

中国.上海目录目录 (1)1 工程介绍 (3)2 EBI系统介绍 (5)2.1系统总体介绍 (5)2.2 EBI 系统主要功能 (6)2.2.1 EBI 系统的特点 (6)2.2.2 操作界面 (7)2.2.3 数据报表 (7)2.2.4控制算法 (8)2.2.5 实时数据库 (8)2.2.6 报警管理 (8)2.2.7趋势图 (9)2.2.8开放性和系统兼容性 (9)3 EBI系统软件操作说明 (10)3.1 EBI系统软件Station(工作站) (10)3.2 工作站的操作 (12)3.2.1 工作站的启动及登录 (12)3.2.2 安全级别的说明 (14)3.2.3 工作站布局的说明 (15)3.2.4 图片的使用 (20)3.2.5 点的说明 (21)3.2.6 工作站的关闭 (22)3.3 EBI软件功能操作 (22)3.3.1 时间程序管理 (22)3.3.2 系统状态监视 (22)3.3.3 报警响应 (28)3.3.5 生成报表 (31)3.3.6 点的详细参数 (34)3.3.7 使用趋势图Trend Displays (39)4 用户图形界面的使用 (42)5 系统安全操作措施 (47)1 工程介绍 Project Introduction1.1工程简介Project Brief Introduction南通联亚药业有限公司是一家出口型专业药品生产厂商,厂区内共有两个制药车间和一个仓库。

HVAC系统包括冷热源系统,空调通风系统等。

设备数量众多,在设备布局上有局部集中,整体分散的特点,被控区间的被控参数指标要求相对比较高。

1.2 BMS系统构成 The structure of BMS南通联亚药业有限公司BMS系统主要的控制内容为L1,L2,L3厂区的AHUU系统,通风系统。

BMS系统共有24台HONEYWELL EXEL5000系列控制器,其中XCL500型22台,XL50两台;服务器一台,为DELL OPTIPLEX 745;通讯设备4台,FAST 5 PORTS HUB 一台,BNA 1CS 3台;APC UPS 四台。

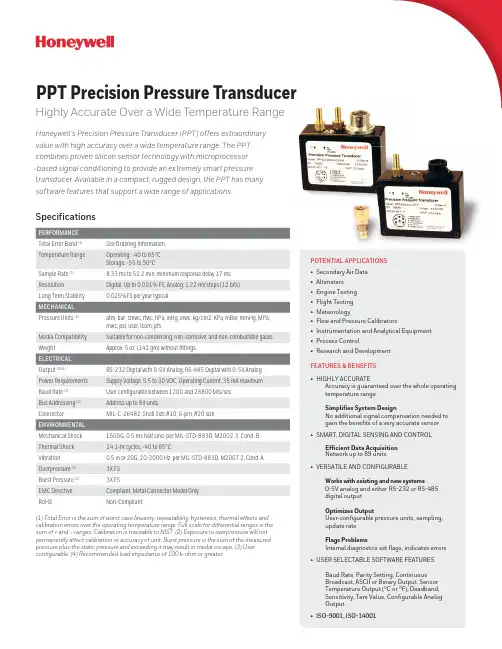

PPT Precision Pressure TransducerHighly Accurate Over a Wide Temperature RangeHoneywell’s Precision Pressure Transducer (PPT) offers extraordinary value with high accuracy over a wide temperature range. The PPT combines proven silicon sensor technology with microprocessor -based signal conditioning to provide an extremely smart pressure transducer. Available in a compact, rugged design, the PPT has many software features that support a wide range of applications.Total Error Band (1) See Ordering Information Temperature Range Operating: -40 to 85ºC Storage: -55 to 90°CSample Rate (3)8.33 ms to 51.2 min; minimum response delay 17 ms Resolution Digital: Up to 0.001% FS, Analog: 1.22 mV steps (12 bits)Long Term Stability 0.025%FS per year typicalPressure Units (3)atm, bar, cmwc, ftwc, hPa, inHg, inwc, kg/cm2, KPa, mBar, mmHg, MPa, mwc, psi, user, lcom, pfsMedia Compatibility Suitable for non-condensing, non-corrosive, and non-combustible gases Weight Approx. 5 oz. (142 gm) without fi ttingsOutput (3) (4)RS-232 Digital with 0-5V Analog, RS-485 Digital with 0-5V Analog Power Requirements Supply Voltage: 5.5 to 30 VDC, Operating Current: 35 mA maximum Baud Rate (3)User confi gurable between 1200 and 28800 bits/sec Bus Addressing (3)Address up to 89 unitsConnector MIL-C-26482, Shell Size #10, 6-pin, #20 sizeMechanical Shock 1500G, 0.5 ms half sine; per MIL-STD-883D, M2002.3, Cond. B Thermal Shock 24 1-hr cycles, -40 to 85°CVibration 0.5 in or 20G, 20-2000 Hz; per MIL-STD-883D, M2007.2, Cond. A Overpressure (2)3X FS Burst Pressure (2)3X FSEMC Directive Compliant, Metal Connector Model Only RoHSNon-CompliantSpecifications(1) Total Error is the sum of worst case linearity, repeatability, hysteresis, thermal effects andcalibration errors over the operating temperature range. Full scale for differential ranges is the sum of + and – ranges. Calibration is traceable to NIST. (2) Exposure to overpressure will not permanently affect calibration or accuracy of unit. Burst pressure is the sum of the measured pressure plus the static pressure and exceeding it may result in media escape. (3) User confi gurable. (4) Recommended load impedance of 100 k-ohm or greater.POTENTIAL APPLICATIONS • Secondary Air Data • Altimeters • Engine Testing • Flight Testing • Meteorology• Flow and Pressure Calibrators• Instrumentation and Analytical Equipment • Process Control• Research and DevelopmentFEATURES & BENEFITS• HIGHLY ACCURATEAccuracy is guaranteed over the whole operating temperature rangeSimplifi es System DesignNo additional signal compensation needed to gain the benefi ts of a very accurate sensor • SMART, DIGITAL SENSING AND CONTROLEffi cient Data Acquisition Network up to 89 units • VERSATILE AND CONFIGURABLEWorks with existing and new systems0-5V analog and either RS-232 or RS-485 digital outputOptimizes Output User-confi gurable pressure units, sampling, update rateFlags Problems Internal diagnostics set fl ags, indicates errors • USER SELECTABLE SOFTWARE FEATURESBaud Rate, Parity Setting, Continuous Broadcast, ASCII or Binary Output, Sensor Temperature Output (°C or °F), Deadband, Sensitivity, Tare Value, Confi gurable Analog Output• ISO-9001, ISO-14001OPTION C Ordering InformationFull Scale Pressure Range Absolute Gauge Differential Digital Total Error Band (1)(2)Analog Total Error Band (1)(2)0001N/A1 PSI N/A±(0.20%FS + 0.04% Abs. Reading) ±(0.24%FS + 0.04% Abs. Reading)0001 N/A N/A ±1 PSI ±(0.10%FS + 0.04% Abs. Reading) ±(0.12%FS + 0.04% Abs. Reading)0002 N/A 2 PSI ±2 PSI ±(0.10%FS + 0.04% Abs. Reading) ±(0.12%FS + 0.04% Abs. Reading)0005 N/A 5 PSI ±5 PSI ±(0.10%FS + 0.04% Abs. Reading) ±(0.12%FS + 0.04% Abs. Reading)0010 N/A 10 PSI ±10 PSI ±0.10%FS Max. ±0.12%FS Max.0015 15 PSI N/A N/A ±0.10%FS Max. ±0.12%FS Max.0020 20 PSI 20 PSI N/A±0.10%FS Max. ±0.12%FS Max.005050 PSIN/AN/A±0.10%FS Max. ±0.12%FS Max. A Absolute 0 (vacuum) to FS N/A G Gage Reference to FS Reference D Differential+FS to –FS rel. to P2+FS to –FS rel. to P1F Filter (blocks debris)G Stainless SwagelokTM (1/8 inch female) K Stainless Swagelok-compatible (1/8 inch male)R Brass barbed, right angle (1/8 inch ID tubing)W Brass barbed (1/8 inch ID tubing)XBrass Swagelok® (1/8 inch female)F Filter (blocks debris)G Stainless Swagelok® (1/8 inch female) K Stainless Swagelok-compatible (1/8 inch male)R Brass barbed, right angle (1/8 inch ID tubing)W Brass barbed (1/8 inch ID tubing)XBrass Swagelok® (1/8 inch female)N Not Applicable (Absolute)2V RS-232 digital, 0-5V analog 5V RS-485 digital, 0-5V analogELECTRICAL CONNECTIONA Plastic 6-pin connectorB Metal 6-pin connector- OPTIONS A Demonstration Kit (2) (RS-232 Only)B Mating ConnectorC Power Supply/Data Cable (RS-232 only)ECertifi cate of ConformanceF Calibration Certifi catePPTPPT Specifi cationsHoneywell Aerospace12001 State Highway 55 Plymouth, MN ADS-14179 rev FN61-2080-000-000 | 02/19© 2019 Honeywell International Inc.DimensionsHoneywell reserves the right to make changes to improve reliability, function or design. Honeywell does not assume any liability arising out of the application or use of any product or circuit described herein; neither does it convey any license under its patent rights nor the rights of others.(1) Tighter accuracy available on somemodels. Consult factory.(2) Demonstration kit includes unit,power supply/data cable (120V), demonstration software, and user manual.ESD (electrostatic discharge) sensitive deviceDamage may occur when subjected to high energy ESD. Proper ESD precautions should be taken to avoid performance degradation or loss of functionality.EOS (electrical overstress) sensitive device Damage may occur when subjected to EOS. Do not exceed specifi ed ratings to avoid performance degradation or loss of functionality.Find out moreFor more information on Honeywell’s Precision Pressure Transducers visit us online at . CustomerServiceEmail:********************OPTION C。

APPLICATIONS:Engine Test StandsFlight Testing Water DepthUnmanned Underwater VehiclesInstrumentation and Analytical Equipment Process ControlResearch and DevelopmentHoneywell’s PPTR offers a rugged, smart pressure transducer for use in harsh environments. It combines proven silicon sensor technology with microprocessor-based signal conditioning to provide an extremely smart pressure transducer. Designed with a hermetically sealed, stainless steel construction, the PPTR operates in severe vibration, thermal and mechanical shock environments. The PPTR has many software features that support a wide range of applications.Digital and AnalogHermeticallySealed±0.20%Accuracy from -40 to 85°C► High Accuracy±0.20% FS Total Error from -40 to 85°C►Simplifies System Design - No additional signal compensation needed to gain the benefits of a very accurate sensor.► Smart, Digital Sensing and Control ►Efficient Data Acquisition - Connect up to 89 units on a network with either RS-232 or RS-485.Easy Interface - Connects to a PC via communication ports.► Versatile and Configurable ►Works with existing and new systems. - All units have 0-5V analog and either RS-232 or RS-485 digital outputs.Isolation diaphragms handle most media - harsh gases or liquids. Optimizes Output - User-configurable pressure units, sampling, update rate.Flags Problems - Internal diagnostics set flags, provide alarms.► User Selectable Software Features ►Baud Rate, Parity Setting, Continuous Broadcast, ASCII or BinaryOutput, Deadband, Sensitivity, Tare Value, Configurable Analog OutputPrecision Pressure Transducer-Ruggedized PPTR AS9100 ISO-9001 ISO-14001PPTRTotal Error: (from -40 to 85°C) Digital: ±0.20% FS Max. (2)Analog: ±0.24% FS Max. (2) Temperature Range:Operating: -40 to 85°C (-40 to 185°F) Storage: -55 to 90°C (-67 to 194°F) Reading Rate (5): 8.33ms to 51.2 min Resolution:Digital: Up to 0.001% FSAnalog: 1.22mV steps (12 bits) Response Delay:(1000/update rate) +1ms, minimum 17ms Pressure Ranges and Type: See Ordering InformationPressure Units (5) : atm, bar, cmwc, ftwc, hPa, inHg, inwc, kg/cm², KPa, mBar, mmHg, MPa, mwc, psi, user, Icom, pfsMedia Compatibility: Liquids and gases com-patible with 316 stainless steel.Typical Weight: 14 oz. (400 gm) 6-pin connector 22 oz. (625 gm) NPT w/pigtail style Output:RS-232 Digital w/0-5V Analog (5) RS-485 Digital w/0-5V Analog (5) Power Requirements:Supply Voltage: 6 to 30 VDC Operating Current: 19 - 27 mABaud Rate (5): 1200, 2400, 4800, 9600, 14400, 19200, 28800Bus Addressing (5): Address up to 89 unitsOverpressure: 3x FS, maximum 6000psi Burst Pressure: 3x FS, maximum 8500psi Mechanical Shock: 1500G, 0.5ms half sine Temp Shock: 24 1-hour cycles, -40 to 85ºC Vibration: 0.5in or 20G’s, 20Hz – 2K HzSPECIFICATIONS CASE OUTLINEORDERING INFORMATIONFULL SCALE PRESSURE RANGEAbsolute Gauge0015 15 PSI N/A 0020 20 PSI 20 PSI 0040 40 PSI 40 PSI 0100 100 PSI 100 PSI 0300 300 PSI 300 PSI 0500 500 PSI 500 PSI 1000 1000 PSI 1000 PSI 1500 1500 PSI 1500 PSI30003000 PSI3000 PSIP1 Pressure P2 PressureA Absolute 0 (vacuum) to FS N/AGGauge Reference to FS ReferenceP1 PRESSURE CONNECTIONP ¼ - 18 NPT (internal)OUTPUTS2V RS-232 digital, 0-5V analog5VRS-485 digital, 0-5V analogELECTRICAL CONFIGURATION AND CONNECTIONB 6-pin connector (4)D½ - 14 NPT external w/4ft pigtail cableOPTIONSA Demonstration Kit (6)B Mating Connector - for 6-pin connector versionC Power Supply/Data Cable - for 6-pin connector (7) E Certificate of ConformanceFCalibration Certificate0500 A P 2V B -BEFTYPE(1) Total Error is the sum of worst case linearity, repeatability, hysteresis, thermal effects and calibra-tion errors from -40 to 85ºC. Calibration is traceable to NIST. (2) Tighter accuracy available on some models. Consult factory. (3) Exposure to overpressure will not permanently affect calibration or accu-racy of unit. Exceeding burst pressure may result in media escape. Mechanical Shock tested per MIL-STD-883D, M2002.3, Cond. B., Vibration tested per MIL-STD-883D, M2007.2, Cond. A. (4) Connect-or MIL-C-26482 Style, Shell Size #10, 6-pin #20 size. (5) User configurable. (6) Demonstration kit includes unit, power supply/data cable, demonstration software, and user manual. (7) Power Supply/Data Cable requires USB port and is available for both RS-232 and RS-485 versions of the PPTR.ESD (electrostatic discharge) sensitive device. Damage may occur when subjected to high energy ESD. Proper ESD precautions should be taken to avoid performance degradation or loss of functionality.EOS (electrical overstress) sensitive device. Damage may occur when subjected to EOS. Do not exceed specified ratings to avoid performance degradation or loss of functionality.Find out more.CustomerServiceEmail:********************Honeywell reserves the right to make changes to improve reliability, function or design. Honeywell does not assume any liability arising out of the application or use of any product or circuit described herein; neither does it convey any license under its patent rights nor the rights of others.Honeywell International 12001 Highway 55 Plymouth, MN 55441ADS-14180December 2016© 2016 Honeywell International Inc.European EMC Directive: Compliant- 6-Pin Connector Model Only RoHS Directive:Non-Compliant。